Patents

Literature

58results about How to "Enable accurate testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

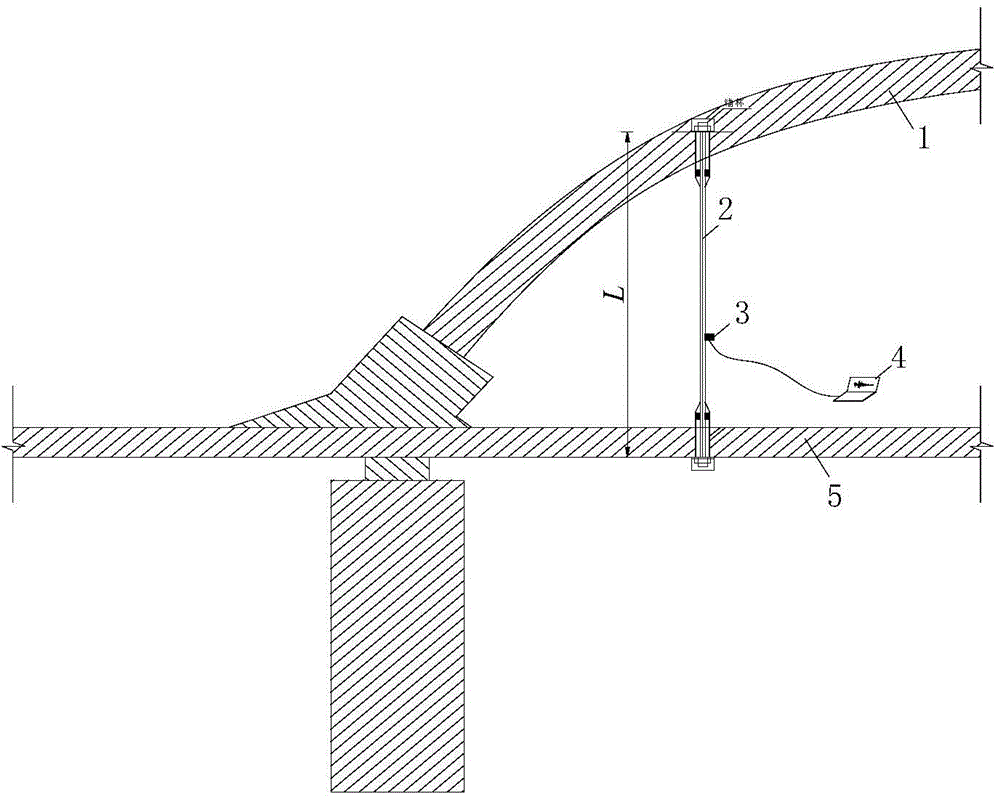

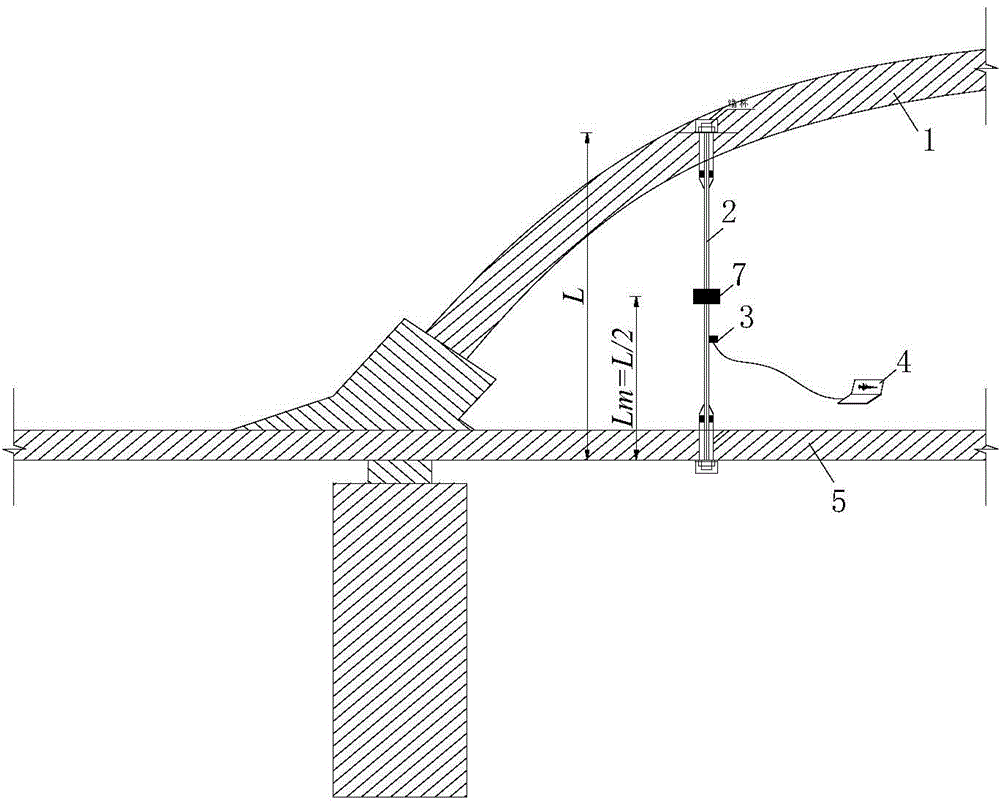

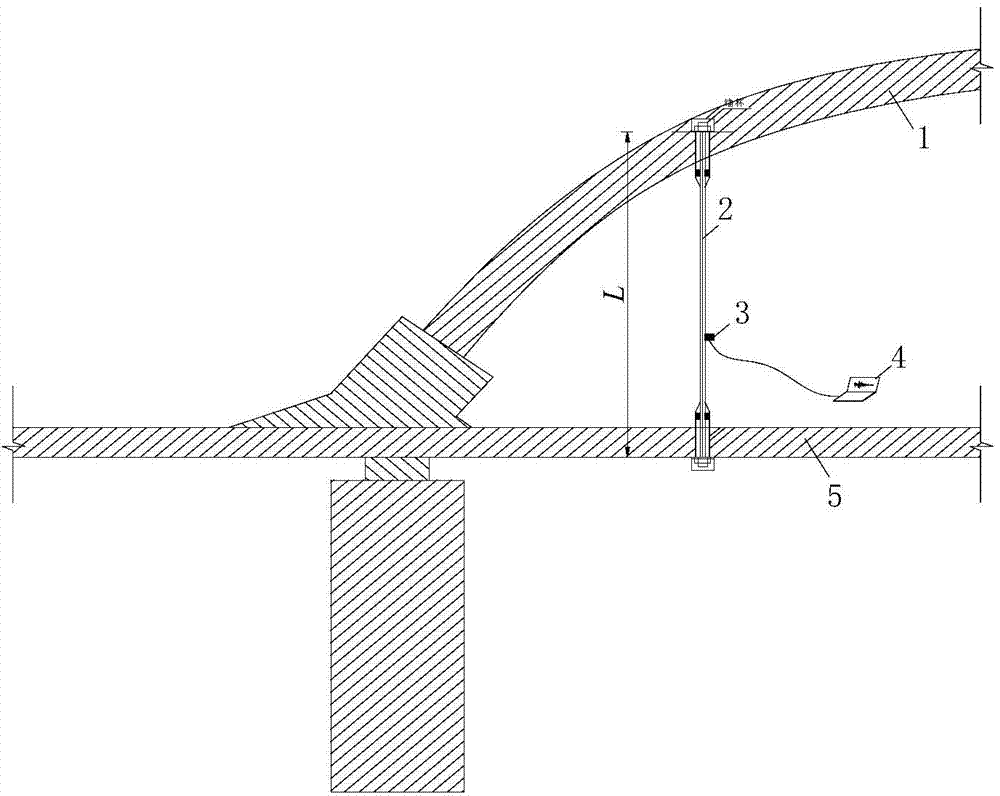

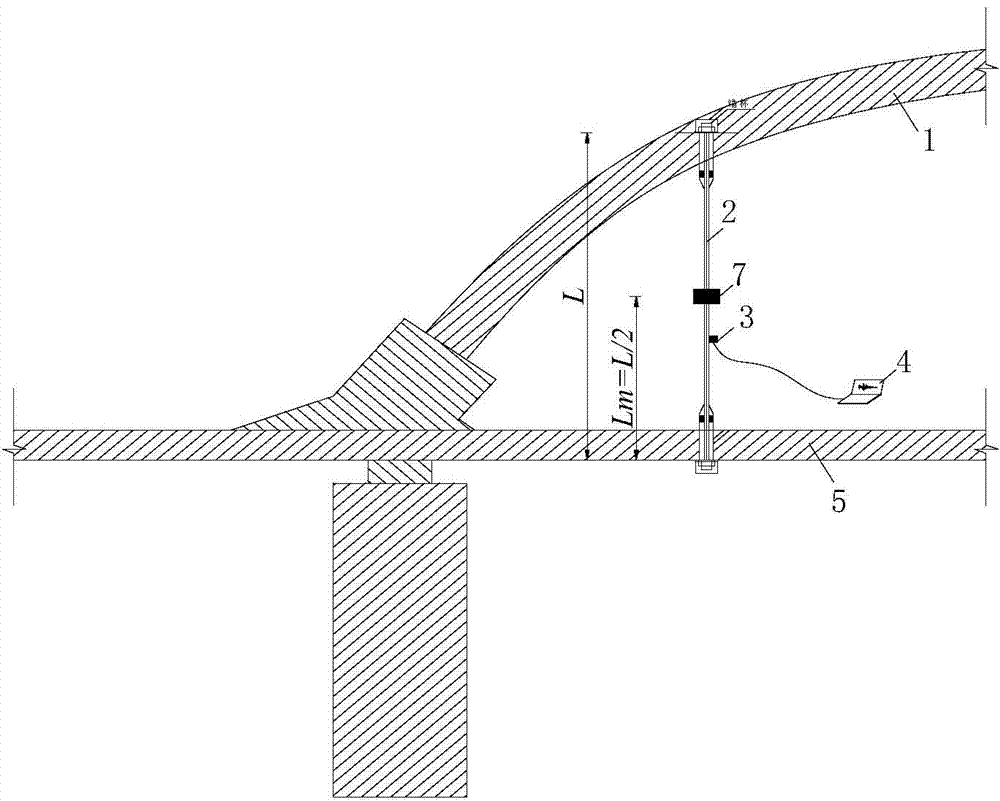

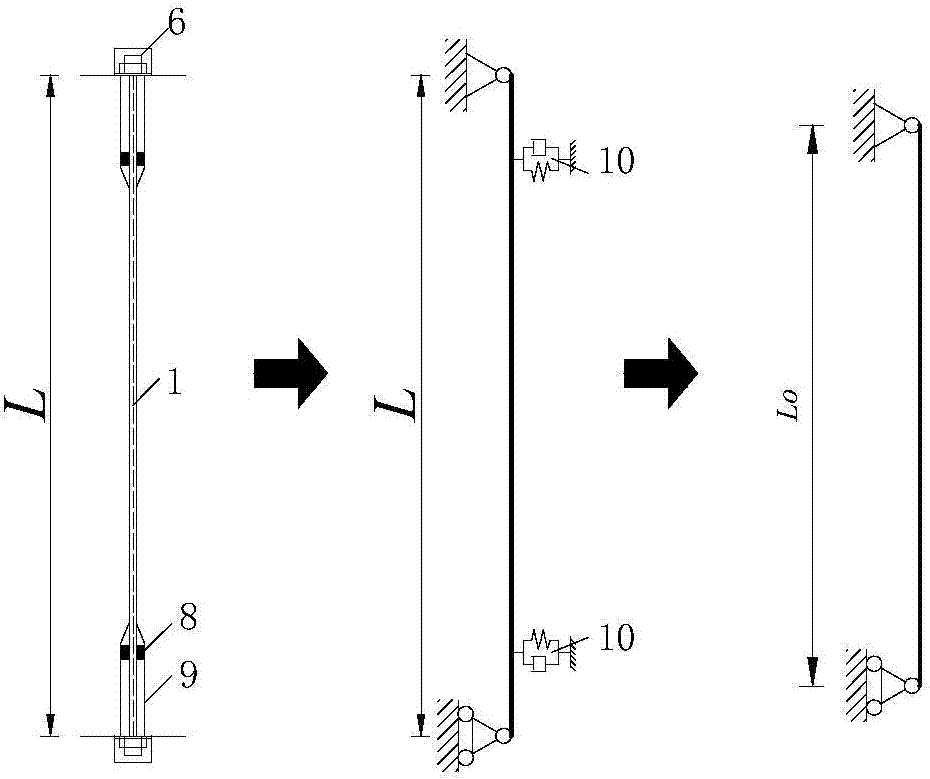

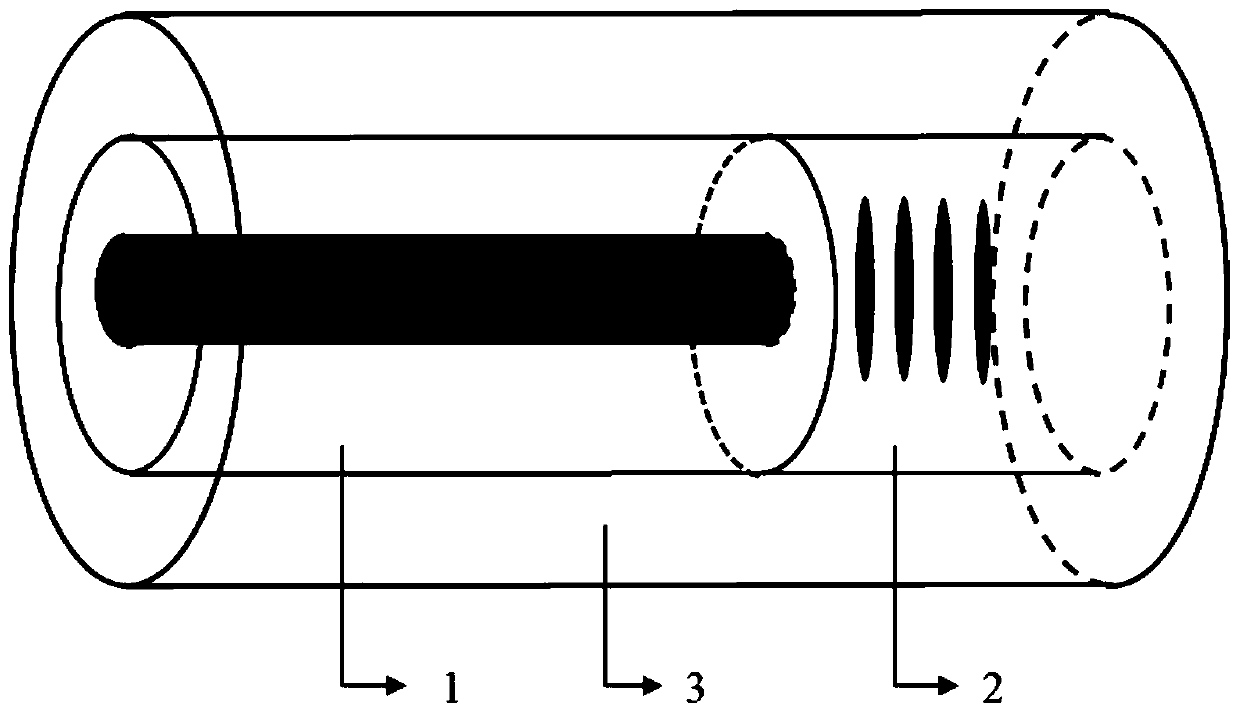

Method for accurately measuring cable force of short boom of boom arch bridge

ActiveCN103557978AEnable accurate testingEasy to operateApparatus for force/torque/work measurementFrequency measurementsEngineering

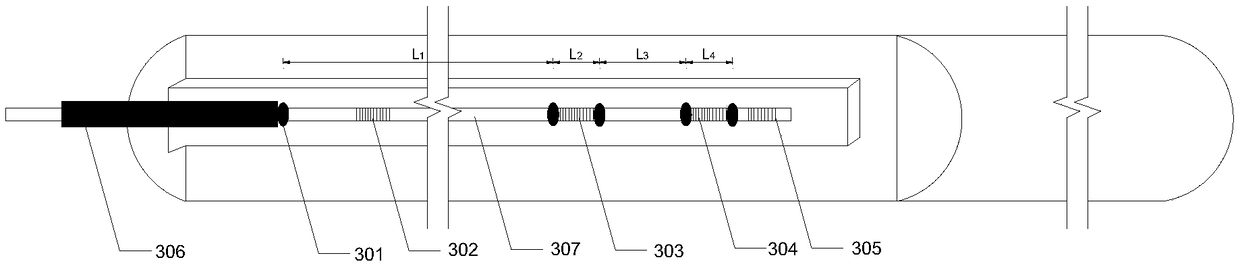

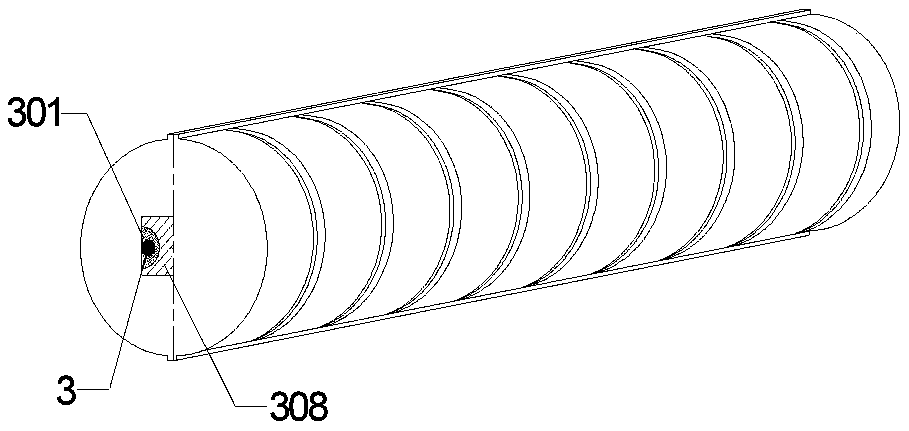

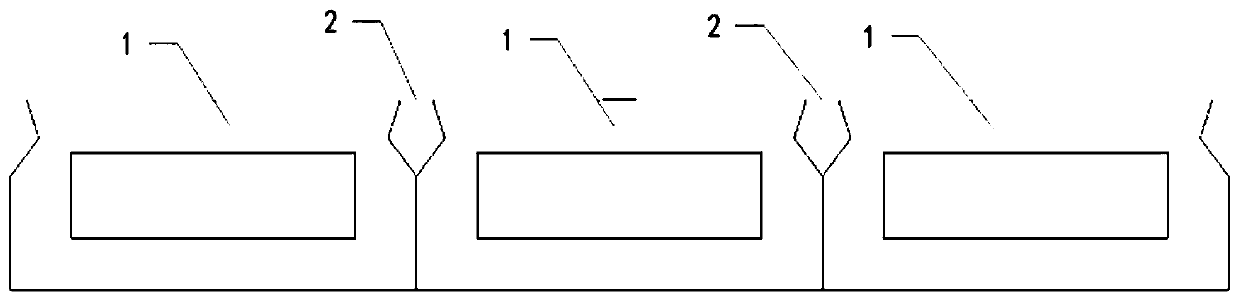

The invention discloses a method for accurately measuring the cable force of a short boom of a boom arch bridge. A relevant measuring model is designed, boundary conditions of the boom are simplified into damping and spring supporting of a simple support boom in a corresponding transverse position, the boom is further equivalent into a simple support stretching rope with the equivalent calculation length, a mass block is additionally arranged in the middle of the boom, a vibration balance equation of ropes is set up before and after the mass block is additionally arranged in the middle of the boom, an algorithm of recognizing the equivalent calculation length L0 of the boom by using measured frequencies of the boom before and after the additional mass block is arranged is finally and optimally formed, and therefore the method for accurately measuring the cable force is set up. According to the method for accurately measuring the cable force, measurement is convenient to conduct, and a user only needs to conduct vibration frequency measurement twice on the boom before and after the additional mass block is arranged. The measuring accuracy is high, and the difficult problem of accurately measuring the cable force of the short boom can be well solved. When the method is applied to the field of detection or construction monitoring of boom arch bridges, the cable force of the short boom can be rapidly and conveniently measured at high accuracy, and therefore reliable essential data are provided for detection and monitoring of the boom arch bridges.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

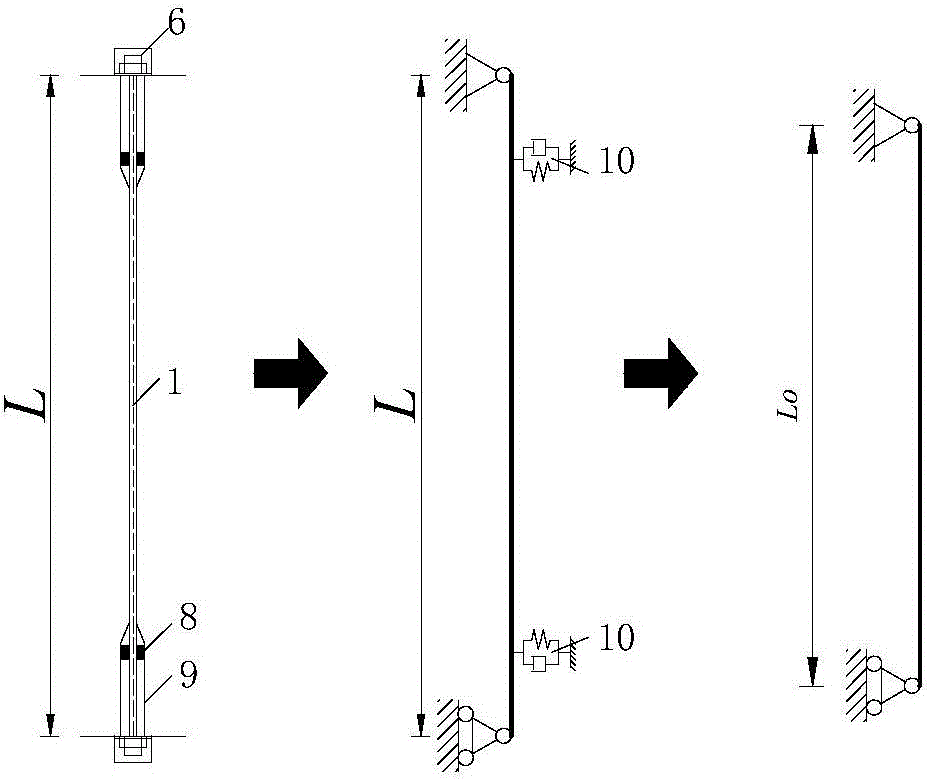

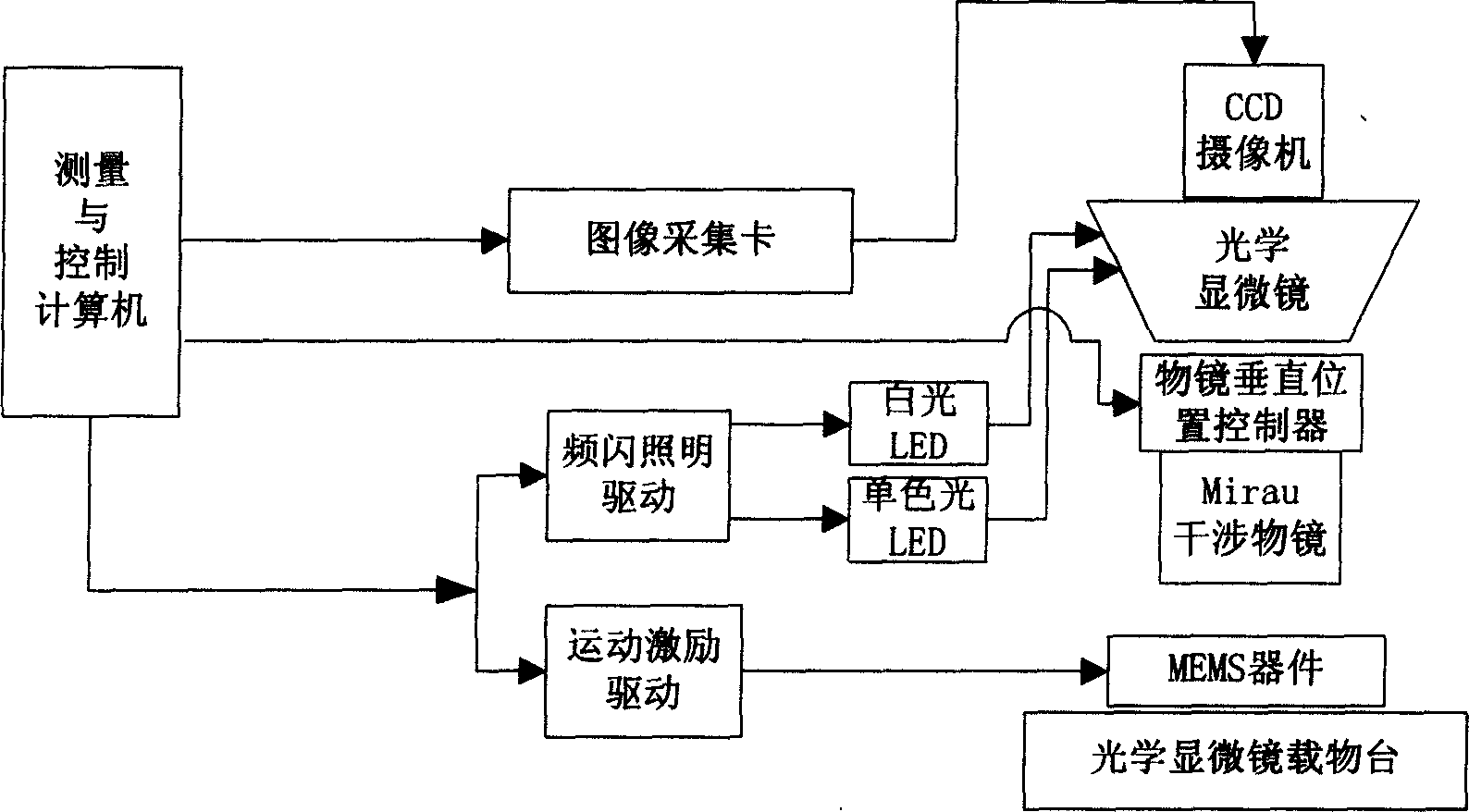

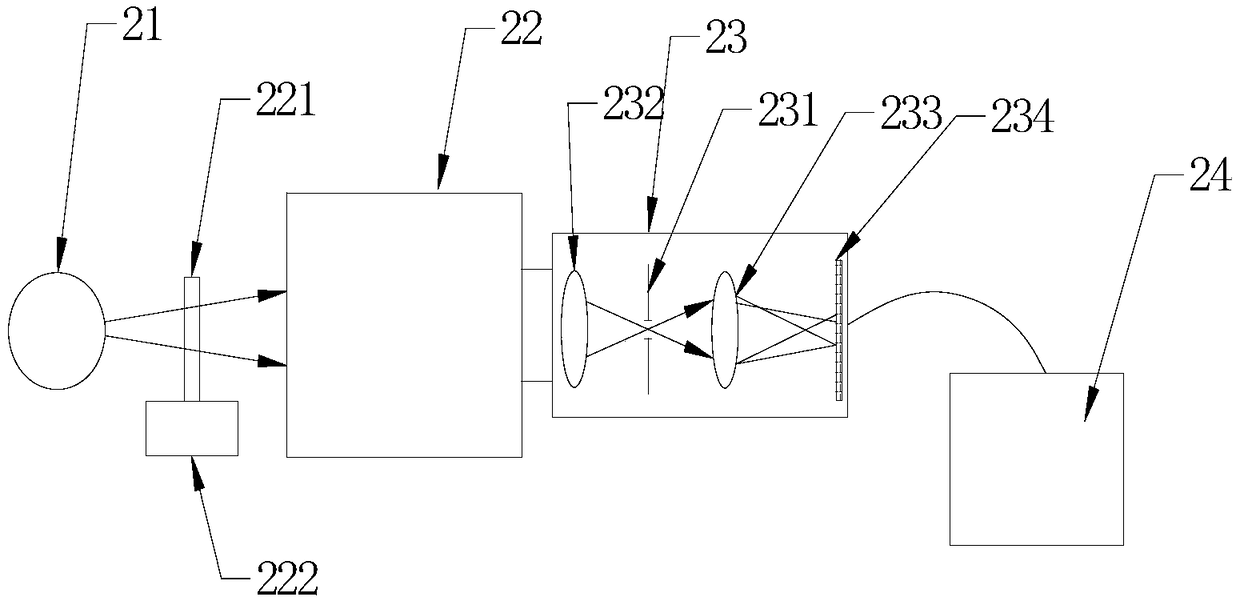

System and method for testing three-dimensional motion of microstructure by image matching and phase shift interference

InactiveCN1654923AAdjustable delay timeAccurate analysis of out-of-plane motion parametersUsing optical meansMicro structureMeasurement point

This invention discloses a system and a method for testing microstructure 3-D motion with image-match and phase shift interference. The system includes an optical microscope, a Mirau interference object glass, its vertical position controller, a strobe lighting driving device, a CCD camera, image collecting cards, a numeric computer and a motion excitation driver, among which, the strobe lighting device drives LEDS of white light and monochromatic light to irradiate the micro structure, which tests the plane motion parameter in white light LED irradiation and tests its out-of -plane motion parameter in monochromatic light LED irradiation. The method includes synchronous control to strobe and drive signals, extraction of plane motion parameter in white light irradiation, set up a relative coordinate system, the obtaining of the surface shape and the extraction coordinate system.

