Patents

Literature

115 results about "Shear reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single plate force-bearing reinforcing method of hollow slab bridge

InactiveCN103061271AAvoid destructionImprove reliabilityBridge erection/assemblyBridge strengtheningWhole bodyBridge deck

The invention relates to a single plate force-bearing reinforcing method of a hollow slab bridge. The single plate force-bearing reinforcing method includes that the original bridge deck pavement is shoveled, hinge joint concrete is removed, defects and cracks of the original hollow slab bridge beam body are processed, strip-shaped steel plates are transversely pasted on the upper surface and the lower surface of the hollow slab bridge in the longitudinal bridge direction at certain intervals, split screws penetrate through drilled holes at the hinge joint position, a counter-force frame is arranged, a wedge-shaped block is embedded between the counter-force frame and the steel plates, and the steel plates are pressurized and pasted in sealing mode and then are positioned and fixed; the counter-force frame is demounted after sticky steel glue is cured; cavities in beam joints are subjected to pressure grouting, shear reinforcements are placed into the top surface of a hollow slab, a reinforcement mesh is reconstructed, and the bridge deck reinforcement mesh and the implanted reinforcements are connected in binding or point welding mode to form a whole body; steel fiber reinforced concrete is poured and waterproof coatings are sprayed; and bituminous concrete is paved. The single plate force-bearing reinforcing method improves transverse load distribution, steel plate pasting reliability and bridge integral force-bearing performance on the premise of preventing hollow slab beam body damage, not changing a structural force-bearing system and not interrupting the traffic.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

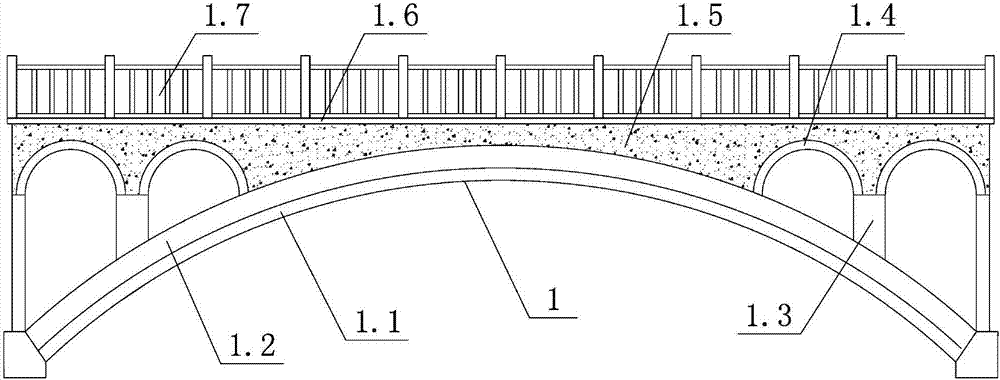

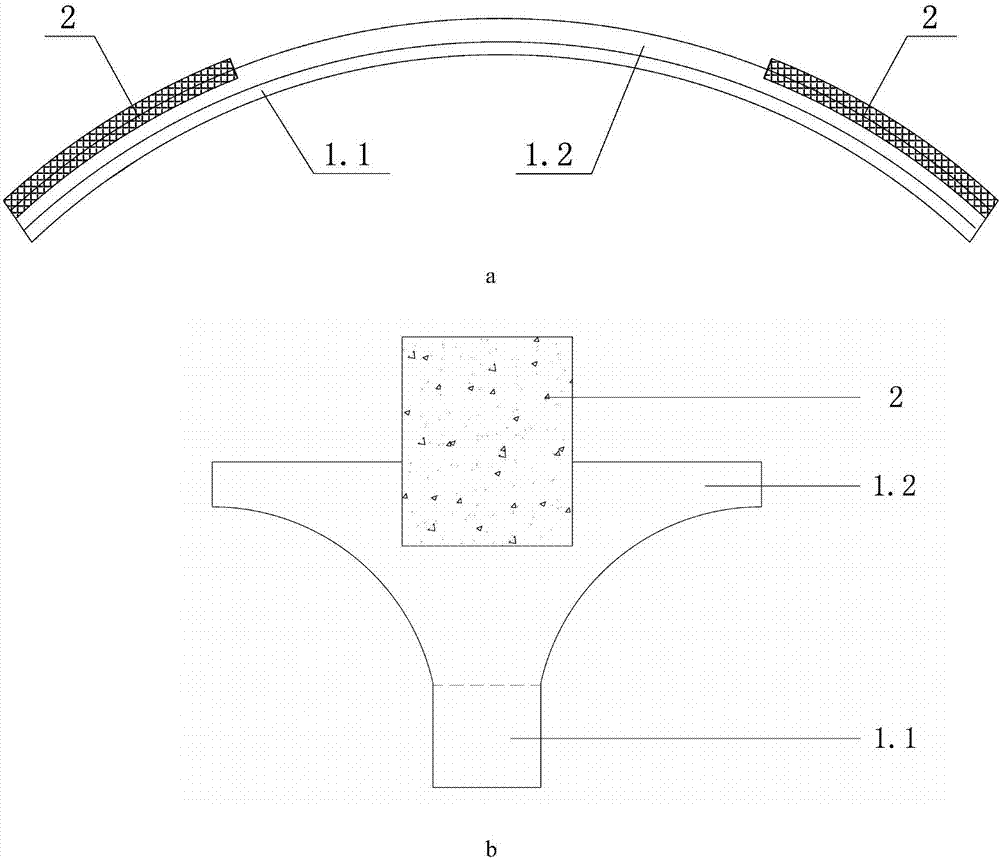

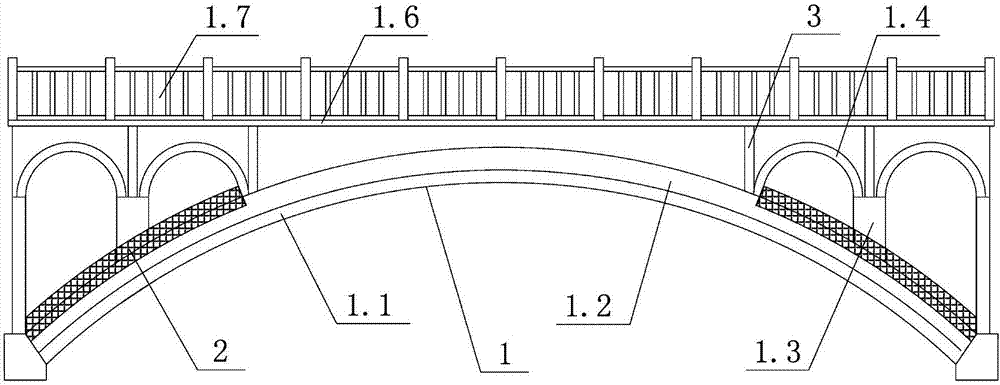

Novel reinforcement method for two-way curved arch bridge

InactiveCN106958208AIncrease weightLess weight gainBridge erection/assemblyBridge strengtheningBridge deckOperability

The invention discloses a novel reinforcement method for a two-way curved arch bridge comprising the following steps: (1) closing to traffic on a bridge deck, dismantling the bridge deck and auxiliary facilities of the bridge deck and removing fillings on arches; (2) cutting rectangular grooves along the two-way curved arch bridge on the top of an extrados corresponding to an original arch rib; (3) chipping the bottom of the rectangular grooves, planting anti-shear reinforcement bars, erecting a formwork on the extrados on the top of the rectangular grooves, assembling the anti-shear reinforcement bars and pouring concrete to form new arch ribs, of which the height is same relative to the extrados, protruding from the extrados; (4) repairing transverse walls, chipping the sections, which are at the outer side of the transverse walls along the two-way curved arch bridge, of the extrados and the new arch ribs, planting reinforcement bars on the extrados and the new arch ribs which are chipped, erecting the formwork and pouring the concrete; (5) chipping the top of the transverse walls, planting vertical reinforcement bars and erecting new columns for supporting the bridge deck; (6) newly building the bridge deck. The novel reinforcement method for the two-way curved arch bridge has the advantages of being small in dead weight of a bridge structure, good in unity of an old structure and a new structure, low in reinforcement cost, good in adaptability, not restricted by surroundings under the two-way curved arch bridge, unchanged about the original appearance of the two-way curved arch bridge, good in operability and good in application prospect.

Owner:WUHAN UNIV OF TECH

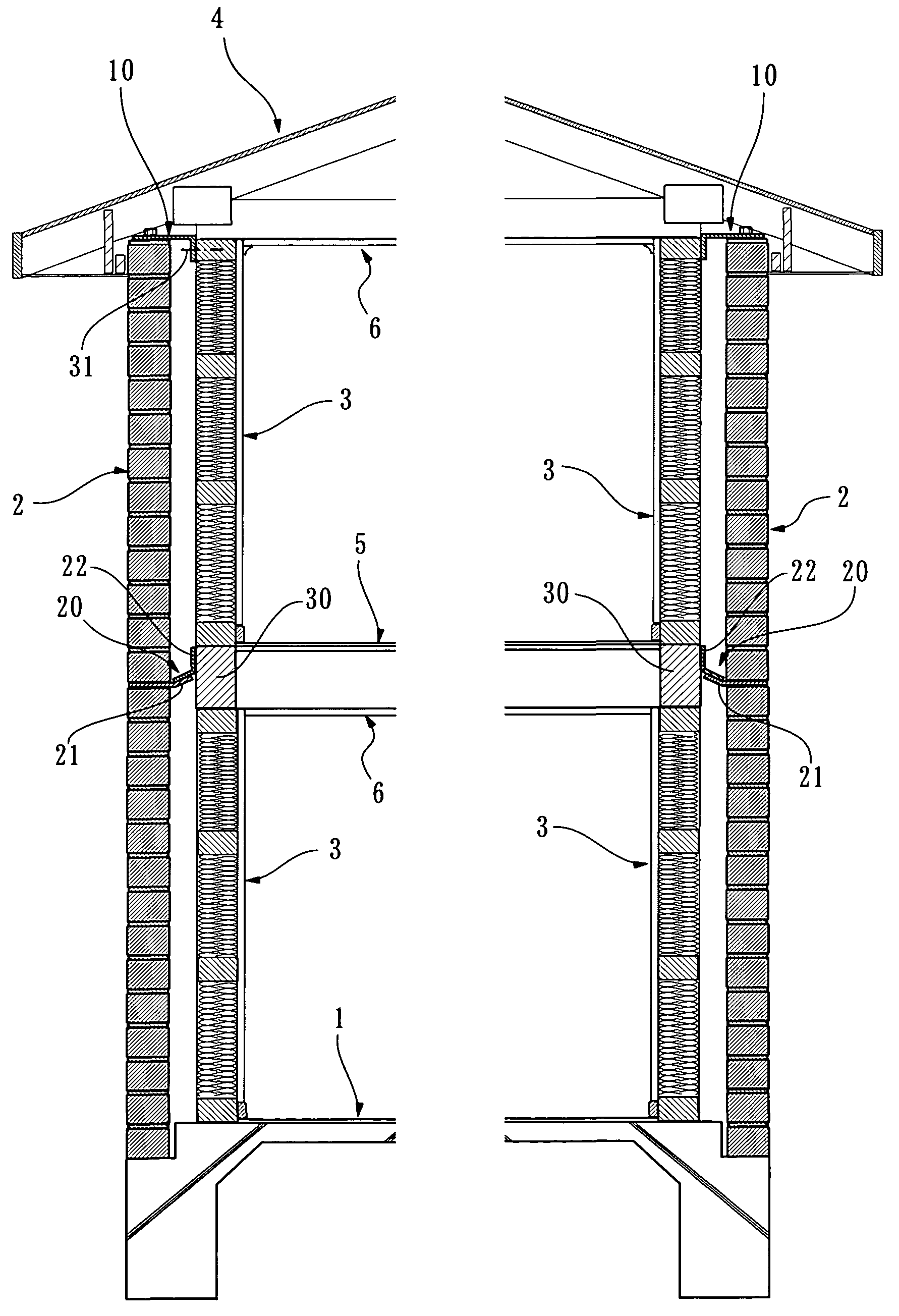

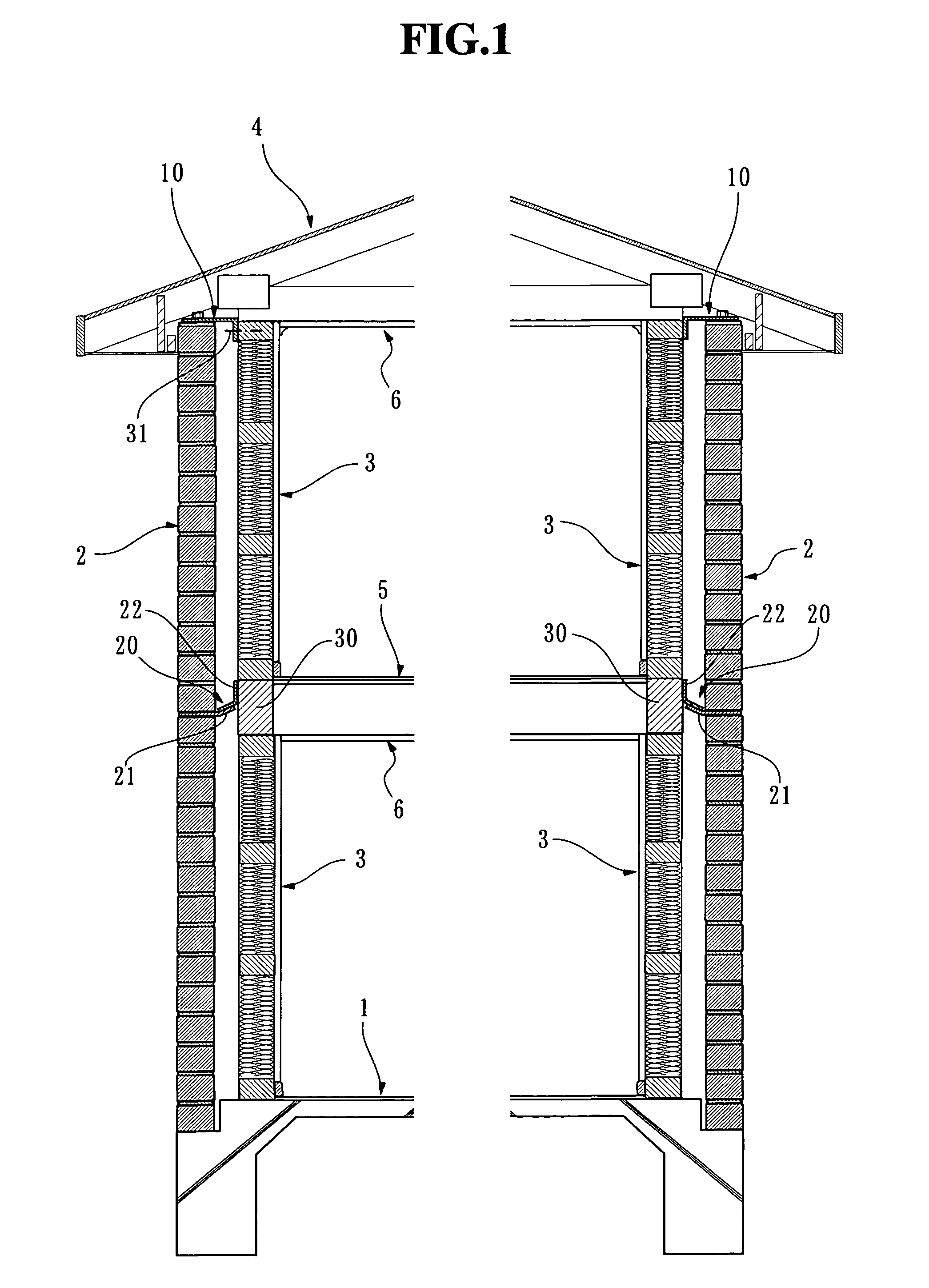

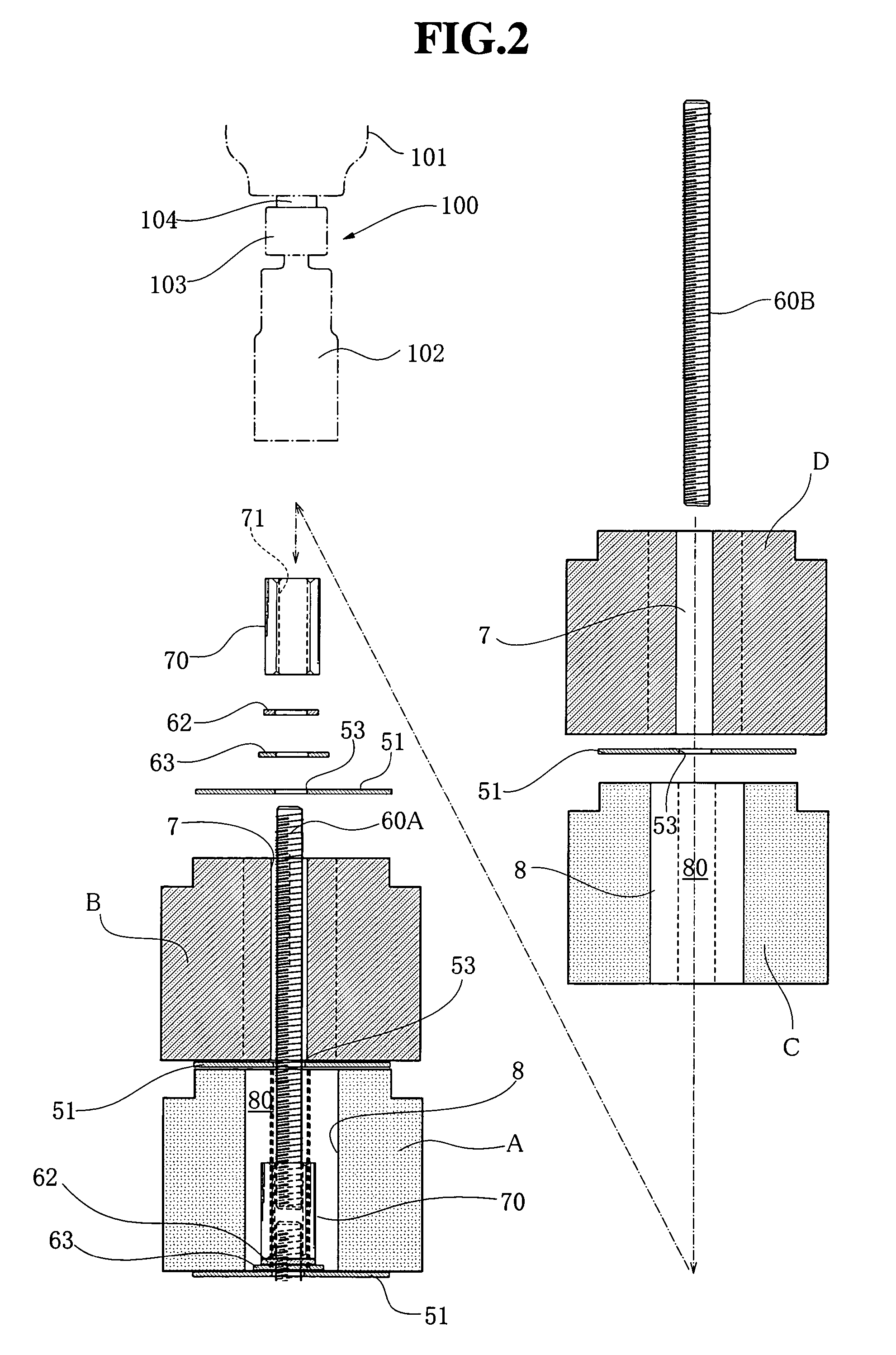

Wall construction of architectural structure

InactiveUS7836646B2Improve the immunitySolve the lack of resistanceCeilingsWallsEarthquake resistanceBrick

A wall structure of an architecture is provided, which comprises an outer wall having resistance against earthquakes and wind and an inner wall relatively inferior in the earthquake-resistance and so forth, so that the outer and inner walls are properly combined to share design loads. The wall structure includes the outer wall (2) of bricklaying structure in which bricks (A˜D) and metal plates (51) are stacked. Fasteners (60,62,63,70) extending through the bolt holes (7) of the bricks are tightened, and the vertically adjacent bricks are integrally connected with each other under prestress of the fasteners. The inner wall (3) is constructed inside of the outer wall, and the shear reinforcement member (10,20) connects the inner and outer walls with each other. The inner wall is constructed by a dry type of construction method, which can support a permanent vertical load such as a roof load. A temporary horizontal load acting on the inner wall, such as a seismic force, is transmitted to the outer wall by the shear reinforcement member.

Owner:JAPAN SCI & TECH CORP

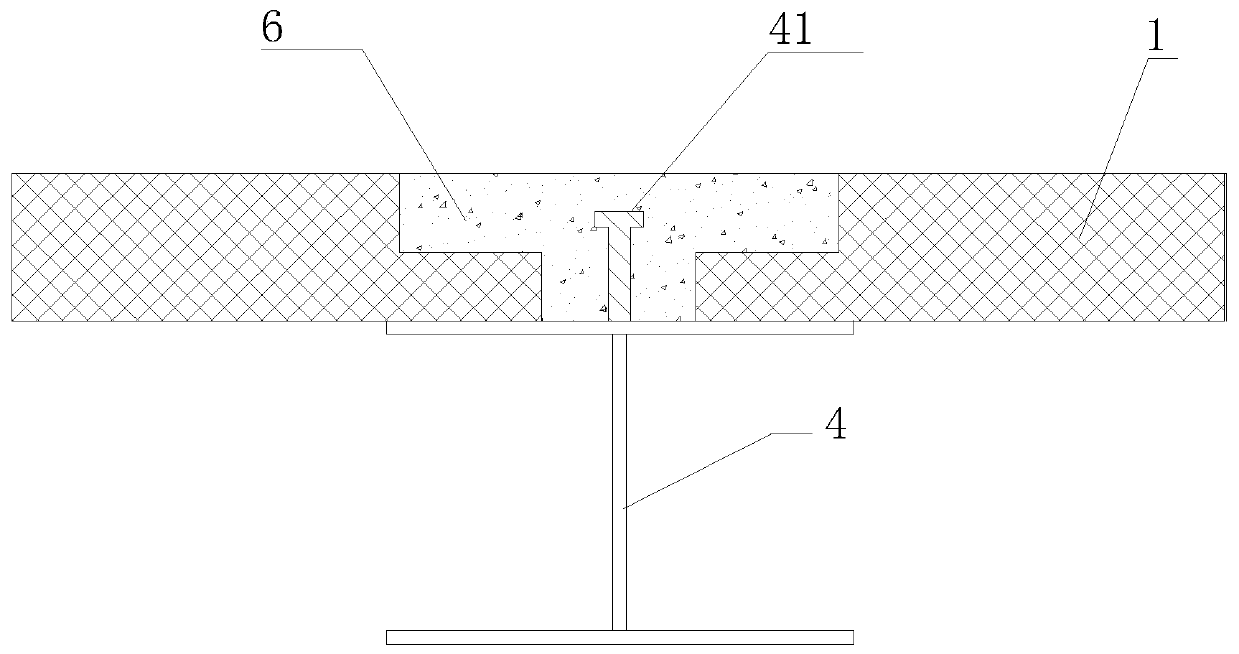

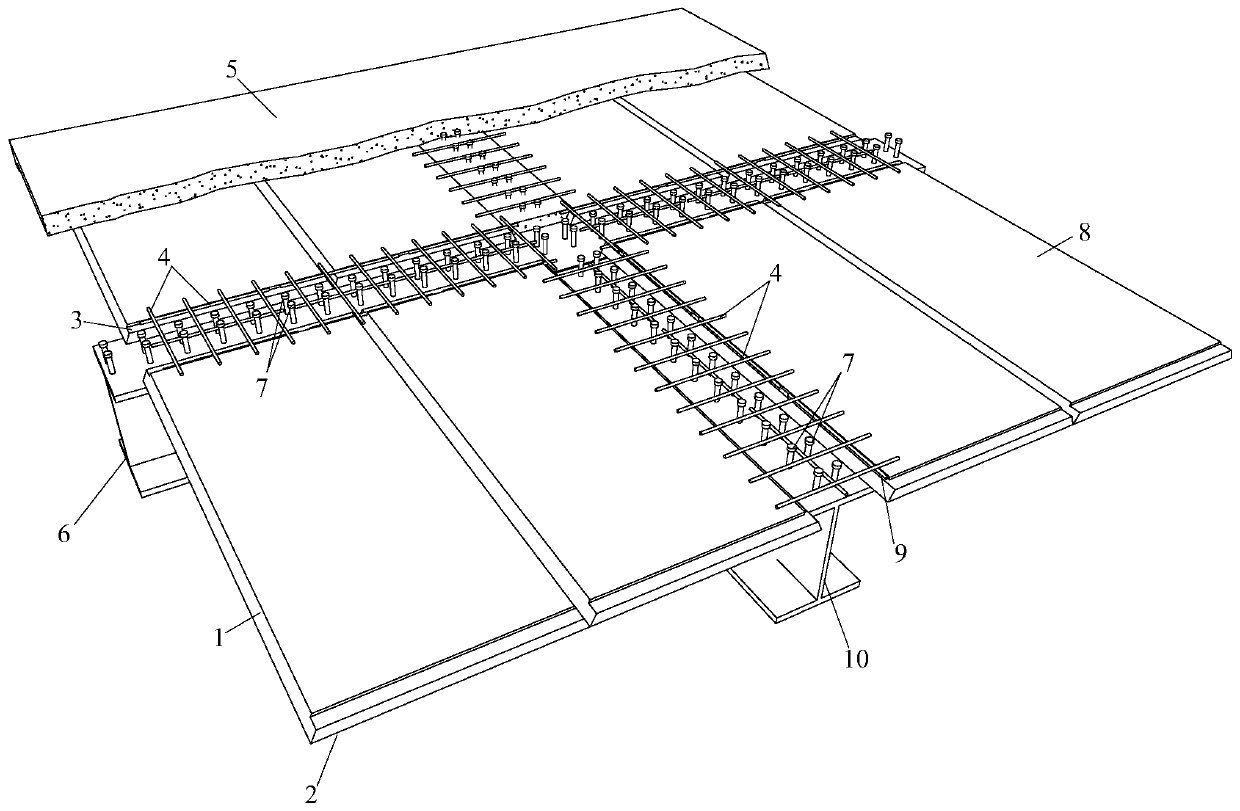

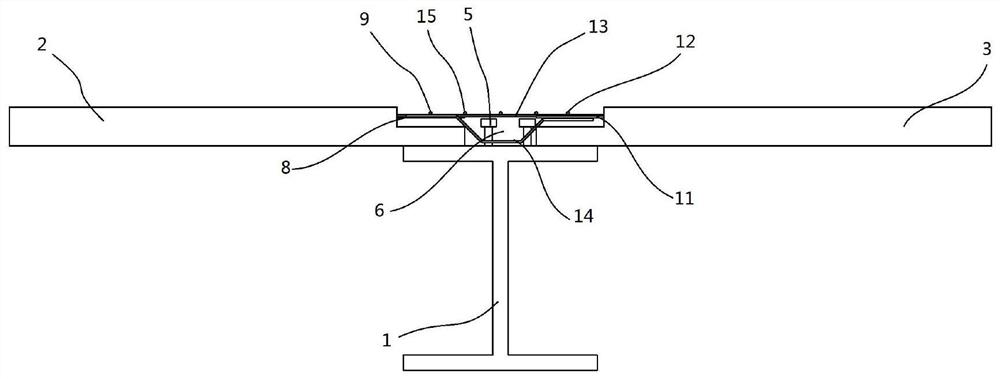

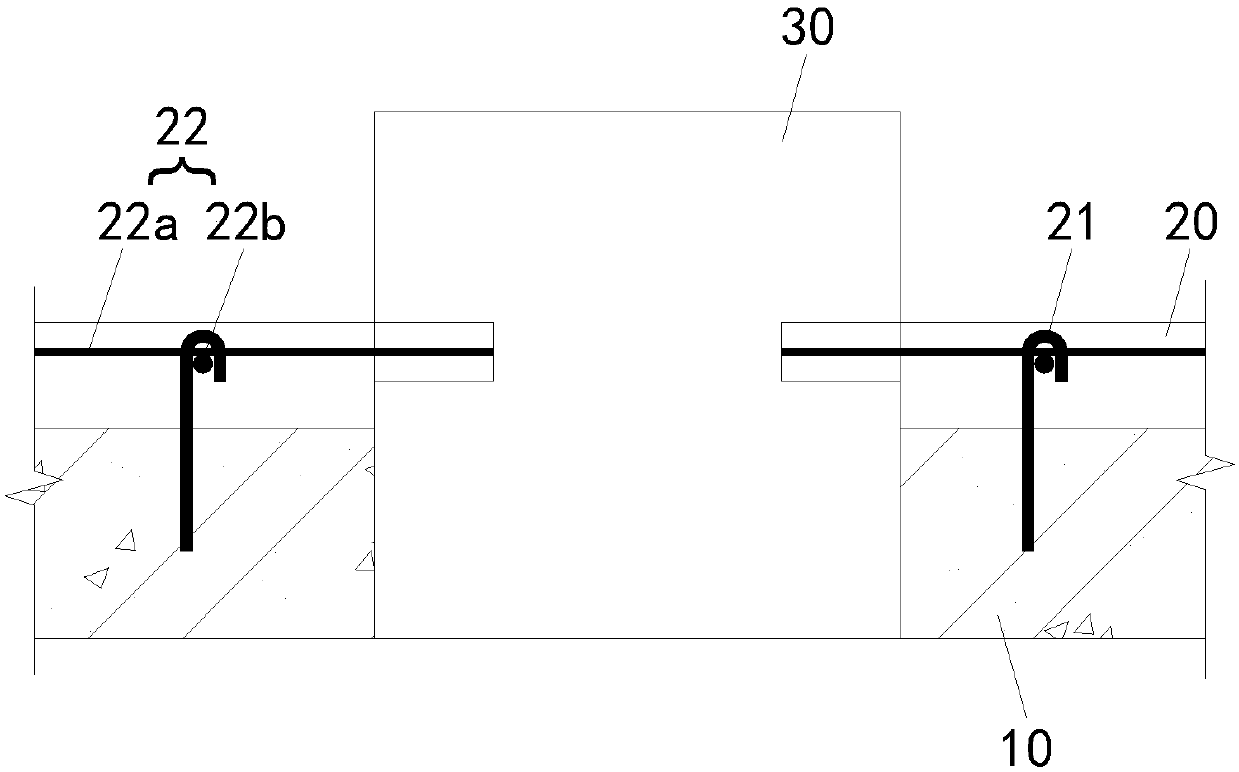

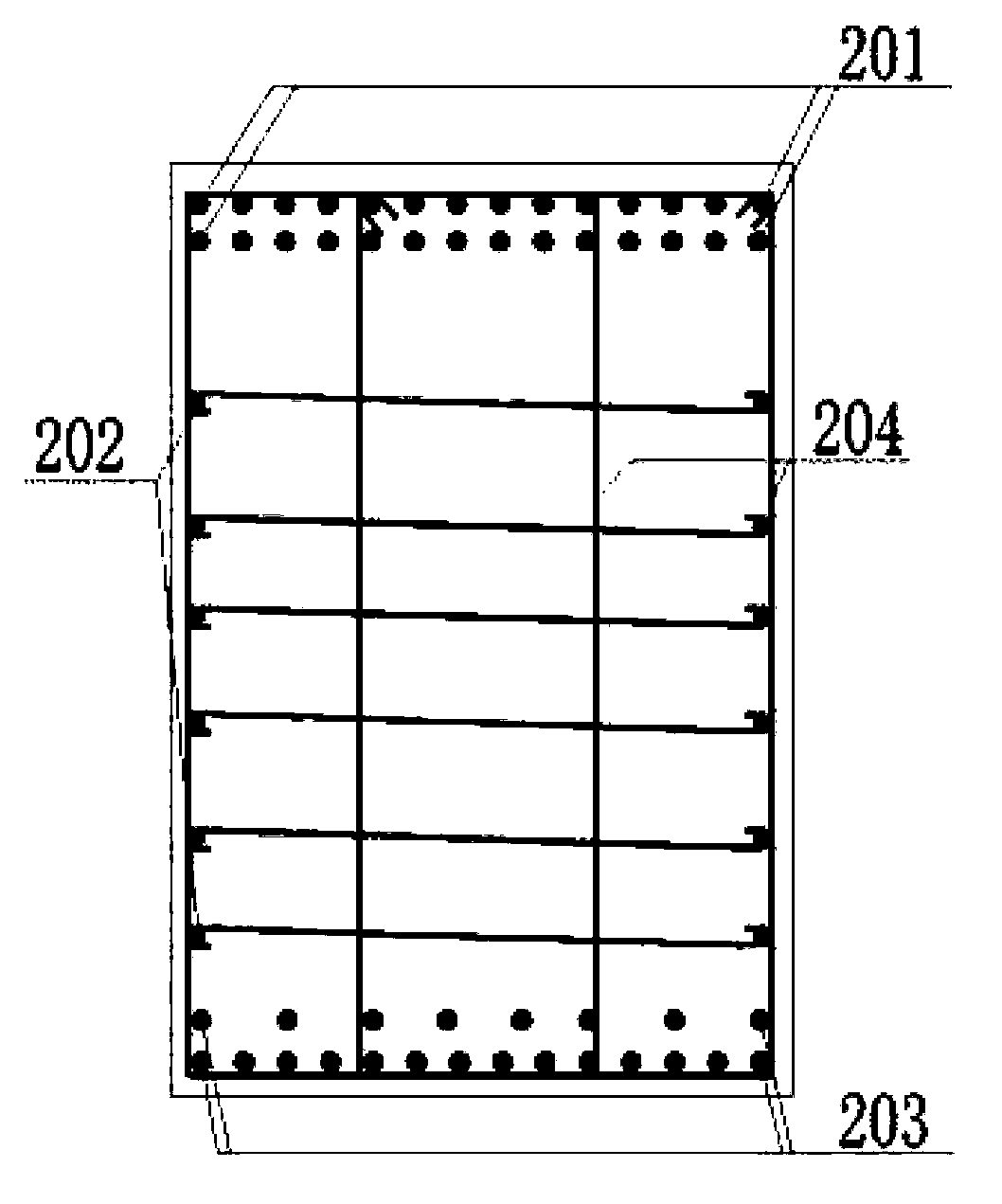

Full-fabricated floor slab assembled-type steel-concrete combined floor

PendingCN110847463ASimple structureImprove performanceClimate change adaptationFloorsFloor slabArchitectural engineering

