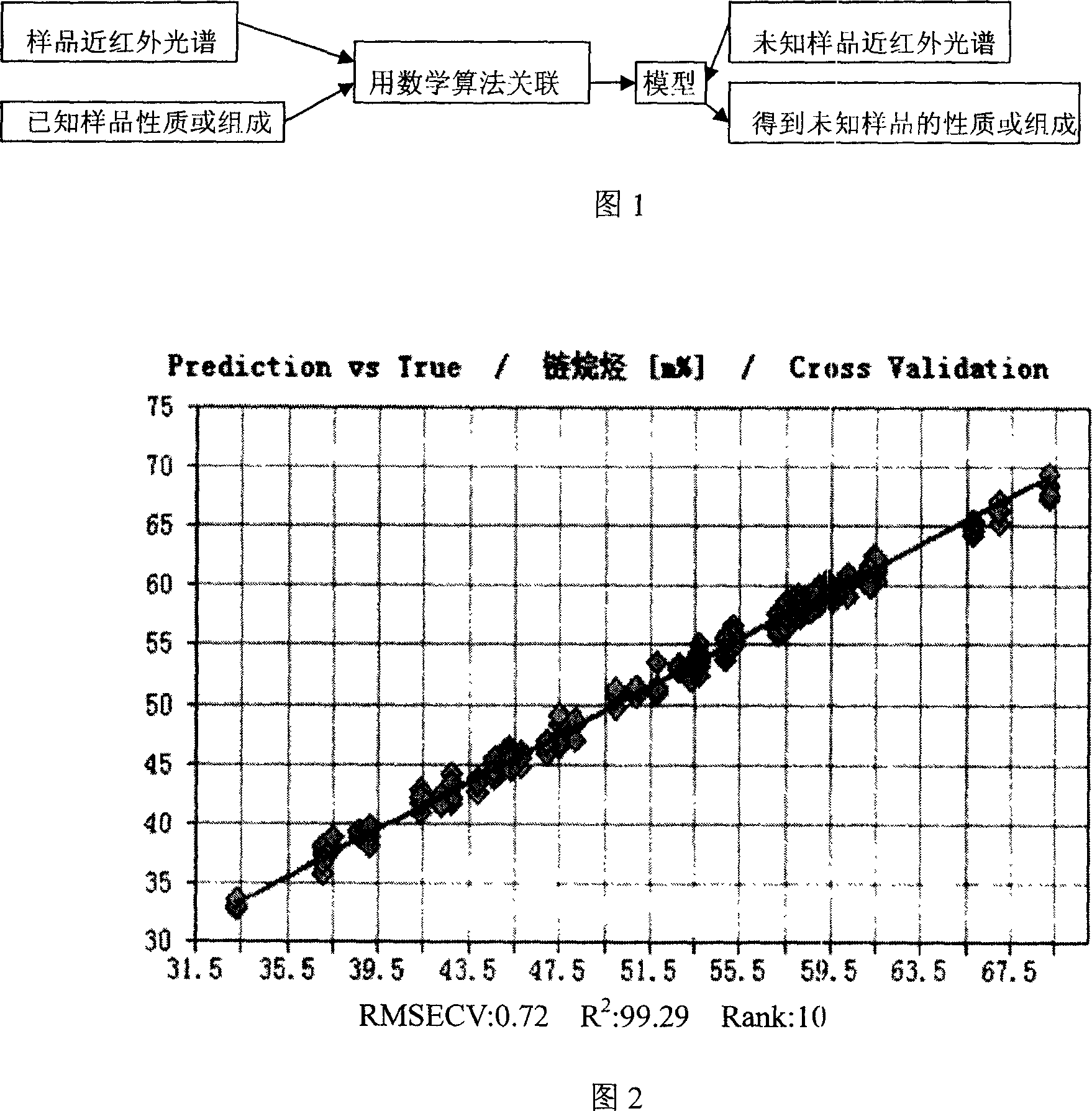

Method for detecting hydrgenated tail-oil paraffin composition using near-infrared spectrum

A tail oil paraffin family, near-infrared spectroscopy technology, applied in the direction of color/spectral characteristic measurement, measurement device, instrument, etc., can solve the problems of inability to meet the production plant, long time required, etc., to achieve accurate test cost, operation space Small, test cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Step 1 collect modeling samples

