Large-aperture complex curved surface optical parameter accurate testing and calibrating device and method

A technology of complex curved surfaces and optical parameters, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inability to accurately measure the position of the apex, the reduction of the accuracy of optical parameter testing, the low accuracy of steel rulers and measuring rods, and achieve the cost of testing Low cost, easy operation and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

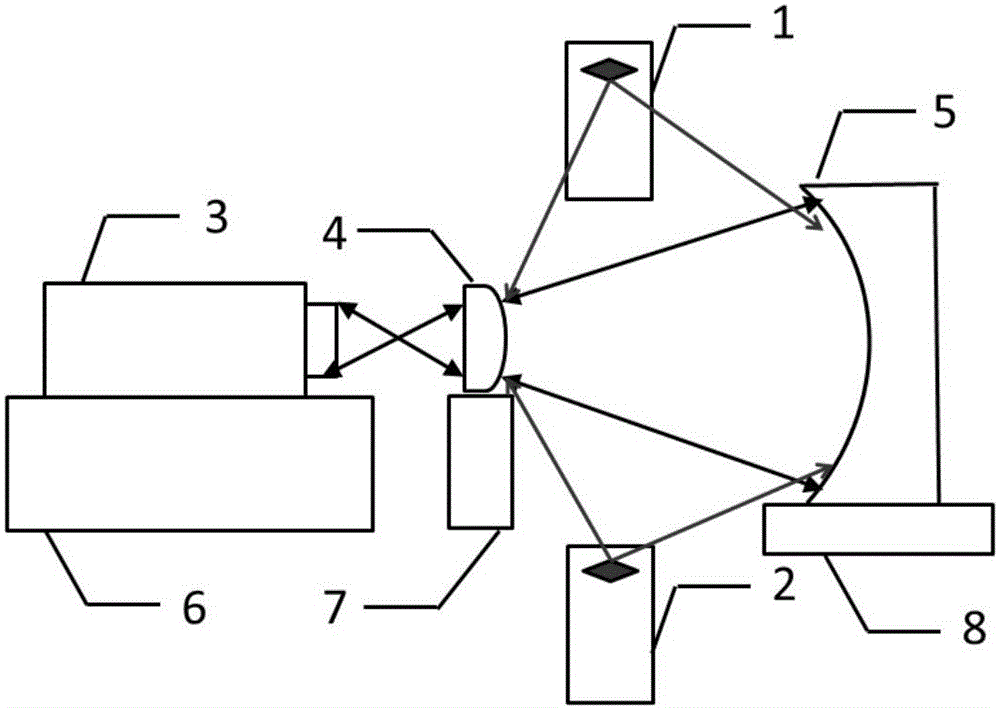

[0030] Embodiment 1, as figure 1 As shown, the device for accurate testing of the optical parameters of the large-caliber complex curved surface of the present invention includes: a laser tracker such as figure 1 As shown in positions 1 and 2, the laser interferometer 3, the compensating element 4, the complex curved surface to be tested 5, the adjustment mechanism 6, the adjustment mechanism 7, the adjustment mechanism 8 and the test calibration module.