The invention discloses a full-fabricated floor slab assembled-type steel-concrete combined floor. The floor comprises an H-shaped steel beam and floor slabs which are disposed on the beam. One or more rows of connection studs or other connectors are disposed on the H-shaped steel beam; the two adjacent floor slabs in the steel beam-floor slab connection position are placed on the two sides of theupper flange of the steel beam; the sections, in the joint connection position on the beam, of the floor slabs are in a step shape; V-shaped notches are formed in the lower portions of the steps in the spliced joint connection positions of the floor slabs; shear reinforcements are put in the notches, in the two sides of the spliced joints, of the floor slabs; reinforcements on the upper portionsof the steps in the spliced joint connection positions of the floor slabs extend out, and lap joint reinforcements are placed to be connected with the extend-out reinforcements of the floor slabs on the two sides of the spliced joints; and UHPC or ECC concrete materials fill in the space between the floor slabs on the two sides of the spliced joints and the steel beam. According to the floor, thestud connectors, the V-shaped notches in the floor slabs, the shear reinforcements, the lap joint reinforcement structure and the post-cast UHPC or ECC concrete materials are skillfully utilized, andreliable connection between the floor slabs and the steel beam is formed.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Fire-resistance enhancing method for the high strength concrete structure

ActiveUS20140068946A1Improve fire resistanceImprove structural performanceStrutsCeramic shaping apparatusHigh strength concreteFiber

Disclosed is a method of enhancing fire resistance of high-strength concrete by mixing a spalling reducer (fiber cocktail) into the concrete to control spalling and performing shear reinforcement of main steel bars using shear stiffeners based on a wire rope and spacers.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH

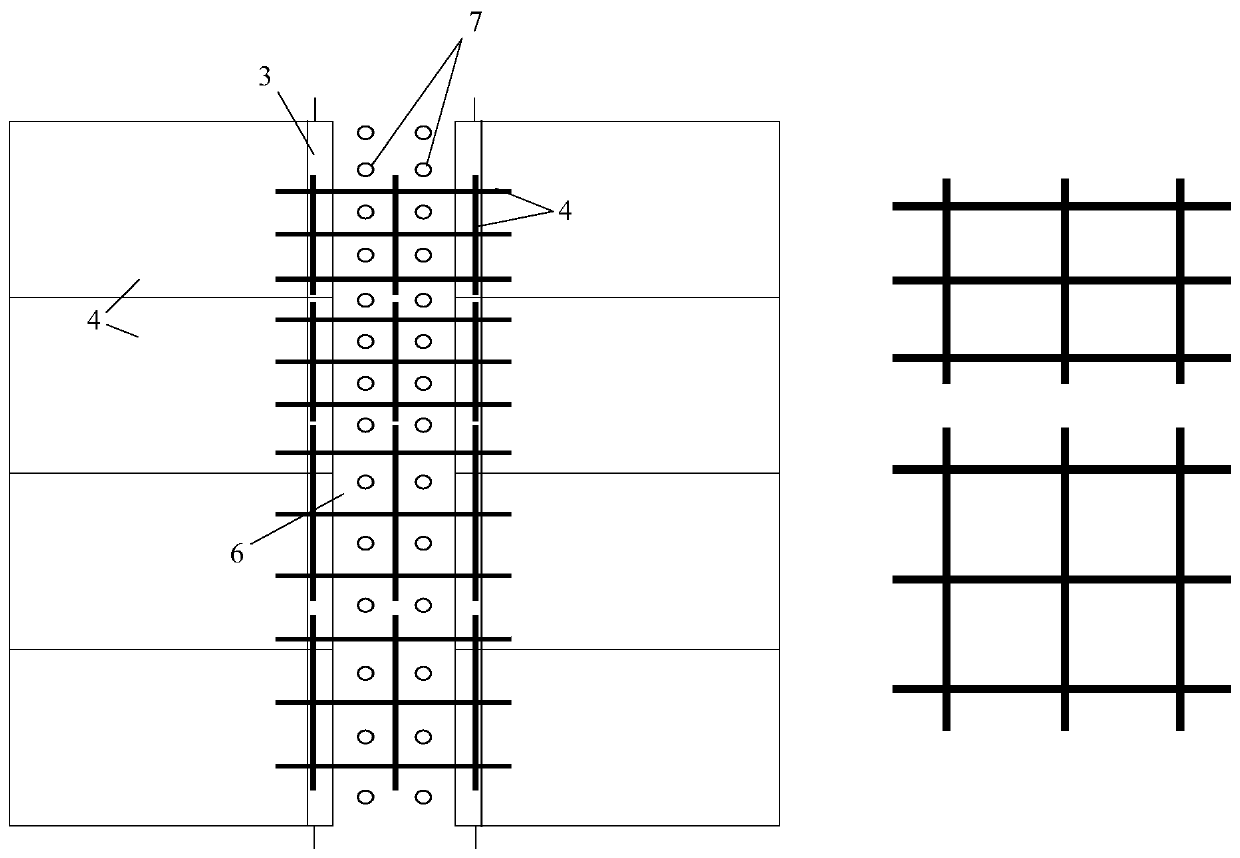

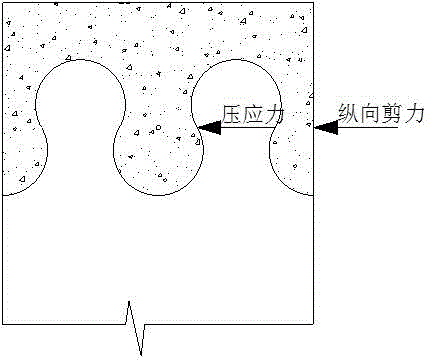

Longitudinal shear reinforcement and precast slab separated laminated slab composite beam

The invention relates to a longitudinal shear reinforcement and precast slab separated laminated slab composite beam, and belongs to the technical field of building structures. The longitudinal shearreinforcement and precast slab separated laminated slab composite beam comprises a concrete precast slab with a platform formed at the end, an additional reinforcement mesh unit and an upper concretepost-cast layer; no reinforcement stretches out of the slab end of the concrete precast slab with the platform formed at the end, meanwhile a step-shaped platform with the certain width is reserved atthe top of the precast slab, and the reinforcement mesh unit which is constituted by longitudinal and transverse reinforcements which are bundled is placed in the platform; and the transverse reinforcements play a longitudinal shear resistance role in the composite beam, the reinforcements in the beam length direction are parallelly placed in the step-shaped platform, and the positioning fixing effect is achieved. In the composite beam, traditional precast slab horizontal reinforcing bars are omitted, and through the modes that the step-shaped platform is formed at the slab end, and the reinforcement mesh unit is embedded, the longitudinal shear resistance problem of the composite beam and the longitudinal shear resistance reinforcement positioning problem are solved; and the longitudinalshear reinforcement and precast slab separated laminated slab composite beam is definite in force transmitting, convenient to construct, and suitable for laminated slab composite beam systems in thefields such as building engineering and bridge engineering.

Owner:TSINGHUA UNIV

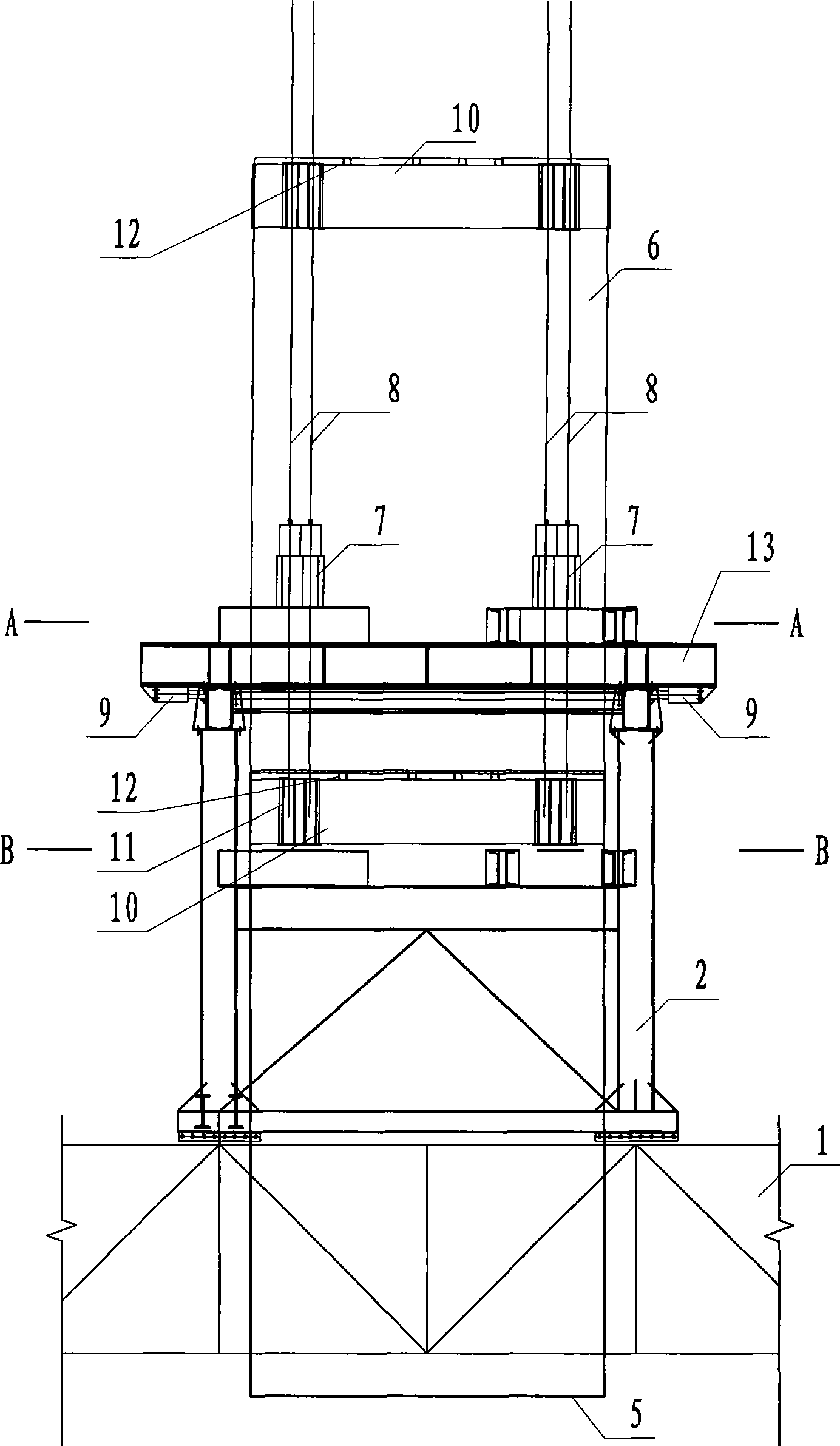

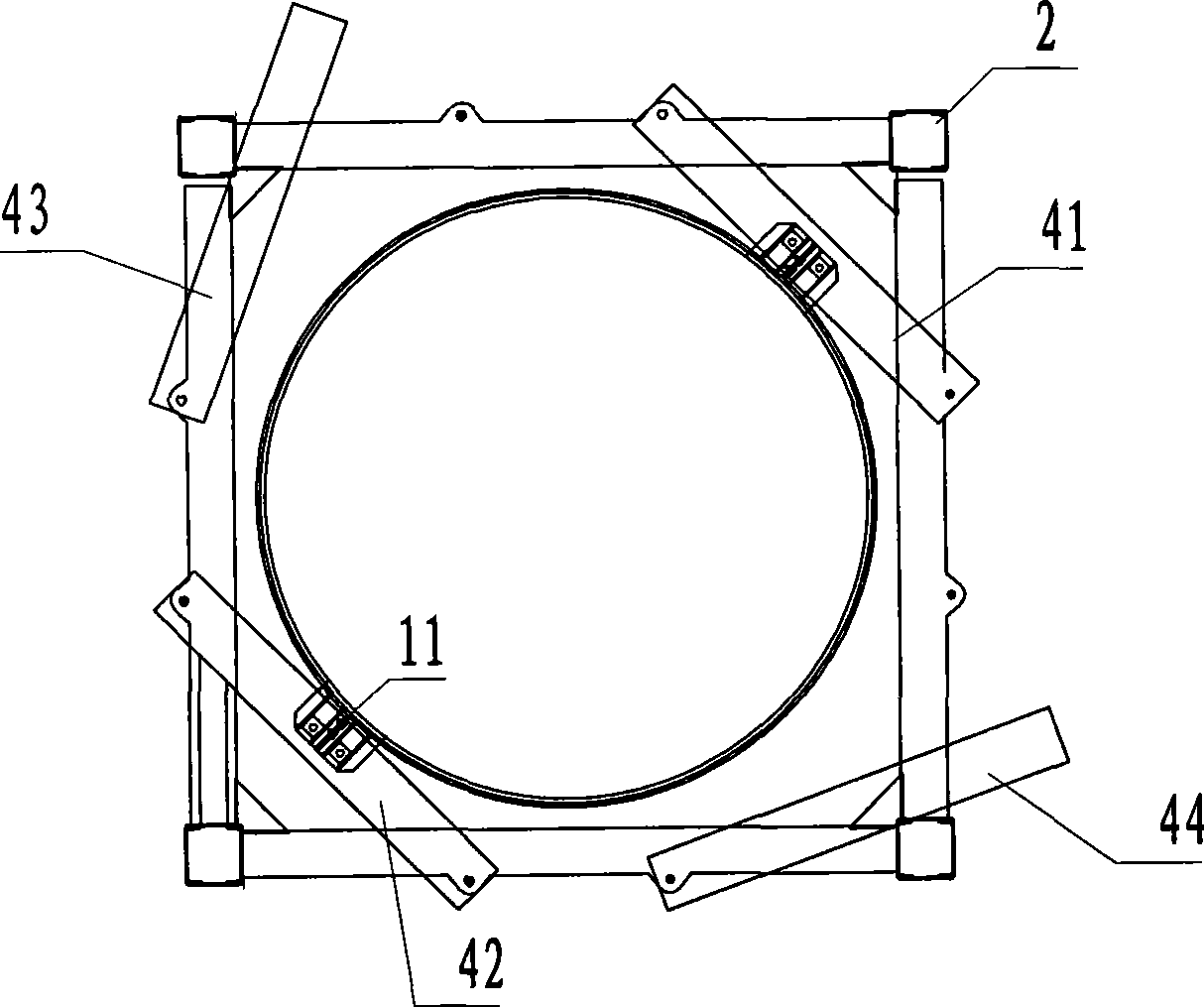

Dropping method for large-tonnage steel liner of drilled pile

The invention discloses a dropping method for large-tonnage steel liner of drilled pile. Being characterized in that a steel shield lower bracket is provided on the drilling platform; the lower bracket is provided with upper and lower supporting system; the upper supporting system is installed with a hanging lower lifting hack; the hanging lower lifting hack is connected to the steel shield lower bracket via the lower hanging bar; then the steel shield lower bracket is continuously hanged and gradually connected to the steel shield, circularly lowering. The invention is a new technology for large-tonnage steel liner of drilled pile. The advantages of the invention are following: 1, light and convenient lowering bracket structure; 2, equipment and materials used in the preparations are easy; 3, decentralization and devolution of hanging bars jack decentralization safe and reliable; 4, steel casing the overall decentralization process is simple and easy to operate; 5, shear reinforcement to prevent the sliding steel hoop decentralization and delegation of more safe and reliable; 6, movable box beam through the telescopic jack can be moved vertically and horizontally to precisely align the delegation of the location of steel casing.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP

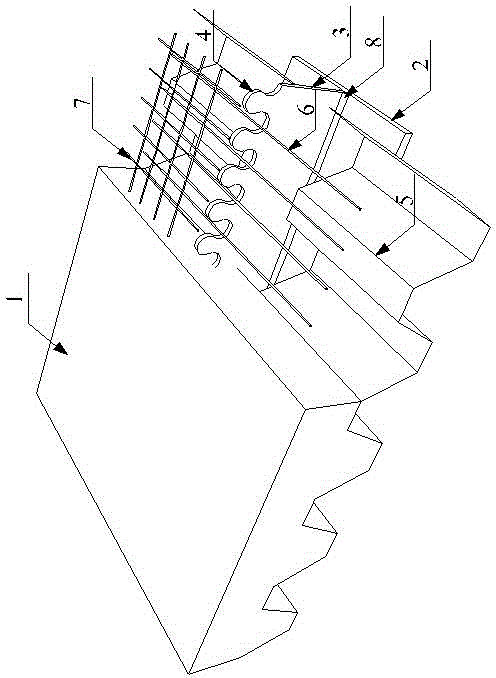

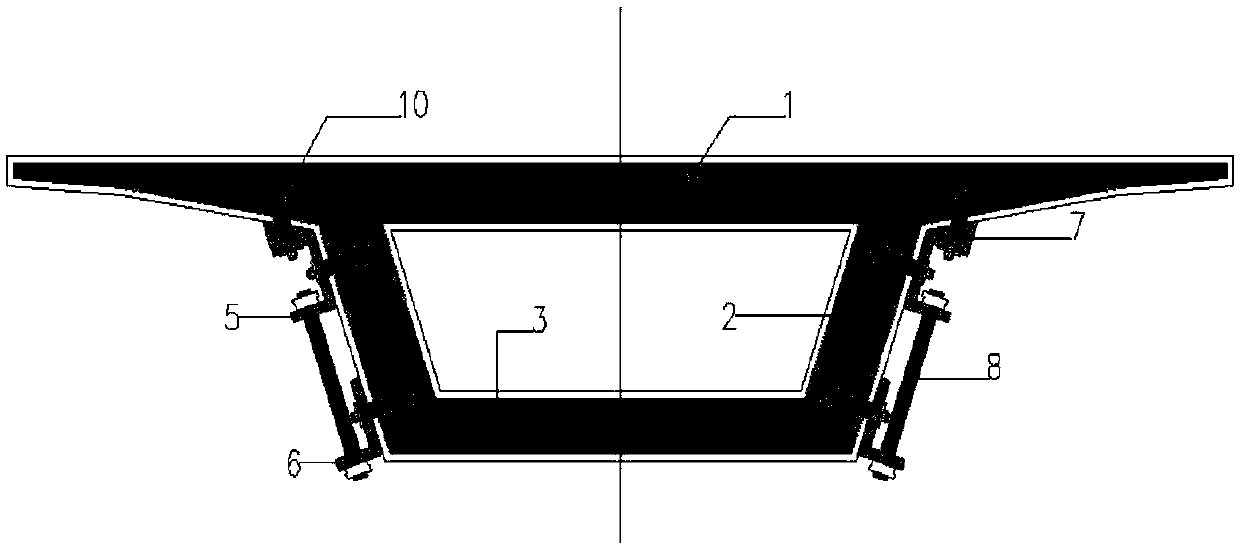

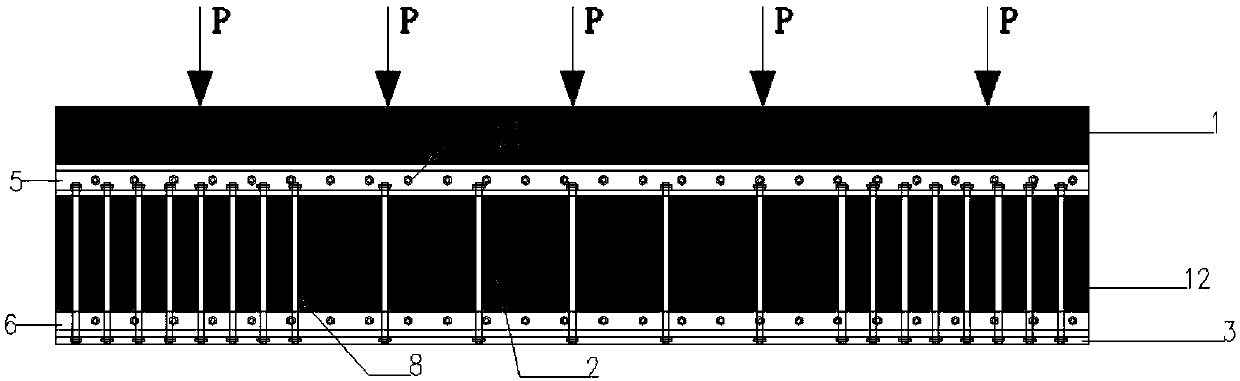

Combined flat beam

InactiveCN104100037AReduce the overall heightLow costLoad-supporting elementsFire proofingConstruction engineeringRebar

The invention belongs to the field of structural engineering of civil engineering and particularly relates to a combined flat beam which structurally comprises a steel beam, pressing steel plates, concrete and shear reinforcements, wherein the steel beam is inverted T-shaped and composed of a steel beam bottom flange and a steel beam web; the upper part of the steel beam web is provided with saw toothed shear connectors; the pressing steel plates are placed on the steel beam bottom flange; the concrete is poured in a closed space formed by the steel beam, the pressing steel plates and end sealing plates; the shear reinforcements are arranged among the saw toothed shear connectors, and one or more shear reinforcements can be placed in each interval. The combined flat beam is greatly shorter than a traditional combined beam, so that the cost in structure, maintenance, equipment and labor is also reduced; the steel beam is coated with concrete, so that the fire-resistant performance of the combined structure is greatly improved, effective transmission of shearing force between steel and concrete is ensured, the construction technology is simplified, and excellent economy is realized.

Owner:TONGJI UNIV

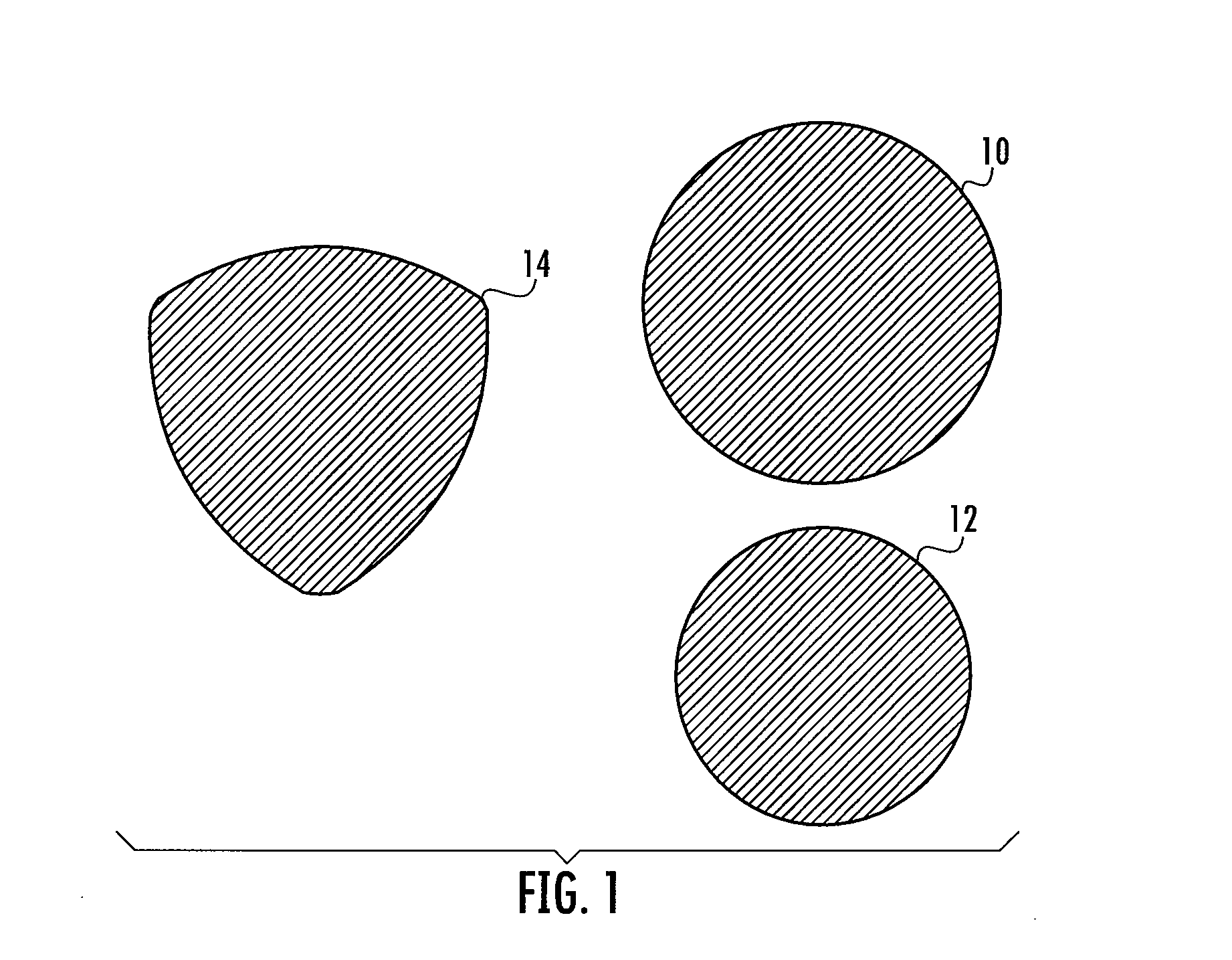

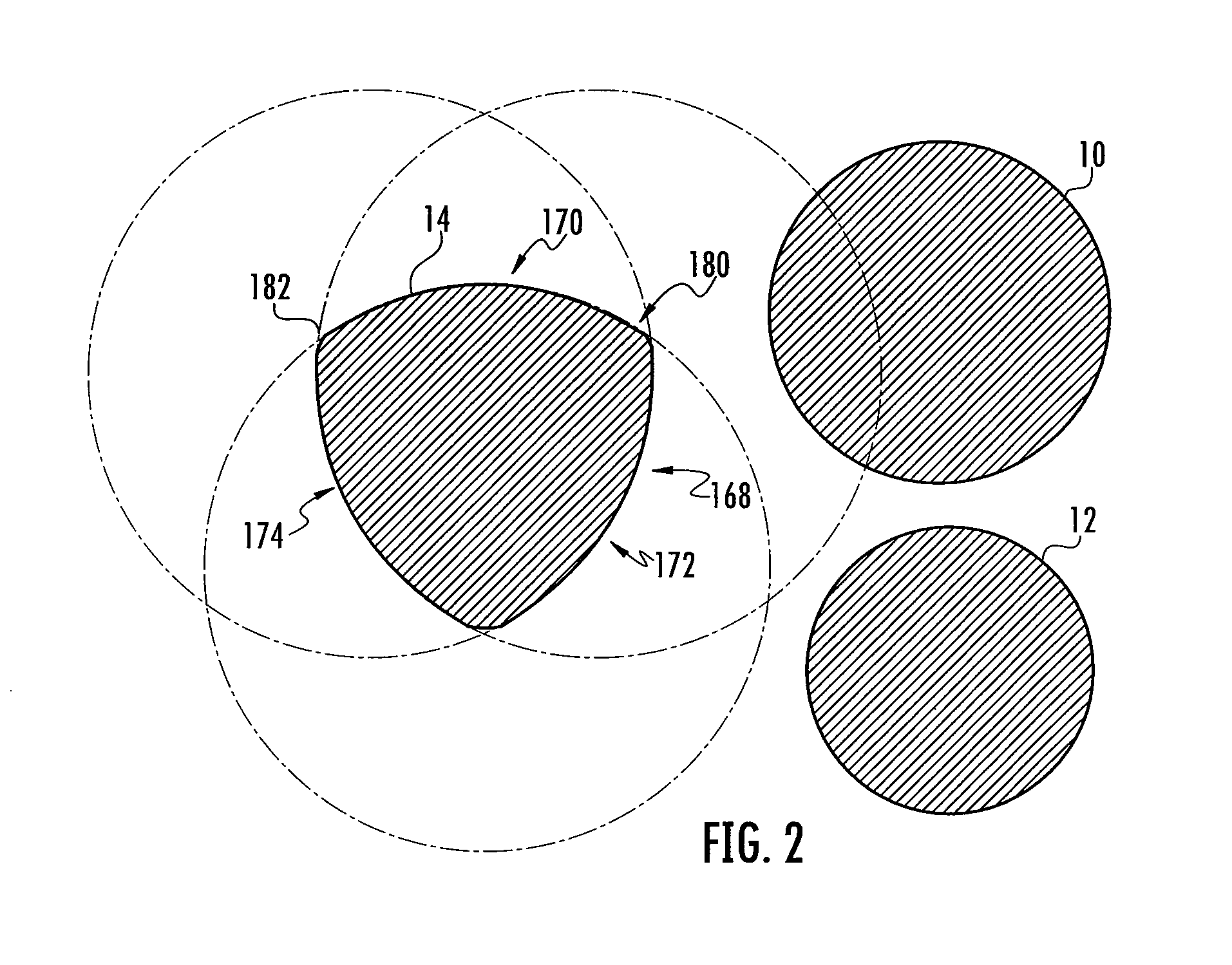

Basalt Basket and Dowel and Method of Manufacture

Basalt basket and dowel system to provide load transfer between adjoining slabs. The basket is designed as a placement jig to properly position dowels during the concrete placement phase of construction. Additionally to provide inherently tinsel and shear reinforcement to the edge of the concrete before during and after the contraction stress of curing concrete is relieved by scoring and to do so without the risk of rust spalling. The baskets and dowels are constructed from continuous basalt fibers admixed with an appropriate adhesive to produce the required strength and provide load predictions in a similar manner to steel calculations. The basalt basket is light weight and the configuration of its tendons interlaces provides sufficient space to allow concrete flow during placement and too prevent tinsel slippage within the cured concrete.

