Laminated slab, connecting structure of laminated slab and composite beam and construction method

A technology for connecting structures and construction methods, which is applied in the direction of load-bearing elongated structural members, structural elements, truss-type structures, etc. The effect of shear performance, high construction efficiency and low reinforcement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

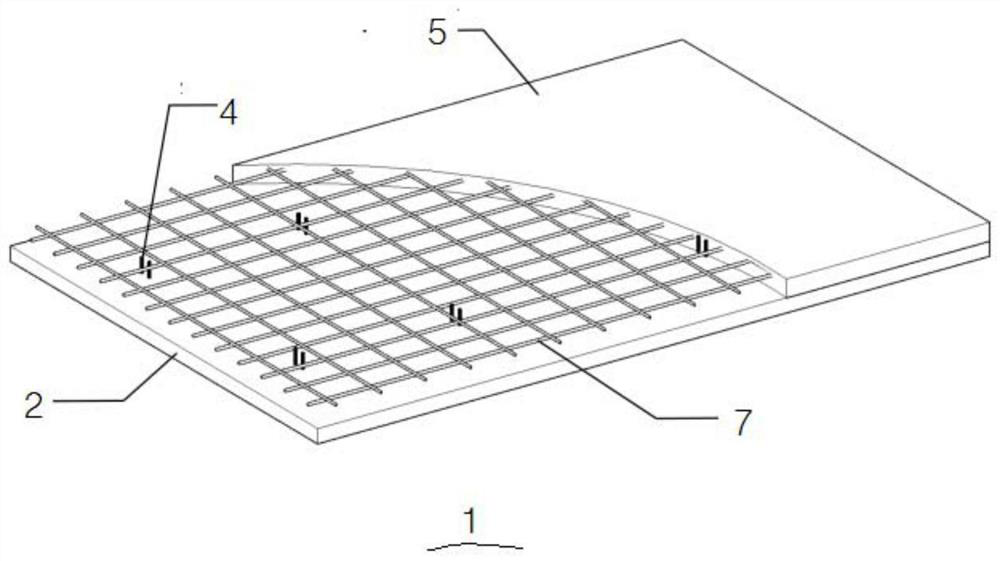

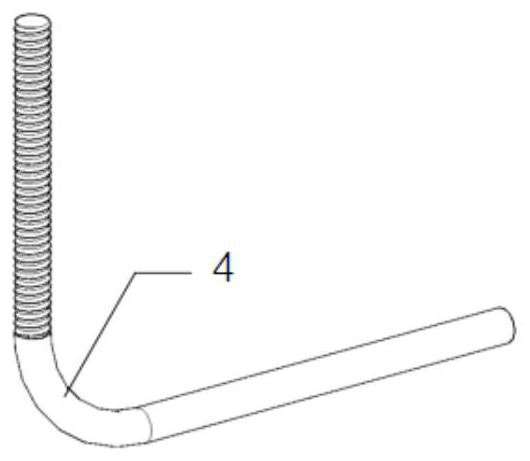

[0045] See attached figure 1 To attach figure 2For illustration, the laminated slab 1 in this embodiment includes a prefabricated layer and a post-cast layer 3, and the prefabricated layer includes a prefabricated floor 2 and a plurality of shear reinforcement bars 4, and the bottom ends of the plurality of shear reinforcement bars 4 are all anchored in the prefabricated floor 2 , the tops are all exposed on the prefabricated bottom plate 2, the post-cast layer 3 includes post-cast concrete 5 and surface layer reinforcement 6, the surface layer reinforcement 6 is arranged on the upper surface of the precast layer, and the post-cast concrete 5 is poured on the upper surface of the prefabricated bottom plate 2. The tops of the first shear bars 4 and the surface layer bars 6 are all anchored in the post-cast concrete 5 . In this embodiment, the two ends of the shear reinforcement 4 are respectively anchored in the prefabricated layer and the post-cast layer 3. By setting the sh...

Embodiment 2

[0048] See attached image 3 to attach Figure 7 , the connection structure between the laminated slab 1 and the composite beam 10 in this embodiment includes the laminated slab 1 and the composite beam 10 in Embodiment 1, and the composite beam 10 includes a steel beam 8 and a plurality of pegs fixed on the surface of the steel beam 8 9. The bottom surface of one side of the prefabricated layer rests on the upper surface of the steel beam 8, the post-cast concrete 5 on the precast layer fills the joint between the steel beam 8 and the precast layer, and the studs 9 are anchored to the post-cast concrete at the joint 5 in. See attached Figure 7 For illustration, the composite beam 10 in this embodiment welds a row of studs 9 on the surface of the steel beam 8, so that the studs 9 are anchored in the post-cast layer 3 of the laminated slab 1, which improves the connection between the composite beam 10 and the laminated slab. 1, the prefabricated layer of the laminated slab ...

Embodiment 3

[0059] See attached Figure 8 And attached Figure 9 , the present embodiment is the construction method of the connection structure between the laminated slab 1 and the composite beam 10 in the improved example of embodiment 2, comprising the following steps:

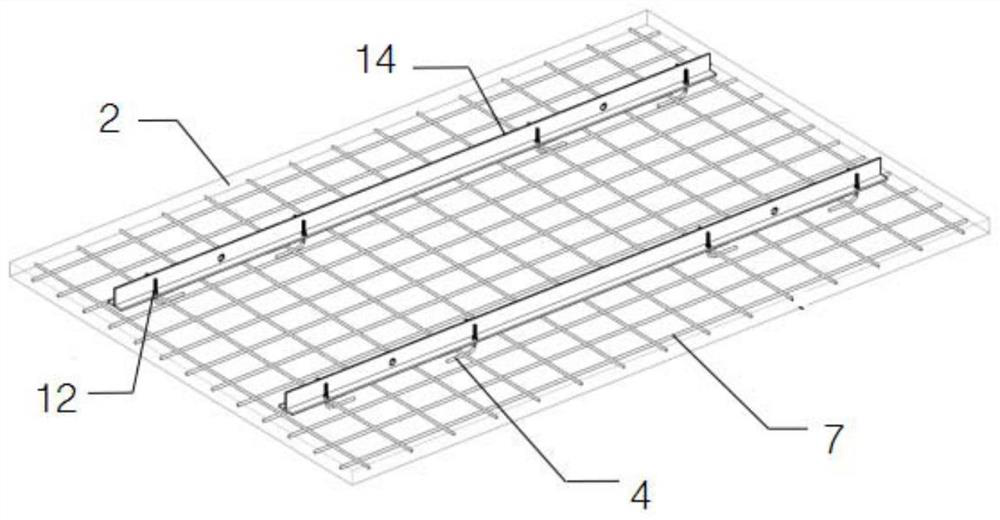

[0060] S1. Production of prefabricated layers: Lay reinforcement mesh 7 and shear reinforcement 4, pour concrete for prefabricated bottom slab 2 and maintain and form, install multiple detachable ribs on the upper surface of prefabricated bottom slab 2, and the top of shear reinforcement 4 passes through detachable The rib, the fixing part is connected with the top of the shear steel bar 4 to fix the detachable rib on the prefabricated bottom plate 2;

[0061] S2. Set vertical support, lift the composite beam 10 and position it on the vertical support, use the detachable rib as the lifting point to lift the first prefabricated layer and the second prefabricated layer respectively, and the first prefabricated layer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com