Owner:TIANJIN UNIV

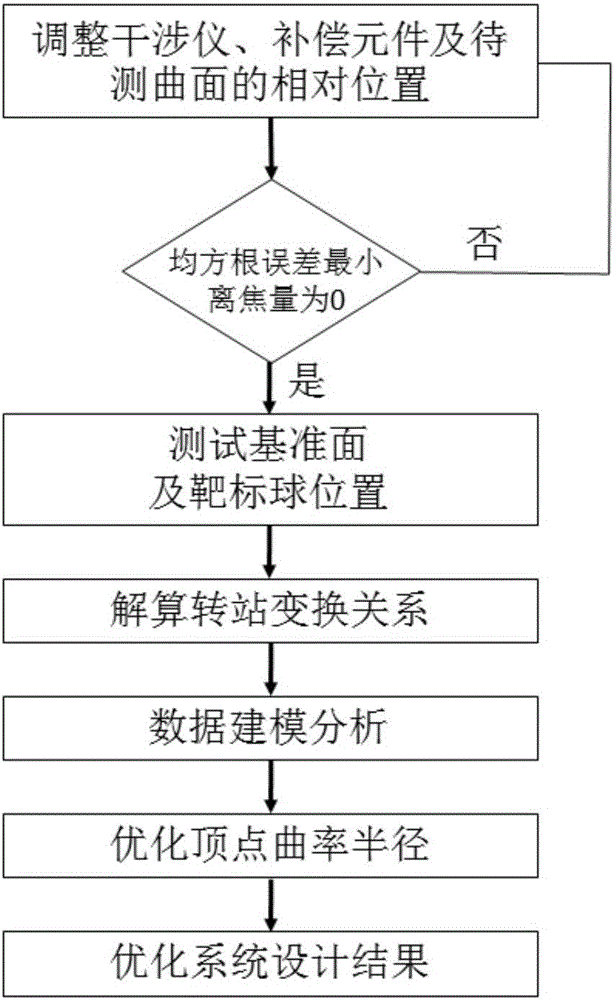

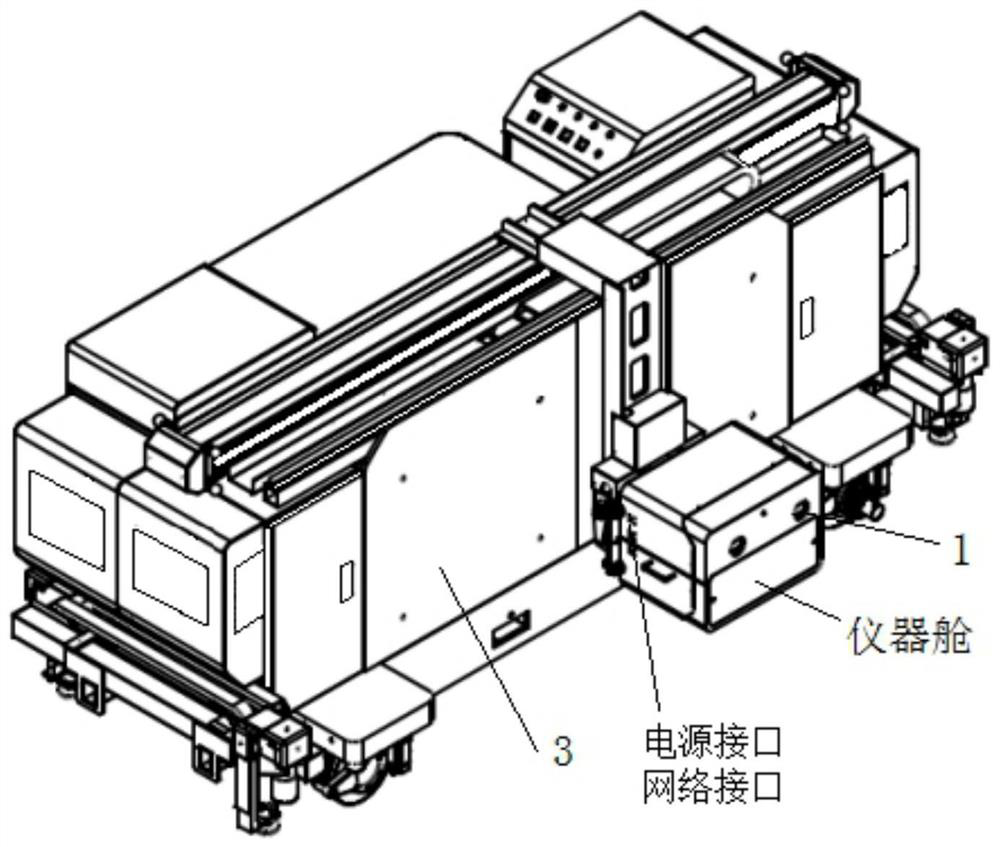

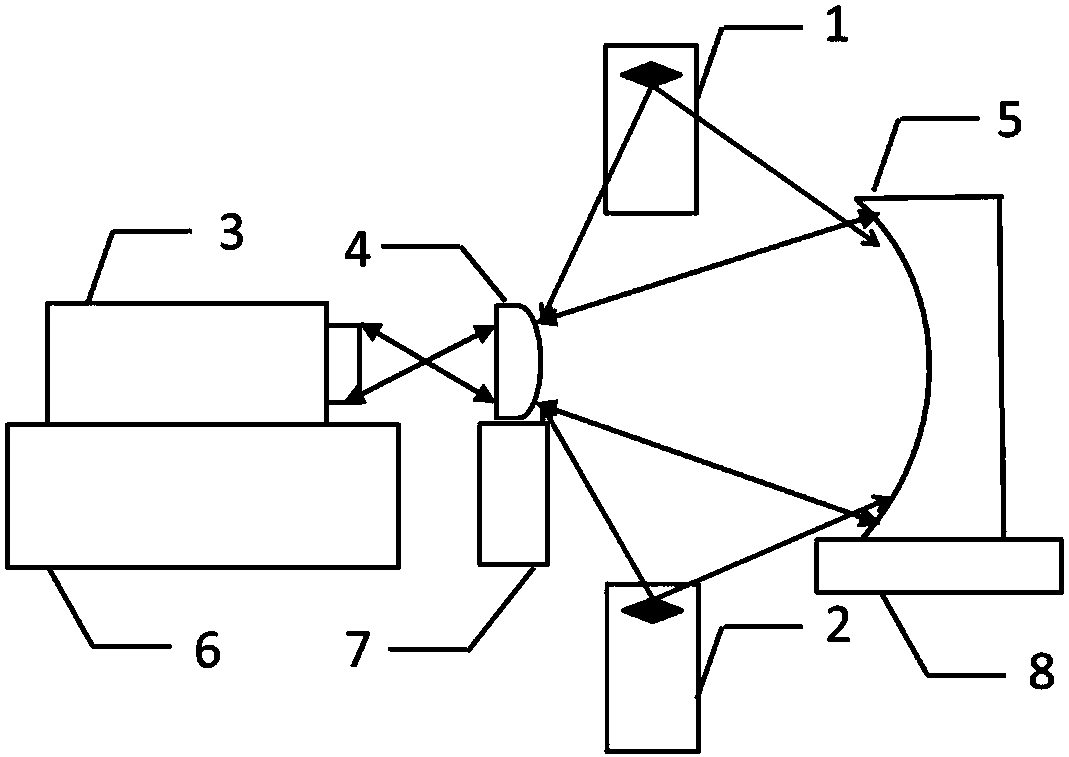

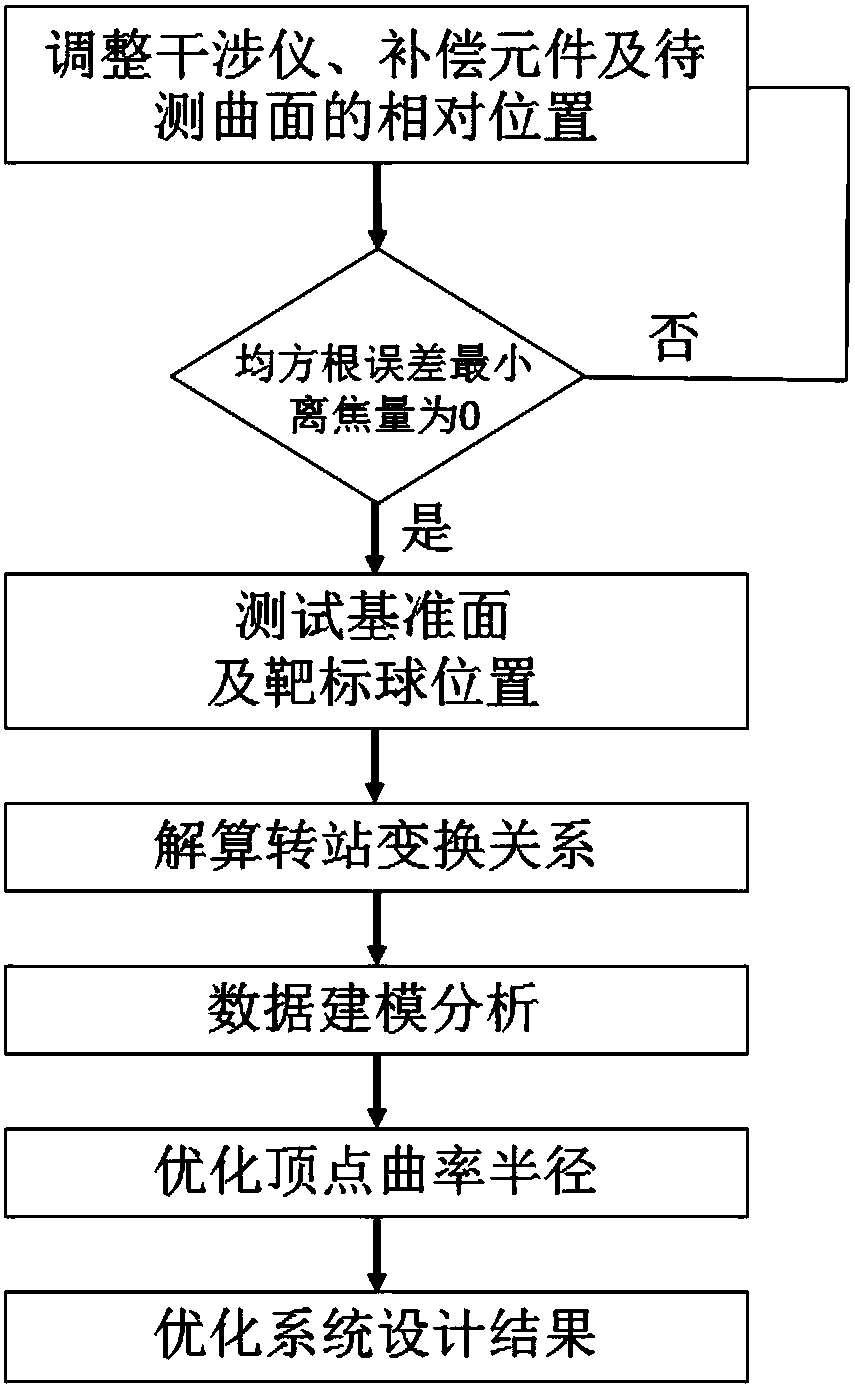

Large-aperture complex curved surface optical parameter accurate testing and calibrating device and method

ActiveCN106840023AEnable accurate testingRealize CalibrationUsing optical meansControl signalEngineering

The invention discloses a large-aperture complex curved surface optical parameter accurate testing and calibrating device and method. The device is used for testing and calibrating a complex curved surface, a testing and calibrating module is used for acquiring the surface shape of the complex curved surface detected by a laser interferometer and transmitting control signals to the laser interferometer, a compensation element and an adjusting mechanism of the complex curved surface to be detected, the adjusting mechanism is controlled to adjust relative positions and relative angles of the laser interferometer, the compensation element and the complex curved surface, so that the root-mean-square error of the surface shape of the complex curved surface is minimum, and the defocusing amount is zero. A transformation matrix calibrating mechanism is used for calibrating a coordinate transformation matrix of a laser tracker in the station transfer process. Coordinates of surface shape data are transformed into the same coordinate system based on the coordinate transformation matrix. All surface shape data in the same coordinate system are subjected to modeling analysis and calculated, design results of an optical checking compensator for the complex curved surface to be detected are further optimized, and the optimized results are optimal design results of the optical checking compensator based on measured parameters of a mirror.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

