Full-fabricated floor slab assembled-type steel-concrete combined floor

A concrete and prefabricated technology, applied in the direction of floor slab, climate change adaptation, building components, etc., can solve the problems of cost waste, insufficient construction speed, large workload, etc., to ensure shear stiffness and bearing capacity, avoid aesthetics, The effect of high installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

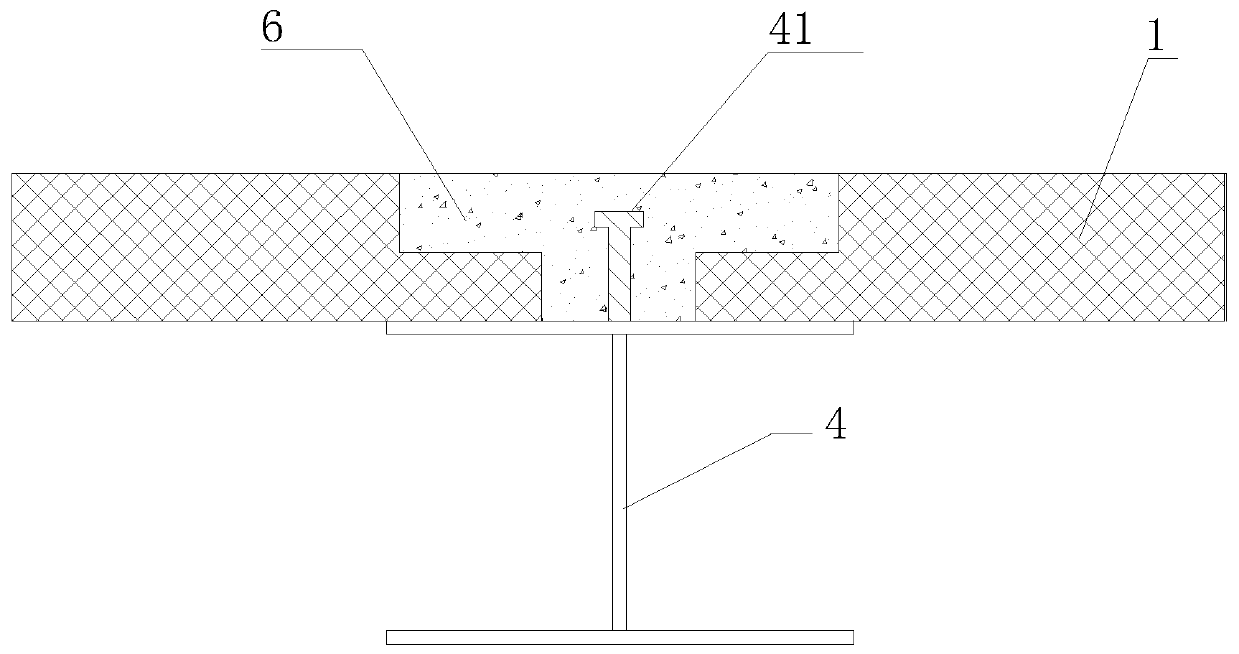

[0031] Such as figure 1 As shown, the fully prefabricated floor slab fabricated steel-concrete composite floor cover of this embodiment includes a beam 4 and a floor slab 1 arranged on the beam. The joint between two adjacent floor slabs is located on the beam, and the floor slab is on the beam. The cross section of the joint is step-shaped, and a plurality of T-shaped connecting nails 41 are arranged in the middle of the beam; concrete 6 is poured at the steps of the two floor slabs, and the concrete connects the two floor slabs and T-shaped connecting nails are connected in one piece.

[0032] Wherein, the height of the T-shaped connecting nail is 2 / 3 of the height of the floor;

Embodiment 2

[0034] This embodiment is a further improvement of embodiment 1, such as Figure 4 to Figure 6 As shown, the upper surface of the floor 1 is provided with reinforcing steel bars 71; the reinforcing steel bars 71 between the two floor slabs are connected by lap steel bars; V-shaped grooves 8 are correspondingly provided on the stage parts of the two floor slabs 1. , Shear ribs 73 are embedded in the V-shaped groove 8.

