Single plate force-bearing reinforcing method of hollow slab bridge

A single-slab-loaded, hollow-slab bridge technology, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve problems such as bridge deck pavement and hinge joint damage, and does not fundamentally solve the overall stress problem, and achieves improved Reliability, the effect of improving the overall mechanical performance of the bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

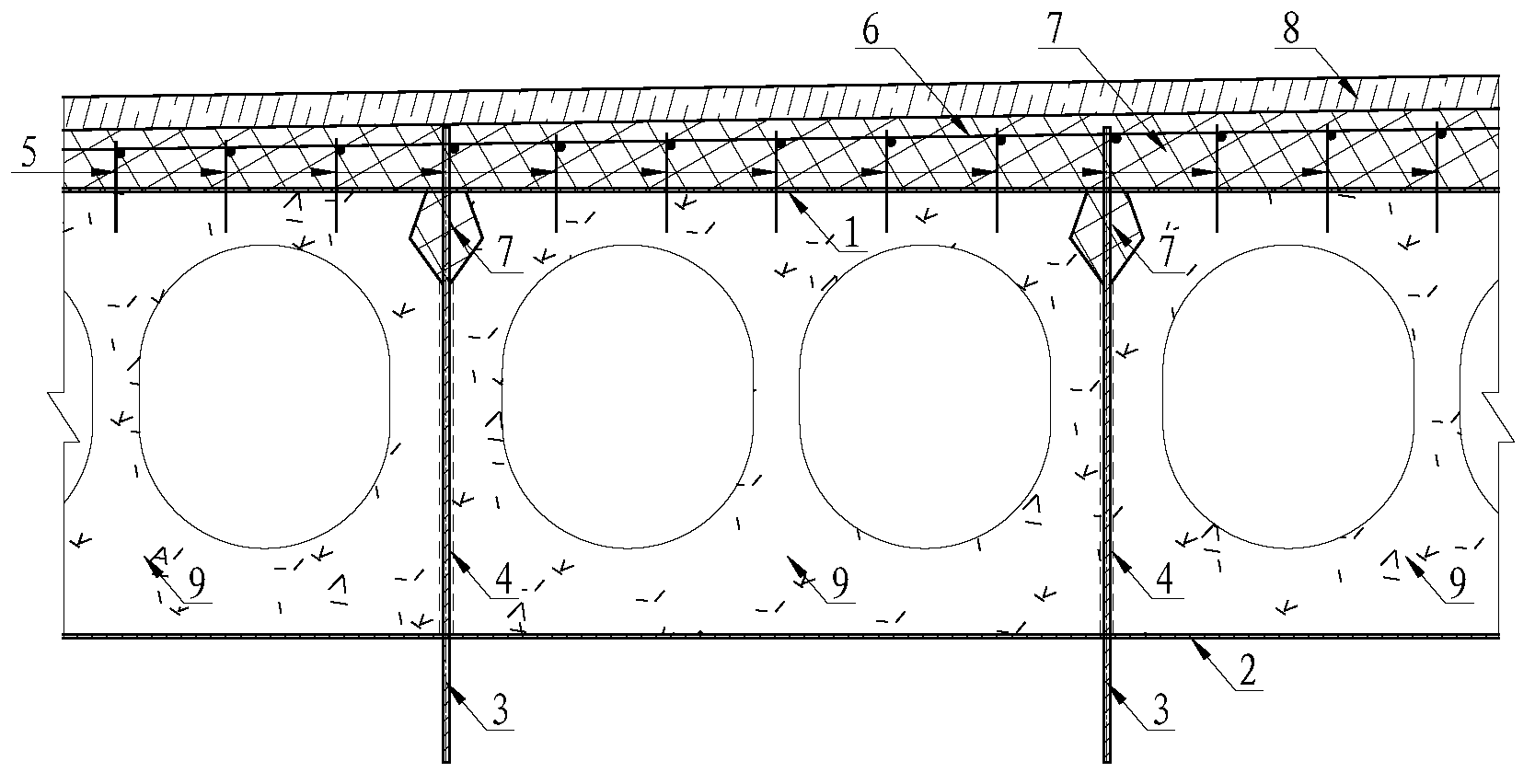

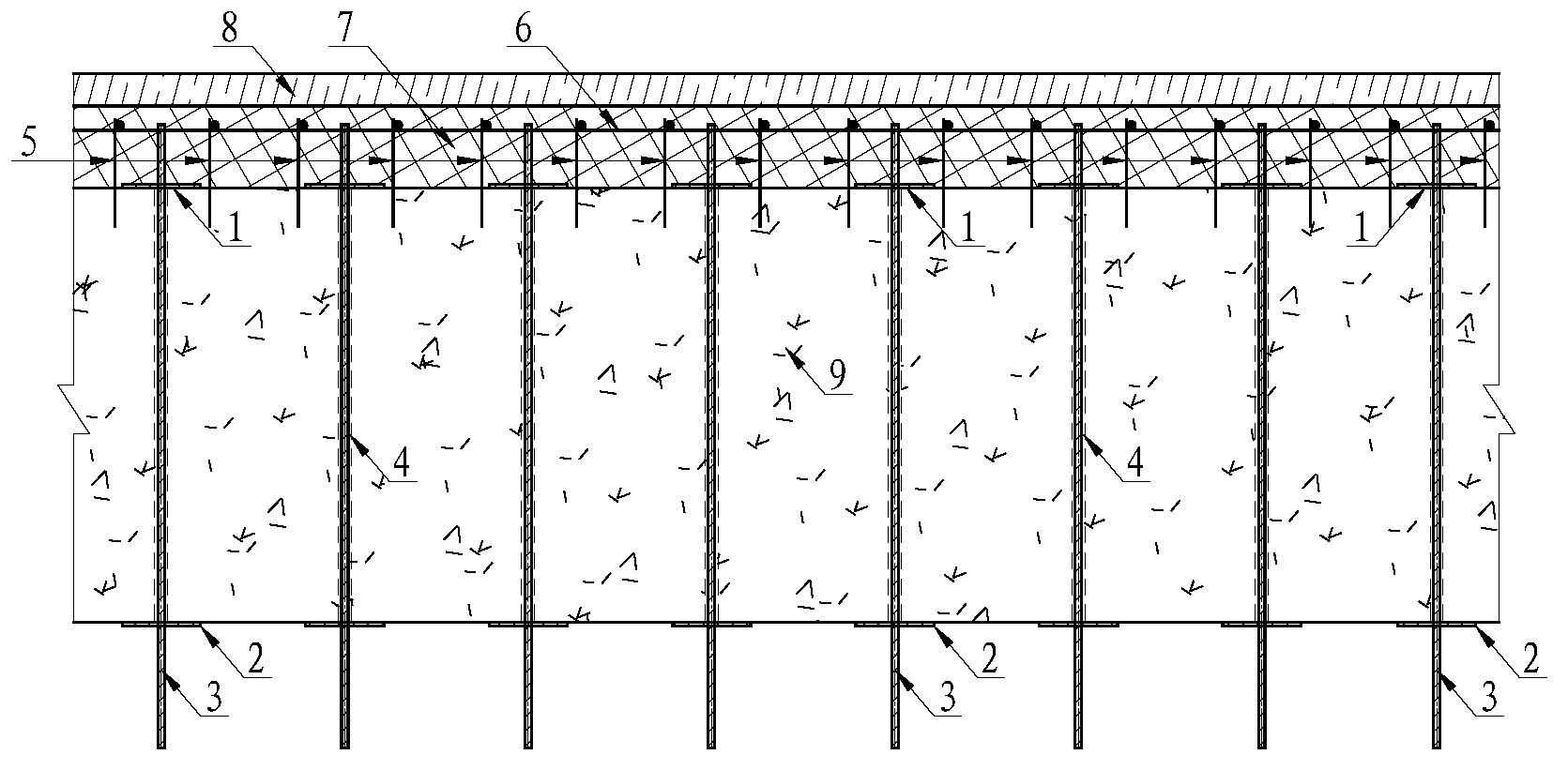

