Patents

Literature

40 results about "Oil paraffin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraffin oil, known as kerosene in Australia and the United States and stove oil in Canada, is an flammable liquid hydrocarbon burned as fuel.

Thermally conductive material and thermally conductive sheet molded from the thermally conductive material

ActiveUS20100012884A1Excellent thermal conductivity and electrical insulationOther chemical processesSemiconductor/solid-state device detailsThermal conductivityFire retardant

Disclosed is a thermally conductive material having excellent heat conductivity and insulating properties and having flame retardancy while retaining flexibility and toughness. More specifically, there is provided a thermally conductive material comprising: a hydrogenated copolymer (1) and / or a modified hydrogenated copolymer (2) in which each has a specific structure and is contained in a specific amount; and zinc oxide (3) comprising a core part and acicular crystal parts extending from the core part in four axial directions. The thermally conductive material optionally further comprises a paraffin oil (4), a flame retardant (5), or a filler (6) having a thermal conductivity of 10 to 400 W / m·K (the zinc oxide (3) is excluded).

Owner:ASAHI KASEI KK

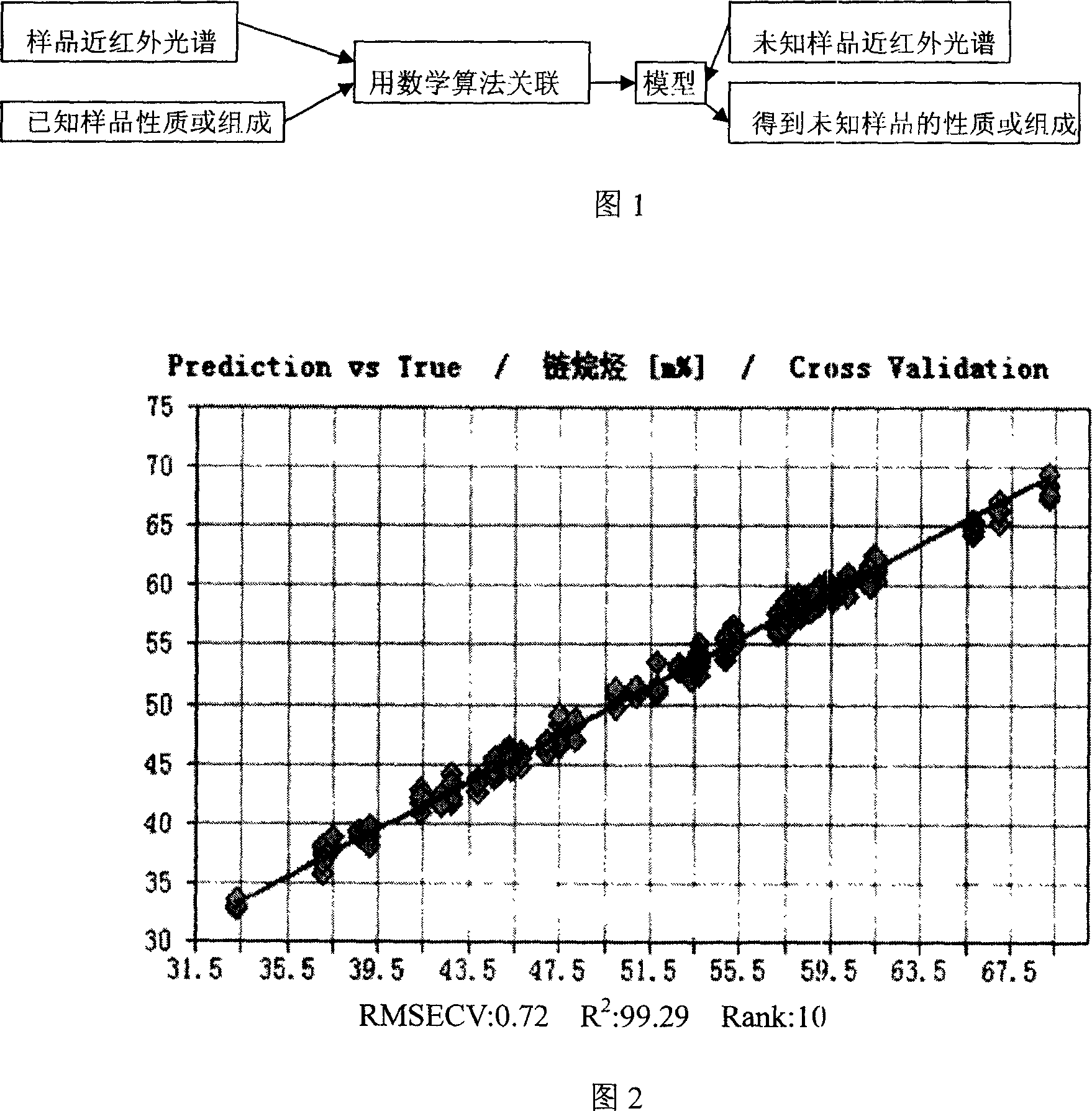

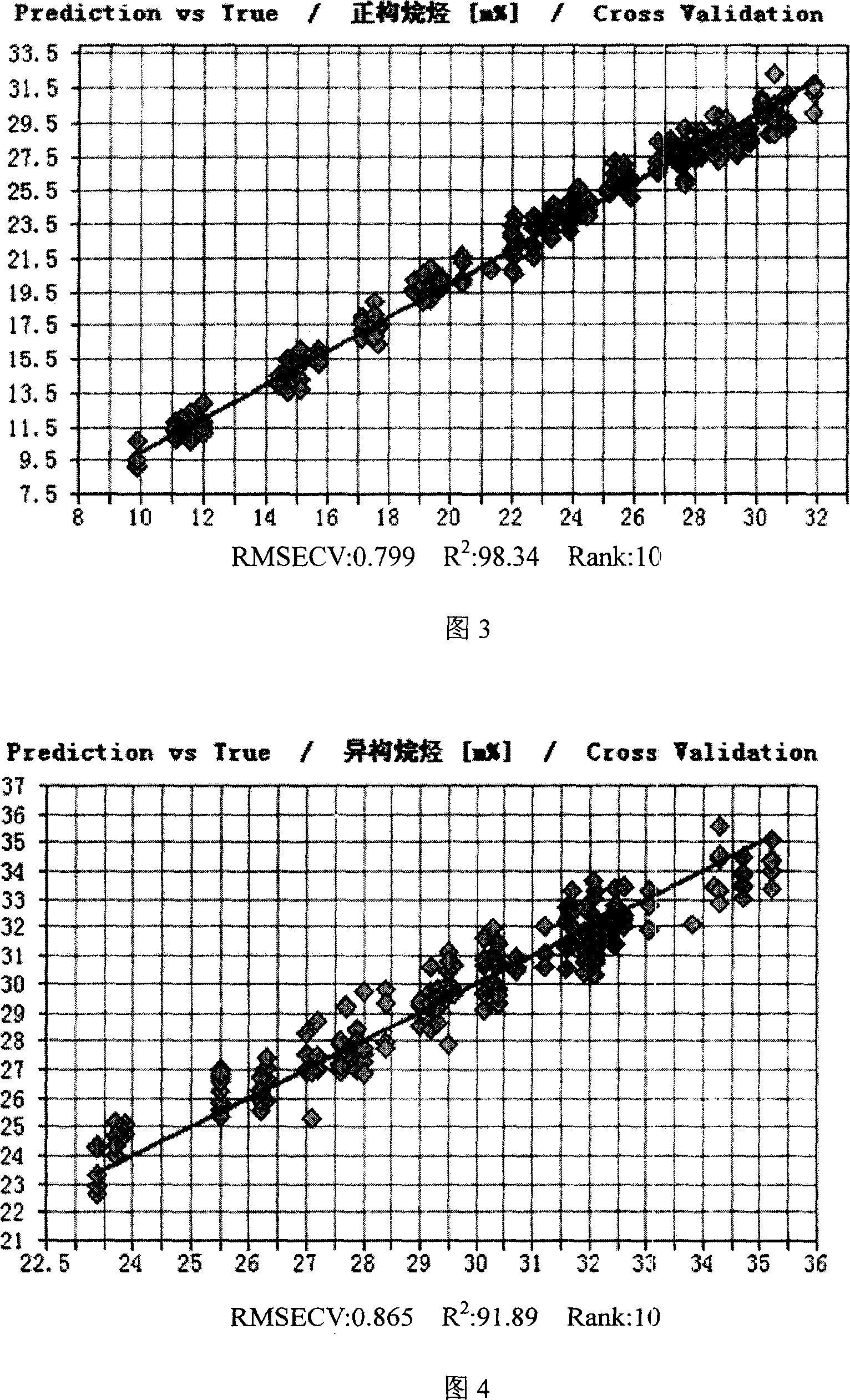

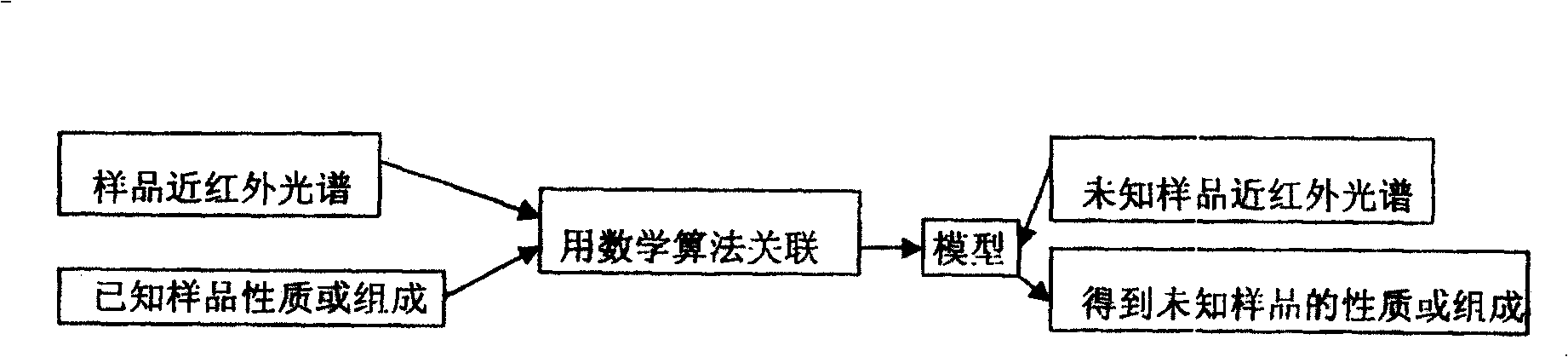

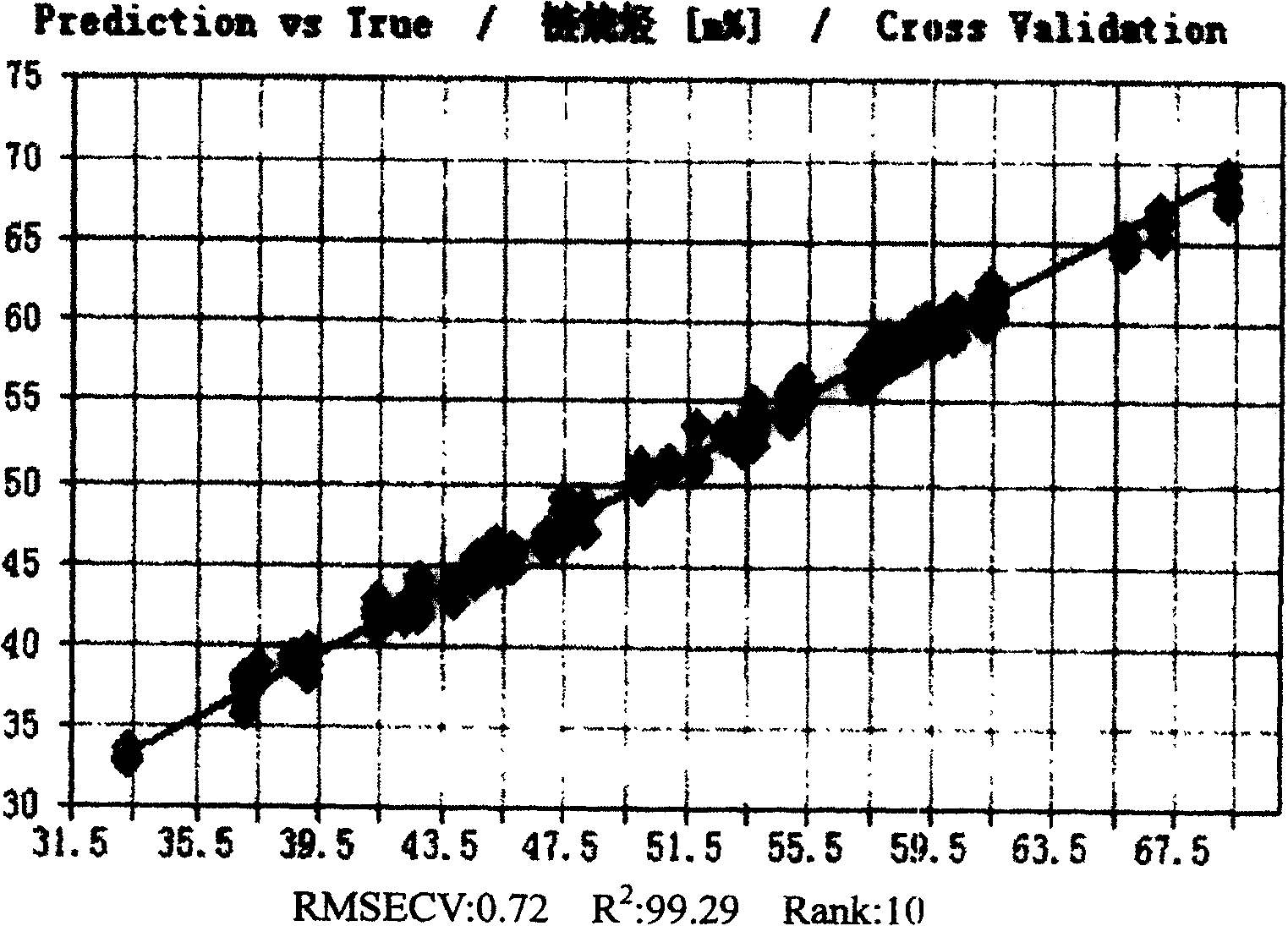

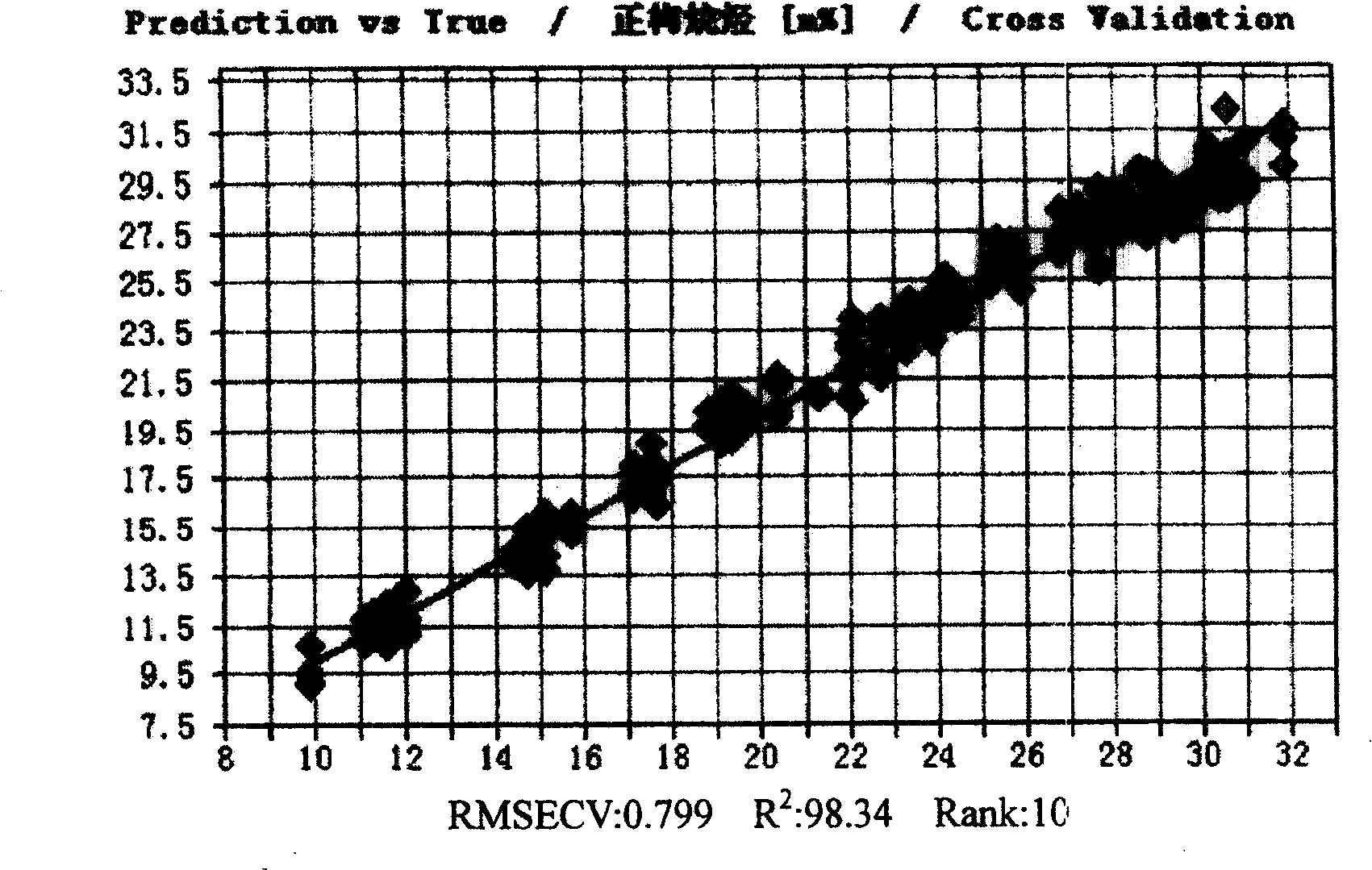

Method for detecting hydrgenated tail-oil paraffin composition using near-infrared spectrum

InactiveCN1979131AThe test method is simple and fastEasy and fast testingComponent separationColor/spectral properties measurementsAlkaneFourier transform on finite groups

The invention relates to a method to test the constitution of hydrogenation tail oil paraffin group by near infrared optical spectrum. It builds up models of paraffin, alkane, and isoalkane by alkene cracking device, and aromatics reformer and oil refining hydrogenation unit. And the content of paraffin, alkane, and isoalkane would be calculated by using the models. It has the advantages of convenient, rapid and accurate.

