Manufacture and mounting method of completely assembled sunken floor

An installation method and full assembly technology, which are applied in the processing of floors, manufacturing tools, building materials, etc., can solve the problems of reducing the efficiency of floor assembly construction and prolonging the construction progress, and achieve a safe and efficient production process. Quality guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

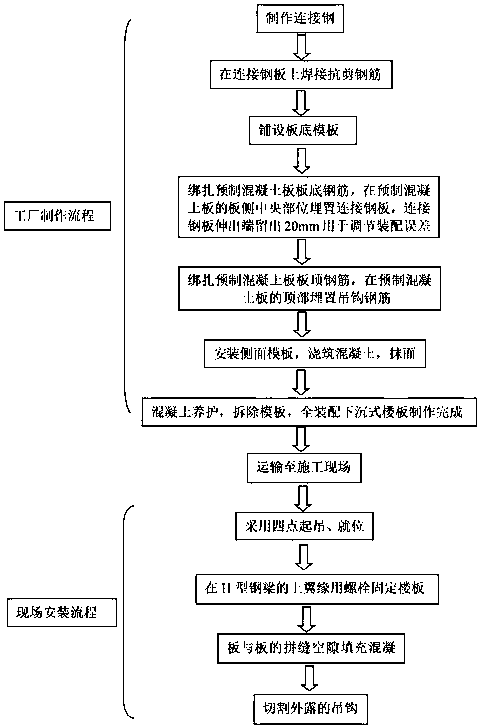

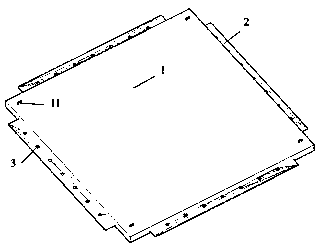

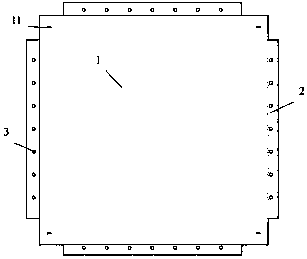

[0030] A method for making and installing a fully assembled sunken floor. The fully assembled sunken floor is composed of a prefabricated concrete slab 1 and a connecting steel plate 2. The four sides of the prefabricated concrete slab 1 are pre-embedded with outstretched connecting steel plates 2, and the connecting steel plates 2 is located in the middle of the side of the prefabricated concrete slab 1. The length × width × = 8000mm × 8000mm × 150mm of the prefabricated concrete slab 1, the double-layer two-way 8@180 steel bars run through. Fully assembled sunken floor slabs are first manufactured in the factory and then transported to the construction site for assembly.

[0031] The method for making and installing a fully assembled sunken floor includes the following steps:

[0032] (1) Make connecting steel plate 2, make 4 connecting steel plates 2 with length×width×thickness=7600mm×450mm×8mm, reserve bolt holes 3 75mm away from the edge of the plate, the diameter of bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com