Owner:GLOBAL ENERGY SCI CALIFORNIA

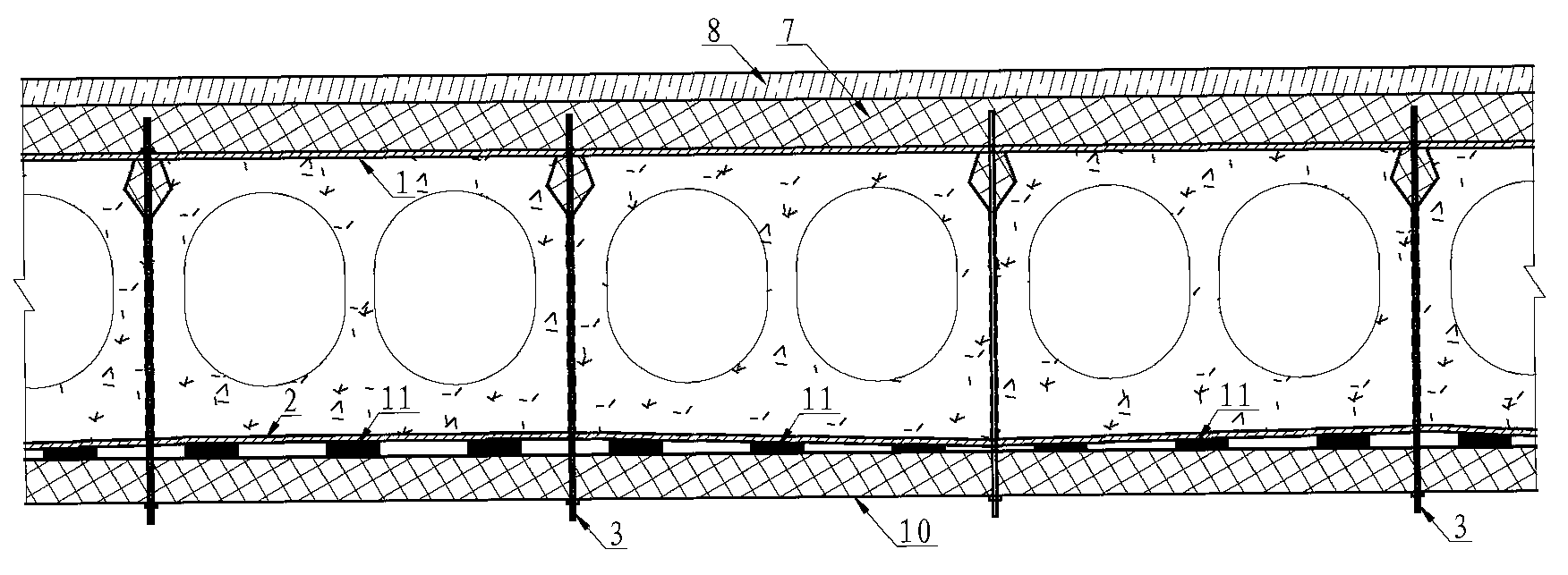

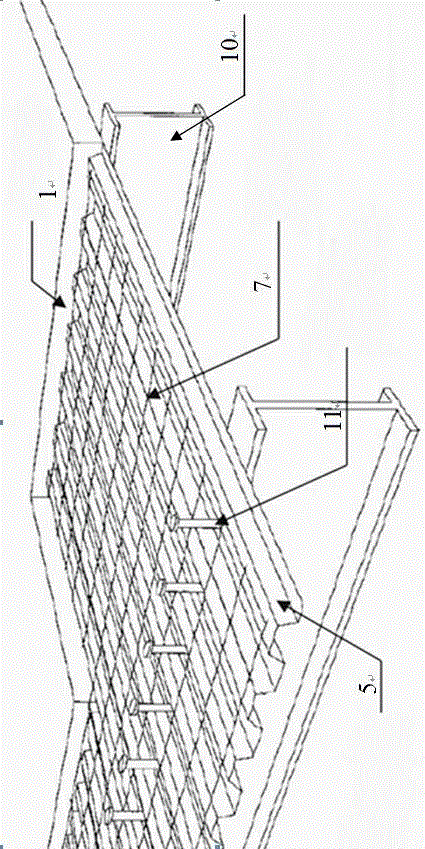

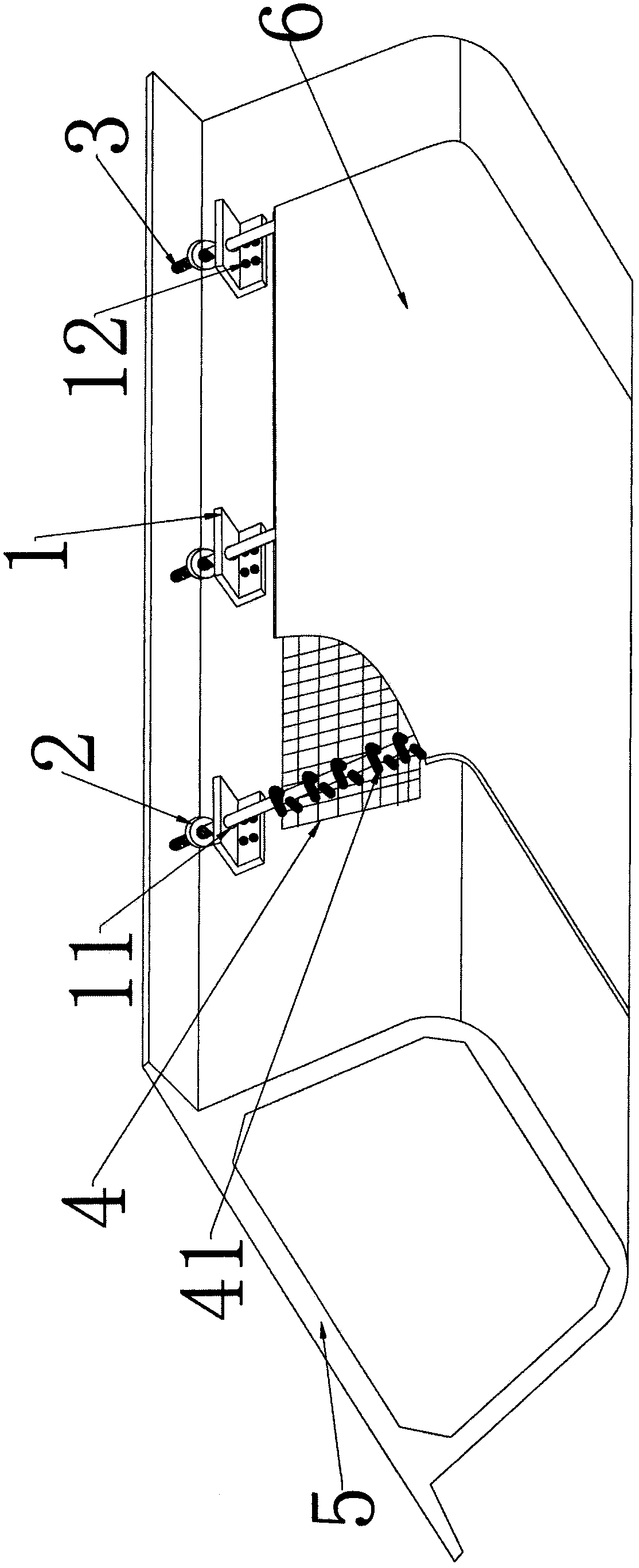

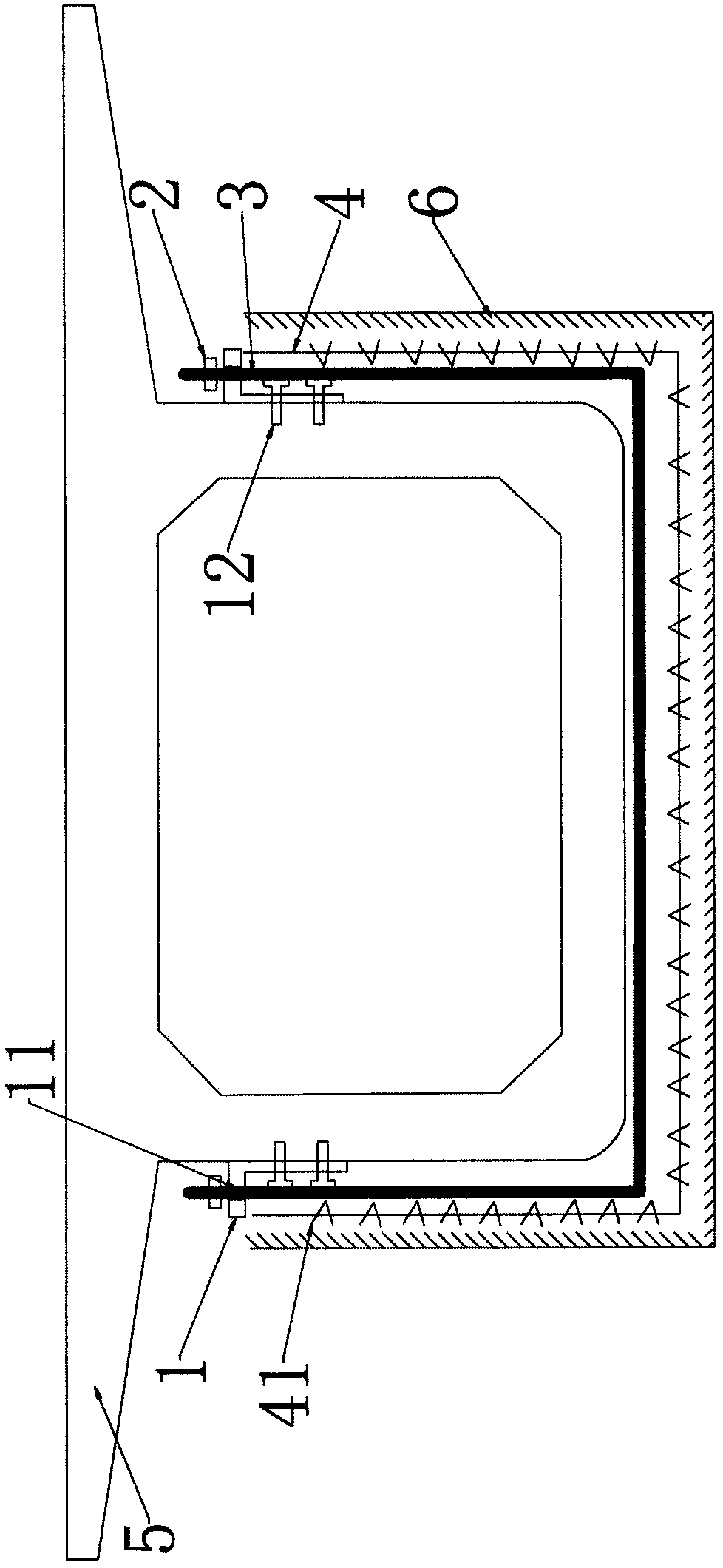

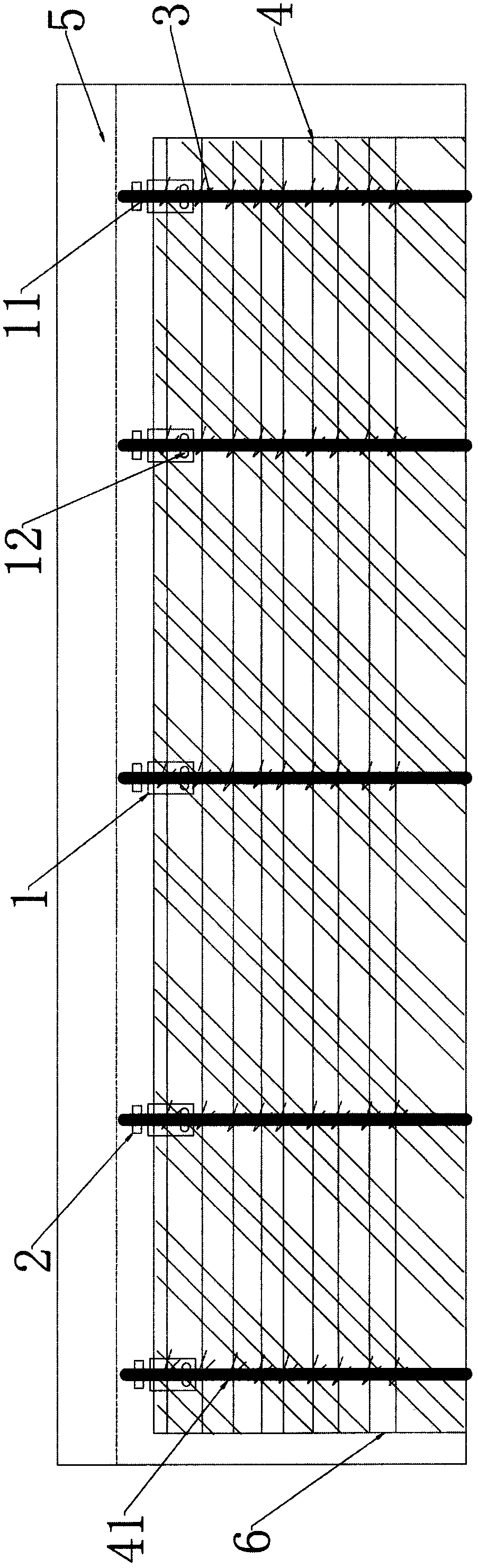

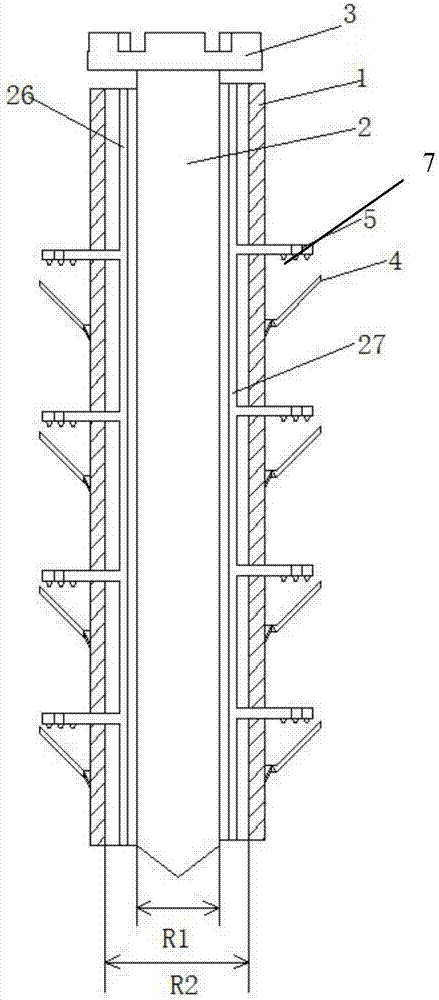

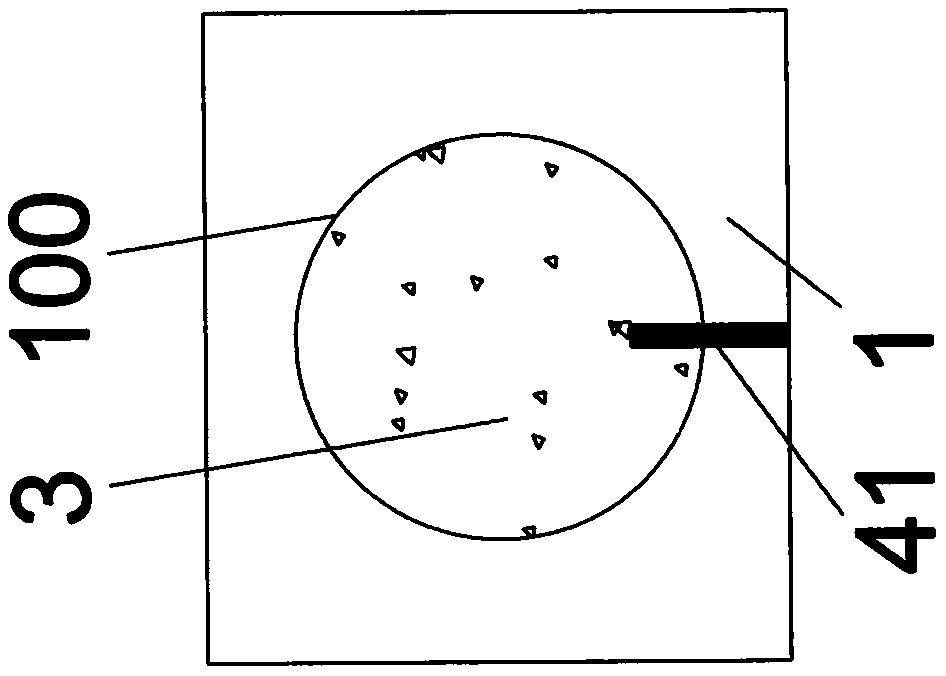

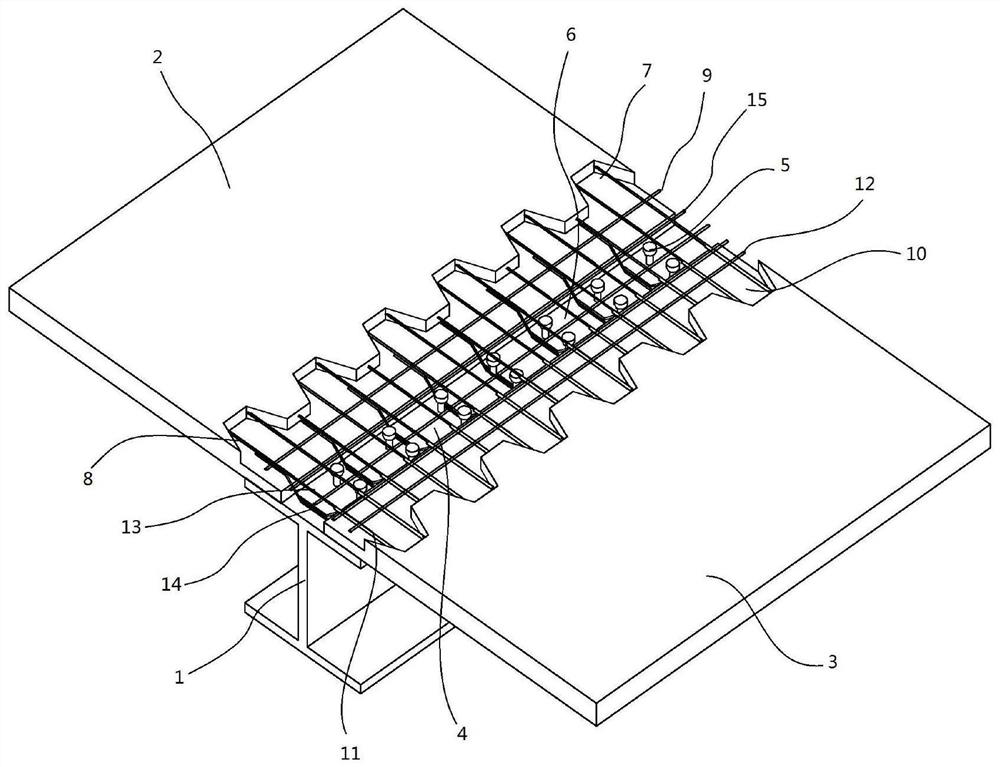

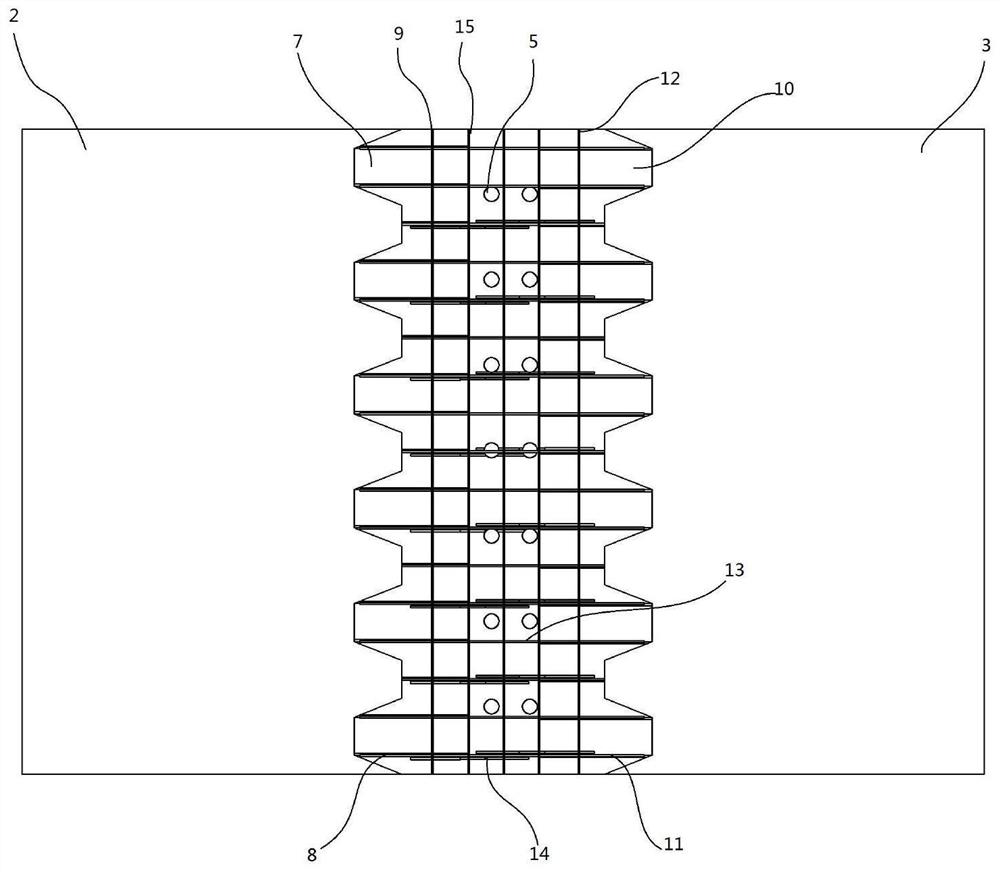

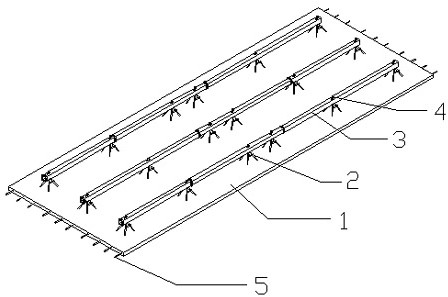

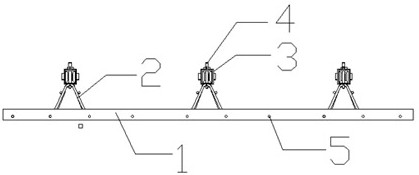

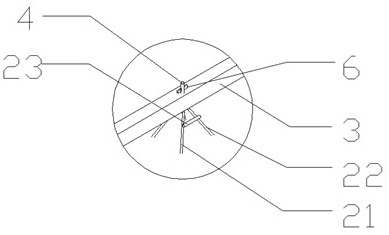

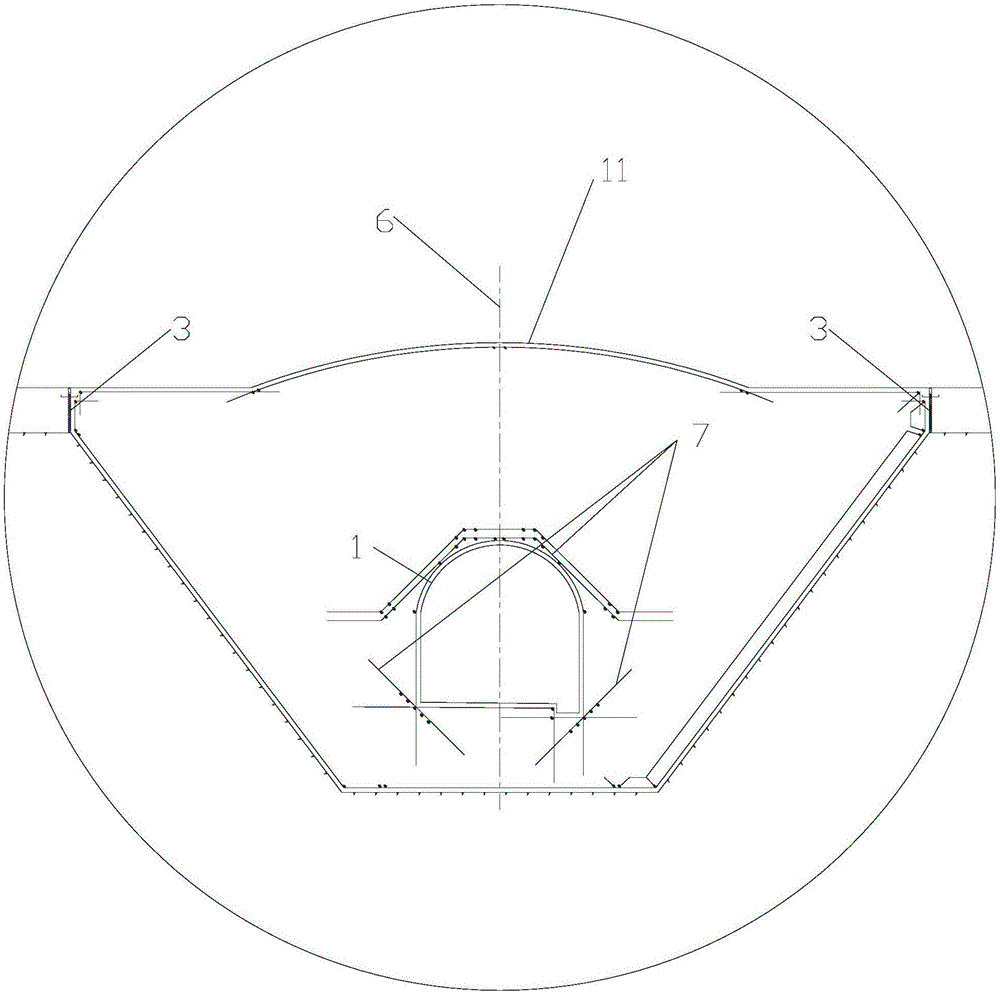

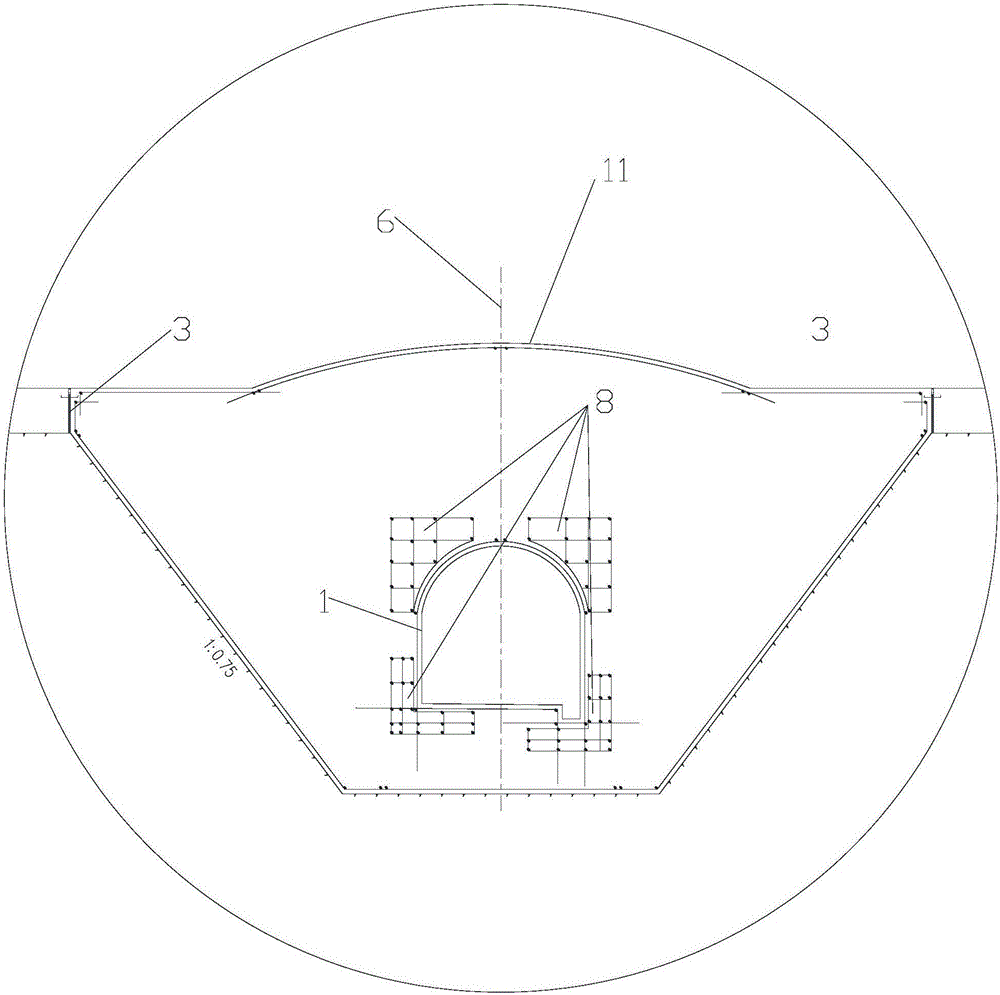

Prestressed U-shaped rid rapid shear-resisting and reinforcing box girder structure and method

PendingCN108894123AIncrease the lengthSmall sizeBridge erection/assemblyBridge strengtheningGratingPre stress

A prestressed U-shaped rid rapid shear-resisting and reinforcing box girder structure jointly comprises an angular anchoring device (1), an anchor ring (2), U-shaped ribs (3), grating ribs (4), a concrete box girder (5) and an anti-cracking mortar layer (6), the U-shaped ribs (3) are perpendicular to the axial direction of the concrete box girder (5) and are arranged at intervals in a U-shaped manner along the side surfaces and the bottom surface of the concrete box girder (5); the two ends of the U-shaped ribs (3) are fixed on the upper portions of the two side surfaces of the concrete box girder (5) through the angular anchoring device (1) and the anchor ring (2); the grating ribs (4) are hung on the outer surfaces of the side surfaces and the bottom surfaces of the concrete box girder (5); and the anti-cracking mortar layer (6) covers the U-shaped ribs (3) and the grating ribs (4) in modes of spraying, smearing or pouring, and is integrally combined to the concrete box girder (5). In the structure, by construction of the U-shaped ribs, prestress loss is reduced, the size of an anchor is also reduced, an anchoring space is decreased, and the reinforcing effect of the concrete boxgirder is continuous and effective.

Owner:NANJING FORESTRY UNIV

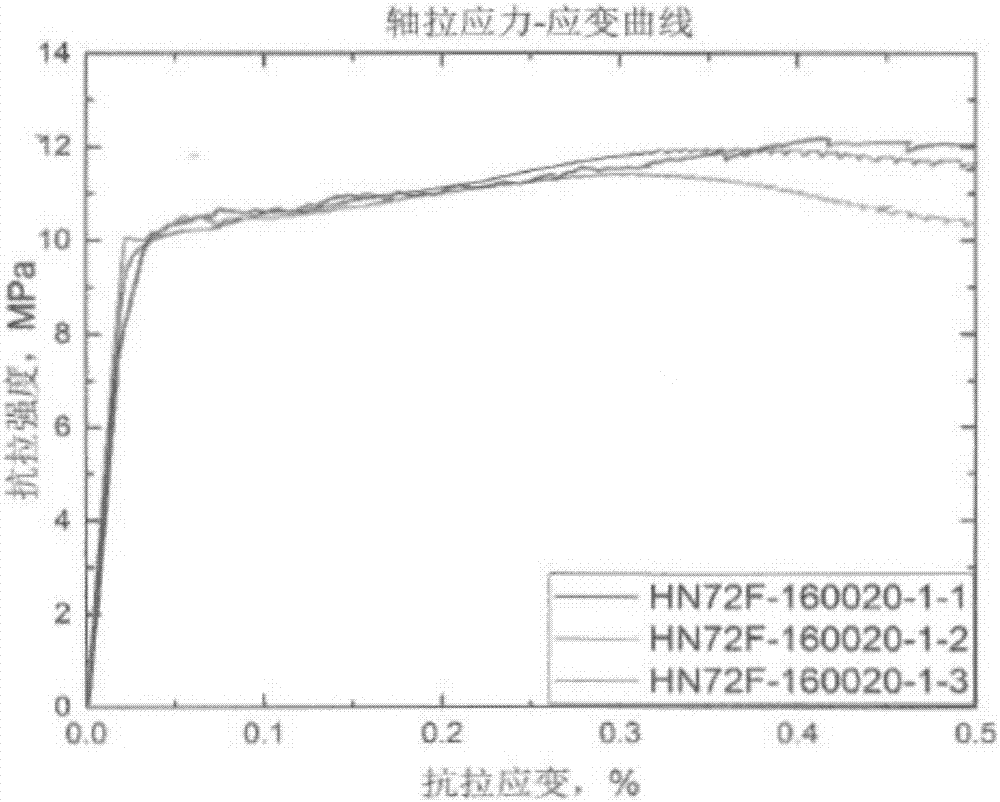

Reinforced concrete structure containing early strength type ultra-high performance concrete

InactiveCN107245947ASolve the problem of long curing time in high temperature steam curingReduce the impactBridge structural detailsBridge erection/assemblyTensile strainFiber

The invention relates to a reinforced concrete structure containing early-strength ultra-high-performance concrete, which includes a construction panel and a reinforced concrete structure body. The reinforced concrete structure body includes a steel skeleton and early-strength ultra-high-performance concrete poured into the steel skeleton , the upper part of the reinforced concrete structure body is provided with a wear layer, and the early-strength ultra-high performance concrete is composed of cement, fine admixtures, aggregates, admixtures, fibers and water, and has the following properties: 3h compressive strength is less than Less than 30MPa, 28d ultimate tensile strain not less than 3000με. Compared with the prior art, the early-strength ultra-high-performance concrete of the present invention has good ductility and is not easy to crack. It can coordinate deformation with the construction panel and improve the mechanical performance of the structure; the steel skeleton is a steel mesh shear structure, reducing The stress range in the construction panel under the action of the vehicle is reduced, and its durability is improved; the reinforced concrete structure is suitable for rapid maintenance of the bridge deck structure, and the impact of construction on traffic is minimized.