Embodiment 3

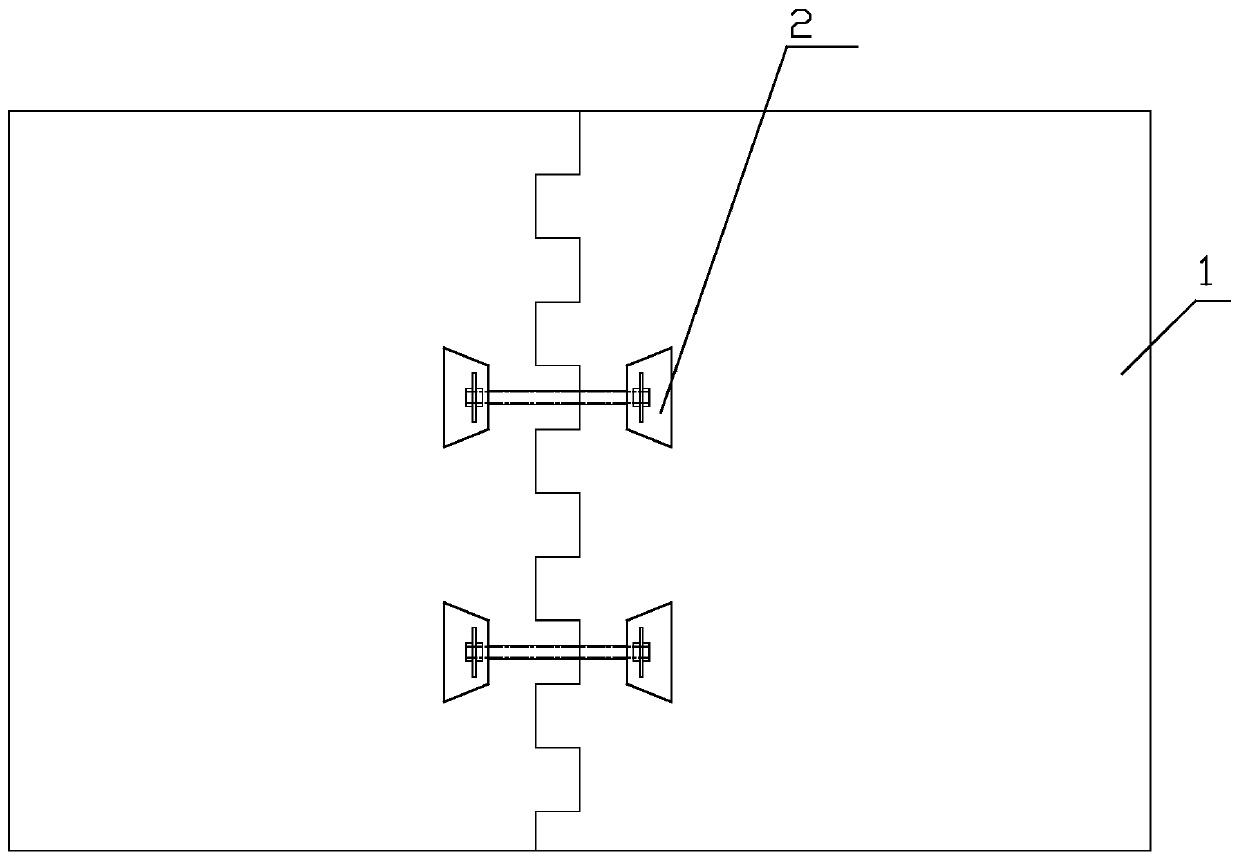

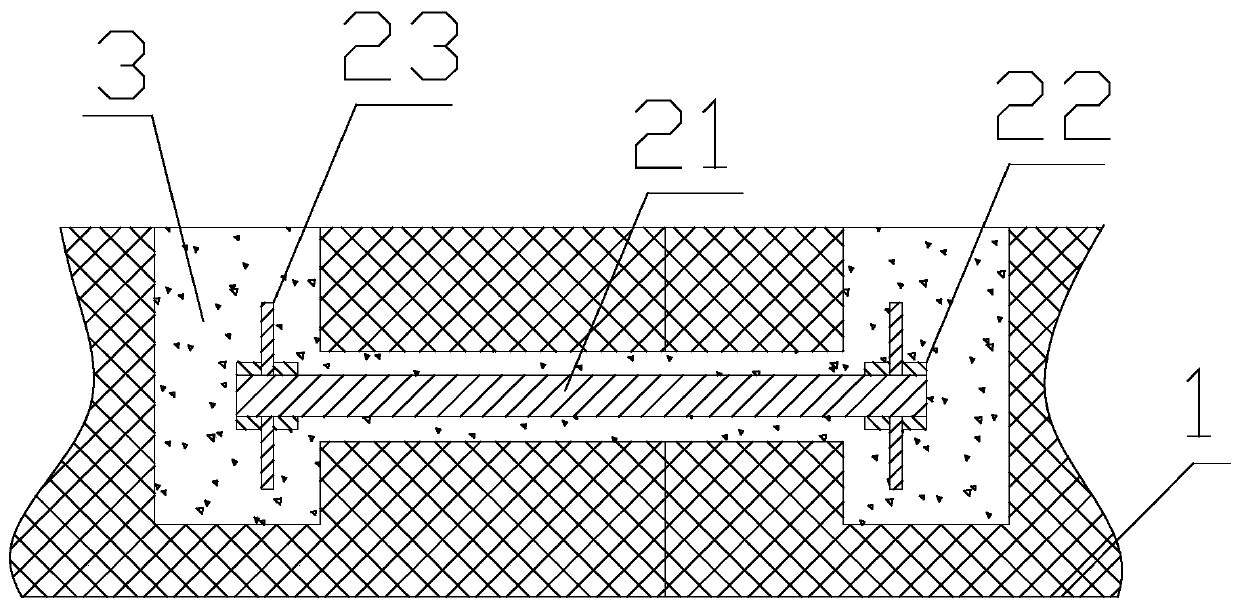

[0036] Such as figure 2 image 3 As shown, the floor slab in this embodiment is a fully prefabricated floor slab, which is formed by splicing two prefabricated floor slabs 1, wherein the joint of the two prefabricated floor slabs has a tooth groove structure, and the two prefabricated floor slabs mesh with each other through the tooth grooves; There are two or more connecting fixtures 2 between the two prefabricated floor slabs, and the connecting fixtures are connected in the following manner:

[0037] A connecting hole is provided at the corresponding position of each prefabricated floor joint;

[0038] An opening slot is provided at the position corresponding to the communicating hole at the splice of each prefabricated floor slab, and the other end of the communicating hole is located in the opening slot; figure 1 As shown, the shape of the open slot is trapezoidal.

[0039] A connecting piece 21 passes through the connecting hole to connect two prefabricated floor slabs;

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com