Owner:YANGZI PETROCHEM

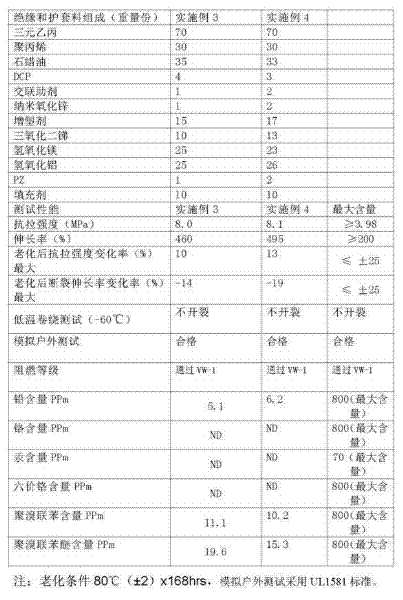

High flame retardant super low temperature resistant environmental flexible cable

ActiveCN102262936AImprove anti-agingGood heat and cold resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlasticizer

The invention relates to the technical field of novel material application, in particular to an environment-friendly flexible cable with high flame retardance and super low temperature resistance. The environment-friendly flexible cable with the high flame retardance and the super low temperature resistance comprises a flexible twisted conductor, an insulating layer and an outer protective layer, wherein the insulating layer is wrapped outside the flexible twisted conductor to form single insulated wires; the outer protective layer wraps at least two single insulated wires; the insulating layer and the outer protective layer are made from the same materials, take an ethylene-propylene-diene monomer as a disperse phase and take polypropylene as a continuous phase; the insulating layer contains a plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant; and the outer protective layer contains the plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant. Due to the adoption of the technical scheme, the environment-friendly flexible cable with the high flame retardance and the super low temperature resistance has high torsion resistance, the super low temperature resistance and flame retardance, is difficult to age and crack and environment-friendly, and can work stably in low temperature environments of below -60 DEG C.

Owner:GUANGDONG ZHONGDE CABLE

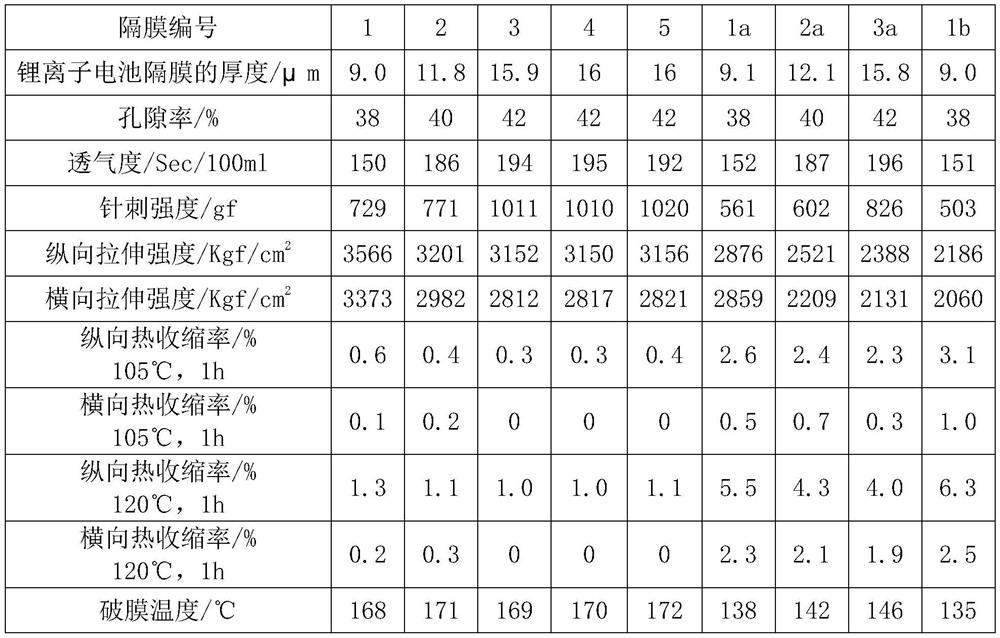

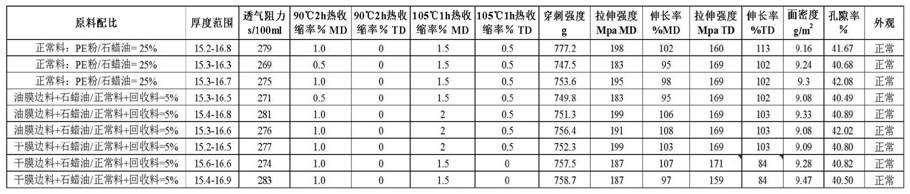

High-strength low-shrinkage lithium ion battery diaphragm and preparation method thereof

PendingCN112259904AChange section propertiesGood dispersionSecondary cellsCell component detailsPhysical chemistryLithium-ion battery

The invention discloses a high-strength low-shrinkage lithium ion battery diaphragm preparation method, which comprises the following steps: 1, mixing high molecular weight polyethylene, inorganic whiskers, a coupling agent and paraffin oil at a high temperature to obtain a mixture; 2, blending the obtained mixture at a high temperature to form a homogeneous blend; 3, cooling and shaping the obtained homogeneous blend to obtain a cast sheet; and 4, sequentially carrying out longitudinal stretching, primary transverse stretching, extraction, secondary transverse stretching, heat setting and winding processes on the obtained cast sheet to obtain the lithium ion battery diaphragm. According to the invention, the prepared lithium ion battery diaphragm has good mechanical strength and high-temperature shrinkage resistance; and the thickness of the lithium ion battery diaphragm is 5-25 [mu]m, compared with the existing lithium ion battery diaphragm, the mechanical strength of the lithium ionbattery diaphragm is improved by about 30%, and the thermal shrinkage rate is obviously reduced.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Efficient oil well paraffin remover

InactiveCN109897617AIncrease hydrationImprove the lubrication effectDrilling compositionWaxBlock structure

The invention discloses an efficient oil well paraffin remover, and belongs to the technical field of oilfield exploitation. Hydrophilic components such as mercaptoethanol are led in and matched to form a water protective film, hydration and lubrication properties of oil paraffin are improved, paraffin dispersion effects are improved, entanglement among a hole structure formed in the preparation process and components such as composite paraffin removal basic materials and composite accessories is achieved, affinity effects on the paraffin in using is improved, and paraffin removal effects areimproved. Added phospholipid has good emulsification functions, so that polar groups in components can extend into the paraffin, phospholipid molecules have more negative charges, local charges can beunbalanced and excluded each other, a blocking structure formed by paraffin accumulation in an oil well is broken, an open area cannot be reduced, an oil pipe cannot be blocked by the paraffin, and dredging effects are improved. The paraffin remover solves the problems that a current frequently-used paraffin remover has low liquidity at low temperature, paraffin remover speed is low, the open area is reduced, and the oil pipe is blocked by the paraffin.

Owner:杭州攻守道贸易有限公司

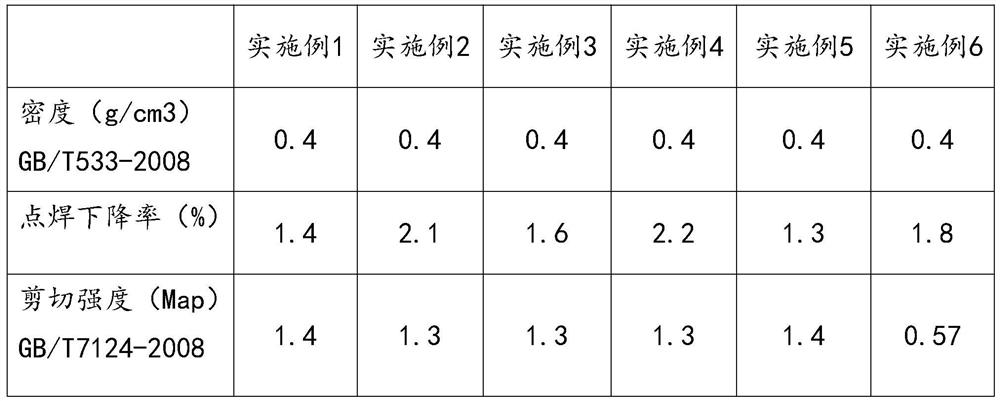

Spot welding sealing foaming rubber pad for vehicle

The invention provides a spot welding sealing foaming rubber pad for a vehicle and belongs to the technical field of vehicle spot welding. The spot welding sealing foaming rubber pad is prepared fromthe following raw materials in parts by weight: butyl rubber 20-30%; 10-20% of paraffin oil; 3-5% of hydrogenated C5 petroleum resin; 5-10% of conductive carbon black; 10-20% of a flame retardant; 10-30% of mica powder; 10-30% of vermiculite powder; 1-2% of zinc oxide; 0.5-1% of stearic acid; 0.5-1% of sulfur; 1.0-3.0% of a crosslinking aid; 1-3% of a foaming agent; and 1-1.8% of an anti-aging agent. The preparation method of the product is simple; the mica powder and vermiculite powder are added, so that noise reduction and shock absorption functions are increased; the prepared rubber pad product can be foamed at high temperature; in the process that an automobile passes through a coating workshop, the foaming filling of the rubber pad in a metal plate can be synchronously achieved on a coating line, and the effects of damping, noise reduction, sound insulation and flame retardance are achieved. The rubber pad can be widely applied to the filling and sealing of gaps of the automobilemetal plate without avoiding welding spots.