Owner:浙江宏日泰耐克新材料科技有限公司

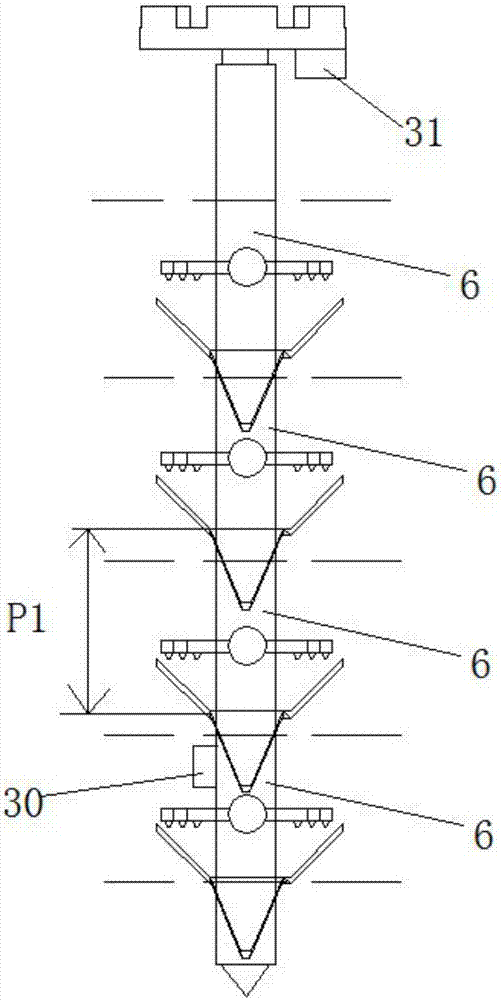

An intelligent monitoring type ground pile

InactiveCN107123217AImprove shear resistanceHigh strengthSoil lifting machinesMeasurement devicesShear capacityEngineering

The invention relates to an intelligent monitoring ground pile, which has a simple structure and low processing difficulty. Without affecting the stability, the number of four-claw platforms and irrigation devices can be selected according to needs, effectively saving costs; There are several four-claw platforms on the top, which increases the contact area between the ground pile and the soil, enhances the shear resistance and strength of the ground pile; through the independent design of the inner cylinder and outer cylinder of the ground pile, the functionality and performance are enhanced. Practicality; through the soil pH sensor, PLC controller and irrigation device, the monitoring and regulation of the pH of the farmland is realized.

Owner:江苏德溢利新材料科技有限公司

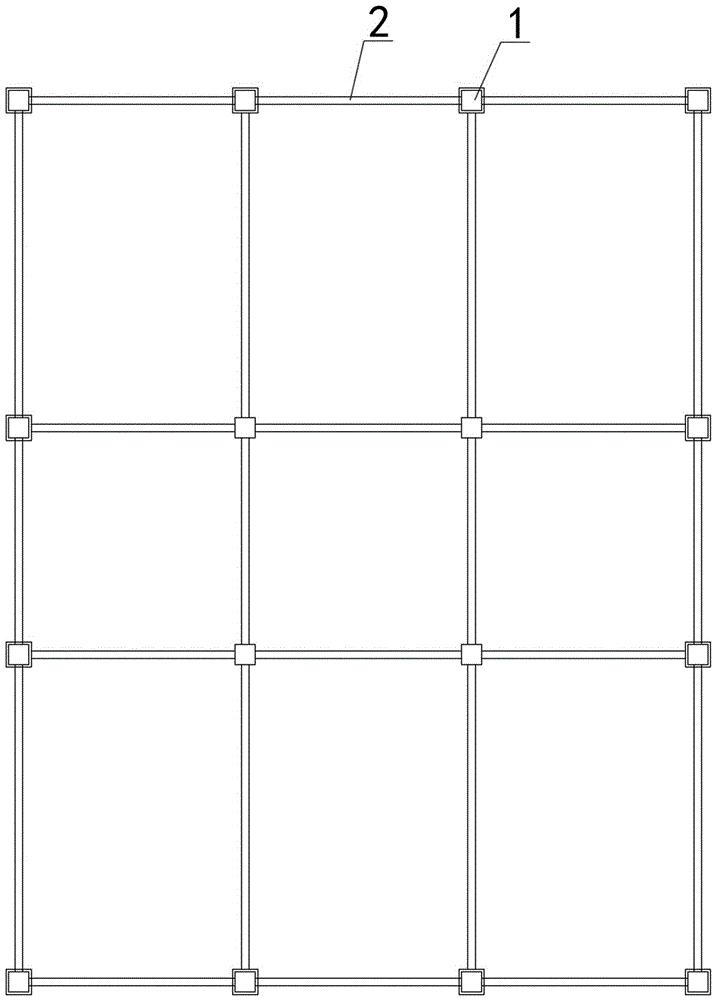

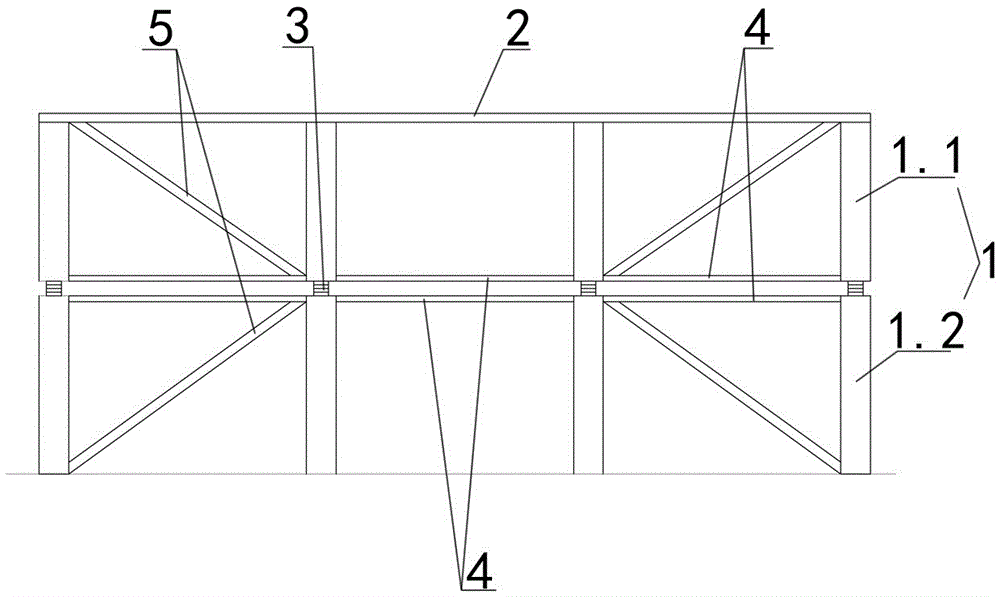

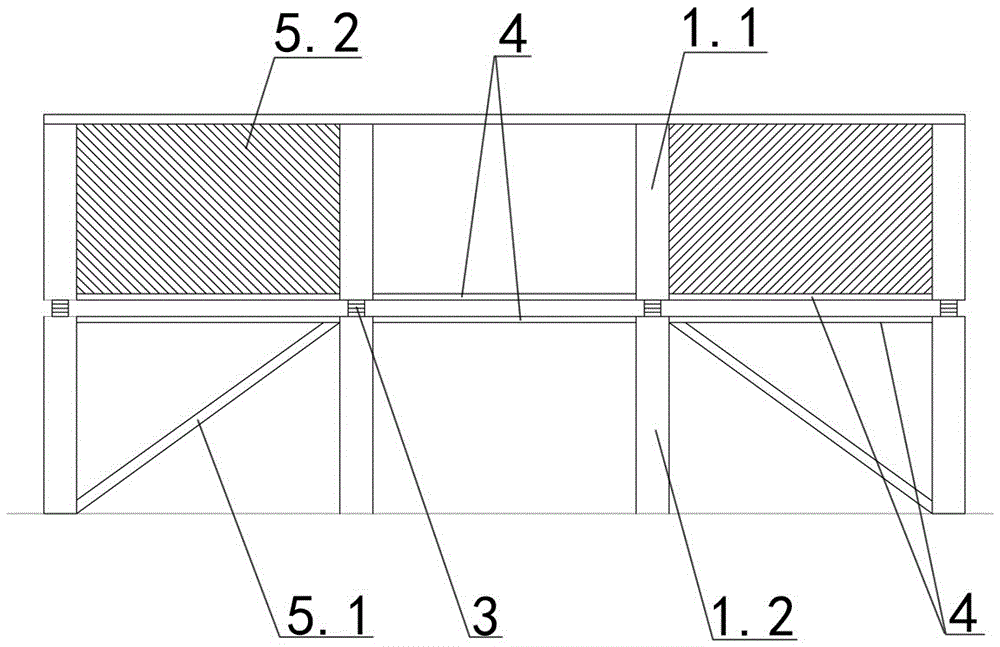

Framework or frame shear reinforcement and reconstruction structure and construction method thereof

ActiveCN106121270AImprove seismic performanceReduce horizontal displacementBuilding repairsProtective buildings/sheltersDevice implantEarthquake resistance

Provided are a framework or frame shear reinforcement and reconstruction structure and a construction method thereof. The framework or frame shear reinforcement and reconstruction structure comprises an original framework column and an original beam plate, and further comprises an earthquake isolation device implanted in the cut-off position of the original framework column, an additional horizontal connection component for inter-column connection of the cut-off position, and an additional lateral load resisting component for reinforcing the additional horizontal connection component. The original framework column is divided into an upper column body and a lower column body with the cut-off position as a boundary. The upper side of the earthquake isolation device is connected with the lower side of the upper column body. The lower side of the earthquake isolation device is connected with the upper side of the lower column body. The additional horizontal connection component is connected between the inner side of the bottom of the upper column body and the inner side of the top of the lower column body. The additional horizontal connection component is connected with the upper column body or the lower column body in a bonded or bolted mode or through embedded steel bars or expansion bolts. By means of the framework or frame shear reinforcement and reconstruction structure, the earthquake resistance of a main structure of a house is greatly improved, the degree of damage to the main structure and non-structural components in the house is decreased, horizontal shift of the framework column in case of an earthquake is reduced, the portions, above and below the earthquake isolation device, of the framework column are limited from horizontally shifting, and the overall earthquake resistance of the framework or frame shear structure is improved.

Owner:姚攀峰

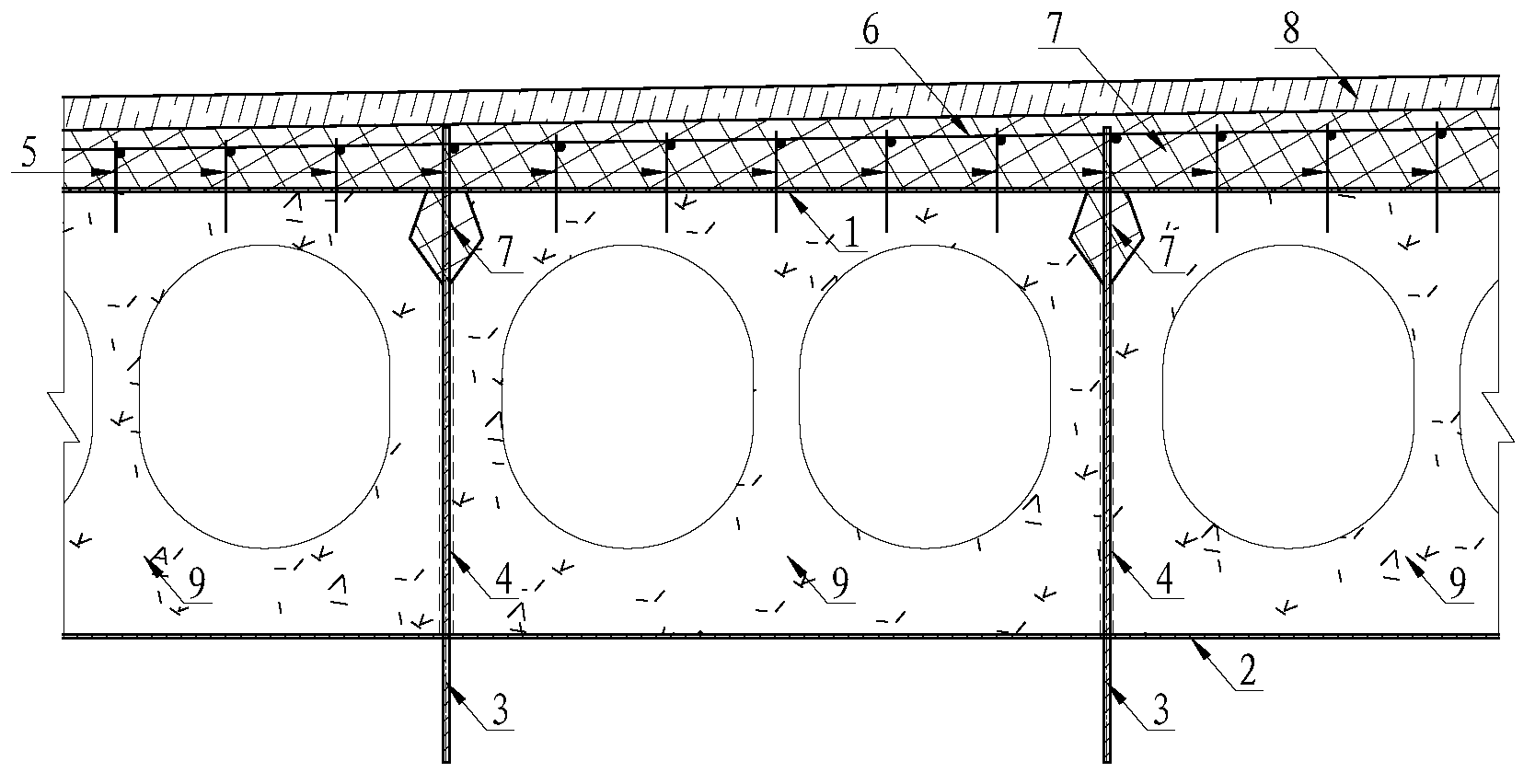

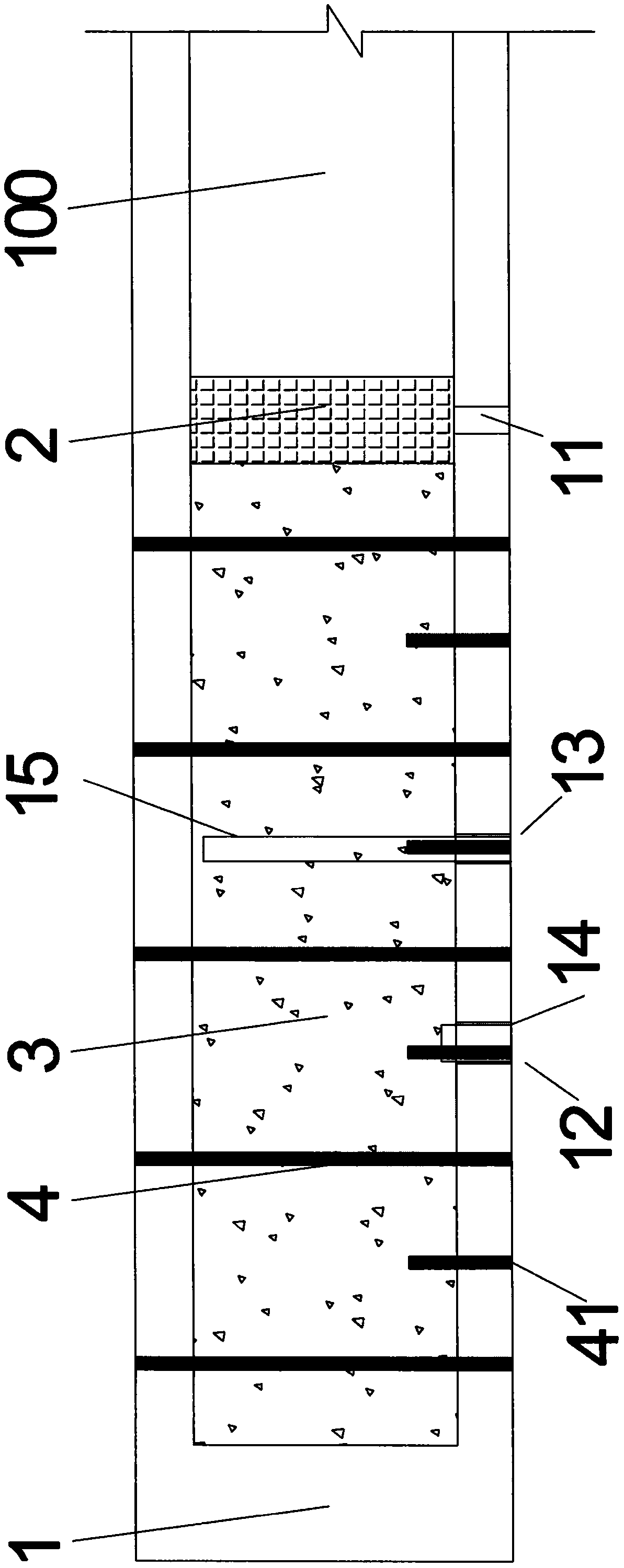

Shear-resistant reinforcing method for small-section hollow beam

PendingCN111364374AImprove construction efficiencyIncreased shear capacityBridge erection/assemblyBridge strengtheningClassical mechanicsRebar

A shear-resistant reinforcing method for a small-section hollow beam Is characterized in that shear-resistant reinforcement of a hollow beam is achieved by forming a hole in the bottom of the hollow beam, burying a pipe, arranging a plugging object to plug the inner end of a cavity of a to-be-reinforced area, pouring a reinforcing body into the cavity of the to-be-reinforced area of the hollow beam, drilling the bottom of the hollow beam from bottom to top and implanting shear-resistant steel bars penetrating through the reinforcing body and the bottom plate and the top plate of the hollow beam. The method can be achieved on the premise that traffic is not interrupted, the appearance of the hollow beam is not changed, the connecting keys effectively connect the reinforcing body and the existing beam body into a whole, the shear-resistant steel bars and the reinforcing body act together, the shear-resistant bearing capacity of the hollow beam is improved, the reinforcing effect is greatly improved, the operation steps are simple, and the construction efficiency is high.

Owner:NANJING FORESTRY UNIV

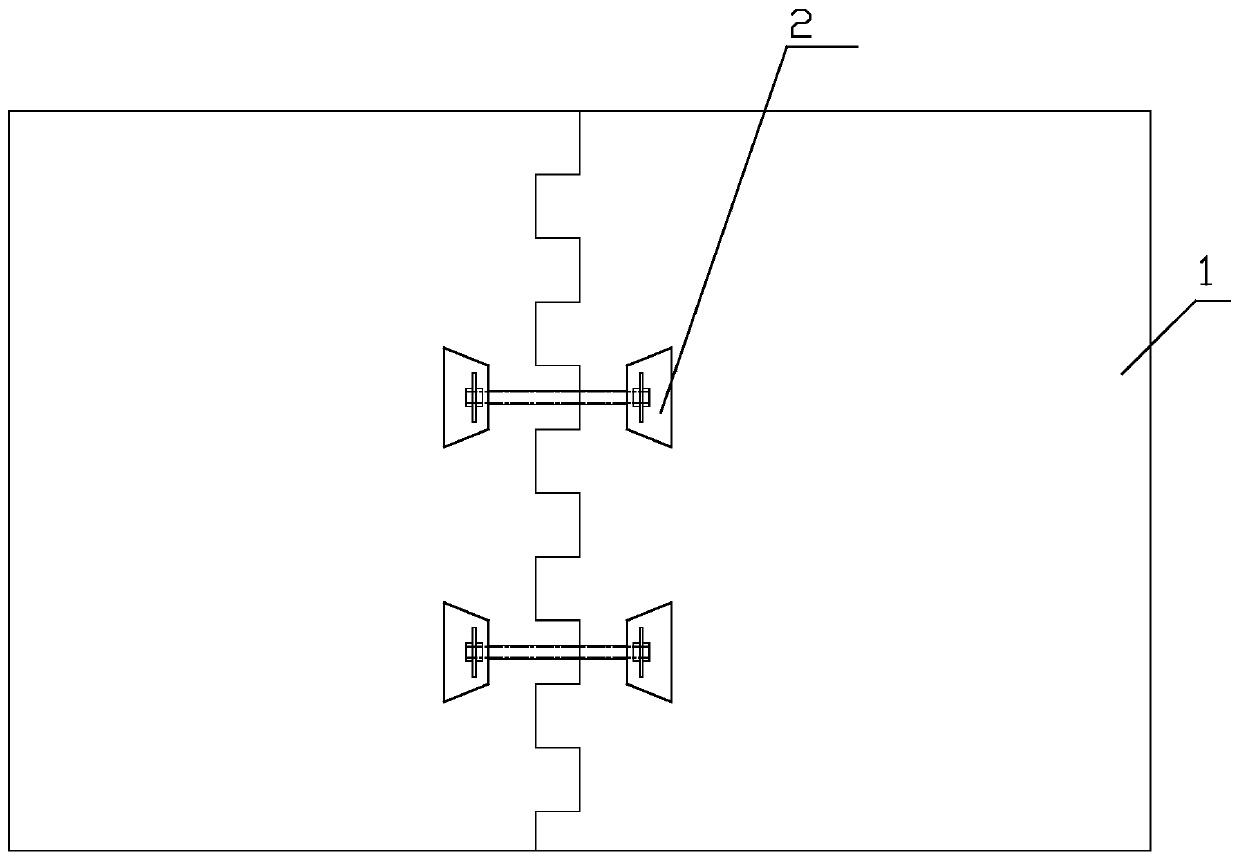

Fabricated floor slab wet connection knot and connection method

PendingCN111677136AImprove performanceImproved performance, shock resistanceFloorsFloor slabShaped beam

The invention discloses a fabricated floor slab wet connection knot and a connection method. The knot comprises a I-shaped beam, a first prefabricated floor slab and a second prefabricated floor slab;a plurality of studs are evenly fixed on the I-shaped beam; the first prefabricated floor slab and the second prefabricated floor slab are correspondingly located at two sides of the studs and form amounting groove; the first prefabricated floor slab is provided with a first groove; the first groove is internally provided with a plurality of first protruding steel bars; a first distributed steelbar is fixed on the plurality of protruding steel bars; the second prefabricated floor slab is provided with a second groove; the second groove is internally provided with a plurality of second protruding steel bars; a second distributed steel bar is fixed on the plurality of second protruding steel bars; corresponding second protruding steel bars and the first protruding steel bars are all interconnected and fixed through additional steel bars, and a plurality of U-shaped shear reinforcement bars are arranged at intervals in the mounting groove; and concrete is poured in the mounting groove,the first groove and the second groove.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Shearing-resisting reinforcement structure for junction domain where connecting beam and wall beam of concrete shear wall are connected

PendingCN111140031AImprove shear mechanical propertiesImprove shear resistanceBuilding repairsProtective buildings/sheltersEarthquake resistanceClassical mechanics

The invention discloses a shearing-resisting reinforcement structure for a junction domain where the connecting beam and the wall beam of a concrete shear wall are connected. The junction domain wherethe connecting beam and the wall beam of the concrete shear wall are connected is reinforced by a rectangular steel plate, wherein the rectangular steel plate the concrete shear wall are anchored through the opposite penetration of high-strength bolts; the side surface of the connecting beam is laterally evenly divided into a plurality of same square unit modules; the top of each square unit module is provided with L-shaped angle iron and a rectangular steel belt; a square steel plate is inlaid in the center of each square unit module through a drilling way, and each square steel plate and the connecting beam are in opposite penetration connection through a high-strength bolt; and each square steel plate is connected with the vertex of each square unit module in a welding way through an inclined shearing-resisting steel plate, wherein the connection way can improve the integral shearing-resisting bearing capacity of the connecting beam and perform a certain protection function for a sub-structure formed by the shear wall and the connecting beam. The shearing reinforcement structure has the characteristics of being reasonable in stress, clear in force transfer, simple in construction and high in shearing-resisting bearing force and anti-seismic properties.