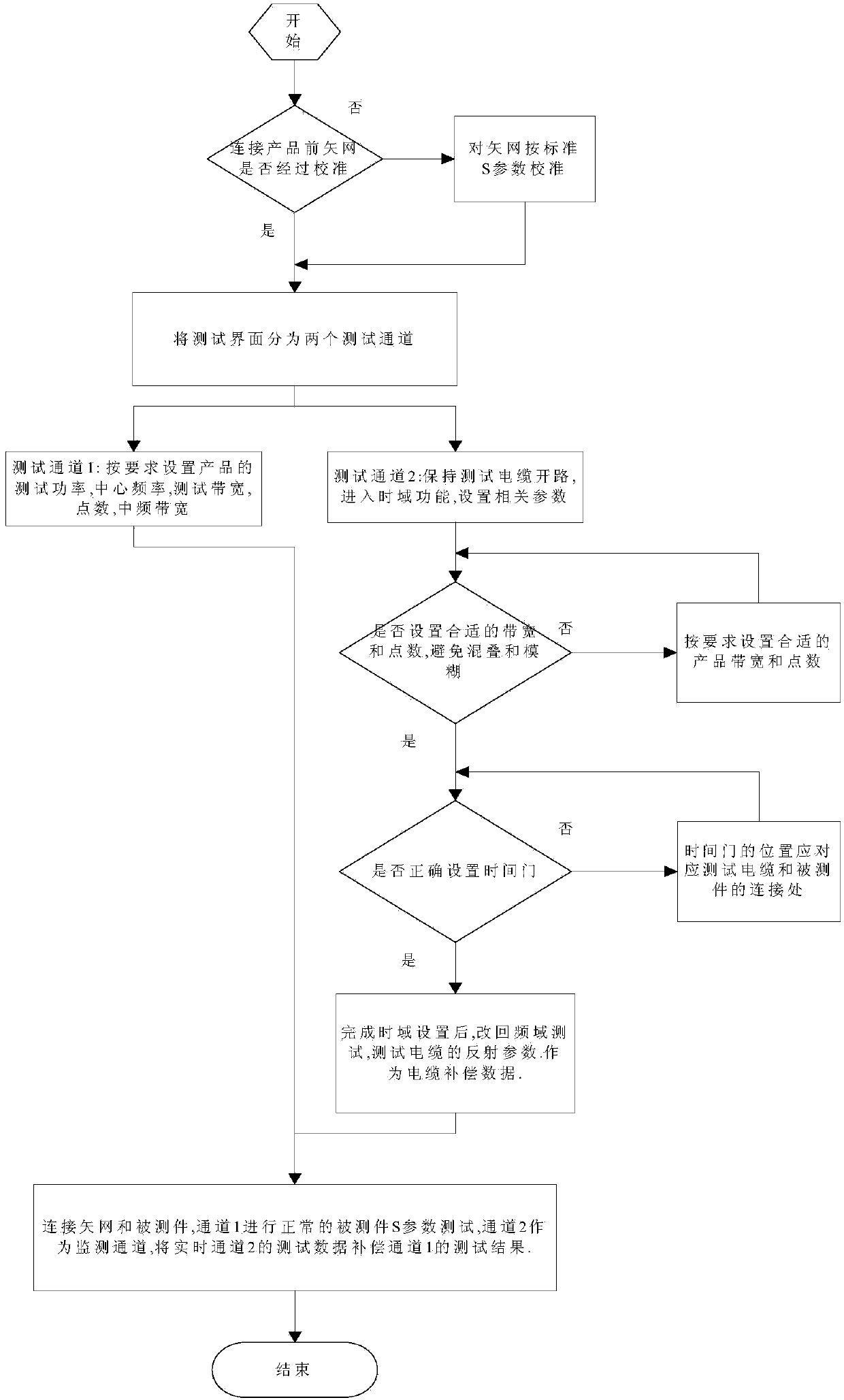

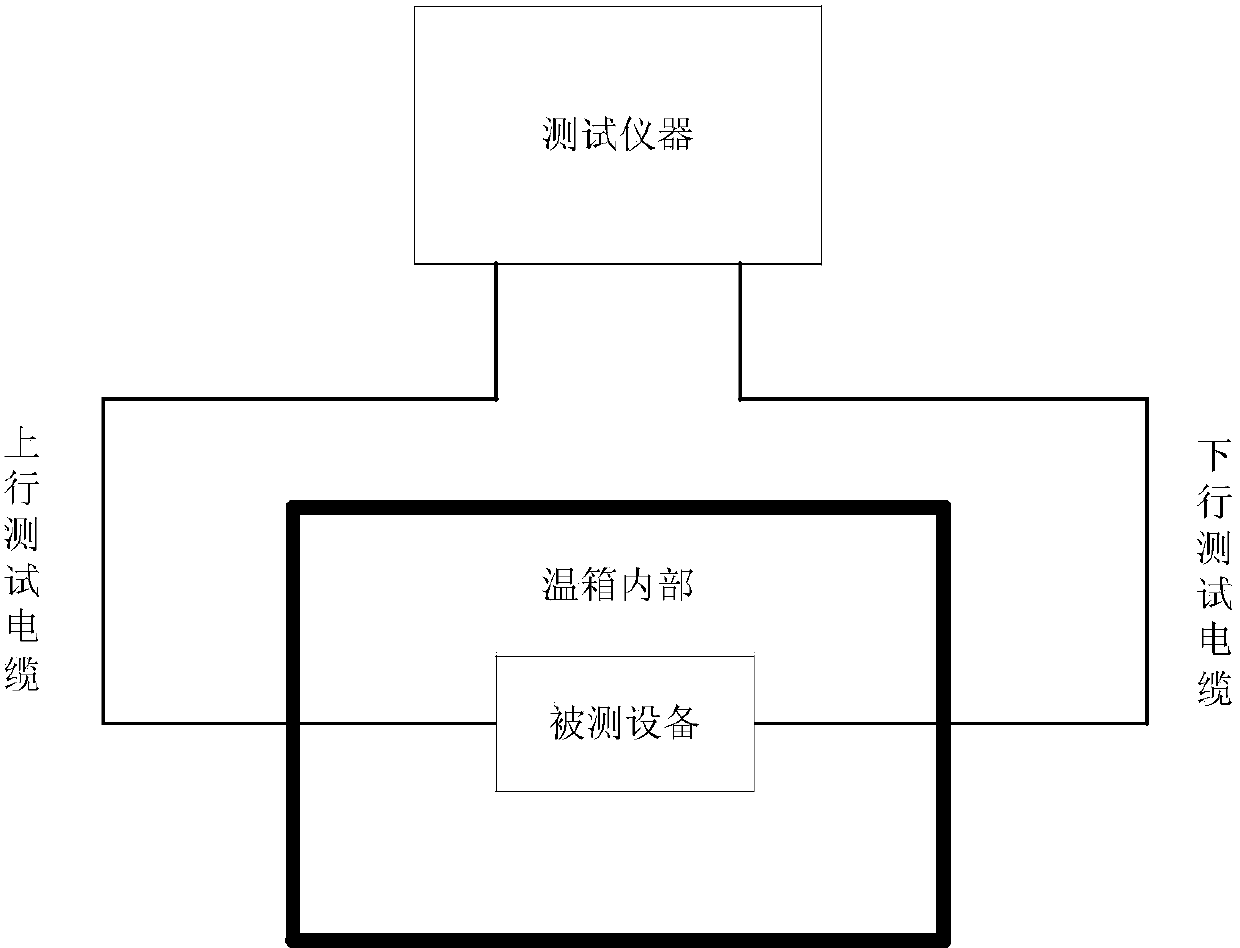

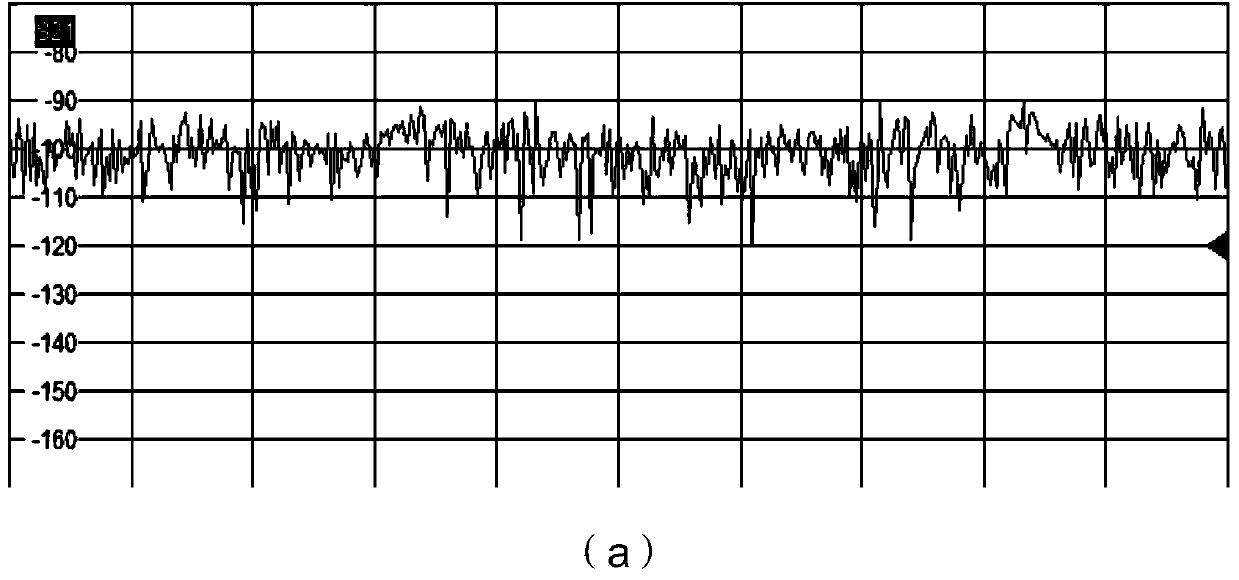

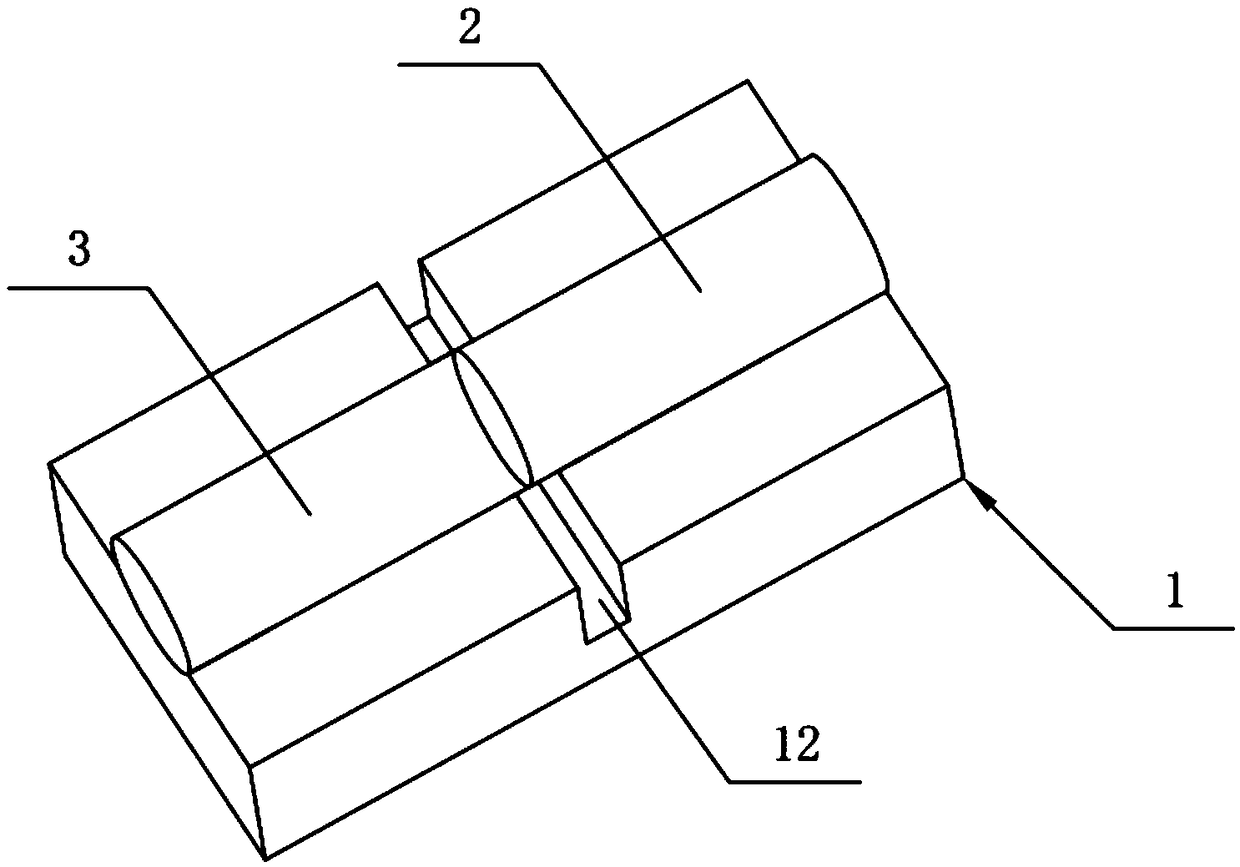

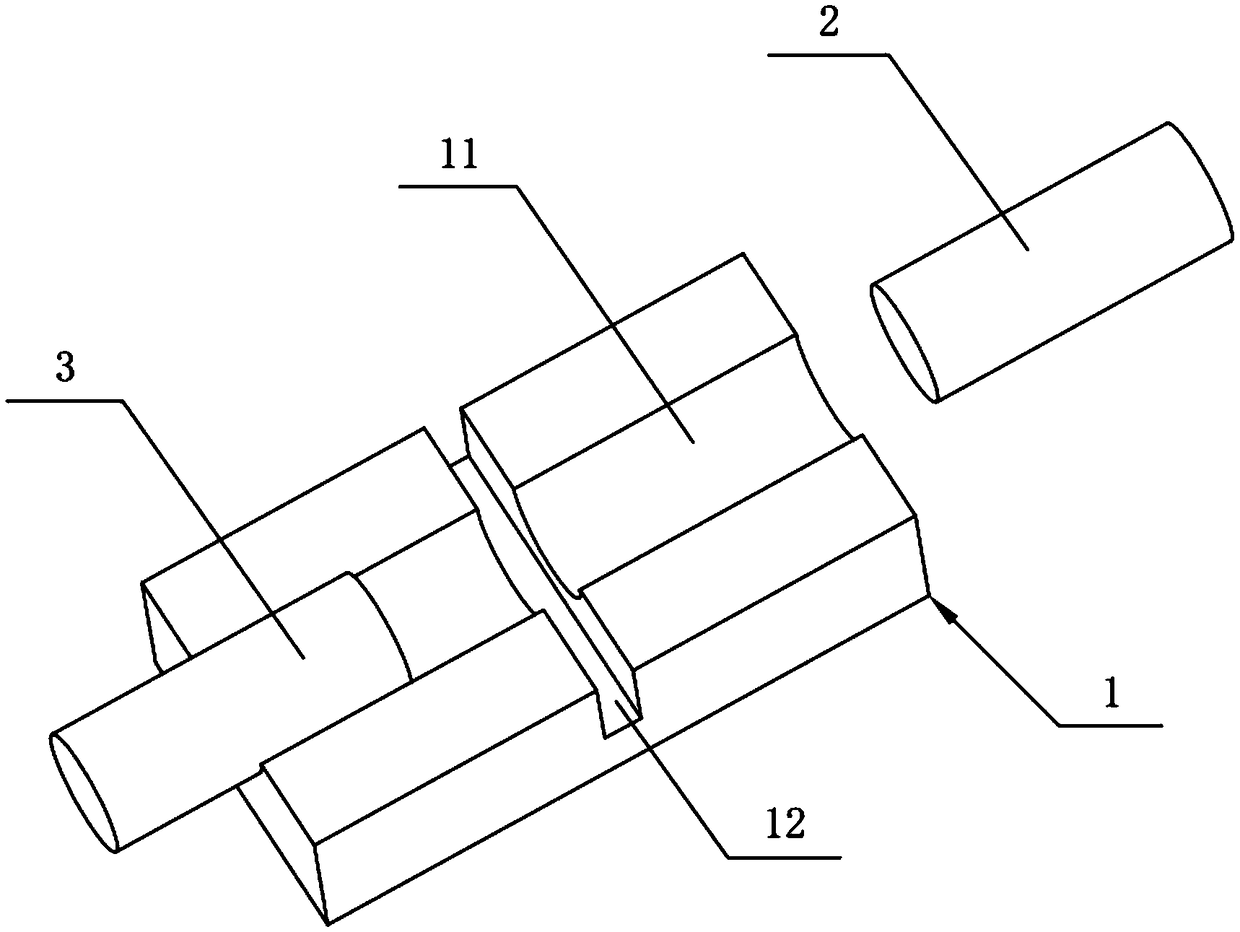

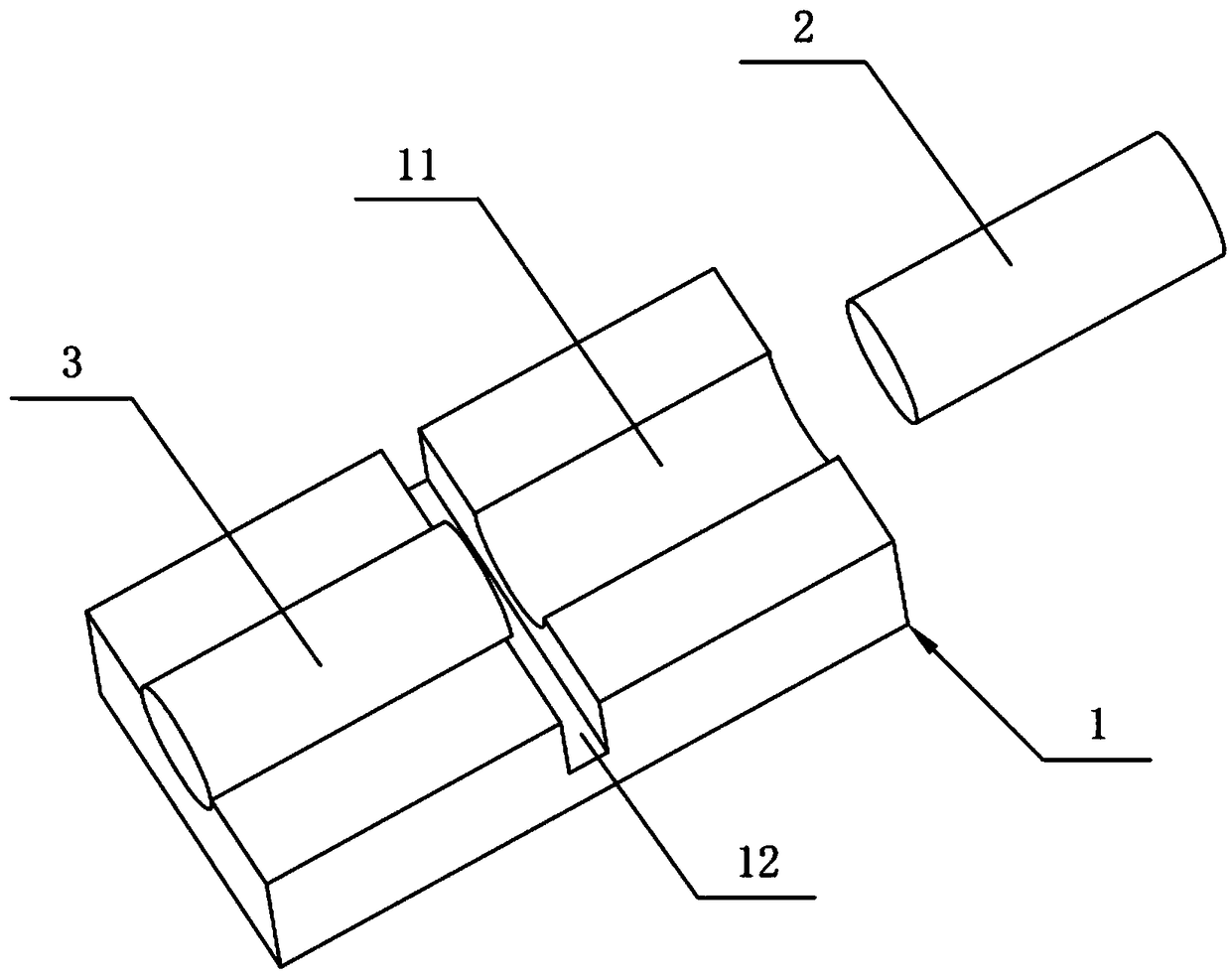

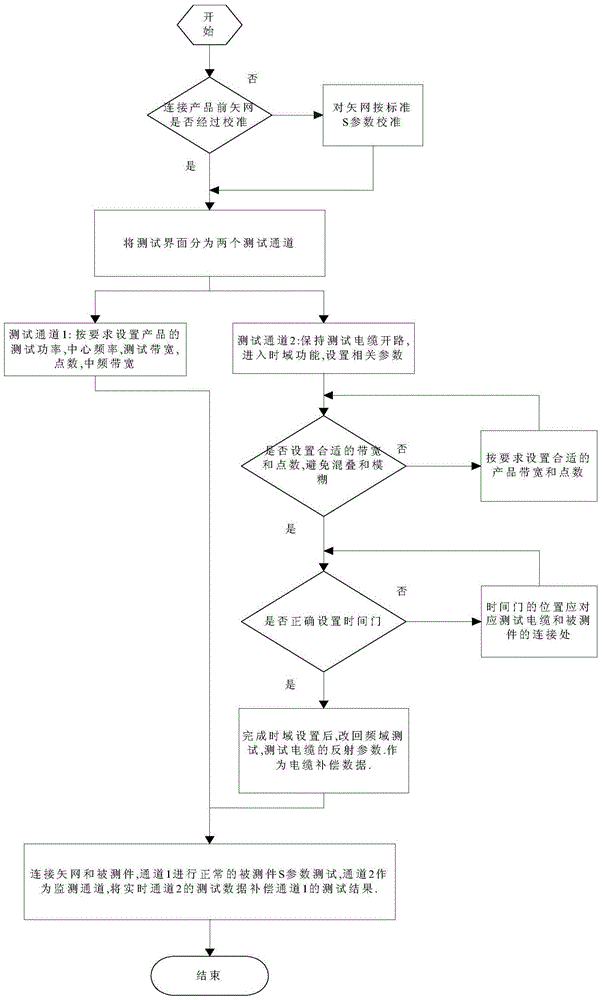

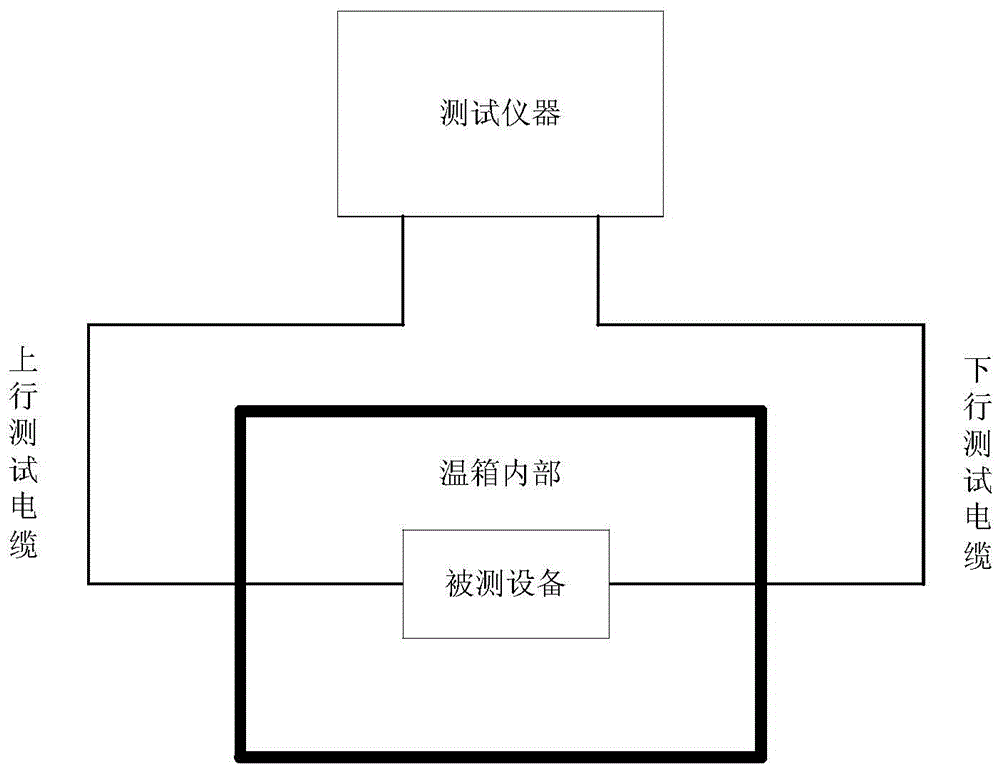

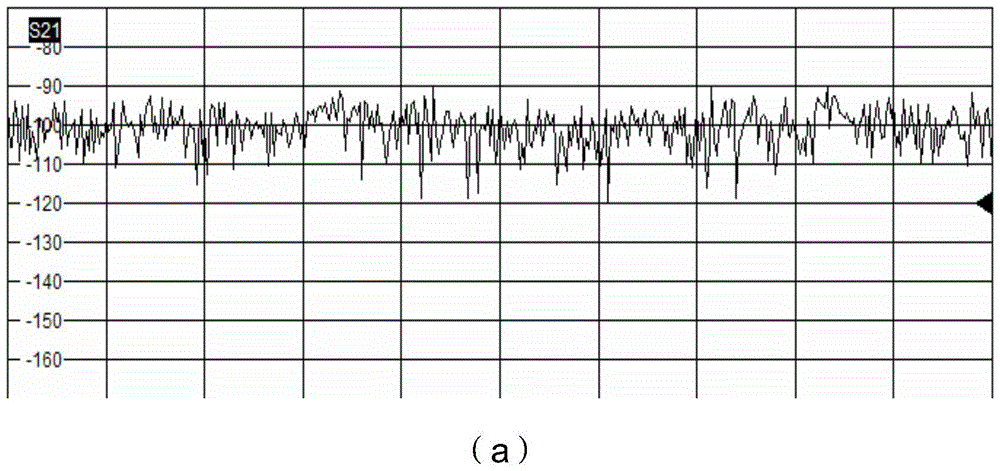

Time-domain dynamic correction method for cable measurement errors in temperature test

ActiveCN104215848AEnable accurate testingThe test result is accurateResistance/reactance/impedenceElectrical testingTime domainProduct testing

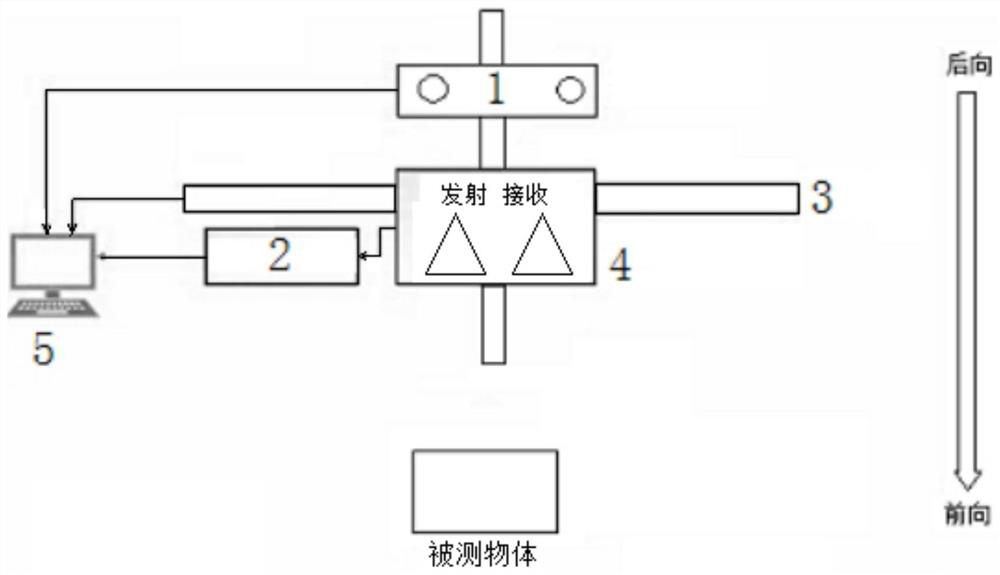

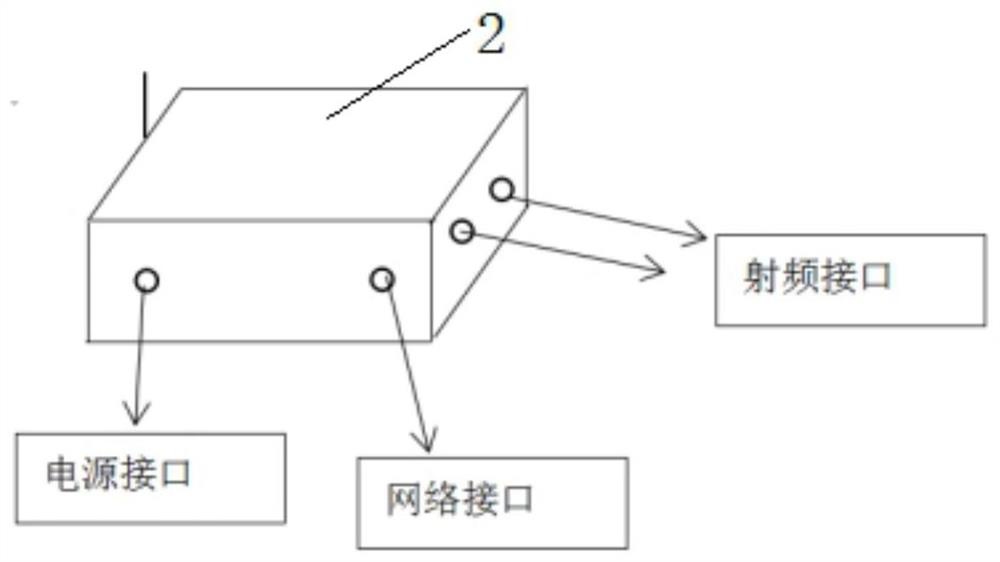

The invention discloses a time-domain dynamic correction method for cable measurement errors in a temperature test. When radio frequency microwave products are tested in a laboratory, radio frequency cables are needed to be used for connecting the detected products with instruments. In order to guarantee accuracy of a product test, the cables must be tested singly before usage to obtain characteristic parameters of the cables, and errors introduced by the cables are corrected in a test system. But when the detected products enter a temperature chamber for a high-low temperature cycling test, the characteristic parameters of the radio frequency cables change along with high and low temperatures, and furthermore, the cables are already connected with the detected products and the instruments in the temperature chamber, single correction can not be carried out, so accuracy of the product test is lowered. By the aid of the method, a problem that the radio frequency test cables can't be tested during temperature cycling is solved, the real-time characteristic parameters of the radio frequency cables in a high-low temperature chamber can be acquired, the acquired cable parameters are used for correcting a test result, and accurate product test in a temperature cycling test can be achieved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

