Method for testing transverse bending resistance of small hinge joint hollow slab bridge combined reinforcing member

A technology of reinforcement member and test method, which is applied in the direction of using stable bending force to test material strength, using stable tension/pressure test material strength, measuring device, etc., can solve the problem of insignificant reinforcement effect and easy damage of small hinged joint , weak structure and other problems, to achieve the effect of simple and fast test method and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

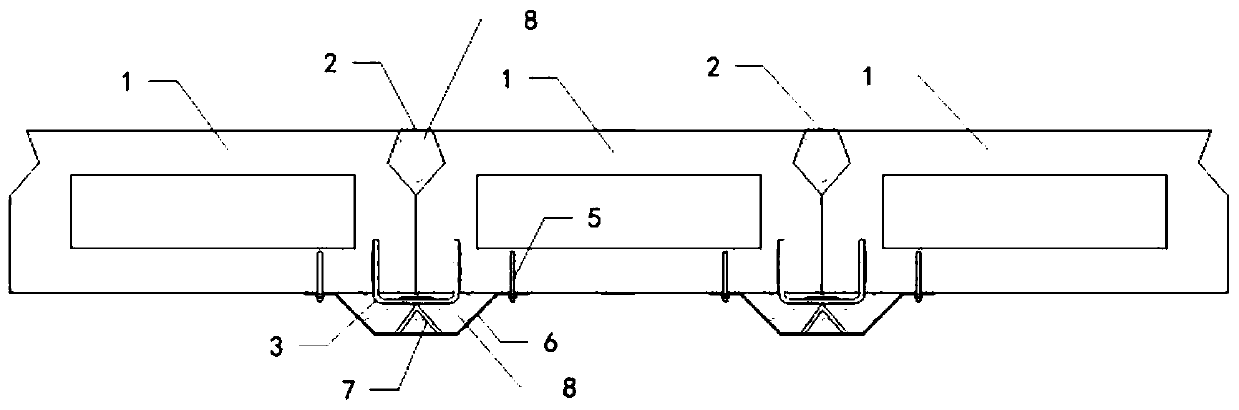

[0032] Such as Figure 1 to Figure 9 As shown, the test method for transverse flexural performance of composite reinforced members of small hinged hollow slab bridges includes the following steps:

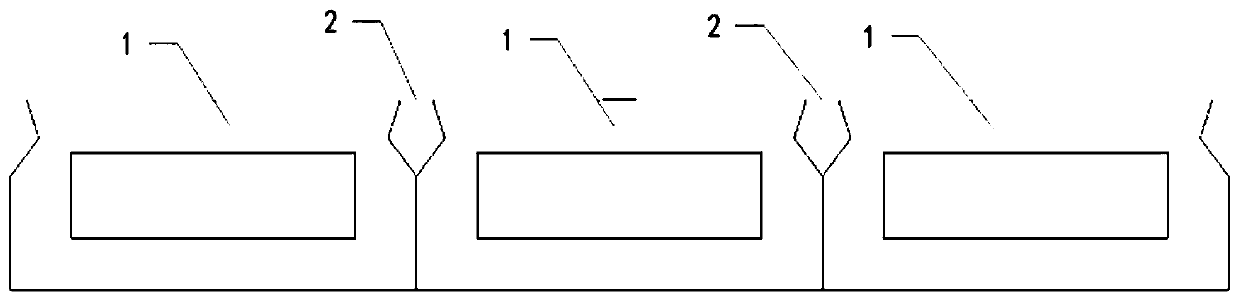

[0033] Step 1, such as figure 1 As shown, three small hinged hollow slab specimens 1 of the same length are cut from the same small hinged hollow slab bridge member, and the three small hinged hollow slab specimens 1 are placed side by side to form two hinged joints 2;

