Spray pyrolysis method of nickel oxide and perovskite solar cell

A spray pyrolysis, nickel oxide technology, applied in the field of solar cells, can solve problems such as unfavorable acquisition, poor liquid wettability, uniform thin film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

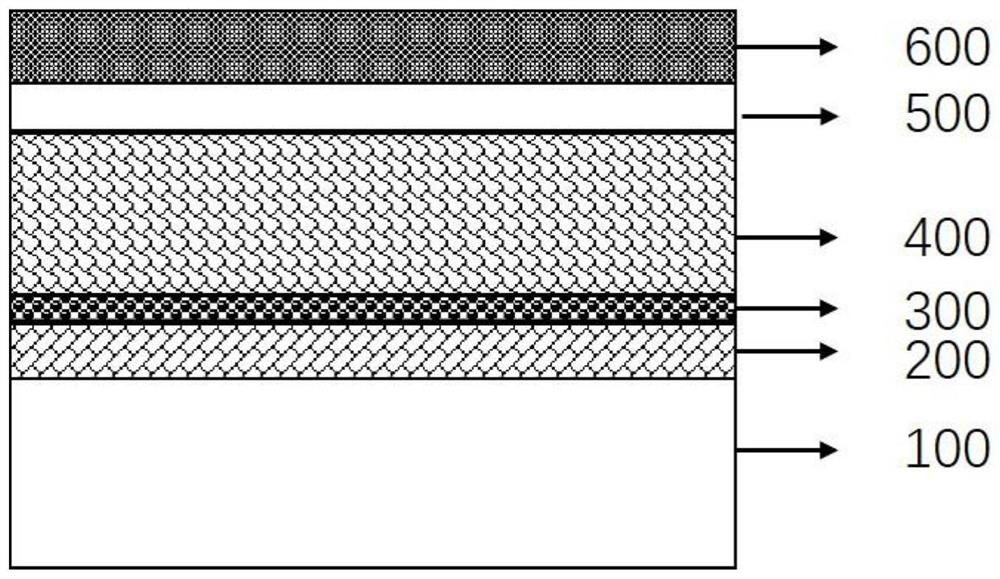

[0052] The present invention also provides a preparation method of the above perovskite solar cell, comprising: compounding a nickel oxide hole transport layer on the surface of the first electrode; coating a perovskite active material precursor solution on the surface of the nickel oxide hole transport layer forming a perovskite active layer; compounding an electron transport layer on the surface of the perovskite active layer; forming a second electrode on the surface of the electron transport layer to obtain a perovskite solar cell.

[0053] Wherein, the first electrode, the hole transport layer, the perovskite active layer, the electron transport layer and the second electrode are the same as described above, and will not be repeated here.

[0054] In the present invention, it is preferable to form the first electrode on the substrate first; the substrate is the same as the above, and will not be repeated here; when the substrate is a glass substrate, it is preferable to us...

Embodiment 1

[0062] 15.7635g of Ni (NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water to obtain Ni(NO 3 ) 2 solution, to Ni(NO 3 ) 2 The solution was added dropwise to 10mol·L -1 NaOH aqueous solution to the solution pH=10, at this time, a precipitate was formed in the solution, the solution was magnetically stirred for 5 min, and then the precipitate was washed with deionized water 3 times, and the precipitate was dried at 80 °C for 6 h, and then placed in a muffle furnace. Annealed at 270 °C for 2 h to obtain NiOx nanoparticles.

[0063] The NiOx nanoparticles were dissolved in deionized water and sonicated for 8 h to obtain a 0.08 mol / L precursor solution. The NiOx precursor solution was deposited on the FTO by spraying equipment, cycled 8 times, the spraying speed was 5 mm / s, and the spraying height was 50 cm to obtain a NiOx hole transport layer with a thickness of 30 nm, which was then annealed at 130 °C for 30 min.