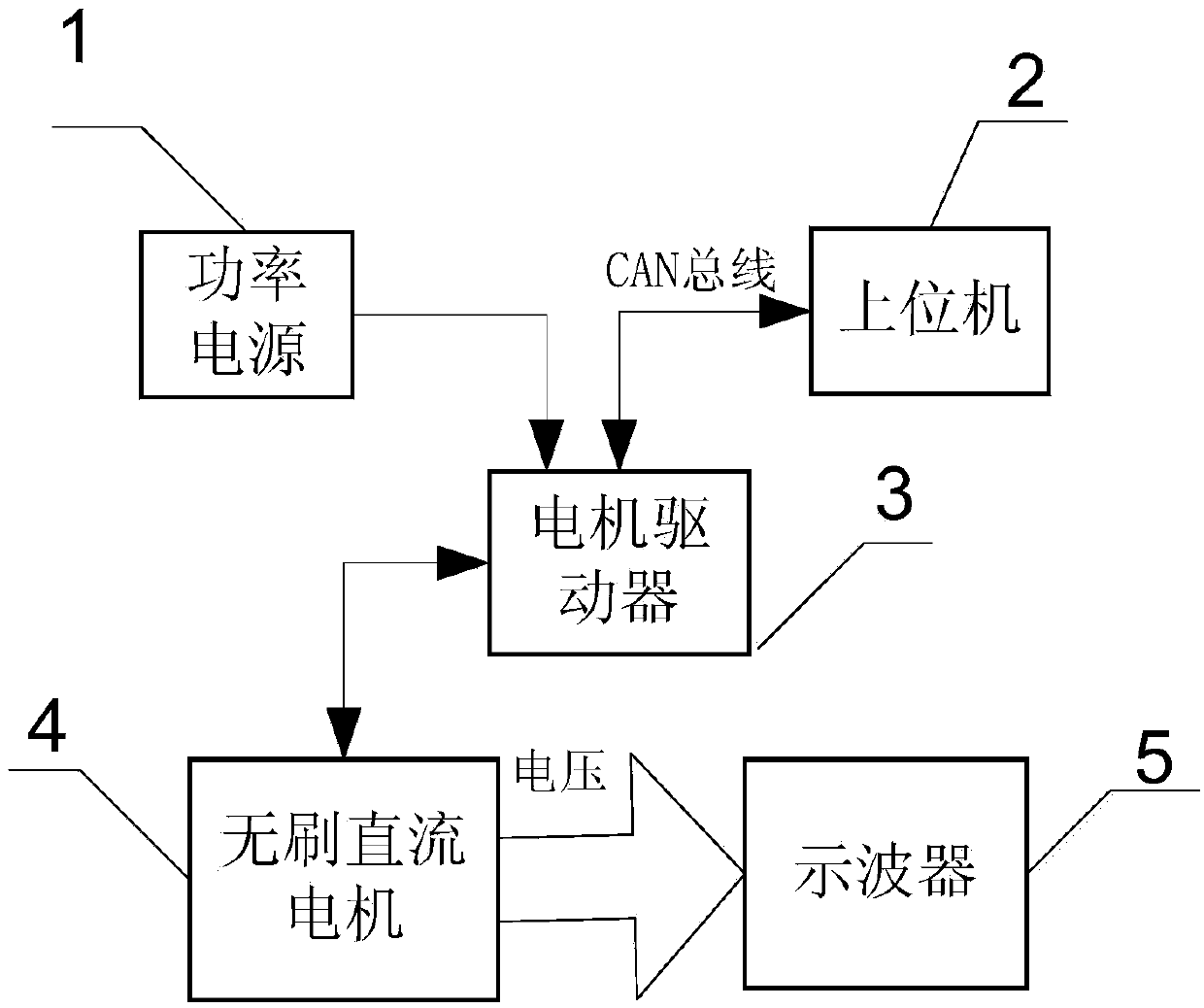

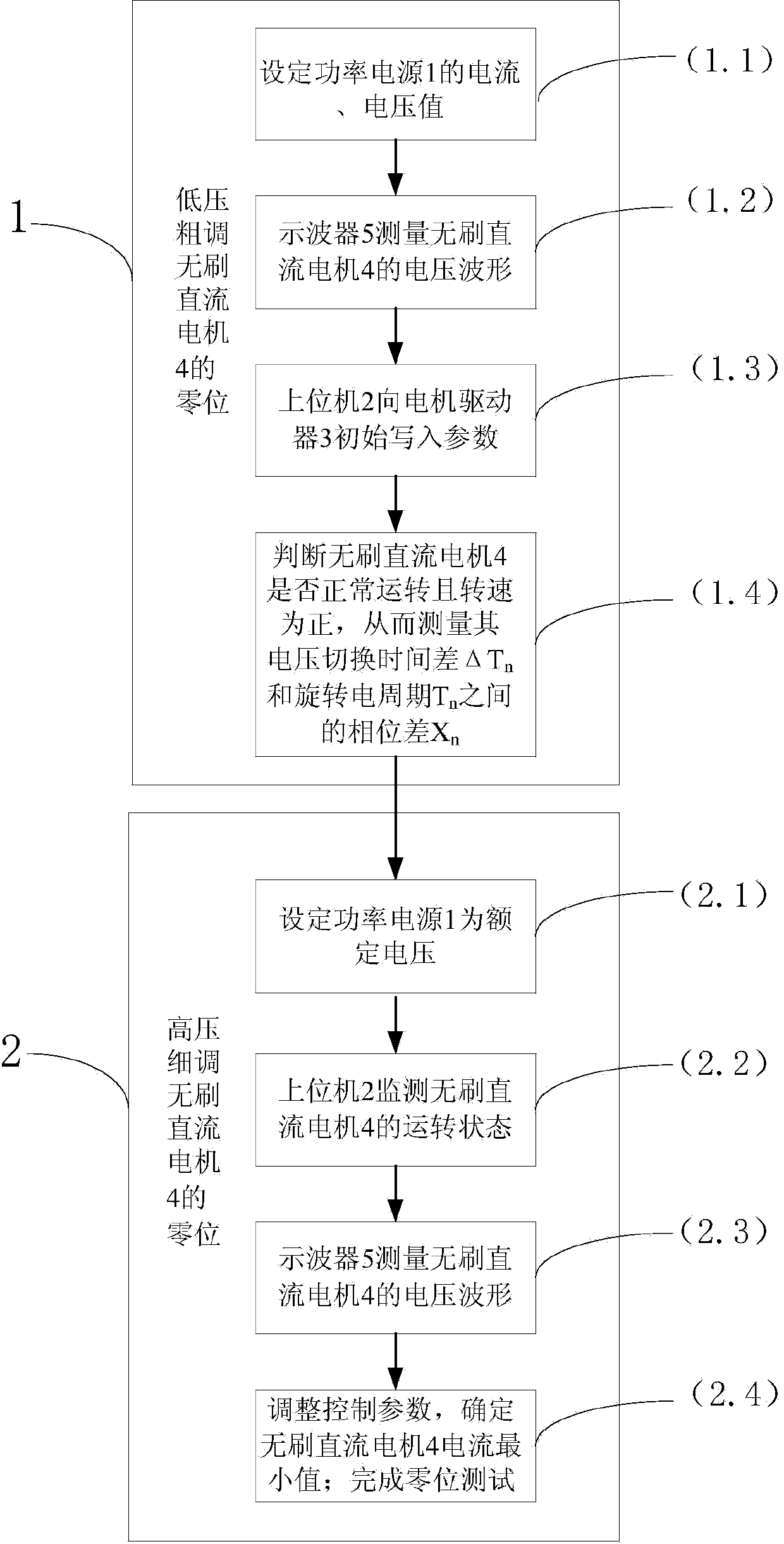

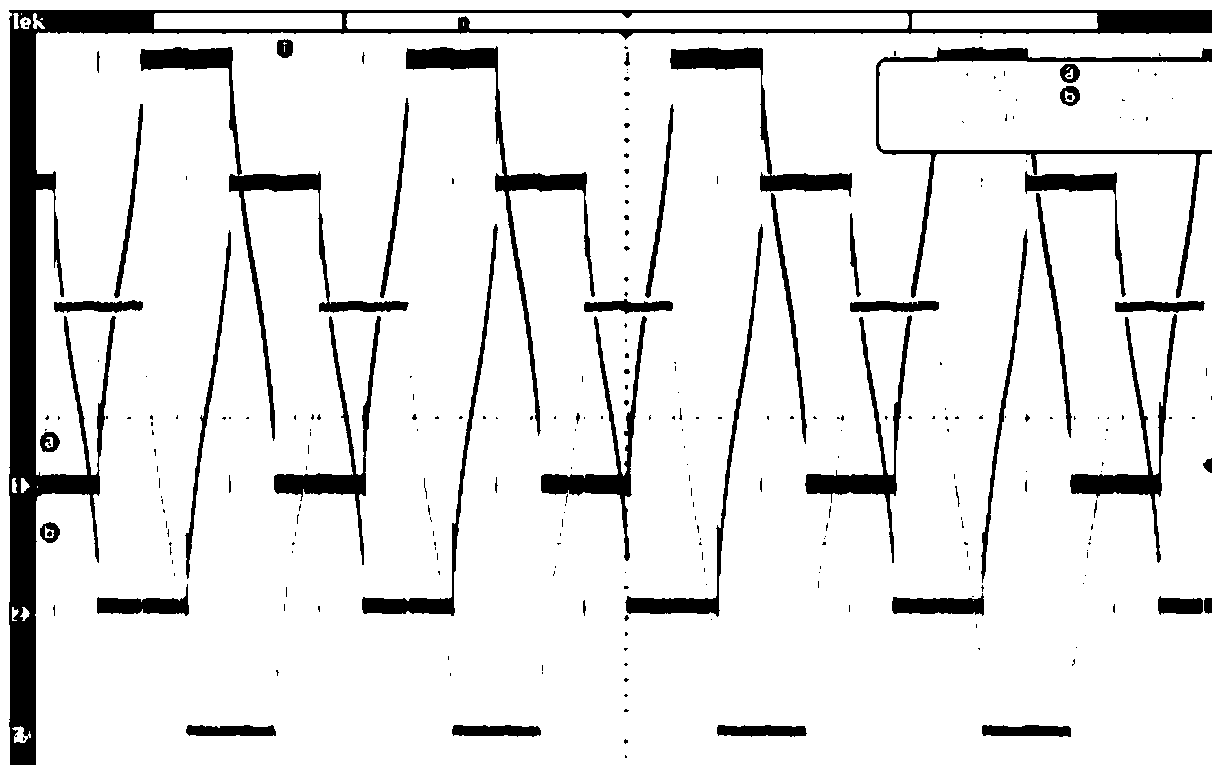

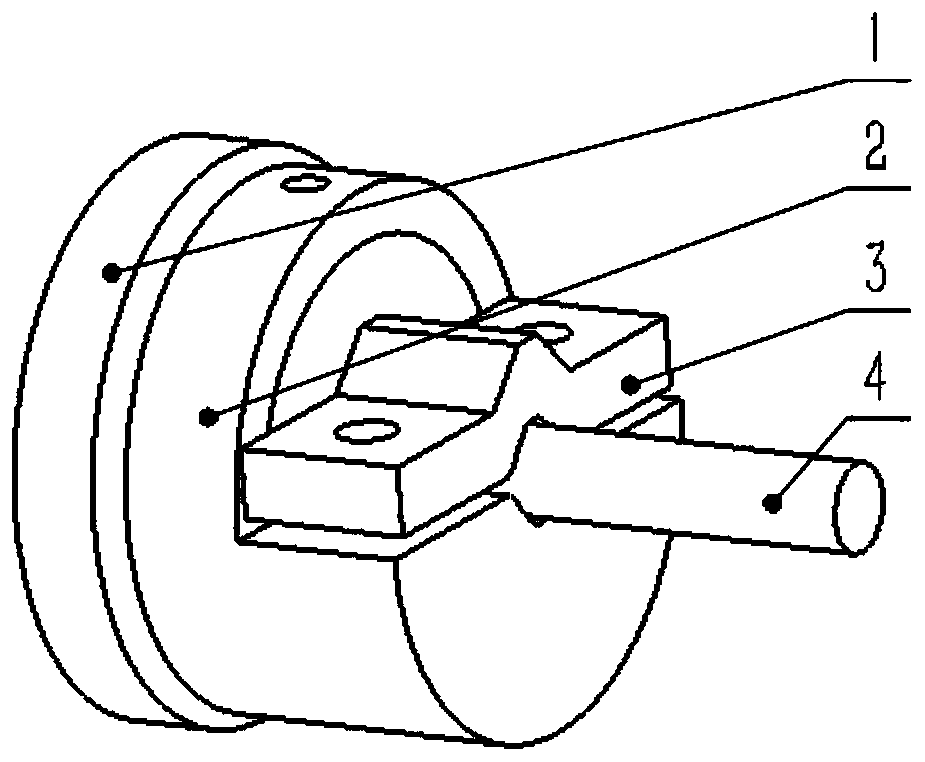

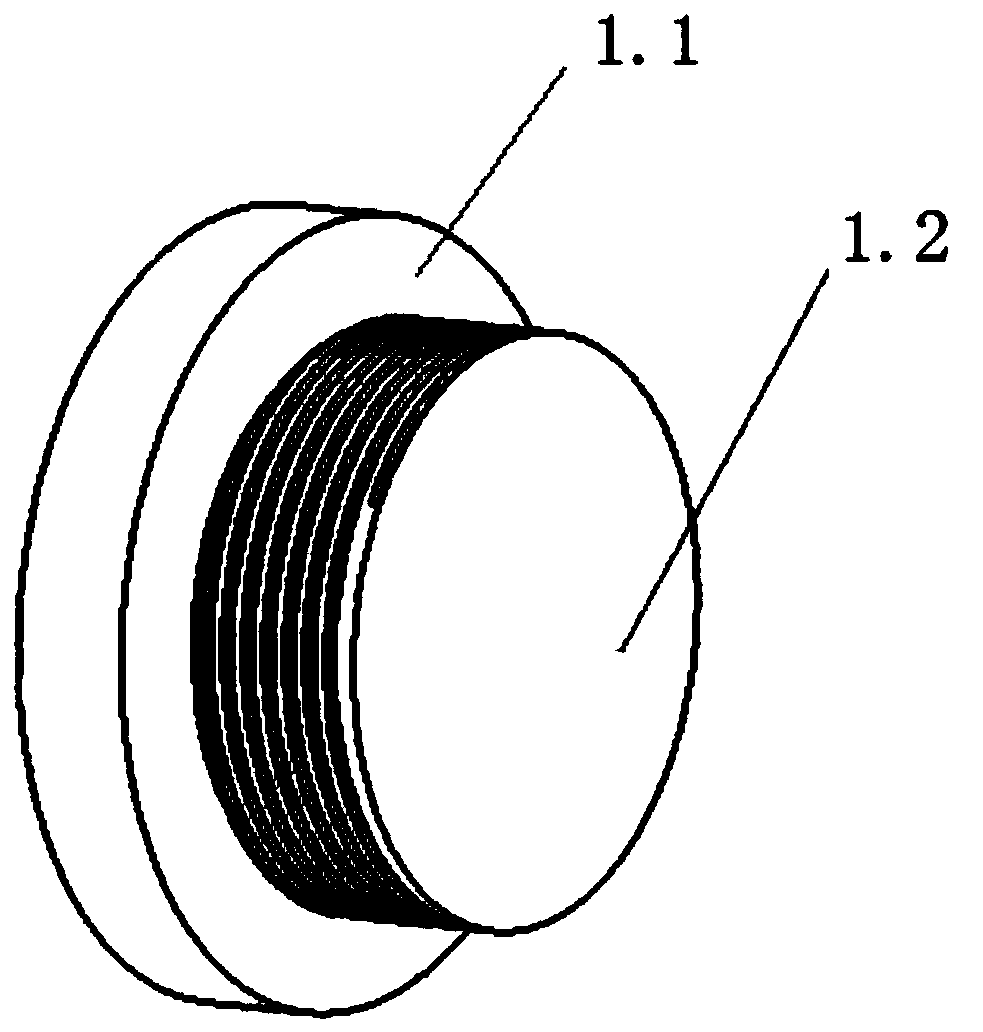

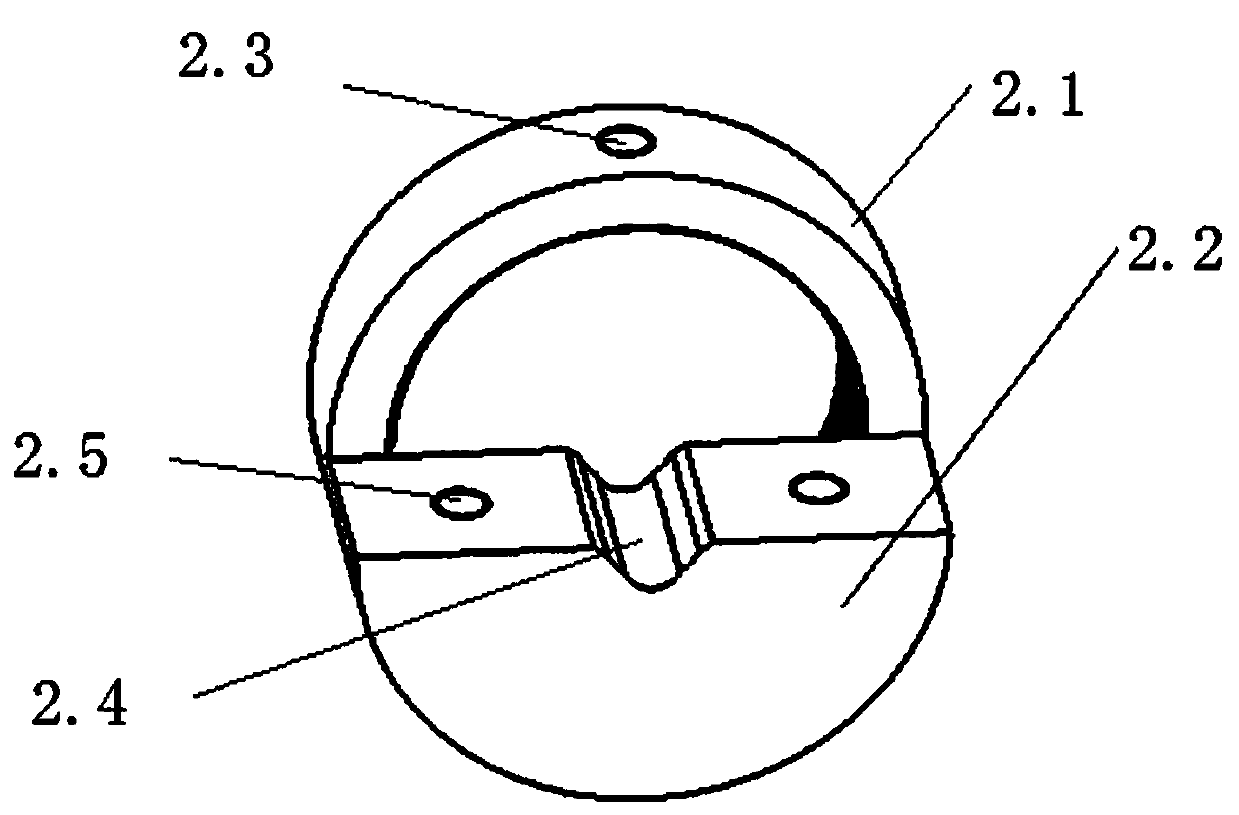

Testing method of electrical zero position of randomly mounted brushless DC (Direct Current) motor of rotary transformer

ActiveCN104198937AImprove efficiencySimple and efficient operationCurrent/voltage measurementDynamo-electric machine testingPower flowRotary transformer

The invention belongs to a testing method of a control zero position of a motor, and particularly discloses a testing method of an electrical zero position of a randomly mounted brushless DC (Direct Current) motor of a rotary transformer. The testing method comprises the steps of: (1) roughly adjusting the zero position of the brushless DC motor at a low voltage, to be specific, setting a current and a voltage value of a power source, measuring a voltage waveform of the motor by an oscilloscope, writing parameters into a motor driver initially by an upper computer, judging whether the motor runs normally and the rotating speed is positive, and accordingly measuring a phase difference Xn between a voltage switching time difference deltaTn and a rotation electric period Tn of the motor; (2) finely adjusting the zero position of the brushless DC motor at a high voltage, to be specific, setting a rated voltage of the power source, monitoring the running state of the motor by the upper computer, (2.3) measuring the voltage waveform of the motor by the oscilloscope, and (2.4) adjusting a control parameter to determine the current minimum value of the motor and finish the zero position testing of the motor. The testing method of the electrical zero position of the randomly mounted brushless DC motor of the rotary transformer can realize precise positioning and control of the motor and realize efficient drive control of the brushless DC motor.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

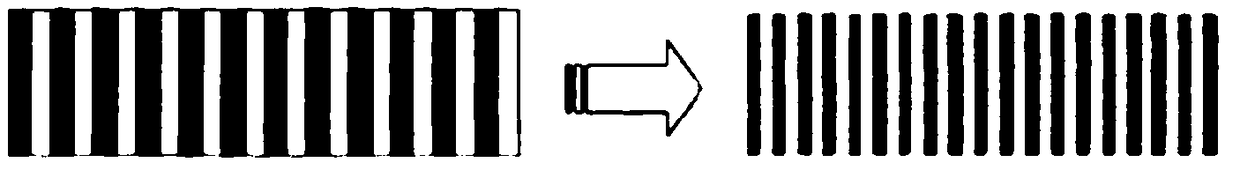

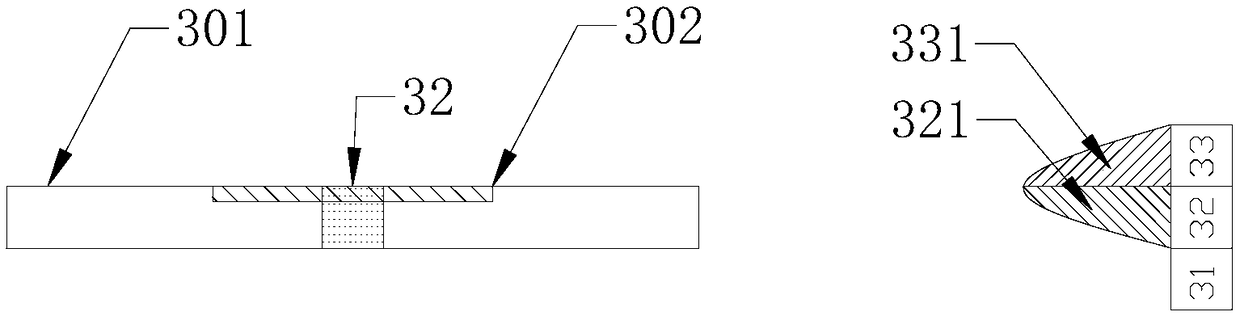

Grating spectrometer image quality measuring method and device

ActiveCN109186759ASolve the untestableEnable accurate testingRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsDiffusion functionImaging quality

The invention discloses a high precision grating spectrometer image quality measuring method and device. The device comprises a monochromatic light source which is homogenized by an integrating sphere, a collimator with a slit target, a tested imaging spectrometer and a data processing system. The slit target is controlled by a micro-displacement table to translate along a direction vertical to aslit of the tested spectrometer. The tested spectrometer can receive a signal of the monochromatic light source, wherein the signal passes the slit target. Through analysis and computing of a relationship between light intensity change of certain group of pixels on the spectrometer and slit movement amount, a line spread function of the spectrometer is obtained; influence of width of the slit target on a test result is removed; and through Fourier transform, an MTF of a system spectrum direction is computed. The object slit is rotated for 90 degrees and scanning is carried out, so the MTF of aspace direction can be tested. According to the method, the problem that a transfer function of the spectrum direction of the imaging spectrometer cannot be tested can be solved, and a precise test for image quality of the imaging spectrometer is realized.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

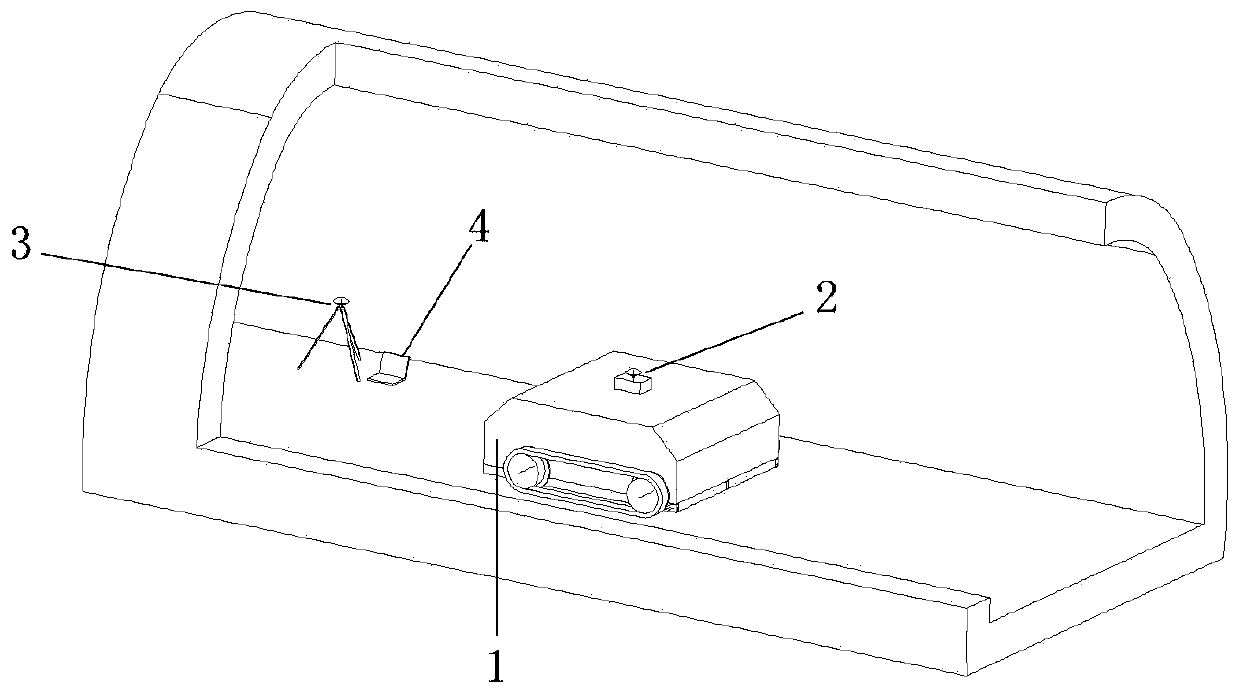

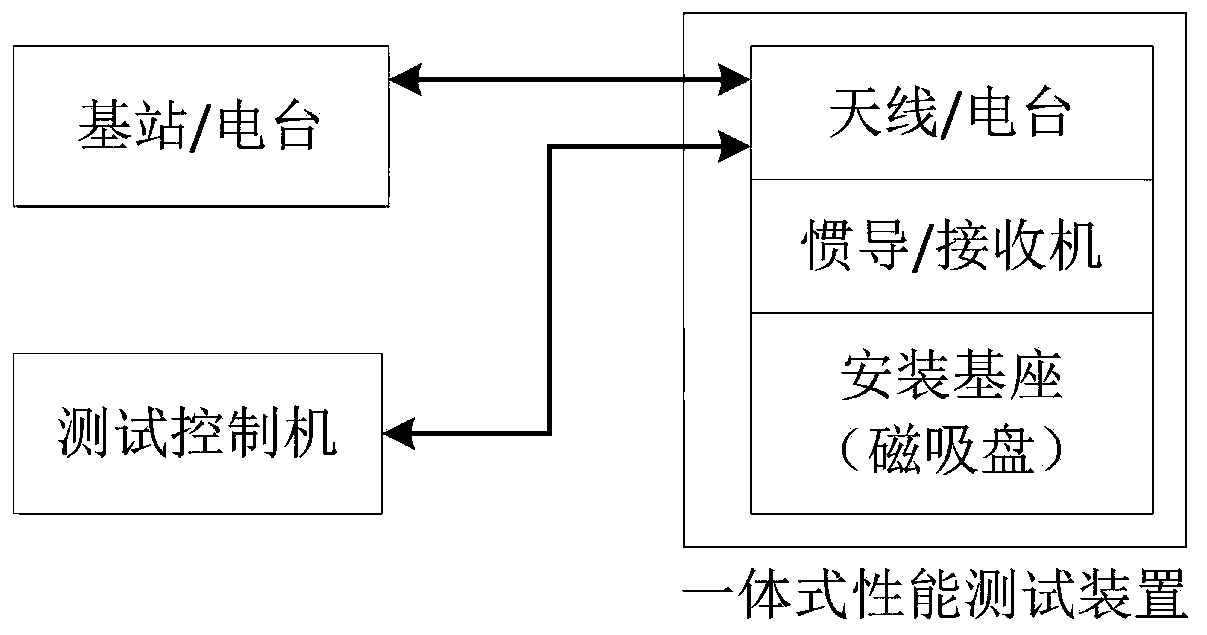

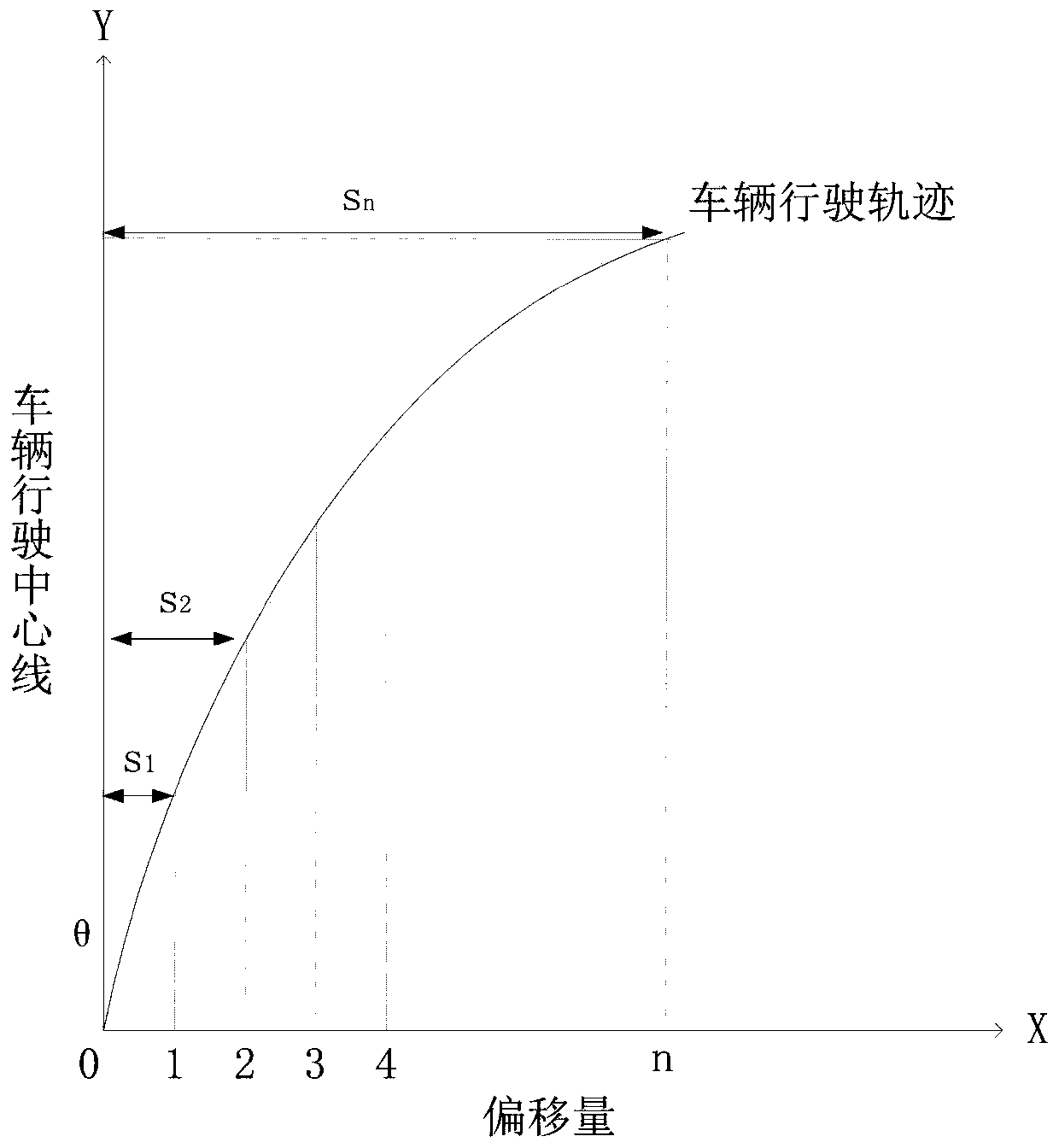

Test system and test method suitable for testing vehicle driving performance

The invention relates to a test system suitable for testing the vehicle driving performance. The system comprises a GNSS base station, a test device and a test control machine. The GNSS base station is erected on a control point with known coordinates; the test device comprises inertial navigation equipment, a mobile terminal receiver and a radio station; the inertial navigation equipment, the mobile terminal receiver and the radio station are fixedly mounted at the top end of the vehicle body; wherein the inertial navigation equipment is fixedly connected with the mobile terminal receiver through a communication cable, the GNSS base station is in communication connection with the mobile terminal receiver through a radio station to obtain high-precision position data in real time, and thetest control machine is connected with the mobile terminal receiver in a wireless communication mode to receive the data. The test system and method suitable for testing the vehicle driving performance can realize accurate test of vehicle offset parameters and drawing of a vehicle driving track, so that the vehicle performance test system can measure vehicle position information simply and quickly.