Owner:WUHU HAICHENG RUBBER & PLASTIC

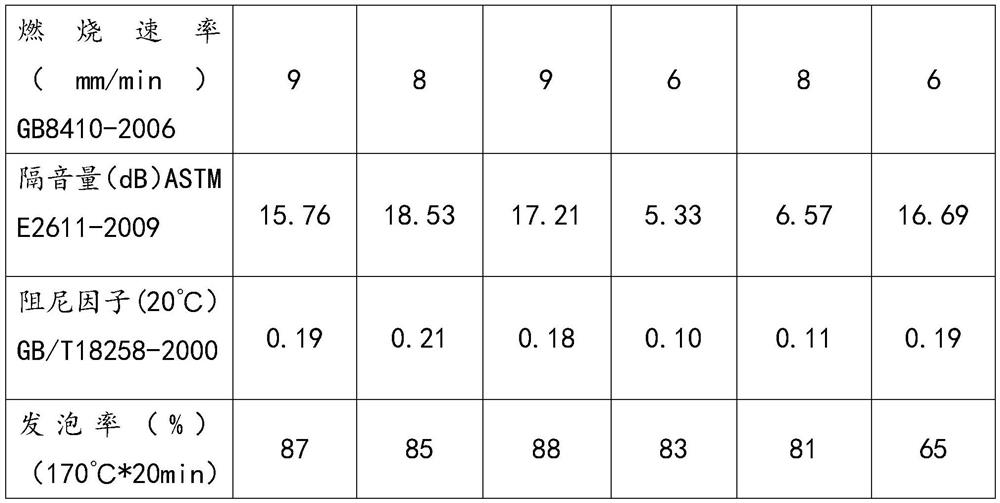

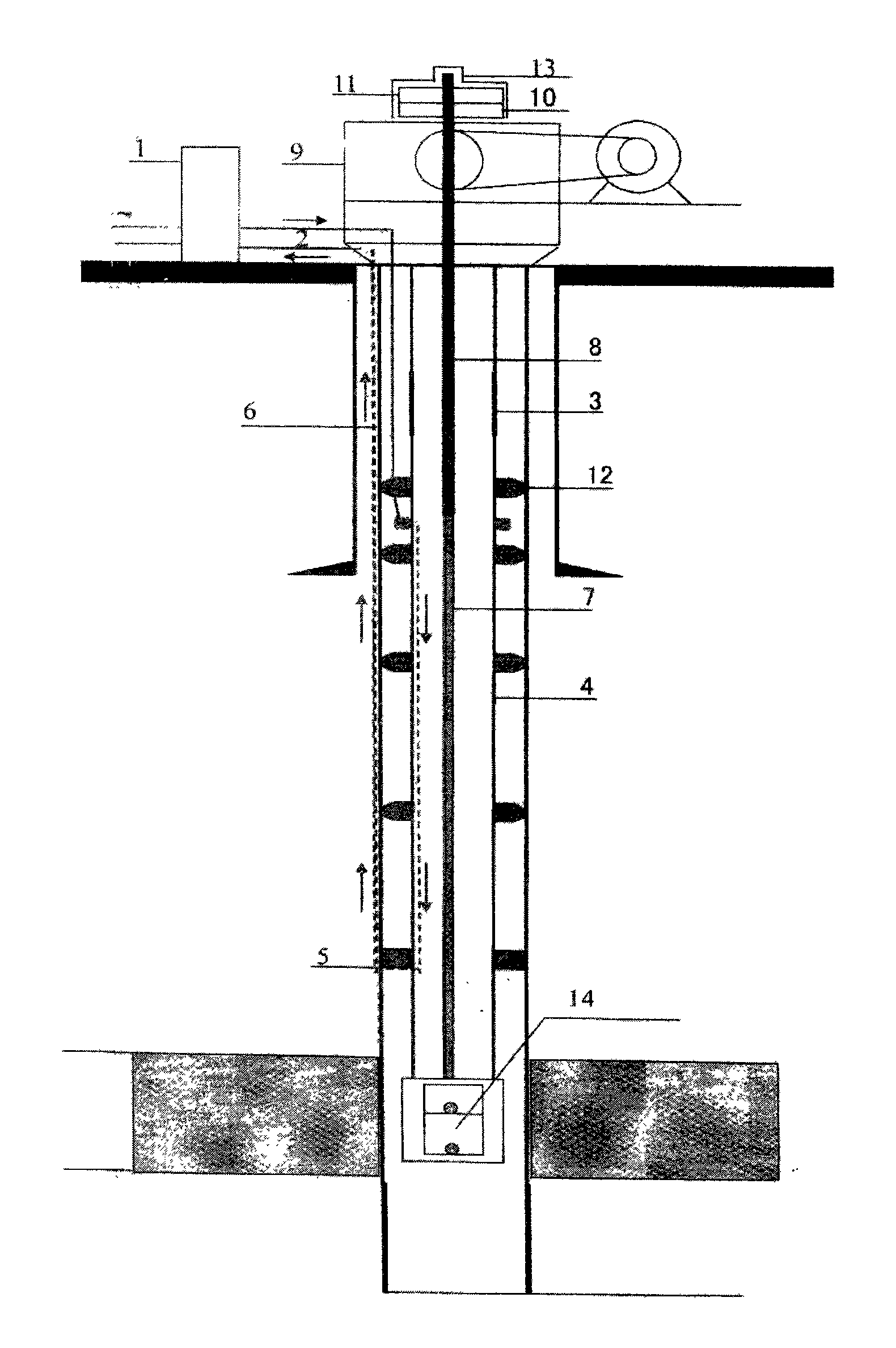

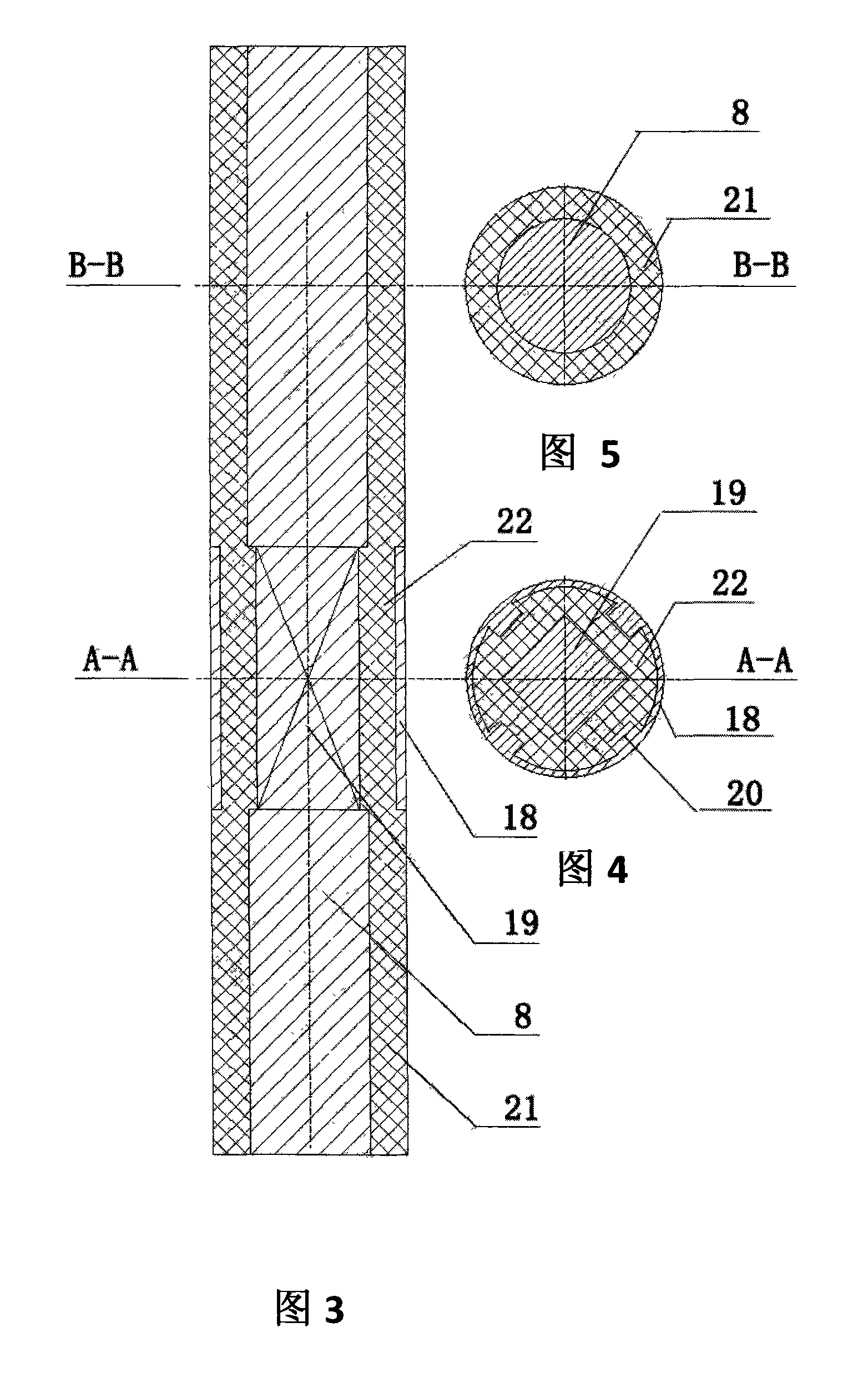

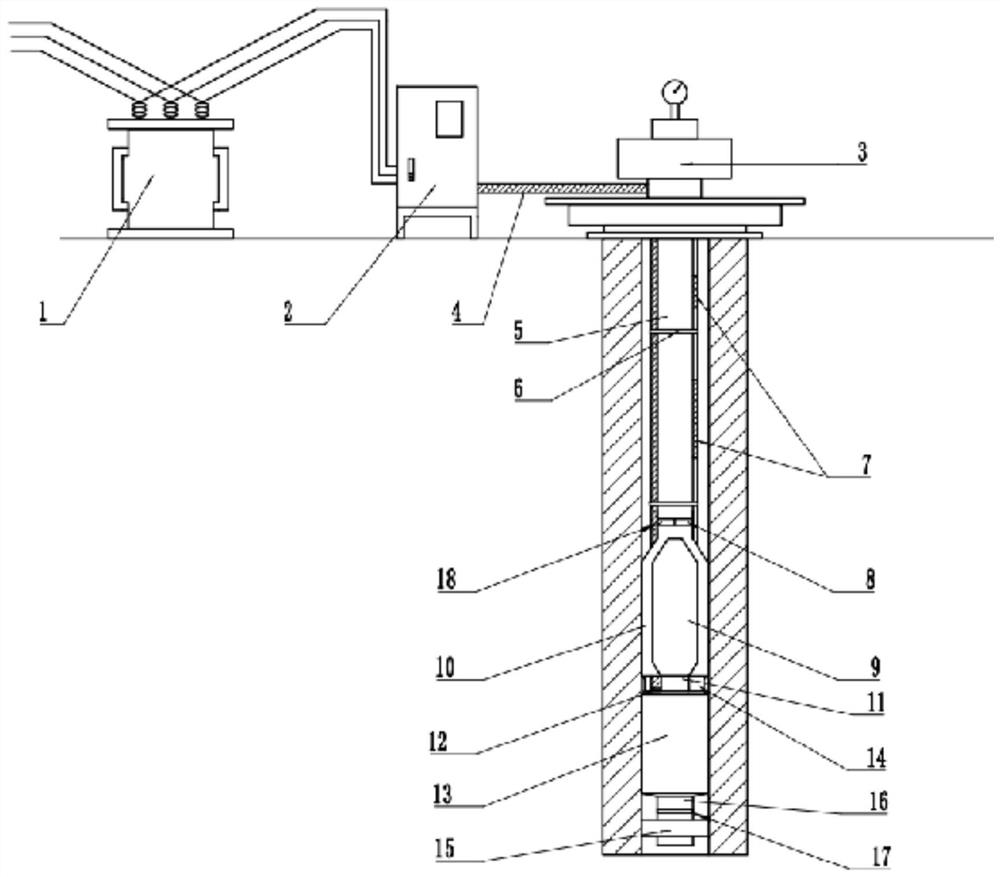

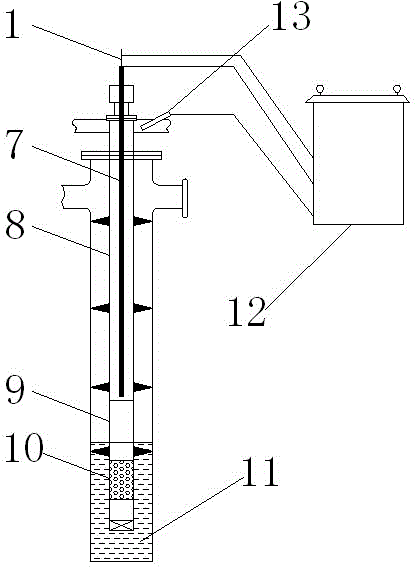

Thick oil paraffin removal device for screw pump electric heating oil pipe

The invention discloses a thick oil paraffin removal device for a screw pump electric heating oil pipe, which is a thick oil paraffin removal device for an electric heating oil pipe of an oil well, in particular an electro-thermal paraffin removal device used in a screw pump oil well. An electric control cabinet is placed on the ground surface. The oil pipe is provided with an insulating short section. The electric control cabinet is connected to the oil pipe on the lower part of the insulating short section through a cable. A communicating device is arranged between the lower part of the oil pipe and a sleeve pipe. The sleeve pipe serves as a current loop through the communicating device. The topmost part of a rotating rod is provided with an insulating polished rod. A driving head is provided with an insulating square clamping seat. The working method of the paraffin removal device comprises the following steps: turning on a power switch of the oil pipe of the electric control cabinet; electrifying and heating the oil pipe on the lower part of the insulating short section; dissolving thick oil; and dissolving paraffin scales adhered to the inner wall of the oil pipe to ensure that the screw pump works normally. Because of an insulating centralizer, the insulating short section, the insulating polished rod and the insulating square clamping seat, land-based facilities are insulated with underground pipe columns and are uncharged. Thus, the screw pump oil well can be applied in thick oil areas.

Owner:金连家

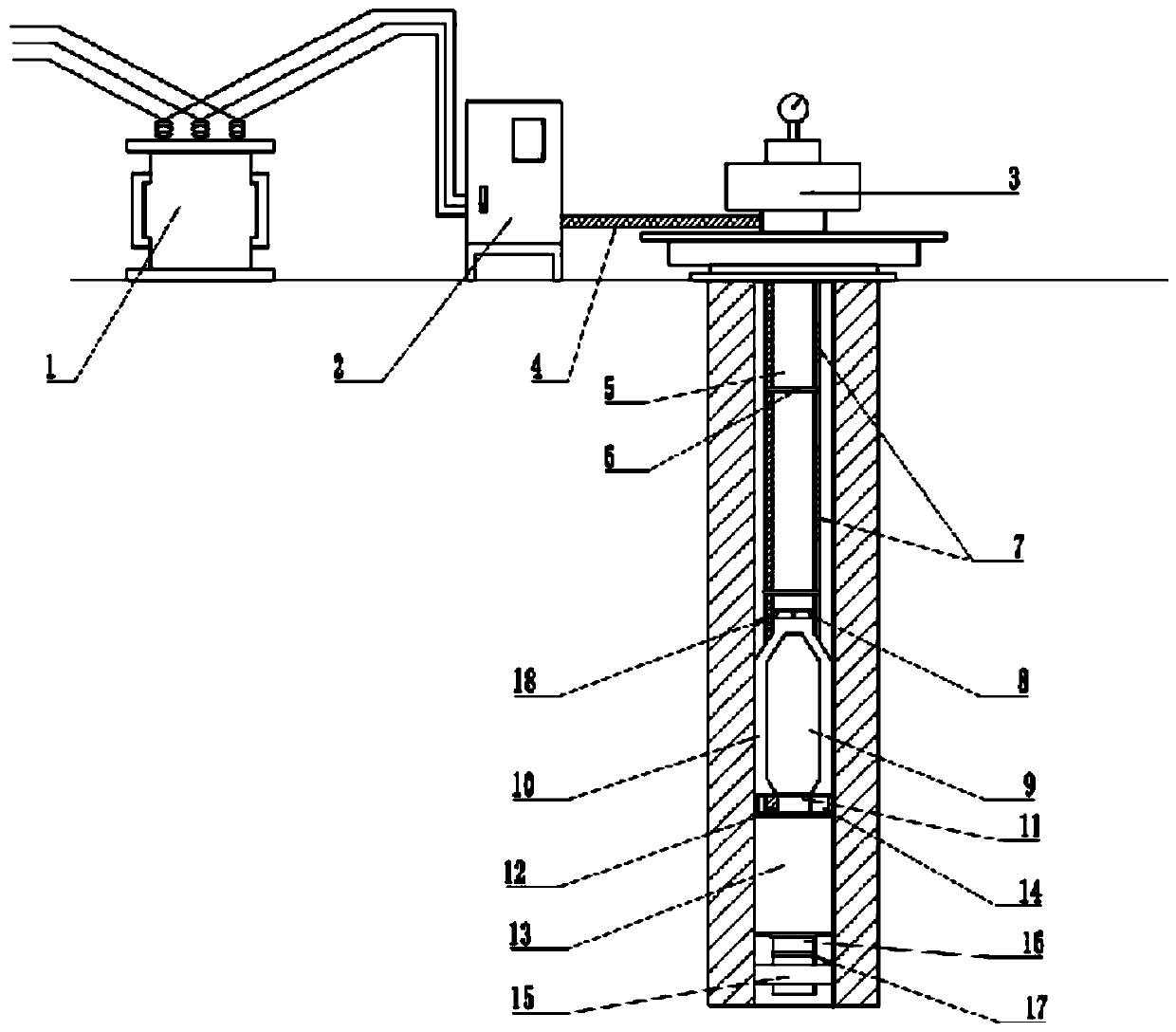

Complete drive control device set for oil-submersible screw pump

The invention relates to the technical field of oil extraction equipment, in particular to a complete drive control device set for an oil-submersible screw pump. The complete drive control device setcomprises a control module, an oil extraction mechanism module and a downhole detection module, wherein the oil extraction mechanism module comprises the oil-submersible screw pump, an oil-submersiblepermanent magnet motor and a composite oil pipe; the downhole detection module comprises a flow sensor, a temperature sensor and a pressure sensor; the control module comprises a high-precision vector frequency converter, a detection signal feedback device and a real-time monitoring control unit; the detection signal feedback device receives downhole first oil temperature, downhole second oil temperature and flow monitoring signals and transmits the downhole first oil temperature, downhole second oil temperature and flow monitoring signals to the real-time monitoring control unit; and the high-precision vector frequency converter carries out vector control on the oil-submersible motor according to the working condition and combined with the magnitude of output currents of the high-precision vector frequency converter. The complete drive control device set for the oil-submersible screw pump solves the problem that power cables in a traditional oil extraction system are easily abraded and corroded. Meanwhile, the problem of oil paraffin deposit at the low temperature is solved, faults are effectively reduced, and an oil well is maintained.

Owner:黑龙江百申环保科技有限公司

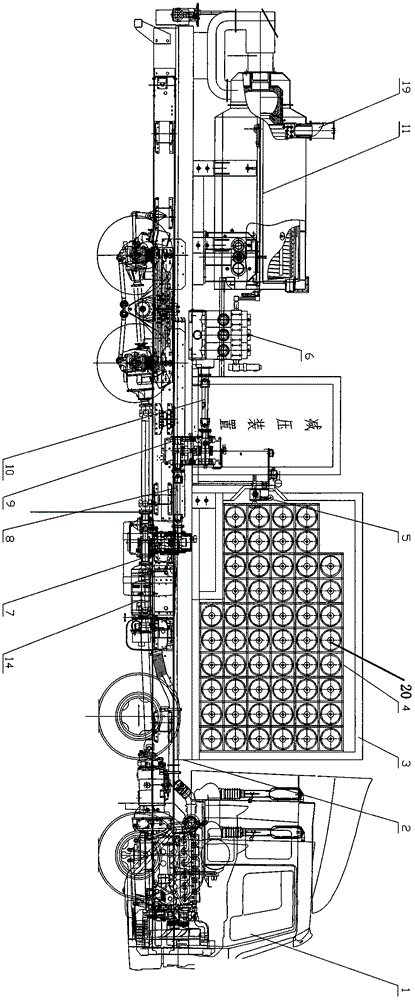

Hot-oil paraffin removal truck

Disclosed is a hot-oil paraffin removal truck. An engine transmission of chassis is connected with a full-power power takeoff box through a transmission shaft, the output of the full-power power takeoff box is connected with a reduction gearbox through a transmission shaft A and is connected with a tri-cylinder plunger pump through a transmission shaft B, an exhaust port of the tri-cylinder plunger pump is communicated with a water inlet of a gas boiler, a burner is arranged at a fire door of the gas boiler, a gas bottle containing cell is arranged in a carriage at the headmost end of a truck frame, a water drainage outlet of the gas boiler is connected with a connector of an oil field user, a fan is arranged on one side of an air supply port of the boiler, a busbar filling port is arranged at the output port of the gas bottle containing cell and is connected with a gas pressure reduction device, cold water enters from a suction inlet of the tri-cylinder plunger pump, medium is outputted by high pressure and delivered to a coiler of the gas boiler, the air is proportionally mixed and burned with low-pressure gas delivered after tri-stage pressure reduction, the medium, namely the cold water, is heated, and the boiler outputs water and steam mixture to the oil field user. The hot-oil paraffin removal truck has the advantages of low oil consumption and cost, and capability of providing sufficient power by clean new energy.

Owner:SHAANXI SHENGHUIYUAN INFORMATION SCI & TECH

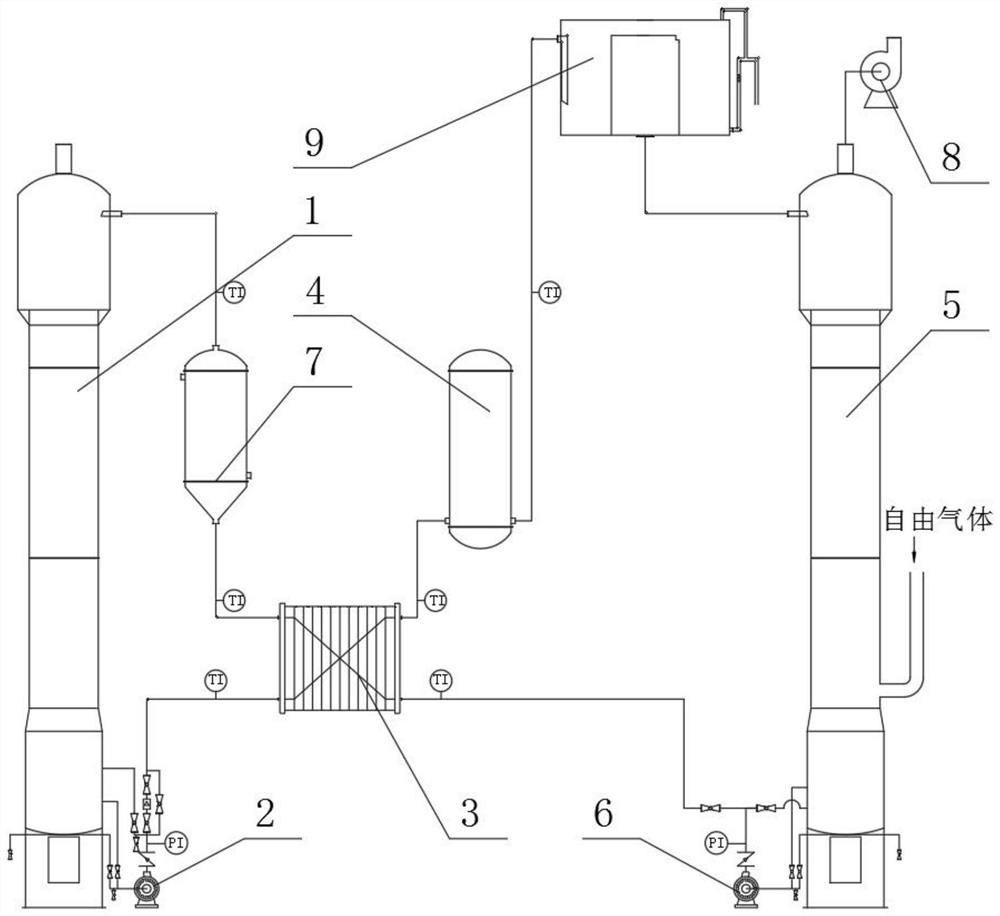

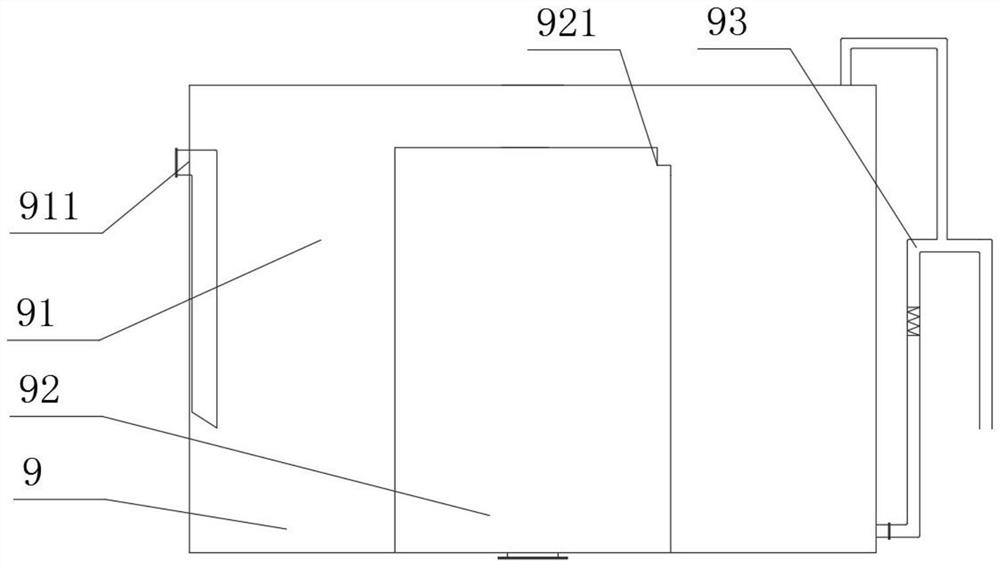

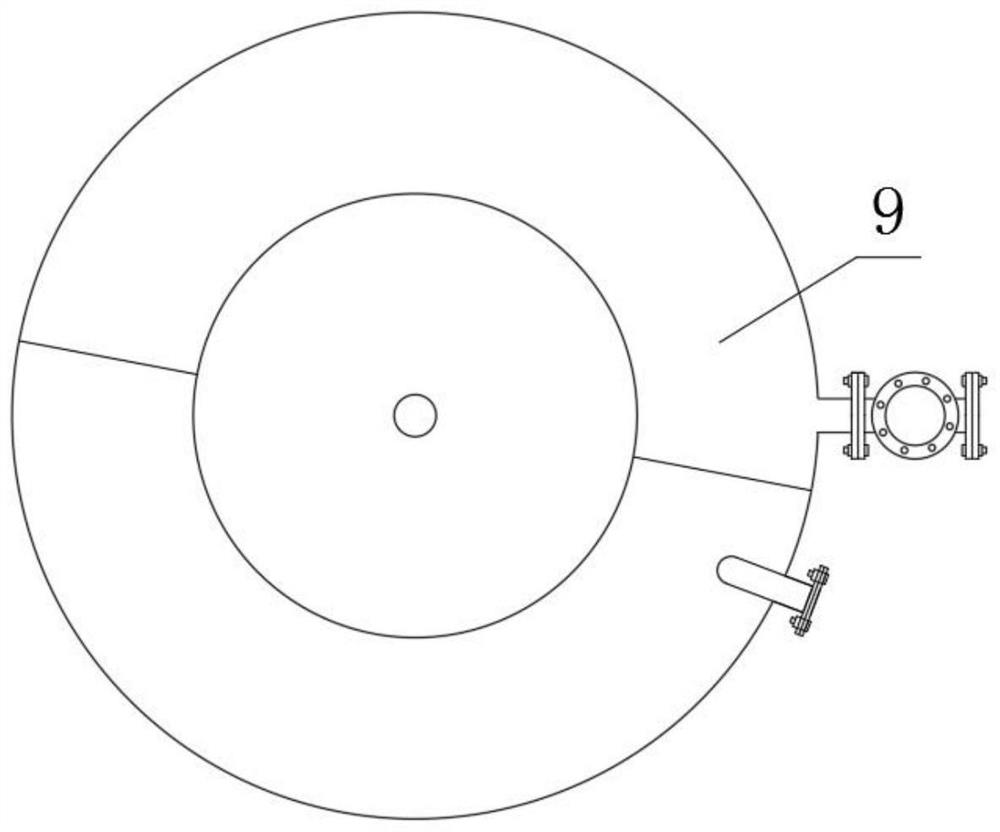

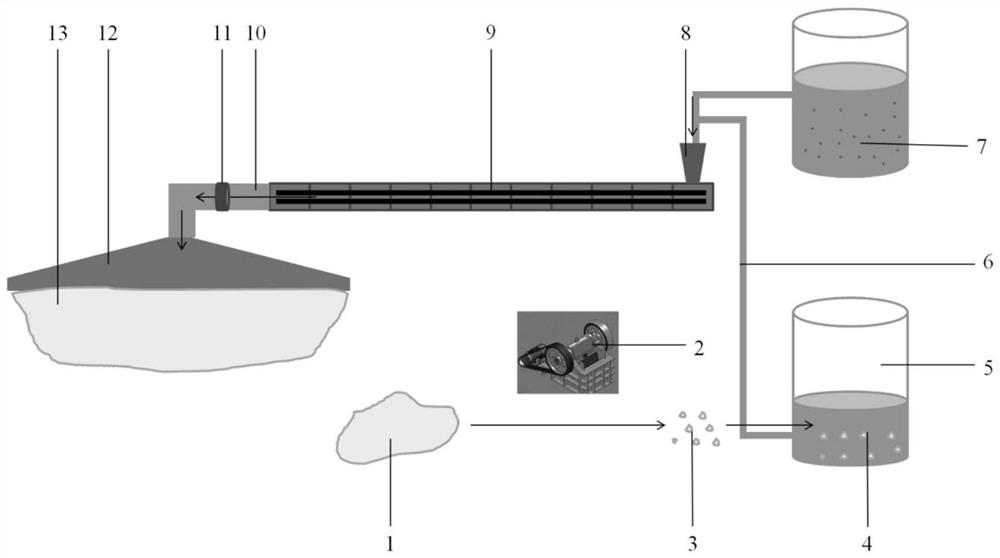

Automatic mineral oil water separation device and process method for solvent tail gas absorption system

PendingCN113440982AReduce consumptionReduce moisture contentDispersed particle separationLiquid separationExhaust gasOil paraffin

The invention discloses an automatic mineral oil water separation device and process method for a solvent tail gas absorption system and belongs to the technical field of tail gas treatment. The device comprises a desorption tower, a lean oil pump, a heat exchanger, a lean oil cooler, an absorption tower, a rich oil pump, a rich oil heater and a tail gas fan, the bottom of the desorption tower is connected with an inlet d of the heat exchanger through the lean oil pump, an outlet b of the heat exchanger is connected with the absorption tower through the lean oil cooler, and the bottom of the absorption tower is connected with an inlet c of the heat exchanger through the rich oil pump; and an outlet a of the heat exchanger is connected with the top of the desorption tower through the rich oil heater, the tail gas fan is mounted at the top of the absorption tower, and an automatic drainage tank is included and arranged on a pipeline communicated between the lean oil cooler and the absorption tower. The device aims to solve the problems of poor reliability of manual discharge and more human factors of manual discharge of waste water in paraffin oil of the existing tail gas system, realizes automatic discharge of paraffin oil before oil feeding of the absorption tower, and reduces solvent consumption and environmental pollution.

