Ultrasonic fuel excitation device

A technology of excitation device and ultrasonic wave, applied in fuel injection device, low pressure fuel injection, low pressure fuel injection and other directions, can solve the problems of large heat loss of engine fuel and low thermal efficiency, and achieve the effect of enhancing equipment power, protecting the environment and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

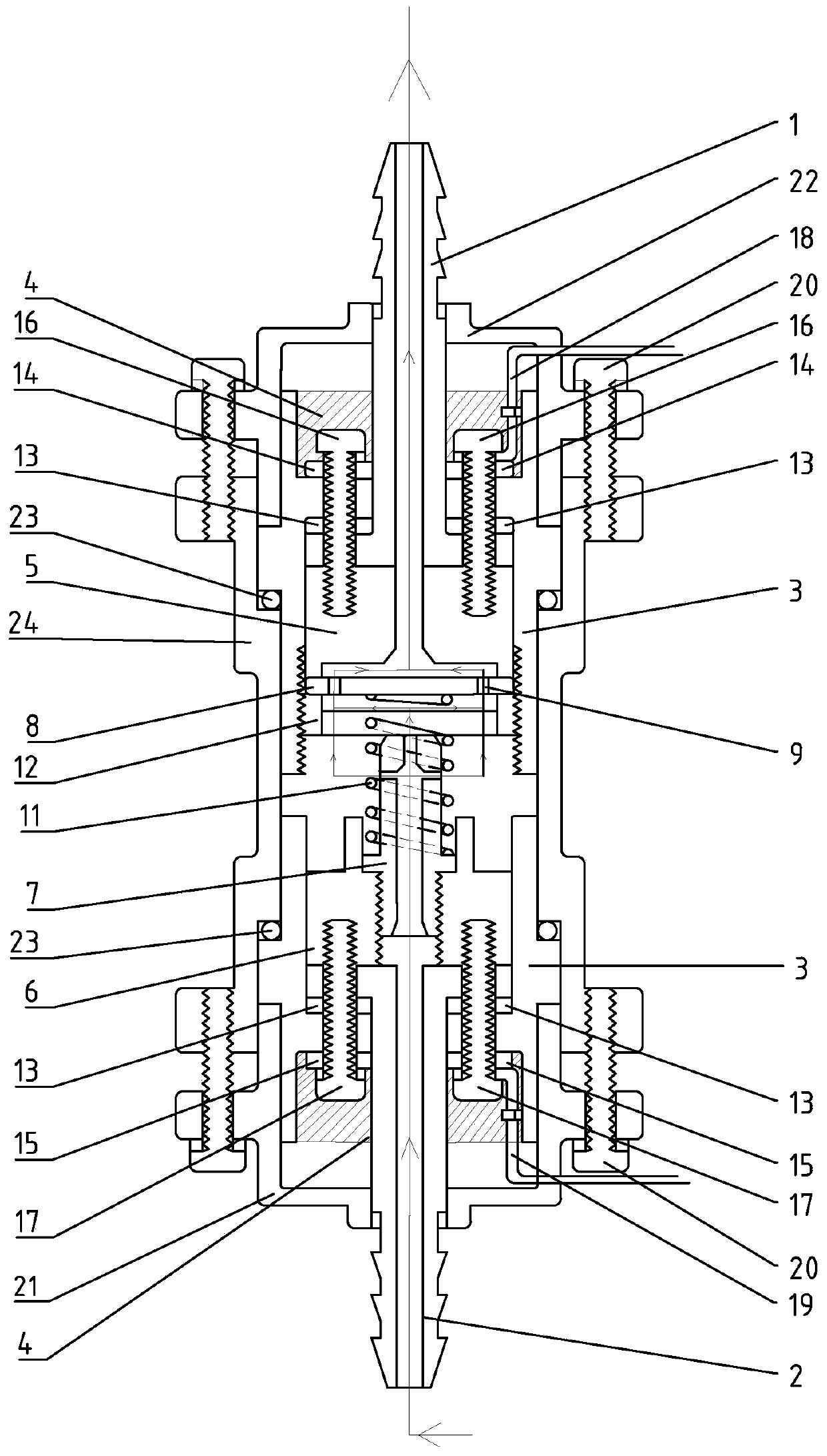

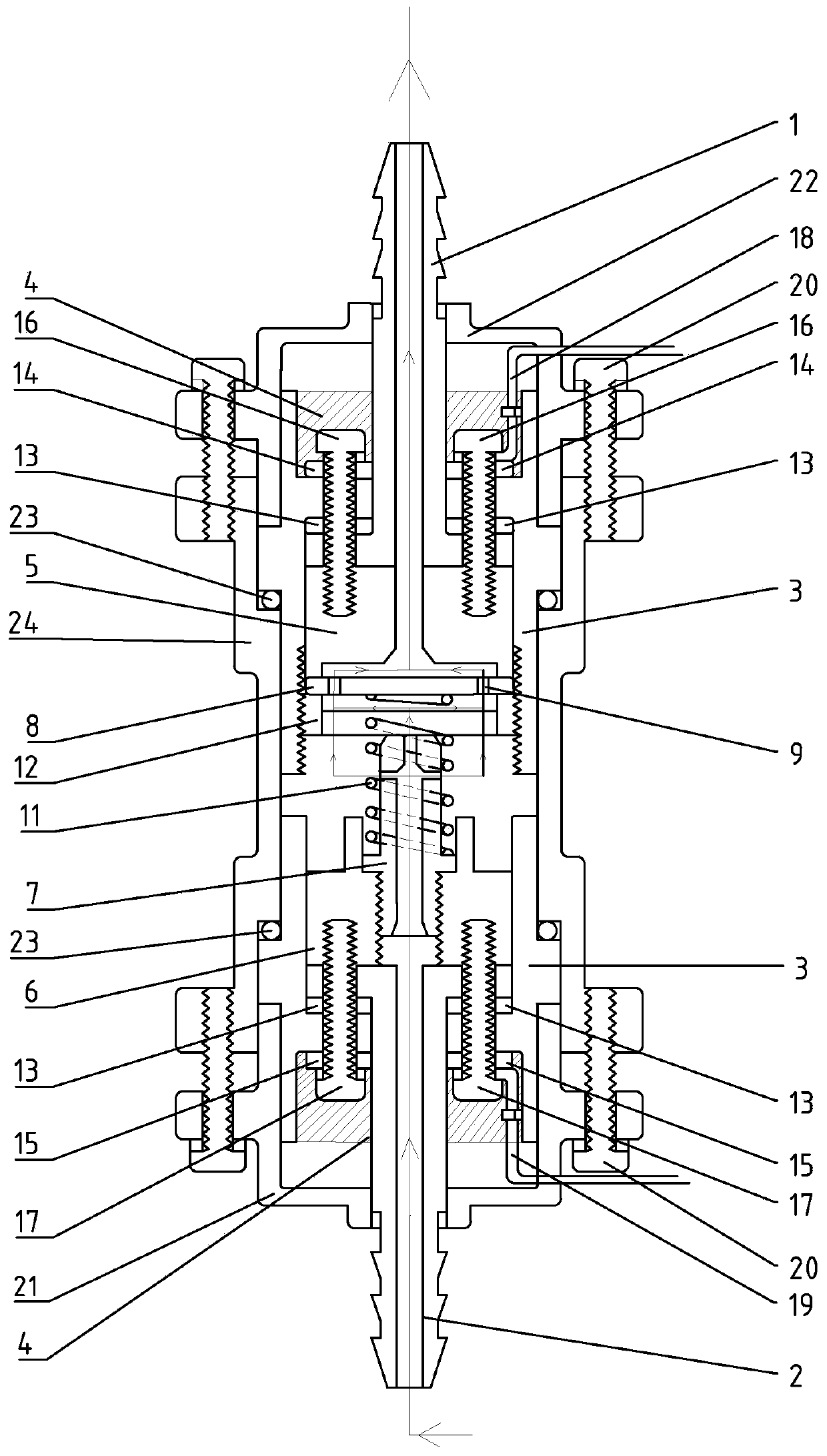

[0027] like figure 1 Shown is a standard ultrasonic fuel excitation device, that is, the ultrasonic transducer unit only includes one ultrasonic transducer sheet 8 .

[0028]The shell of the ultrasonic fuel excitation device is composed of an outer metal shell and an inner insulating shell, wherein the outer metal shell is composed of an inlet metal seal 21 , an outlet metal seal 22 and a metal shell 24 . The inlet metal seal 21 is fixed on the bottom of the metal shell 24 by two shell screws 20 , and the outlet metal seal 22 is fixed on the top of the metal shell 24 by the shell screws 20 . The inner insulating layer is composed of the inlet insulating oil nipple 2, the outlet insulating oil nipple 1 and the insulating shell 3. The inlet insulating nozzle 2 is hermetically arranged in the inlet metal head 21, and has a fuel inlet inside. The outlet insulating oil nozzle 1 is sealed and arranged in the outlet metal sealing head 22, and has a fuel outlet inside. The insulati...

