Alcohol-based fuel without eye fumigation in use

A technology of alcohol-based fuels and additives, applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of low calorific value of alcohol-based fuels, insufficient fuel, and smoke smoke, etc., to improve fuel combustion Working conditions, easy ignition, effect of increasing octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

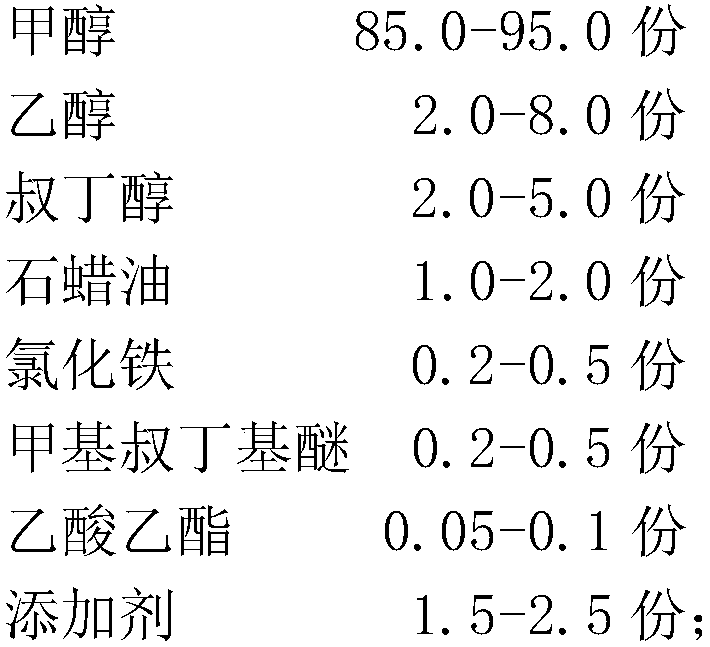

[0025] Prepare an alcohol-based fuel that does not smudge the eyes when used, and mix according to the following components and ratios (stir evenly at room temperature) to obtain an alcohol-based fuel that does not smudge the eyes when used:

[0026]

[0027] Described additive obtains by following preparation method:

[0028] ①Pressure treatment: put the loquat leaf residue extracted by water into a high-pressure tank, and pressurize to 3kg / cm 2 , to make the pressure uniform, maintain 5-10min, and then release the pressure within 1-5s;

[0029] ②Distillation treatment: put the material obtained in step ① into the still, and heat it to burn or pass in steam at the bottom of the still. When the hot steam is filled in the still, the steam is introduced into the condenser through the condenser tube, and then passed through Oil-water separator to collect oil phase;

[0030] ③High-shear homogenizer treatment: process the oil phase obtained in step ② through a high-shear homog...

Embodiment 2

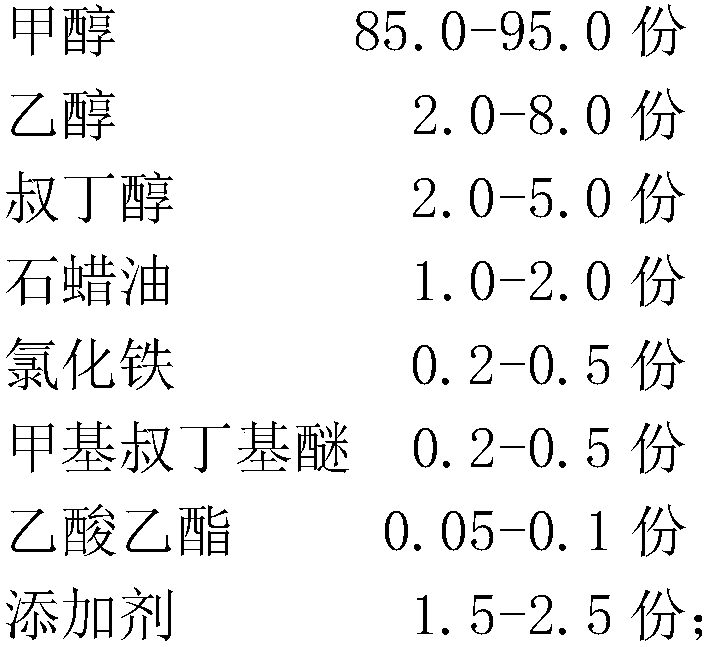

[0032] Prepare an alcohol-based fuel that does not smudge the eyes when used, and mix according to the following components and ratios (stir evenly at room temperature) to obtain an alcohol-based fuel that does not smudge the eyes when used:

[0033]

[0034] Described additive obtains by following preparation method:

[0035] ①Pressure treatment: put the loquat leaf residue extracted by water into a high-pressure tank, and pressurize to 3kg / cm 2 , to make the pressure uniform, maintain 5-10min, and then release the pressure within 1-5s;

[0036] ②Distillation treatment: Put the material obtained in step ① into the still, and heat it to burn or pass in steam at the bottom of the still. When the hot steam is filled in the still, the steam is introduced into the condenser through the condenser tube, and then passed through Oil-water separator to collect oil phase;

[0037] ③High-shear homogenizer treatment: process the oil phase obtained in step ② through a high-shear homog...

Embodiment 3

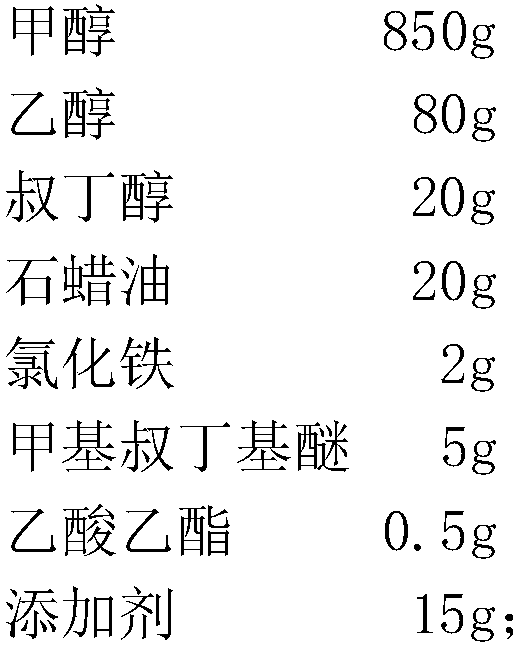

[0039] Prepare an alcohol-based fuel that does not smudge the eyes when used, and mix according to the following components and ratios (stir evenly at room temperature) to obtain an alcohol-based fuel that does not smudge the eyes when used:

[0040]

[0041] Described additive obtains by following preparation method:

[0042] ①Pressure treatment: put the loquat leaf residue extracted by water into a high-pressure tank, and pressurize to 3kg / cm 2, to make the pressure uniform, maintain 5-10min, and then release the pressure within 1-5s;

[0043] ②Distillation treatment: Put the material obtained in step ① into the still, and heat it to burn or pass in steam at the bottom of the still. When the hot steam is filled in the still, the steam is introduced into the condenser through the condenser tube, and then passed through Oil-water separator to collect oil phase;

[0044] ③High-shear homogenizer treatment: process the oil phase obtained in step ② through a high-shear homoge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com