Owner:JIUSAN OILS & GRAINS IND GRP CO LTD

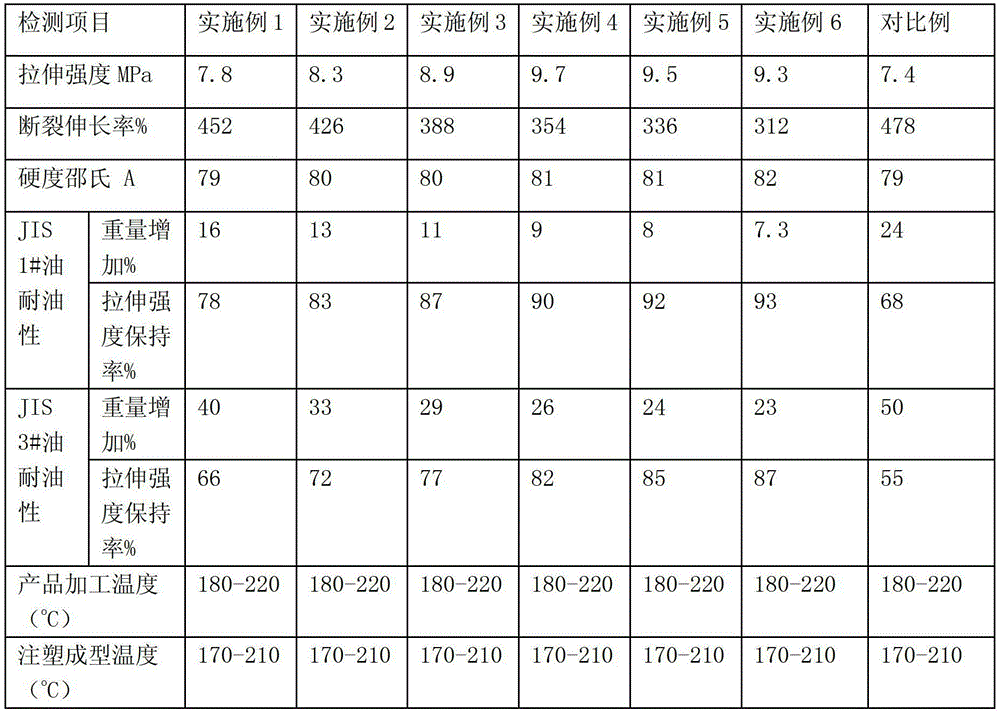

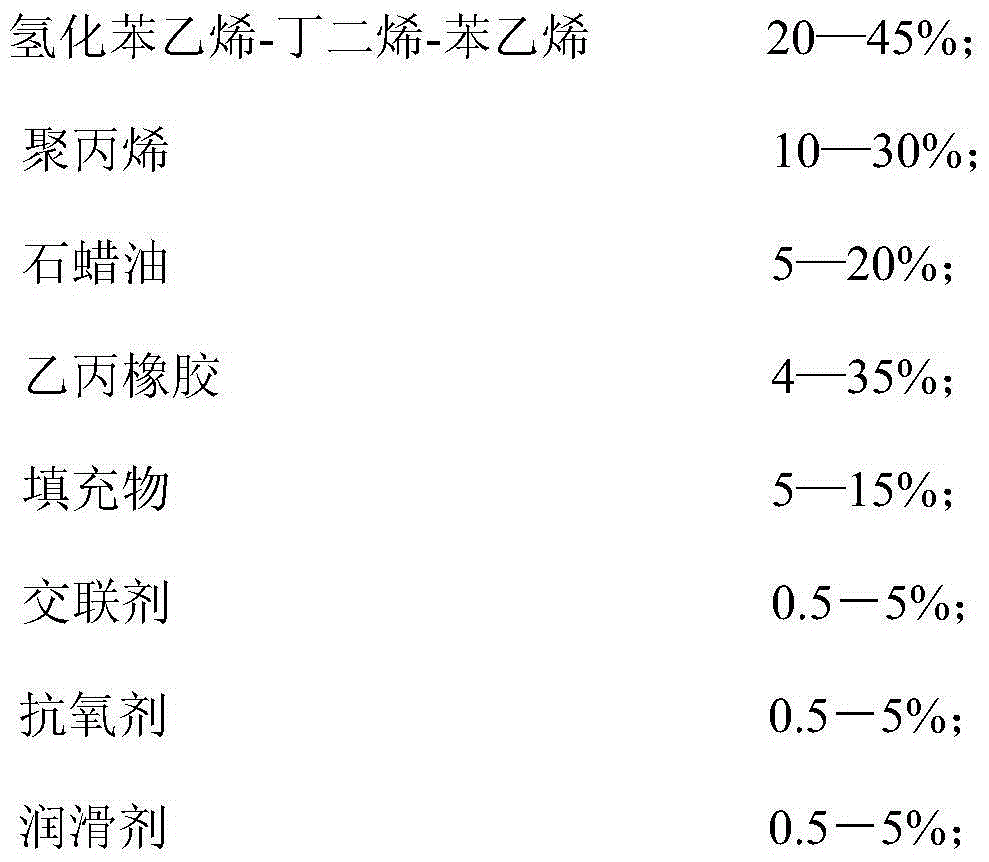

A kind of fog surface oil-resistant elastomer cable material and preparation method thereof

ActiveCN103172965BGood fog effectGood oil resistancePlastic/resin/waxes insulatorsElastomerAntioxidant

The invention provides a matted oil-resistant elastomeric cable material and a preparation method thereof. The cable material comprises the following components by weight percent: 20 to 45 percent of hydrogenated styrene-butadiene-styrene, 10 to 30 percent of polypropylene, 5 to 20 percent of paroline, 4 to 35 percent of ethylene propylene rubber, 5 to 15 percent of filler, 0.5 to 5 percent of a cross-linking agent, 0.5 to 5 percent of an antioxidant and 0.5 to 5 percent of a lubricant. The matted oil-resistant elastomeric cable material ensures that a cable has matted effect and also has good oil resistance and mechanical property, and can meet the requirements of oil resistant occasions.

Owner:深圳市益力盛电子有限公司

Method for detecting hydrgenated tail-oil paraffin composition using near-infrared spectrum

InactiveCN100443883CThe test method is simple and fastEasy and fast testingComponent separationColor/spectral properties measurementsAlkaneFourier transform on finite groups

The invention relates to a method to test the constitution of hydrogenation tail oil paraffin group by near infrared optical spectrum. It builds up models of paraffin, alkane, and isoalkane by alkene cracking device, and aromatics reformer and oil refining hydrogenation unit. And the content of paraffin, alkane, and isoalkane would be calculated by using the models. It has the advantages of convenient, rapid and accurate.

Owner:YANGZI PETROCHEM

Waste film recovery method

PendingCN112936666AAvoid wastingAvoid pollutionPlastic recyclingMechanical material recoveryPhysical chemistryManufactured material

A waste film recovery method is used in a lithium battery diaphragm production process, and comprises the following steps: collecting waste films generated in the lithium battery diaphragm production process, and classifying and storing the collected waste films according to oil films and dry films; separately putting the oil films and the dry films into a crusher to be crushed, so that oil film fragments and dry film fragments are formed; placing the oil film fragments or the dry film fragments with the measured oil content in a mixing tank, adding paraffin oil to prepare a corresponding recycled material, and then heating and stirring; and pumping the recycled material and the normal material into a double-screw extruder according to a ratio through a pump, and extruding to form a recycled finished product diaphragm. According to the method, the waste films generated in normal production of the wet diaphragm are extruded and reprocessed again, so that the waste films are recycled, on one hand, the production cost is reduced by saving raw materials, on the other hand, the waste film treatment procedure is omitted, and pollution to the environment is avoided.