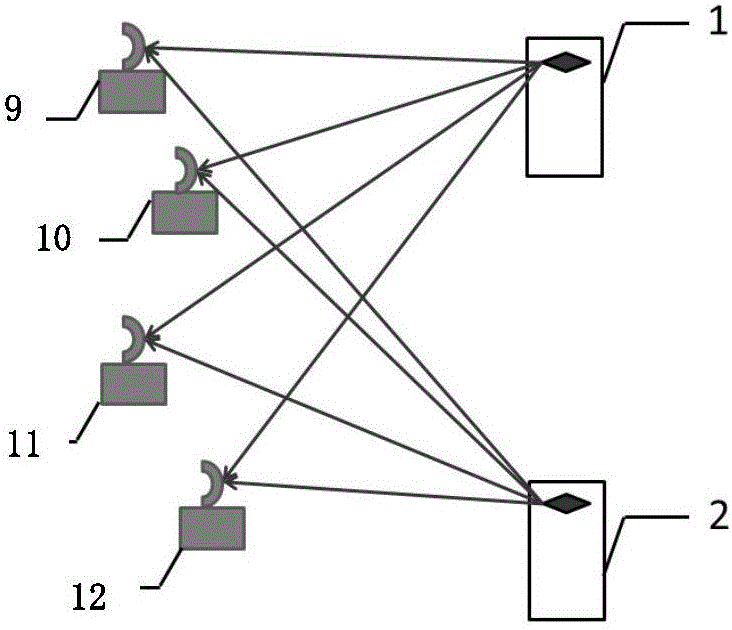

[0031] Such as figure 2 As shown, the device of the present invention for establishing a transformation matrix between two laser trackers includes a laser tracker figure 2 As shown in position 1 and position 2, ball seat 9, ball seat 10, ball seat 11, ball seat 12.

[0032] combine figure 1 with figure 2 To illustrate the specific implementation of the present invention, the large-caliber complex curved surface optical parameter accurate test and calibration device tests and calibrates the complex curved surface 5 to ...

Embodiment 2

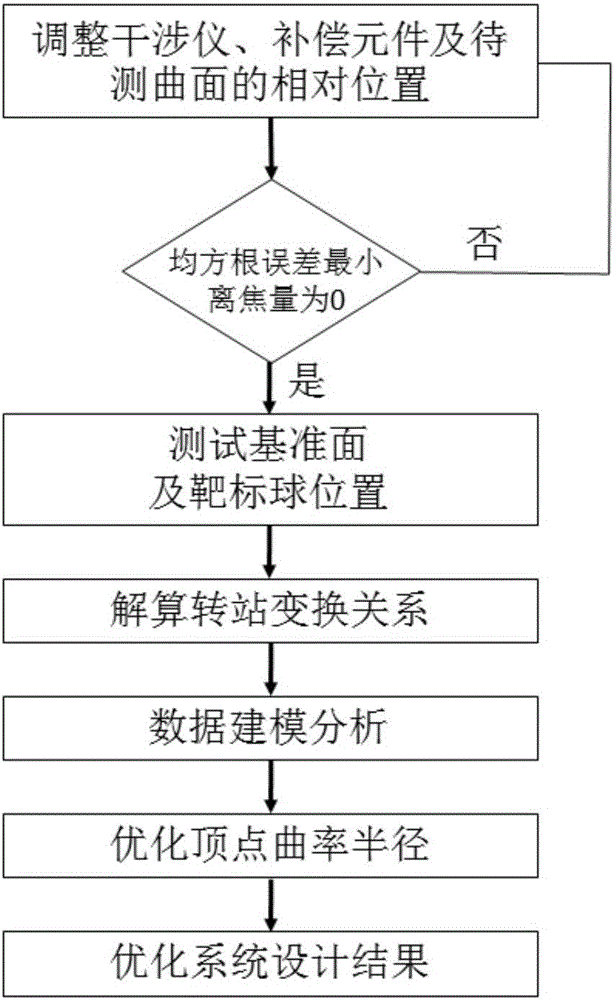

[0039] Embodiment 2, the method for testing and calibrating the large-diameter complex curved surface optical parameters accurate test and calibrating device as in embodiment 1, the method specifically includes the following steps:

[0040] Step 1) Adjust the relative position and relative angle of the first adjustment mechanism 6, the second adjustment mechanism 7 and the third adjustment mechanism 8, so that the root mean square error of the surface shape of the complex curved surface detected by the laser interferometer 3 is the smallest and defocused amount is zero;

[0041] Step 2) Place the laser tracker in N positions in turn, and the laser tracker tests the reflective surface of the complex curved surface 5 to be tested and the surface shape data of all measurable reference planes at each position, and tests the fixed M balls The coordinates of the target ball position of the seat;

[0042] Step 3) based on the target ball position coordinates measured in step 2), est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com