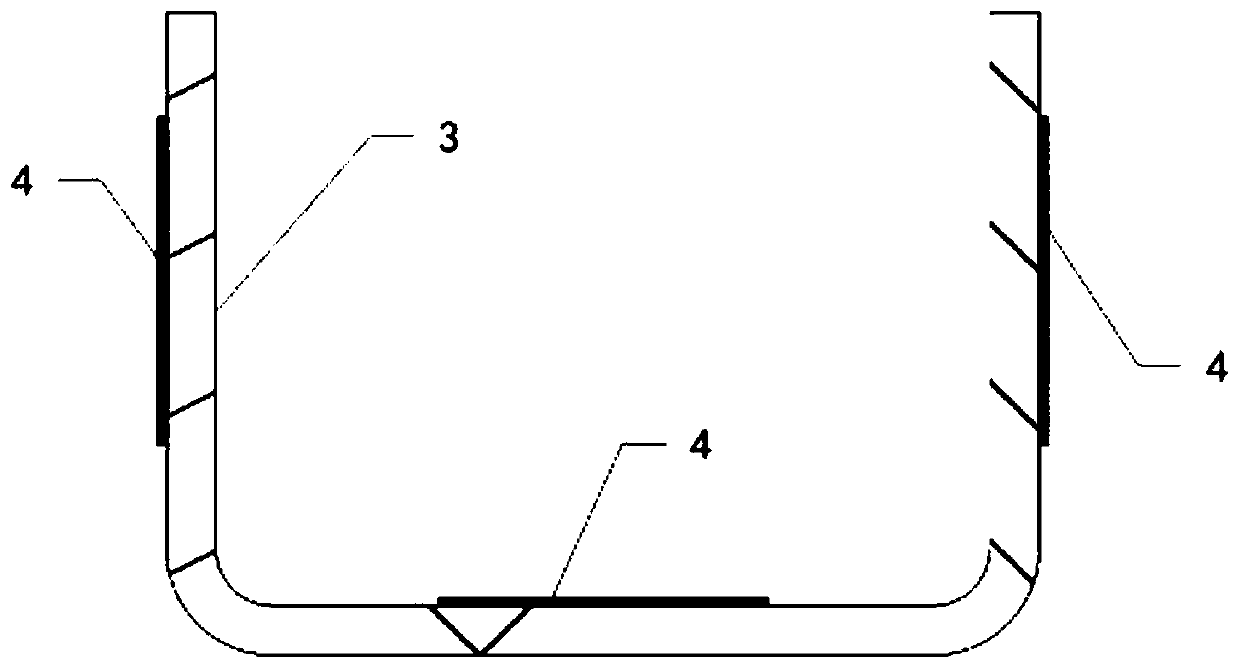

[0034] Step two, such as figure 2 As shown, the U-shaped shear reinforcement 3 is prepared, and at least three resistance strain gauges 4 are arranged on the U-shaped shear reinforcement 3, and the resistance strain gauges 4 are respectively arranged on the outside of the vertical reinforcement of the U-shaped shear reinforcement 3. side and upper sides of transverse reinforcement;

[0035] Step three, such as image 3 As shown, the U-shaped shear reinforcement 3 is implanted at the bottom position below the h...

Embodiment 2

[0044] Such as Figure 1 to Figure 9 As shown, the test method for transverse flexural performance of composite reinforced members of small hinged hollow slab bridges includes the following steps:

[0045] Step 1, such as figure 1 As shown, three small hinged hollow slab specimens 1 of the same length are cut from the same small hinged hollow slab bridge member, and the three small hinged hollow slab specimens 1 are placed side by side to form two hinged joints 2;

[0046] Step two, such as figure 2 As shown, the U-shaped shear reinforcement 3 is prepared, and at least three resistance strain gauges 4 are arranged on the U-shaped shear reinforcement 3, and the resistance strain gauges 4 are respectively arranged on the outside of the vertical reinforcement of the U-shaped shear reinforcement 3. side and upper sides of transverse reinforcement;

[0047] Step three, such as image 3 As shown, the U-shaped shear reinforcement 3 is implanted at the bottom position below the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com