Owner:九江冠力新材料有限公司

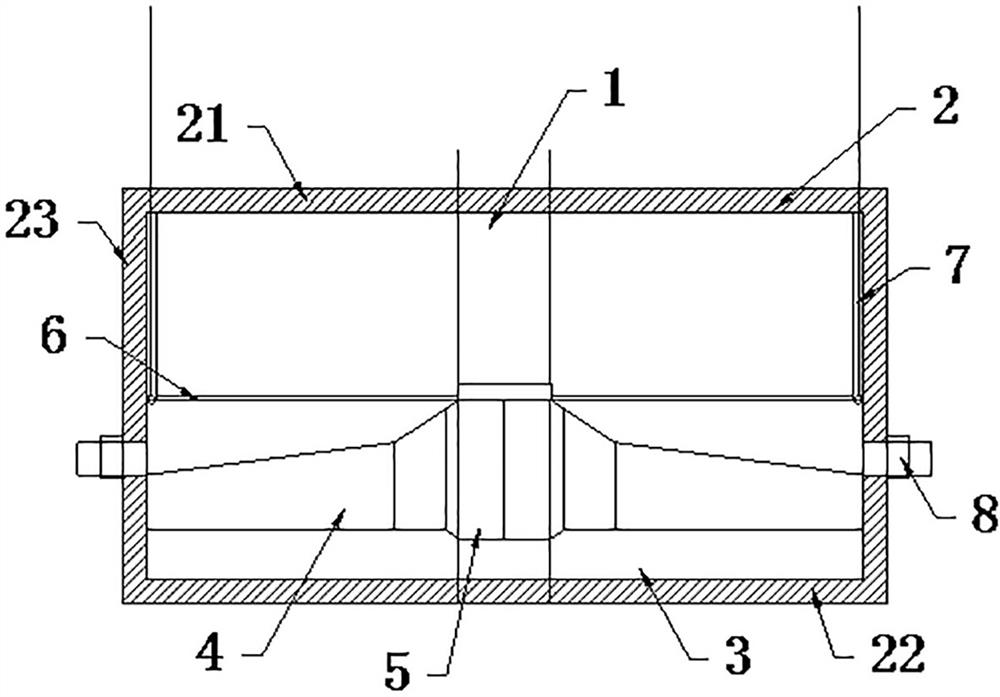

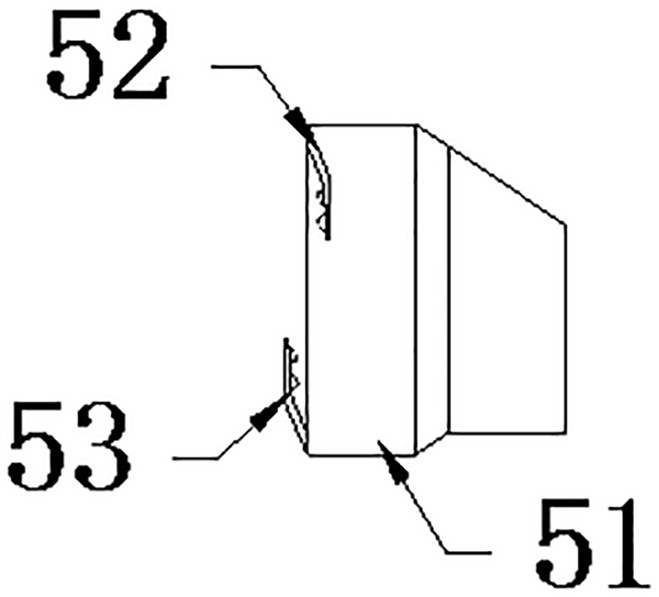

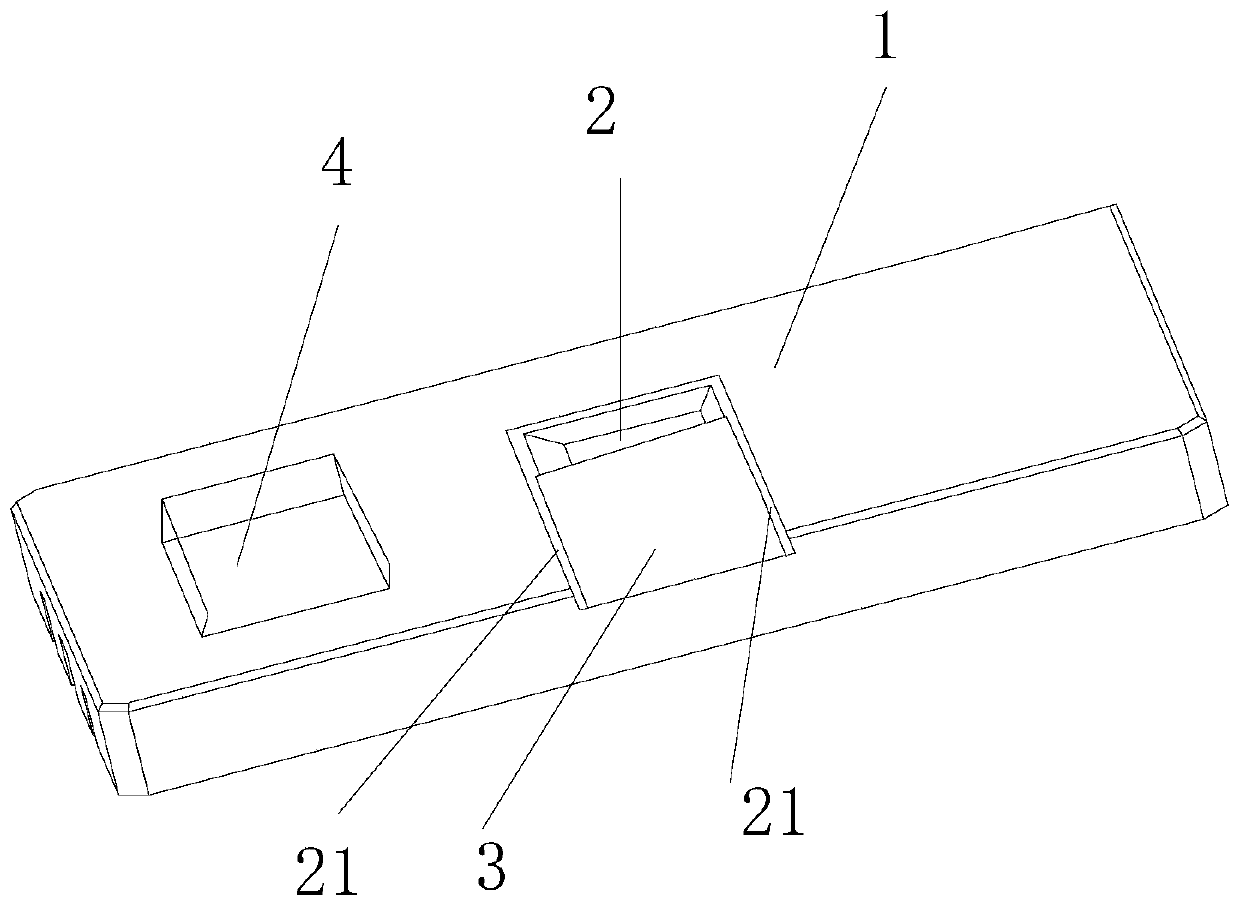

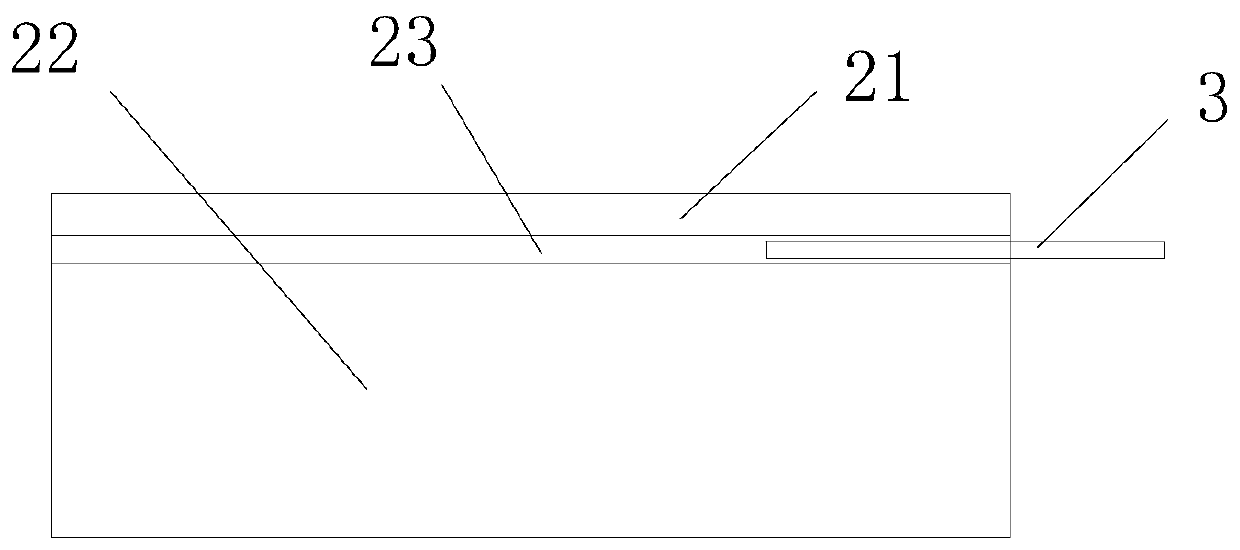

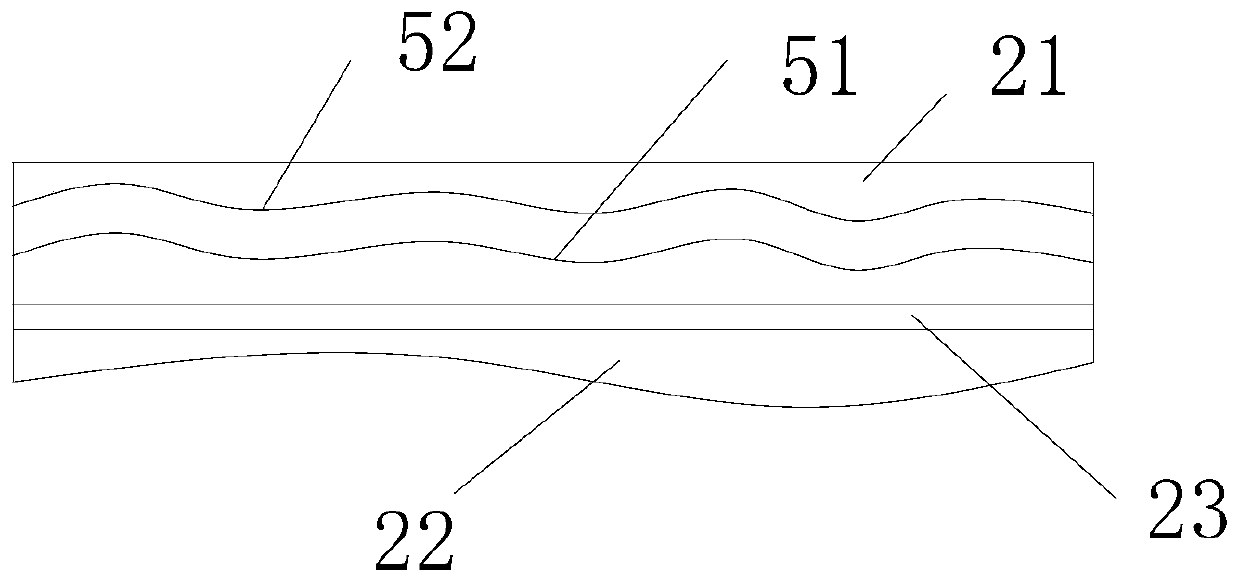

A sucker rod anti-spray self-sealing wax scraping guide device

The invention discloses a sucker rod blowout-preventing, self-sealing, paraffin scraping and flow guiding device. A sucker rod penetrates through the center of a shell, and a paraffin scraping deviceis mounted in the shell and arranged on the sucker rod in a sleeving mode. Circular flow guiding plates are arranged on the two sides of the paraffin scraping device, at least one flow guiding pipe isarranged on the side wall of the shell, and the outer ends of the flow guiding plates are connected with the flow guiding pipes. Filtering plates are arranged above the flow guiding plate, casing pipes are arranged in the centers of the filtering plates and mounted at the upper end of the paraffin scraping device, and the two ends of the flow guiding pates are movably connected with the side wallof the shell, and steel wire ropes are arranged at the edges of the flow guiding plates and penetrate through an upper cover plate. According to the sucker rod blowout-preventing, self-sealing, paraffin scraping and flow guiding device, the flow guiding plates are arranged at the edge of the existing paraffin scraping device, and the filtering plates are fixed to the paraffin scraping device, sothat when the rocker rod moves vertically, oil paraffin scraped by the paraffin scraping device is stacked on the filtering plates and falls to the flow guiding plates from screening holes, and impurities remain on the filtering plates; and the flow guiding plates are slopes, so that the oil paraffin flows into flow guiding grooves along the slopes and further is flatly discharged from the flow guiding pipes.

Owner:河北鸿凯石油科技有限公司

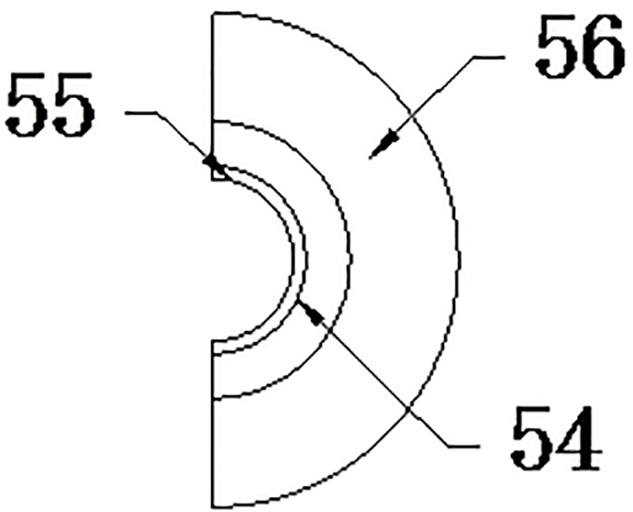

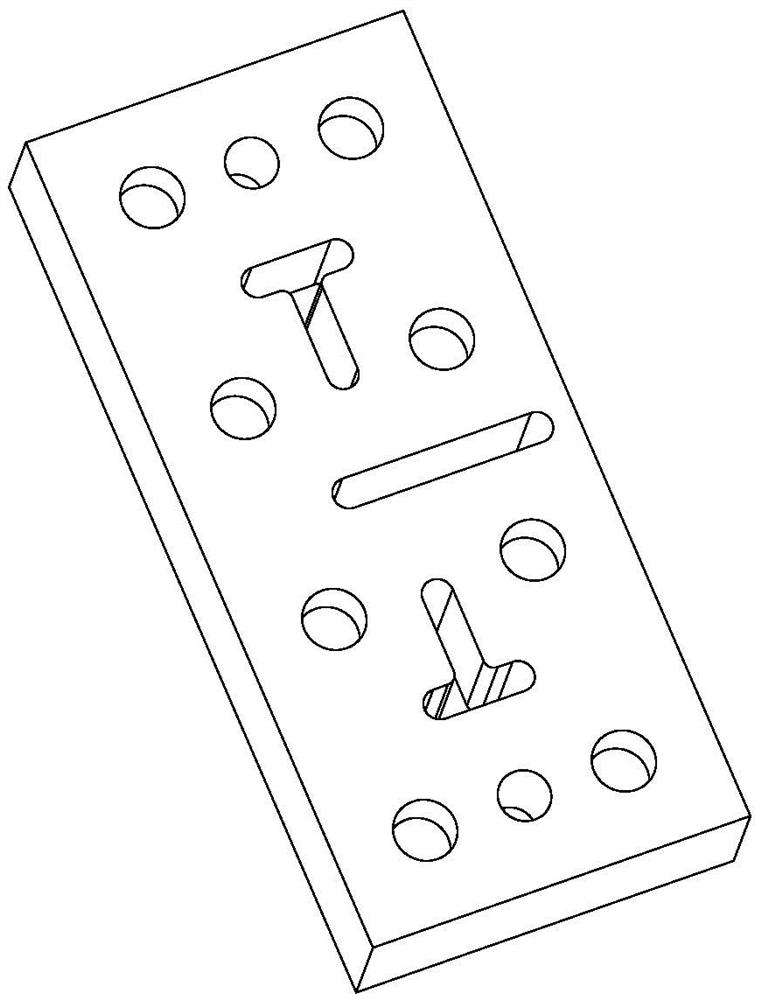

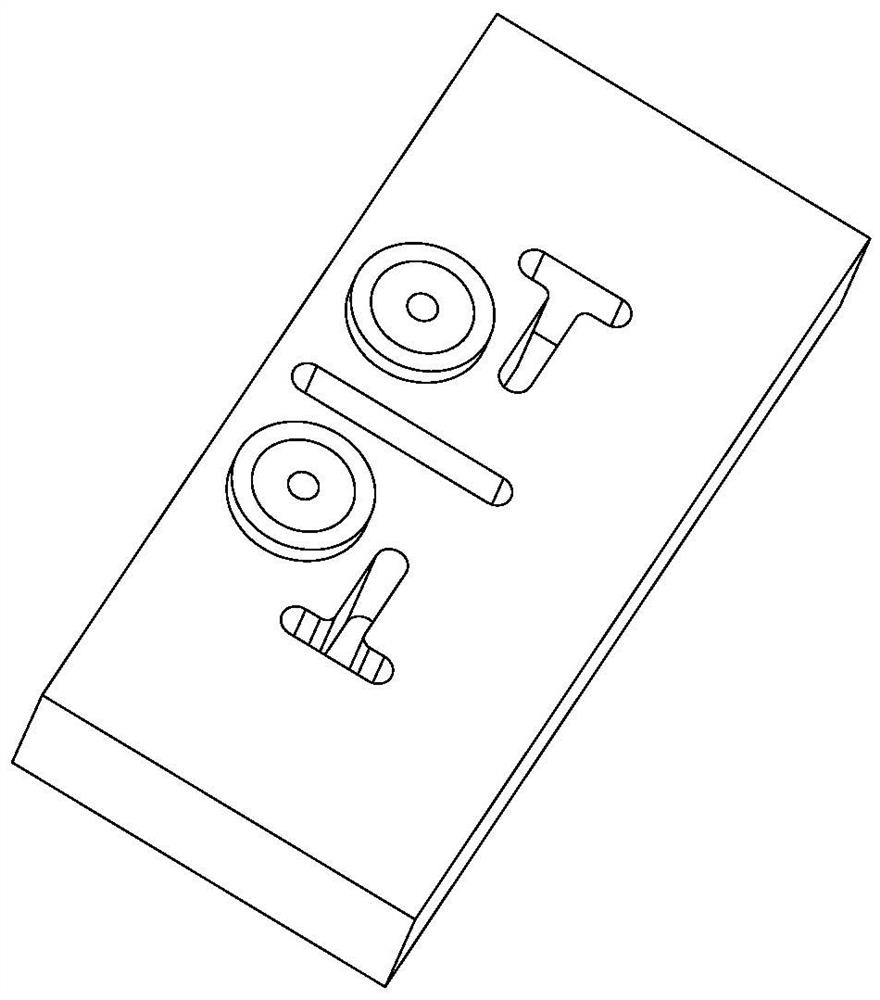

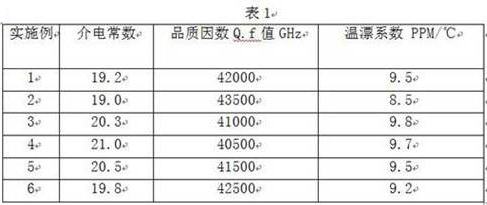

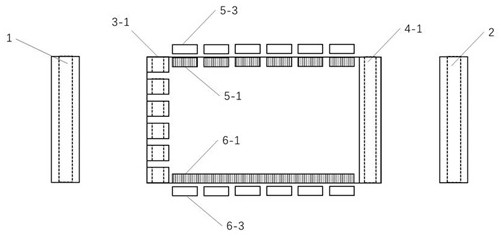

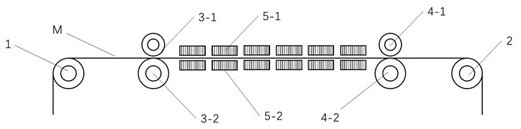

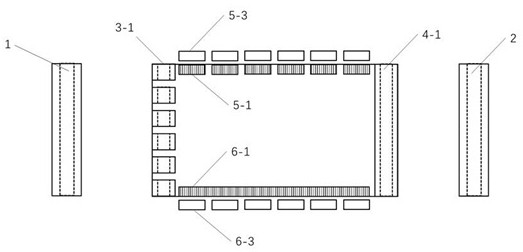

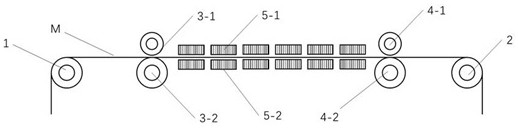

High-performance composite dielectric filter, material thereof, and preparation method of material

The invention discloses a high-performance composite dielectric filter, a material thereof, and a preparation method of the material. Ceramic powder, deionized water and a dispersing agent are mixed in proportion, and undergo the working procedures of ball milling, drying, pre-sintering, smashing, secondary grinding, drying, stirring, extrusion injection molding, baking, hot pressing and the like to prepare the high-performance composite dielectric filter material. The powder obtained after the first drying is subjected to 1330 DEG C high temperature pre-sintering, the high temperature sintering is not required during the subsequent preparation process, and the paraffin oil and the coupling agent only need to be volatilized at the temperature of 380 DEG C so as to reduce the industrial energy consumption and the production cost of the material production system, such that the production efficiency of the material production system is improved; and PTFE is added into the material obtained after secondary drying, so that the prepared high-performance composite dielectric filter material has relatively good flexibility, and a component prepared from the high-performance composite dielectric filter material is not prone to cracking in a use process.

Owner:CHENZHOU GONGTIAN ELECTRONICS CERAMICS TECH

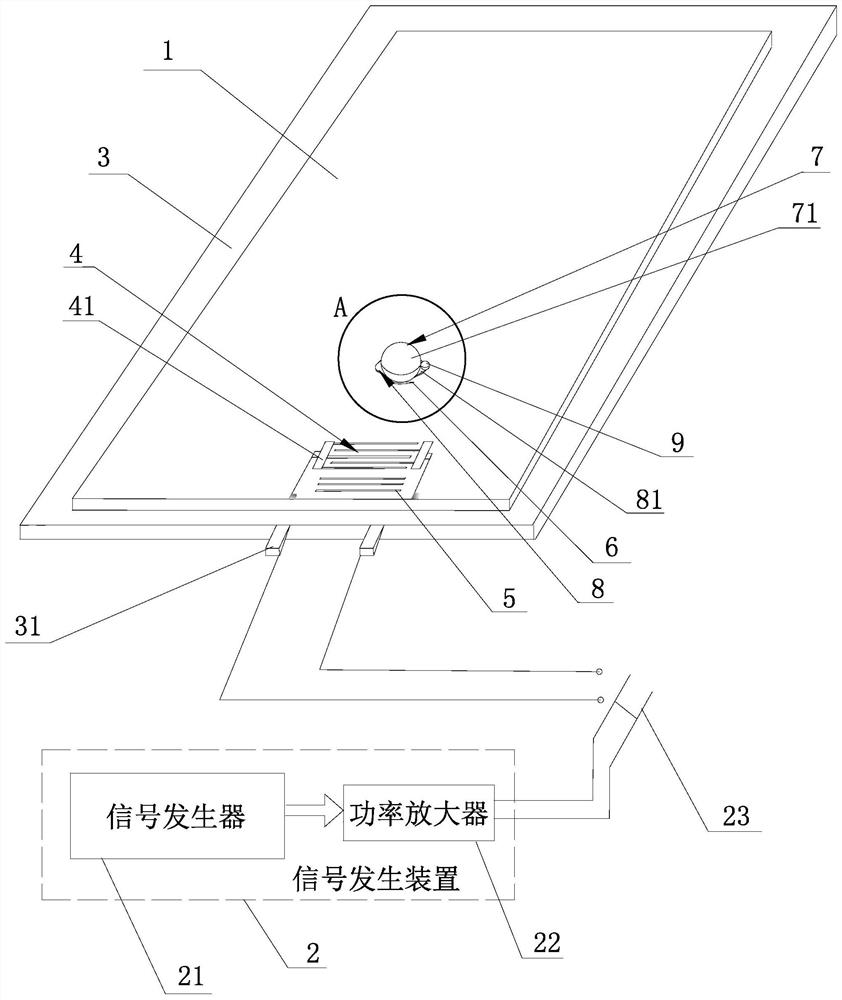

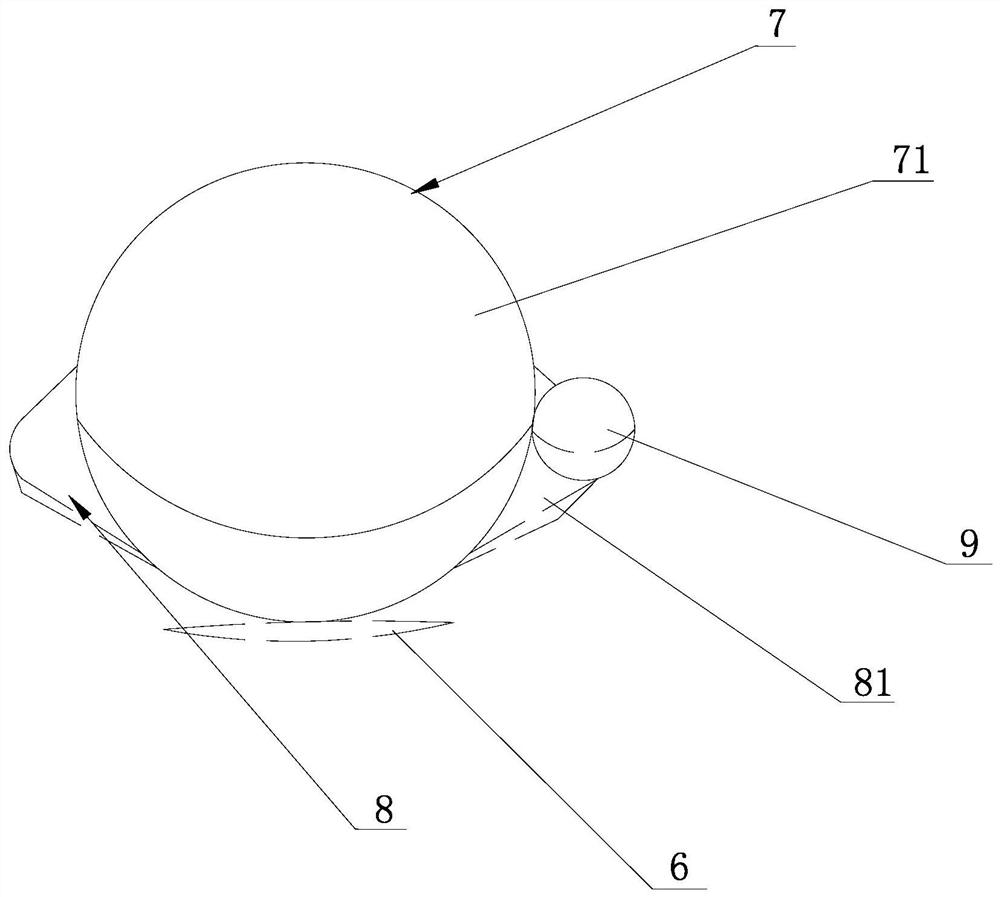

A device and method for microfluidic transport on a piezoelectric substrate

InactiveCN109926111BAvoid direct radiationRealize transportationLaboratory glasswaresBio moleculesMicrosphere

The invention discloses a device and method for transporting microfluid on a piezoelectric substrate. On the working surface of the electric substrate and on the propagation path of the surface acoustic wave excited by one of the unweighted interdigital transducers, paraffin oil is dropped, and microsphere beads are placed on the paraffin oil, and the upper hemispherical surface of the microsphere beads is used as a In the first liquid storage area of the aqueous microfluid to be transported; the unweighted interdigital transducer corresponding to the paraffin oil excites the surface acoustic wave after the RF electric signal is loaded, and the surface acoustic wave radiates into the paraffin oil to drive the paraffin oil Drive the microspheres to slide along the propagation path of the surface acoustic wave to realize the transportation of the aqueous solution microfluid stored in the first liquid storage area; the advantage is that it avoids the direct radiation of the surface acoustic wave into the aqueous solution microfluid, and solves the problem of the temperature of the microfluid Elevation causes problems with evaporation and decreased activity of biomolecules.

