Basalt Basket and Dowel and Method of Manufacture

a basket and dowel technology, applied in the field of concrete reinforcement, can solve the problems of affecting the performance of concrete, and affecting the performance of concrete, and achieve the effect of improving the loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

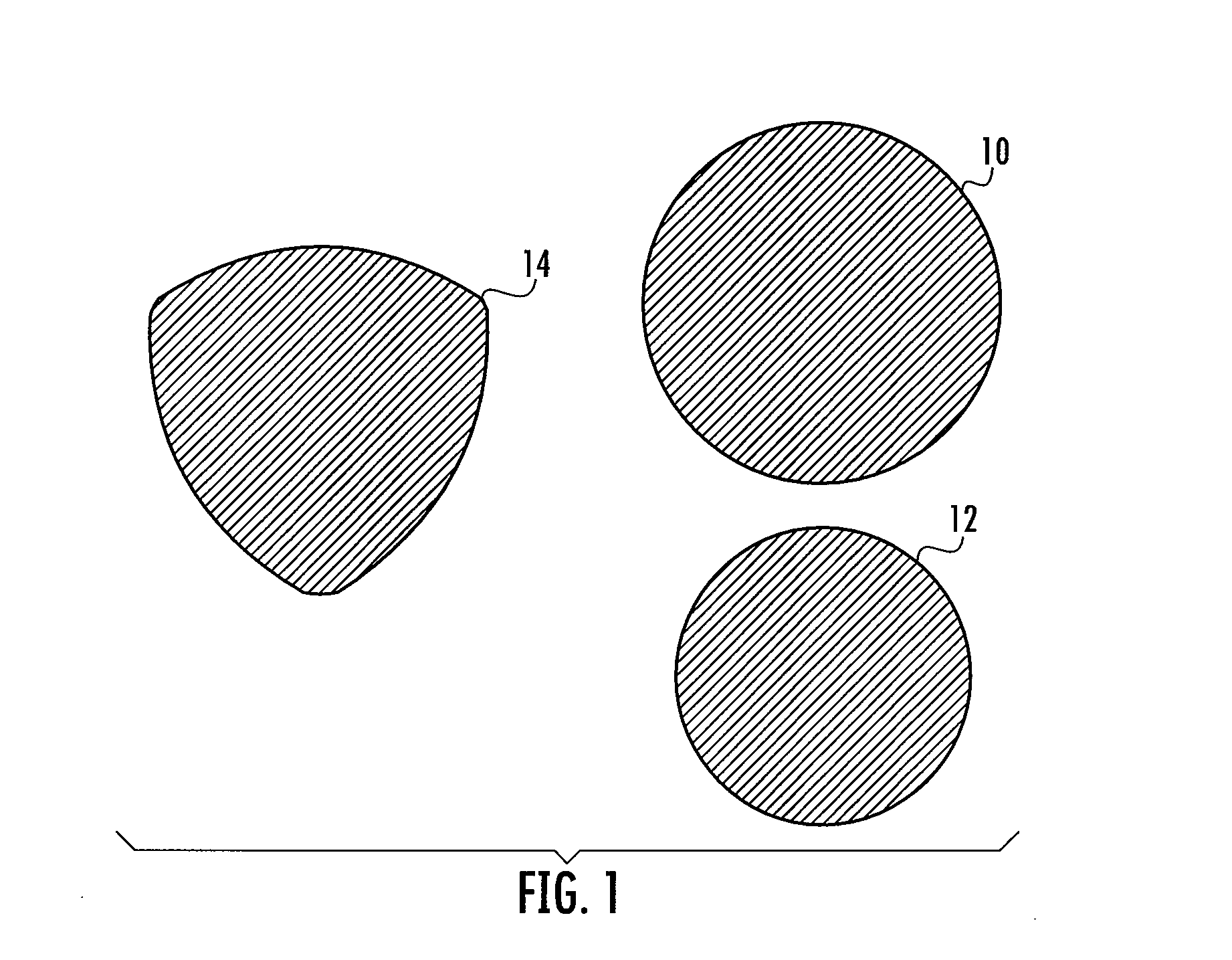

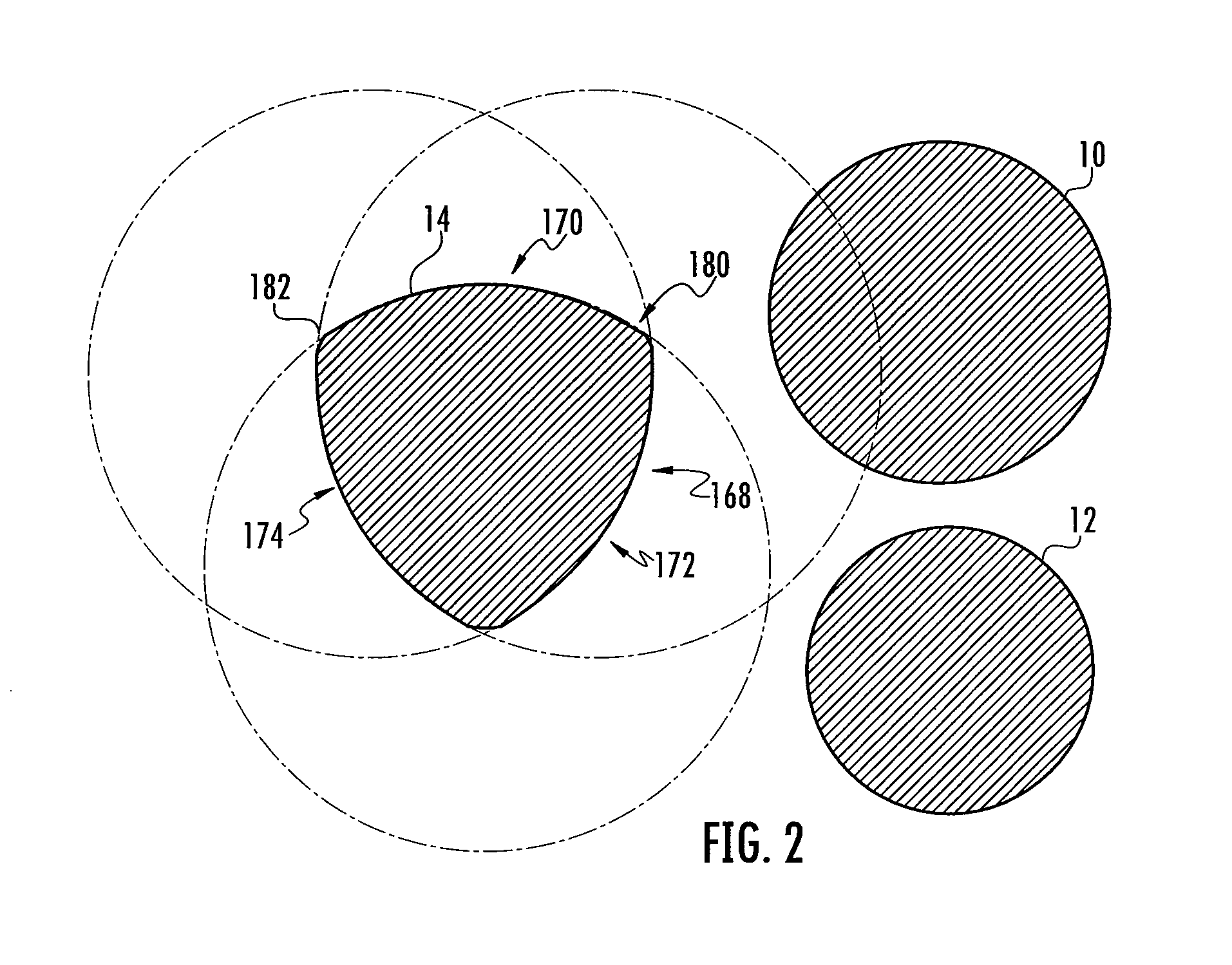

[0038]The purpose of the dowels is to transfer loads across a joint without restricting joint movement due to thermal contraction and expansion of the concrete. Studies have shown that larger dowels are more effective in transferring loads and in reducing faulting. Dowels should be corrosion-resistant to prevent dowel seizure, which causes the joint to lock up. Epoxy-coated and stainless steel dowels have been shown to adequately prevent corrosion. Smooth dowels are the most widely used method of transferring load across expansion joints. Expansion joint dowels are specially fabricated with a cap on one end of each dowel that creates a void in the slab to accommodate the dowel as the adjacent slab closes the expansion joint.

