Small-radius arch ring construction method of arch bridge of continuous slab

A small-radius continuous slab technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of arch ring formwork erection, concrete pouring, etc., and achieve cost saving, simple construction process and ideal construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

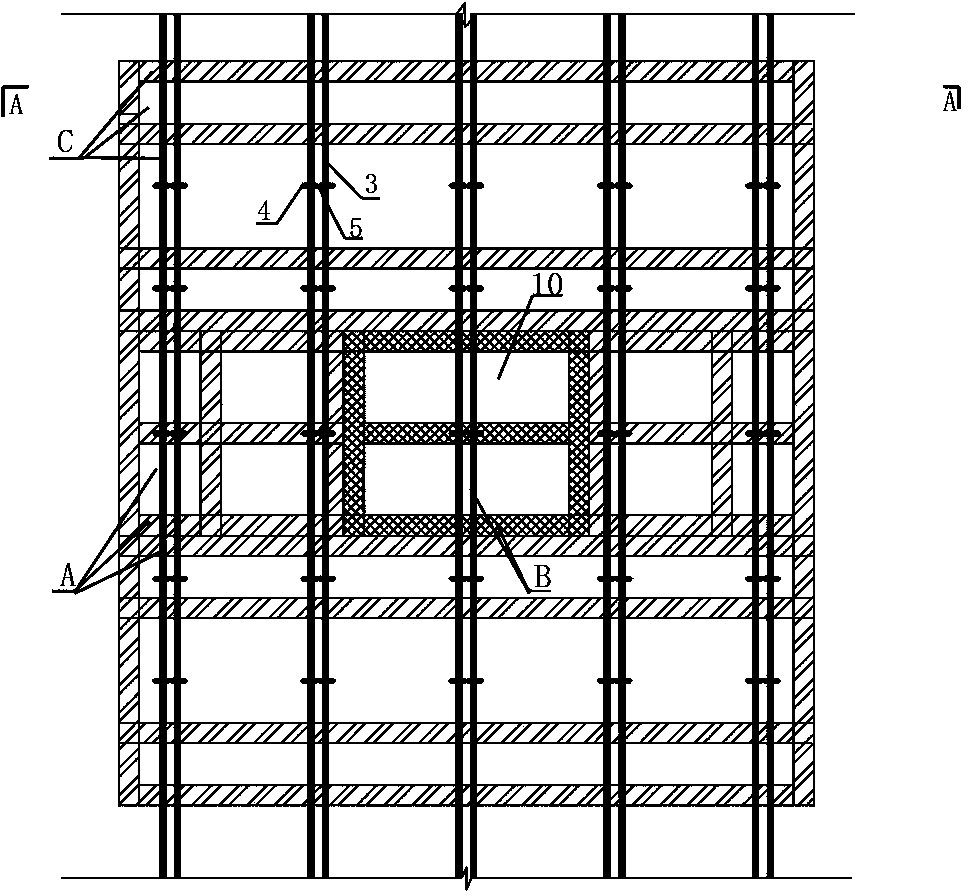

[0037] Examples see figure 1 Shown, 1, a kind of continuous slab arch bridge small-radius arch ring construction method is characterized in that: the steps are as follows:

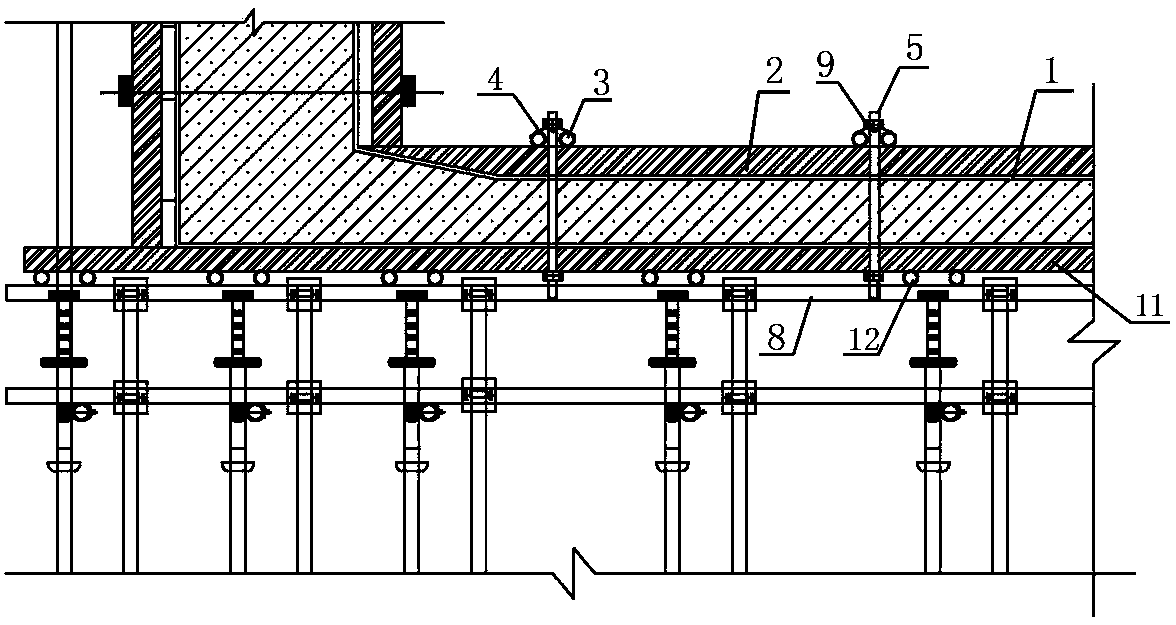

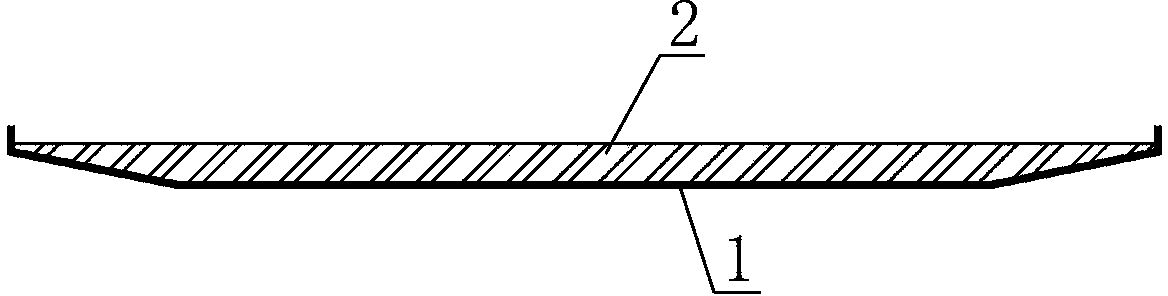

[0038] Step 1, support the bottom plate formwork and side formwork of the arch ring, the bottom plate formwork includes the standard box slab arch bridge bottom plate formwork C, the bottom plate formwork limit device, the box slab arch bridge bottom plate compression mold formwork and the bottom plate lower formwork; The formwork C on the bottom plate of the box-shaped arch bridge and the die formwork on the bottom plate of the box-shaped arch bridge are all tied by the template limit device on the bottom plate and the lower formwork of the bottom plate; The formwork panel 11 and the lower formwork secondary keel 12 of the bottom form form.

[0039] Step 2, one-time symmetrical pouring of the arch feet at both ends of the arch ring;

[0040] Step 3: Concrete the bottom plate of the arch ring, the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com