Owner:武夷学院

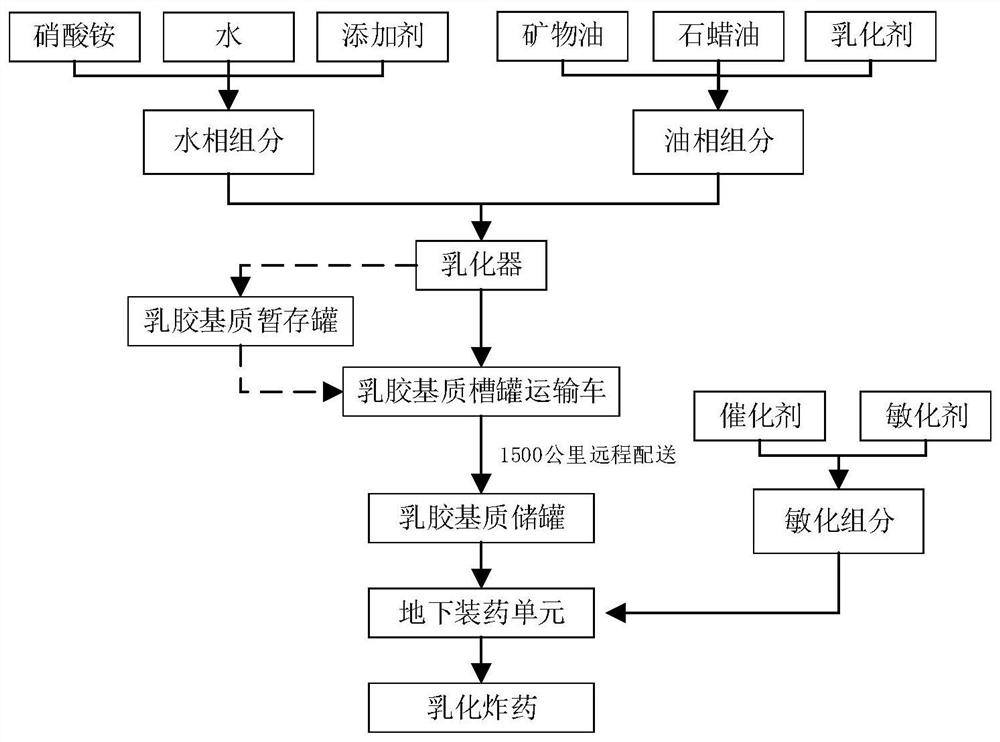

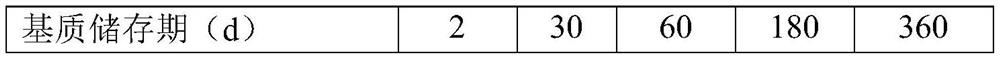

Remote distribution underground mining emulsion matrix, emulsion explosive and preparation method thereof

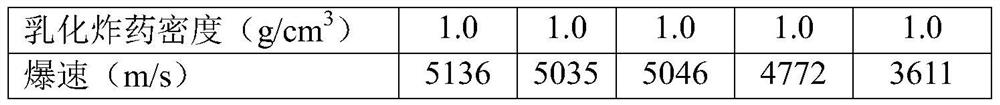

InactiveCN111995486AStrong anti-turbulence abilityMedium viscosityExplosive working-up apparatusExplosive AgentsPtru catalyst

The invention discloses a remote distribution underground mining emulsion matrix, which comprises a water phase component and an oil phase component, and the oil phase component comprises mineral oil,paraffin oil and an emulsifier. is the invention also discloses an emulsion explosive comprising an emulsion matrix, a catalyst, and a sensitizer. The invention further discloses a preparation methodof the remote distribution underground mining emulsion matrix. The preparation method comprises the following steps: preparing the water phase; preparing the oil phase; adjusting the flow rate of a pump according to the ratio of the water phase to the oil phase, adjusting the rotating speed of an emulsifier according to the viscosity of the target emulsion matrix, pumping the water phase and theoil phase to the emulsifier, and emulsifying to form the emulsion matrix. The emulsion matrix disclosed by the invention has good bumping resistance, can be remotely distributed to mines within 1500 kilometers for users to use, and can be sensitized at normal temperature to form the emulsion explosive. The explosive can be sensitized after being installed in an upward blast hole, the explosive return phenomenon is avoided, the blasting cost can be greatly reduced, the blasting effect is effectively improved, and dangerous factors existing in blasting construction and other construction processes are greatly reduced.

Owner:BEIJING AUXIN CHEM TECH LTD

Method for treating inner surface of microchannel

ActiveCN111545260BResidue reductionImprove accuracyLaboratory glasswaresBiological testingCentrifugationEngineering

This paper provides a method for processing the inner surface of the microchannel, including 1) paraffin oil is delivered to the microchannel through a sample inlet communicated with the microchannel, so that the paraffin oil and the microchannel surface contact, and 2) the paraffin oil was removed from the injection port by reverse centrifugation. The microfluidic chip processed by the method can greatly reduce the residue of samples in the chip, so as to improve the accuracy of experimental results.

Owner:TIANJIN DEXIANG BIOTECHNOLOGY CO LTD

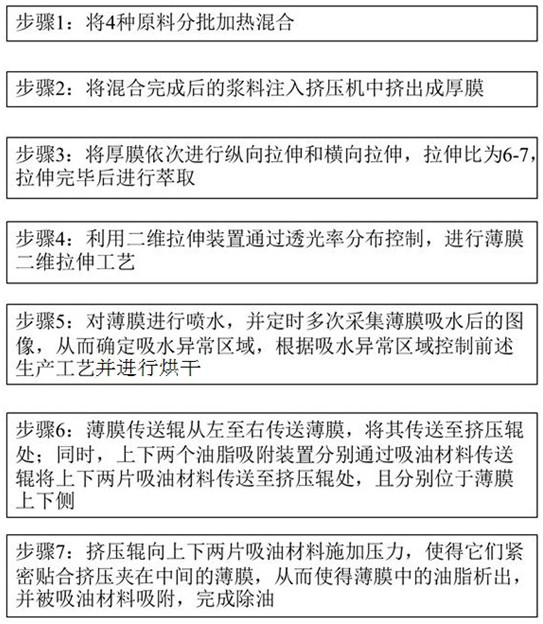

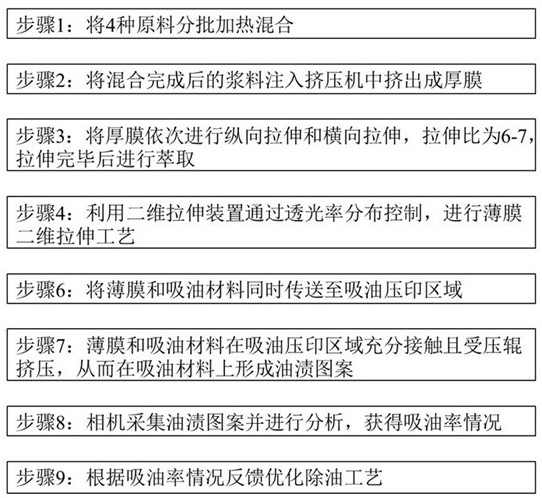

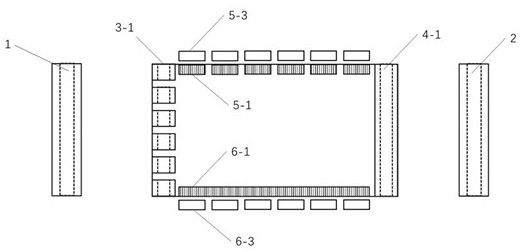

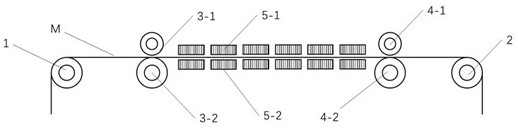

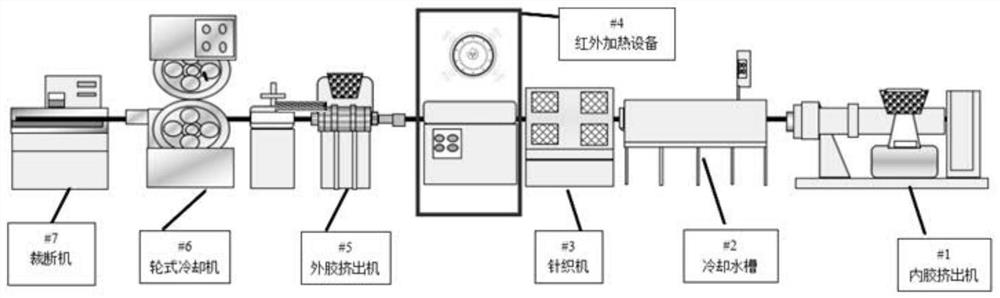

Film without grease residue and preparation method thereof

ActiveCN111933867AReduce usageAvoid damageLi-accumulatorsCell component detailsCresolSilicon dioxide nanoparticles

The present invention provides a film without grease residue and a preparation method thereof. The method comprises the steps of: mixing and heating polyethylene, paraffin oil, silicon dioxide nanoparticles and 4, 4'-sulfo-bis(6-tert-butyl-m-cresol) in batches, performing extrusion molding, performing transverse stretching and longitudinal stretching respectively, and performing two-dimensional stretching; and after stretching is finished, feeding the film into an oil removal device, and carrying out oil removal operation on the film under the action of an extrusion roller and an oil absorption material, so as to prepare the lithium battery diaphragm without grease residues.