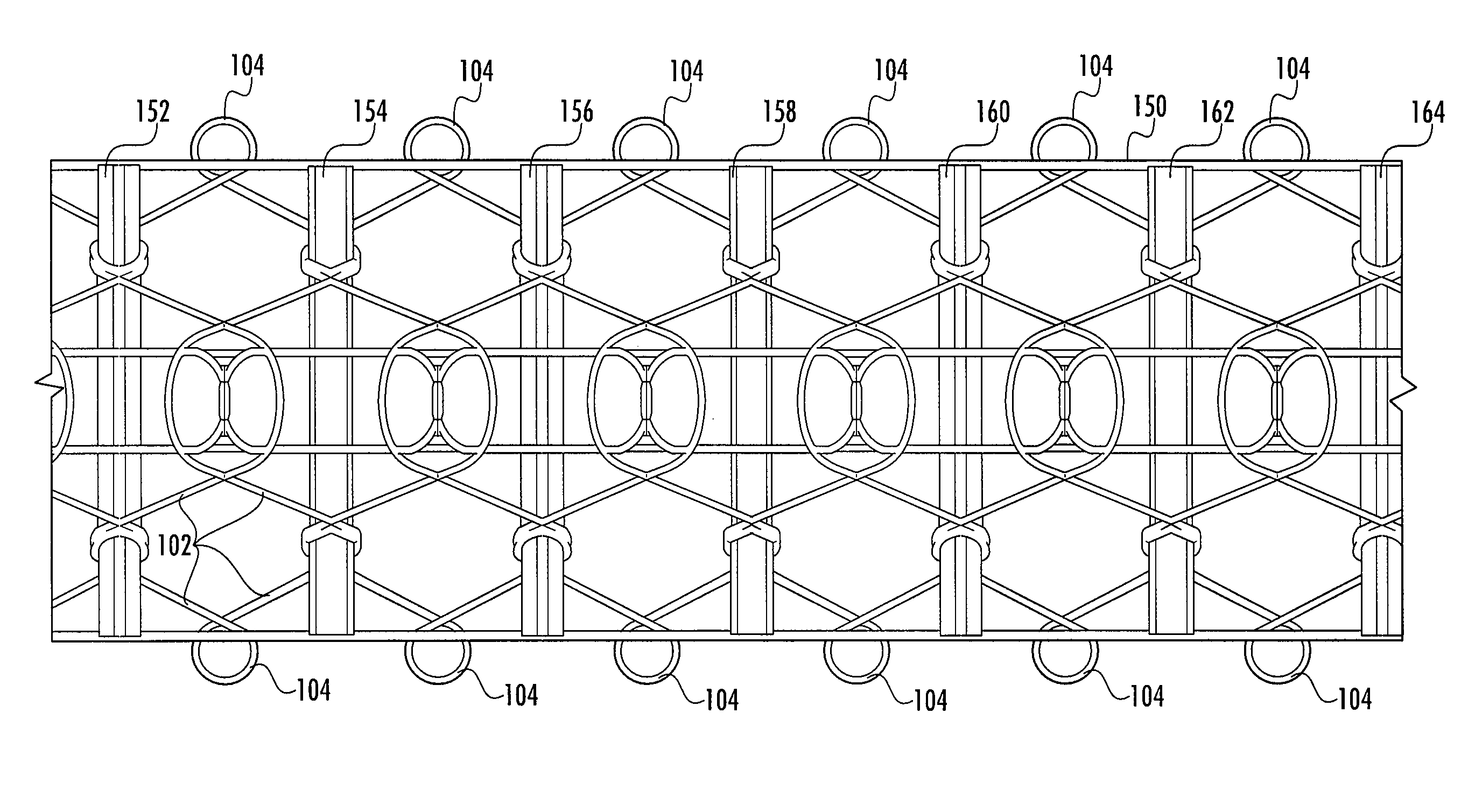

[0039]Dowel baskets are used to ensure that the dowels are properly aligned. Conventional dowel baskets are constructed from steel, are about 24″×12′ in dimension. A steel dowel basket weighs about 50 lbs and a steel dowel that is about 1½″×24″ weigh about 20 lbs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com