Owner:TIANJIN NAVIGATION INSTR RES INST

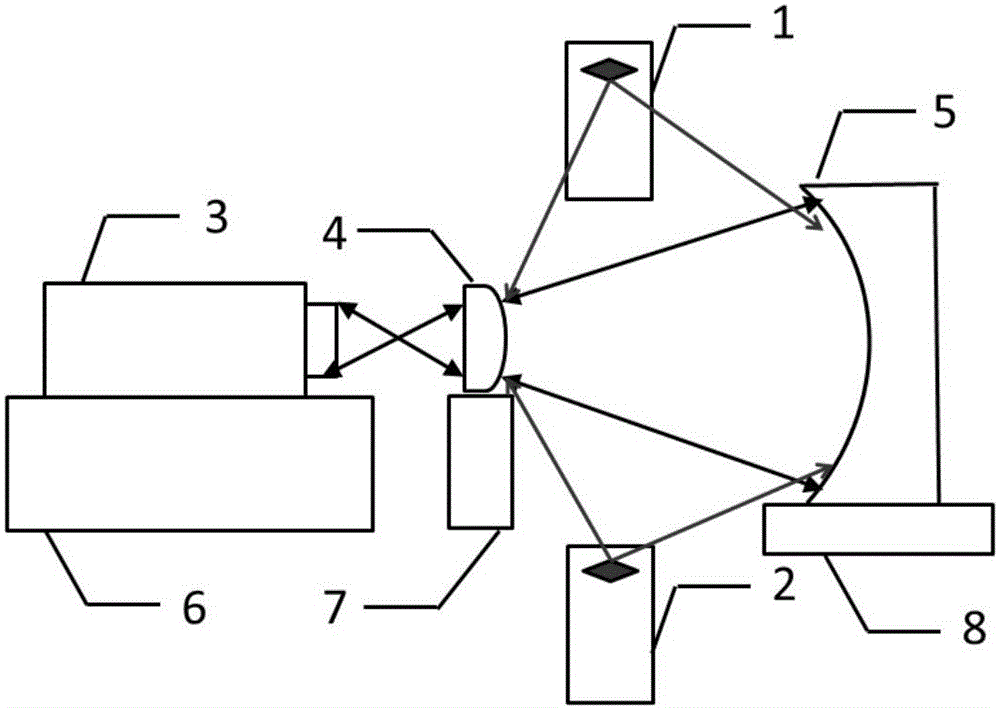

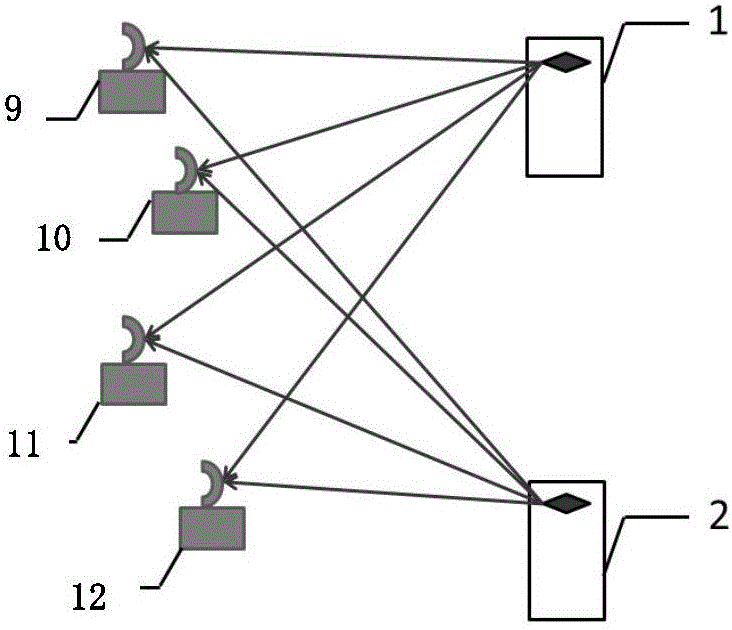

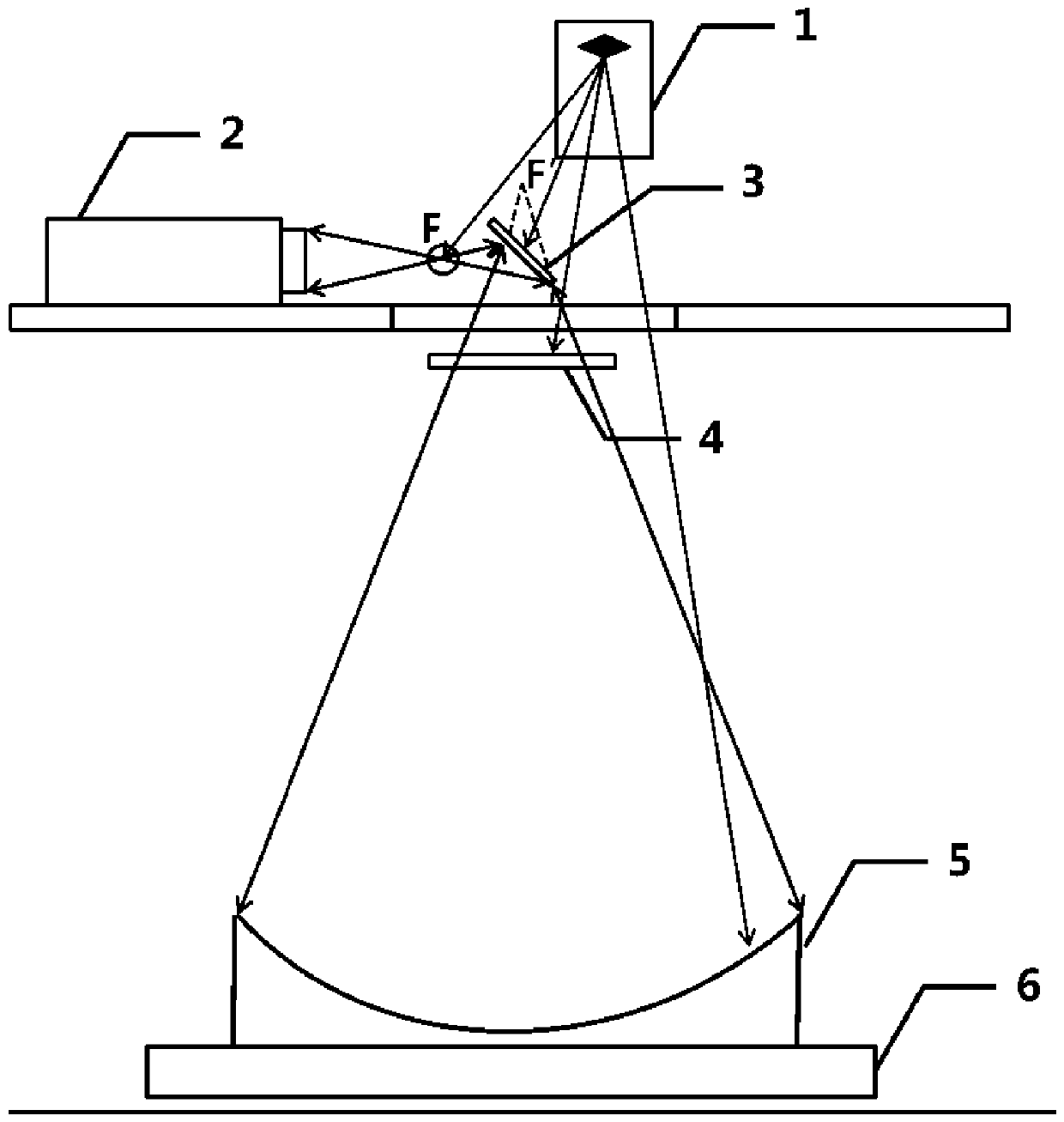

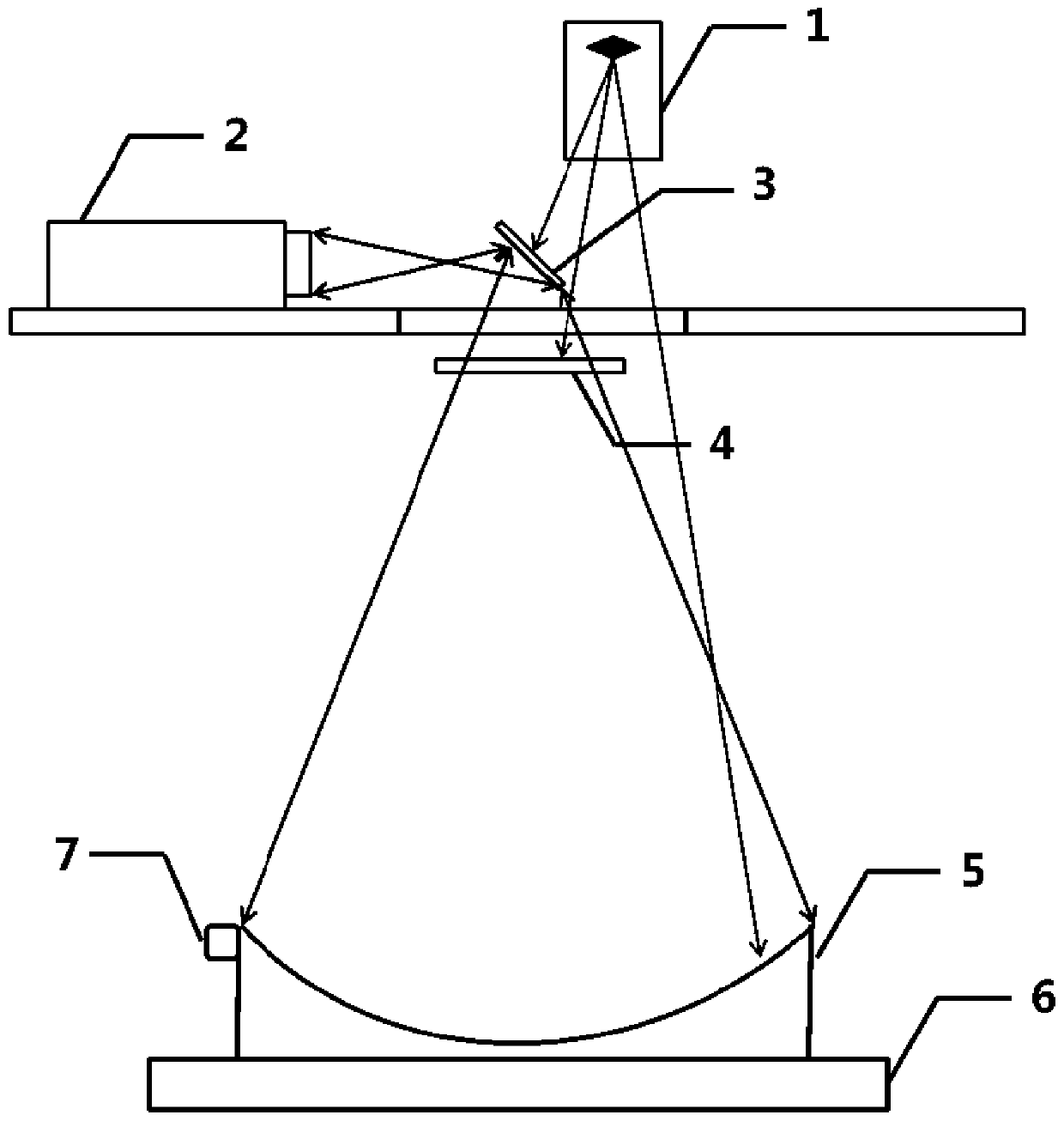

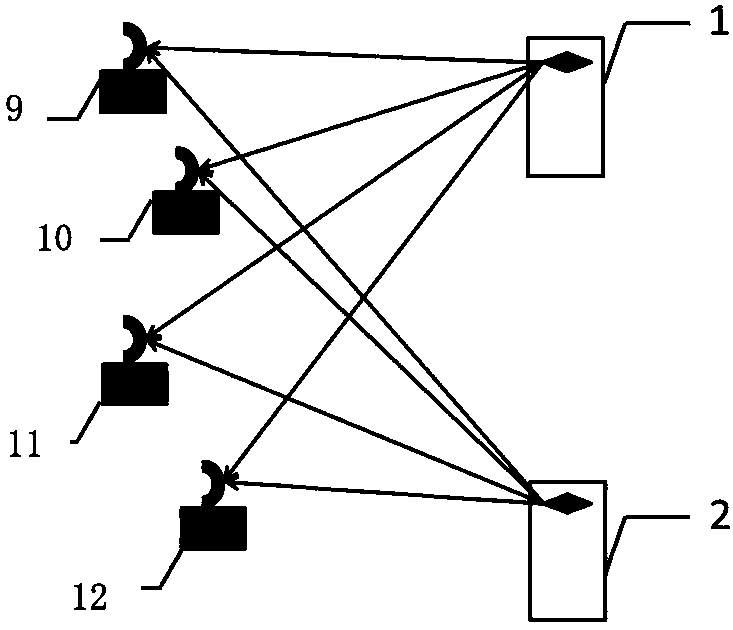

Accurate testing device and method for geometric parameter of complex optical curved surface

ActiveCN109724532AEnable accurate testingPhysical concepts are clearUsing optical meansOptoelectronicsLaser tracker

An accurate testing device and a method for geometric parameters of a complex optical curved surface, suitable for accurate testing of geometric parameters of all vertical test intervention folding optical path with a large-caliber complex optical curved surface. The device comprises a laser tracker (1), a laser interferometer (2), a folding mirror (3), a compensation element (4), and an adjustingmechanism (6). The position and angle between the laser interferometer (2), the folding mirror (3), the compensation element (4), a to-be-tested optical curved surface (5), and the adjusting mechanism (6) are adjustable. The target ball of the laser tracker (1) is placed near an interferometer focus (F). The accurate testing of the geometric parameters such as the vertex curvature radius R, the off-axis quantity d, and the eccentricity Delta of the large-caliber complex optical curved surface is realized mainly by measure of the interferometer focus, all reference surface features of the complex curved surface, and the folding mirror characteristic with geometric operations such as mirroring and projection. The device and the method provided by the invention have simple process of data processing, calculation, and operation, low testing cost, and great versatility.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

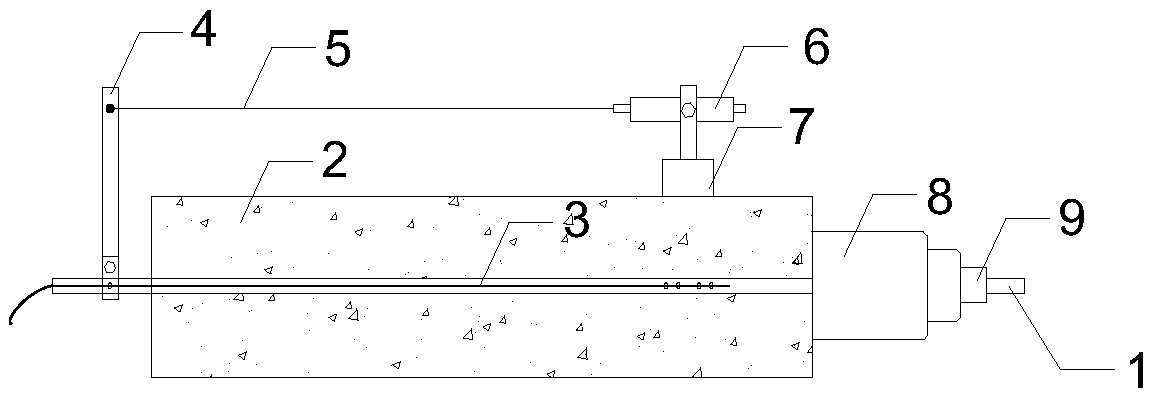

Fiber sensor-based reinforced concrete bonding and slipping constitutive test method and device

InactiveCN109060538AEasy to testAccurate measurementMaterial strength using tensile/compressive forcesFiberEngineering

The invention discloses a fiber sensor-based reinforced concrete bonding and slipping constitutive test method and device. The device comprises a reinforcement steel bar, concrete, a fiber grating, adisplacement transferring device, a thin wire, a displacement meter, a displacement meter support, a drawing device and an anchoring tool, wherein a stress monitoring grating, a slipping monitoring grating and a temperature compensation grating are arranged on a fiber and are fixed in reinforcement steel bar groove holes by welding glass, two ends of the reinforcement steel bar extend out of the concrete, the displacement transferring device and the drawing device are respectively arranged at the two ends of the reinforcement steel bar, the displacement transferring device is connected with the displacement meter by the thin wire, local slipping quantity is measured by combining the slipping monitoring grating, the stress monitoring grating is used for measuring local bonding stress of thereinforcement steel bar, and the drawing device is used for drawing and loading. With the monitoring device and method provided by the invention, accurate test on a local bonding and slipping constitutive model between a long drawing test piece reinforcement steel bar and the concrete can be achieved, an error of a short drawing test piece caused by average stress and a slipping value is reduced,and particularly, accurate measurement of a curve a bonding and slipping reduction segment under large slipping can be achieved.

Owner:XIANGTAN UNIV

RCS detection system based on binocular vision, and detection method thereof

PendingCN112781530AImplementation locationAccurate testing for performanceUsing optical meansEngineeringVisual perception

The invention discloses an RCS detection system based on binocular vision, and a detection method thereof. The system and the method can realize that during RCS detection, a detected object and a detection scene are subjected to three-dimensional reconstruction, a three-dimensional scene coordinate system is converted to be consistent with a world coordinate system, namely an RCS detection coordinate system, and an RCS detection numerical value is superposed with a reconstructed three-dimensional model, so the RCS characteristic value of the position of the measured object can be accurately checked. For example, a stealth aircraft is parked on a parking apron or a hangar, 360 DEG shooting is carried out around A stealth aircraft through a binocular vision camera, three-dimensional reconstruction of the stealth aircraft and the parking apron or the hangar is achieved, a three-dimensional model of a measured object is generated, meanwhile relevant coordinates of the stealth aircraft and the position of the stealth aircraft are generated, then the RCS detection value of the stealth aircraft in a world coordinate system is acquired, the RCS detection value and the three-dimensional model of the stealth aircraft are superposed through a computer, the condition of the stealth aircraft is analyzed, and related information is fed back.

Owner:陕西昱琛航空设备股份有限公司

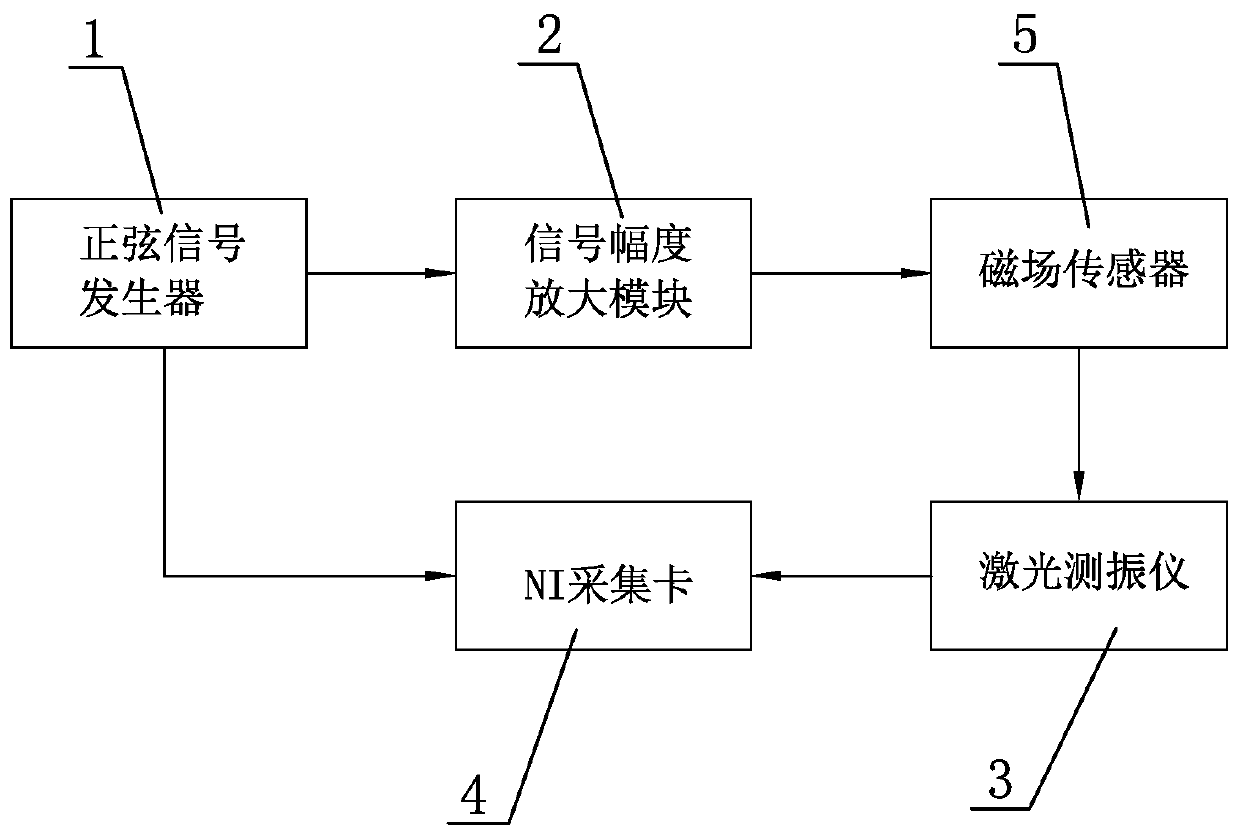

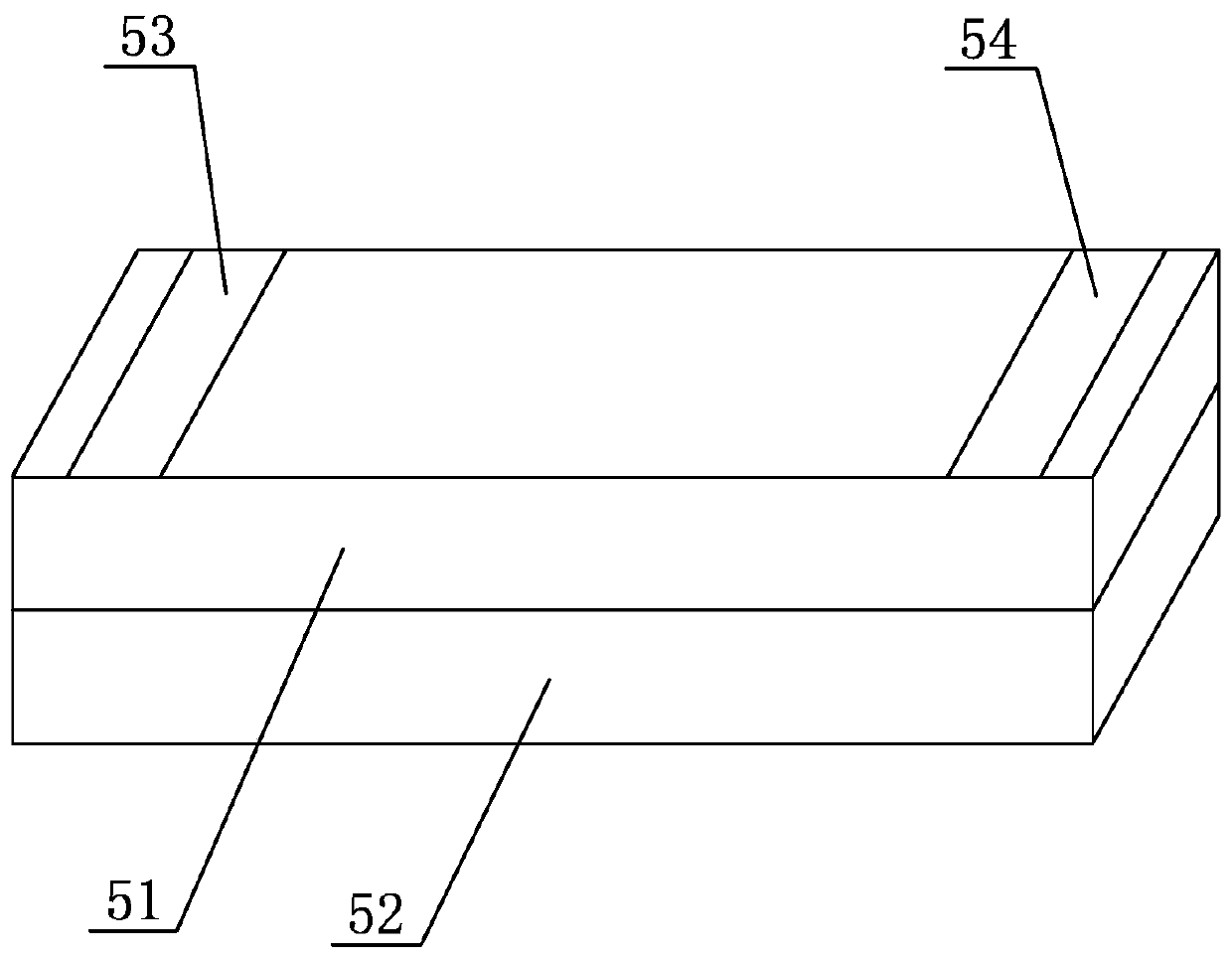

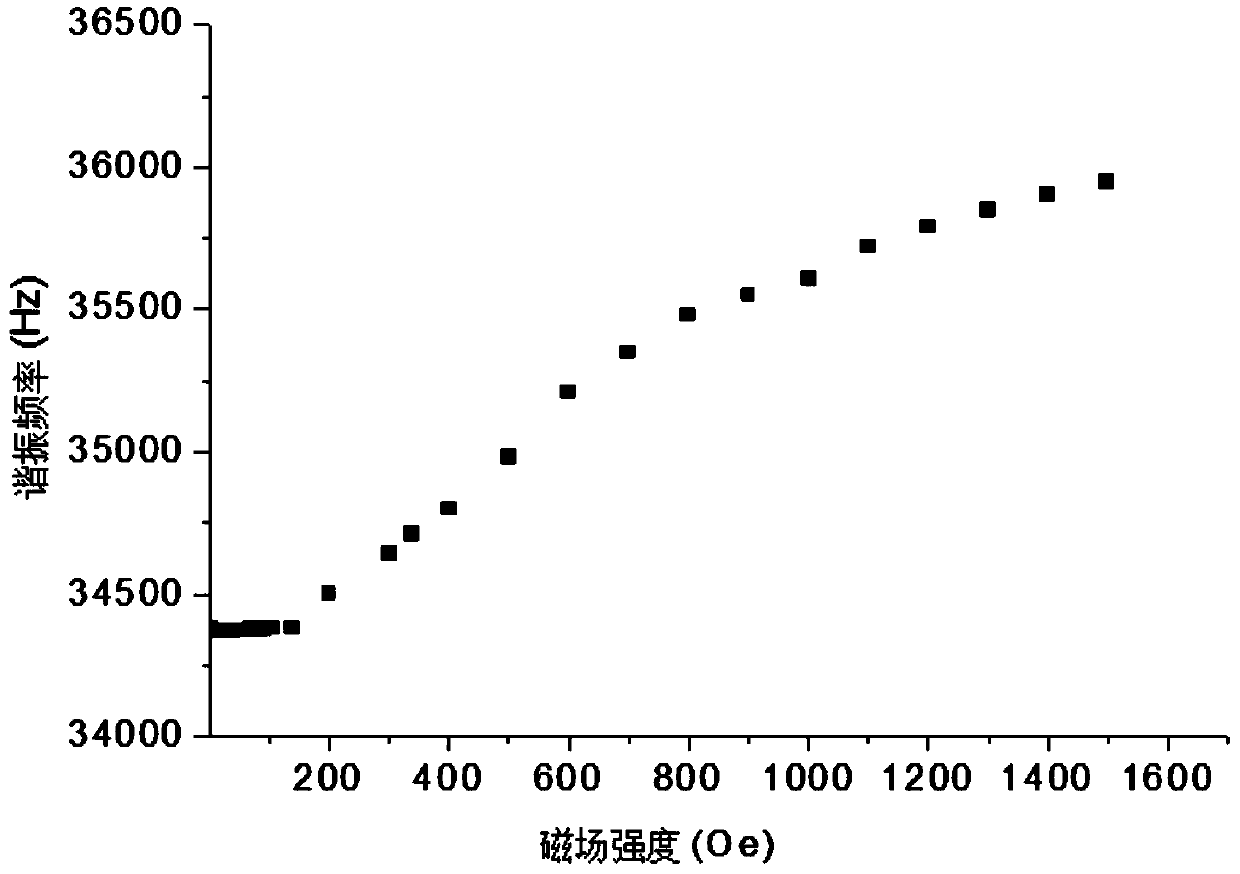

Method for testing direct-current magnetic field intensity

ActiveCN110632537AEnable accurate testingEliminate Interference and AttenuationResonant frequencyUsing wave/particle radiation meansMagnetic field magnitudeNuclear magnetic resonance

The invention discloses a method for testing the direct-current magnetic field intensity. A sinusoidal signal generator, a signal amplitude amplification module, a laser vibration meter, an NI acquisition card and a transverse-field-excited magnetic field sensor are arranged. The method has the following advantages: the direct-current magnetic field intensity is determined based on the resonant frequency of the magnetic field sensor under the transverse field excitation, so that the influence of the temperature on the magnetic field sensor is eliminated; the direct-current magnetic field in different intensity ranges is determined based on resonant frequencies of the magnetic field sensor in three different vibration modes, so that the direct-current magnetic field intensity is accuratelytested; and since the positive electrode and the negative electrode on the magnetic field sensor are arranged at the same side of the piezoelectric material layer, all electrodes and leads are arranged at the rear end of the magnetic field sensor, so that the interference and attenuation of the electrode to magnetic field detection signal are eliminated and the accuracy of magnetic field intensitytesting is further ensured.

Owner:NINGBO UNIV

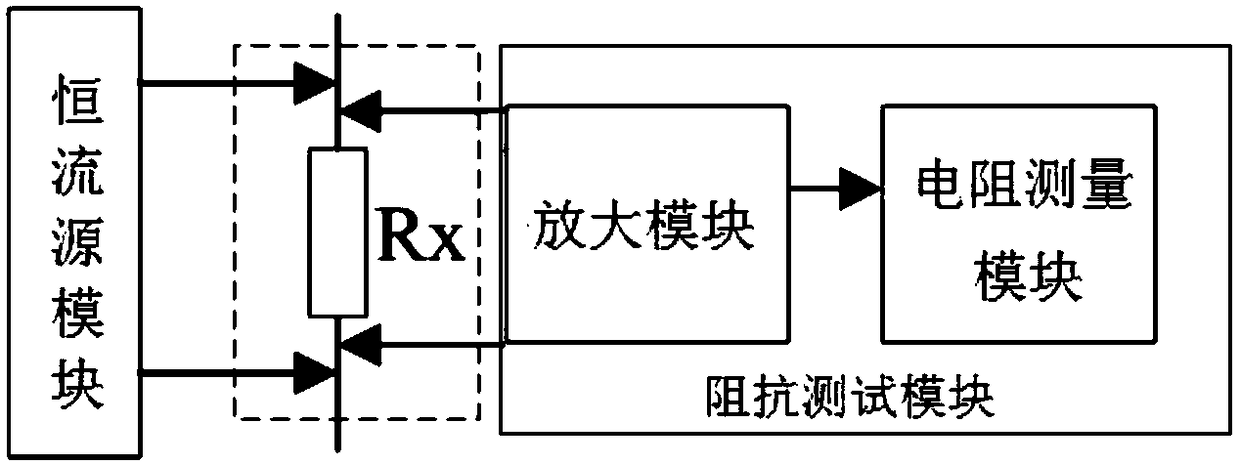

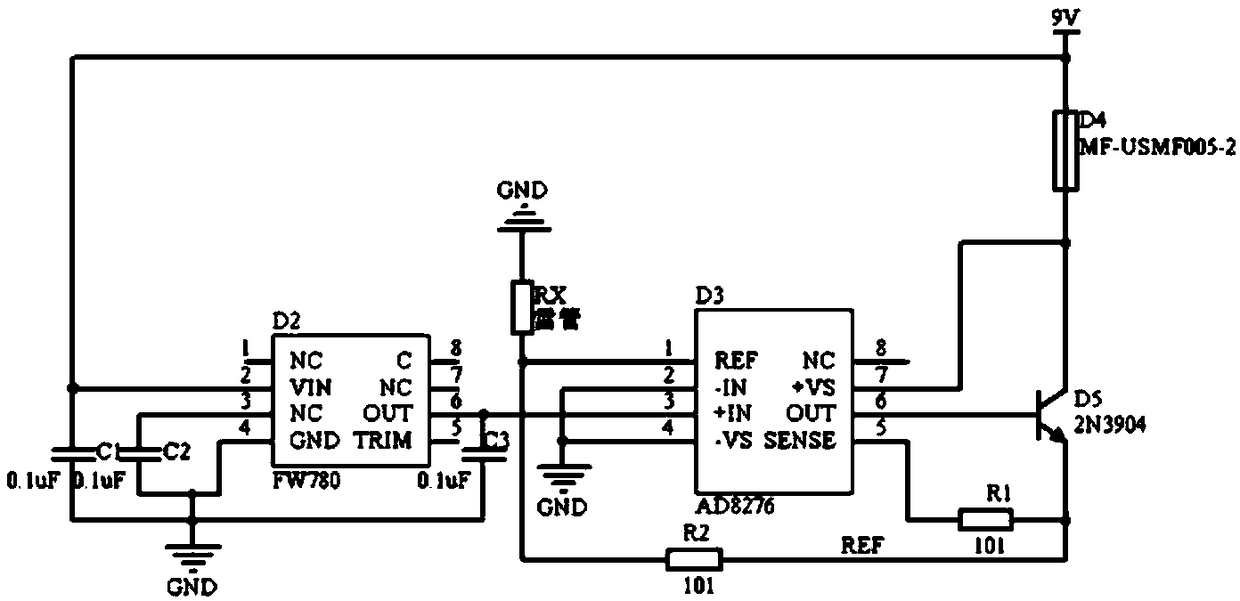

Detonator resistor testing device with overcurrent protection

PendingCN108872652AEnable accurate testingPrevent detonationOverload protection arrangementsDetonatorElectrical resistance and conductance

The invention discloses a detonator resistor testing device with overcurrent protection; the testing device comprises a constant flow source module and an impedance testing module; a loop formed by ato-be-tested detonator resistor and the constant flow source module and a loop formed by the to-be-tested detonator resistor and the impedance testing module are mutually isolated; the impedance testing module comprises an amplification module and a resistor measuring module. A milliampere level precision constant flow source is selected to power up the to-be-tested detonator resistor; the constant flow source module has an overload protector so as to effectively prevent detonator blast problems caused by overlarge current flow when short circuit happens, and thus ensuring the detonator live-line testing safety; the amplification module is designed so as to precisely test the detonator miniature resistors, thus ensuring the detonator resistor testing reliability.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

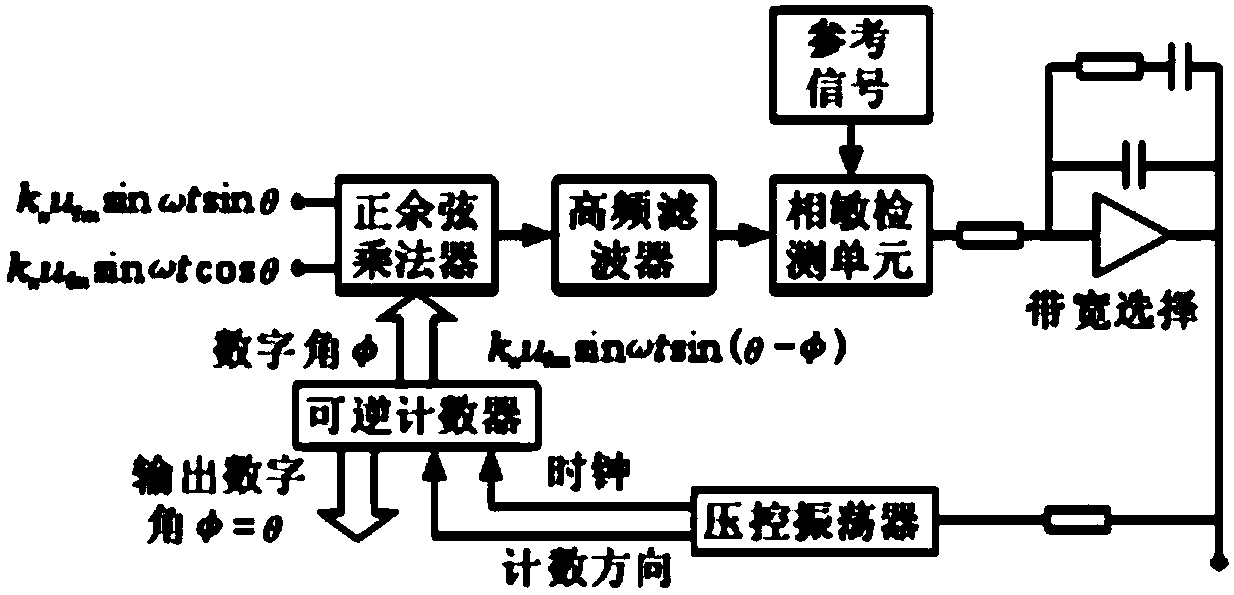

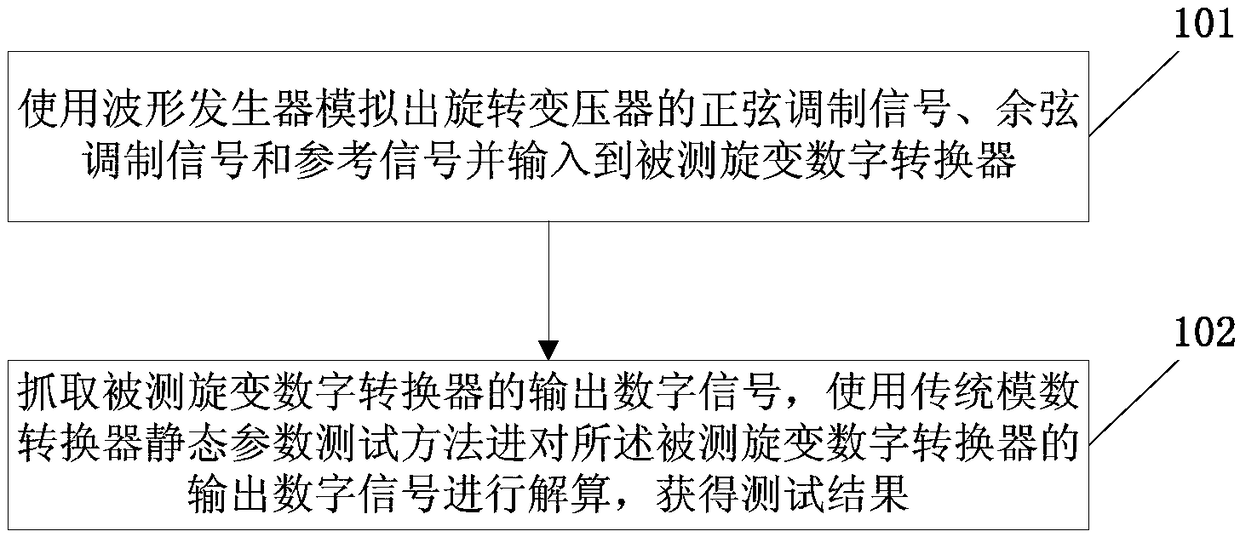

Method for testing conversion precision of resolver-to-digital converter

InactiveCN108667460AConversion Accuracy Test AccurateEnable accurate testingAnalogue/digital conversion calibration/testingDigital down converterAngle modulation

The invention discloses a method for testing conversion precision of a resolver-to-digital converter. The method comprises the following steps of simulating a sinusoidal modulation signal, a cosine modulation signal and a reference signal of a resolver by using a waveform generator, and inputting the signals to a tested resolver-to-digital converter; and capturing an output digital signal of the tested resolver-to-digital converter, and utilizing a traditional ADC static parameter testing method to solve the output digital signal of the tested resolver-to-digital converter in order to obtain atest result. According to the method, sine and cosine angle modulation output signals and the reference signal of the resolver are simulated through any waveform generator and are input to the testedresolver-to-digital converter, and a set of corresponding solving methods for the precision of an output conversion angle of the resolver-to-digital converter are used, the accurate testing of the conversion precision of the resolver-to-digital converter is achieved, and a testing process is efficient and reliable.

