A movable steel casing and a construction method for cast-in-situ piles using the steel casing

A construction method and technology of steel casing, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of reducing the quality of pile foundation and easy collapse of concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

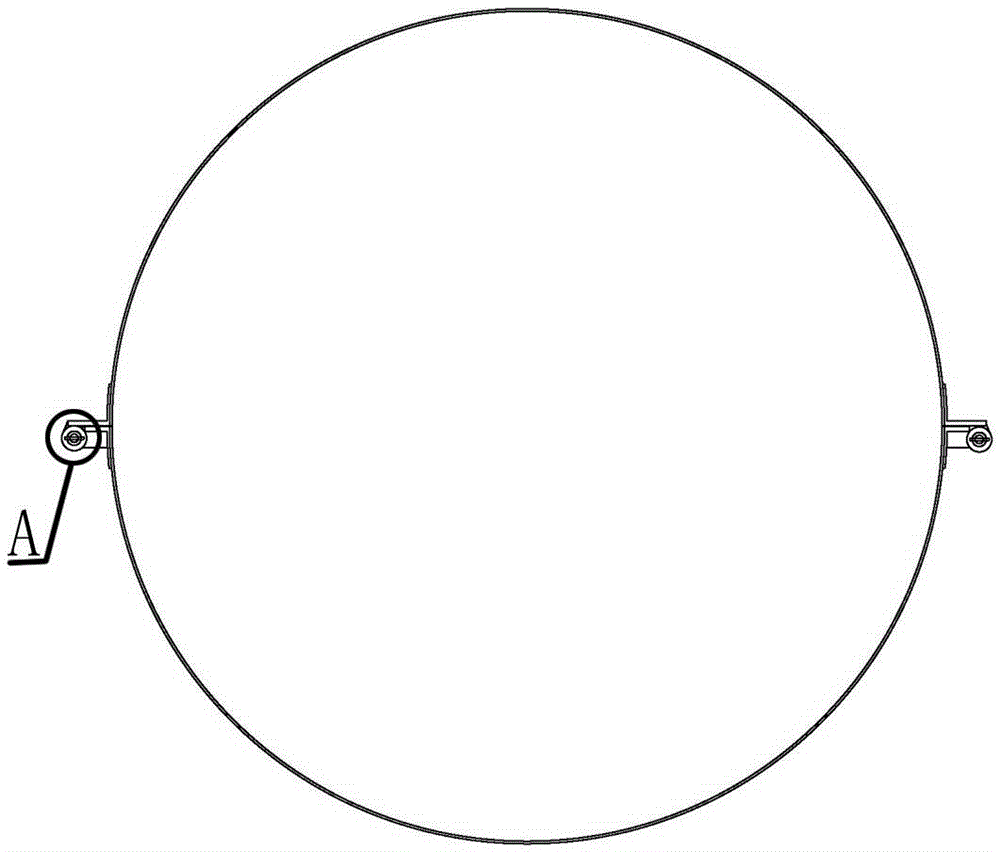

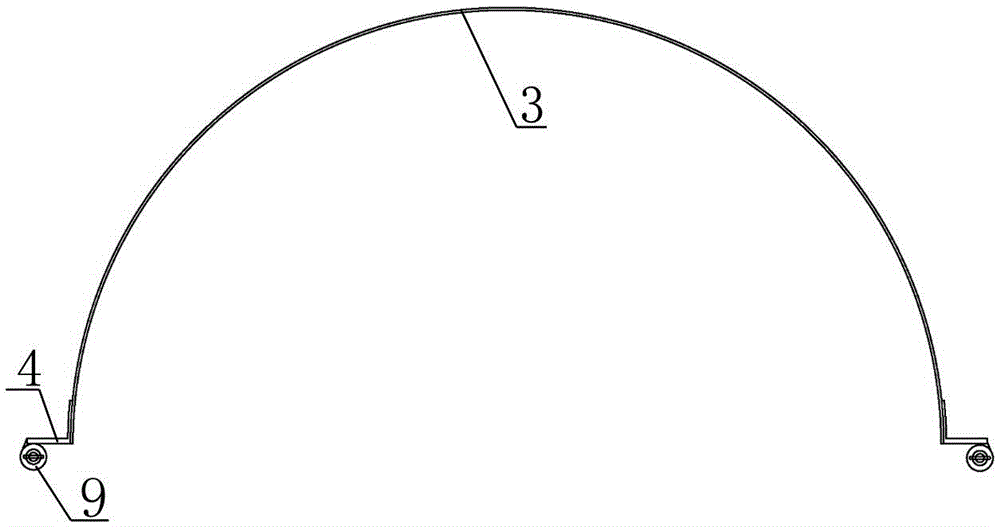

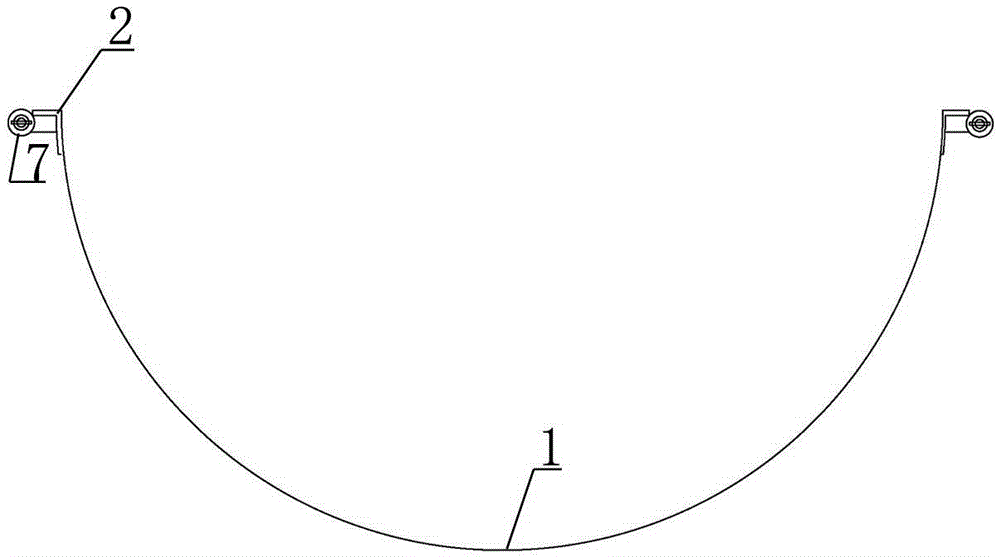

[0038] Examples see Figure 1 to Figure 5 As shown, a movable steel casing is composed of a front semicircular cylinder wall 1 and a rear semicircular cylinder wall 3. The diameters and heights of the front semicircular cylinder wall 1 and the rear semicircular cylinder wall 3 are are the same;

[0039] The opening of the front semicircular cylinder wall 1 is welded with two sets of unequal angle steels 2, and the backs of the long limbs of the unequal angle steels 2 are closely attached to the outside of the opening of the front semicircular cylinder wall 1. , the lower sleeve 7 is welded at intervals between the tips of the short limbs;

[0040] The opening of the rear semicircular cylinder wall 3 is welded with two sets of equilateral angle steel 4, and the back of one limb of the equilateral angle steel 4 is close to the outside of the opening of the rear semicircular cylinder wall 3. , the back of the other limb is welded with an upper sleeve 9 at intervals close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com