Owner:河南银金达新材料股份有限公司

A kind of electric ignition match and preparation method thereof

Owner:MINNAN NORMAL UNIV

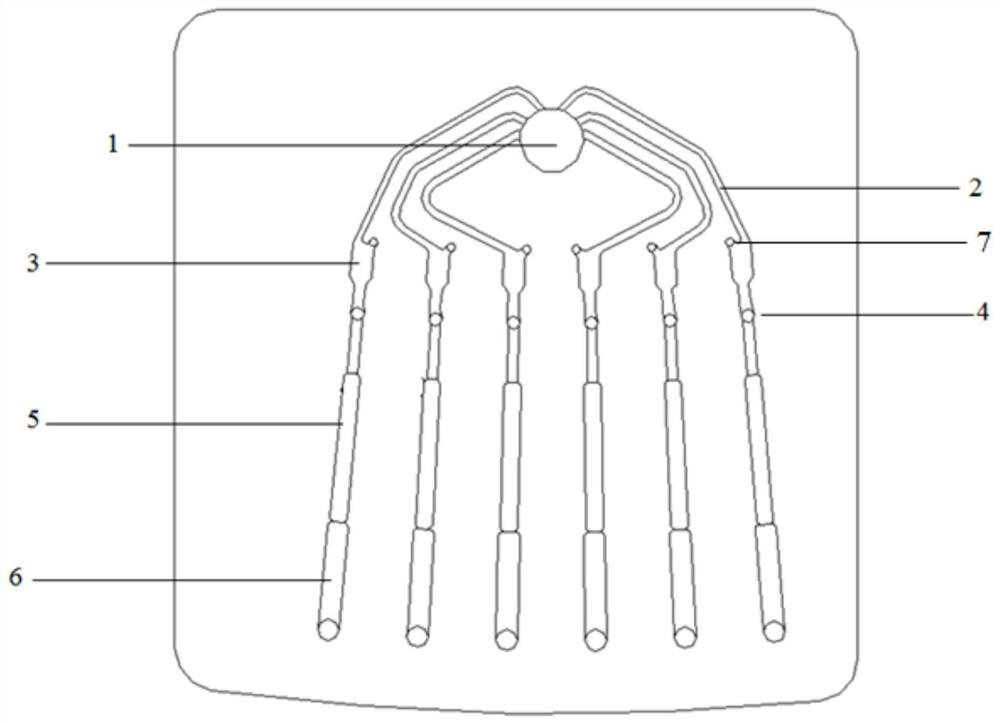

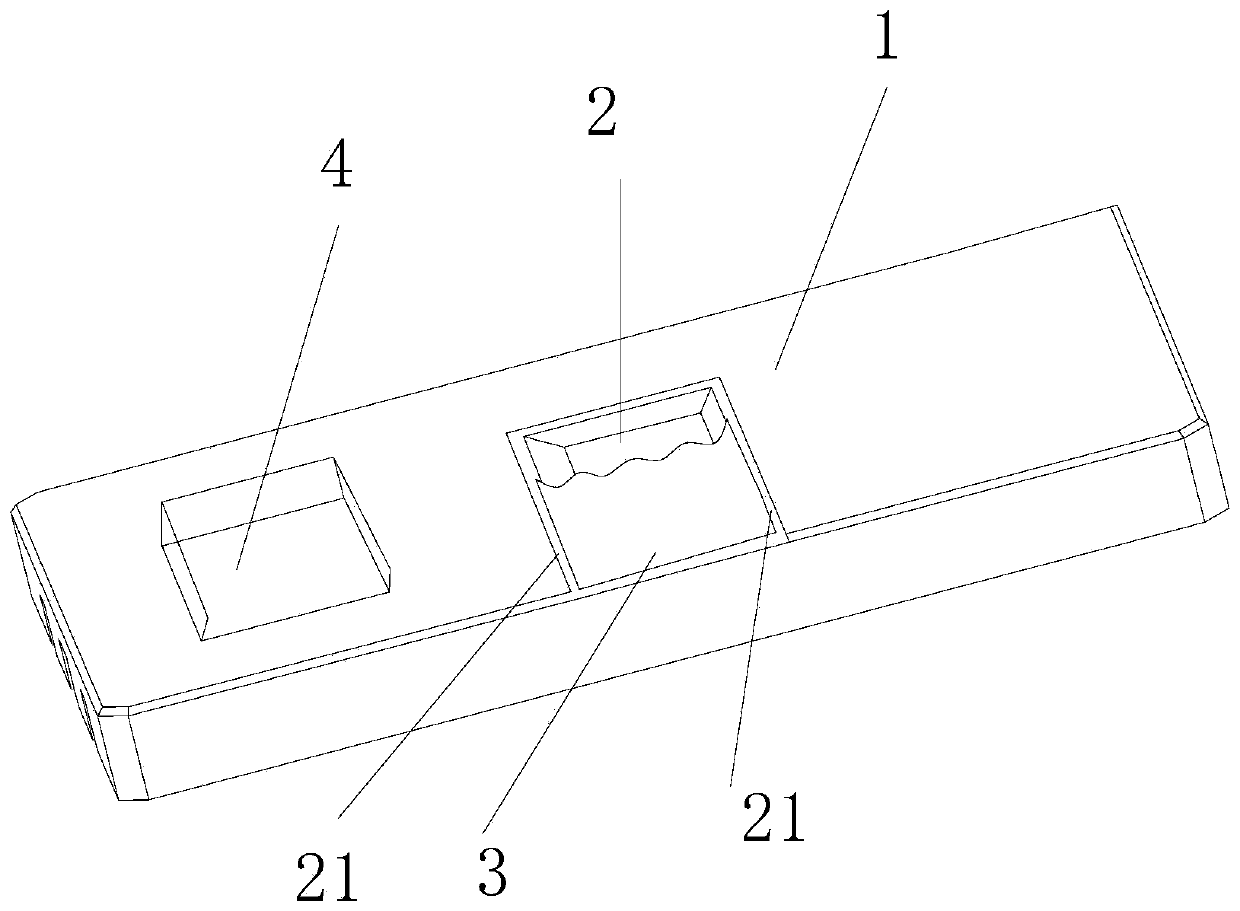

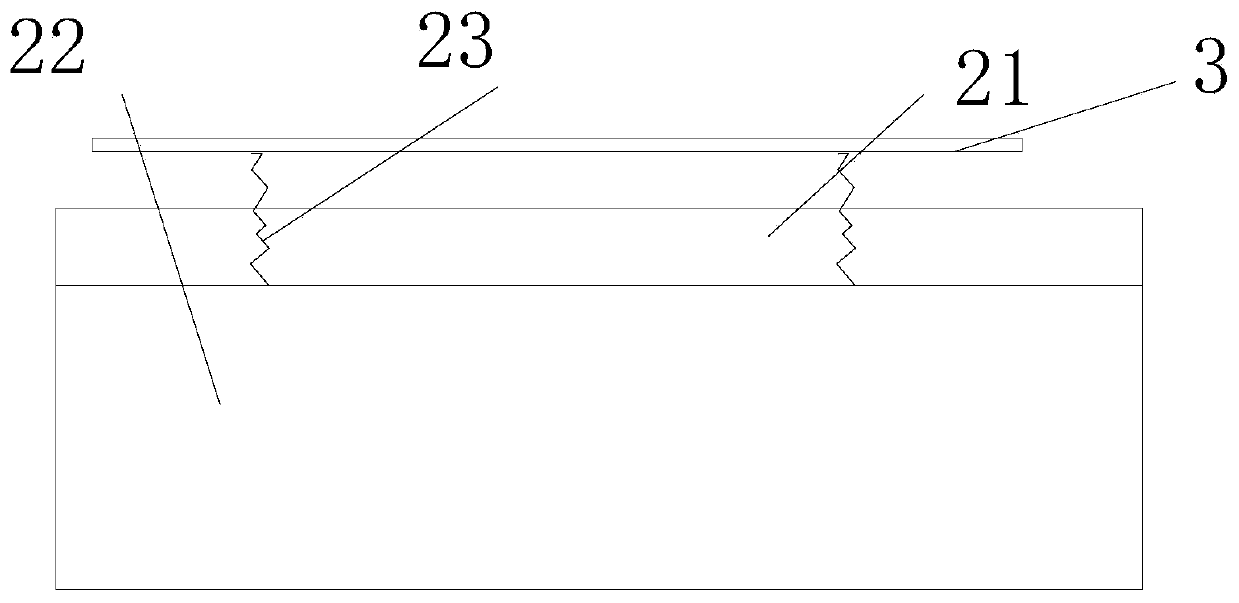

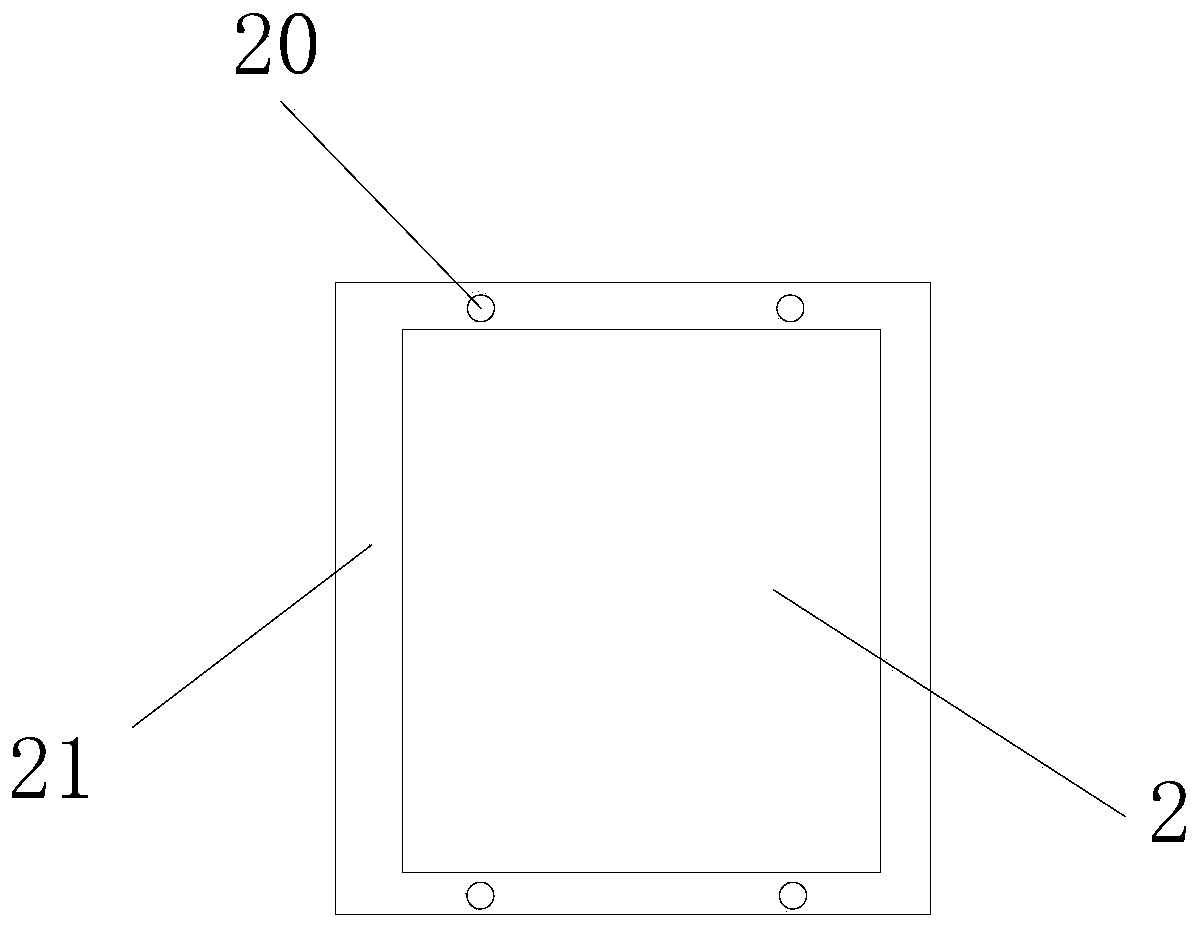

Oil seal device for digital PCR chip

ActiveCN111286459AGuaranteed stabilityReduce mistakesBioreactor/fermenter combinationsBiological substance pretreatmentsPcr chipEngineering

The invention provides an oil seal device for a digital PCR chip, which comprises a substrate, wherein the substrate is made of an aluminum material, a groove is formed in the middle part of the substrate, the groove is used as a container for placing a reaction chip, an upper cover is arranged on the groove, the upper cover slides relative to the substrate to seal a chip, and paraffin oil with athickness of 0.3-0.5 mm is used as an oil seal structure at the position, corresponding to the chip, of the upper cover; a plurality of springs are arranged at the upper end of the inner side wall ofthe groove, one end of each spring is connected with the upper cover, and the side face of the groove in the upper side of the upper cover after the upper cover is buckled is an oil sealing face. By means of full-closed and semi-automatic operation, the manual operation process is reduced, and therefore errors caused by manual operation can be reduced to the maximum extent; a good heat-conductingmedium is selected, so that the heat conductivity of the device as a reaction chip container is fully guaranteed, and the stability of reaction conditions is fully guaranteed; the upper cover surfaceis made of the materials and of a structure that can fully guarantee later result detection effectiveness.

Owner:宁波胤瑞生物医学仪器有限责任公司

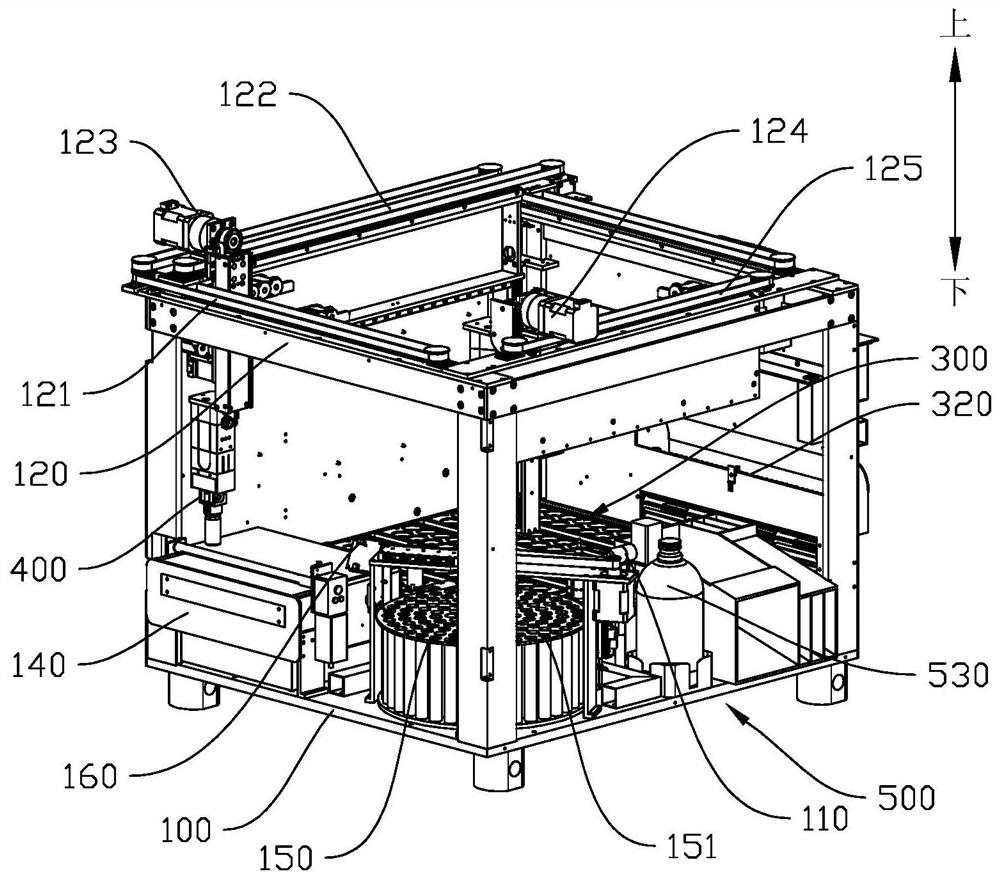

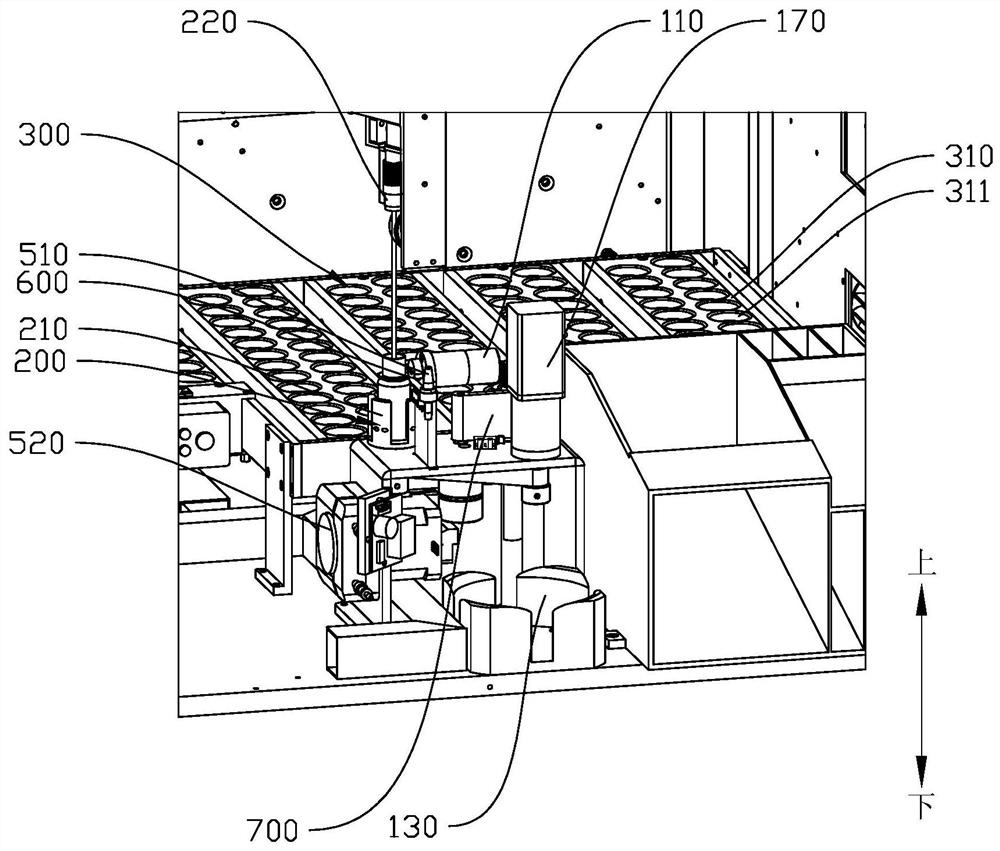

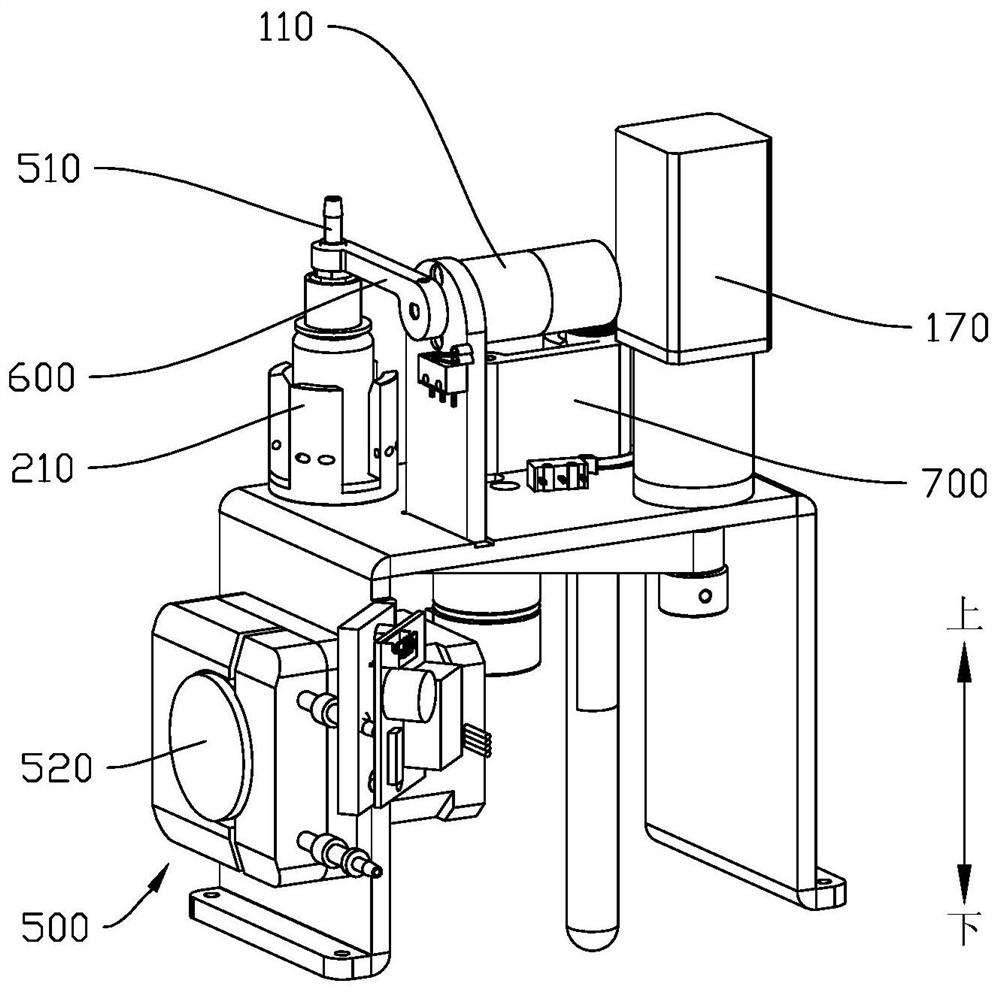

B-group workstation

PendingCN113252650APrevent precipitationAvoid Delayed InspectionsMaterial analysis by observing effect on chemical indicatorEngineeringMachine

The invention discloses a B-group workstation which comprises a machine table, an elution mechanism, an incubation swinging mechanism, a carrying clamping jaw, an oil supply mechanism and a first visual detection module. A refrigerating chamber and a turntable are arranged on the machine table, a plurality of first accommodating grooves for limiting test tubes are formed in the turntable, and the elution mechanism is used for adding a sample liquid in the test tubes into the developing bottles; the oil supply mechanism is used for adding paraffin oil into the developing bottles; the incubation swinging mechanism comprises a plurality of swinging arms which are in swinging connection with the machine table, and a plurality of second accommodating grooves for limiting the developing bottles are formed in the swinging arms; the first visual detection module is arranged in the second accommodating grooves to detect the color changes of the mixed liquids in the developing bottles; and the carrying clamping jaw can ascend and descend and slide in the horizontal direction, can clamp bottle caps of the developing bottles, and is used for carrying the developing bottles between the refrigerating chamber and the elution mechanism and between the elution mechanism and the swing arms. An B-group inspection process does not need excessive interference of personnel so that the labor cost is reduced.