Owner:NANJING UNIV OF TECH +1

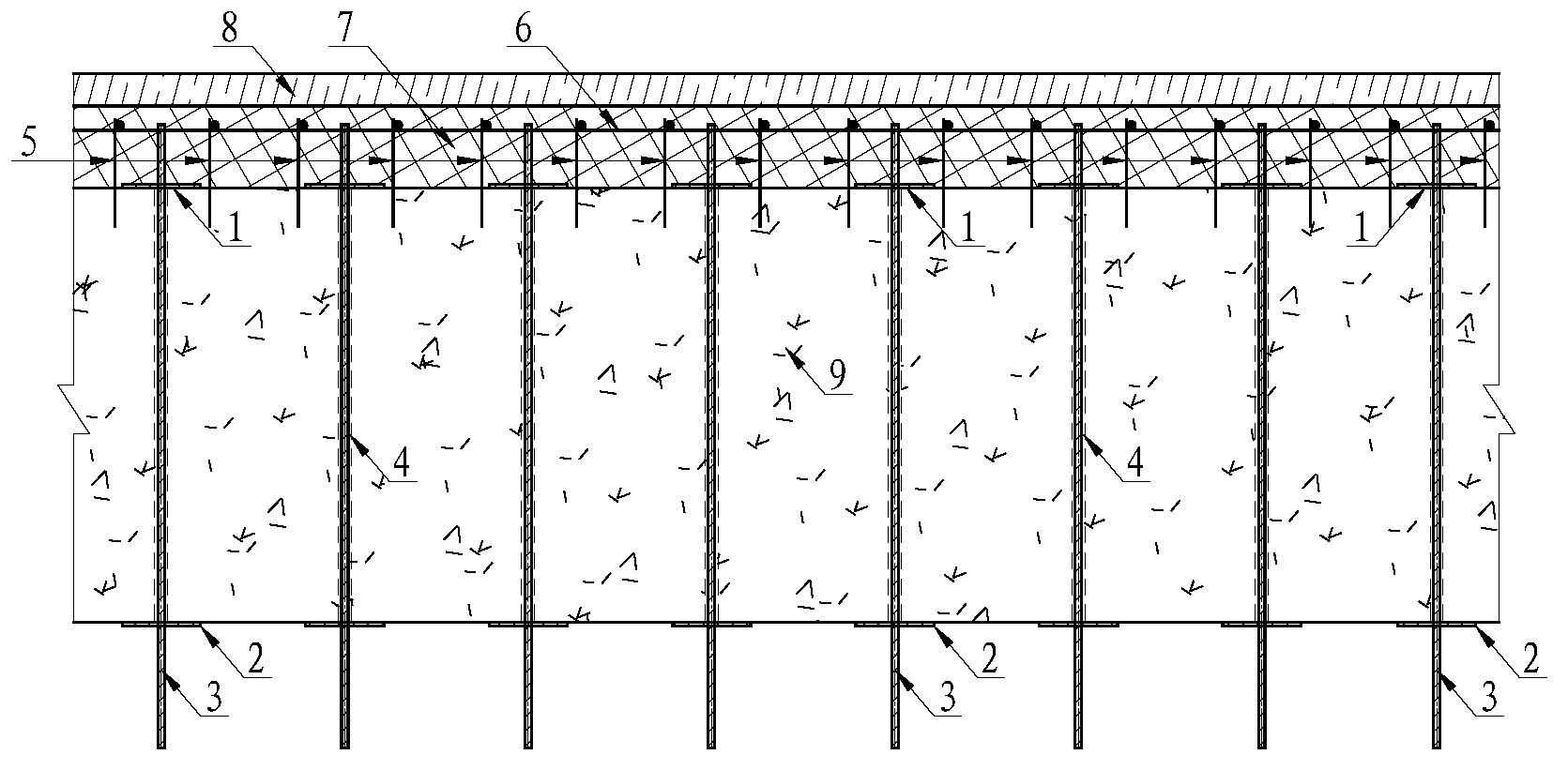

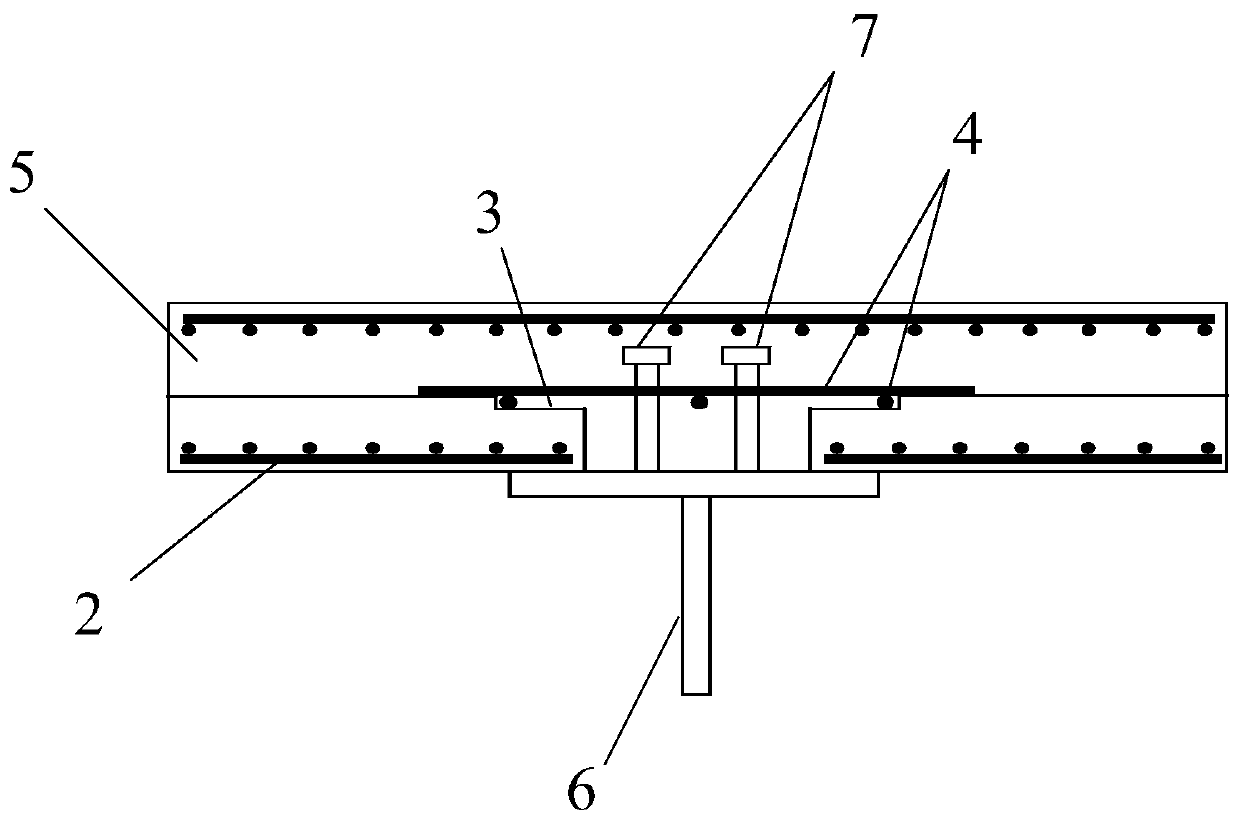

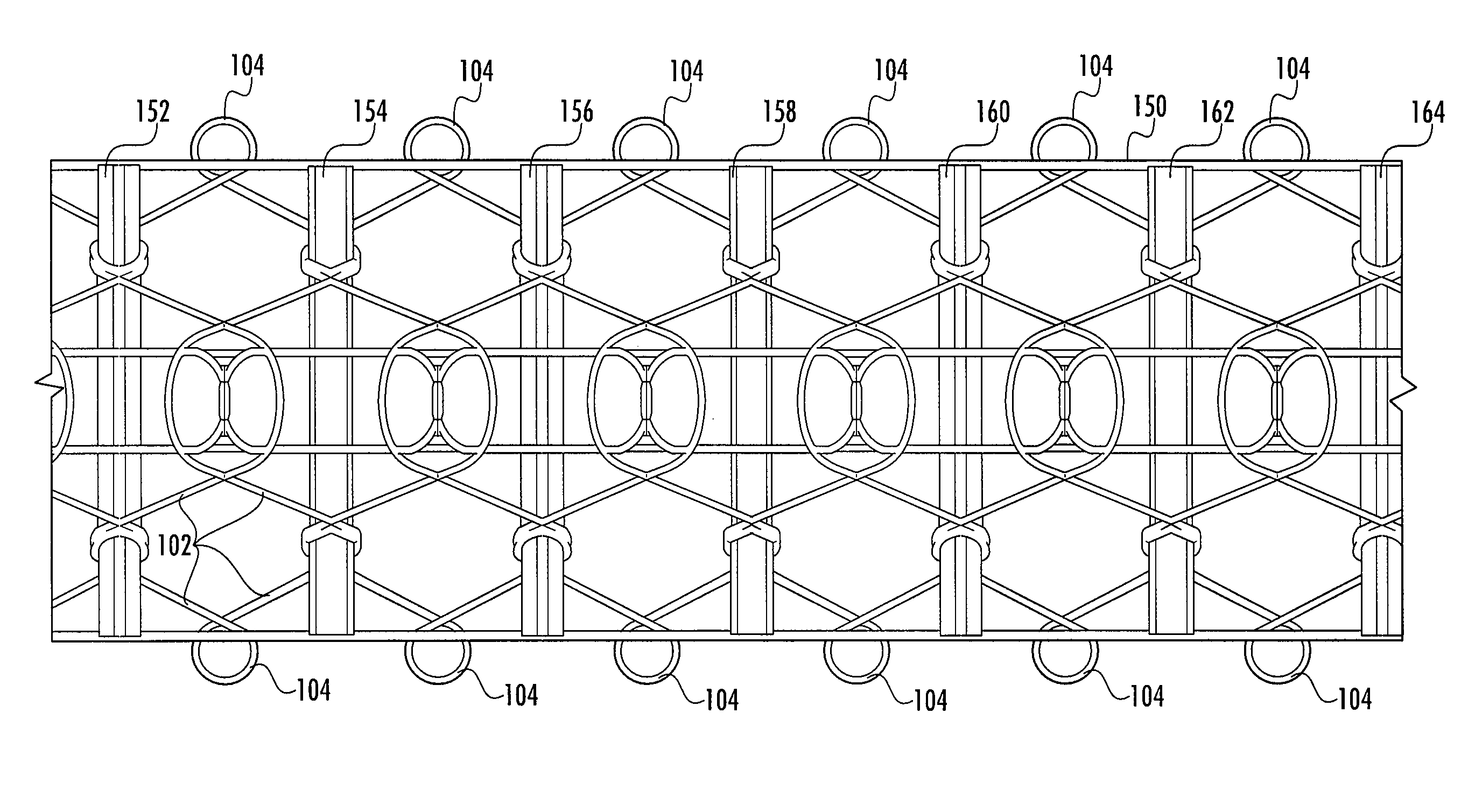

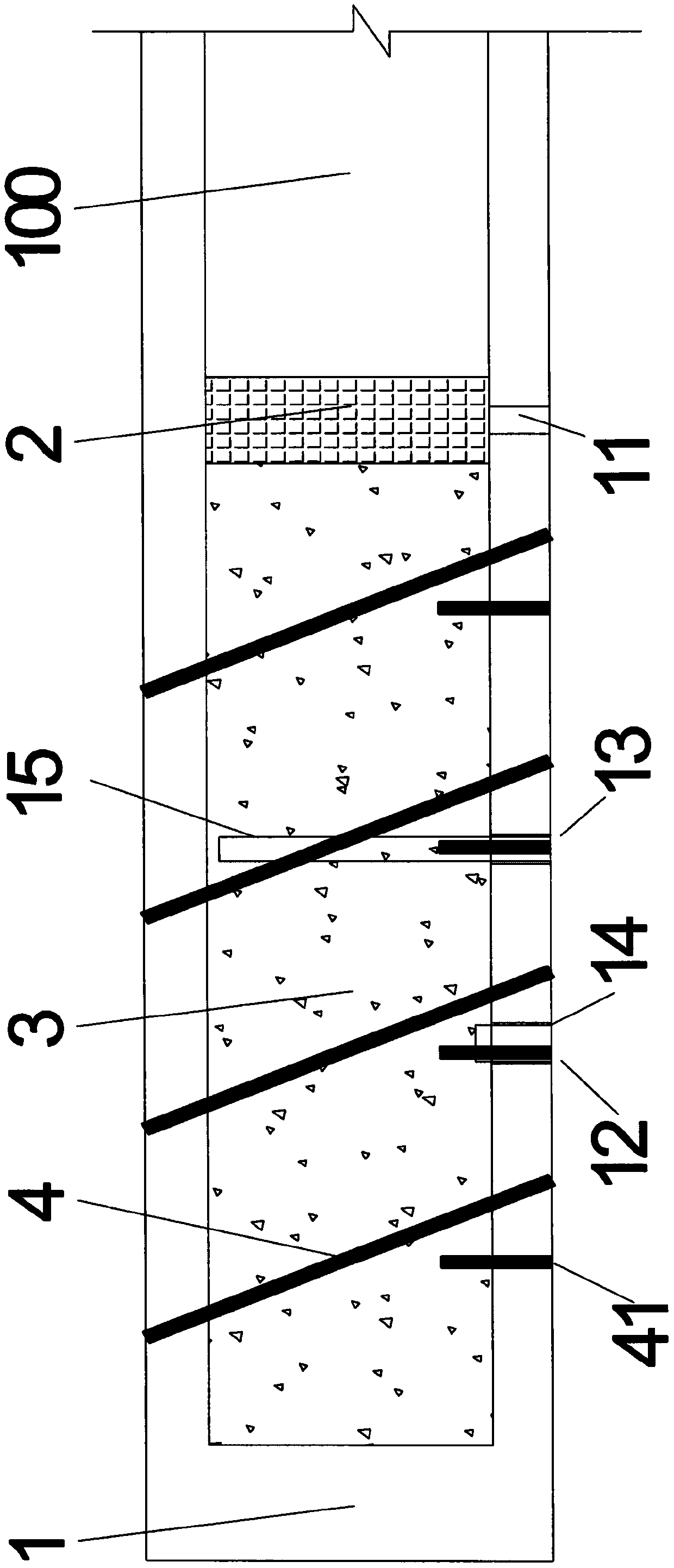

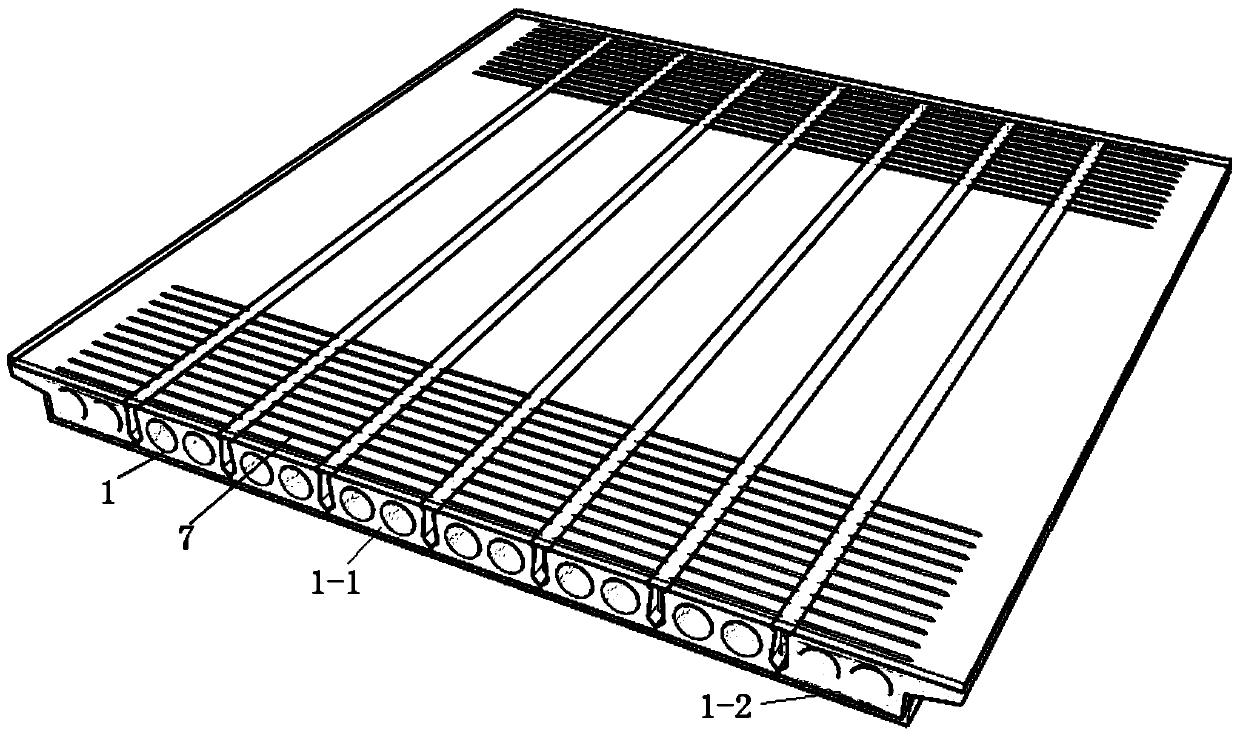

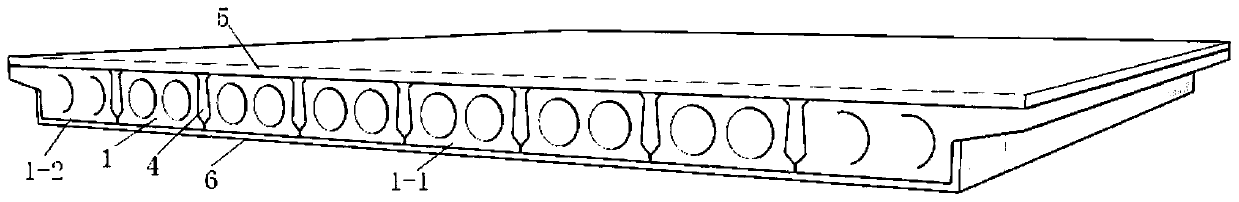

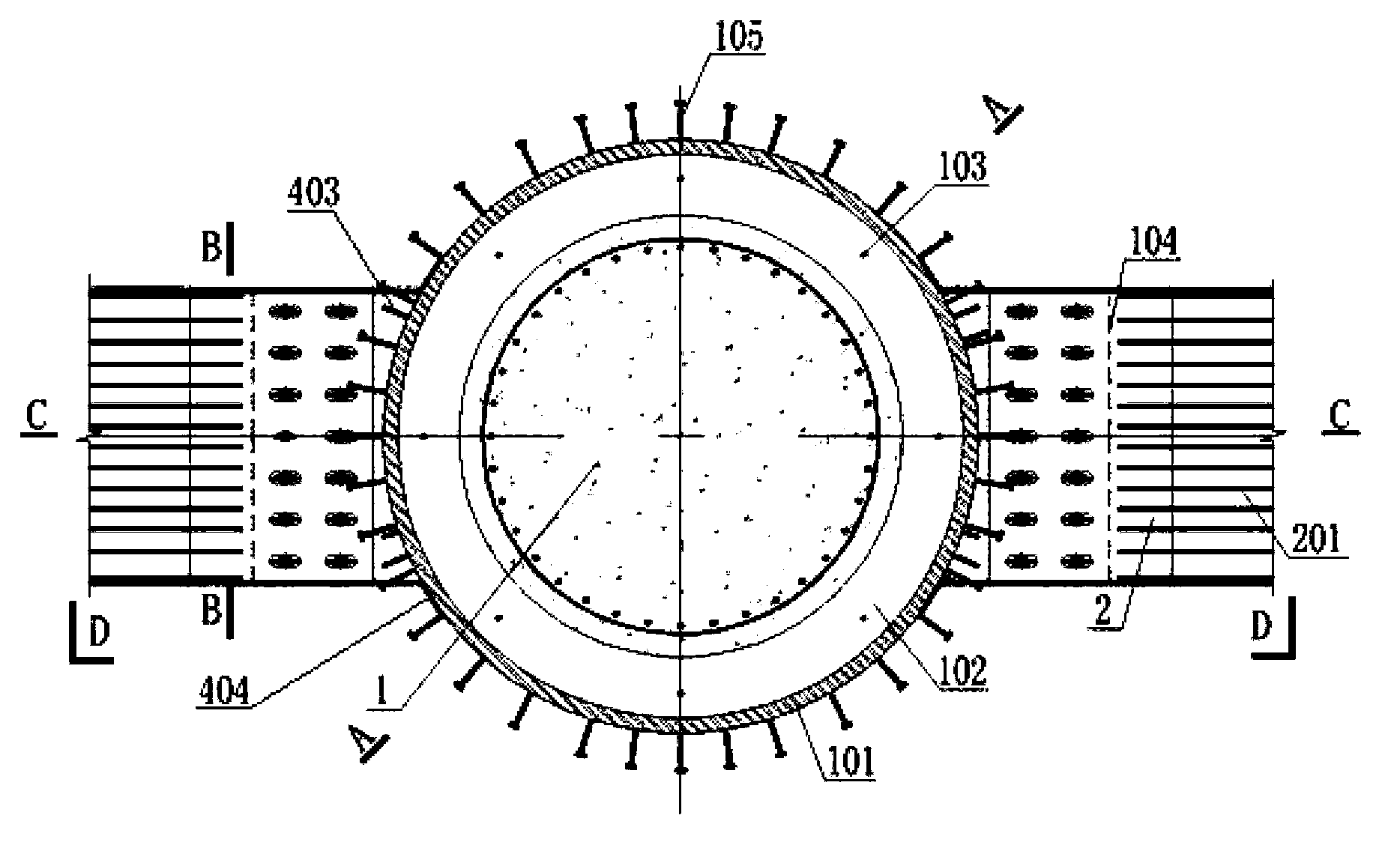

Wide hollow slab oblique section shearing resistance reinforcing method

ActiveCN110747754AImprove the shear bearing capacity of the inclined sectionEnhanced shear capacity of oblique sectionsBridge erection/assemblyBridge strengtheningMesh reinforcementEngineering

The invention discloses a wide hollow slab oblique section shearing resistance reinforcing method. The method comprises the steps that original concrete paving, bituminous concrete paving and hinge joints on a hollow slab bridge are removed; a plurality of drilled holes are formed in edges of center sills and edge beans of the hollow slab bridge correspondingly; a plurality of stirrups are arranged on the center sills and the edge beams in a sleeved mode in the positions of the drilled holes correspondingly, and oblique bend bars are connected between the stirrups; oblique bend bars are connected in the positions, located at webs of the edge beams, between the stirrups sleeved with the edge beams correspondingly; steel bars are embedded in bottom plates of the center sills and the edge beams correspondingly according to a preset spacing; concrete is used for pouring the spaces and joints between the center sills, so that new hinge joints are formed; a ribbed steel mesh is arranged on the upper surfaces of the center sills and the edge beams, and then new concrete paving is formed through pouring; and concrete is poured at the bottoms of the center sills and the edge beams and websof the edge beams correspondingly, and reinforcing is completed. By means of the method provided by the invention, secondary erected stirrups and the oblique bend bars can be utilized for reinforcinga hollow slab on the premise that the cost is reduced, and a good reinforcing effect can be achieved.

Owner:CHANGAN UNIV

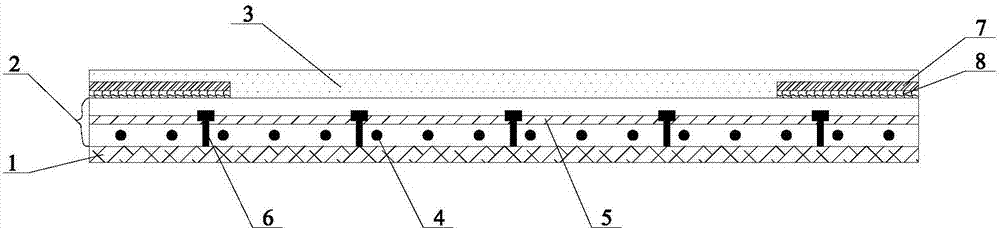

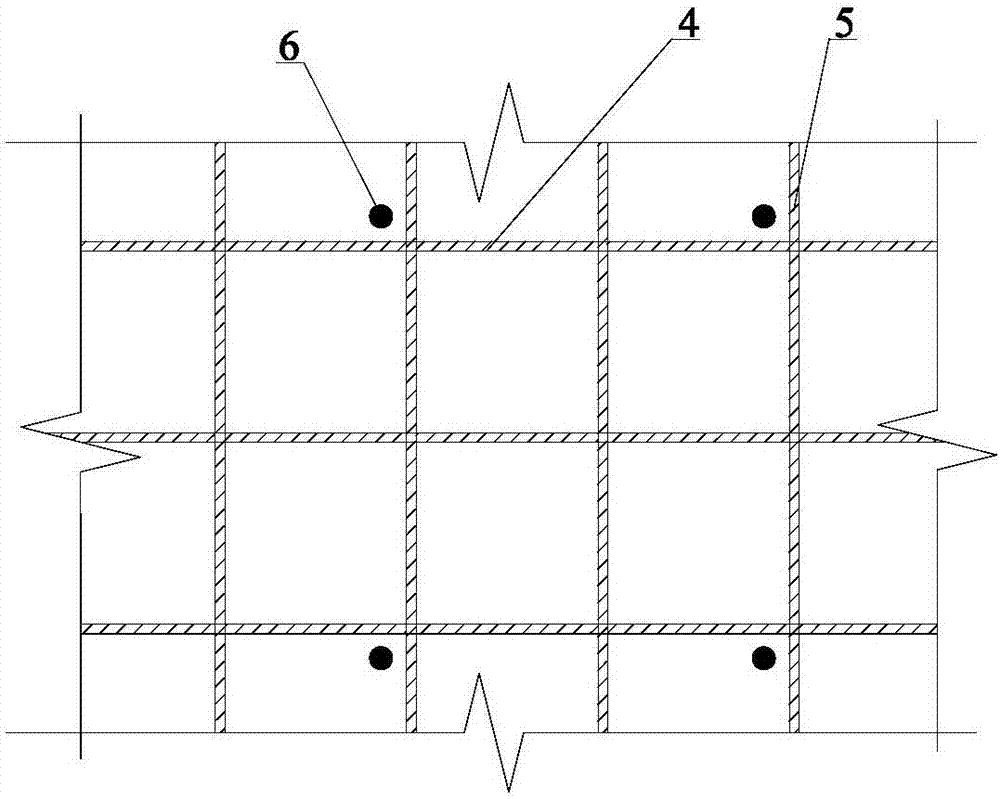

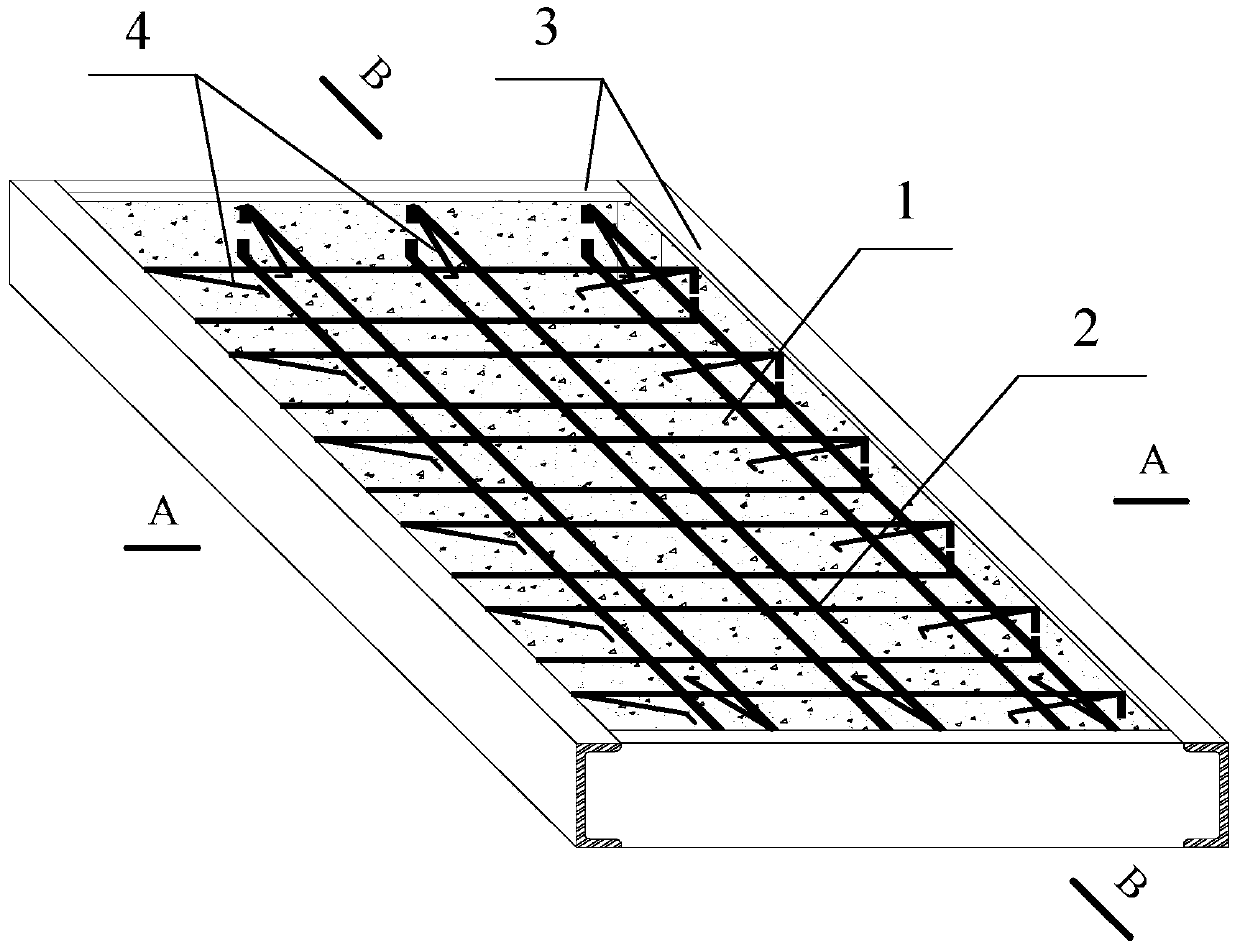

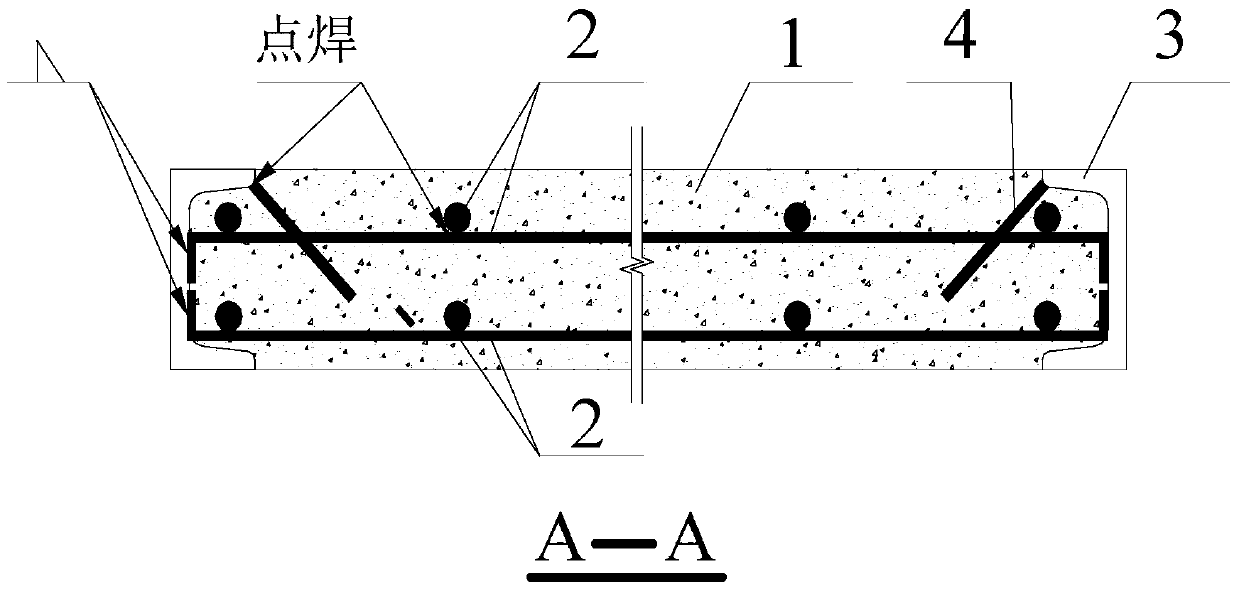

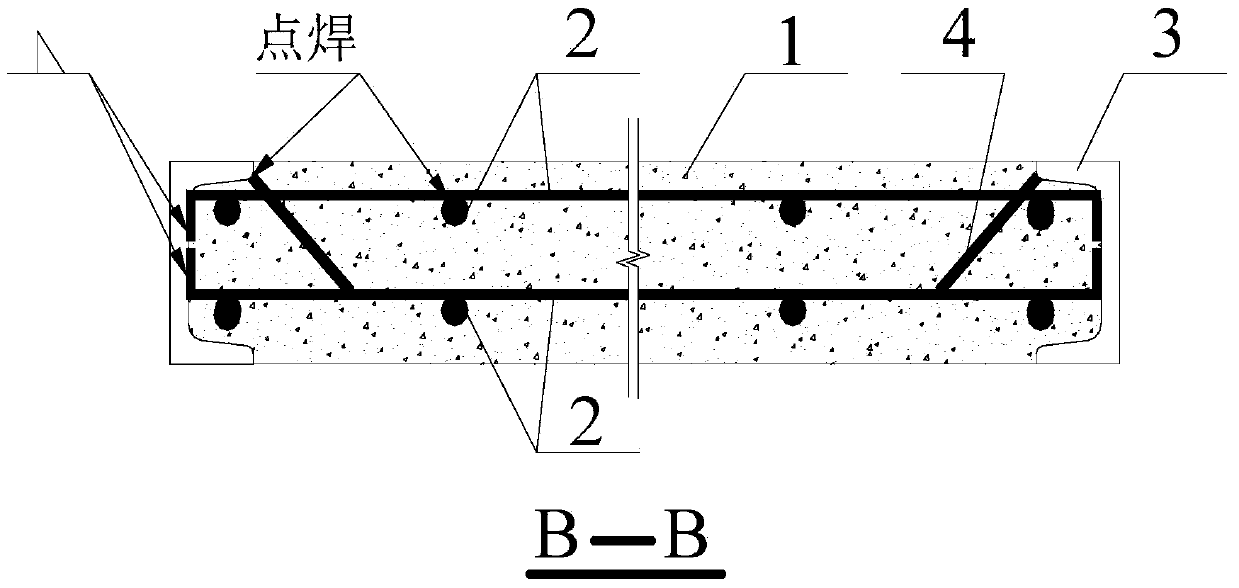

Reinforced concrete plate with shear reinforcement steel channel frame at periphery

ActiveCN103758275AGuaranteed positioningReduced shear slipConstruction materialFloor slabMesh reinforcement

The invention discloses a reinforced concrete plate with a shear reinforcement steel channel frame at the periphery, and belongs to the field of building materials. The reinforced concrete plate comprises concrete, a dual-layer steel mesh reinforcement, steel channel and shear reinforcements, wherein the steel channel is welded to form the frame; the shear reinforcements are spot welded on the steel channel, form angles of 45 degrees together with the plane of the plate, and are positioned at the inner side edge of a steel channel opening corresponding to the end part of a reinforcing steel bar of the upper-layer steel mesh reinforcement; the steel mesh reinforcement comprises longitudinal reinforcements and transverse reinforcements which are arranged at intervals in a uniform staggered manner; the longitudinal reinforcements and transverse reinforcements are arranged at equal intervals; the steel mesh reinforcement serves as the framework of the plate and is arranged in the thickness direction of the plate in a layering manner; the periphery of the steel mesh reinforcement is welded to the steel channel frame, and the middle is wrapped with concrete. The reinforced concrete plate disclosed by the invention is simple in structure, convenient to manufacture, and excellent in bending resistance, shear resistance, and anti-seismic property, can realize standardized and industrial production of floor slabs, and has an important significance in realizing the industrial production target of steel structure buildings.

