Construction method of volute layer concrete flat pouring

A construction method and concrete technology, which can be used in infrastructure engineering, construction, etc., can solve the problems of long construction time, existing pouring joints, and difficult filling of inner corners, and achieve the effect of short construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

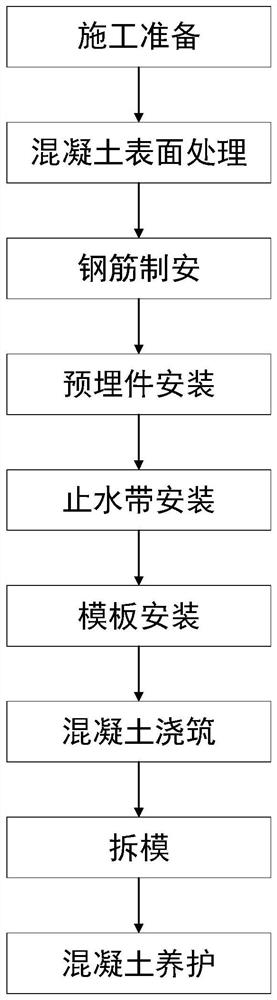

[0058] Example. A kind of volute layer concrete pouring construction method, such as figure 1 shown, including the following steps:

[0059] A. Construction preparation: Confirm and inspect construction electricity, construction water, construction drainage, construction roads, construction concrete, construction steel bars and construction drawings required for construction;

[0060]B. Concrete surface treatment: chiseling and cleaning the concrete of the previous layer of construction to ensure that the leveling layer meets the acceptance criteria for concrete construction joints;

[0061] C. Reinforcement system and installation: production, processing and installation of steel bars for construction;

[0062] D. Installation of embedded parts: install, measure and check the embedded parts, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com