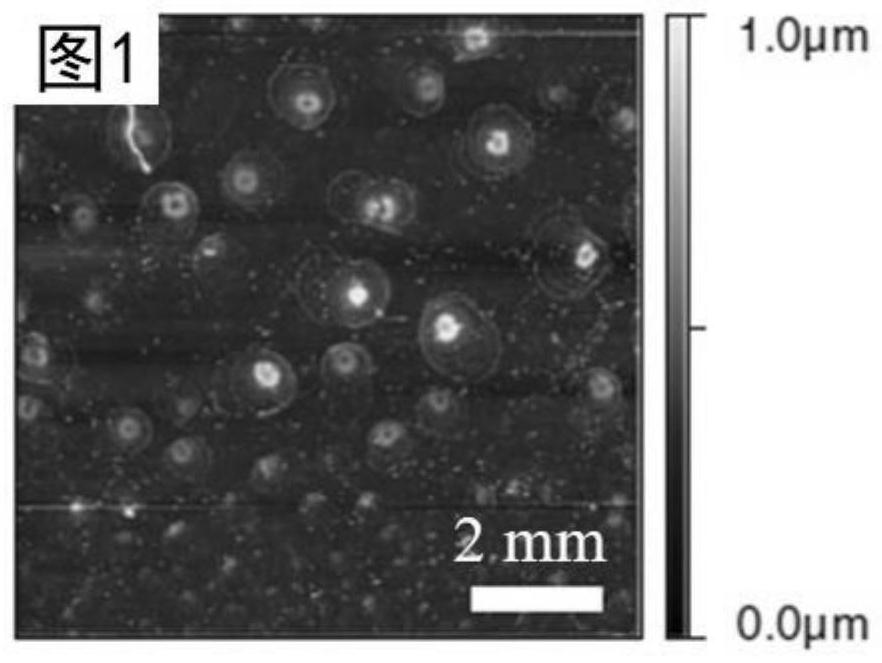

[0064] Use atomic force microscope to analyze th...

Embodiment 2

[0066] 15.7635g of Ni (NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water to obtain Ni(NO 3 ) 2 solution, to Ni(NO 3 ) 2 The solution was added dropwise to 10mol·L -1 NaOH aqueous solution to the solution pH=10, at this time a precipitate was formed in the solution, the solution was magnetically stirred for 5 min, then the precipitate was washed with deionized water 3 times, and the precipitate was dried at 80 °C for 6 h, and then placed in a muffle furnace. Annealed at 270 °C for 2 h to obtain NiOx nanoparticles.

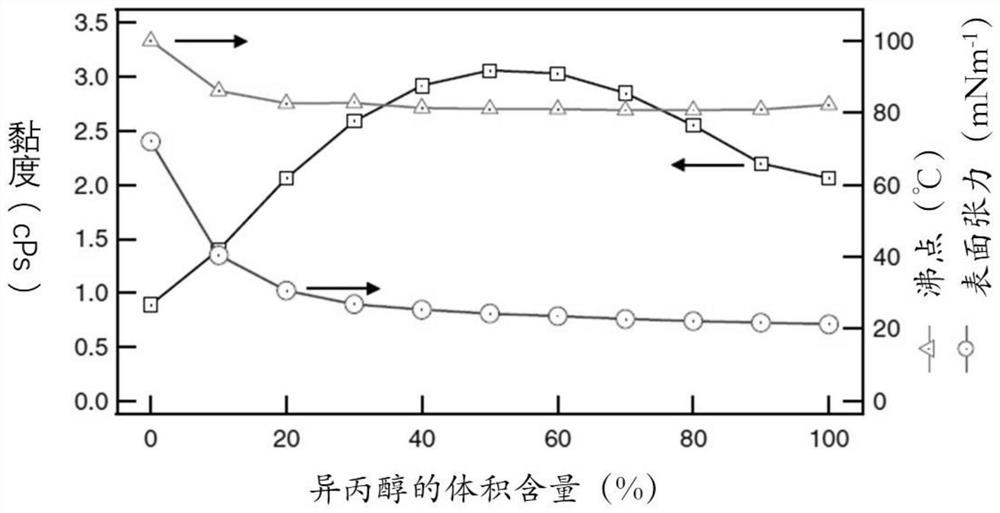

[0067] The NiOx nanoparticles were dissolved in deionized water and isopropanol, wherein the volume ratio of deionized water and isopropanol was 9:1, and then sonicated for 8 h to obtain a 0.1 mol / L precursor solution. The NiOx precursor solution was deposited on the FTO by spraying equipment, cycled 8 times, the spraying speed was 5 mm / s, and the spraying height was 50 cm to obtain a NiOx hole transport layer with a thickness of 30 nm, which was th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com