Owner:MAANSHAN LANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

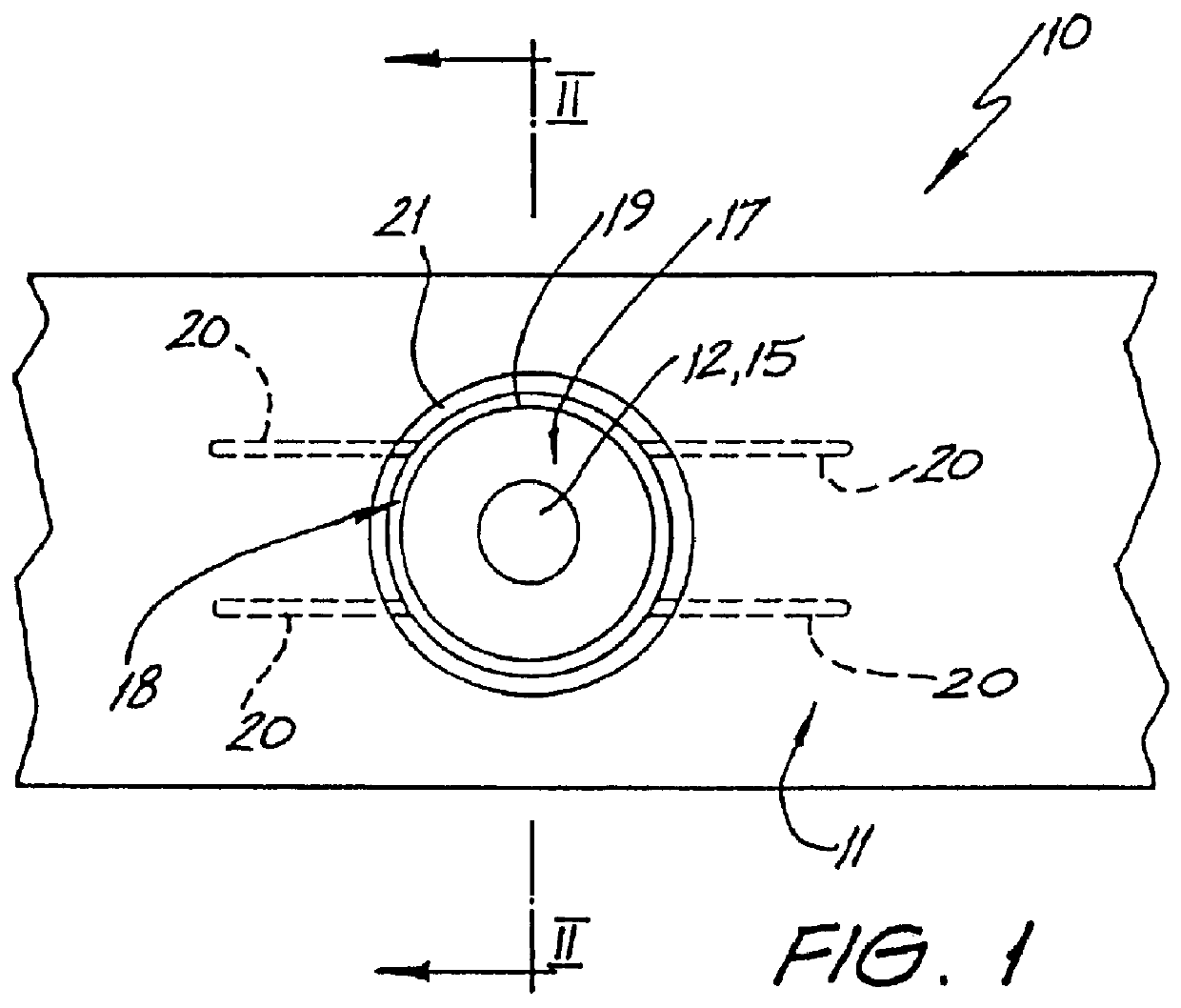

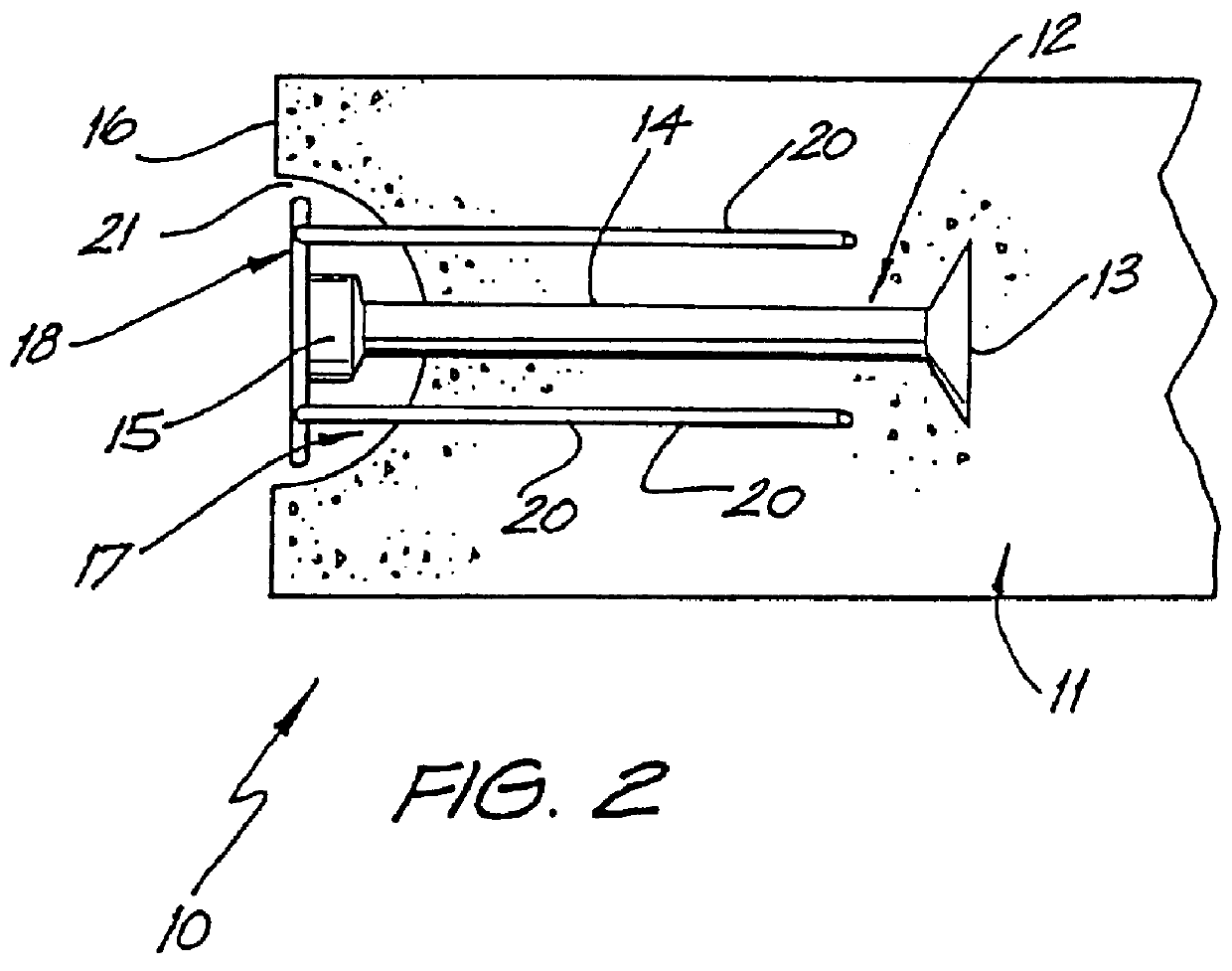

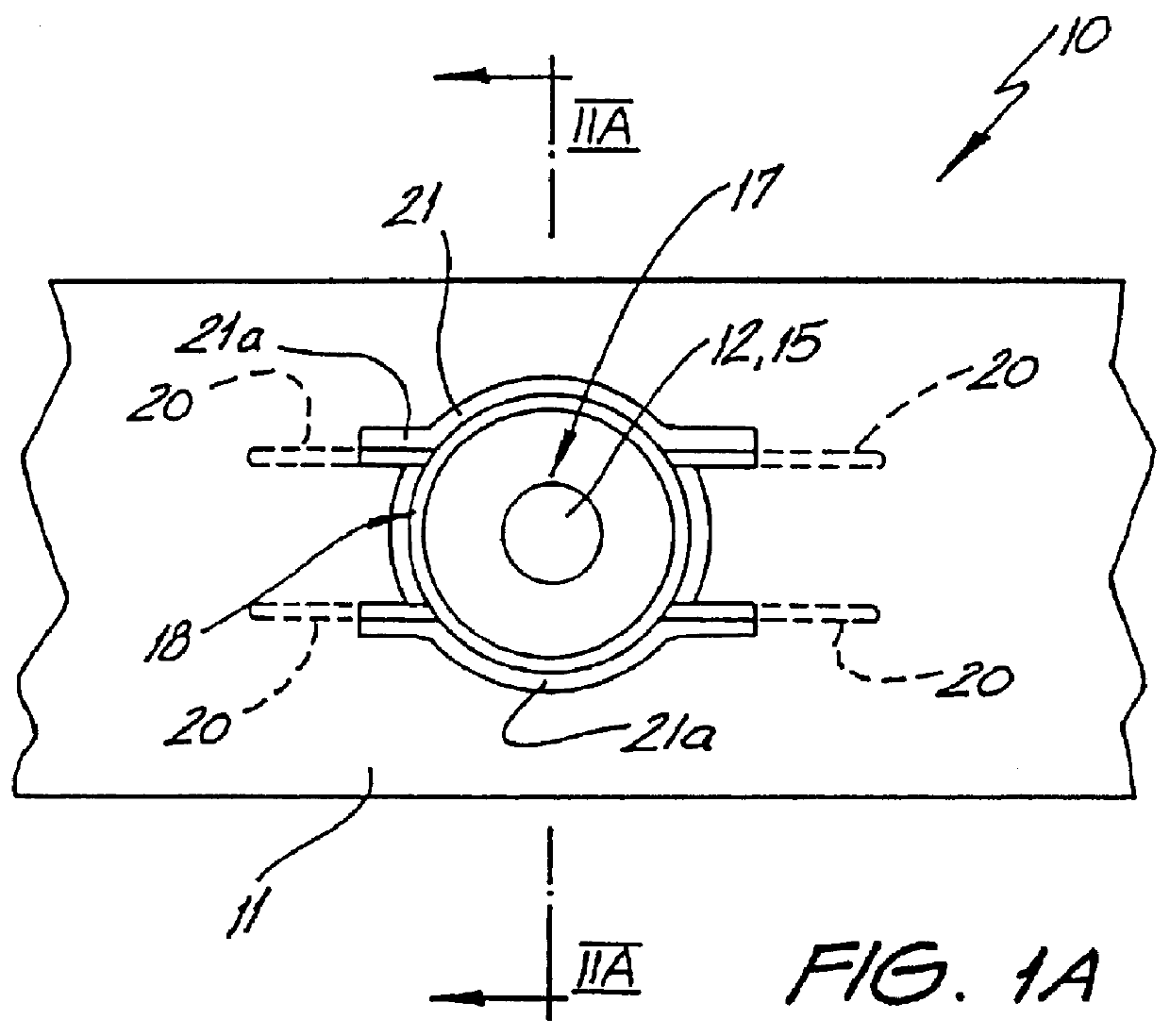

Edge lifting recess former and reinforcement system

A recess former (130) is adapted for forming a recess (133) around the head of an anchor element (131) which is embedded in an edge of a concrete slab during casting thereof. The recess former (130) has an outer curved surface extending from a flat base surface. The outer surface has a hole at its apex to allow the anchor (131) to extend out of the recess former (130). A web (137) is located at the outer surface and has a channel (138) which is adapted for positioning of shear reinforcement means. The web (137) forming an air gap after the recess former (130) is removed from the recess.

Owner:ITW RAMSET AUSTRALIA

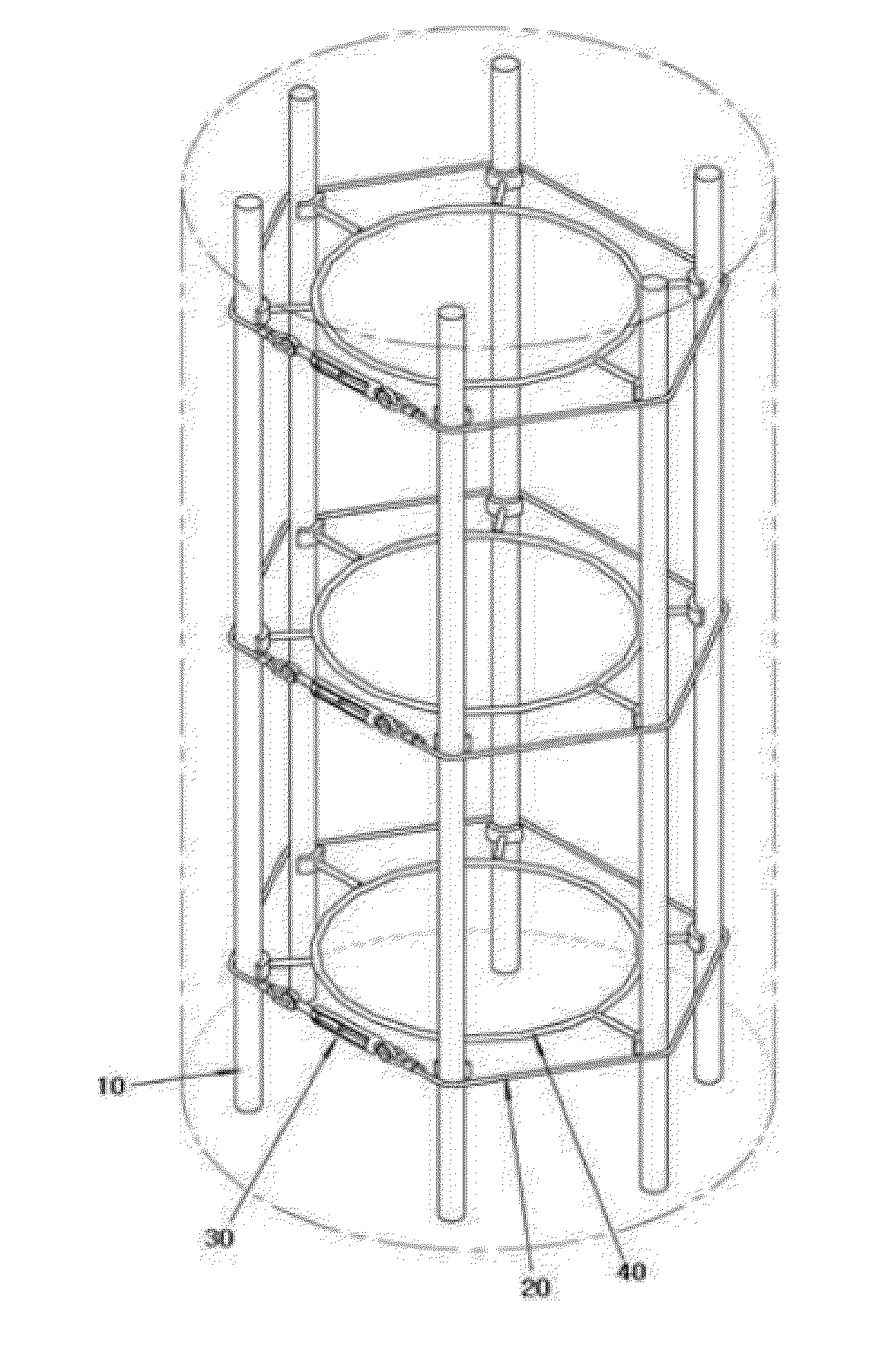

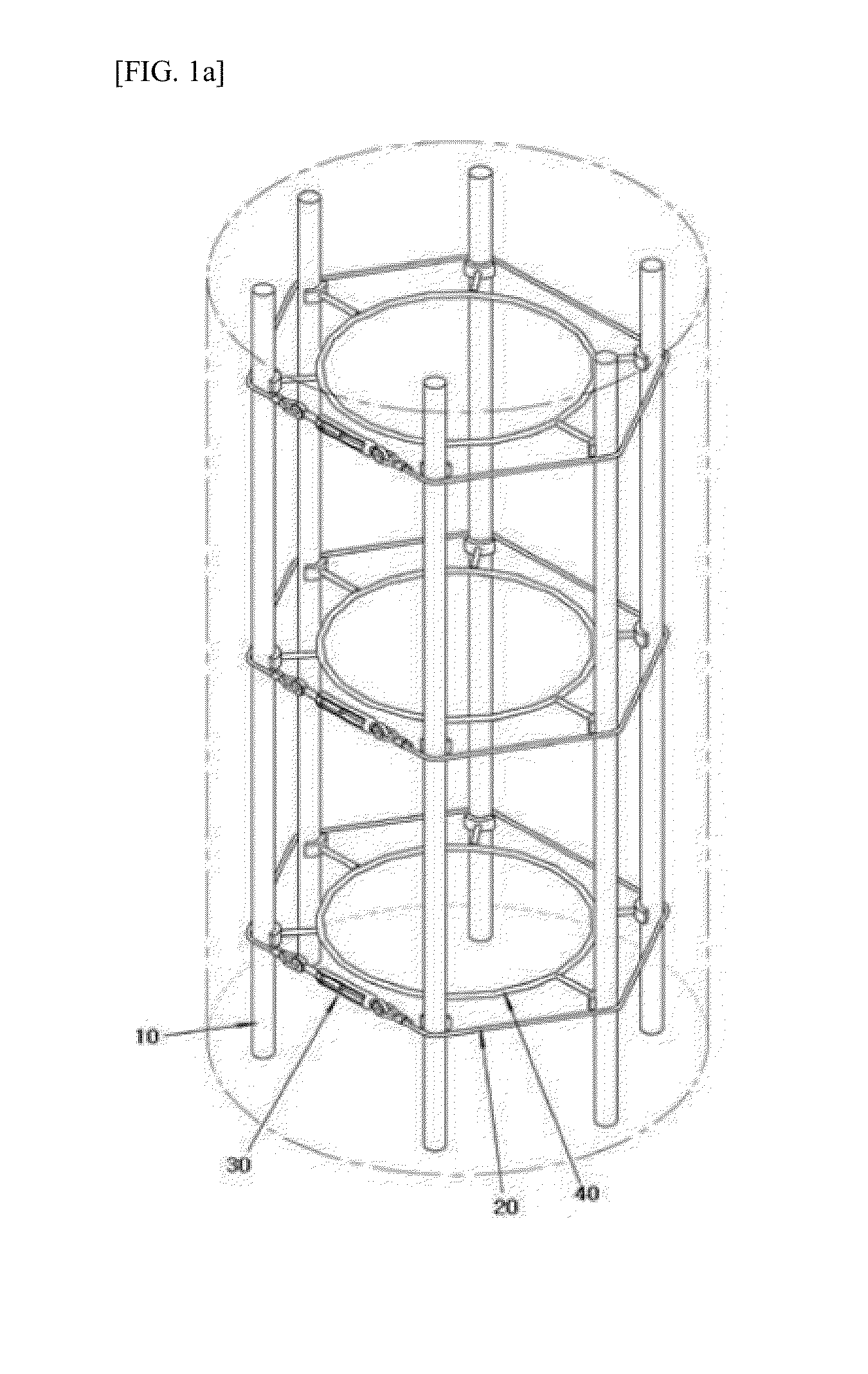

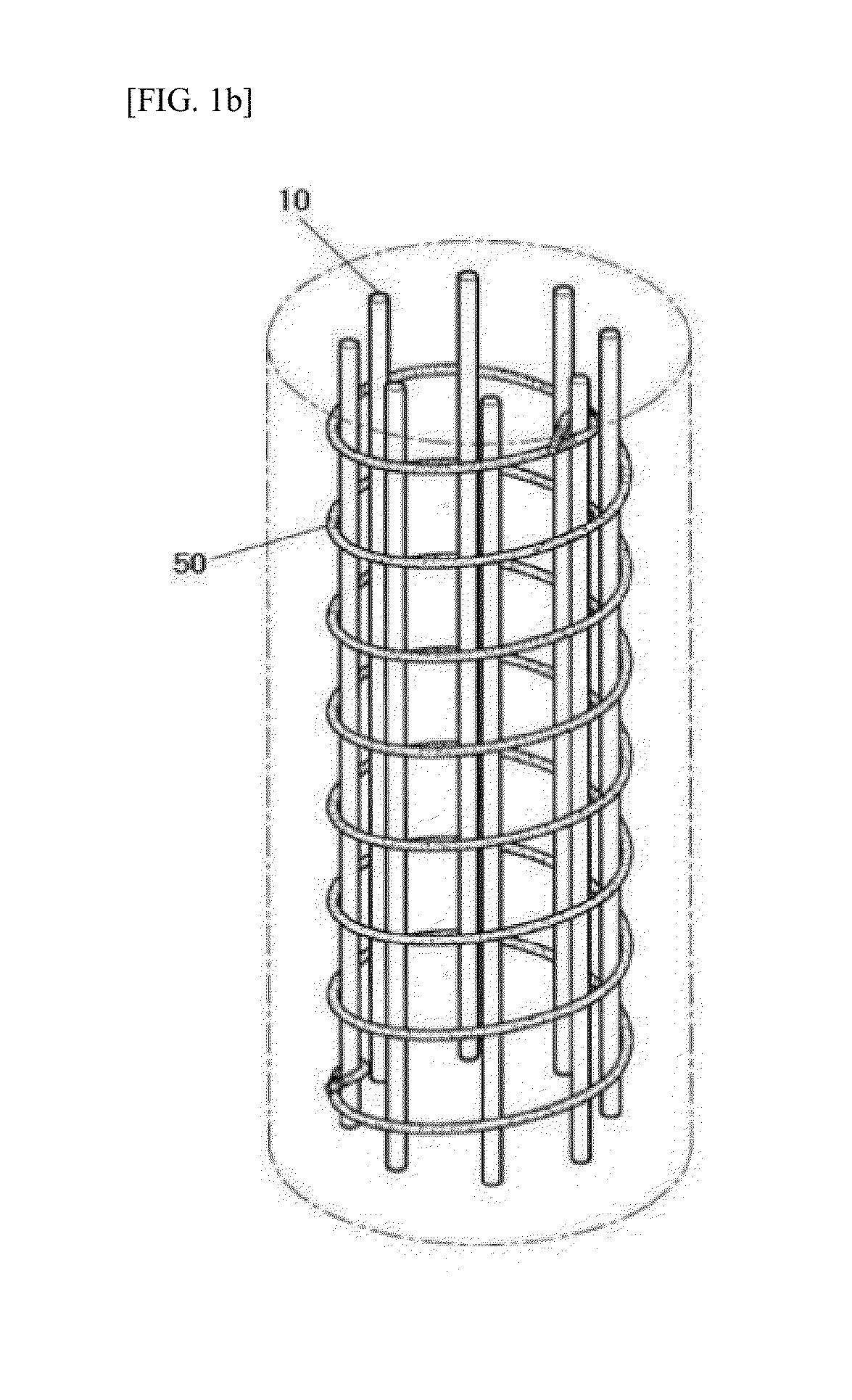

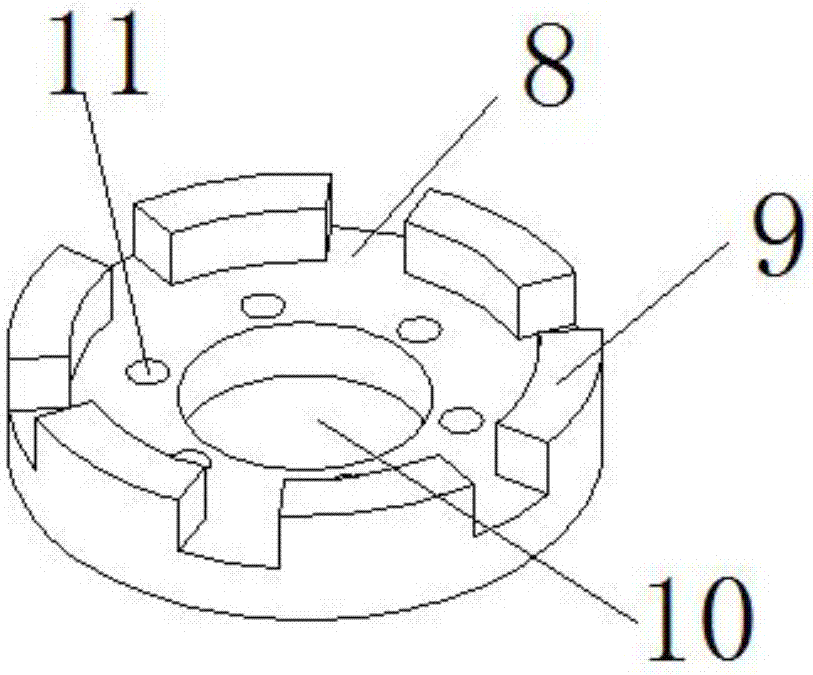

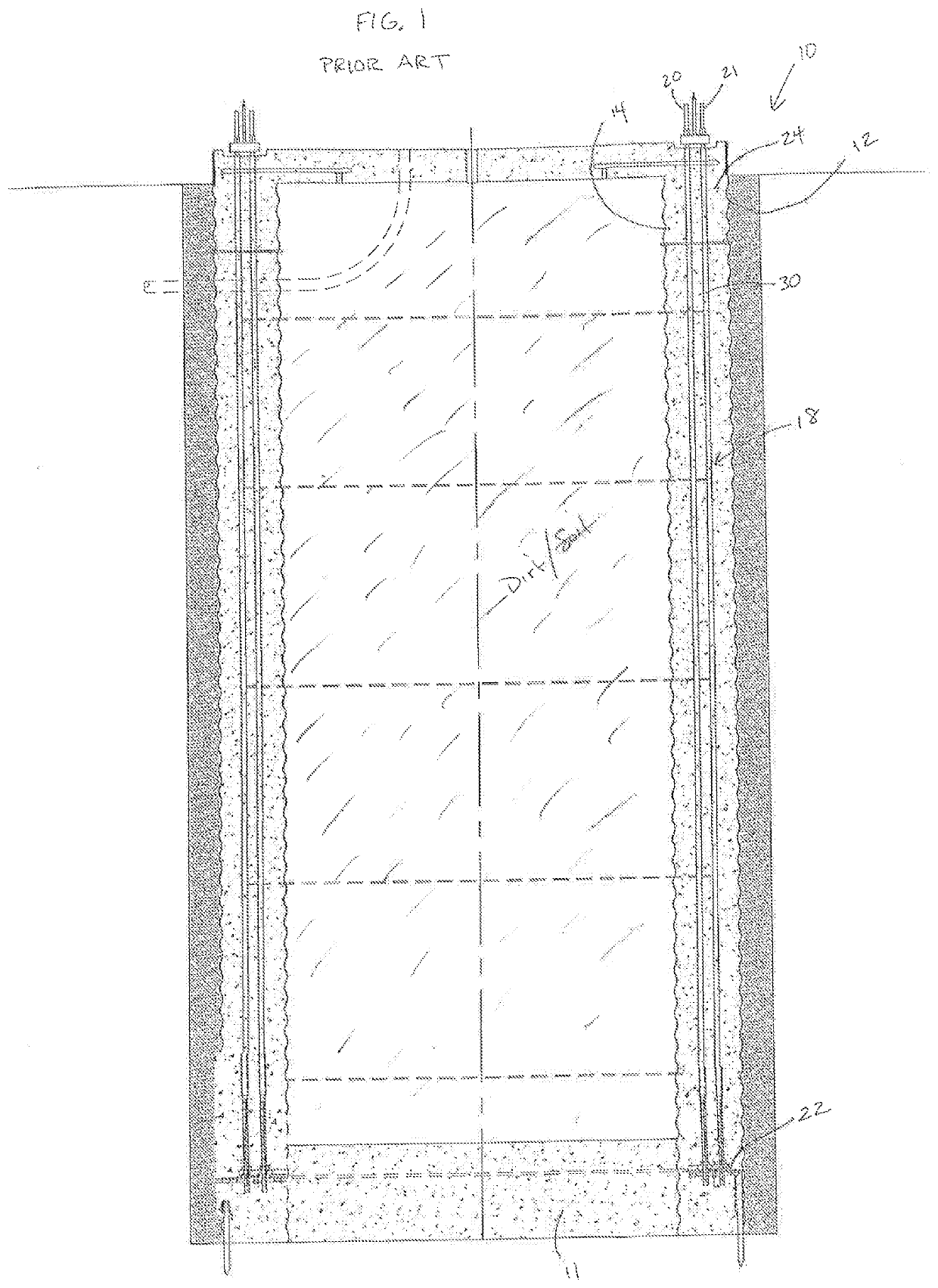

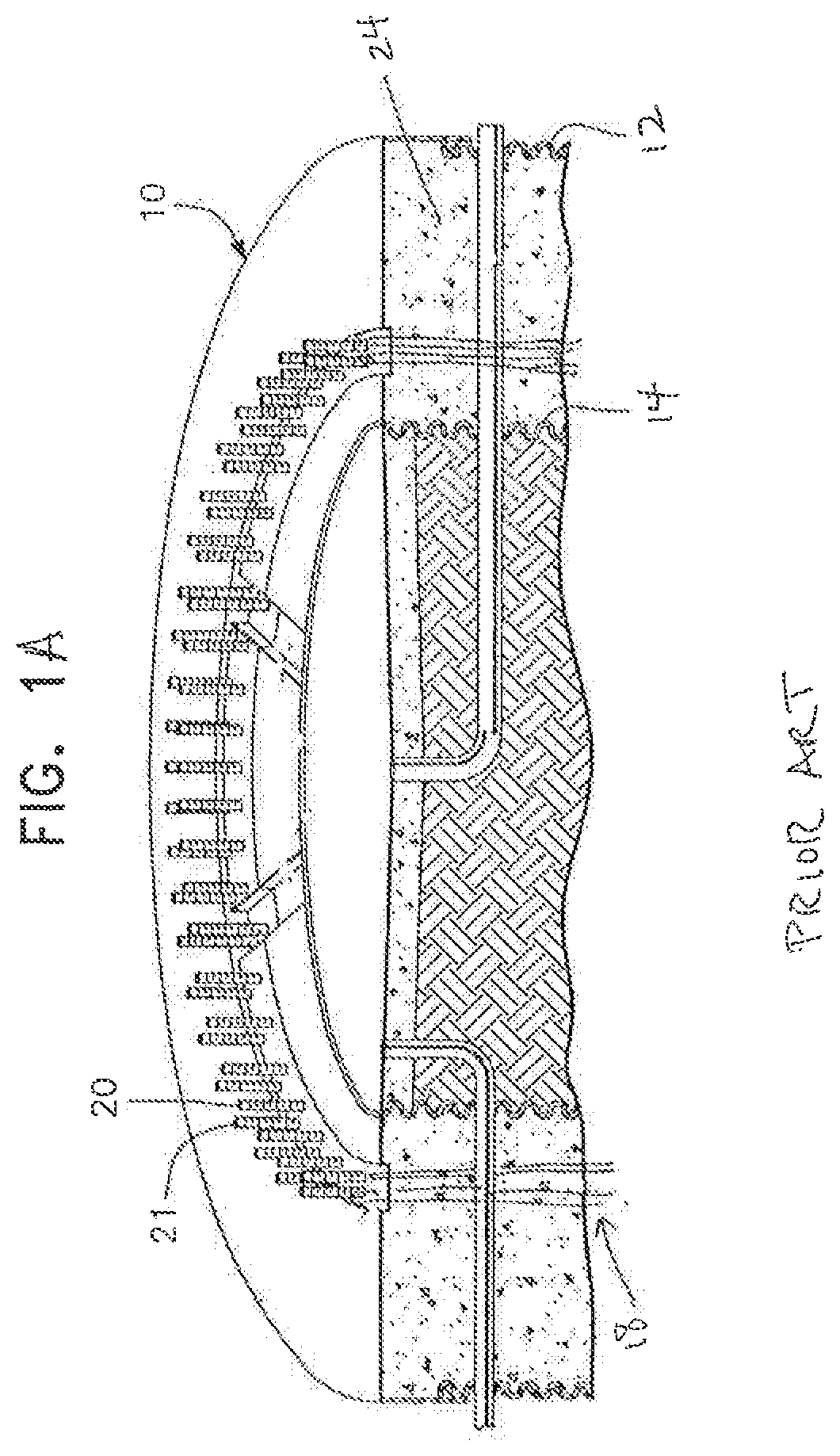

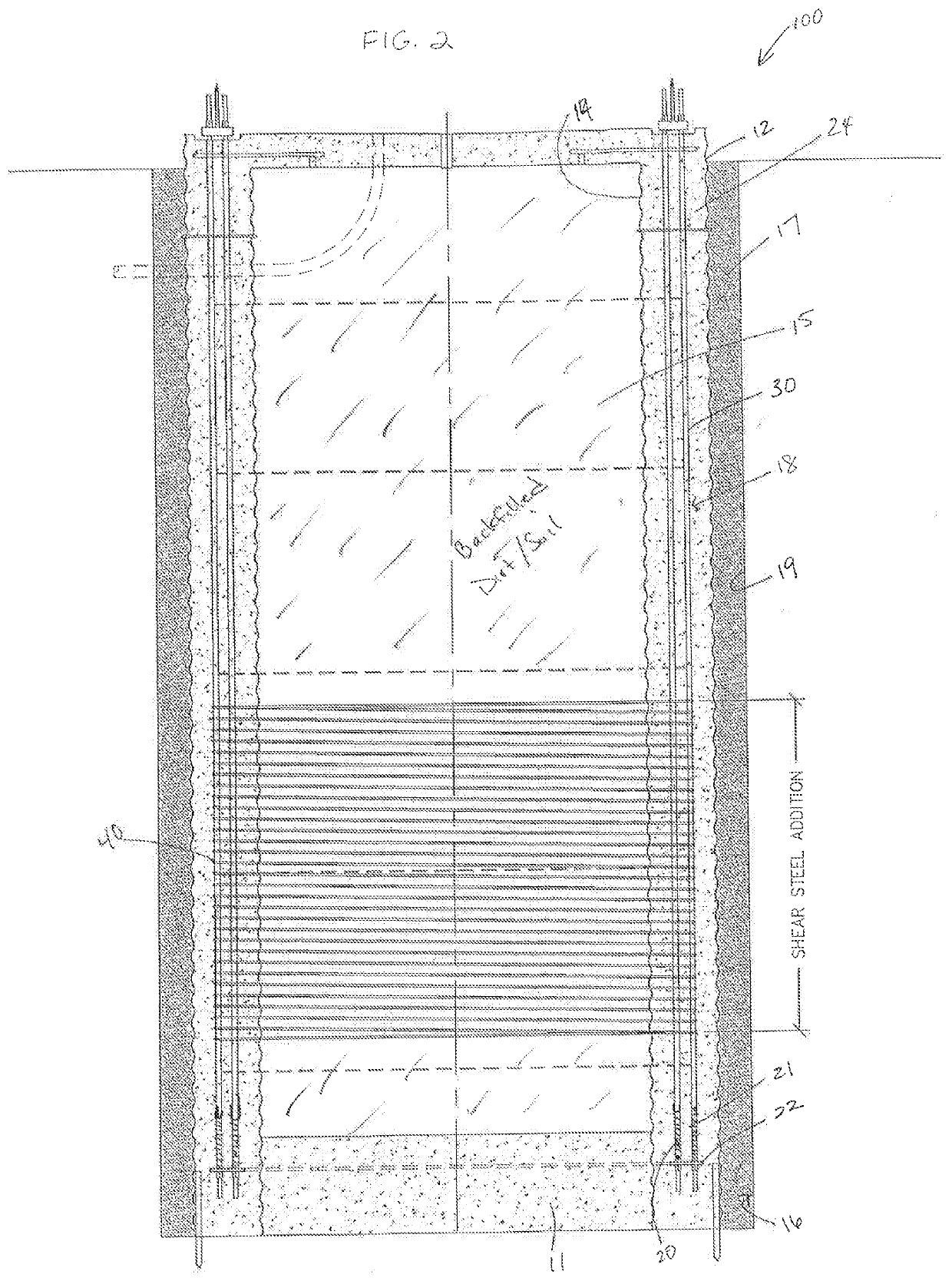

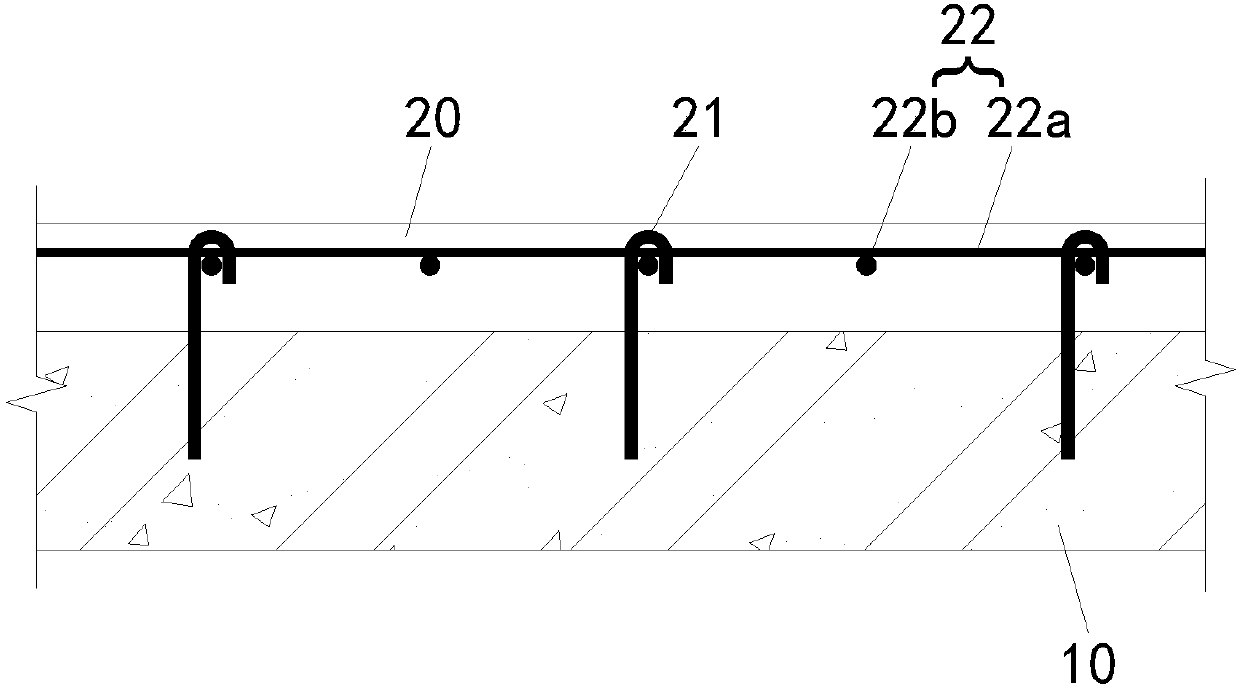

Concrete pier foundation with lateral shear reinforcing loops and methods of constructing the same

ActiveUS20200032476A1Increase lateral shear stress resistanceEliminate needBulkheads/pilesLateral shearTower

A concrete pier foundation having a plurality of sleeved tower anchor bolts embedded therein and a spiral loop encasement providing lateral shear reinforcement is provided. The spiral loop encasement surrounds at least a lower portion of the concrete pier and is formed by hoop steel wrapped around the perimeter of the tower anchor bolt cage. In proper soils or rock the spiral loop encasement can eliminate the need for corrugated metal pipes, reducing the cost and complexity of construction.