Owner:CASIC DEFENSE TECH RES & TEST CENT

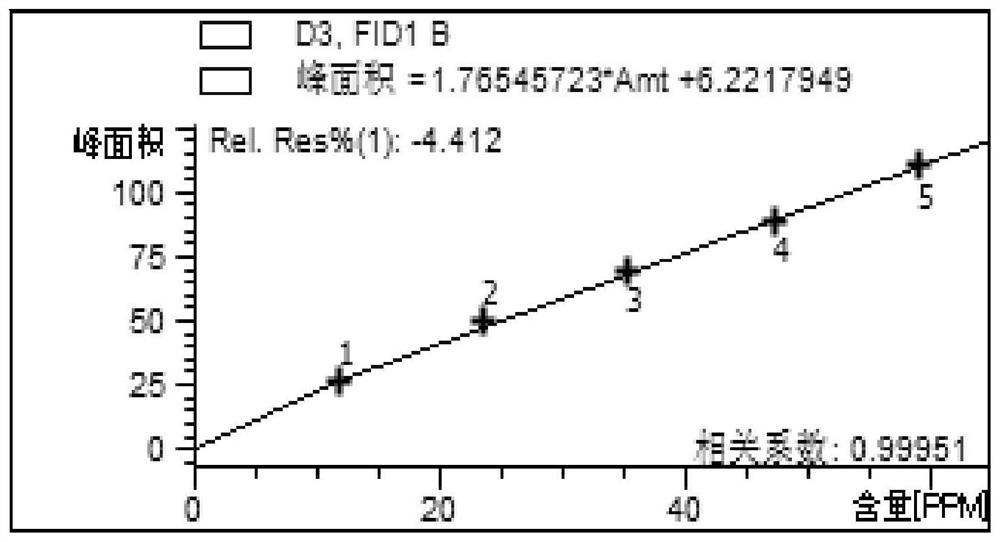

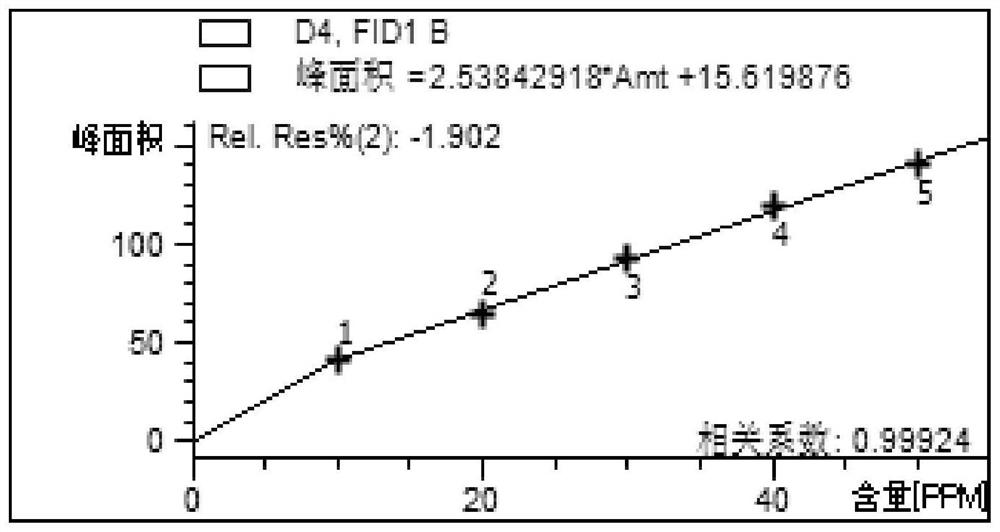

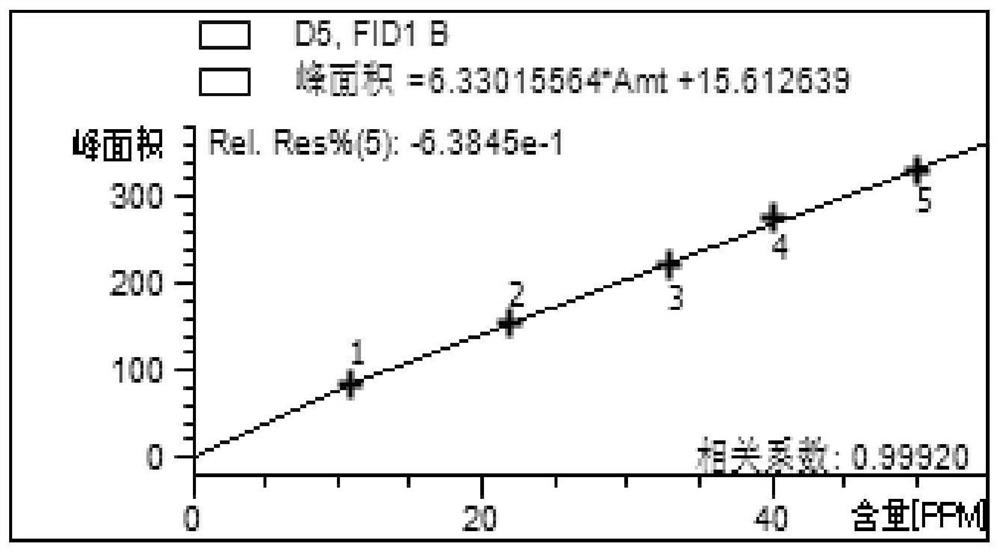

Method for determining content of residual methylsiloxane in organosilicon softener by using HS-GC external standard method

PendingCN111929384AEnable accurate testingHigh precisionComponent separationGas liquid chromatographicOrganosolv

The invention belongs to the technical field of analytical chemistry, and particularly relates to a method for determining the content of residual methylsiloxane in an organosilicon softener by usingan HS-GC external standard method. A headspace gas chromatograph is used for detection, and an external standard method is used for quantitative analysis. The gas chromatograph is an Agilent gas chromatograph 7890B, the gas chromatographic analysis conditions are as follows: a chromatographic column is DB-1701 or a chromatographic column with equivalent polarity, the column length is 30m, the column inner diameter is 320 microns, the initial column temperature is 100 DEG C, the temperature is kept for 2 minutes, then the temperature is increased to 260 DEG C at the rate of 10 DEG C / min, the temperature is kept for 10 minutes, and the carrier gas flow rate is 3mL / min. The method has the advantages of high precision, good reproducibility, no need of any solvent extraction pretreatment operation on the sample, reduction of the use amount of the organic solvent, shortening of the analysis time, and simplicity and safety.

Owner:ZIBO LURUI FINE CHEM CO LTD

Accurate test method for short suspender cable force of suspender arch bridge

ActiveCN103557978BEnable accurate testingEasy to operateApparatus for force/torque/work measurementFrequency measurementsEngineering

The invention discloses a method for accurately measuring the cable force of a short boom of a boom arch bridge. A relevant measuring model is designed, boundary conditions of the boom are simplified into damping and spring supporting of a simple support boom in a corresponding transverse position, the boom is further equivalent into a simple support stretching rope with the equivalent calculation length, a mass block is additionally arranged in the middle of the boom, a vibration balance equation of ropes is set up before and after the mass block is additionally arranged in the middle of the boom, an algorithm of recognizing the equivalent calculation length L0 of the boom by using measured frequencies of the boom before and after the additional mass block is arranged is finally and optimally formed, and therefore the method for accurately measuring the cable force is set up. According to the method for accurately measuring the cable force, measurement is convenient to conduct, and a user only needs to conduct vibration frequency measurement twice on the boom before and after the additional mass block is arranged. The measuring accuracy is high, and the difficult problem of accurately measuring the cable force of the short boom can be well solved. When the method is applied to the field of detection or construction monitoring of boom arch bridges, the cable force of the short boom can be rapidly and conveniently measured at high accuracy, and therefore reliable essential data are provided for detection and monitoring of the boom arch bridges.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

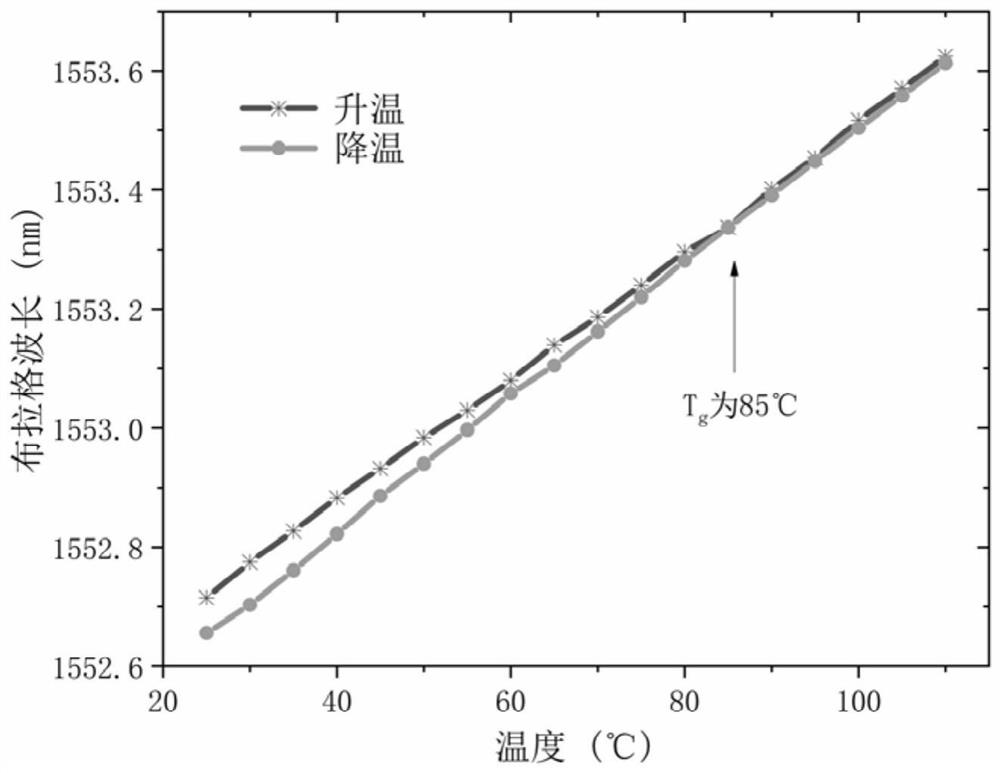

Extreme environment resistant sapphire fiber bragg grating sensor and temperature detection method thereof

ActiveCN110118614AEnable accurate testingEffective temperature detectionThermometers using physical/chemical changesGratingFiber Bragg grating

The invention discloses an extreme environment resistant sapphire fiber bragg grating sensor and a temperature detection method thereof. In view of the problem of application of a temperature sensor under extreme conditions, the extreme environment resistant sapphire fiber bragg grating sensor comprises: performing fusion splicing on a sapphire crystal fiber with a flat section and a flatly cut single mode fiber, as well as engraving a grating at a single mode near field position on the sapphire crystal fiber close to a fusion splicing point, and coating a protective material at the outside ofthe grated sapphire crystal fiber and the single mode fiber to obtain a sapphire crystal fiber bragg grating temperature sensor; performing mode selection on the light transmitted to a sapphire crystal fiber bragg grating area through the single mode fiber, so that the light of only a few modes or a single mode is transmitted into the sapphire crystal fiber bragg grating area; and when the external temperature changes, the effective refractive index and the grating period of the sapphire crystal fiber bragg grating change, so that the center wavelength changes, and the external temperature change is obtained by demodulation by recording the center wavelength of the sapphire crystal fiber bragg grating.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

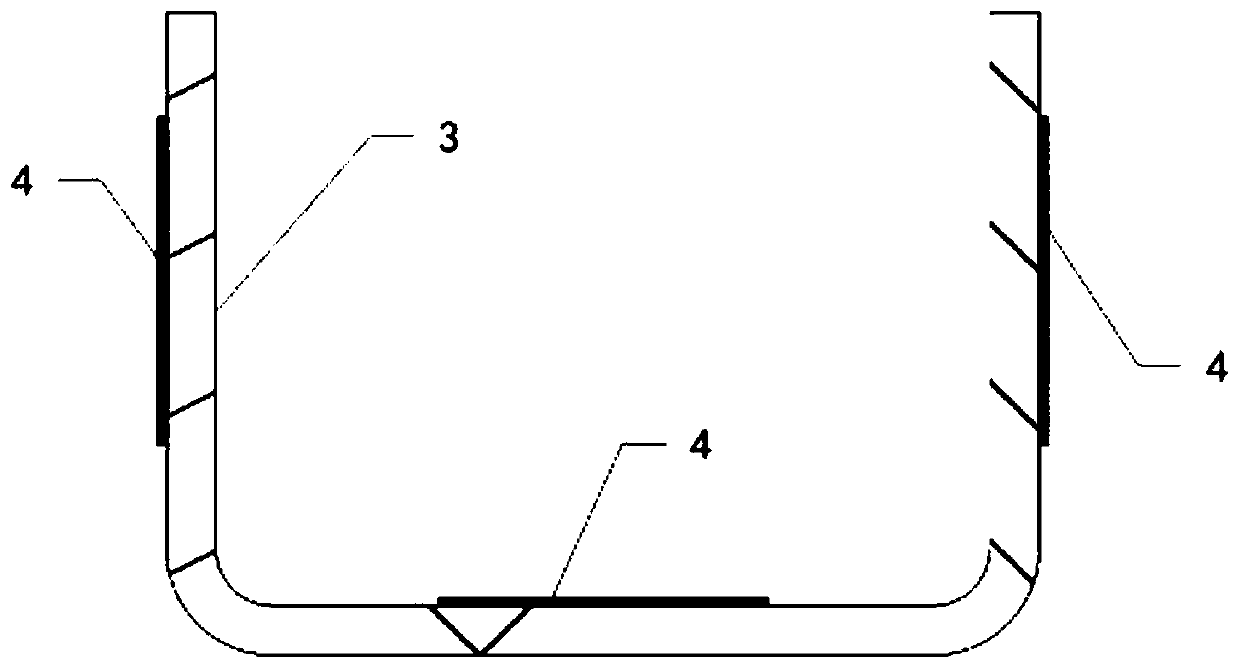

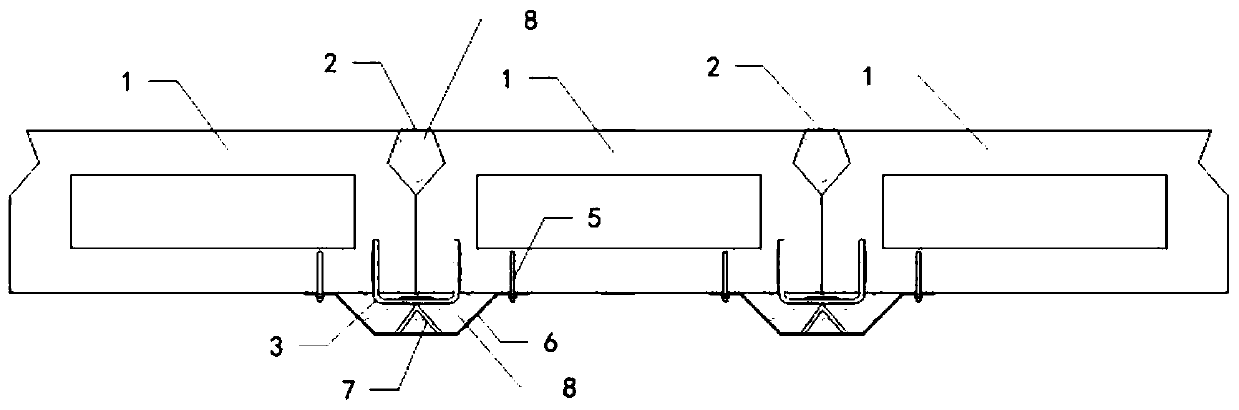

Method for testing transverse bending resistance of small hinge joint hollow slab bridge combined reinforcing member

ActiveCN111458220AEnable accurate testingThe test method is simple and fastMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesEngineeringRebar

The invention discloses a method for testing the transverse bending resistance of a small hinge joint hollow slab bridge combined reinforcing member and relates to the technical field of bridge reinforcement. The method comprises sample piece manufacturing and testing. According to the method of the invention, the small hinge joint hollow slab bridge combined reinforcing member is subjected to miniaturization processing, so that the goal of accurately testing the member in a laboratory is achieved; in a testing process, a static strain acquisition system is adopted to record the strain conditions of U-shaped shear reinforcements, flanged trapezoidal steel plates and concrete, meanwhile, record the displacement of the midspan and fulcrum of a test member, so that the various transverse bending resistance performance parameters of the small hinge joint hollow slab bridge combined reinforcing member are obtained. The test method is simple, convenient, rapid and high in operability.

Owner:TAIZHOU UNIV +1

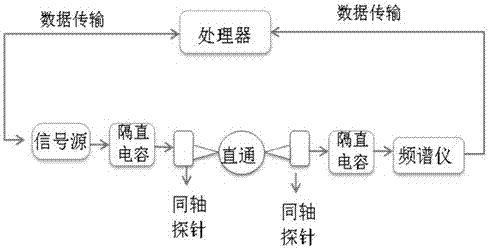

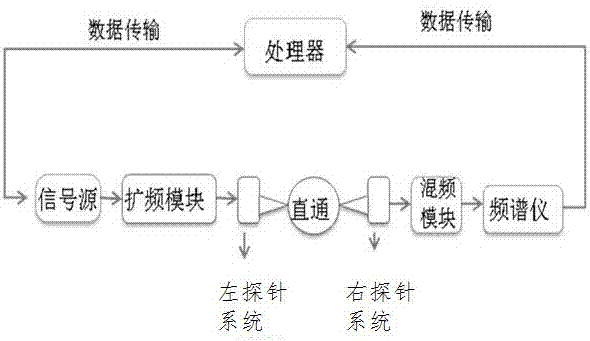

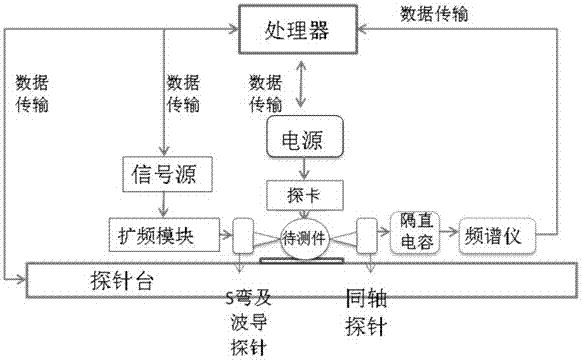

On-chip test system and test method for millimeter wave frequency divider

InactiveCN106990347AEnable accurate testingImprove test efficiencyRadiofrequency circuit testingTest efficiencyProbe card

The invention provides an on-chip test system for a millimeter wave frequency divider. The structure of the on-chip test system for a millimeter wave frequency divider includes a processor, a probe bench, a signal source, a spread spectrum module, a frequency spectrograph, a power supply, a direct current probe card, a left probe system and a right probe system. The on-chip test method for a millimeter wave frequency divider includes the steps: 1) testing the link loss during the process of connecting an output end of a frequency divider chip to the frequency spectrograph; 2) determining whether the test link is connected normally; 3) connecting a frequency divider chip to be tested, and controlling the power supply to supply power to enable the frequency divider to work normally; 4) acquiring data; 5) calculating the work frequency range and the output power of the frequency divider chip to be tested by means of the processor; and 6) determining whether or not to perform tests of other frequency divider chips. The on-chip test system for a millimeter wave frequency divider has the advantages of 1) realizing accurate testing of the work frequency range and the output power of the millimeter wave frequency division circuit; and 2) realizing the on-chip automatic test of the millimeter wave frequency divider, and improving the testing efficiency.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