Embodiment 2

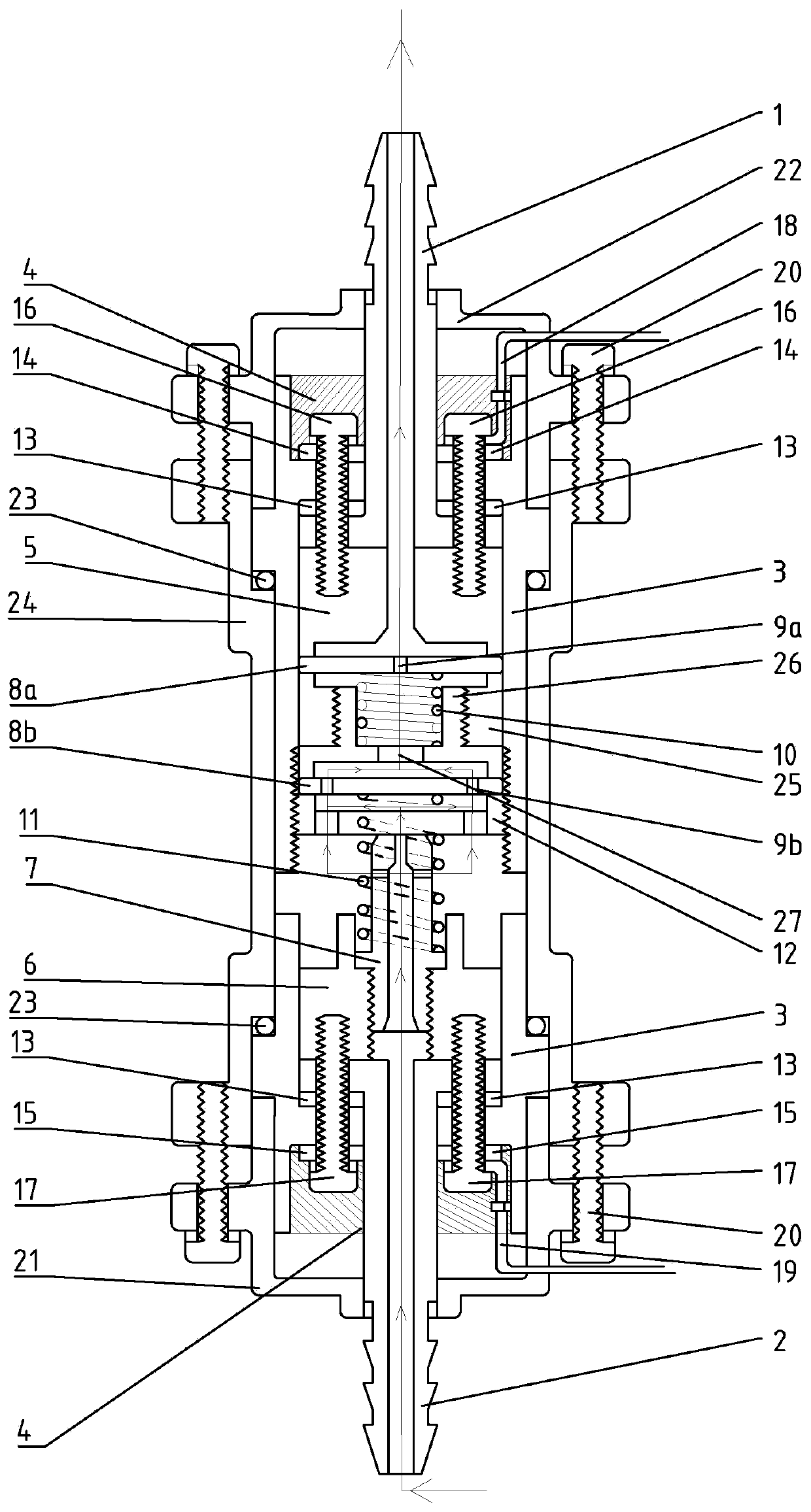

[0035] like figure 2 Shown is an enhanced ultrasonic fuel excitation device, that is, the ultrasonic transducer unit includes two ultrasonic transducers connected in series, namely a first ultrasonic transducer 8a and a second ultrasonic transducer 8b.

[0036] The shell of the ultrasonic fuel excitation device is composed of an outer metal shell and an inner insulating shell, wherein the outer metal shell is composed of an inlet metal seal 21 , an outlet metal seal 22 and a metal shell 24 . The inlet metal sealing head 21 is fixed on the bottom of the metal casing 24 by two casing screws 20 , and the outlet metal sealing head 22 is fixed on the top of the metal casing 24 by two casing screws 20 . The inner insulating layer is composed of the inlet insulating oil nipple 2, the outlet insulating oil nipple 1 and the insulating shell 3. The inlet insulating nozzle 2 is hermetically arranged in the inlet metal head 21, and has a fuel inlet inside. The outlet insulating oil noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com