Active variable-stiffness leveling pile and construction method thereof

A construction method and variable stiffness technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as reducing pile cost, foundation and superstructure affecting structural safety, etc., to reduce cost, eliminate potential safety hazards, reduce added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

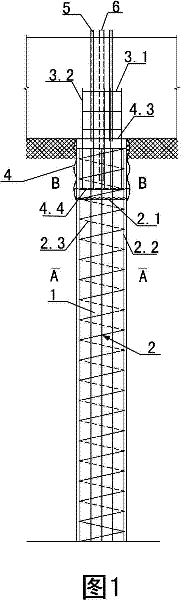

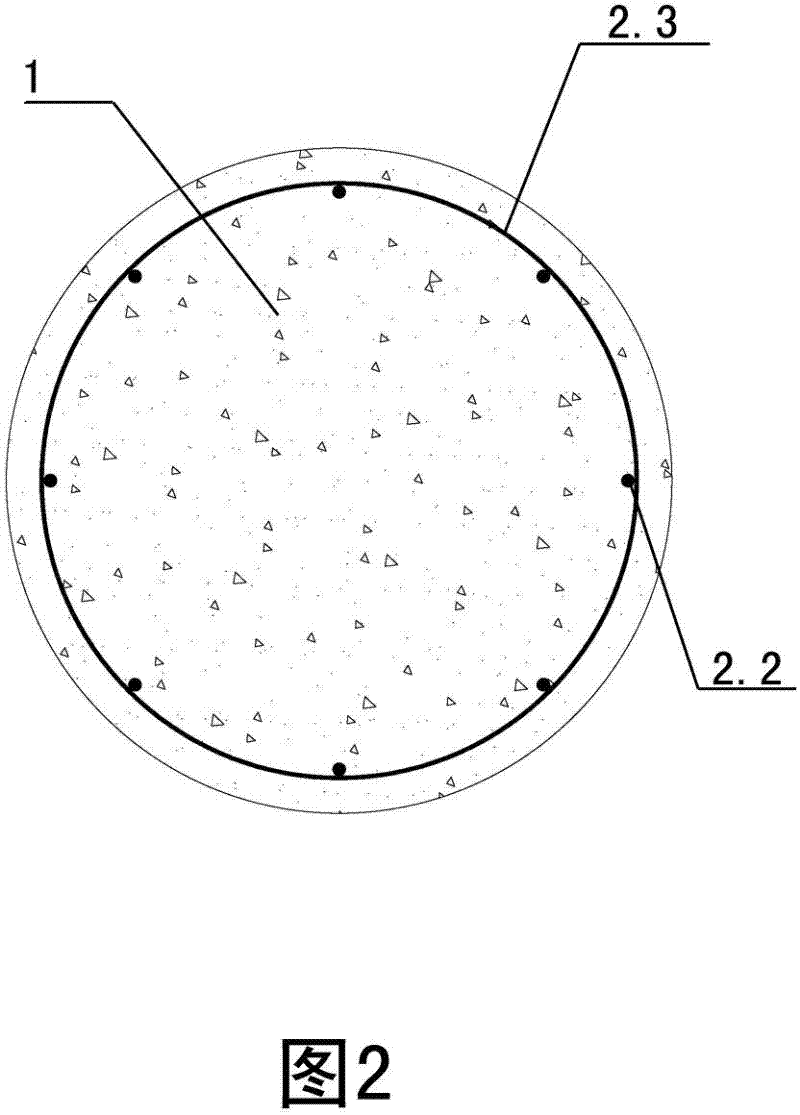

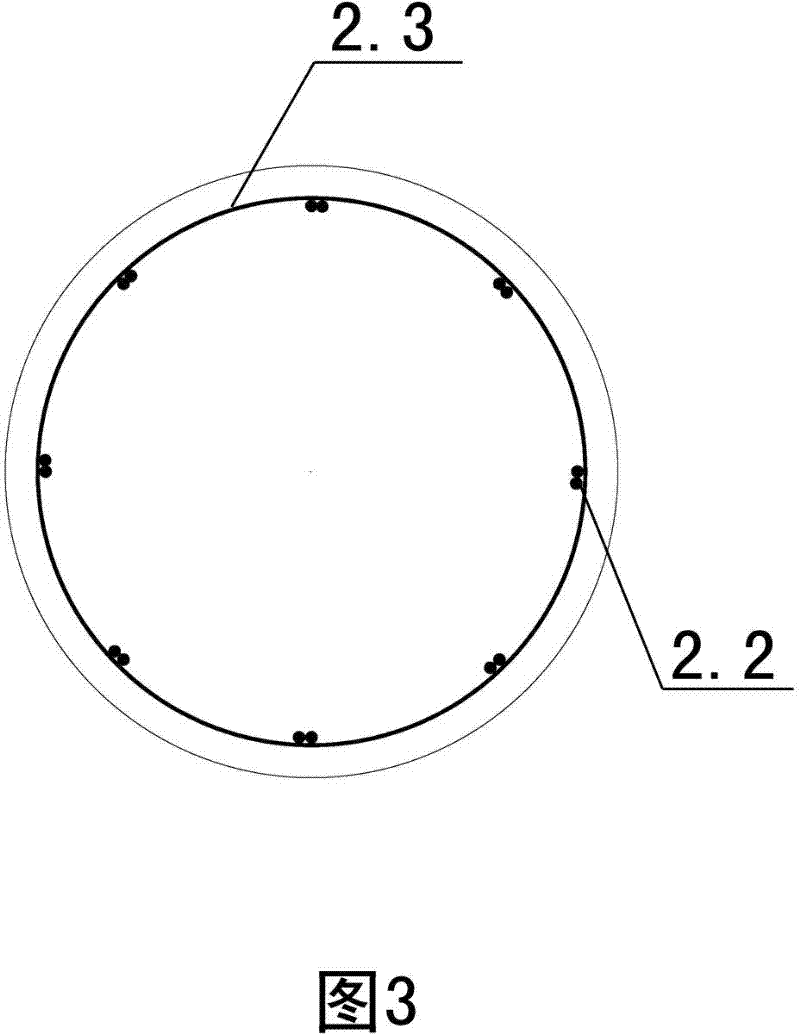

[0066] Embodiment one sees Figure 1 ~ Figure 4 and Figure 30-32 As shown, an active variable stiffness leveling pile is located at the bottom of the foundation 8, and is formed by cast-in-situ pile body reinforcement cage 2 and pile body concrete 1 welded by transverse reinforcement 2.1, longitudinal reinforcement 2.2 and pile stirrup 2.3 , also includes the leveling section, the leveling section is located on the top of the reinforced concrete pile body, including the leveling steel cage 3, the leveling tube 4, the exhaust pipe 5, the pouring tube 6 and the post-cast concrete 7, and the leveling tube 4 is set on the steel bar The upper part of the concrete pile body is composed of the cylinder wall 4.1 and the partition plate. The leveling reinforcement cage 3 is located on the top of the leveling cylinder 4 and is integrated with the foundation 8. It has a built-in exhaust pipe 5 and pouring pipe 6 to level the longitudinal reinforcement. 3.2 and the pouring pipe 6 extend...

Embodiment 2

[0079] Embodiment two see Figure 27 ~ Figure 29 , on the basis of the above-mentioned construction method, the first step is to carry out mud wall protection while forming the hole.

[0080] In the second step, the welded pile reinforcement cage 2 is inserted into the post-casting equipment 11; in the third step, the post-grouting layer 12 is poured by the post-casting equipment 11 when pouring the concrete for the pile body.

[0081] The hole forming method in Step 1 described in the above-mentioned embodiments 1 and 2 is manual digging, rotary drilling, impact hole forming or grab bucket hole forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com