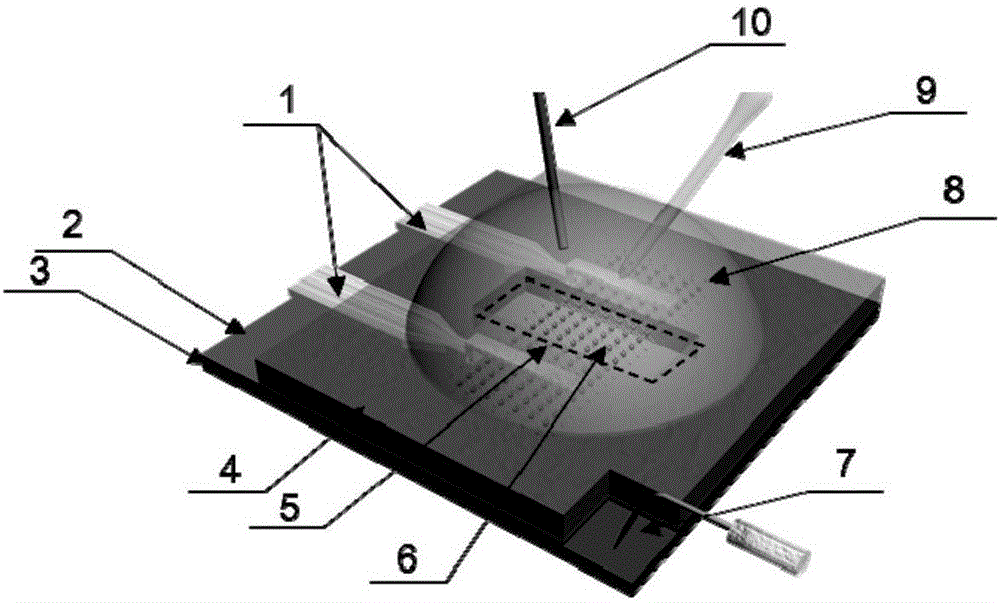

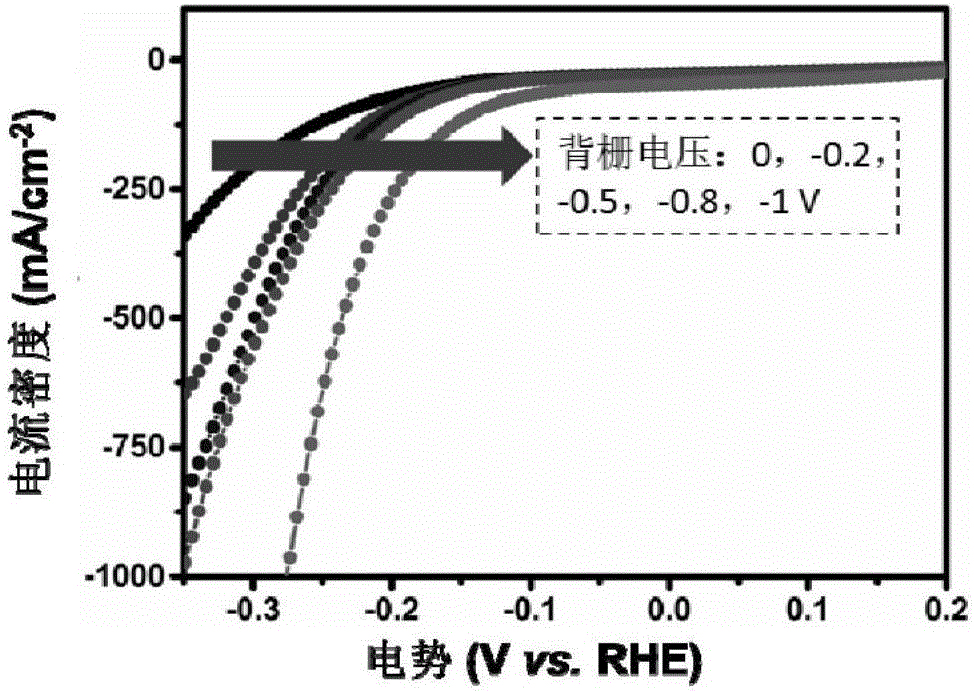

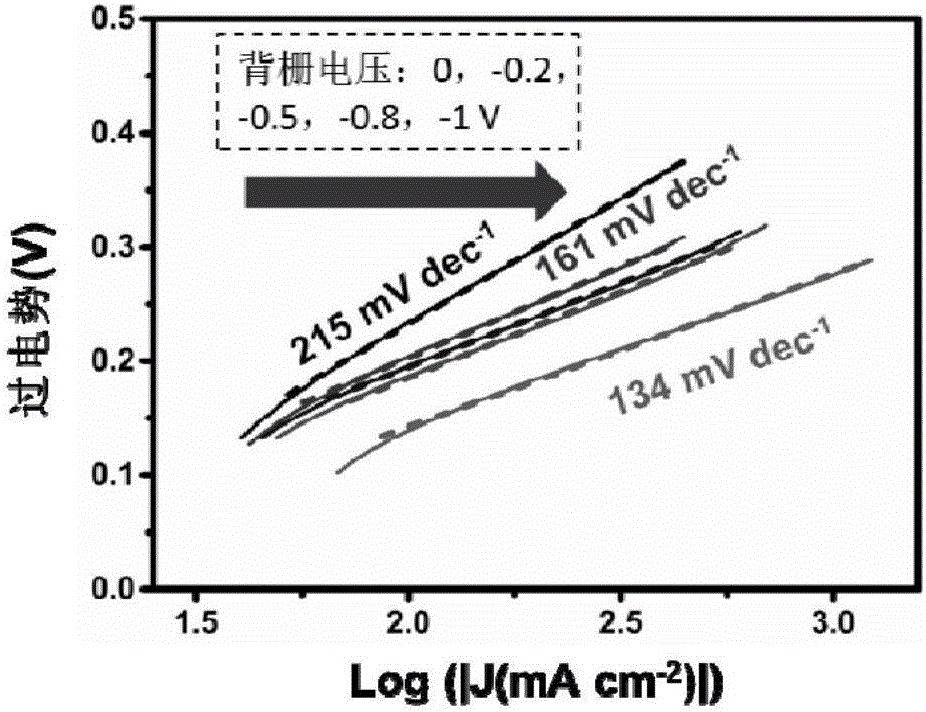

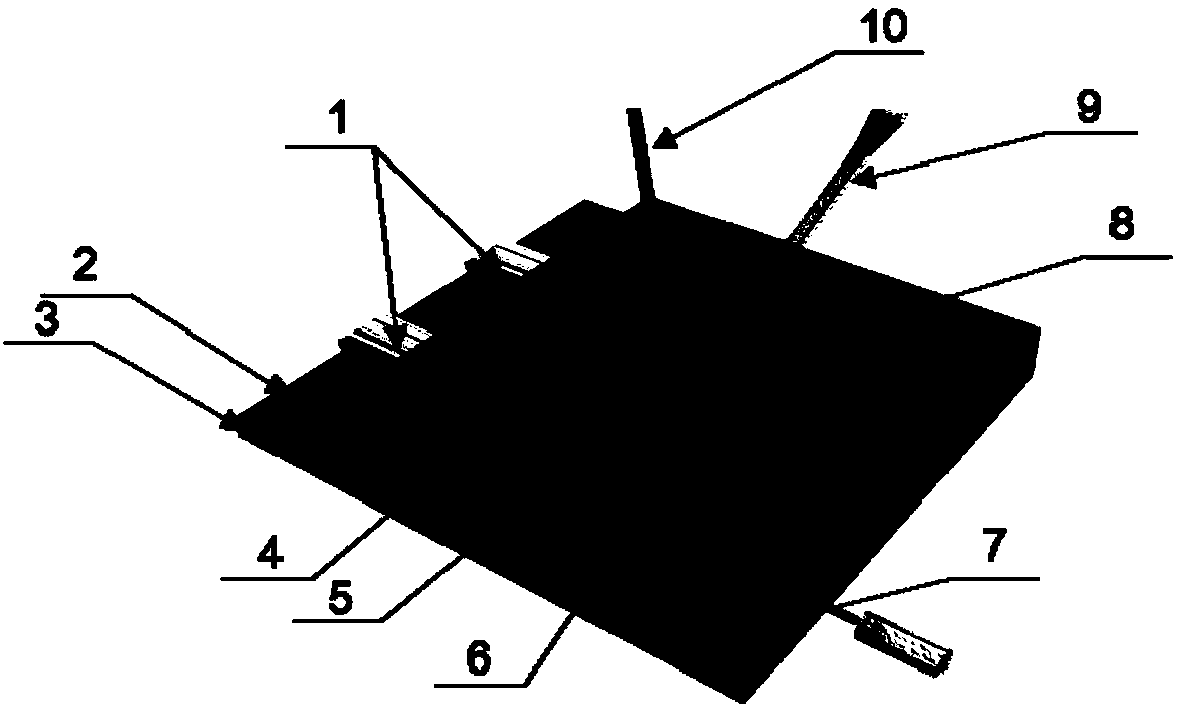

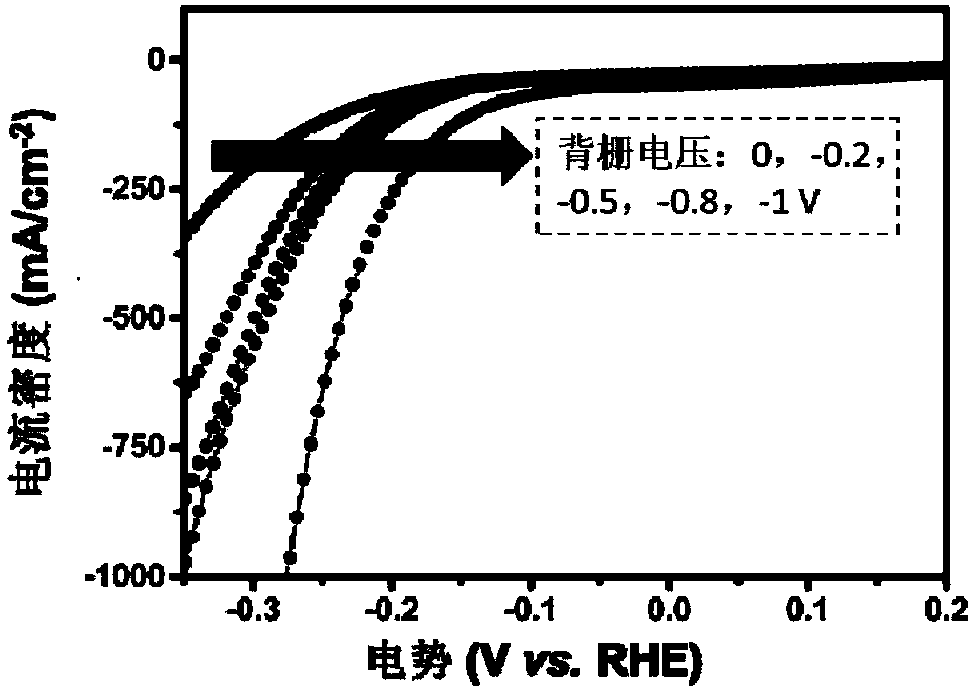

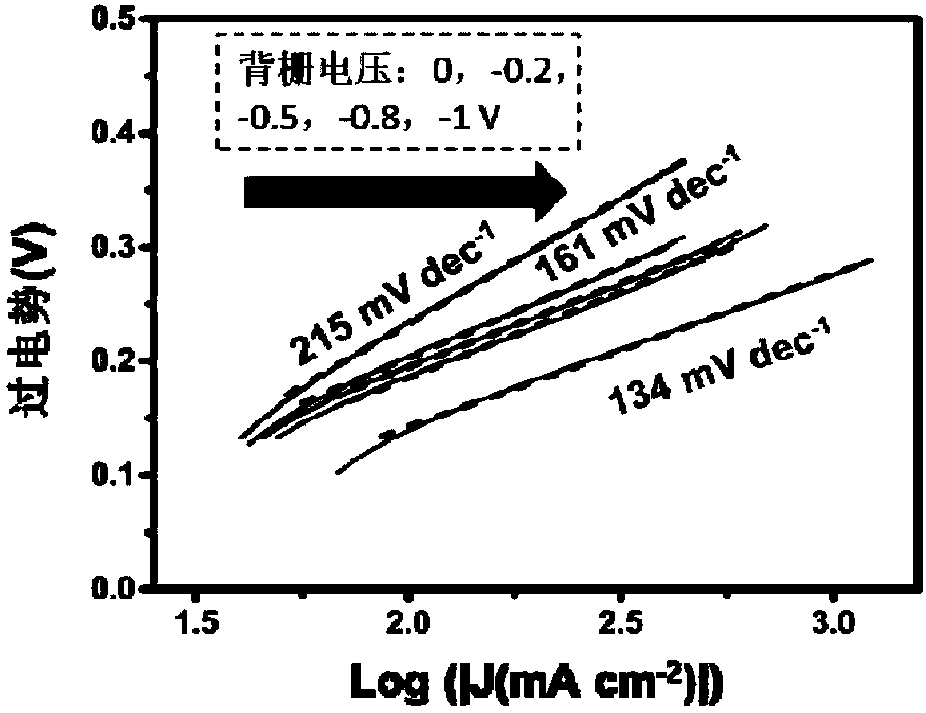

Preparing method for field effect electro-catalysis hydrogen production device

ActiveCN106555207AAccurate Testing and CharacterizationOptimizing Material Catalytic PerformanceMaterial nanotechnologyElectrode shape/formsHydrogen productionOxide

The invention relates to a preparing method for a field effect electro-catalysis hydrogen production device. At least one layer of VSe2 nano sheet is dispersed to a silicon substrate with an oxide layer, wherein the nano sheet serves as a channel material, the oxide layer serves as a dielectric layer, and metal micro electrodes are manufactured at the two ends of the channel material; spin coating of an insulation layer is conducted, and a rectangular window is etched between the two metal micro electrodes; and the oxide layer is removed from the blank side of the silicon substrate, a contact point of a back gate electrode is manufactured, and an electrolyte is injected to the surface of the device to obtain the field effect electro-catalysis hydrogen production device. The preparing method has the beneficial effects that the preparing method can serve as the new strategy for optimizing the electro-catalysis performance of nano materials.

Owner:WUHAN UNIV OF TECH

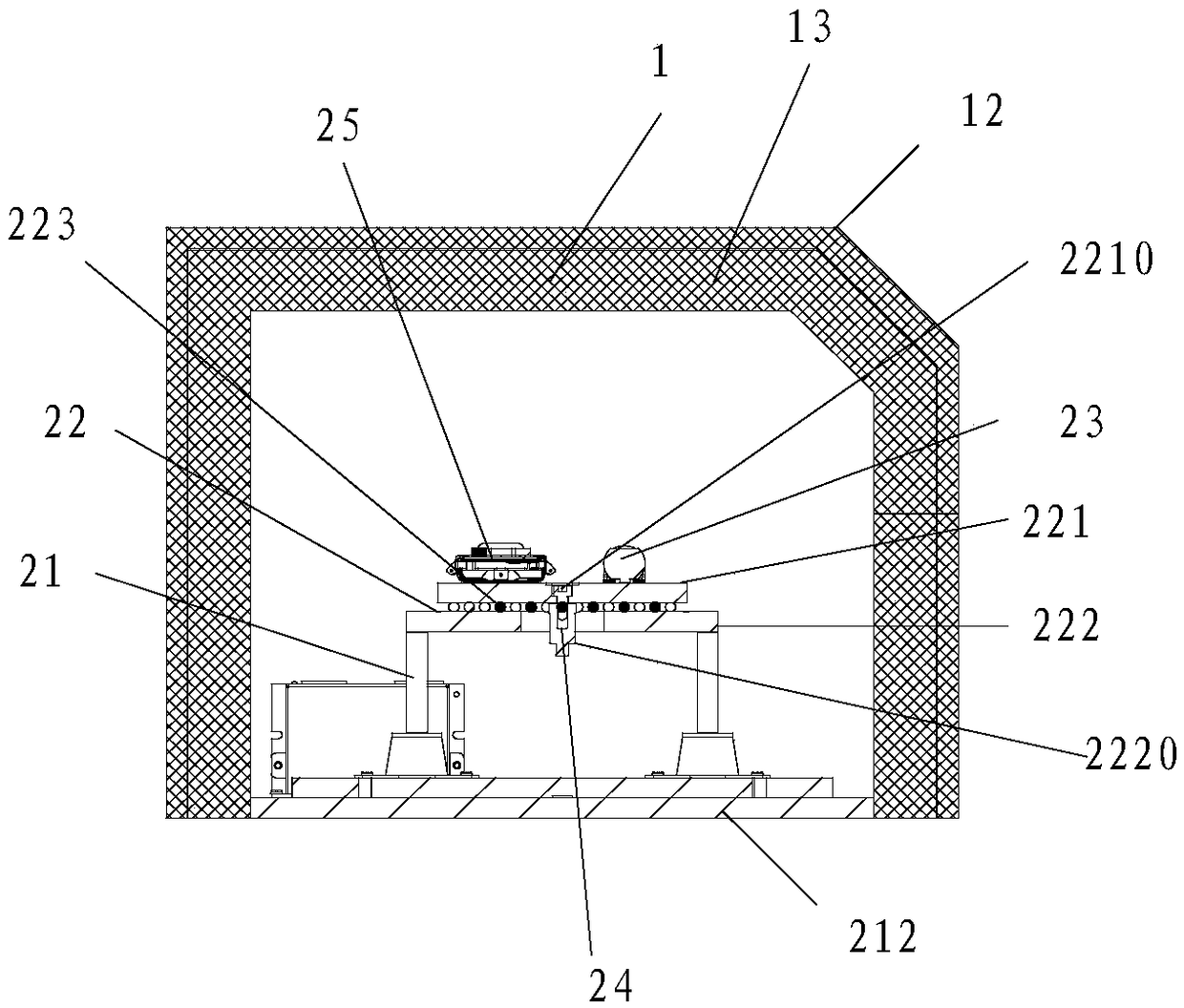

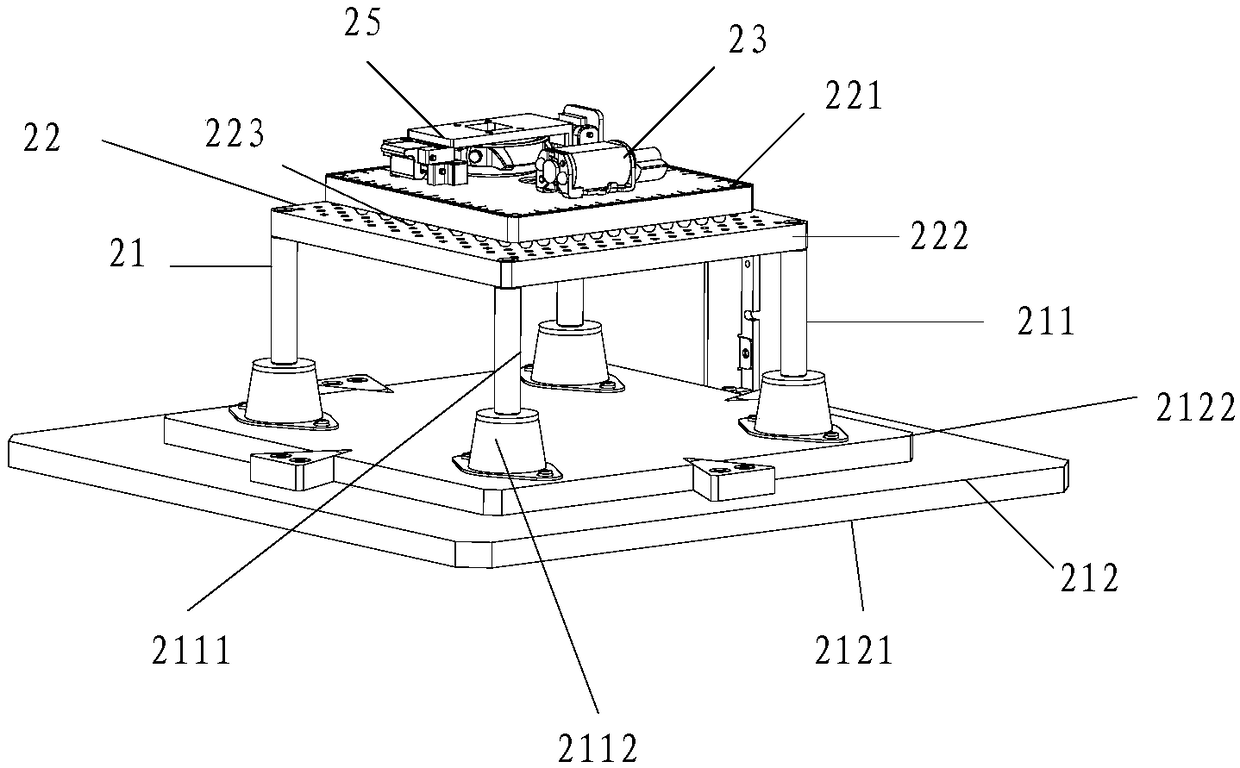

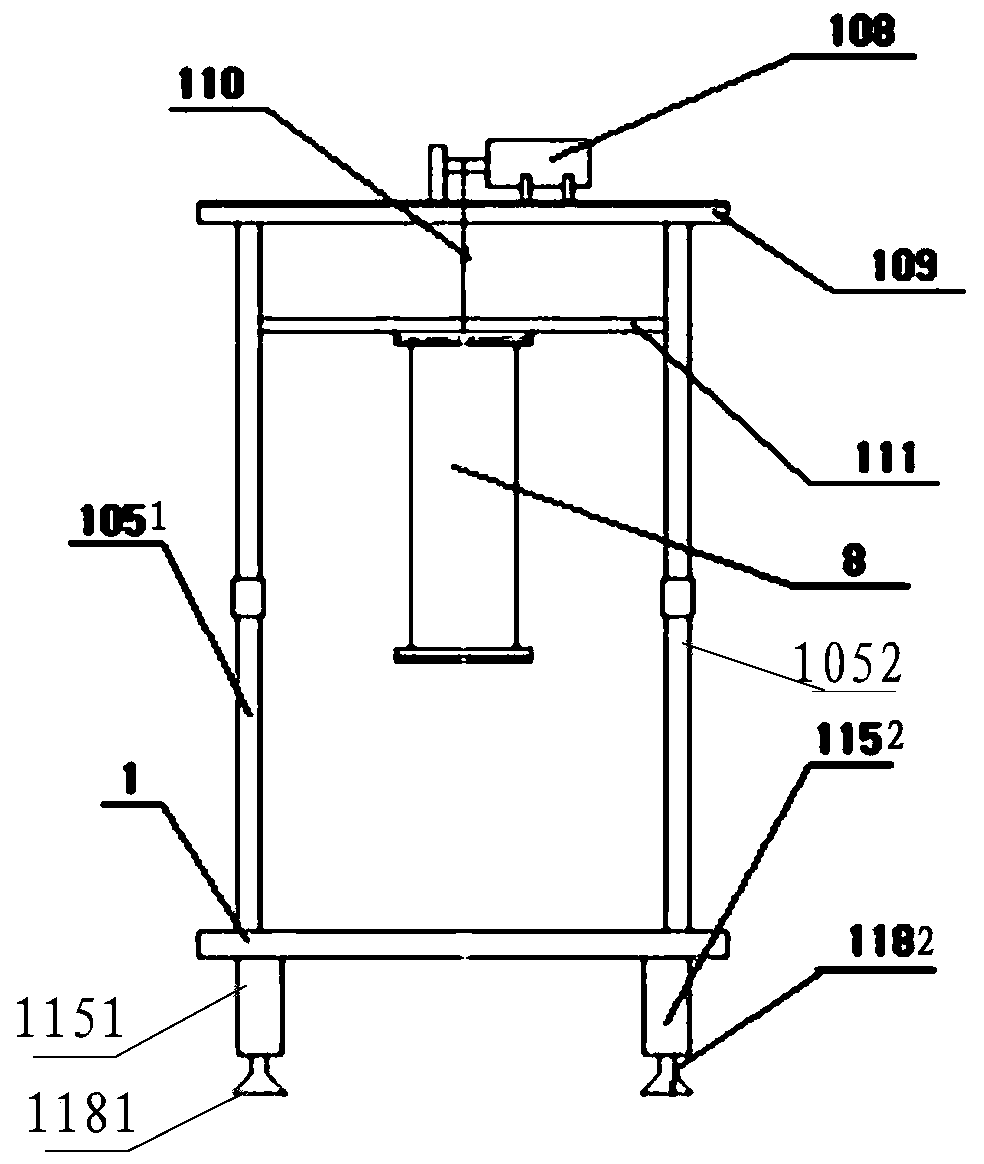

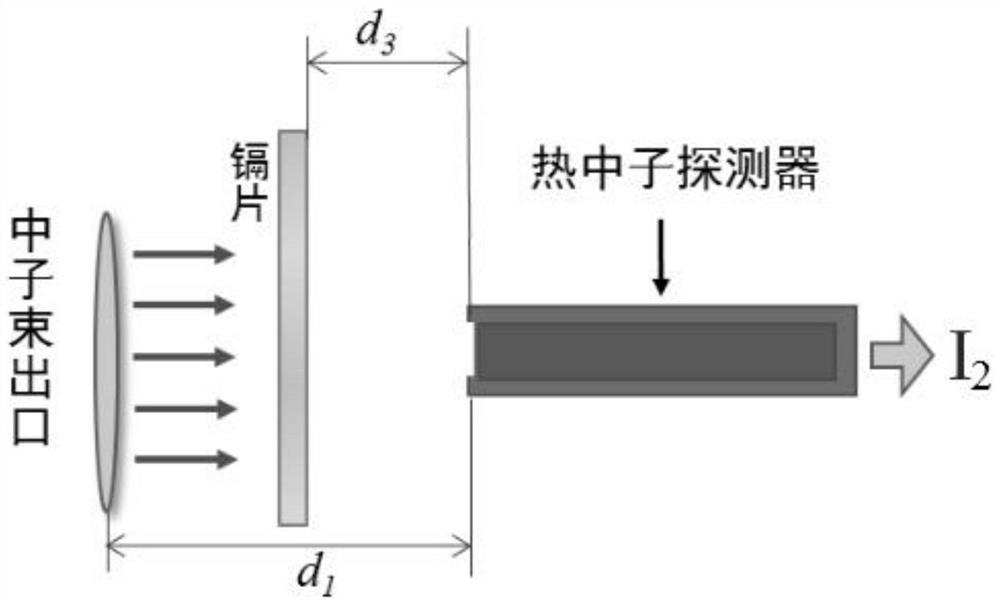

Vibration source detecting facility and method

ActiveCN109000874AAvoid Vibration InterferenceWeak vibration is easy to detectVibration testingEngineeringVibration source

The embodiment of the invention provides a vibration source detecting facility and method. The vibration source detecting facility comprises a shielding case used for shielding outside noise, and a vibration source detecting device located in the shielding case. The vibration source detecting device comprises a damping support, a bearing table, a variable-frequency vibration motor, a vibration sensor and a fixing assembly used for fixing a to-be-detected product, wherein the bearing table is arranged on the damping support, and the variable-frequency vibration motor, the vibration sensor and the fixing assembly are arranged on the bearing table. According to the vibration source detecting facility and method, weak vibration of the to-be-detected product can be tested precisely under various outside interference situations.

Owner:GOERTEK INC

Inter-layer adhesive force testing component

InactiveCN108982356AImplement Adhesion TestTest implementation of interlayer adhesionUsing mechanical meansMaterial analysisInter layerTest sample

The invention belongs to the technical field of adhesive force testing, and discloses an inter-layer adhesive force testing component. The component comprises a pedestal, a first drawing column and asecond drawing column, wherein the first drawing column is arranged on the pedestal in a sliding mode; the second drawing column is arranged on the pedestal; two opposite end faces of the first drawing column and the second drawing column can be respectively adhered to two sides of a to-be-tested sample part, and the sliding direction of the first drawing column is vertical to the end face, to which the to-be-tested sample part is adhered, of the first drawing column. The first drawing column and / or the second drawing column are / is driven by drawing equipment such as a drawing machine to movein an axial direction so as to enable the first drawing column or the second drawing column to apply drawing force to the to-be-tested sample part, so that the inter-layer adhesive force testing to the to-be-tested sample part is realized. Moreover, the structure can guarantee that the drawing force is applied in the inter-layer direction which is vertical to the to-be-tested sample part, and thenthe inter-layer axial adhesive force testing of the to-be-tested sample part is realized.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

A Time Domain Dynamic Correction Method for Cable Measurement Error in Temperature Test

ActiveCN104215848BEnable accurate testingThe test result is accurateResistance/reactance/impedenceElectrical testingTime domainMicrowave

The invention discloses a time-domain dynamic correction method for cable measurement errors in a temperature test. When radio frequency microwave products are tested in a laboratory, radio frequency cables are needed to be used for connecting the detected products with instruments. In order to guarantee accuracy of a product test, the cables must be tested singly before usage to obtain characteristic parameters of the cables, and errors introduced by the cables are corrected in a test system. But when the detected products enter a temperature chamber for a high-low temperature cycling test, the characteristic parameters of the radio frequency cables change along with high and low temperatures, and furthermore, the cables are already connected with the detected products and the instruments in the temperature chamber, single correction can not be carried out, so accuracy of the product test is lowered. By the aid of the method, a problem that the radio frequency test cables can't be tested during temperature cycling is solved, the real-time characteristic parameters of the radio frequency cables in a high-low temperature chamber can be acquired, the acquired cable parameters are used for correcting a test result, and accurate product test in a temperature cycling test can be achieved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

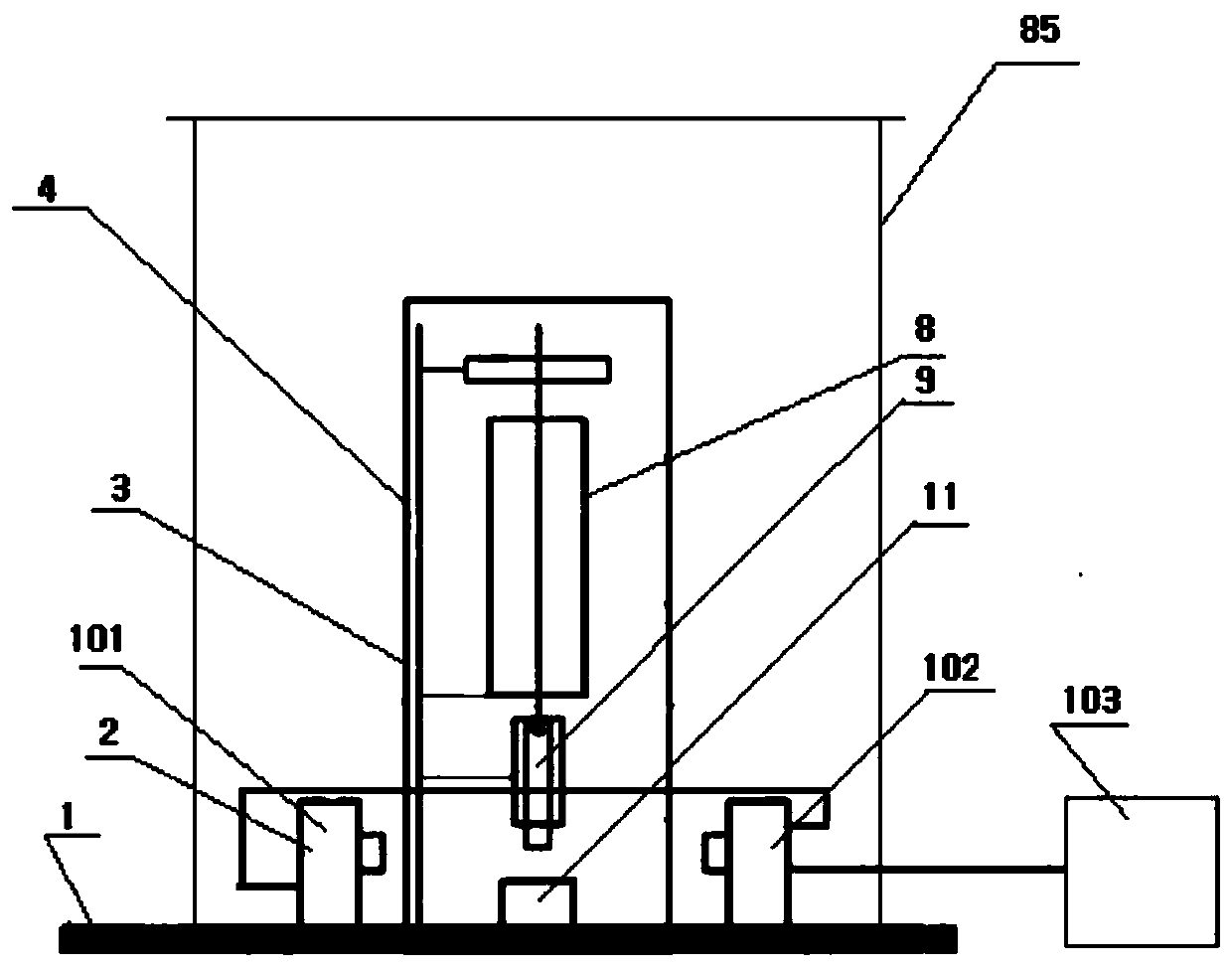

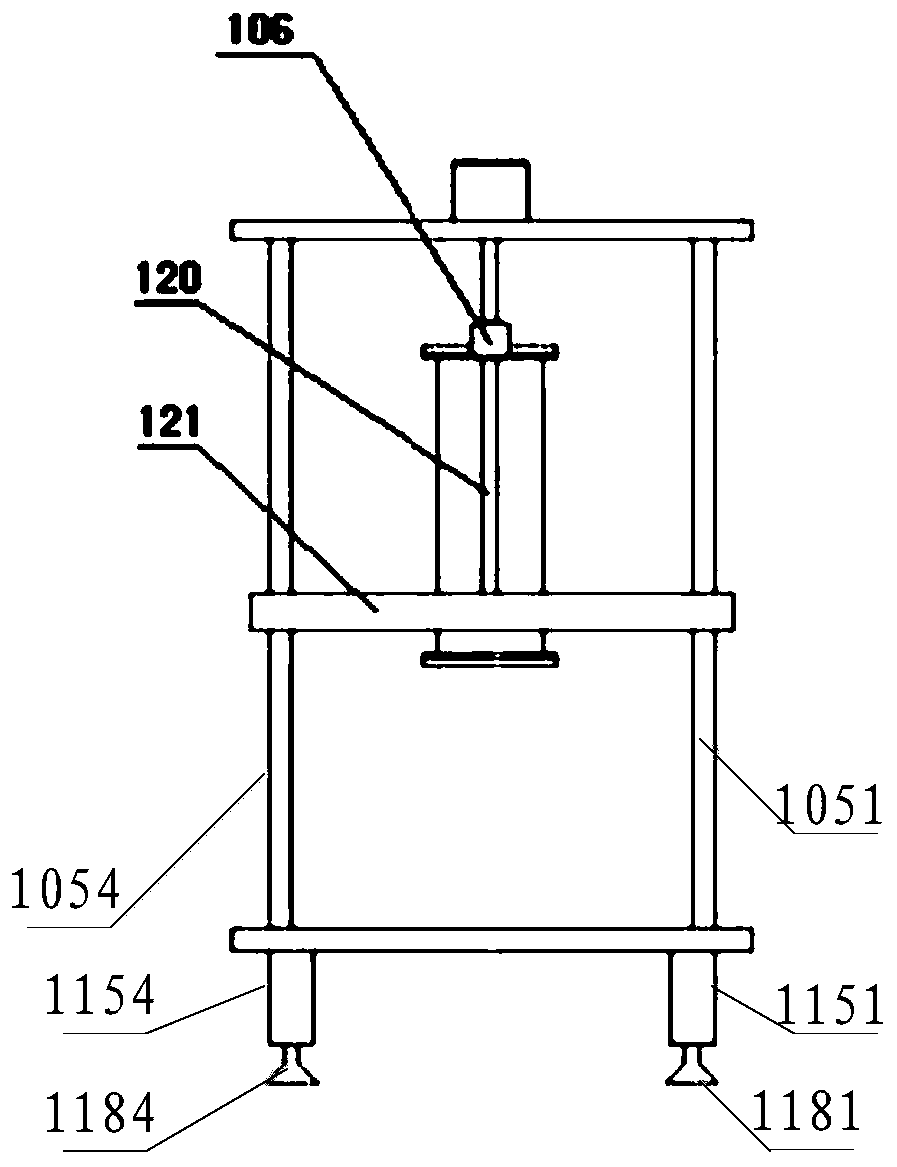

High-temperature thermal expansion performance tester for high-thermal-conductivity high-modulus carbon fibers

