Prestress FRP sheet shear-resistant reinforced concrete beam experimental device

A technology of concrete beams and FRP sheets, which is applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of easy corrosion of steel plates, influence of interface bonding performance, and large increase in the self-weight of concrete beams. Extensive, performance-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

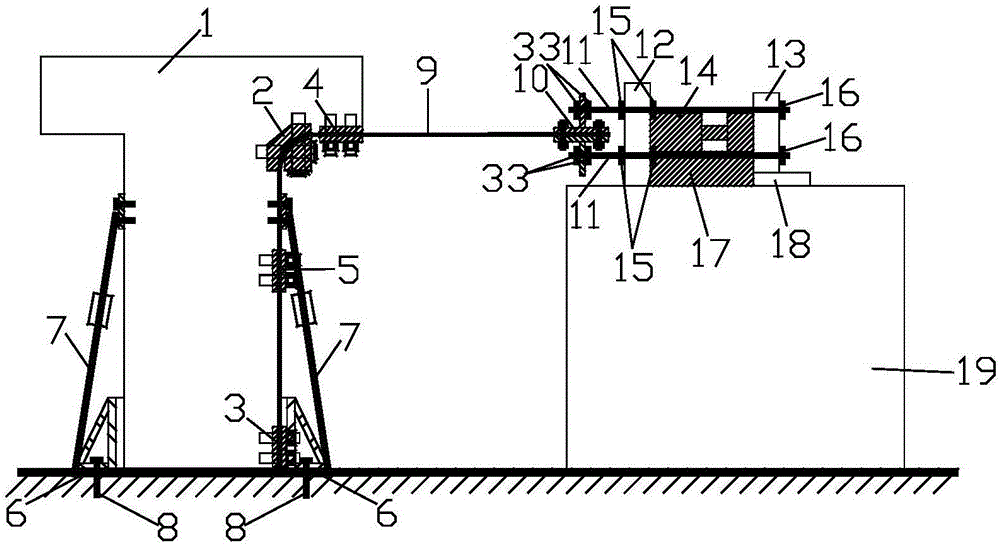

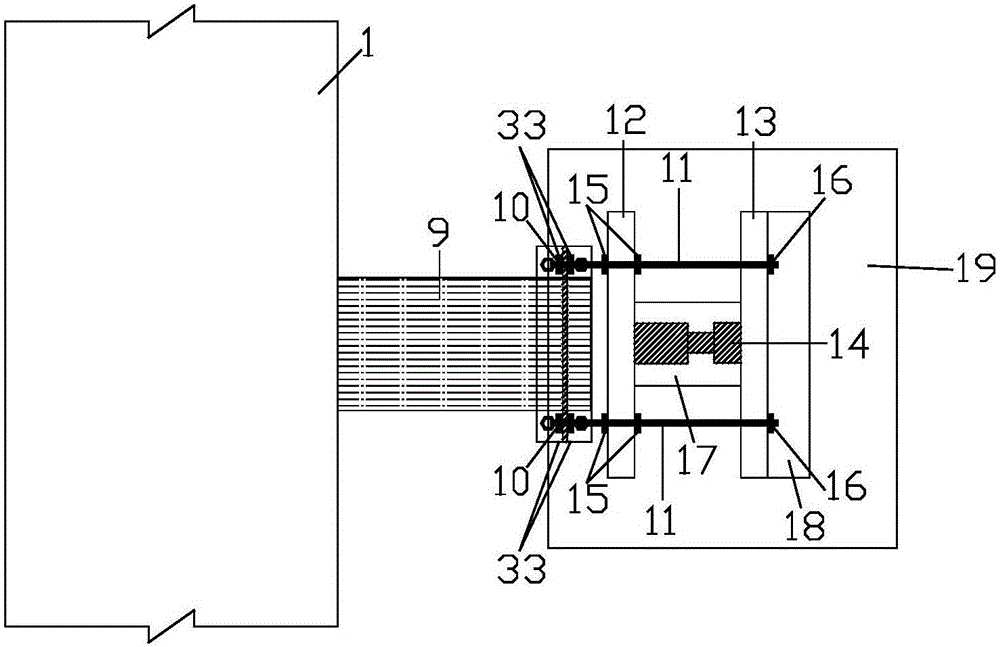

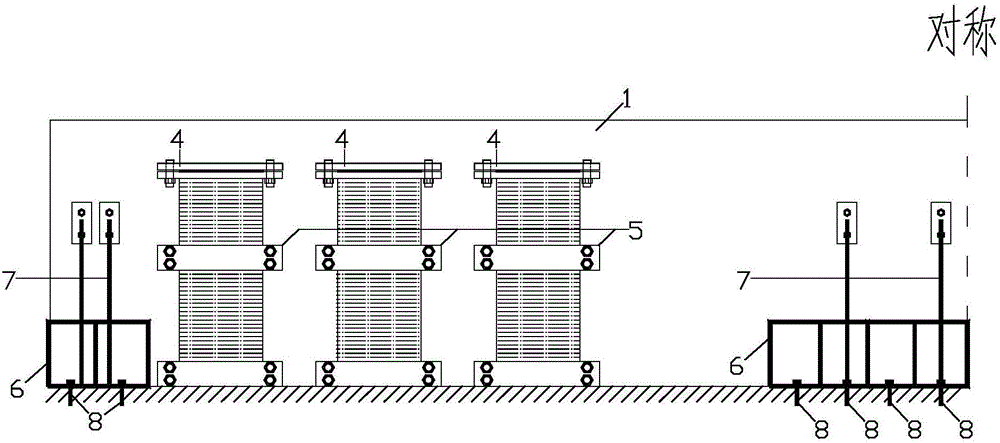

[0041] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0042] The prestressed FRP sheet anti-shear strengthening concrete beam experimental device of the present invention includes a steering device 2 arranged at the junction of the flange plate and the web of the concrete beam, an anchoring device 3 at the front end of the FRP sheet, a steel bead 5 in the middle of the FRP sheet, and an FRP sheet Anchor device at back end of sheet 4, FRP sheet tension end fixture 10, front steel plate at tension end 12, rear steel plate at tension end 13, jack 14, limit device 6, stabilizing device 7, jack support 17, tension stand 19. Polytetrafluoroethylene plate 18. Screw rod 11 connected to the clamp at the tension end of the FRP sheet and passing through the steel plate at the front of the tension end and the steel plate at the rear of the tension end.

[0043] The steering device 2 includes an inner steering block 20 embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com