Owner:TERRACON CONSULTANTS INC

Connecting structure of reserved external wall and newly-constructed reinforced concrete horizontal component and construction method of connecting structure

InactiveCN107700668AImprove stabilityAvoid damageBuilding material handlingReinforced concreteSteel bar

The connection structure of the retained outer wall and the new steel-concrete horizontal component and the construction method thereof of the present invention relate to the technical field of building reconstruction engineering. Aiming at the problems of adding support or thickening the wall to reinforce and retain the outer wall, the internal space of the building is occupied, and the construction efficiency is low and the quality is poor. The inner lining wall is close to the inner side of the reserved outer wall, and a steel grid frame is embedded in the inner lining wall, and a number of tension bars are arranged between the reserved outer wall and the inner lining wall. It is connected with the longitudinal reinforcement of the steel grid frame, and the two ends of the horizontal shear reinforcement are implanted into the retained outer wall and the new steel-concrete horizontal member respectively. Construction method: connect one end of the tie bar with the reserved outer wall by planting bars, erect the steel grid frame of the inner wall, set the prefabricated elbow at the other end of the tie bar on the longitudinal bar of the steel grid frame, set up the formwork and pour the inner lining Wall; connect one end of several horizontal shear steel bars to the retained exterior wall by planting bars, and implant the other end into the newly-built steel-concrete horizontal member.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

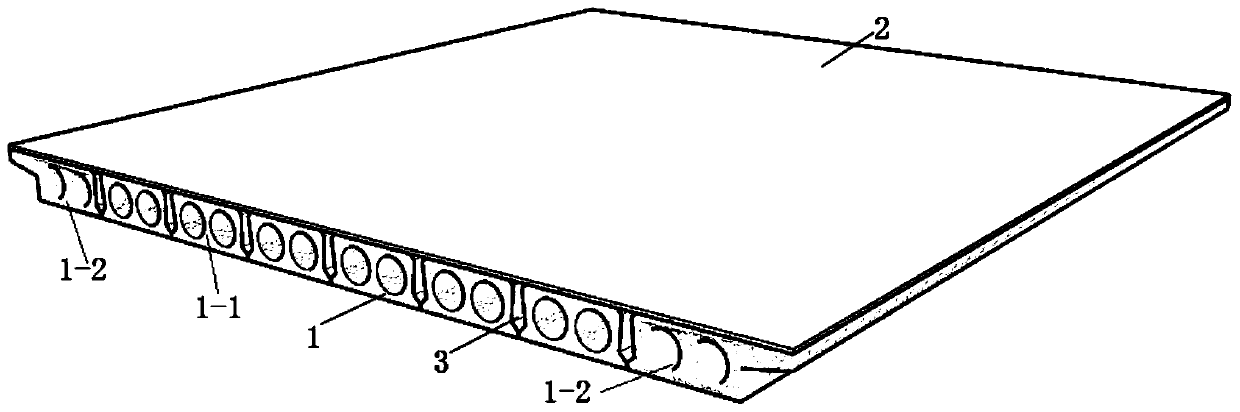

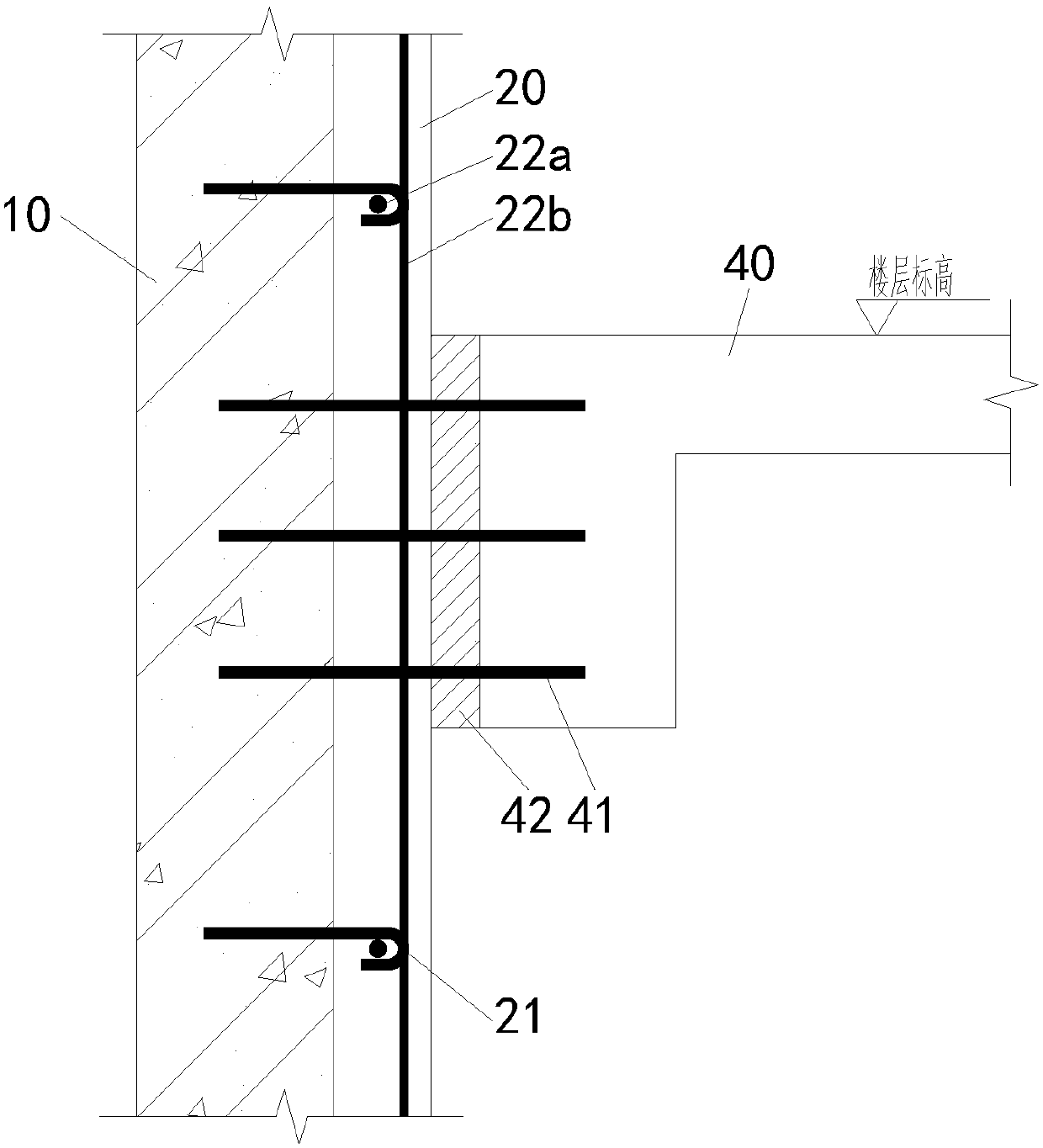

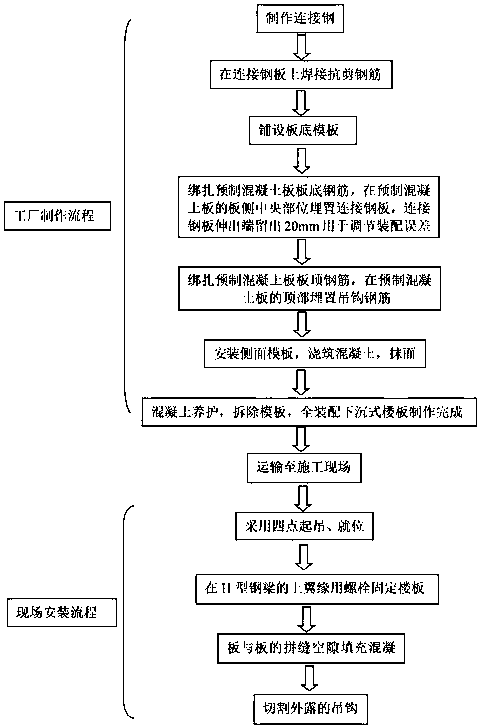

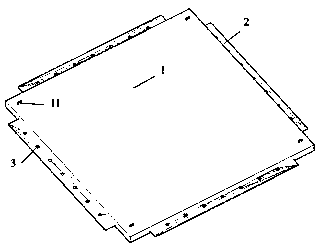

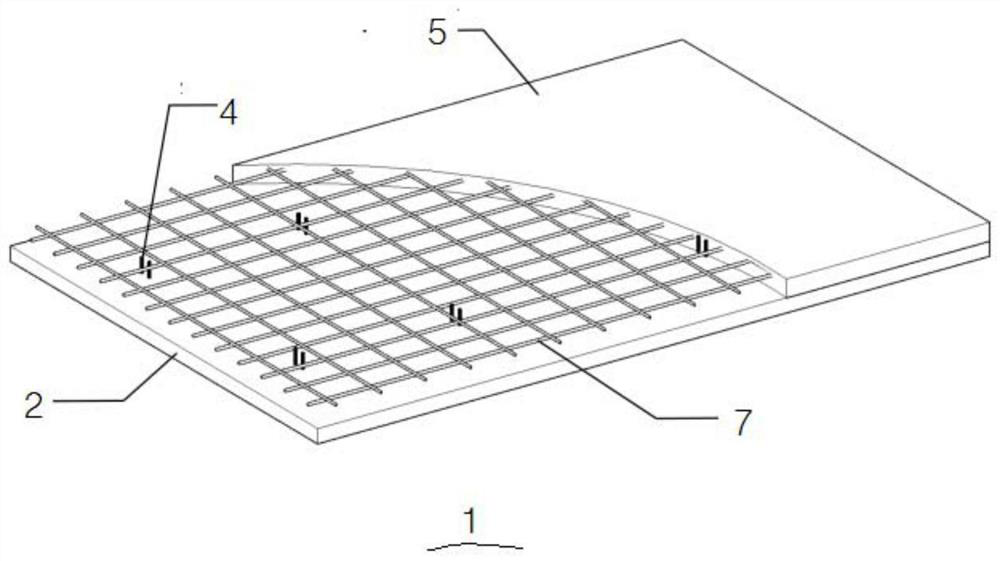

Manufacture and mounting method of completely assembled sunken floor

InactiveCN108571173ASafe and efficient preparationGuarantee product qualityFloorsCeramic shaping apparatusRebarPrecast concrete

The invention belongs to the field of civil engineering and relates to a manufacture and mounting method of a completely assembled sunken floor. The completely assembled sunken floor comprises precastconcrete plates and connecting steel plates. The manufacture and mounting method comprises the following steps: manufacturing the connecting steel plates; welding shear reinforcements on the connecting steel plates; laying plate bottom templates; binding plate bottom reinforcements, and embedding the connecting steel plates in the center of plate sides binding plate top reinforcements, and embedding lifting hook reinforcements; mounting side templates, pouring concrete and performing plastering; curing concrete, removing the templates, and completing manufacture; transporting the product to aconstruction site; hoisting the product by four points in place; fixing the floor to a top flange of an H steel beam through bolts; filling splice gaps between plates with concrete; cutting the exposed lifting hook reinforcements. According to the completely assembled sunken floor manufactured in a factory, the manufacture process is safe and efficient, and manufacture quality is guaranteed. Thecompletely assembled sunken floor is connected with the H steel beam through the bolts on a construction site, field welding is avoided, and assembly efficiency is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

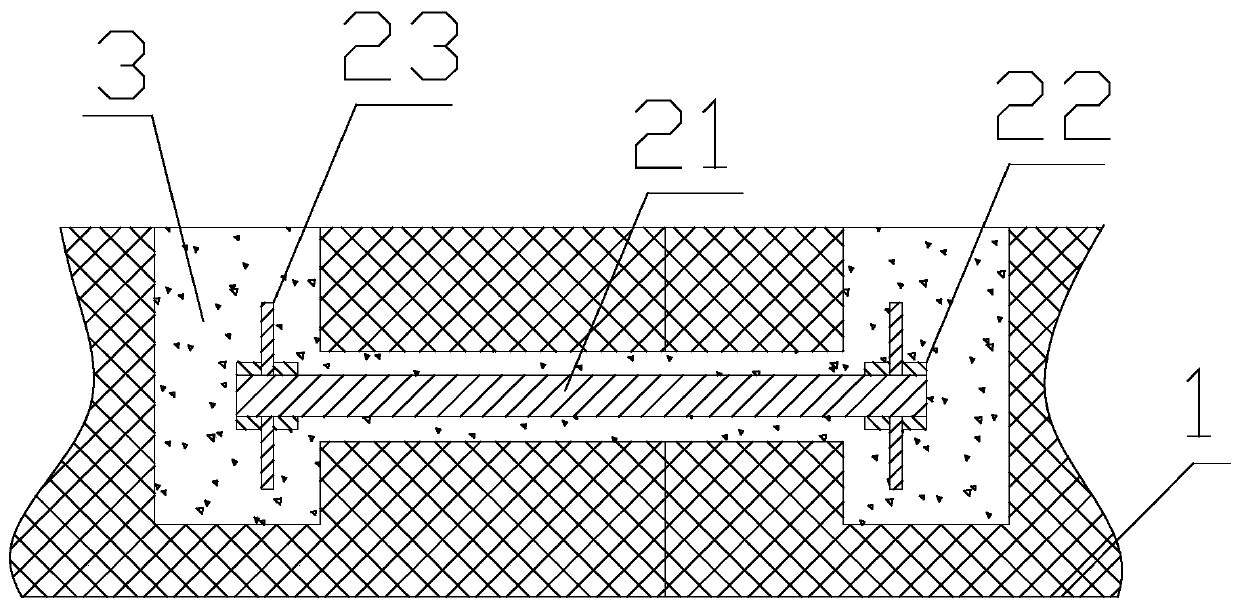

Laminated slab, connecting structure of laminated slab and composite beam and construction method

The invention discloses a laminated slab, a connecting structure of the laminated slab and a composite beam and a construction method. The laminated slab comprises a prefabricated layer and a post-pouring layer, the prefabricated layer comprises a prefabricated bottom plate and a plurality of shear reinforcements, the post-pouring layer comprises post-pouring concrete and surface layer reinforcements, the post-pouring concrete is poured on the prefabricated bottom plate, and the top ends of the shear reinforcements and the surface layer reinforcements are anchored in the post-pouring concrete. The connecting structure of the laminated slab and the composite beam comprises the laminated slab and the composite beam, the composite beam comprises a steel beam and studs, the prefabricated layer is placed on the steel beam, and a splicing seam between the steel beam and the prefabricated layer is filled with the post-pouring concrete. The construction method of the connecting structure of the laminated slab and the composite beam comprises the steps that S1, the prefabricated layer is produced; S2, the composite beam is hoisted and positioned, the prefabricated layer is hoisted and placed on the steel beam; and S3, the surface layer reinforcements are paved, and the post-pouring concrete is poured. The laminated slab is high in shear resistance and good in integrity; and the connecting structure of the laminated slab and the composite beam and the construction method are high in efficiency, the laminated slab is high in rigidity, and the using amount of the reinforcements is low.

Owner:筑友智造建设科技集团有限公司

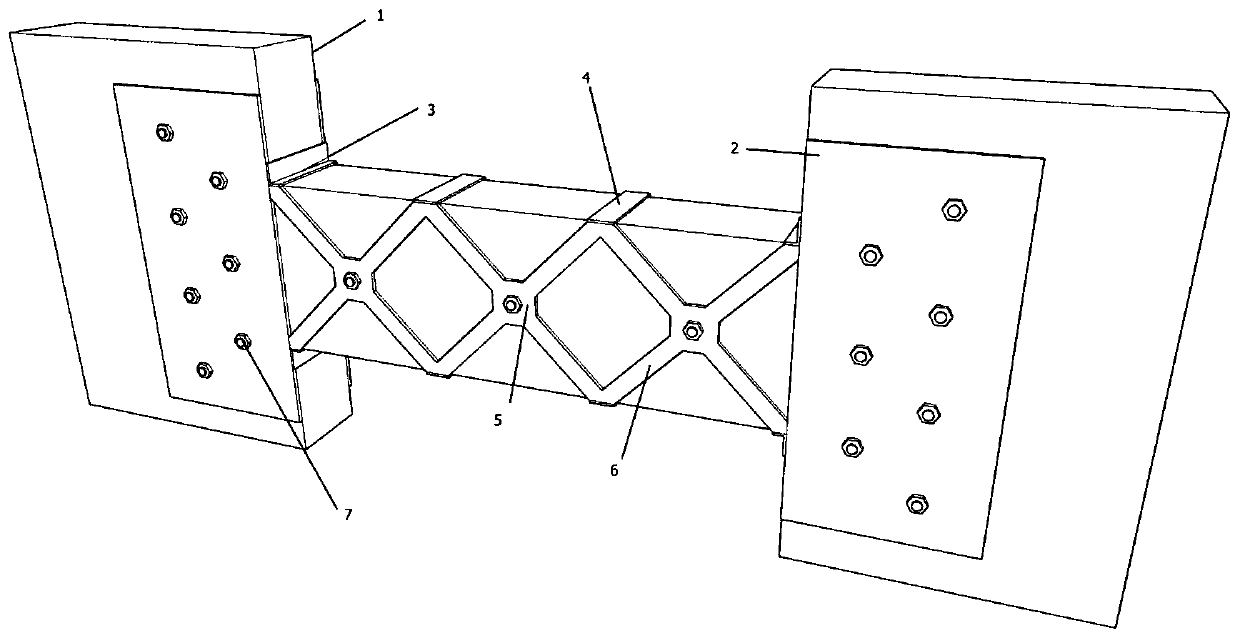

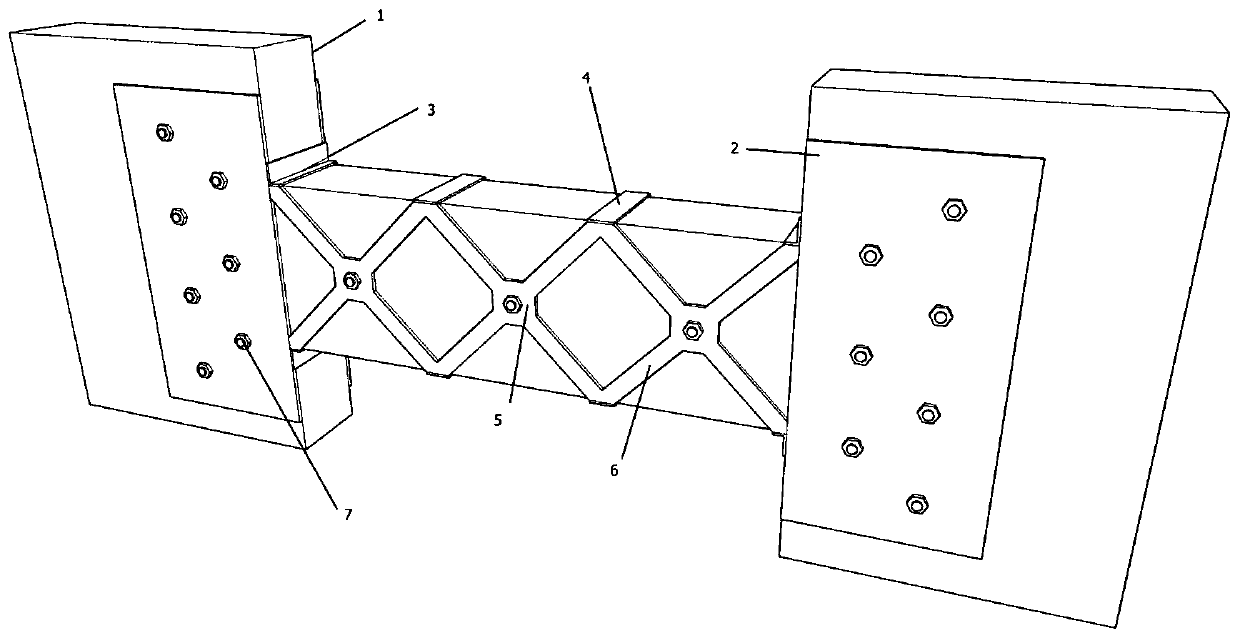

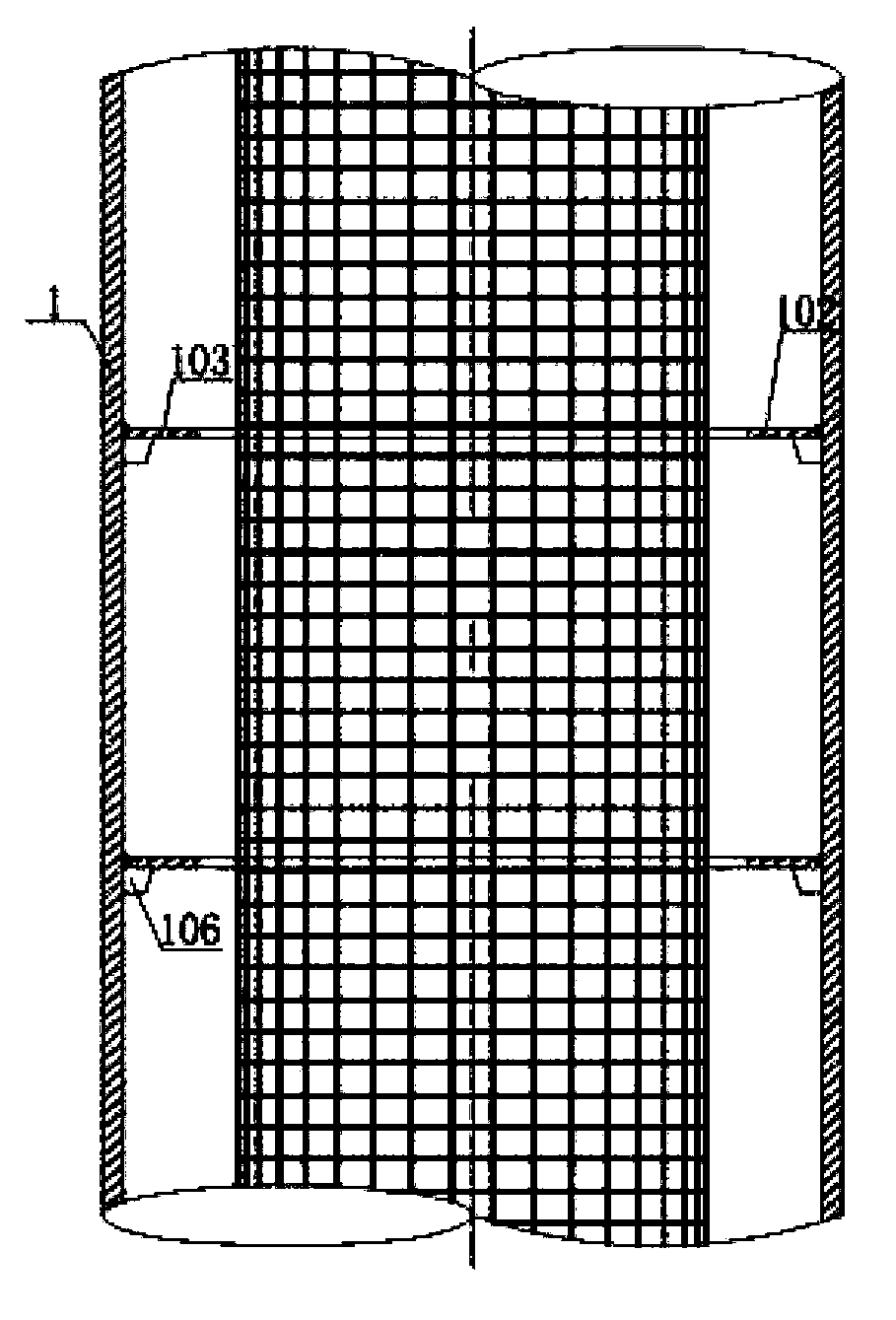

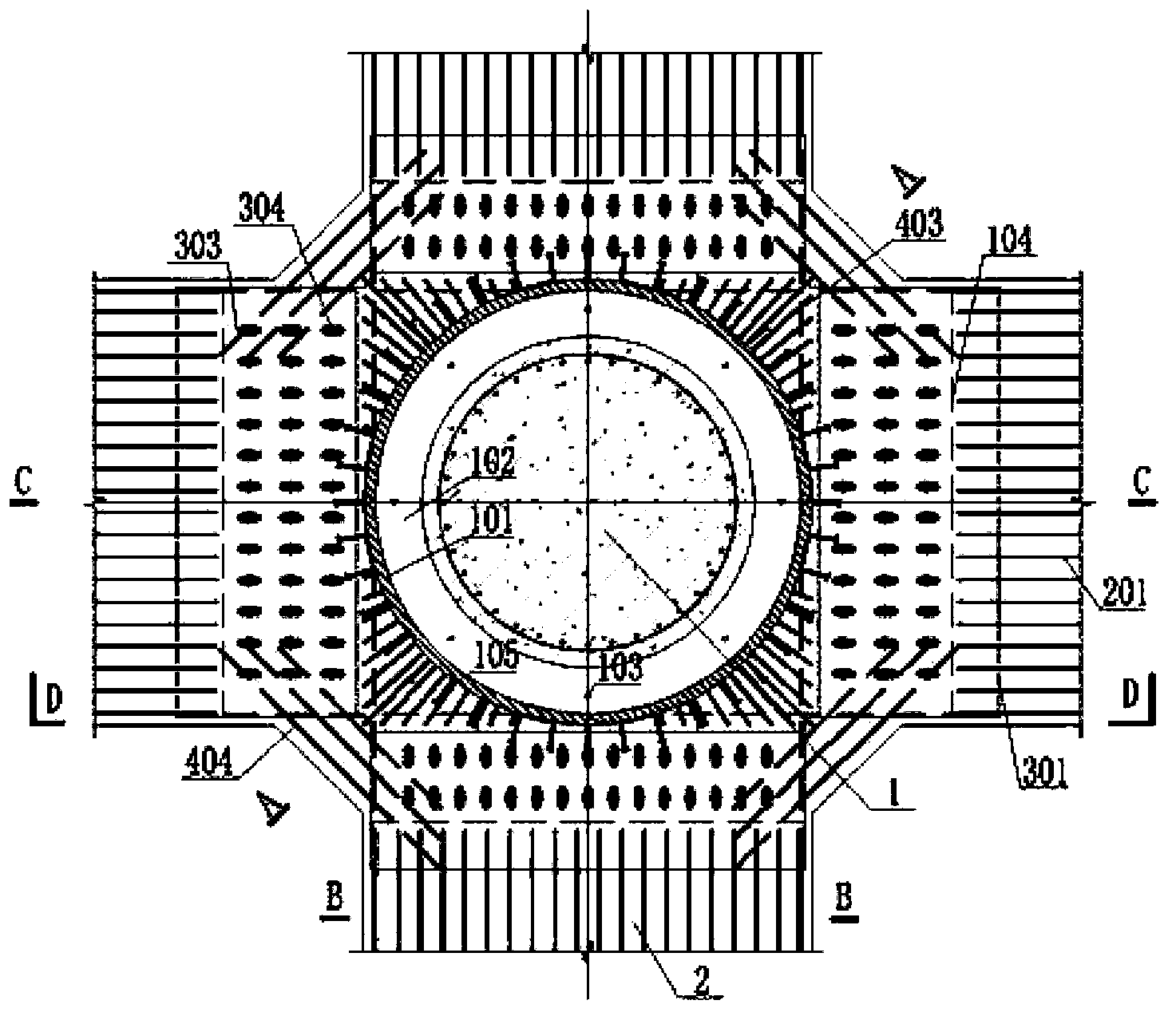

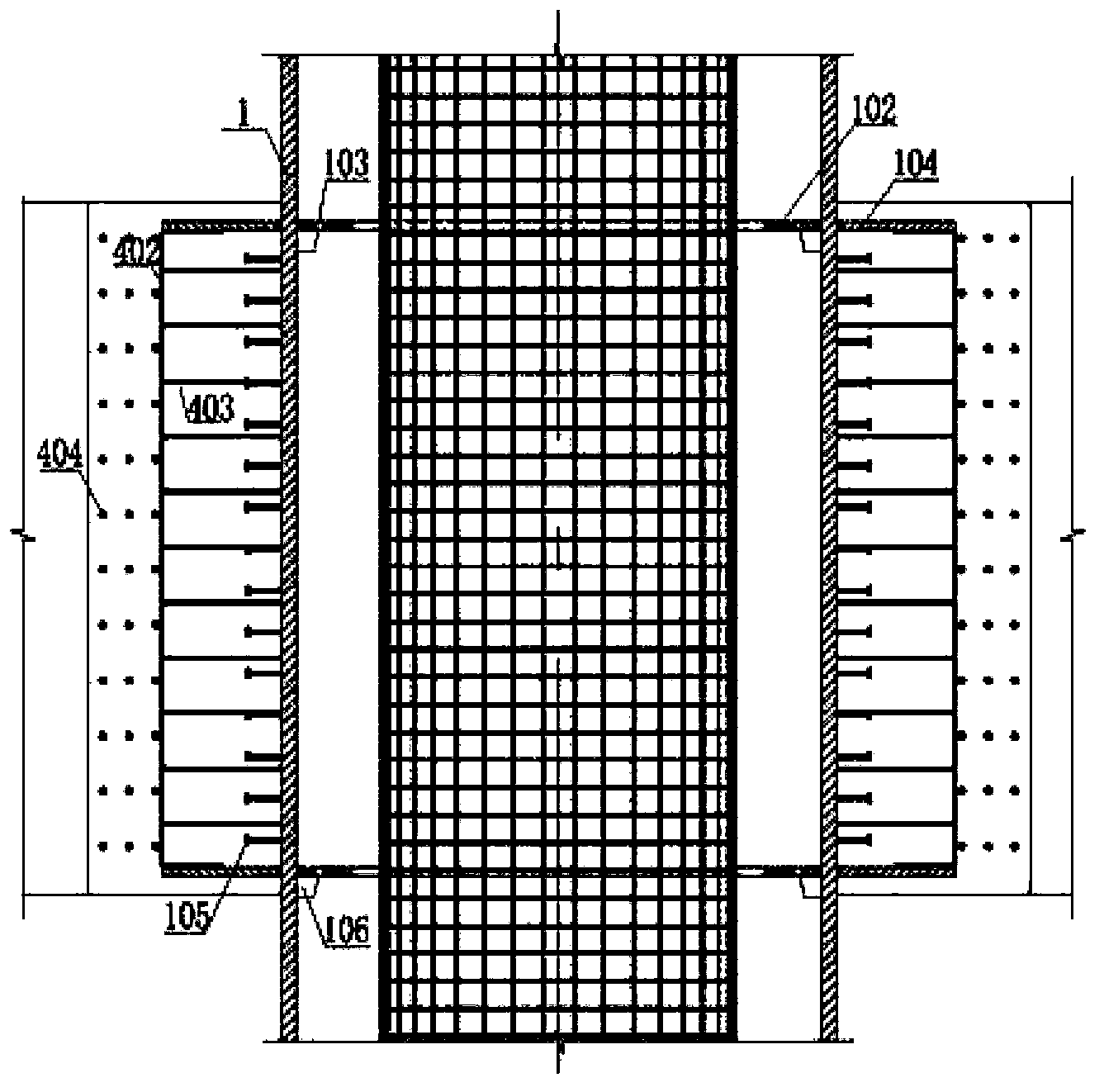

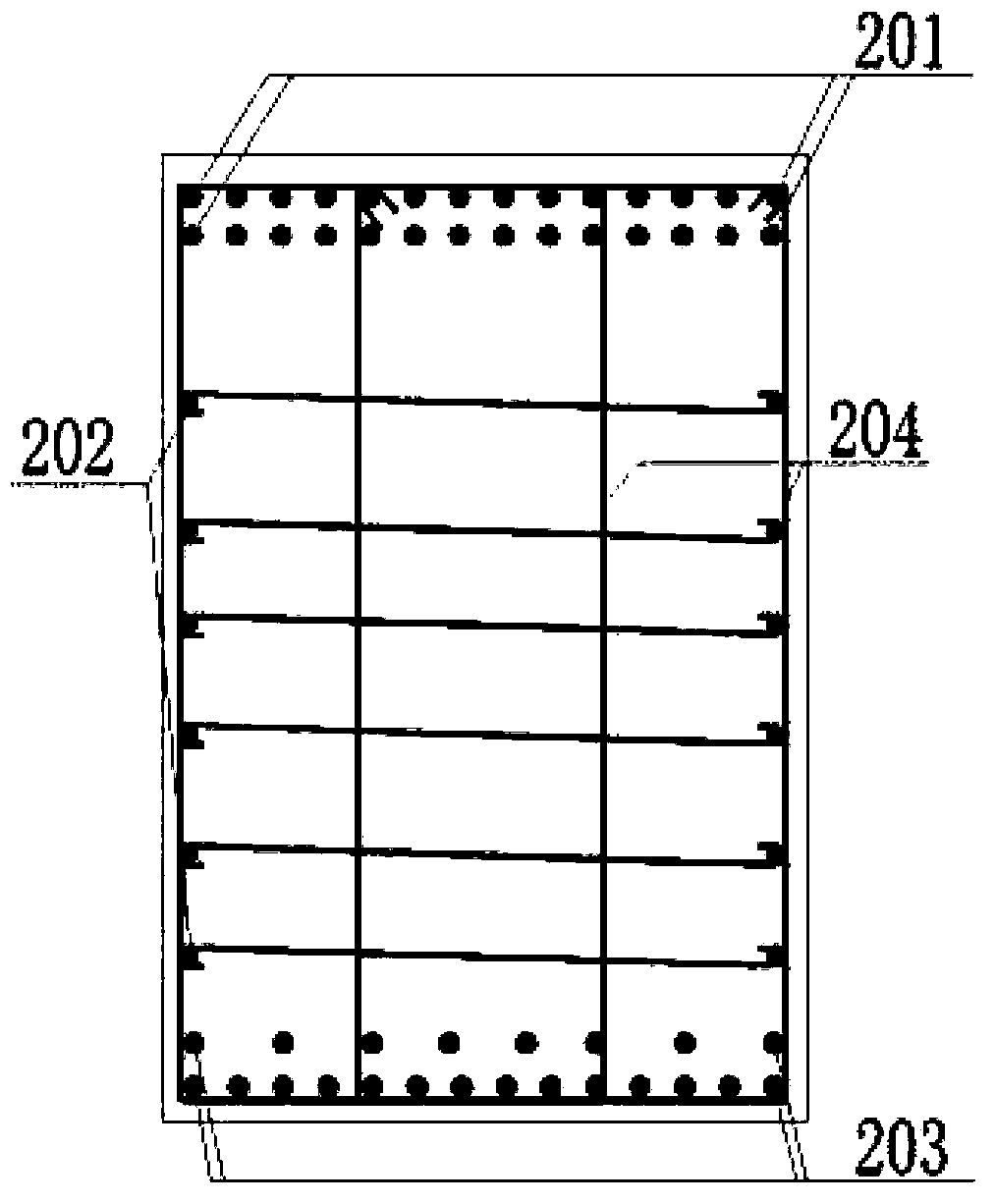

Middle layer joint connecting structure of concrete-filled steel tubular column and reinforced concrete beams

