Bottom microarch-type gallery structure of HCRFD (High Core Rockfill Dam)

A technology of rockfill dams and high core walls, applied in the field of micro-arch corridor structures at the bottom of the dam, can solve problems such as corridor cracking, water leakage, and affecting the safe operation of the dam, so as to reduce shear stress and improve mechanical characteristics , The effect of reducing the risk of penetration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

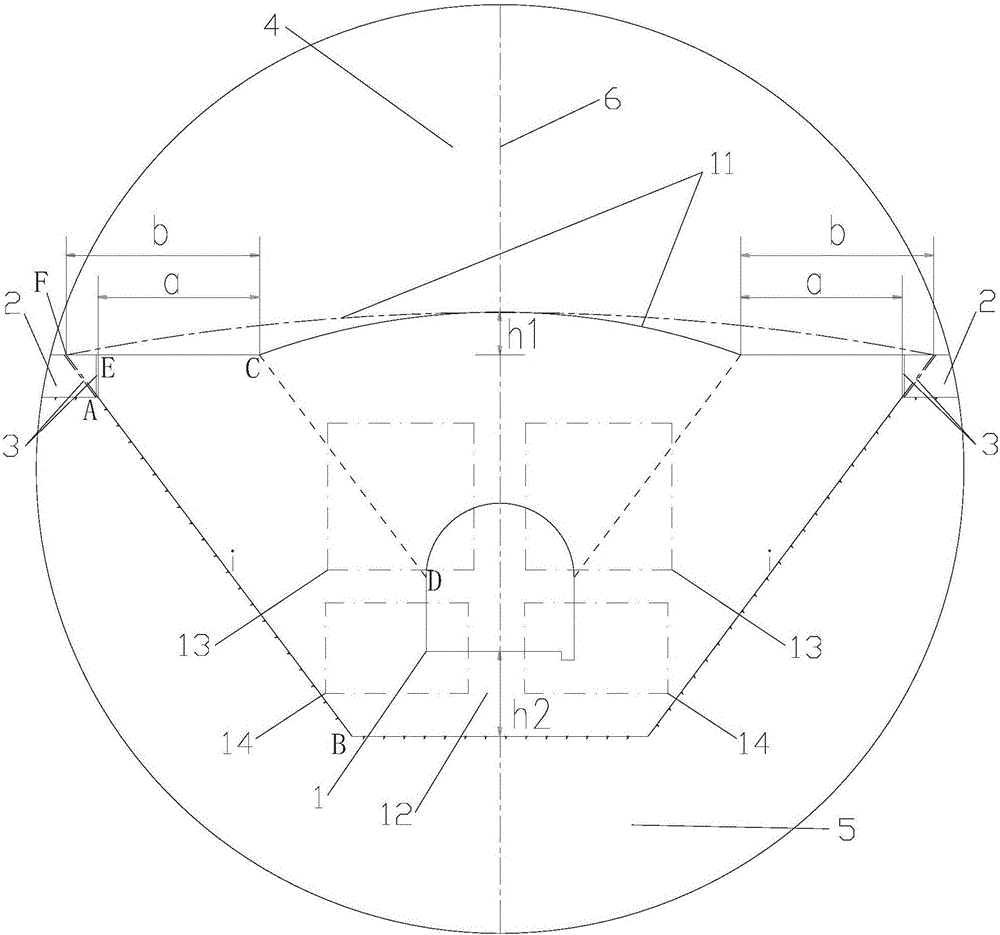

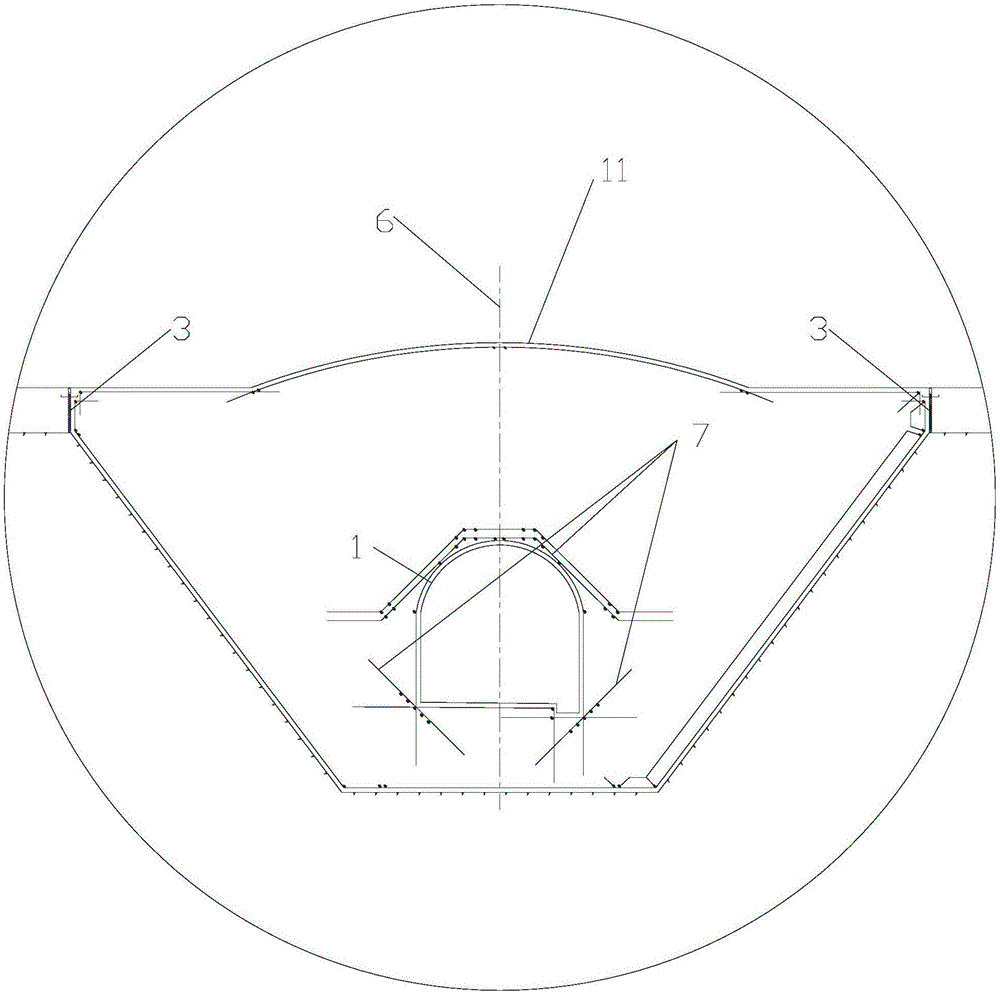

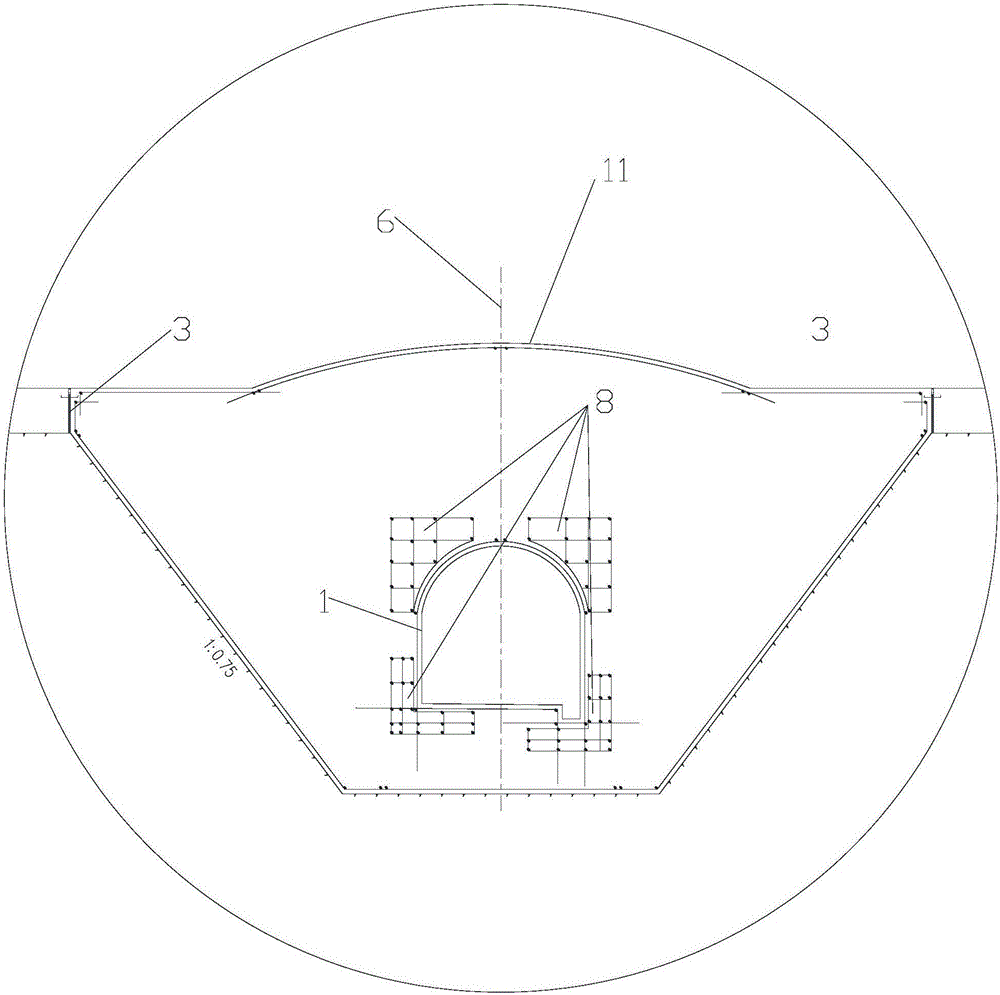

[0020] Such as figure 1 As shown, the micro-arch corridor structure at the bottom of the high core wall rockfill dam of the present invention includes the corridor 1 at the bottom of the core wall 4, and the bottom of the corridor 1 is a backing plate 12 of concrete. In order to ensure safety requirements, the backing plate 12 The backing plate thickness h2 should be greater than or equal to 2.0m. Below the backing plate 12 is the bedrock 5, and the excavation line of the bedrock 5, that is, the excavation boundary line, is in the shape of an inverted isosceles trapezoid. The top of the corridor 1 protrudes upwards and combines with the corridor to form a micro-arch structure 11, and the height h1 of the convex part of the top of the micro-arch structure 11 is preferably 0.8m-1.2m. Both the gallery 1 and the micro-arch structure 11 are centered on the dam axis 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com