Combined flat beam

A technology of flat beams and steel beams, which is applied in the field of composite flat beams, can solve the problems of insufficient effectiveness and reliability of shear force transmission between steel and concrete, and the height does not reach the optimal effect, so as to simplify the construction process, optimize economy, The effect of improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

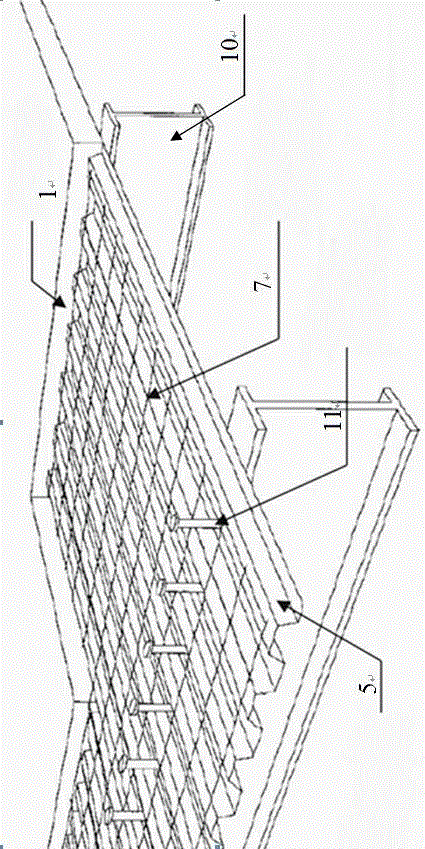

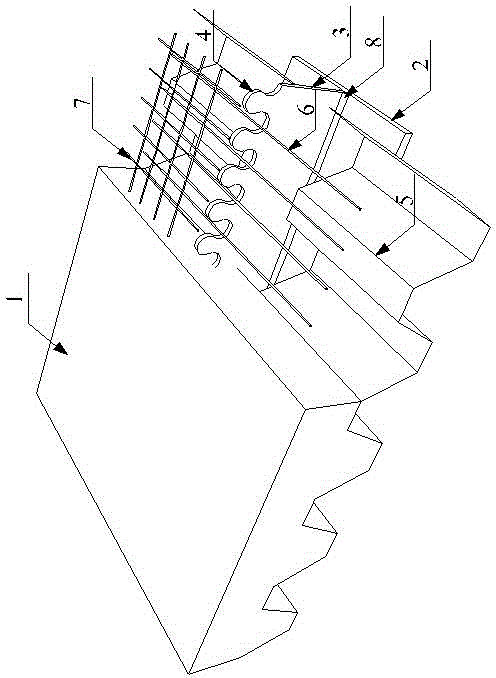

[0032] Such as figure 2 Described novel composite flat beam, its structure is:

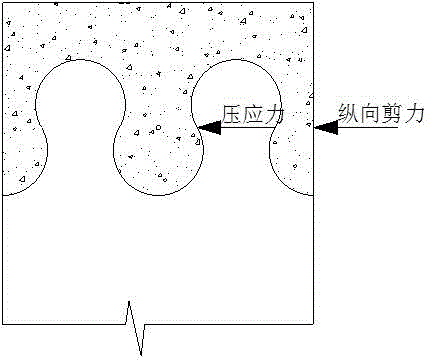

[0033] Including a steel beam, the steel beam includes a steel beam lower flange 2 and a steel beam web 3, which is an inverted T shape (or inverted π shape) composed of a steel beam lower flange 2 and a steel beam web 3, and the steel beam The lower flange 2 and the steel beam web 3 are connected by a weld 8; the upper part of the steel beam web 3 has a zigzag shear connector 4, and the zigzag shear connector 4 is a composite flat beam The only shear transfer device, such as image 3 shown.

[0034] It includes a profiled steel plate 5, which is pressed in a concave-convex wave shape, and the concave part of the profiled steel plate 5 is directly placed on the lower flange 2 of the steel beam (it can also be welded on the lower flange 2 of the steel beam by sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com