ActiveCN110823944AEnable accurate testingMaterial thermal coefficient of expansionFiberThermal dilatation

The invention discloses a high-temperature thermal expansion performance tester for high-thermal-conductivity high-modulus carbon fibers. The tester comprises a fixed platform, a laser scanning displacement measuring instrument, a furnace shell lifting device, a furnace shell, a measuring main body, a heating furnace body, a measured sample piece and a constant-temperature reference table; the furnace shell lifting device is arranged on the fixed platform, is connected with the furnace shell and can drive the furnace shell to move up and down; the laser scanning displacement measuring instrument, the furnace shell and the constant-temperature reference table are all arranged on the fixed platform; the laser scanning displacement measuring instrument, the furnace shell, the measuring main body, the heating furnace body, the measured sample piece and the constant-temperature reference table are positioned in the furnace shell lifting device; the measuring main body is positioned in the furnace shell and is connected with the heating furnace body; the measured sample piece is connected with the measuring main body; and the heating furnace body sleeves the tested sample piece. According to the device and the method, the axial linear expansion coefficient of a fiber material can be accurately tested under the condition of medium-high temperature from room temperature to 1000 DEG C.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

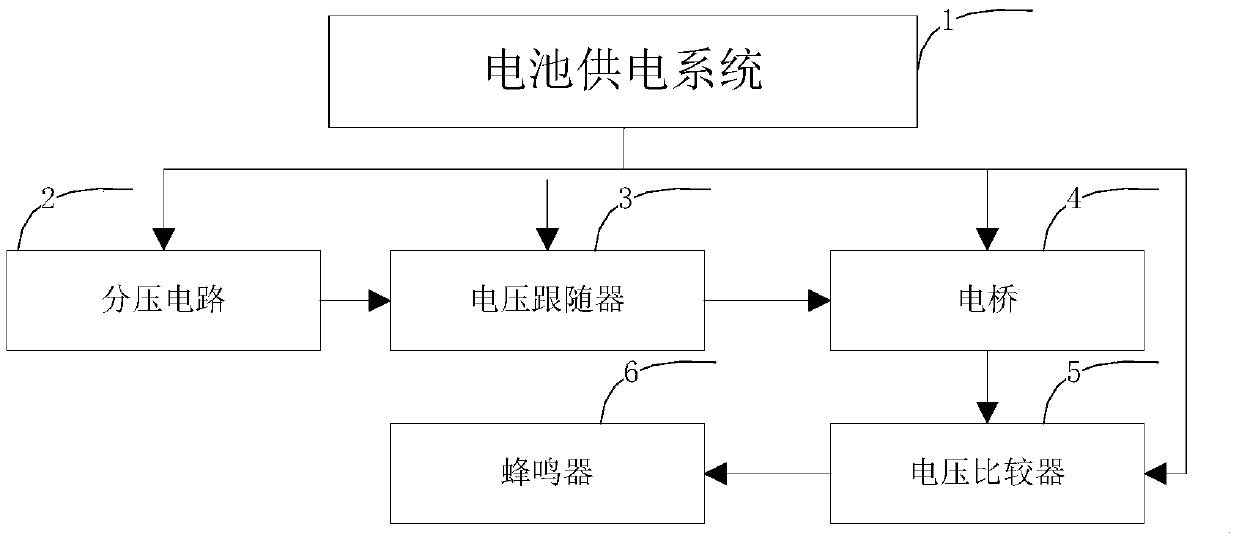

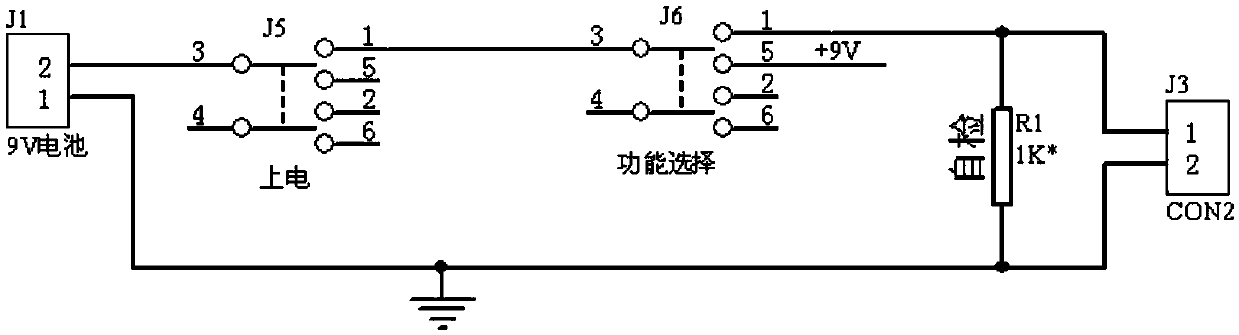

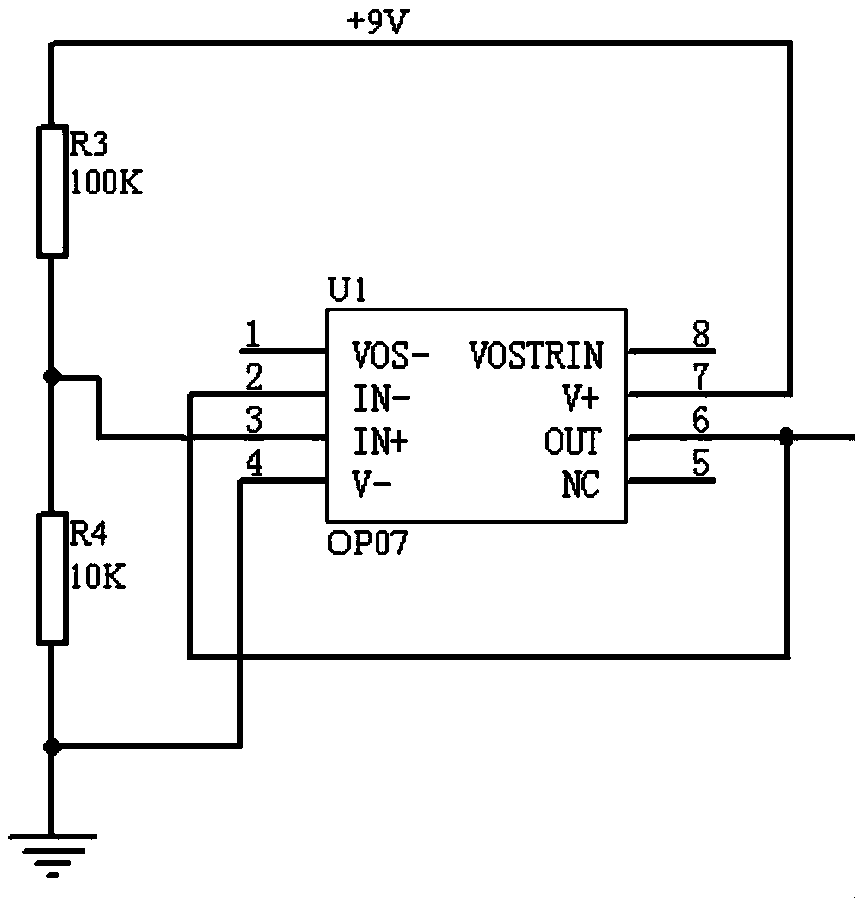

Device for low resistance conduction

InactiveCN105510758AEnable accurate testingReduce the actual threshold resistanceElectrical testingElectrical resistance and conductanceDividing circuits

The invention discloses a test device for low resistance conduction. The test device is used for conduction tests of low resistance. The test device is characterized in that the test device includes a battery power supply system, a voltage dividing circuit, a voltage follower, a voltage comparator, a bridge circuit and a buzzer; the output end of the battery power supply system is connected with the inputs end of the voltage dividing circuit, the voltage follower and the bridge circuit; the input end of the voltage follower is connected with output end of the voltage dividing circuit; the input end of the bridge is connected with the output end of the voltage follower; the input end of the voltage comparator is connected with the output end of the bridge; and the output end of the buzzer is connected with the input end of the voltage comparator. The test device of the invention is mainly used for conduction tests of printed wires and cables. With the device adopted, false alarm faults caused by large maximum on resistance of a multimeter can be eliminated, and the reliability of conduction detection can be improved. The test device has the advantages of portable convenience and convenience in battery replacement.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

Capacitive sensor stability testing device

ActiveCN111289030AHigh measurement accuracyStrong clamping forceInstrumentsStructural engineeringMechanical engineering

The invention discloses a capacitive sensor stability testing device, which comprises a base, a connecting body and an upper cover, wherein the base is detachably connected with the connecting body, and the upper cover is detachably connected with the connecting body; the connecting body comprises a connecting ring, the connecting ring is fixedly connected with a mounting base, and the connectingring and the mounting base are integrally formed; a first through groove is formed in the mounting base, and a plurality of grooves with different sizes are formed in the inner walls of the first through groove; a capacitance sensor is placed in the first through groove; a limiting block is arranged on the top surface of the upper cover, and a second through groove is formed in the bottom surfaceof the upper cover; and the upper cover is detachably connected with the mounting base. The capacitive sensor stability testing device is simple in structure, is convenient to clamp and disassemble, and can meet the stability testing demands of capacitive sensors with different diameters; and the test surface is a grinding surface, the grinding grade is K grade, and the detection precision of thestability of the capacitive sensor is effectively improved.

Owner:NAT INST OF METROLOGY CHINA

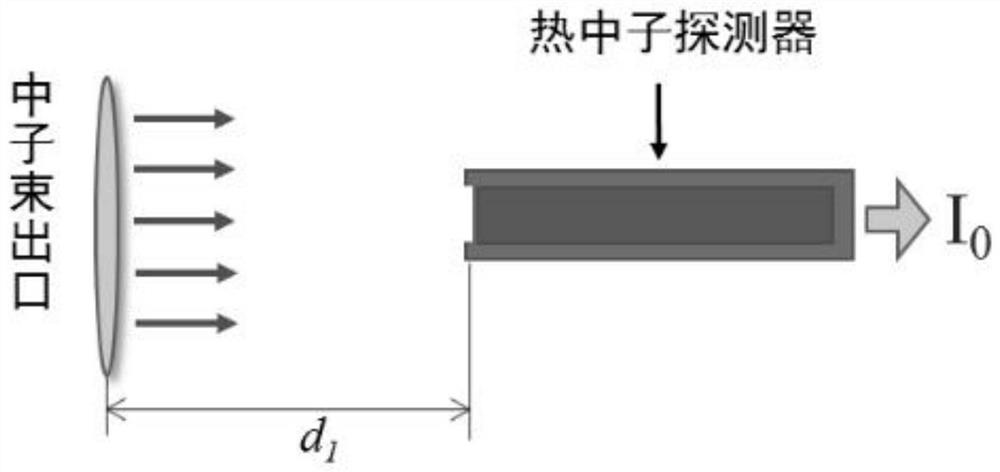

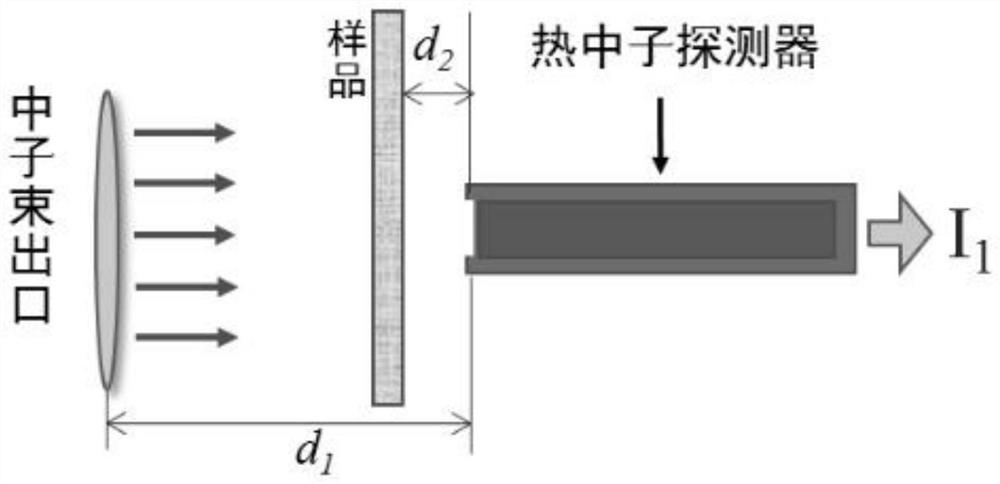

Method for testing thermal neutron shielding performance of material

PendingCN114660096AEnable accurate testingMaterial analysis by transmitting radiationNuclear energy generationRadiation protectionNuclear engineering

The invention relates to the technical field of nuclear technology and application, and provides a method for testing thermal neutron shielding performance of a material. According to the invention, by utilizing the characteristics that a thermal neutron region with the neutron absorption cross section within 0.5 eV of cadmium is very large and the cross section is sharply reduced when the neutron absorption cross section exceeds 0.5 eV, thermal neutrons with energy below 0.5 eV are distinguished from other neutrons through two measurements of adding a cadmium sheet shield and not adding the cadmium sheet shield, so that a part contributed by the thermal neutrons in the detector is obtained. The method provided by the invention can realize the accurate test of the thermal neutron shielding performance of the material, and can be directly applied to the thermal neutron shielding performance test of the radiation protection material required in various nuclear-related places such as nuclear power plants, military reactor operation, nuclear material processing and the like.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

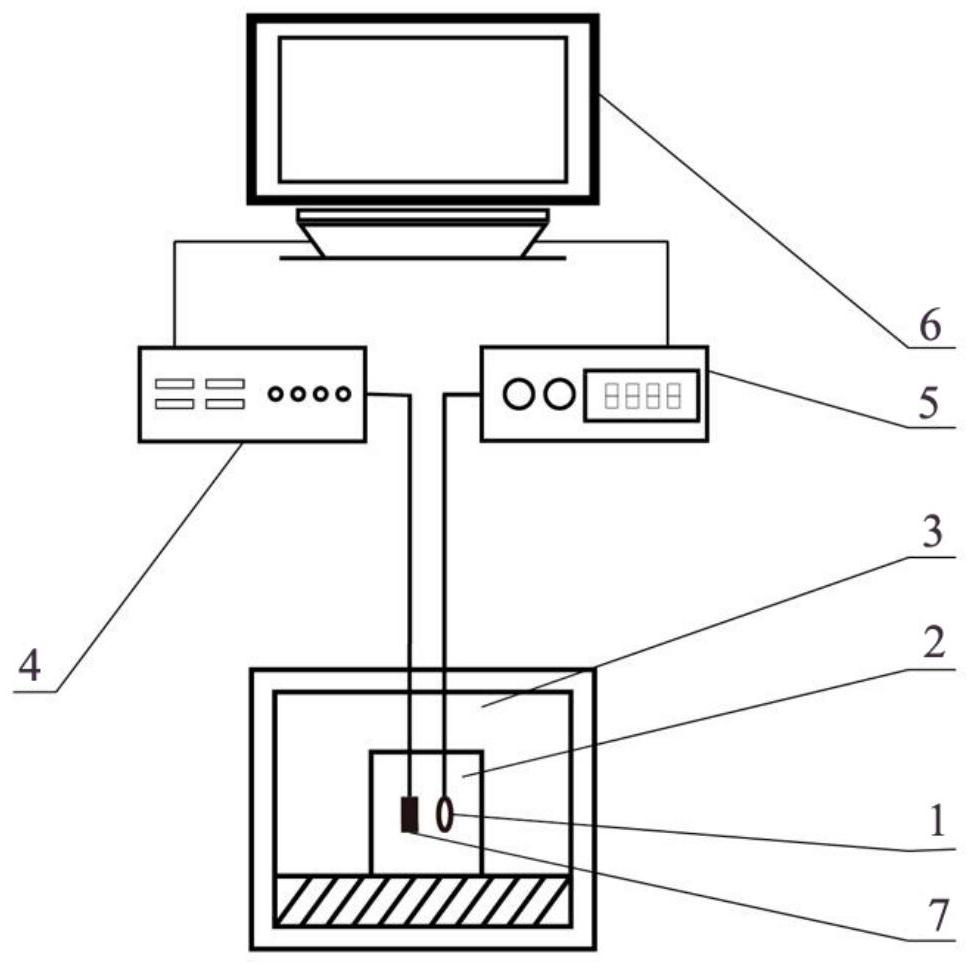

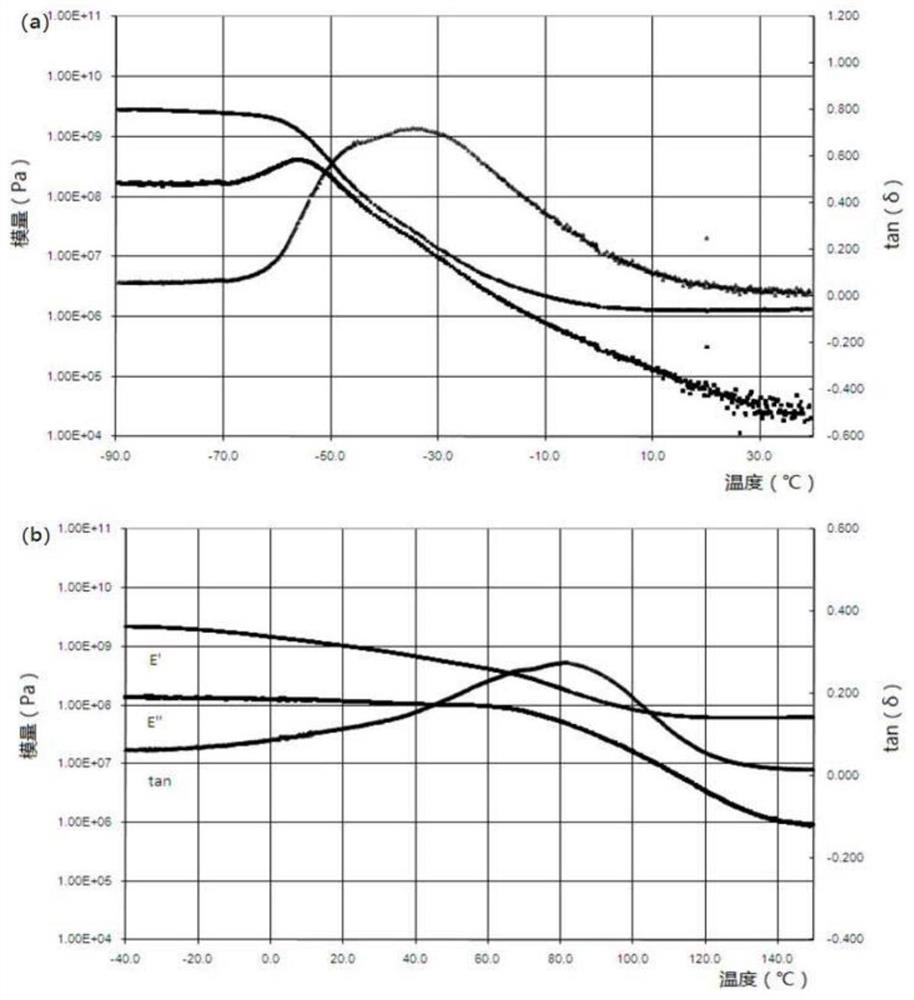

Vitrification transition temperature detection method based on grating coating of wire drawing tower

ActiveCN113670471AEnable accurate testingThe test method is simple and fastThermometers using physical/chemical changesInvestigating phase/state changeGratingTower

The invention discloses a vitrification transition temperature detection method based on a grating coating of a fiber drawing tower. The vitrification transition temperature detection method based on a grating coating of a fiber drawing tower comprises the following steps: selecting a first coating test method or a second coating test method according to the known range of the vitrification transition temperature of a to-be-detected coating of a fiber drawing tower optical fiber; and performing testing in a vitrification transition temperature testing device based on the grating coating of the wire drawing tower. According to the method, the known range of the to-be-tested coating is preliminarily classified, then the first coating testing method and the second coating testing method are adaptively selected, and in cooperation with the vitrification transition temperature testing device based on the wire drawing tower grating coating, vitrification transition temperatures of a coating with higher Tg and a coating with lower Tg are accurately tested, so that a to-be-tested grating coating sample does not need to be specially treated, and the testing method is simple.

Owner:WUHAN UNIV OF TECH

Device and method for precise testing and calibration of optical parameters of large-caliber complex curved surface

ActiveCN106840023BEnable accurate testingRealize CalibrationUsing optical meansControl signalEngineering

The invention discloses a device for accurately testing and calibrating the optical parameters of a complex curved surface with a large diameter. The device performs testing and calibrating for the complex curved surface to be tested; The signal is sent to the laser interferometer, the compensation element and the adjustment mechanism of the complex curved surface to be measured, and the adjustment mechanism is controlled to adjust the relative position and relative angle of the three, so that the root mean square error of the surface shape of the complex curved surface is the smallest and the defocus amount is zero. ;Use the transformation matrix calibration mechanism to calibrate the coordinate transformation matrix of the laser tracker during the transfer process; based on the coordinate transformation matrix, the surface data are transformed into the same coordinate system; all surface data in the same coordinate system are Modeling analysis and calculation, and then the design results of the optical inspection compensator for the complex surface to be tested are further optimized, and the optimization result is the optimal design result of the optical inspection compensator based on the measured parameters of the mirror.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

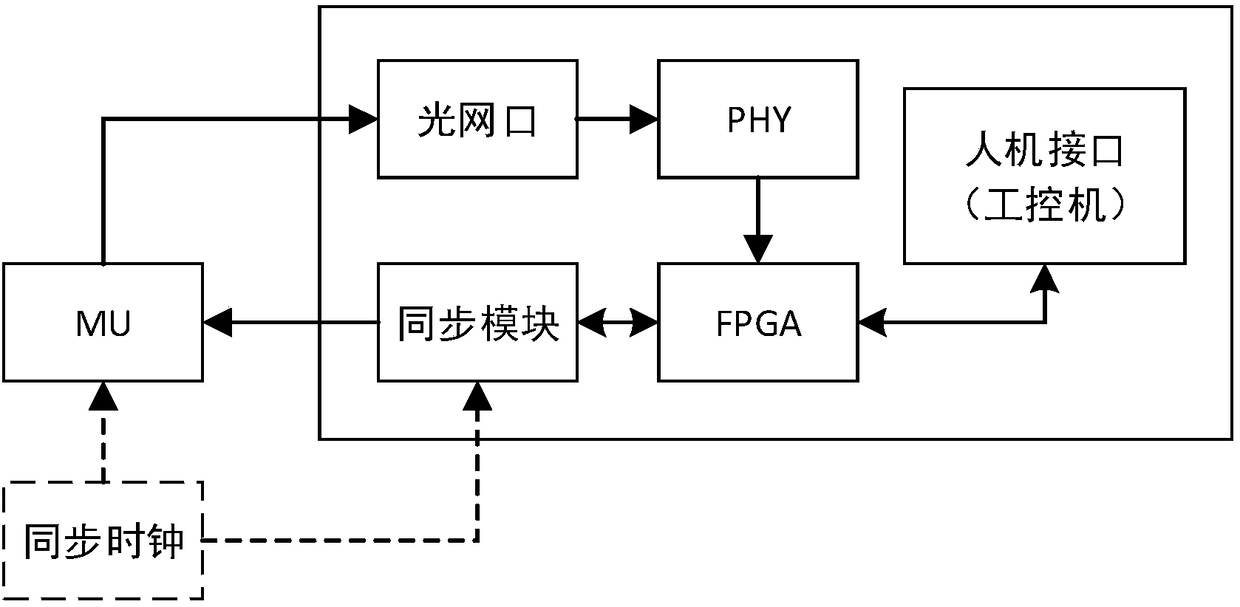

Intelligent substation merging unit absolute delay test device

InactiveCN108318846AEnable accurate testingElectrical measurementsError checkingHuman–machine interface

The invention discloses an intelligent substation merging unit absolute delay test device. An output message of a merging unit generates a new delay after passing through a switch and other network hardware devices. Since delays caused by different transmission networks are not uniform, the merging unit cannot determine the new delays, and the new delays cannot be counted into rated delays. The device provided by the invention comprises an optical network port, an Ethernet PHY chip, a field programmable logic gate array FPGA, a synchronization module and a human machine interface. The opticalnetwork port and the Ethernet PHY chip are in one-way communication. The Ethernet PHY chip and the field programmable logic gate array FPGA are in one-way communication. The field programmable logic gate array FPGA and the synchronization module are in two-way communication. The field programmable logic gate array FPGA and the human machine interface are in two-way communication. According to theinvention, the absolute delay of the merging unit is accurately tested, and a technical support is provided for asynchronous error checking of an electronic transformer.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Preparation method of field-effect electrocatalytic hydrogen production device

ActiveCN106555207BImprove electrocatalytic performanceEnable accurate testingMaterial nanotechnologyElectrode shape/formsElectrolytic agentInsulation layer

The invention relates to a preparing method for a field effect electro-catalysis hydrogen production device. At least one layer of VSe2 nano sheet is dispersed to a silicon substrate with an oxide layer, wherein the nano sheet serves as a channel material, the oxide layer serves as a dielectric layer, and metal micro electrodes are manufactured at the two ends of the channel material; spin coating of an insulation layer is conducted, and a rectangular window is etched between the two metal micro electrodes; and the oxide layer is removed from the blank side of the silicon substrate, a contact point of a back gate electrode is manufactured, and an electrolyte is injected to the surface of the device to obtain the field effect electro-catalysis hydrogen production device. The preparing method has the beneficial effects that the preparing method can serve as the new strategy for optimizing the electro-catalysis performance of nano materials.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com