Rod Material Transfer Device

A transfer device and material technology, applied in food science, application, tobacco, etc., can solve problems such as low efficiency, chain movement speed limit, equipment failure, etc., to achieve the effect of improving production efficiency, ensuring production quality, and reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

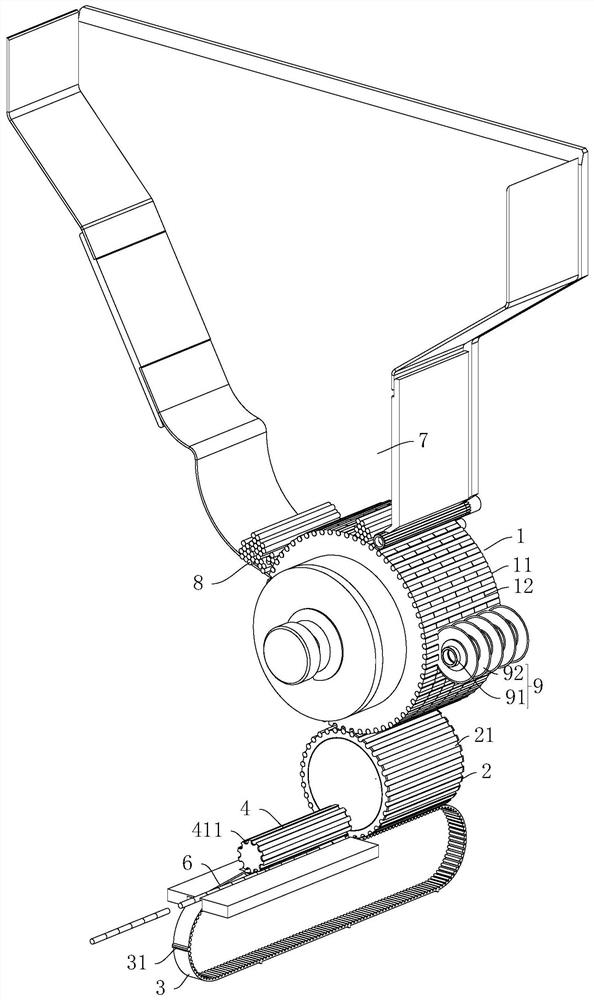

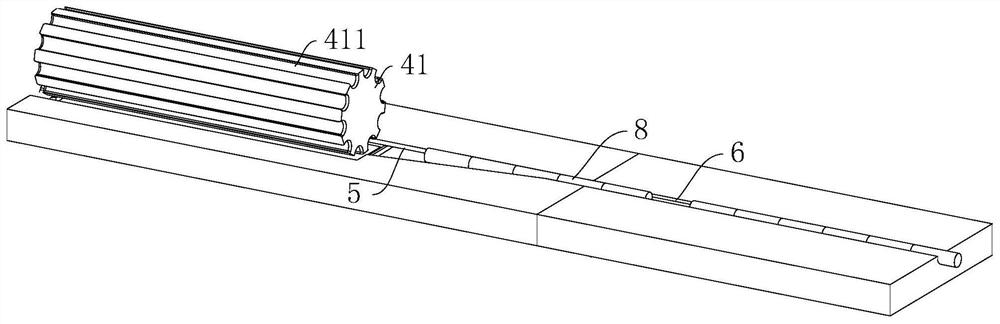

[0033] Embodiment 1: rod-shaped material transfer device, such as figure 1 As shown, including a frame, the frame is provided with a rotating feeding wheel 1 and a material storage bucket 7, and the material storage bucket 7 is filled with a rod-shaped material 8. The lower end of the material storage bucket 7 is provided with an opening, and the upper end of the feeding wheel 1 inside the opening. There are multiple material grooves 11 on the circumferential surface of the feed wheel 1, the length of the material grooves 11 is set along the axial direction of the feed wheel 1, and the multiple material grooves 11 are evenly distributed along the circumferential direction of the feed wheel 1. A negative pressure system is provided on the frame, and the negative pressure system can be a negative pressure suction fan. The feeding wheel 1 is provided with an inner chamber 1 connected with the negative pressure system and a plurality of air holes 1, and the inner chamber 1 commun...

Embodiment 2

[0039] Embodiment 2: Rod-shaped material transfer device, the difference from Embodiment 1 is that the frame is provided with a transition wheel that is rotated and is used to drive the drive motor 5 that the transition wheel rotates, and the transition wheel is provided with a plurality of transition materials. Groove, the length of the transition trough is set along the axial direction of the transition wheel, and a number of transition troughs are evenly distributed along the circumferential direction of the transition wheel. The transition wheel is equipped with an inner cavity three connected with a negative pressure system and a plurality of air holes three, and the inner cavity three passes through the air holes Three are connected with the transition trough at each place. The transition wheel is located between the feed wheel 1 and the discharge wheel 2, and abuts against the feed wheel 1 and the discharge wheel 2 at the same time.

Embodiment 3

[0040] Embodiment 3: a bar-shaped material transfer device, the difference from Embodiment 2 is that a plurality of transition wheels are provided between the feed wheel 1 and the discharge wheel 2 . The toggle part 4 can also be a cylinder made of other flexible materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com