Owner:ZHUHAI DL BIOTECH CO LTD

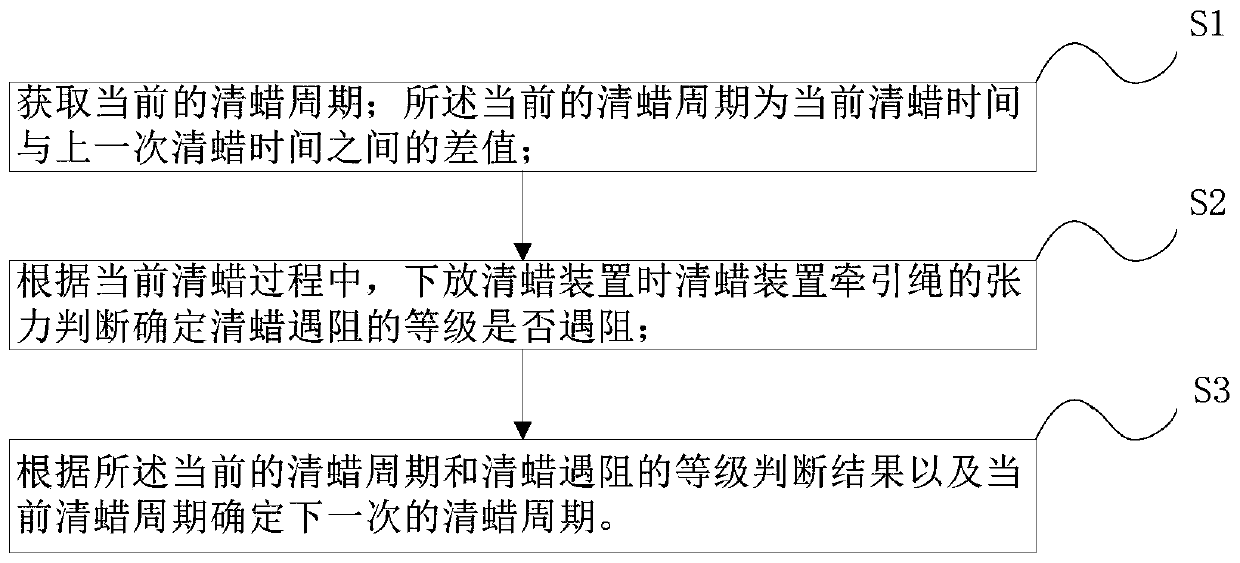

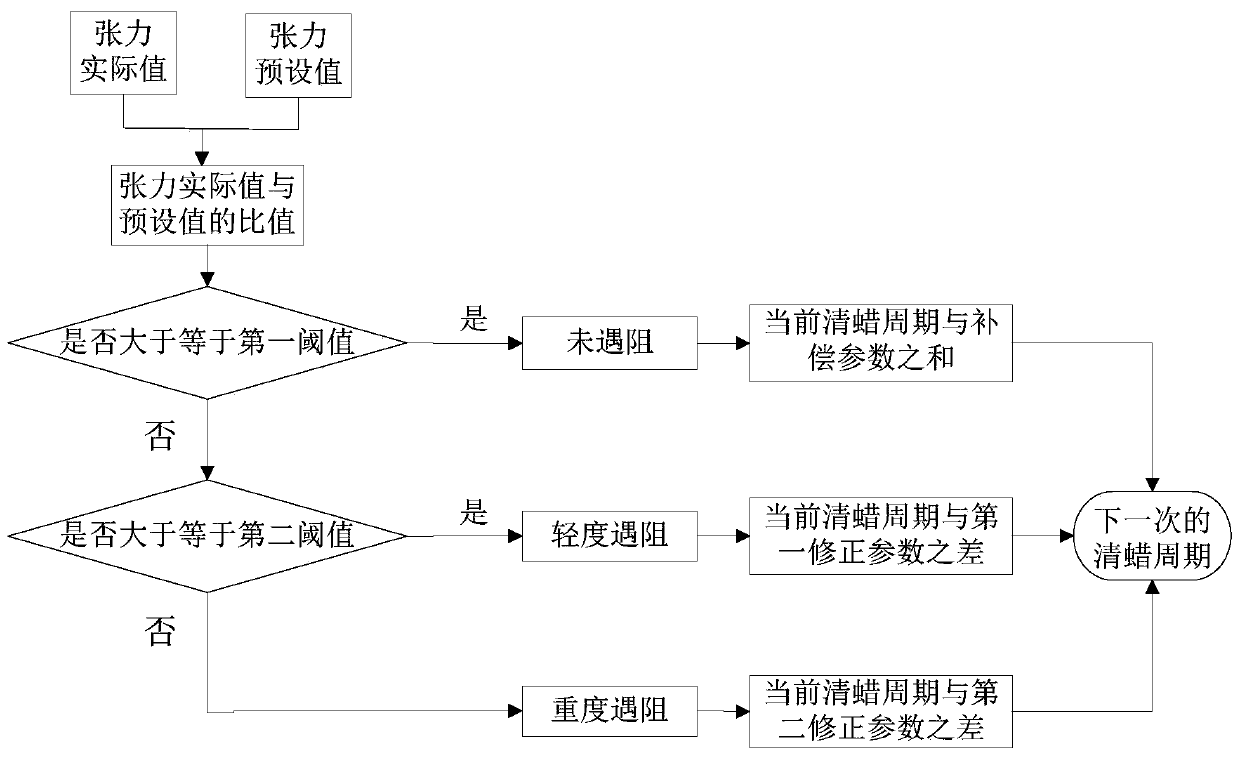

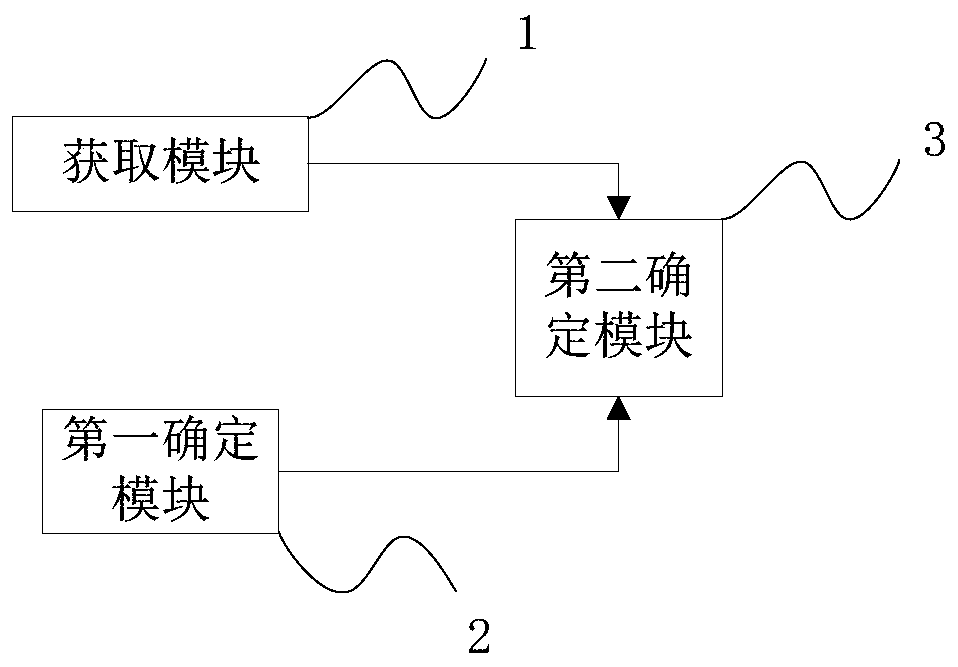

Method and system for determining paraffin removal period of oil well

The invention provides a method and system for determining a paraffin removal period of an oil well, and belongs to the technical field of oil extraction engineering. The method comprises the following steps of obtaining a current paraffin removal period, wherein the current paraffin removal period is the difference value between current paraffin removal time and previous paraffin removal time; determining the level for blocking paraffin removal according to the tension of a traction rope when a paraffin removal device is lowered in the current paraffin removal process; and determining the next paraffin removal period according to the current paraffin removal period and the level for blocking paraffin removal. The next paraffin removal period is determined by the current paraffin removal period and the level for blocking paraffin removal, a paraffin removal plan can be formulated in advance, and the problems that the paraffin removal times are too few, so that oil paraffin precipitation is serious, and oil well production is influenced or the problems that the manpower, time and capital are wasted due to too many times of oil well paraffin removal are avoided. The method and the system for determining the paraffin removal period of the oil well have very strong practicability and effectiveness.

Owner:PETROCHINA CO LTD

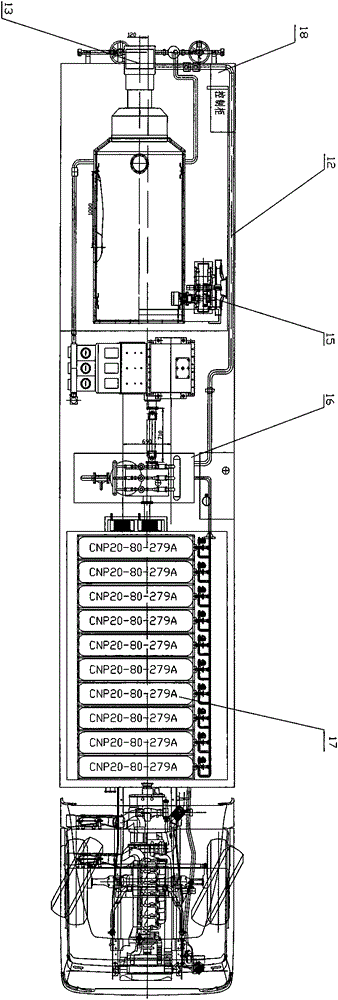

A complete set of drive control device for submersible screw pump

ActiveCN111287701BReduce vibrationSolve the problem of low temperature waxingSurveyDrilling rodsFrequency changerControl cell

Owner:黑龙江百申环保科技有限公司

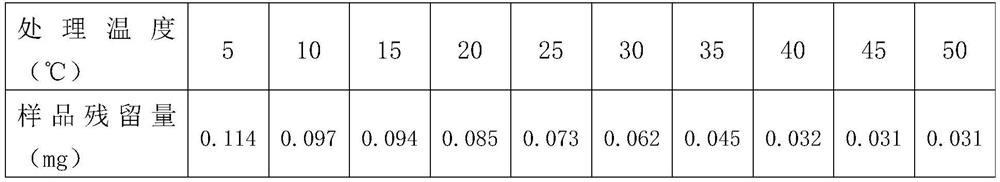

A Membrane Preparation Method Based on Oil Content Feedback Process

ActiveCN111933869BJudgment of oil contentEasy to judgeLi-accumulatorsCell component detailsCresolSilicon dioxide

Owner:河南银金达新材料股份有限公司

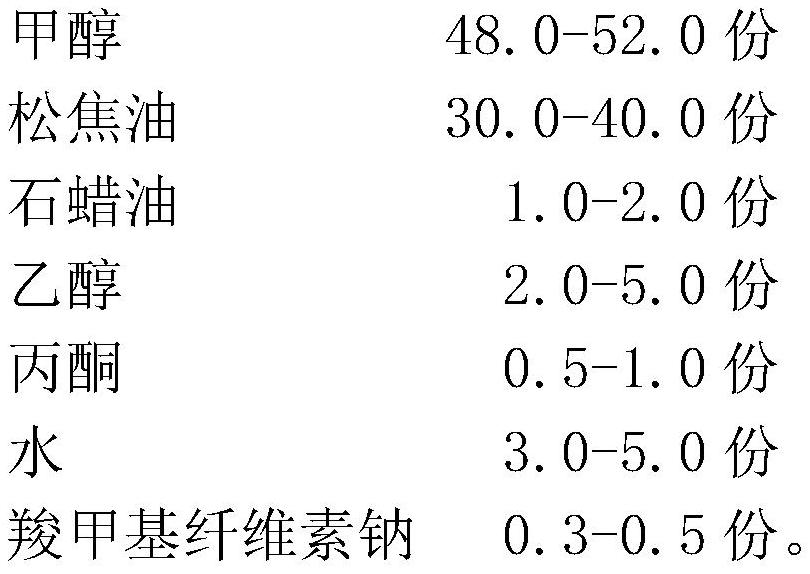

Alcohol-based fuel for boilers with good stability

ActiveCN108559554BHigh calorific valueProne to delaminationLiquid carbonaceous fuelsFuel additivesCarboxymethyl celluloseCellulose

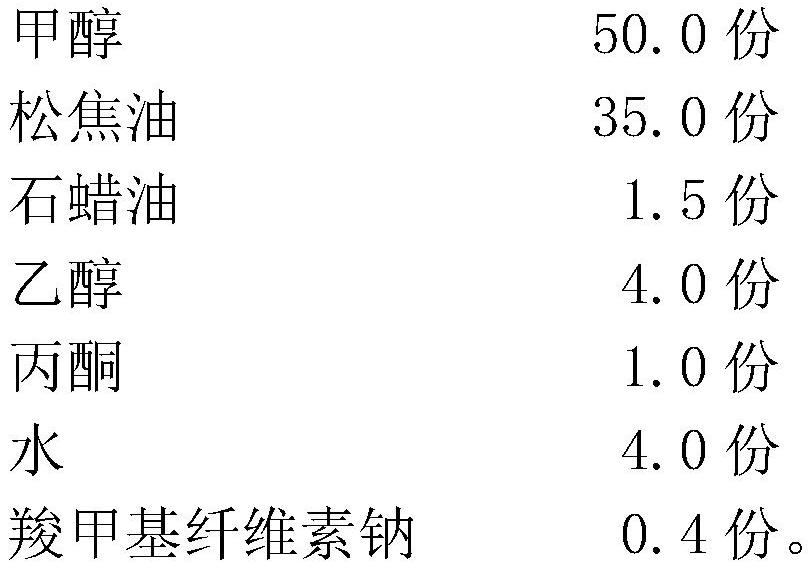

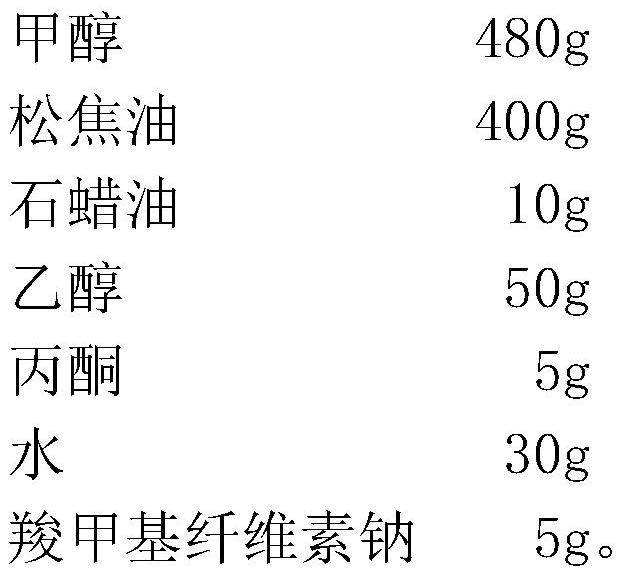

The invention discloses alcohol-based fuel with high stability for a boiler. The alcohol-based fuel is prepared from the following components in parts by weight: 48.0-52.0 parts of methanol, 30.0-40.0parts of pine tar, 1.0-2.0 parts of paroline, 2.0-5.0 parts of ethanol, 0.5-1.0 parts of acetone, 3.0-5.0 parts of water and 0.3-0.5 part of sodium carboxymethyl cellulose.

Owner:GUILIN GANLONG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

Dedicated oil adjusting paraffin removal device for rodless oil production and device with paraffin removal device

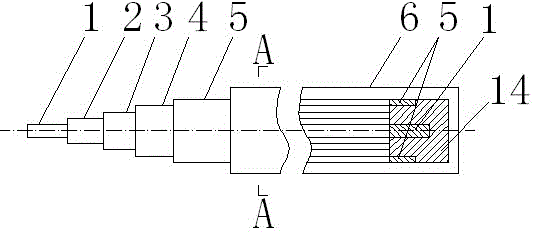

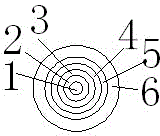

InactiveCN105089558AIncrease temperatureAvoid conductionCleaning apparatusInsulationElectricityGlass fiber

The invention discloses a dedicated oil adjusting paraffin removing device for rodless oil production and a device with the dedicated oil paraffin removal device. The dedicated oil adjusting paraffin removing device comprises a copper conductor, and structurally comprises the copper conductor, a polyimide film, fluoroplastic, glass fiber cloth, a stainless steel heating tube and an insulating heat-conducting jacket arranged from inside out respectively; the right end of the copper conductor is electrically connected with the right end of the stainless steel heating tube; and the insulating heat-conducting jacket is arranged at the right end of the electric joint of the right end of the copper conductor and the right end of the stainless steel heating tube. The device with the dedicated oil adjusting paraffin removing device for rodless oil production comprises the dedicated oil adjusting paraffin removing device for rodless oil production and a medium-frequency inverter, wherein the medium-frequency inverter is electrically connected with the upper end of the copper conductor of the dedicated oil adjusting paraffin removing device for rodless oil production and the upper end of the stainless steel heating tube. The dedicated oil adjusting paraffin removal device for rodless oil production is mounted in a rodless oil production pump, so that higher paraffin removal efficiency is achieved, paraffin accumulation in the rodless oil production pump and an oil production pipe is avoided, oil production efficiency is improved, paraffin removal cost is lowered, and great convenience is brought to maintenance of oil production equipment.

Owner:XINXIANG XIAFENG ELECTRIC LTC

Oil seal device for digital PCR chip

ActiveCN111304072AGuaranteed stabilityReduce mistakesBioreactor/fermenter combinationsBiological substance pretreatmentsPcr chipOil paraffin

The invention provides an oil seal device for a digital PCR chip. The device comprises a base, the base is made of an aluminum material, a groove is formed in the middle part of the base, the groove is used as a container for placing a reaction chip, an upper cover is arranged on the groove, the upper cover slides relative to the substrate to seal the chip, and paraffin oil with a thickness of 0.3-0.5 mm is used as an oil seal structure at the position, corresponding to the chip, of the upper cover; and sliding grooves are formed in the two opposite sides of the inner side of the groove, the upper cover can horizontally slide in the sliding grooves, and the upper side faces of the side walls of the sliding grooves are oil sealing faces. Due to full-closed and semi-automatic operation of the device, the manual operation process is reduced, and therefore errors caused by manual operation can be reduced to the maximum extent; a good heat-conducting medium is selected, so that the heat conductivity of the device as a reaction chip container is fully guaranteed, and the stability of reaction conditions is fully guaranteed; and a material and a structure adopted by the upper cover surface can fully guarantee effectiveness of later result detection.

Owner:宁波胤瑞生物医学仪器有限责任公司

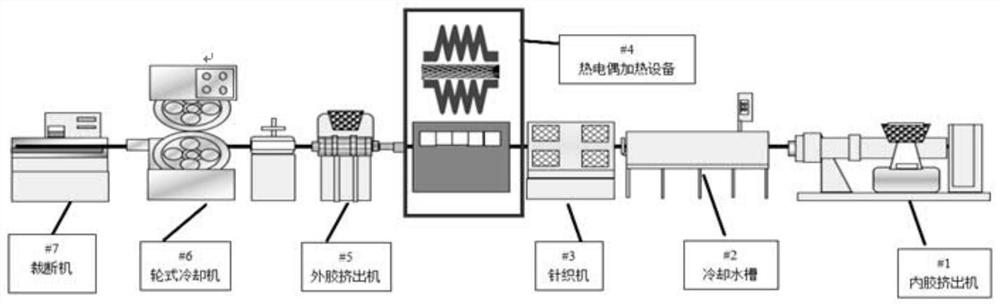

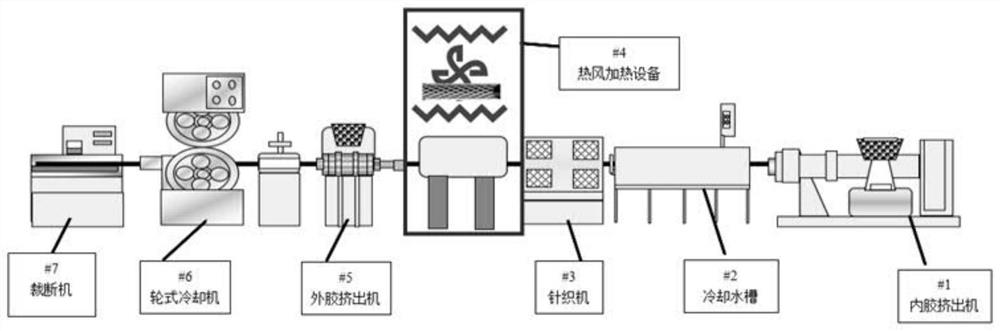

Rubber hose and preparation method thereof

PendingCN113878940AGuaranteed bonding effectGood compatibilitySynthetic resin layered productsRubber layered productsRubber materialPolymer science

The invention provides a rubber hose and a preparation method thereof, and relates to the technical field of rubber hose preparation. The rubber hose sequentially comprises an inner rubber layer, a fiber reinforced layer and an outer rubber layer from inside to outside. A plasticizer in the rubber material of the inner rubber layer is paraffin oil, the molecular weight of Ca in the paraffin oil is 6-8%, and the paraffin oil is a plasticizer with active small molecules. The inner rubber layer added with the plasticizer can move towards the surface of an inner rubber pipe after being baked at high temperature, so that the surface of the inner pipe is relatively high in oiliness. Therefore, when the inner pipe is heated and then passes through an outer rubber extruder, the inner pipe is in a high-temperature soft state, the surface of the inner pipe has certain oiliness, and the inner and outer rubber adhesion of a product can be well guaranteed.

Owner:江苏鹏翎胶管有限公司

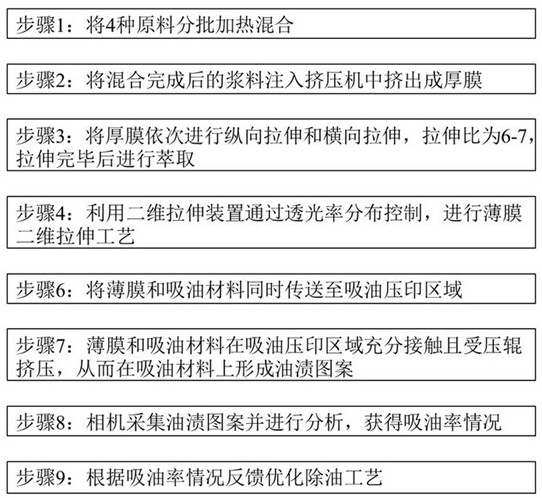

Film preparation method based on oil content feedback process

ActiveCN111933869AJudgment of oil contentEasy to judgeLi-accumulatorsCell component detailsCresolMaterials science

The invention relates to a film preparation method based on an oil content feedback process, which comprises the following steps: mixing and heating polyethylene, paraffin oil, silicon dioxide nanoparticles and 4, 4'-thiobis(6-tert-butyl m-cresol) in batches, carrying out extrusion molding, respectively carrying out transverse stretching and longitudinal stretching, and carrying out two-dimensional stretching; and after stretching is finished, feeding the film into an oil content analysis device, and optimally controlling an oil removal device according to the oil stain distribution conditionon the oil absorption material, so as to finally prepare the lithium battery diaphragm with low oil content.

Owner:河南银金达新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com