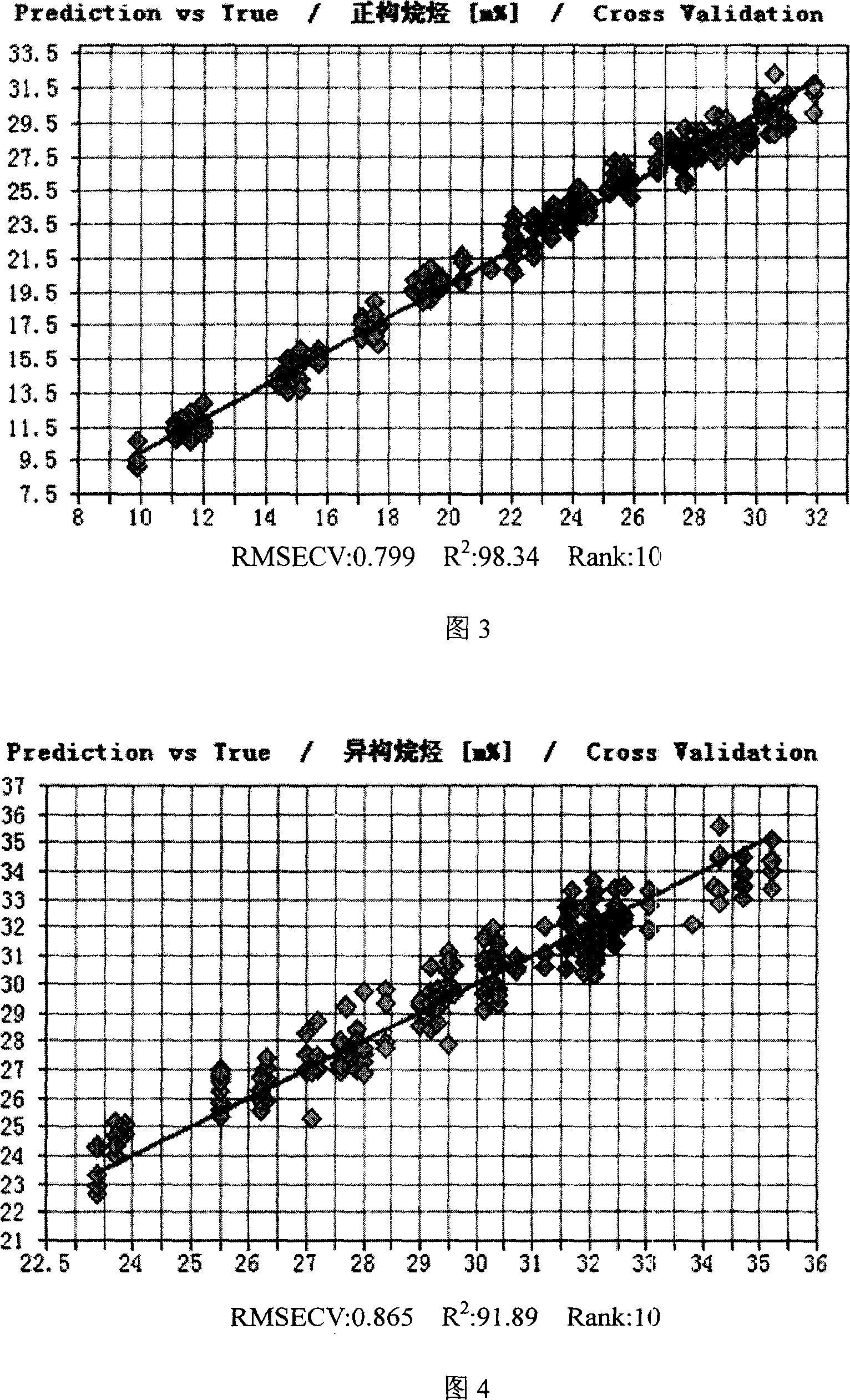

[0055] 1.1 Collect samples to establish the model of paraffins in hydrogenated tail oil, see Table 1:

[0056] Determination mass fraction range of model I: (33.3~69.2)m%

[0057] 1.2 Collect samples to establish the n-paraffin model in hydrogenated tail oil, see Table 1:

[0058] Determination mass fraction range of Model II: (9.9~31.9)m%

[0059] 1.3 Collect samples to establish isoparaffin model in hydrogenated tail oil, see Table 1:

[0060] The measured mass fraction range of Model III: (23.4~34.7)m%

[0061] Table 1 Modeling sample, chemical value (m%), measured value (m%) and residual error table (m%)

[0062] chemical value

Model I

Model II

Model III

serial number

chemical value

measured value

residual

chemical value

measured value

residual

chemical value

measured value

residual

1#

2#

3#

4#

5#

6#

7#

8#

9#

10#

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com