InactiveCN103898983AImprove stress toleranceImprove plastic deformation abilityBuilding constructionsReinforced concreteSteel bar

The invention relates to the field of structural engineering technologies, in particular to a middle layer joint connecting structure of a concrete-filled steel tubular column and reinforced concrete beams. The middle layer joint connecting structure comprises the concrete-filled steel tubular column and the reinforced concrete beams connected with the concrete-filled steel tubular column. The concrete-filled steel tubular column comprises a steel tube, an annular stiffening plate and vertical stiffening ribs are arranged in the steel tube, column end transition plates are arranged outside the steel tube and connected with upper main reinforcement connecting plates on the upper portions of the reinforced concrete beams and lower main reinforcement connecting plates on the lower portions of the reinforced concrete beams through high-strength bolts, and joint shear reinforcements are arranged at the connecting position between every two adjacent reinforced concrete beams. Connecting joints between the concrete-filled steel tubular column and the reinforced concrete beams are connected through high-strength bolts, concrete is cast, so that stress and plastic deformation capacity of a beam column are improved, the on-site welding quantity is small, construction is easy, and the middle layer joint connecting structure has the advantages of being good in ductility, easy and convenient to manufacture and install and convenient to repair after an earthquake and has good application prospects in the fields of large-scale public buildings and others.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

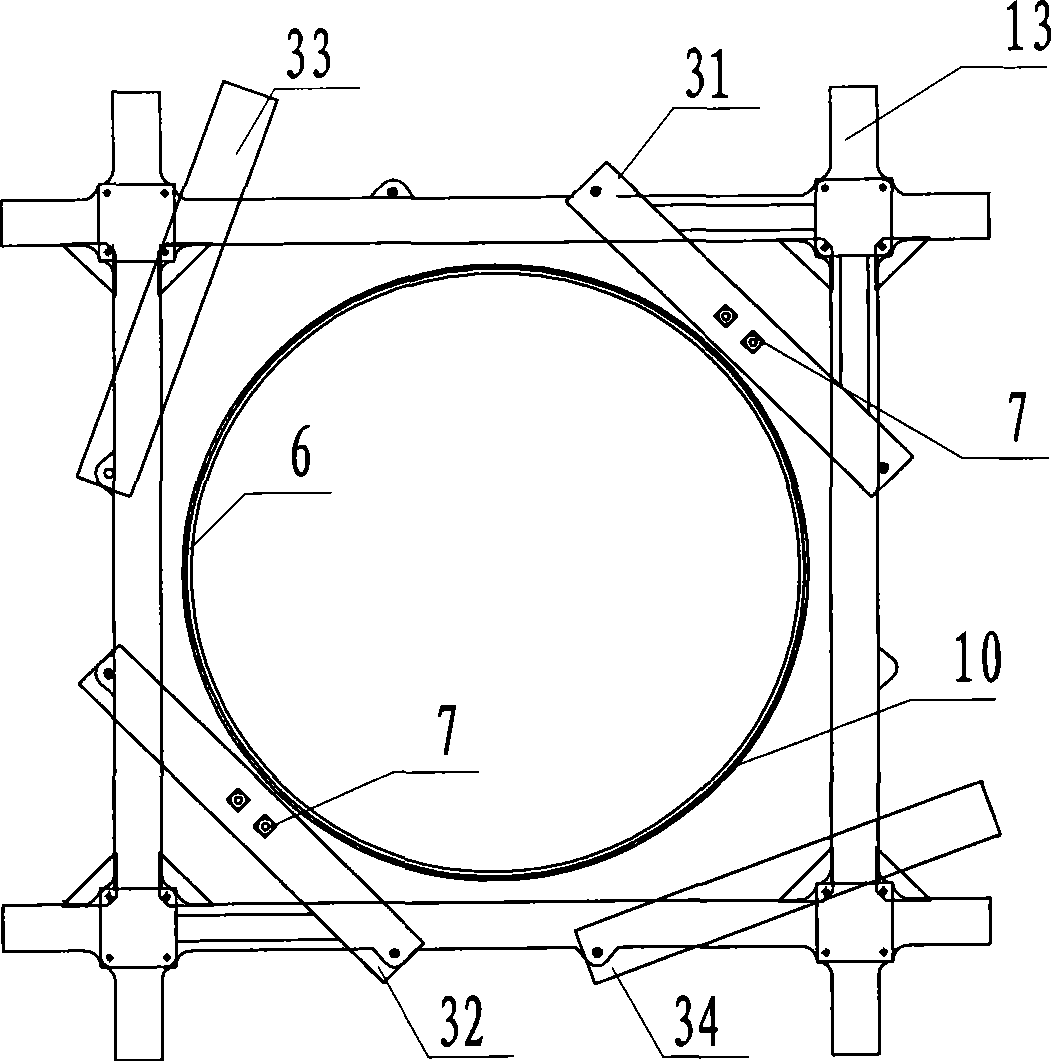

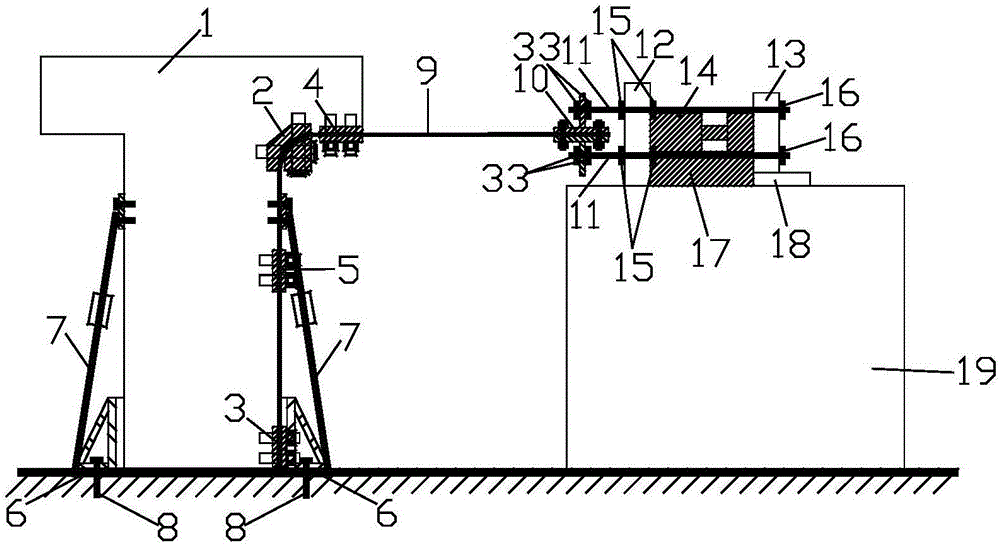

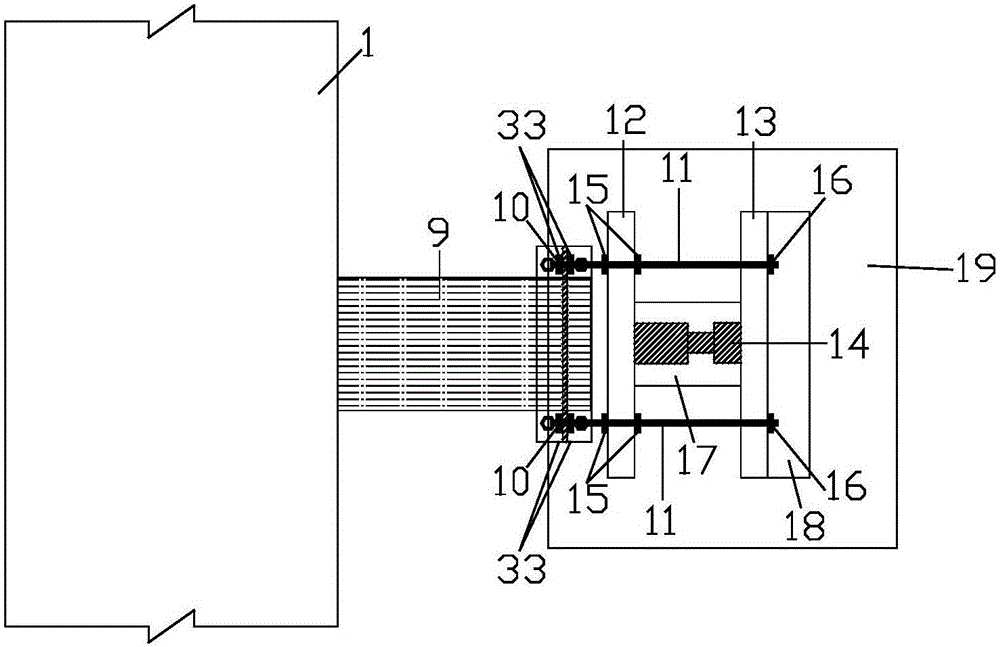

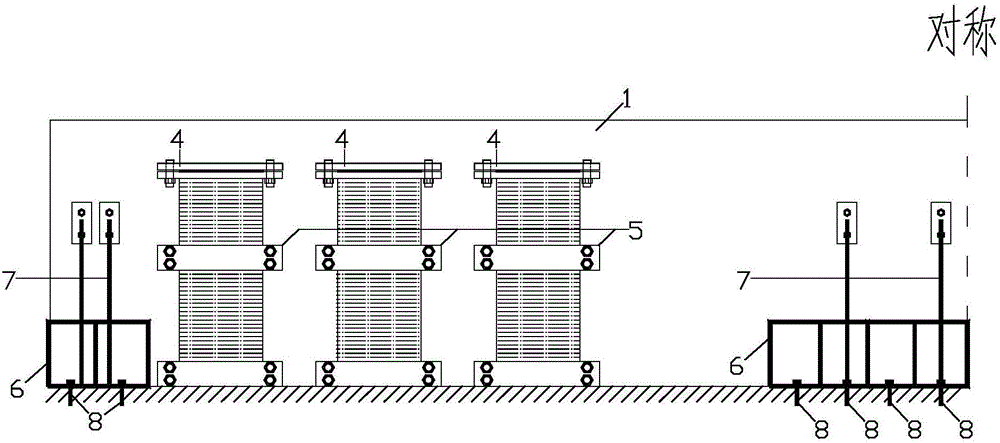

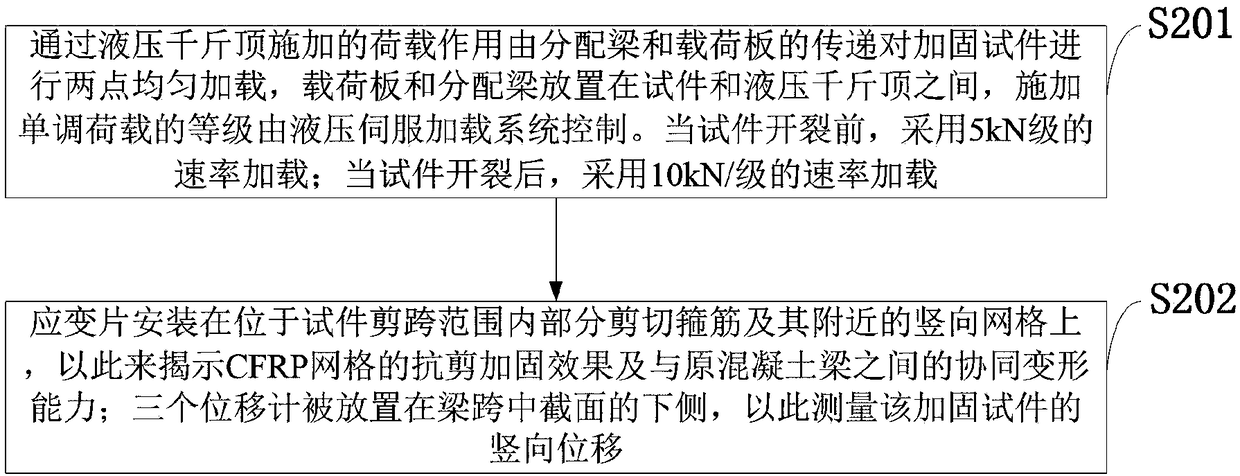

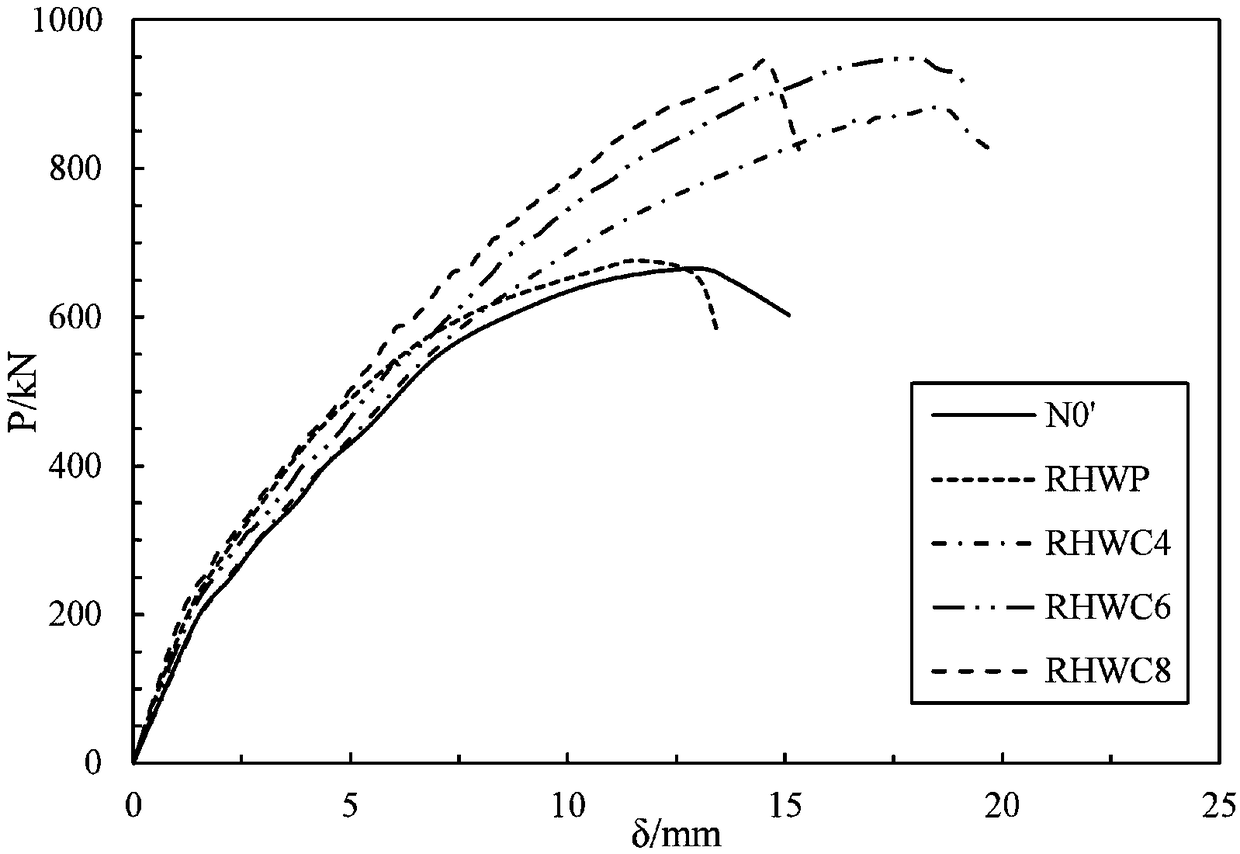

Prestress FRP sheet shear-resistant reinforced concrete beam experimental device

ActiveCN106836021AExtensive constructionEasy constructionBuilding repairsBridge erection/assemblySheet steelConcrete beams

The invention discloses a prestress FRP sheet shear-resistant reinforced concrete beam experimental device. The prestress FRP sheet shear-resistant reinforced concrete beam experimental device comprises a concrete beam, a stretching-drawing pedestal directly facing one side of a concrete beam web, a steering device arranged on the joint of a concrete beam flange plate and the web, an FRP sheet front end anchoring device arranged at the bottom end of the concrete beam web, an FRP sheet middle steel pressing strip arranged in the middle of the concrete beam web, an FRP sheet rear end anchoring device arranged on the lower side of the outer end of the concrete beam flange plate, a limiting device, a stabilizing device, a jack transversely fixed to the stretching-drawing pedestal, a stretching-drawing end front steel plate, a stretching-drawing end rear steel plate, a screw penetrating through the stretching-drawing end front steel plate and the stretching-drawing end rear steel plate, and an FRP sheet stretching-drawing end clamp arranged on the part, near one end of the concrete beam, of the screw. The limiting device and the stabilizing device are arranged on the side face of the concrete beam web. The stretching-drawing end front steel plate and the stretching-drawing end rear steel plate are located on the two sides of the jack. The prestress FRP sheet shear-resistant reinforced concrete beam experimental device is simple to manufacture, fast and convenient to install and capable of applying prestress to an FRP sheet and then pasting the FRP sheet onto the side face of the concrete beam, and the function of shear-resistant reinforcement is achieved.

Owner:江苏纬信工程咨询有限公司

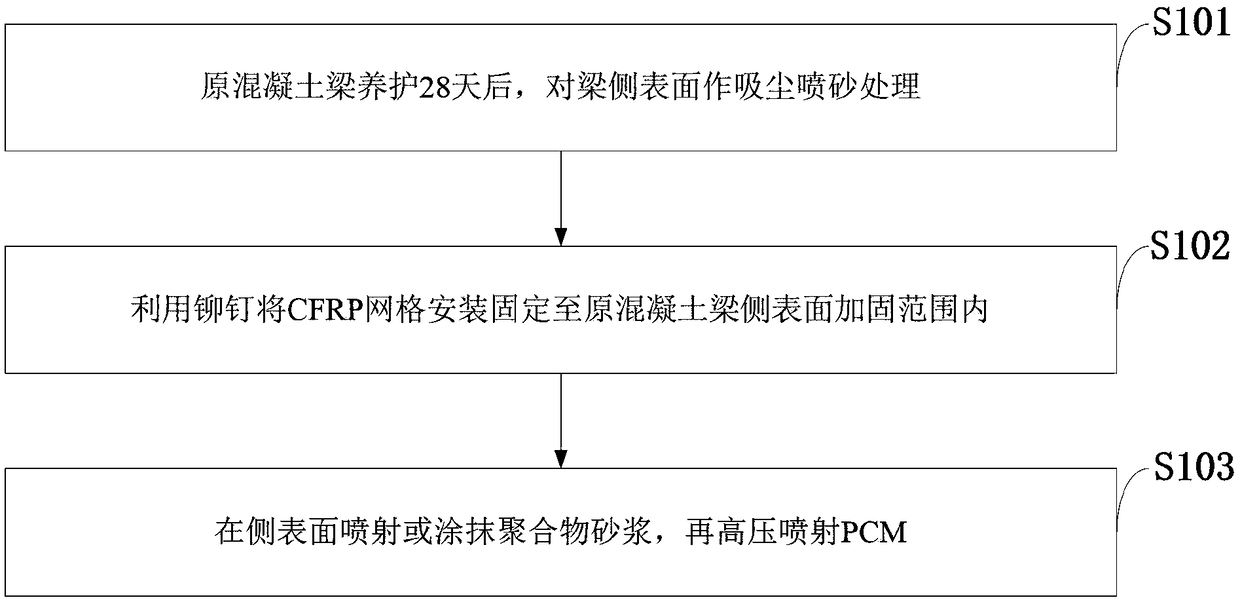

Shear strengthening method for reinforced concrete beam by using CFRP grid-PCM strengthening layer

InactiveCN109184248AIncrease stiffnessImprove bearing capacityBuilding repairsMaterial strength using steady shearing forcesComputer Aided DesignConcrete beams

The invention belongs to the technical field of computer aided design, and discloses a shear strengthening method for a reinforced concrete beam by using a CFRP grid-PCM strengthening layer. After 28days of maintenance of the original concrete beam, dust cleaning and sand blasting are carried out on the outer surface of the original concrete beam; a rivet is used as a temporary anchor, and the CFRP grid is fixedly arranged on the side surface of the original concrete beam; polymer mortar is sprayed or applied on the original concrete beam and the outer surface of the CFRP grid; and finally, high-pressure PCM spraying is carried out on the side surface. After the original concrete beam is compositely strengthened through the CFRP grid-PCM, the shear capacity is increased by 30% to 40%, andthus, the effect of improving the shear capacity of the reinforced concrete beam strengthened by the CFRP grid-PCM is remarkable; and besides, in order to more reasonably and effectively predict theshear capacity of the reinforced concrete beam strengthened by the CFRP grid-PCM, a design calculation formula based on CFRP grid effective strain is proposed.

Owner:SOUTHWEST JIAOTONG UNIV

Assembly tool type truss superimposed sheet and construction method thereof

PendingCN111648512AReduce processing costsReduce construction costsFloorsBuilding reinforcementsPre stressRebar

The invention relates to an assembly tool type truss superimposed sheet and a construction method thereof. An assembly tool type truss is included. The assembly tool type truss further comprises an anti-shear reinforcement bracket and truss support beams, wherein the anti-shear reinforcement bracket is pyramid-shaped. The truss support beams in the assembly tool type truss are of tool type assembly structures; round holes are provided at the junction of the truss support beams and the anti-shear reinforcement bracket; the truss support beams are arranged in a segmented manner; and the truss support beams are connected in an socket-and-spigot manner. The construction method of the assembly tool type truss superimposed sheet comprises the steps of manufacturing the anti-shear reinforcement bracket, T-shaped connection portions, the truss support beams and a base plate in sequence; connecting and combining the anti-shear reinforcement bracket and the truss support beams; paving anti-shearreinforcement bracket and truss support beam combined members on horizontal and vertical reinforcements; conducting concrete pouring of prestressed superimposed sheets; mounting prestressed superimposed sheets; pouring a second layer of superimposed concrete; and disassembling the truss support beams.

Owner:山东高速德建集团有限公司

Top layer joint connecting structure of concrete-filled steel tubular column and reinforced concrete beams

InactiveCN103898984AImprove stress toleranceImprove plastic deformation abilityShock proofingReinforced concreteEngineering

The invention relates to the field of structural engineering technologies, in particular to a top layer joint connecting structure of a concrete-filled steel tubular column and reinforced concrete beams. The top layer joint connecting structure comprises the concrete-filled steel tubular column and the reinforced concrete beams connected with the concrete-filled steel tubular column. The concrete-filled steel tubular column comprises a steel tube, and an annular stiffening plate and vertical stiffening ribs are arranged in the steel tube. Column end transition plates are arranged outside the steel tube and connected with upper main reinforcement connecting plates on the upper portion of the reinforced concrete beams and lower main reinforcement connecting plates on the lower portions of the reinforced concrete beams through high-strength bolts. Joint shear reinforcements are arranged at the connecting position between every two adjacent reinforced concrete beams. Connecting joints between the concrete-filled steel tubular column and the reinforced concrete beams are connected through the high-strength bolts, concrete is cast, stress and plastic deformation capacity of a beam column are improved, the on-site welding quantity is small, construction is easy, and the top layer joint connecting structure has the advantages of being good in ductility, easy and convenient to manufacture and install and convenient to repair after an earthquake and has good application prospects in the fields of large-scale public buildings and others.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

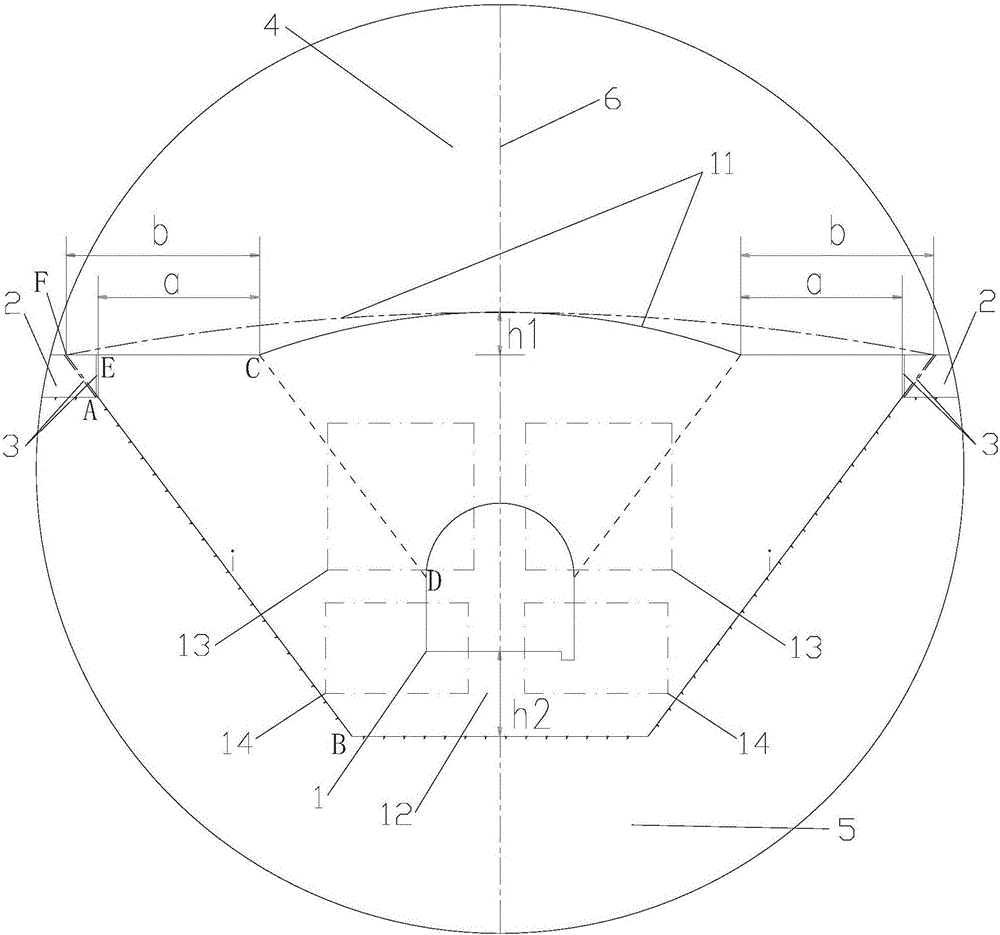

Bottom microarch-type gallery structure of HCRFD (High Core Rockfill Dam)

ActiveCN106351183AReduce shear stressReduce risk of penetration breachesEarth-fill damsRock-fill damsShear stressBedrock

The invention discloses a bottom microarch-type gallery structure of an HCRFD (High core Rockfill Dam) and relates to the field of water conservancy and hydropower engineering. The bottom microarch-type gallery structure is used for solving the problem that large dam safety is influenced by cracking and water leakage inevitably generated in a HCRFD on a bedrock. The adopted technical scheme is as follows: the bottom microarch-type gallery structure of the HCRFD comprises a gallery at the bottom of a core, and the top of the gallery is protruded upwards to be combined with the gallery so as to form a microarch structure, so that the force transferring route of the structure is changed by use of the microarch structure. Compared with a plateau type gallery structure, the microarch-type gallery structure has the characteristics that the increased concrete quantity is less, whereas the shear stress of a vertex angle region of the gallery can be obviously reduced; furthermore, the top shear stress region and bottom shear stress region of the gallery are provided with shear reinforcement structures, so that the stress characteristic of the gallery structure can be obviously improved, the risk that seepage failure occurs due to cracks caused by damage of shear stress at the top of the gallery is reduced, the problems of cracking and water leakage of the HCRFD on the bedrock are solved, the operation safety of a large dam is improved, and the economical efficiency of engineering is obviously improved.

Owner:POWERCHINA CHENGDU ENG

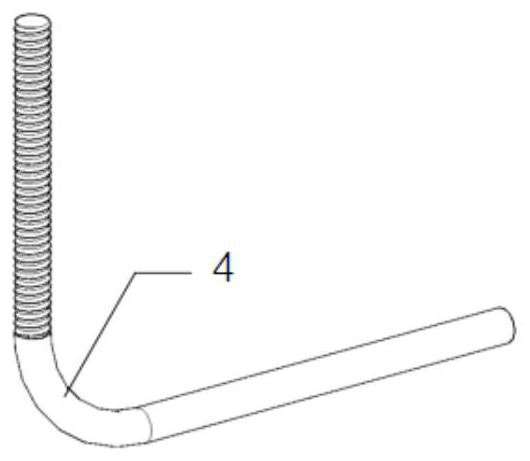

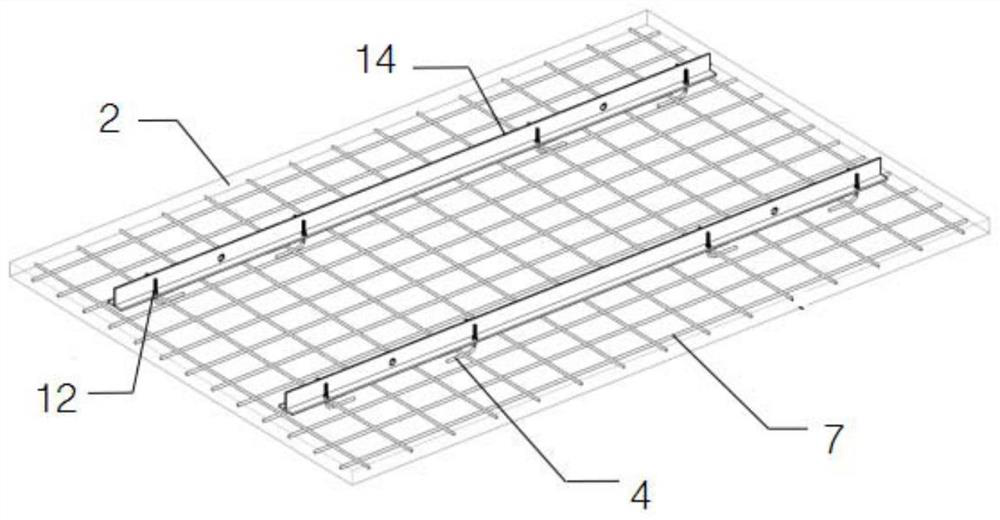

Anti-shearing reinforcement device and method for concrete box girder web

ActiveCN109537478ASolve the problem of excessive main tensile stressAvoid corrosionBridge erection/assemblyBridge strengtheningPre stressRebar

The invention relates to an anti-shearing reinforcement device and method for a concrete box girder web. In order to solve the problem that in existing engineering technologies, the concrete box girder web has cracking inclined cracks and insufficient anti-shearing bearing capacity, an external vertical prestressing tendon reinforcement device and method are provided. The device comprises groove-shaped steel, L-shaped steel, vertical prestressing tendons, wedge-shaped steel cushion blocks and an anti-corrosion coating at the outer side of the web. The groove-shaped steel is horizontally fixedto the junction of the upper end of the web and a top plate in the girder length direction. The L-shaped steel (6) is horizontally fixed to the lower end of the web in the girder length direction andis parallel to the groove-shaped steel (5). The vertical prestressing tendons are vertically mounted on the groove-shaped steel and the L-shaped steel, and it is ensured that the vertical prestressingtendons are parallel to the plane of the web. According to the anti-shearing reinforcement device and method, the web is connected with the top plate and a bottom plate through finish rolling twistedsteel, the force transmission path is definite, the risk that web concrete is pulled broken is reduced, and meanwhile, midspan deformation is reduced; the problem of insufficient main tensile stressof the web concrete is effectively solved, and the situations of continuous extension of the inclined cracks of the web or new inclined cracks are prevented.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com