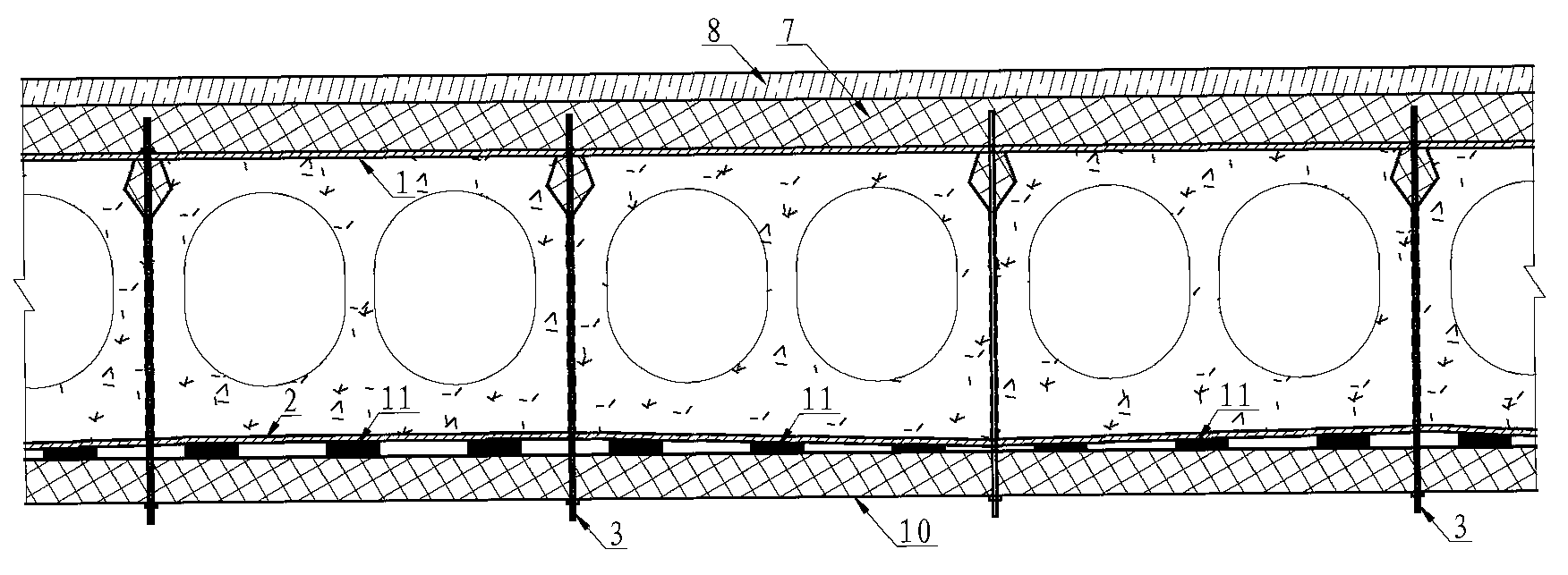

[0021] The present invention positions and fixes the steel plates 1 and 2 pasted on the upper and lower surfaces of the hollow plate by pulling the screw 3, and applies pressure to improve the reliability of the pasting of the steel plates and improve the lateral distribution of the load; by performing pressure grouting on the cavities in the beam joints 4. Close the holes and improve the connection performance between the hollow slabs; by implanting shear steel bars 5 on the top surface of the hollow slabs, resetting the steel mesh 6, and pouring steel fiber concrete 7 and asphalt concrete 8, the overall mechanical performance of the hollow slabs is improved.

[0022] Refer to the attached figure 1 , 2 The present invention is described in detail. Concrete steps of the present invention are as follows:

[0023] 1) Remove the original bridge deck pavement, the construction process is as follows:

[0024] ①Remove the asphalt concrete of the original surface layer with a mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com