Vitrification transition temperature detection method based on grating coating of wire drawing tower

A technology of glass transition and detection method, which is applied in the directions of thermometers, thermometers, and heat measurement by physical/chemical changes, which can solve the problems of insufficient glass transition temperature testing and achieve the effect of simple and convenient testing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

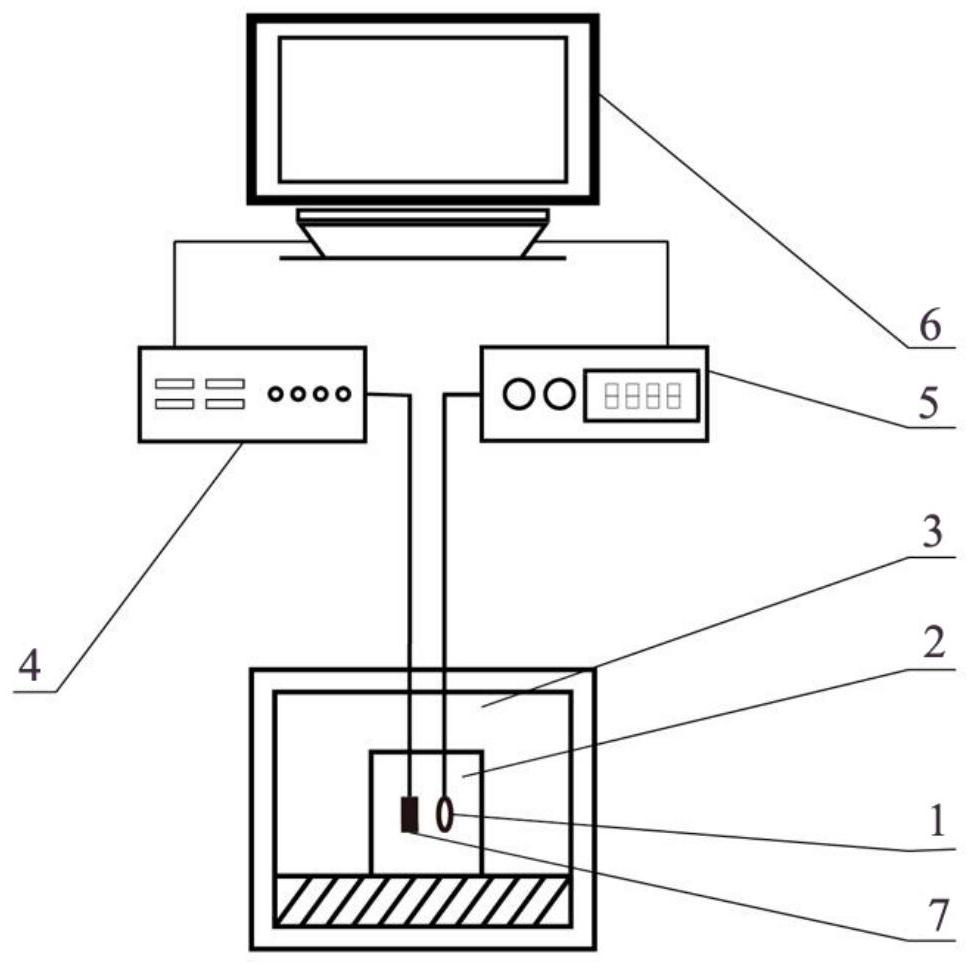

Image

Examples

Embodiment 1

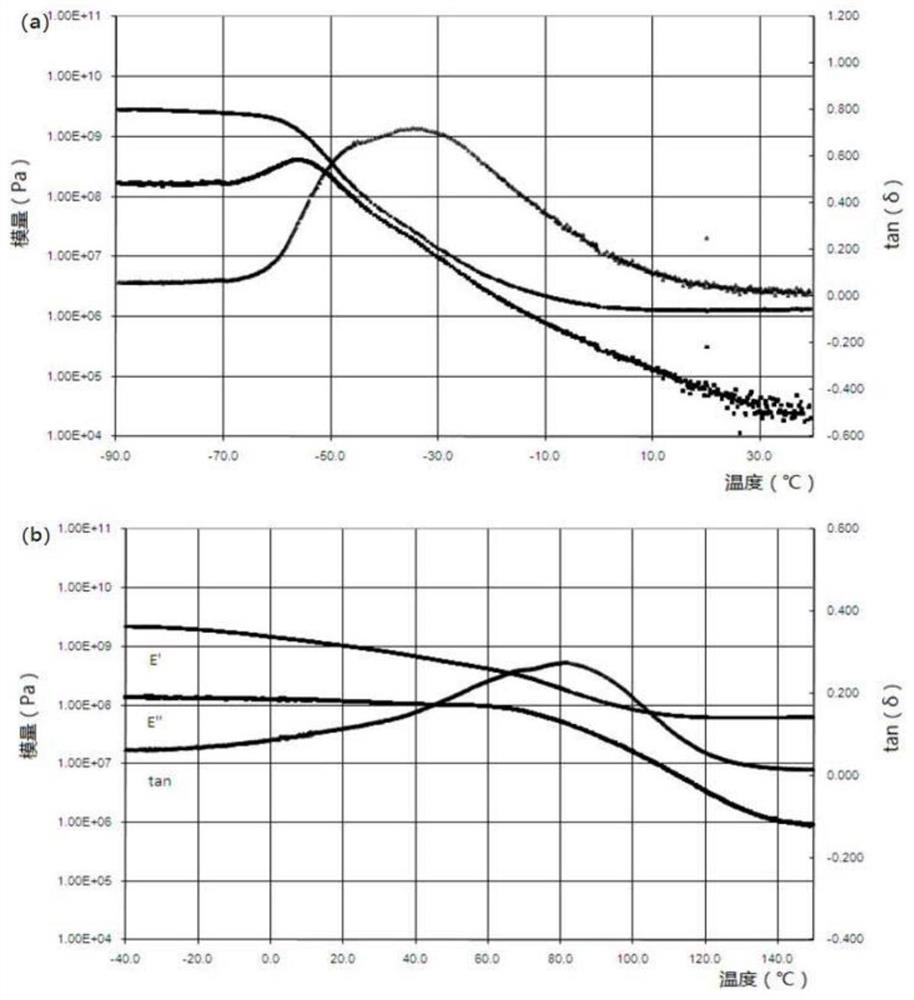

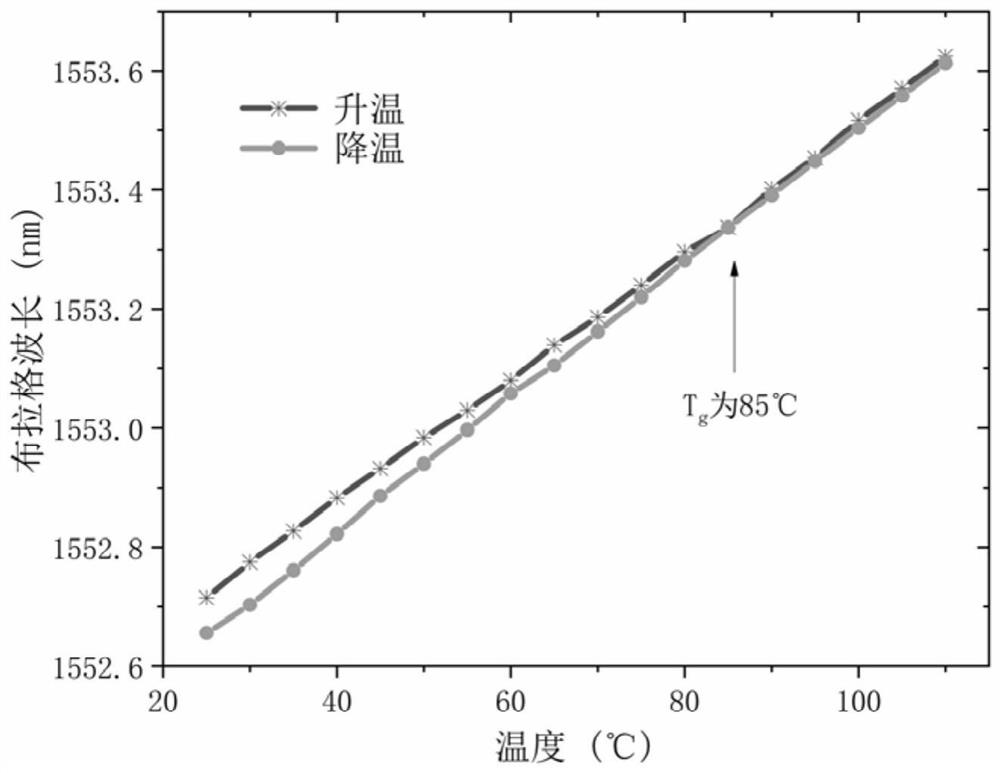

[0039] In this example, two polyacrylate glues produced by Shanghai Feikai Photoelectric Materials Co., Ltd. were used to verify the above test method, and the DMA method was used to test the two kinds of glue. The results are as follows figure 2 As shown, 2(a) is No. 2 test glue, and 2(b) is No. 1 test glue. Among them, the model of No. 1 test glue is KG200-2, which has fast curing speed, large modulus, good mechanical strength, high glass transition temperature, and the known range of glass transition temperature is about 80°C, which belongs to type I polymer coating. Layer; No. 2 test glue model is KG100-1Y-1, the glue curing speed is fast, the modulus is low, the elasticity is good, the known range of the glass transition temperature is -50 ~ -30 ℃, it belongs to the type II polymer coating.

[0040] By the height of the modulus of elasticity of the two kinds of test glues, the No. 1 test glue is selected to be tested in the glass transition temperature testing device bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com