Fuse cavity structure and electric connection box

A technology of electrical connection box and cavity structure, applied in the direction of electrical components, circuits, emergency protection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

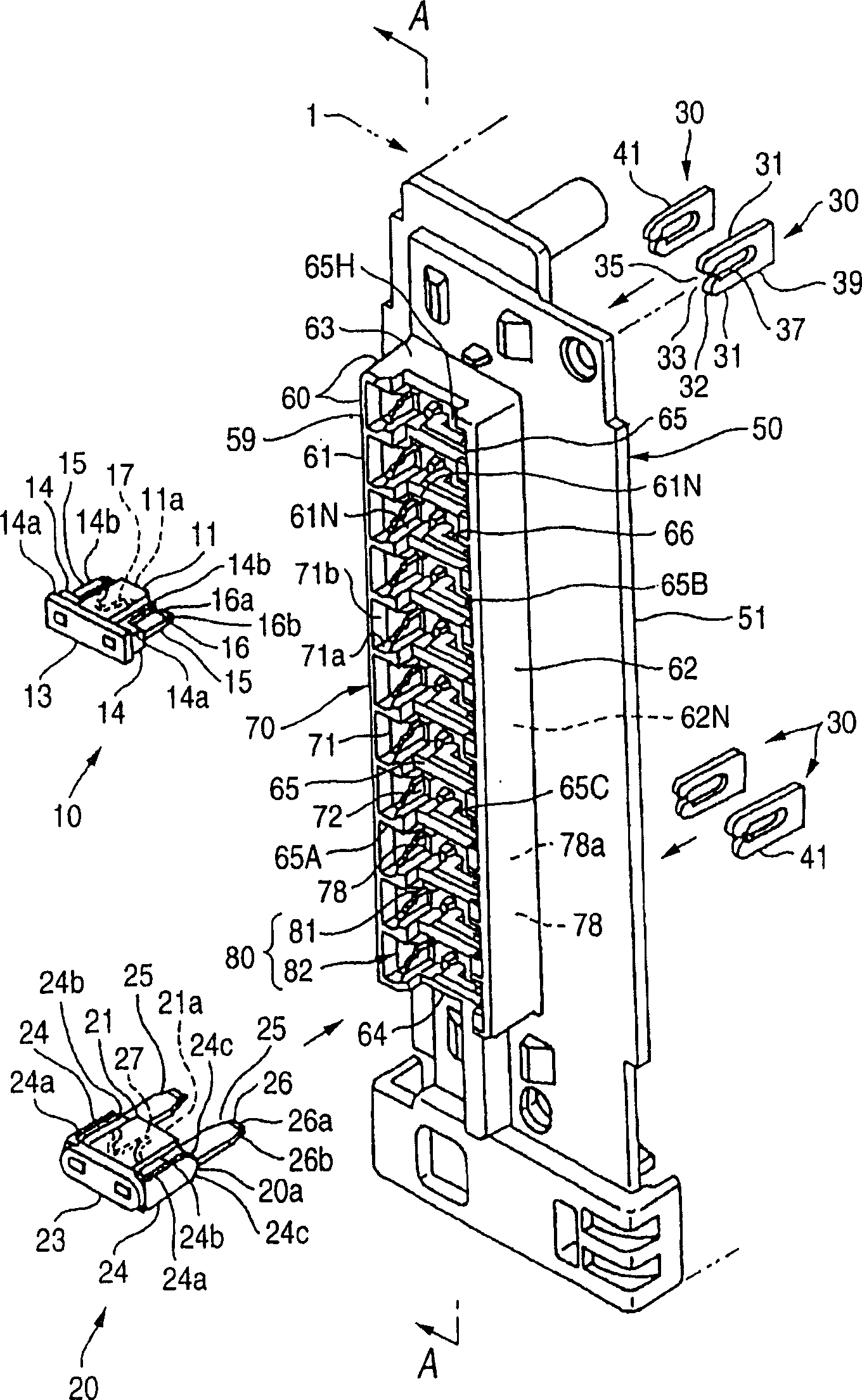

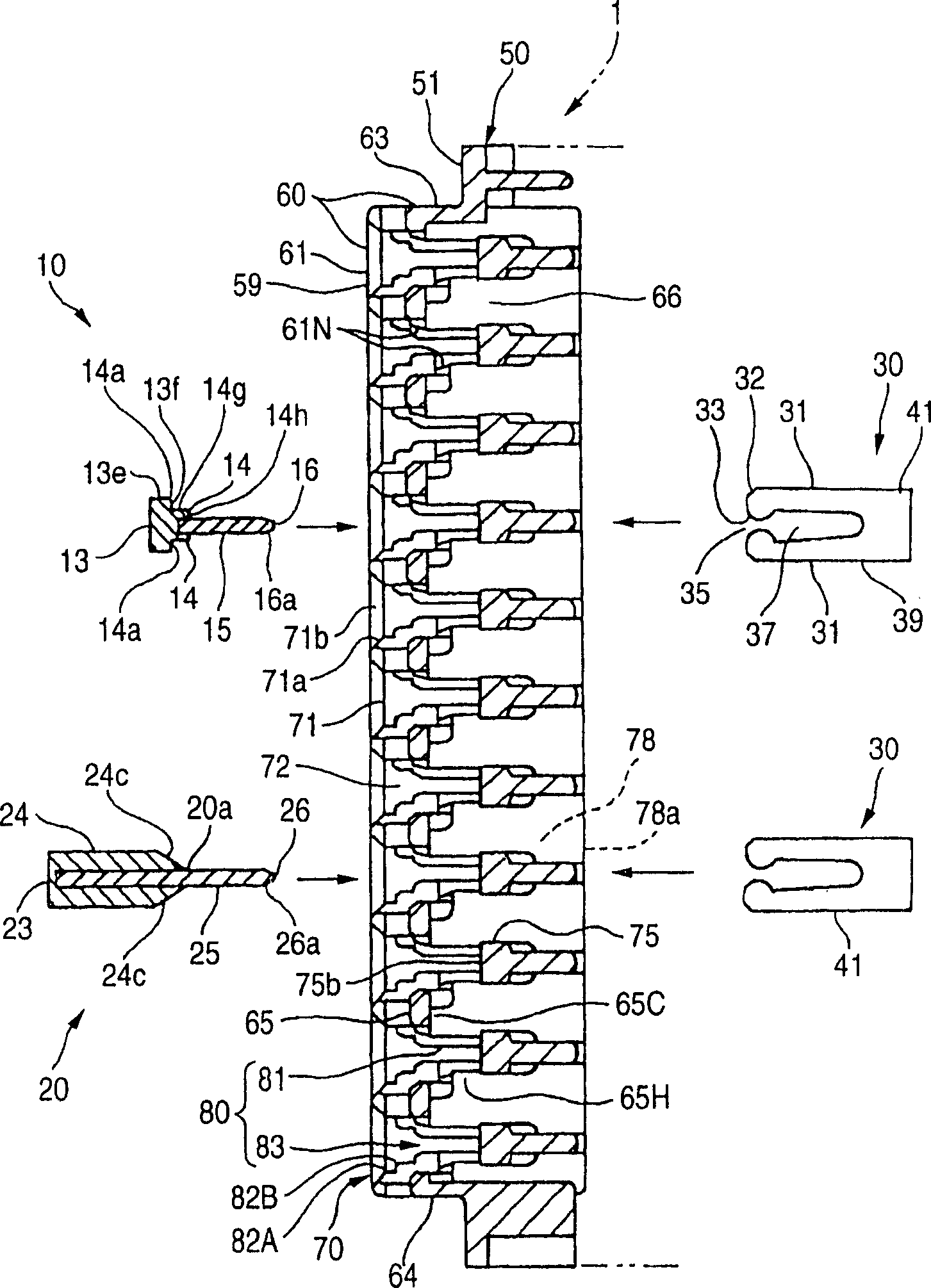

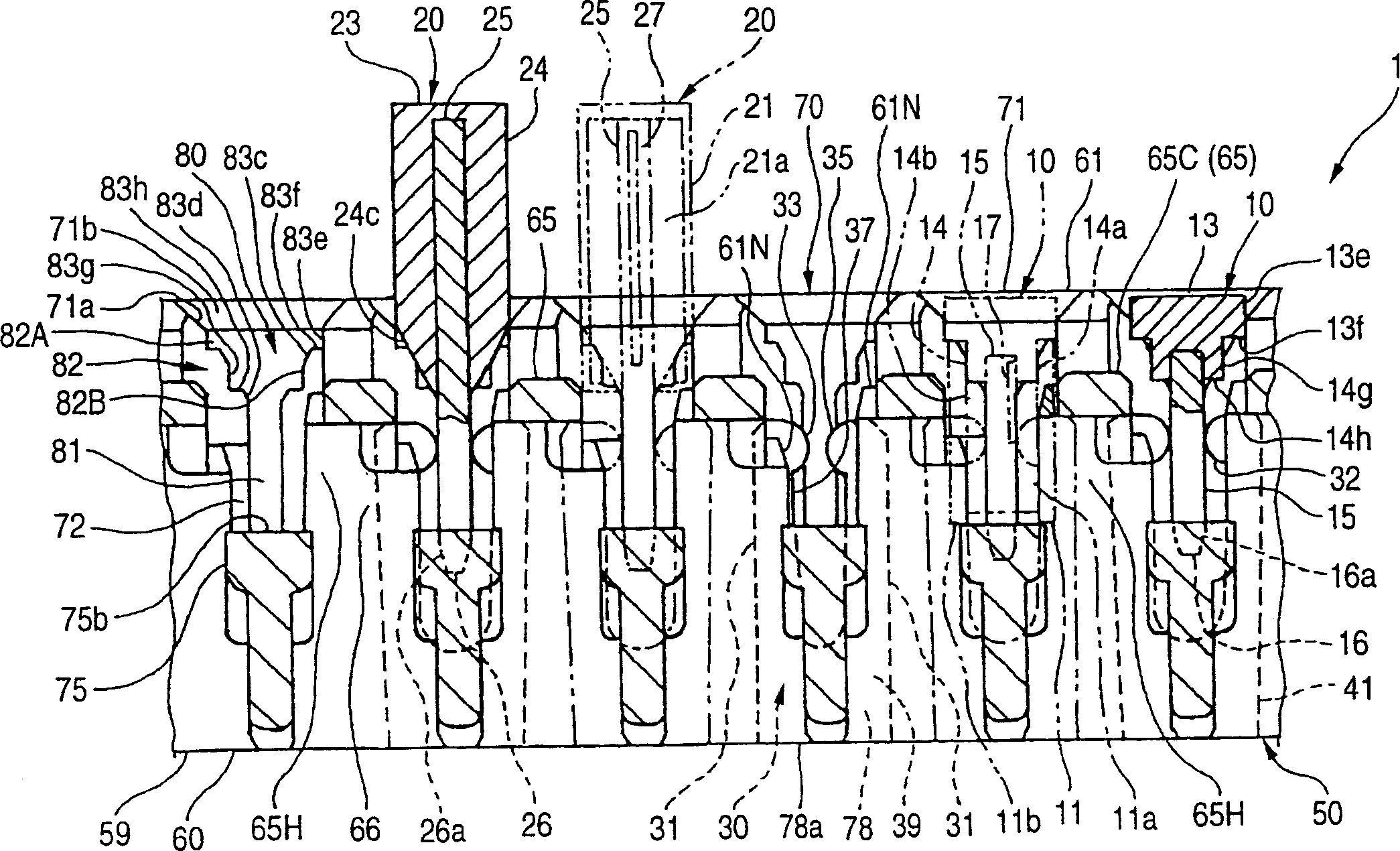

[0054] Hereinafter, a first embodiment of the fuse cavity structure and the electrical connection box according to the present invention will be described in detail by referring to the accompanying drawings.

[0055] figure 1 is an exploded perspective view showing a first embodiment of a fuse cavity structure and an electrical connection box according to the present invention, figure 2 is a longitudinal sectional view showing the structure of the fuse chamber and the electrical connection box, while image 3 is an explanatory view showing the structure of the fuse chamber and the electrical connection box.

[0056] Each part of the main part in each figure is shown as a schematic diagram, which is partly simplified, thereby making the main part easy to understand and easy to observe. Also, for the first fuse 10 and the second fuse 20 , overlapping parts are put together for explanation for the sake of convenience.

[0057] Two types of fuses, namely, the first fuse 10 an...

no. 2 example

[0094] A second embodiment of a fuse chamber structure and an electrical connection box according to the present invention will be explained in detail by referring to the accompanying drawings.

[0095] Figure 5 is an exploded perspective view showing a second embodiment of a fuse cavity structure and an electrical connection box according to the present invention, Image 6 is a longitudinal sectional view showing the structure of the fuse cavity and the electrical connection box according to this embodiment, and Figure 7 is an explanatory view showing the structure of the fuse cavity and the electrical connection box according to this embodiment.

[0096] In order to make the main part of each figure easy to understand, each constituent part is partially shortened, thereby being shown as an easy-to-view schematic diagram. For convenience, the same parts of the first fuse 10 and the second fuse 20 as those of the first embodiment of the present invention are explained toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com