Spray nozzle

A technology of nozzles and sprinklers, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of complex nozzle structure, easy clogging, and affecting the normal use of nozzles, and achieve the effect of simple structure, not easy to clog nozzles, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings and embodiments.

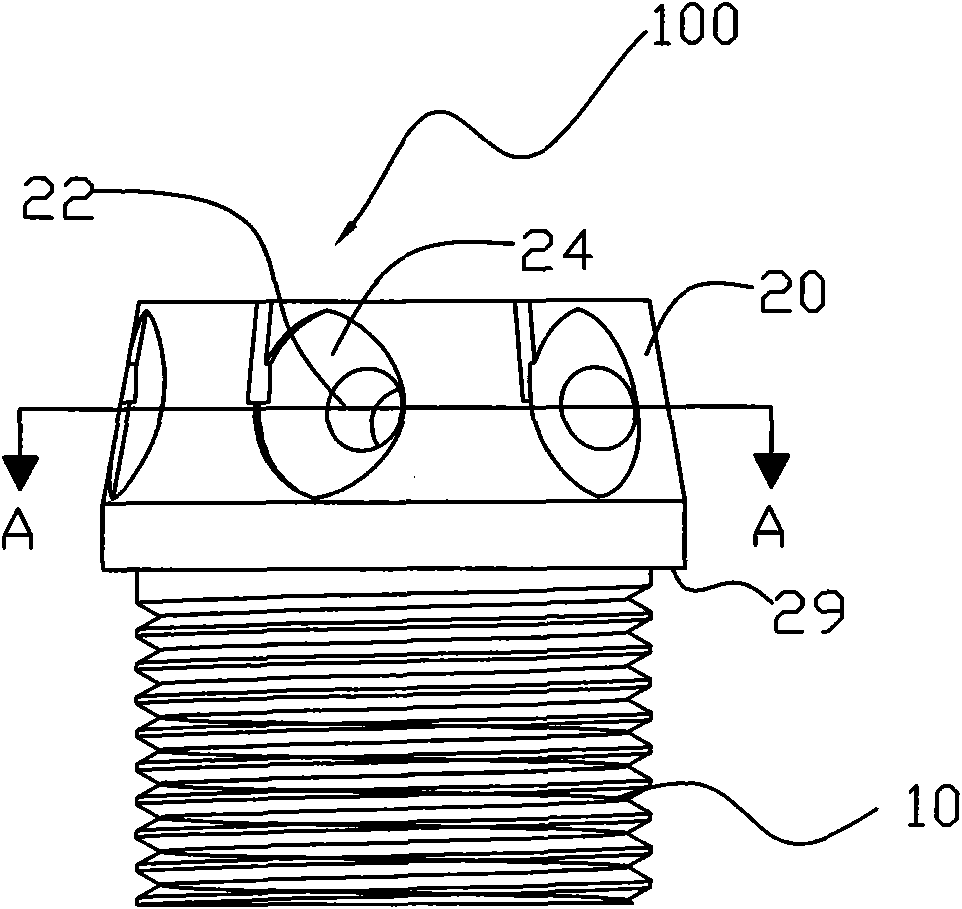

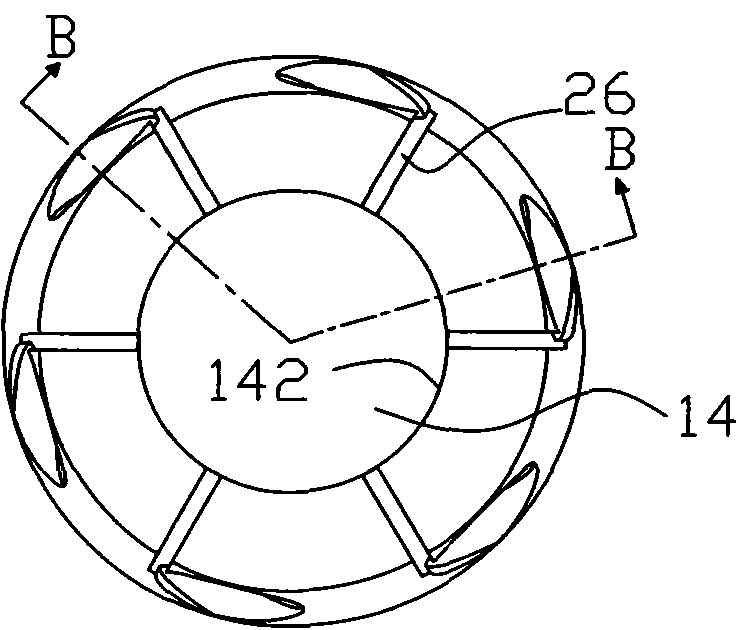

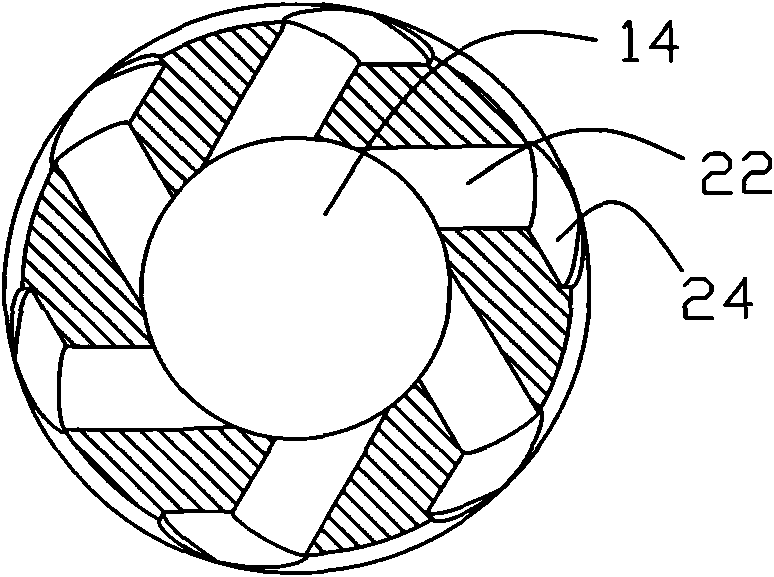

[0013] refer to Figure 1-4 The nozzle 100 provided by the present invention includes a cylindrical threaded connection portion 10 and a spray head 20 formed at one end of the threaded connection portion 10 and having a diameter larger than the diameter of the threaded connection portion 10 . An abutment wall 29 is formed between the threaded connection portion 10 and the spray head 20 for resisting the axial loosening of the threaded connection between the threaded connection portion 10 and the external pipeline.

[0014] The threaded connection portion 10 is used to fix and seal the entire nozzle 100 with other devices for providing liquid, such as water pipes, in the form of threads, so as to spray and atomize the liquid through the nozzle 100 .

[0015] The inside of the threaded connection portion 10 is axially provided with a flow control hole 12 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com