Shear-resistant reinforcing method for small-section hollow beam

A technology of hollow beams and small cross-sections, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of bridge structure increase, waste of resources, long construction period, etc., and achieve improved shear bearing capacity, improved reinforcement effect, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

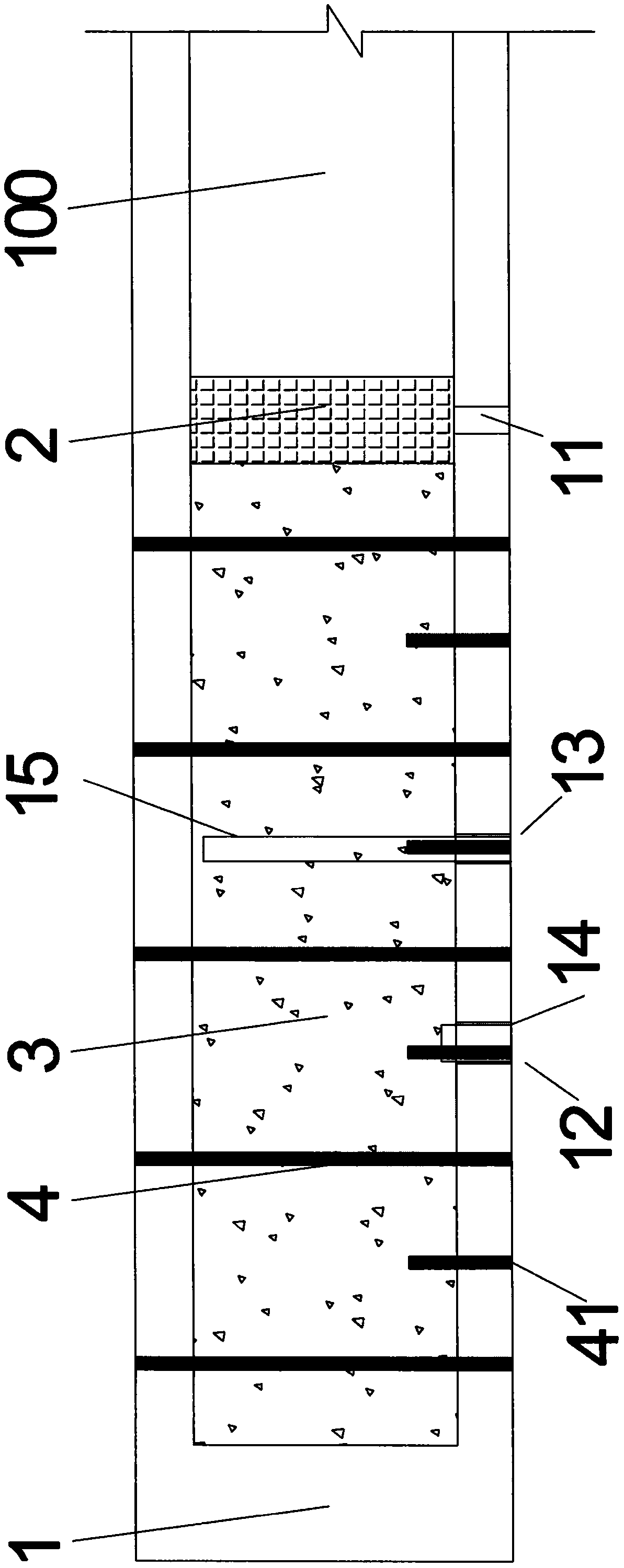

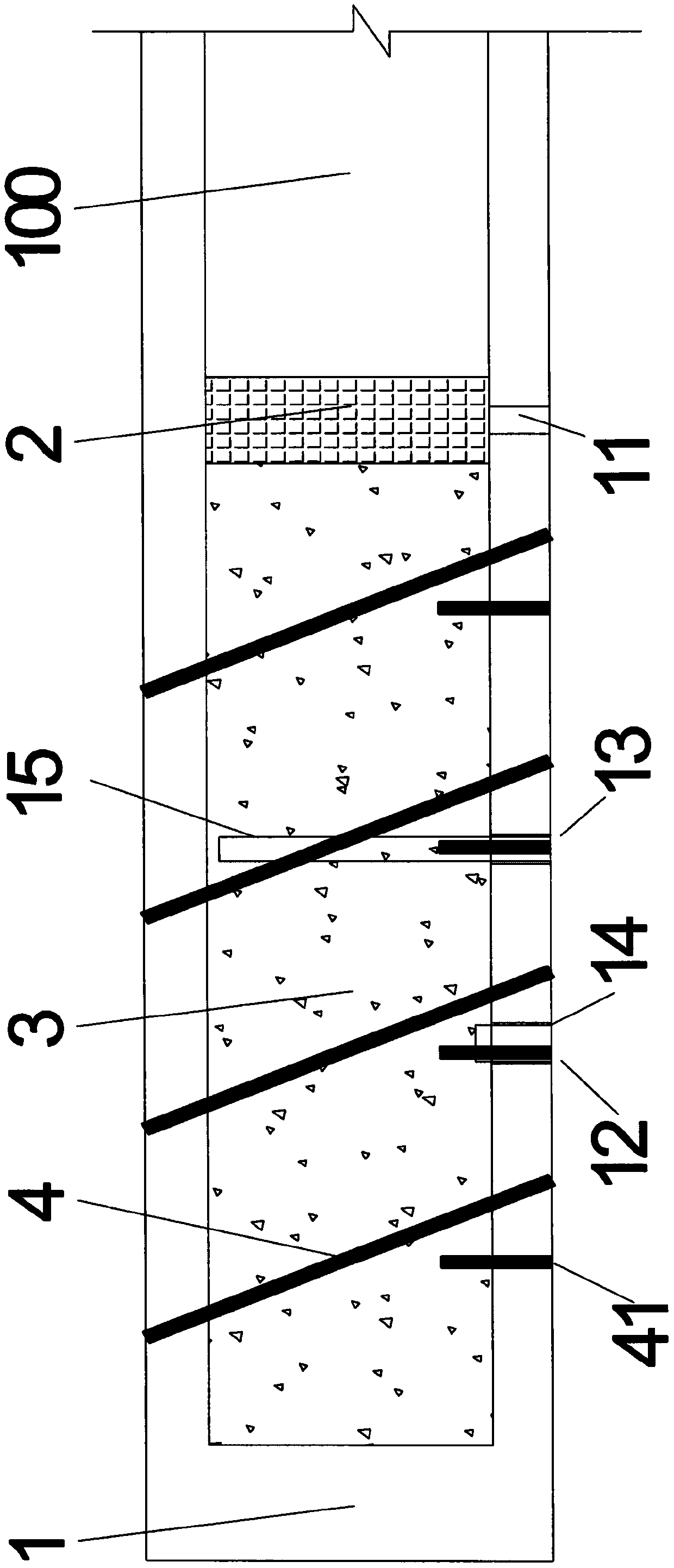

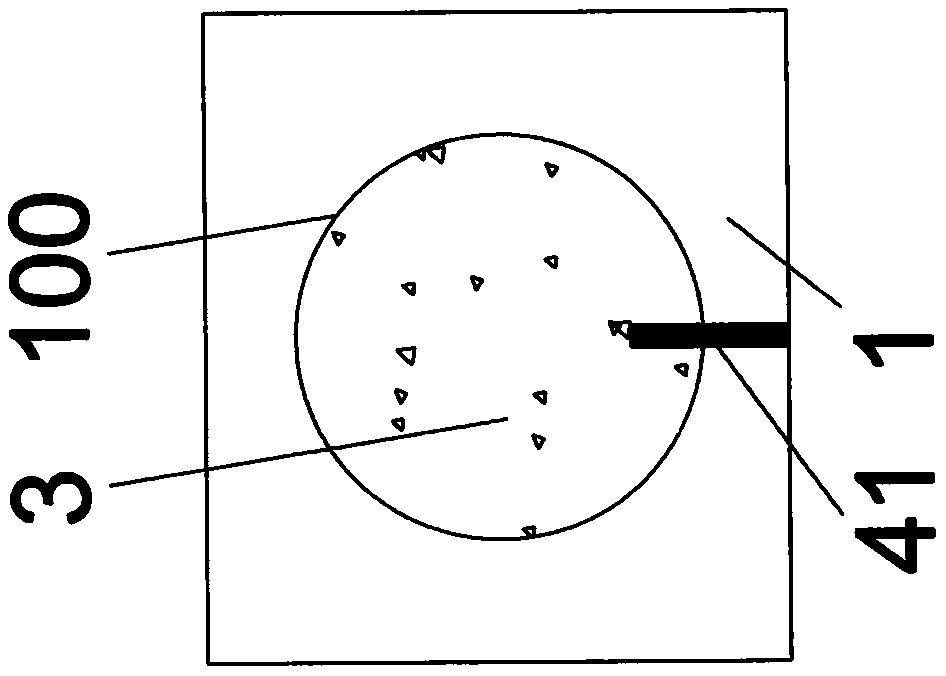

[0040] The present invention will be further described below in conjunction with the accompanying drawings. As shown in the accompanying drawings, a small-section hollow beam shear reinforcement method is characterized in that: by opening holes and embedding pipes at the bottom of the hollow slab girder, a plugging is provided. Plug the inner end of the cavity in the area to be reinforced with material, pour reinforcement into the cavity of the area to be reinforced in the hollow slab beam, drill holes from the bottom of the hollow beam from bottom to top, and implant through the reinforcement and the hollow beam The shear reinforcement of the top and bottom slabs is used to realize the shear reinforcement of the hollow beam. The specific steps are as follows:

[0041] A. Opening and embedding pipes: For the bottom of the hollow beam 1, plugging holes 11, filling holes 12 and air outlet holes 13 are set, which correspond to more than one left and right half-spans of each cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com