Extreme environment resistant sapphire fiber bragg grating sensor and temperature detection method thereof

A fiber grating, sapphire crystal technology, applied in thermometers, thermometers, instruments, etc. with physical/chemical changes, can solve the problems of weak accident resistance, large equipment size and cable volume, and increased demodulation complexity, etc. Sensitivity, effect of effective temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

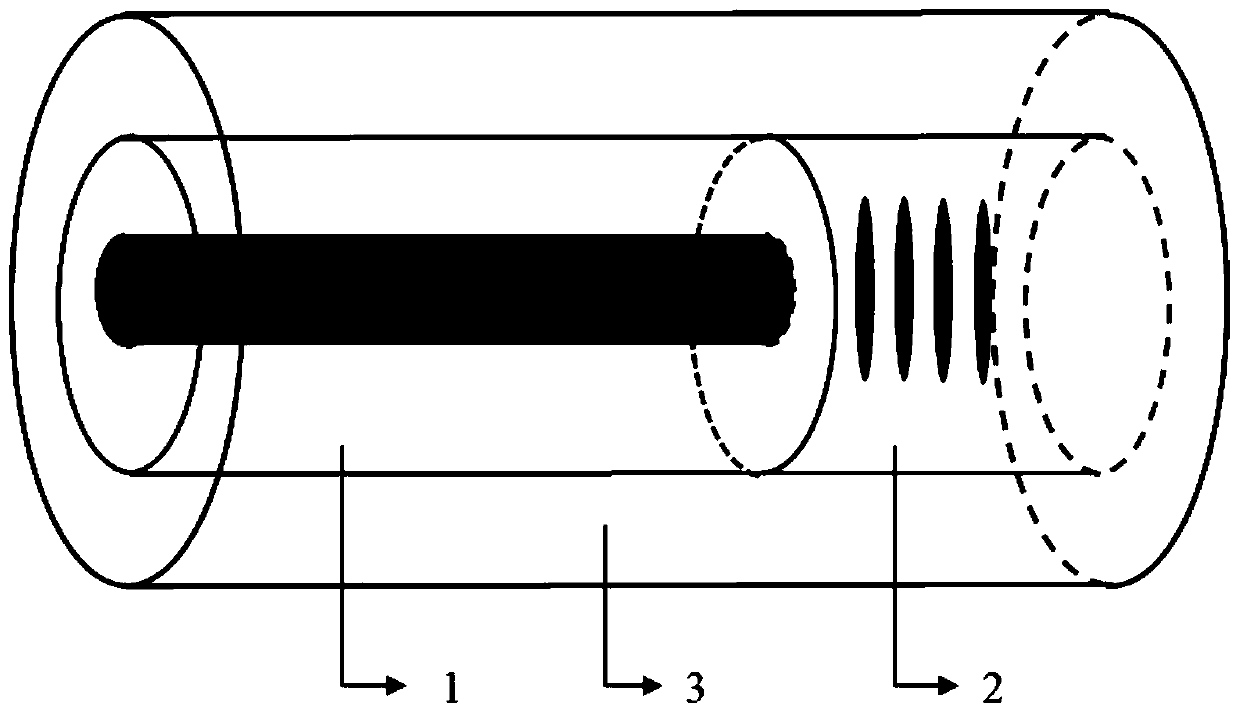

[0017] Such as figure 1 As shown, the sapphire crystal fiber grating temperature sensor includes a single-mode sensing fiber 1 , a sapphire crystal fiber grating 2 and a coating layer 3 . The production method is realized, and the specific steps are as follows:

[0018] A. Grinding one end of the sapphire crystal fiber to make the end face flat;

[0019] B. cutting the end face of the single-mode sensing fiber 2;

[0020] C. Splice the flattened section of the sapphire crystal fiber and the cut flat end face of the single-mode sensing fiber 2;

[0021] D. A fiber grating made by femtosecond laser point-to-point technology at the single-mode near-field position near the fusion point on the sapphire crystal fiber;

[0022] E. Coating materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com