Prestressed U-shaped rid rapid shear-resisting and reinforcing box girder structure and method

A prestressed, U-shaped technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of small length of prestressed tendon, large loss of prestressed force, difficult tension, etc., and achieve fast processing and forming speed, reduce The effect of anchoring space and ensuring long-term performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

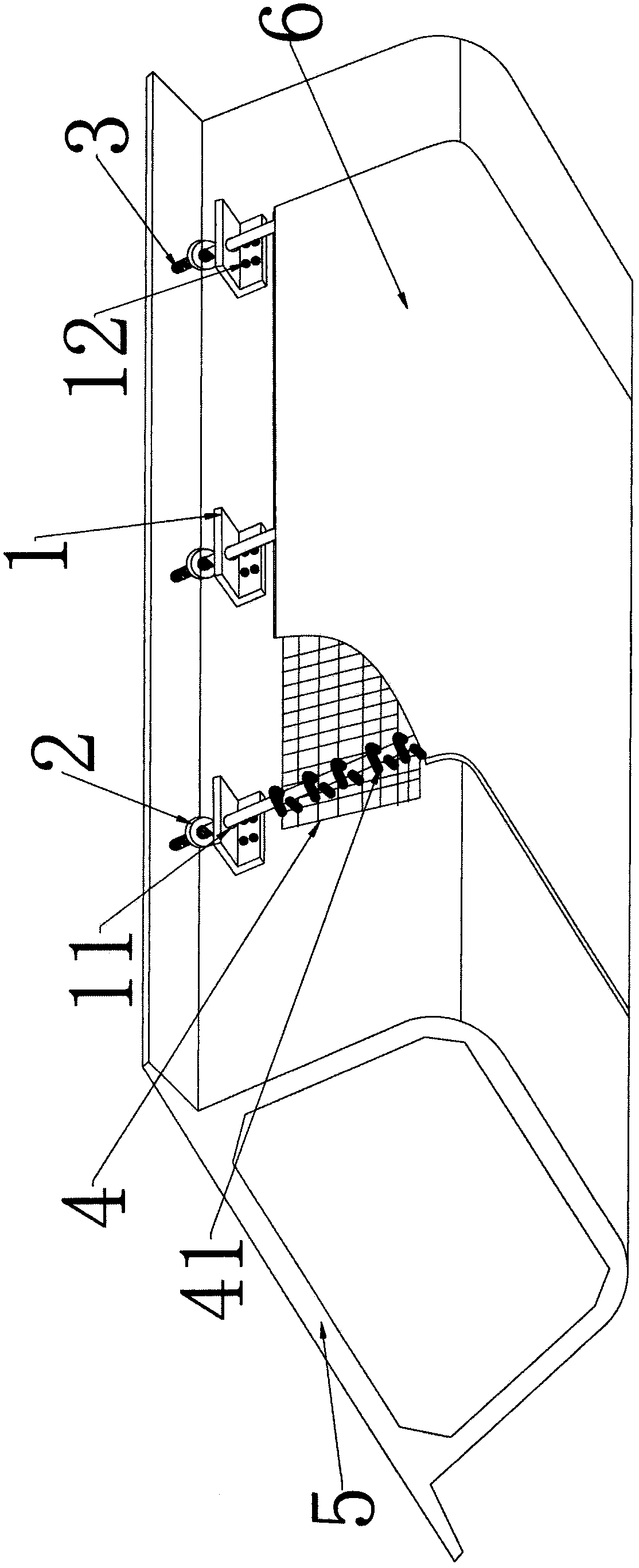

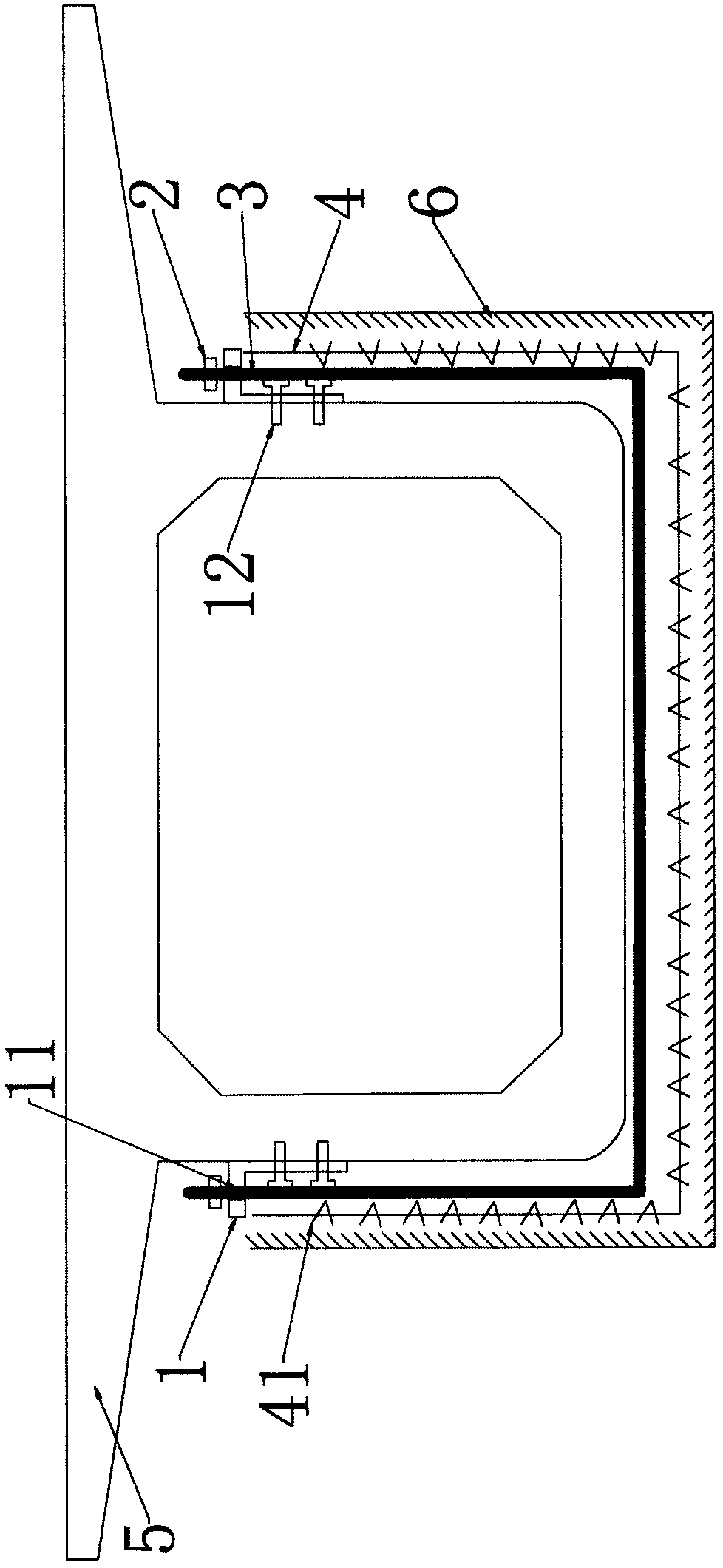

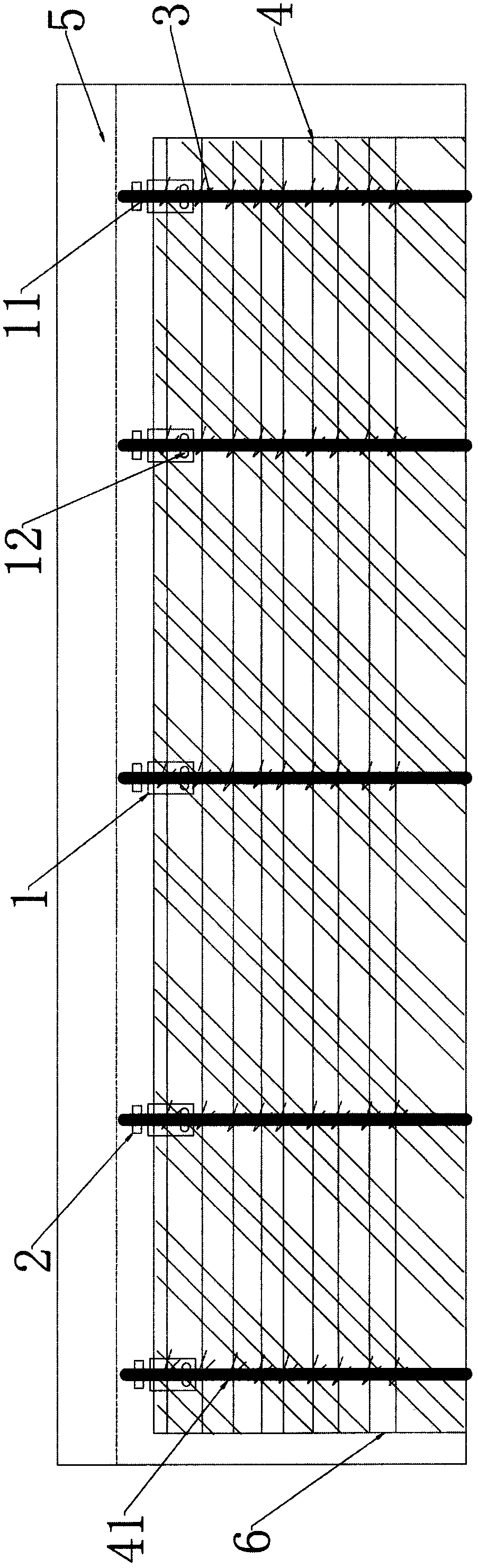

[0052] The present invention will be further described below in conjunction with the drawings.

[0053] As shown in the figure, a pre-stressed U-shaped bar fast shear-resistant reinforced box girder structure is composed of angle anchoring device 1, anchor ring 2, U-shaped bar 3, grid bar 4, concrete box girder 5, and anti-cracking mortar Layer 6 is composed of U-shaped ribs 3 perpendicular to the axial direction of the concrete box girder 5 along the side and bottom of the concrete box girder 5 at U-shaped intervals, with an arrangement interval of 0.3 to 1.5m. The two ends of the U-shaped ribs 3 pass through the corners. The anchoring device 1 and the anchor ring 2 are fixed on the upper two sides of the concrete box girder 5. The corner anchoring device 1 and the concrete box girder 5 are fixed on the side of the concrete box girder 5 by anchor bolts 12 and structural glue. U-shaped bars 3 Passing through the reserved slot 11 of the angle anchoring device 1, the U-shaped bar 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com