Paper plastic package anti-fluffing sealing and coating process and paper plastic package

A paper-plastic and wool-sealing technology, which is applied in the field of paper-plastic processing, can solve the problems of inability to fit paper-plastic packaging, fine dander, etc., and achieve the effects of uniformity and easy atomization, easy sealing and coating, and easy dissolving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

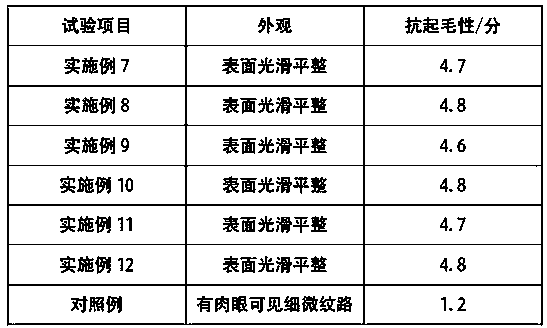

Examples

Embodiment 1

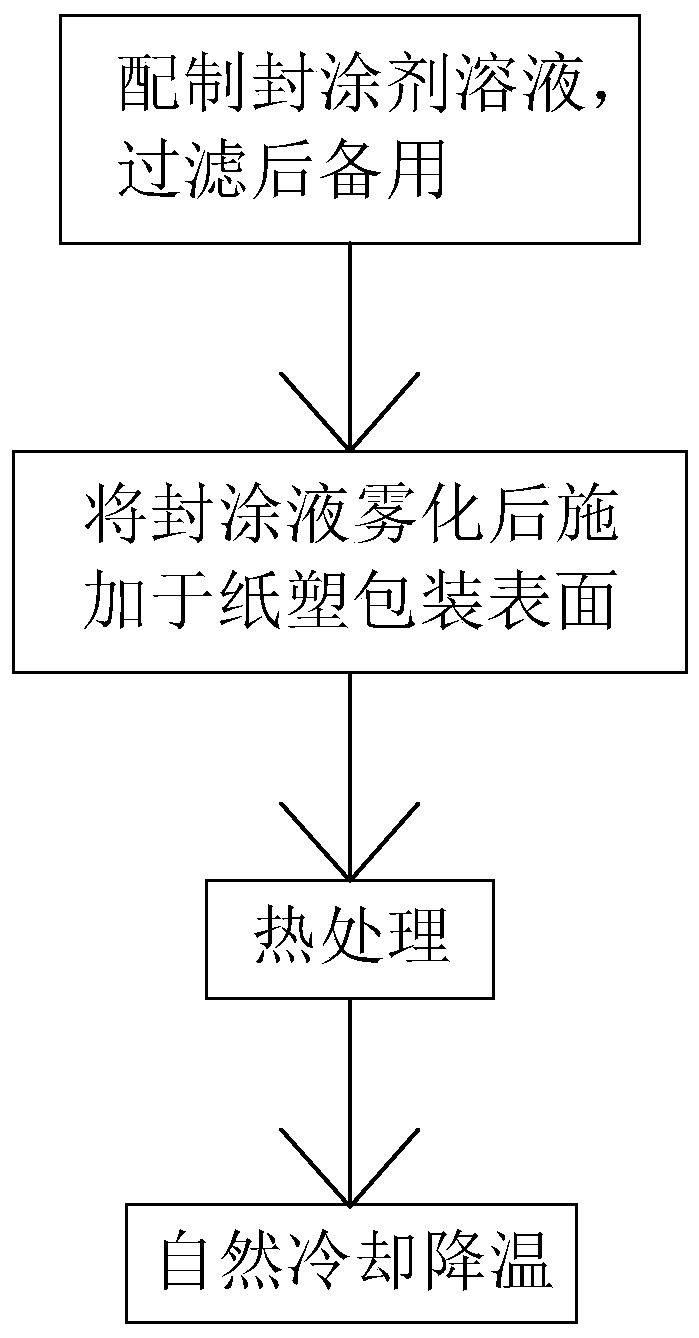

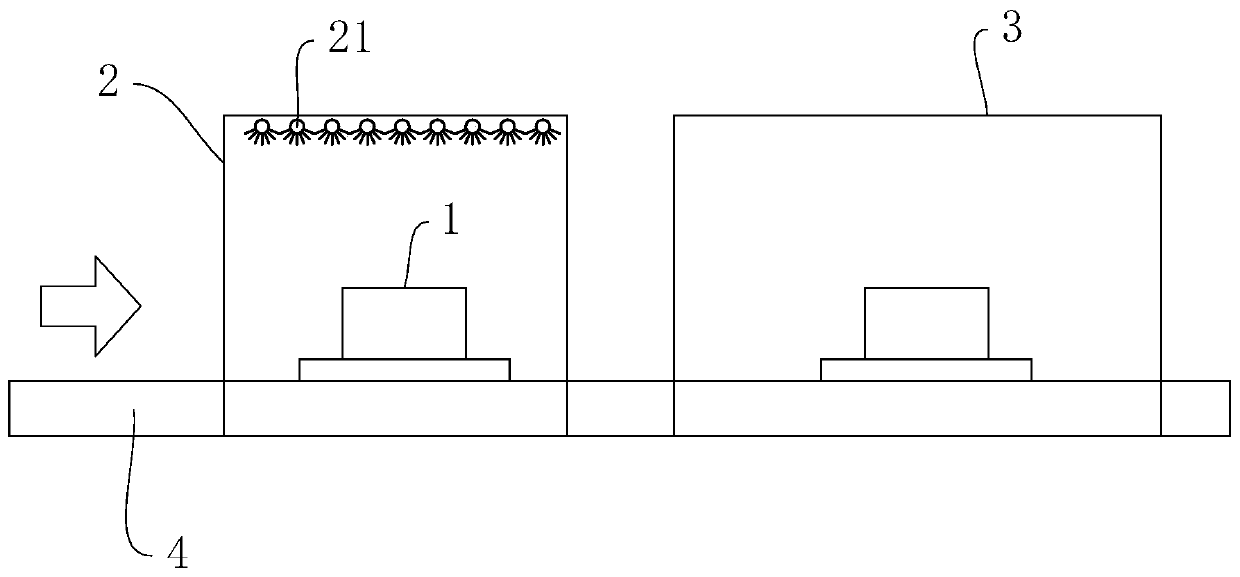

[0045] A paper-plastic packaging anti-pilling sealing coating process, with reference to figure 1 and figure 2 , which includes the following steps:

[0046] Prepare α-chitin into an aqueous solution with a concentration of 10wt% with hot water at 90°C, filter while it is hot, and obtain a sealing solution for future use. The sealing liquid is sprayed through the high-pressure nozzle 21 into the atomization chamber 2 equipped with a heating device, and a uniform and fine mist of the sealing liquid is formed in the atomization chamber 2 . The inside of the atomization chamber 2 is heated to 90° C. with a heating device in advance and kept warm. Then, the formed paper-plastic package 1 is sent into the atomization chamber 2 with the opening facing up by means of the conveyor 4, and the residence time of the paper-plastic package 1 in the atomization chamber 2 is controlled to be 3 seconds, so that the surface of the paper-plastic package 1 is evenly adhered to Layer sealing ...

Embodiment 2

[0048] A paper-plastic packaging anti-pilling sealing coating process, with reference to figure 1 and figure 2 , which includes the following steps:

[0049] Use an aqueous solution of acetic acid at 80°C and a concentration of 5wt% to prepare the sealing agent into an aqueous solution with a concentration of 12wt%. : 1 ratio, filtered while hot, to obtain the sealing solution for later use. The sealing liquid is sprayed through the high-pressure nozzle 21 into the atomization chamber 2 equipped with a heating device, and a uniform and fine mist of the sealing liquid is formed in the atomization chamber 2 . The inside of the atomization chamber 2 is heated to 95° C. with a heating device in advance and kept warm. Then, the formed paper-plastic package 1 is sent into the atomization chamber 2 with the opening facing upwards by means of the conveyor 4, and the residence time of the paper-plastic package 1 in the atomization chamber 2 is controlled to be 20s, so that the surf...

Embodiment 3

[0051] A paper-plastic packaging anti-pilling sealing coating process, with reference to figure 1 and figure 2 , which includes the following steps:

[0052] Prepare N-maleyl chitosan into an aqueous solution with a concentration of 10 wt% by using an aqueous solution of acetic acid at 80°C and a concentration of 5 wt%, and filter while it is hot to obtain a sealing solution for use. The sealing liquid is sprayed through the high-pressure nozzle 21 into the atomization chamber 2 equipped with a heating device, and a uniform and fine mist of the sealing liquid is formed in the atomization chamber 2 . The inside of the atomization chamber 2 is heated to 90° C. with a heating device in advance and kept warm. Then, the molded paper-plastic package 1 is sent into the atomization chamber 2 with the opening facing up by means of the conveyor 4, and the residence time of the paper-plastic package 1 in the atomization chamber 2 is controlled to be 10s, so that the surface of the pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com