Dropping method for large-tonnage steel liner of drilled pile

A technology of steel casing and large tonnage, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of huge equipment and input materials, etc., and achieve the effect of light structure, easy operation, safe and reliable decentralization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

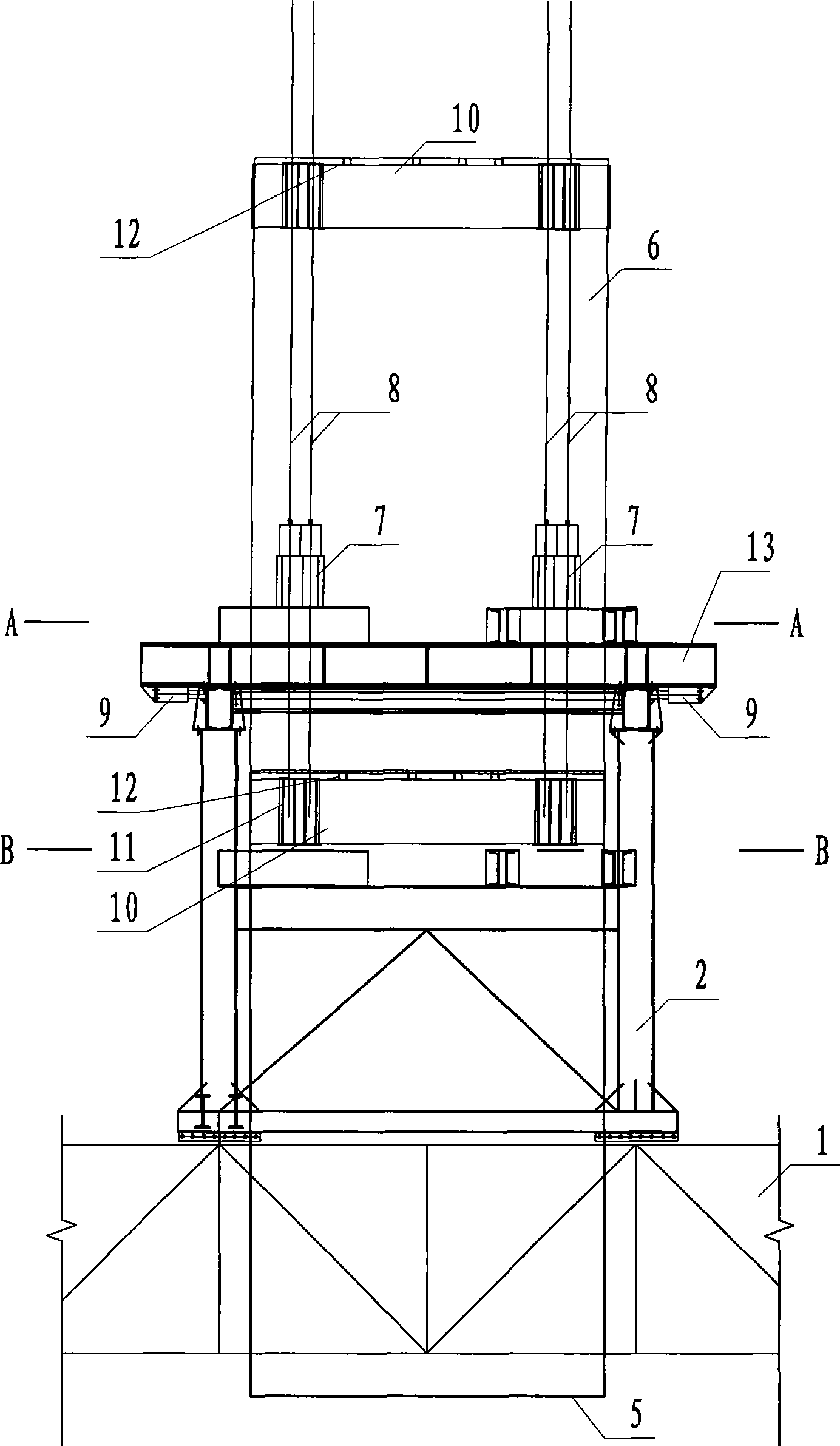

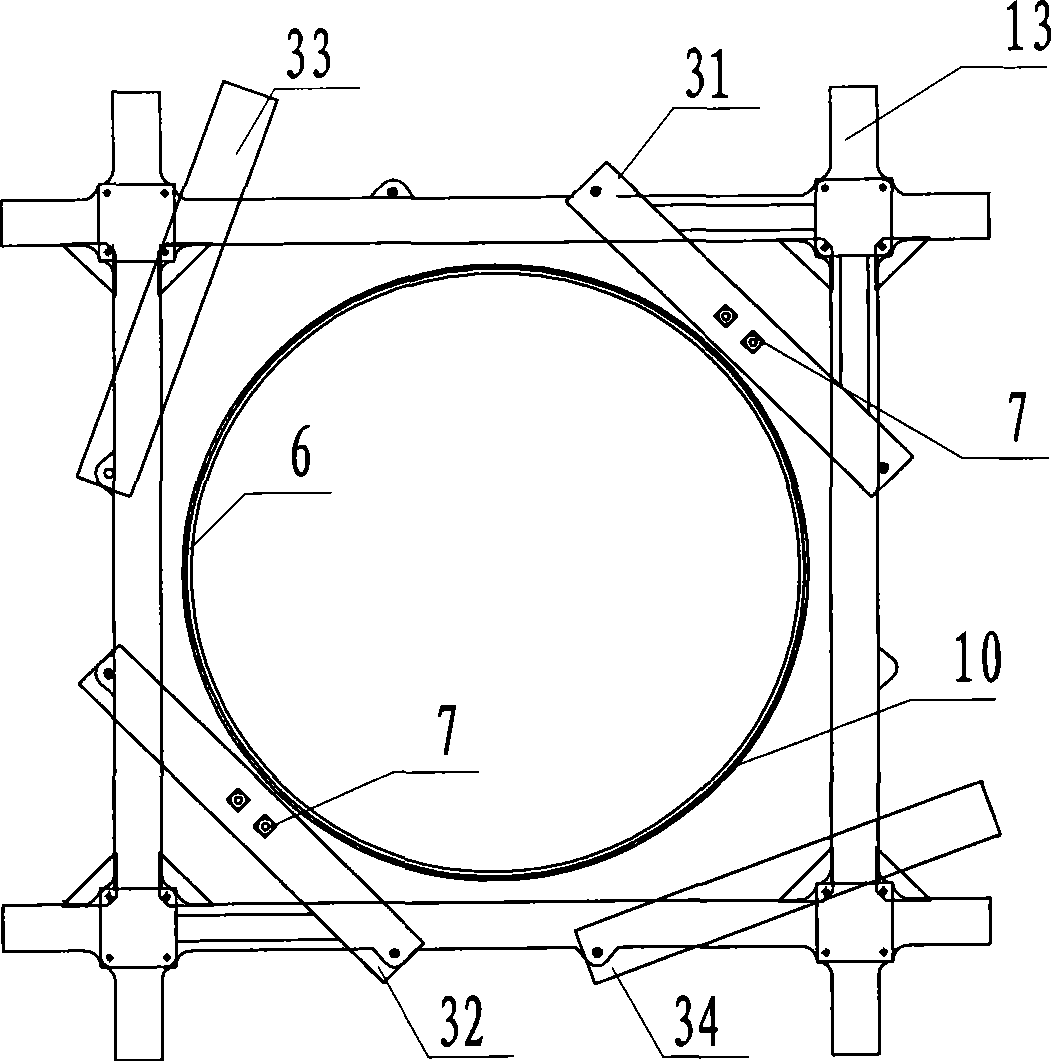

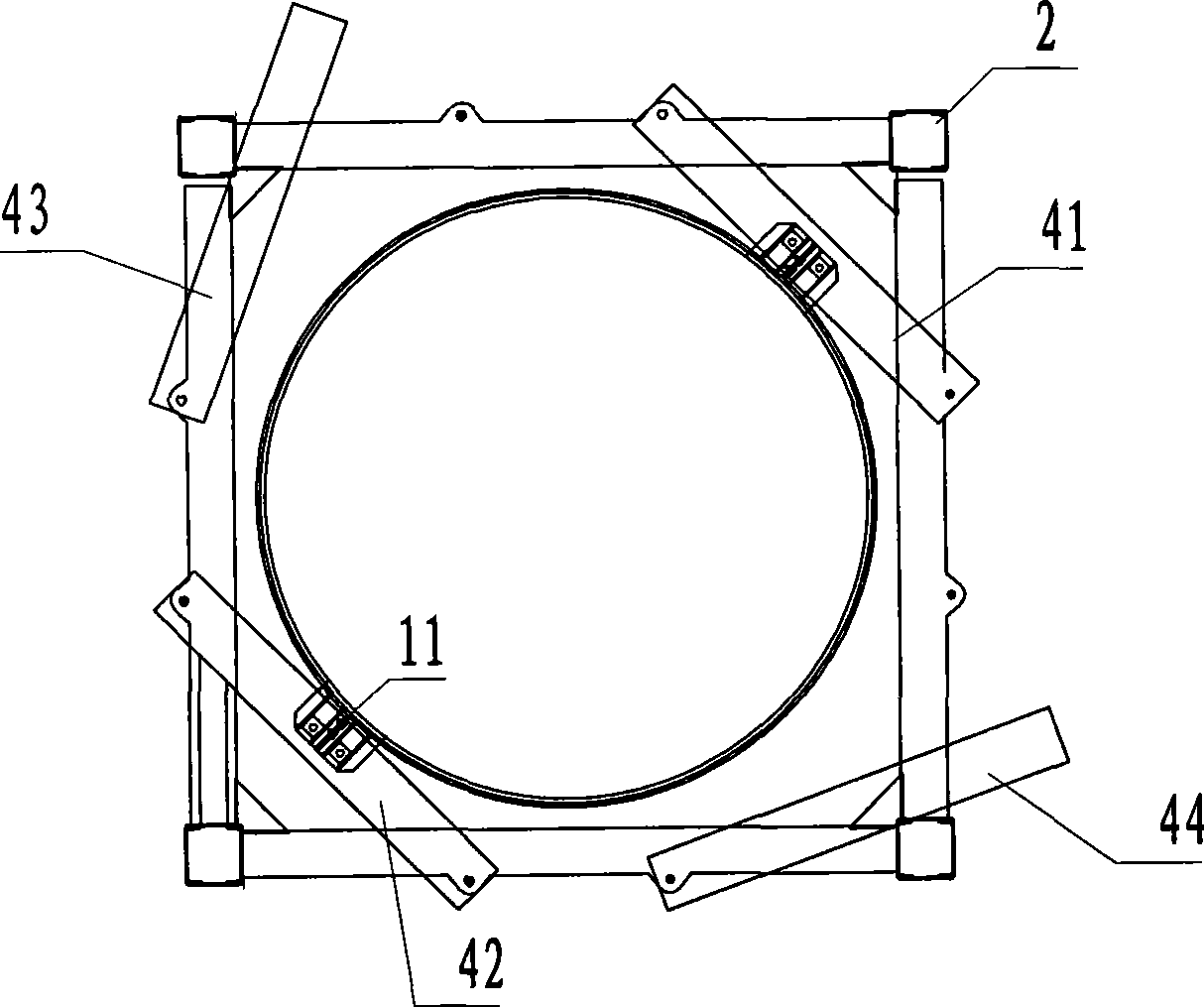

[0019] Depend on figure 1 , figure 2 and image 3 In the shown method for lowering the large-tonnage steel casing of bored piles, a steel casing lowering support 2 is provided on the construction drilling platform 1, and an upper support system, a movable frame beam 13 and The lower support system, the movable frame beam 13 is flexibly connected with the lower support 2 through the vertical and horizontal movement jack 9, and the upper and lower support systems have the same structure, which are respectively surrounded by four distribution beams 31, 32, 33, 34 and 41, 42, 43, 44, both ends of the distribution beams 41, 42, 43, 44 are movably connected with the lowering support 2, and both ends of the distribution beams 31, 32, 33, 34 are movably connected with the movable frame beam 13, Then the steel hoop 10 with two steel hoop lugs 11 is fixed on the upper positions of all steel casings 5,6, and the outer rings of steel casings 5,6 above the steel hoop 10 are installed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com