Method for testing direct-current magnetic field intensity

A technology of magnetic field strength and DC magnetic field, applied in the size/direction of magnetic field, measuring device, measuring resonant frequency, etc., can solve the problems of long response time, quantification error of digital frequency meter reading, influence of water diamagnetic susceptibility, etc. Achieve the effect of eliminating interference and attenuation, good frequency stability, and accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

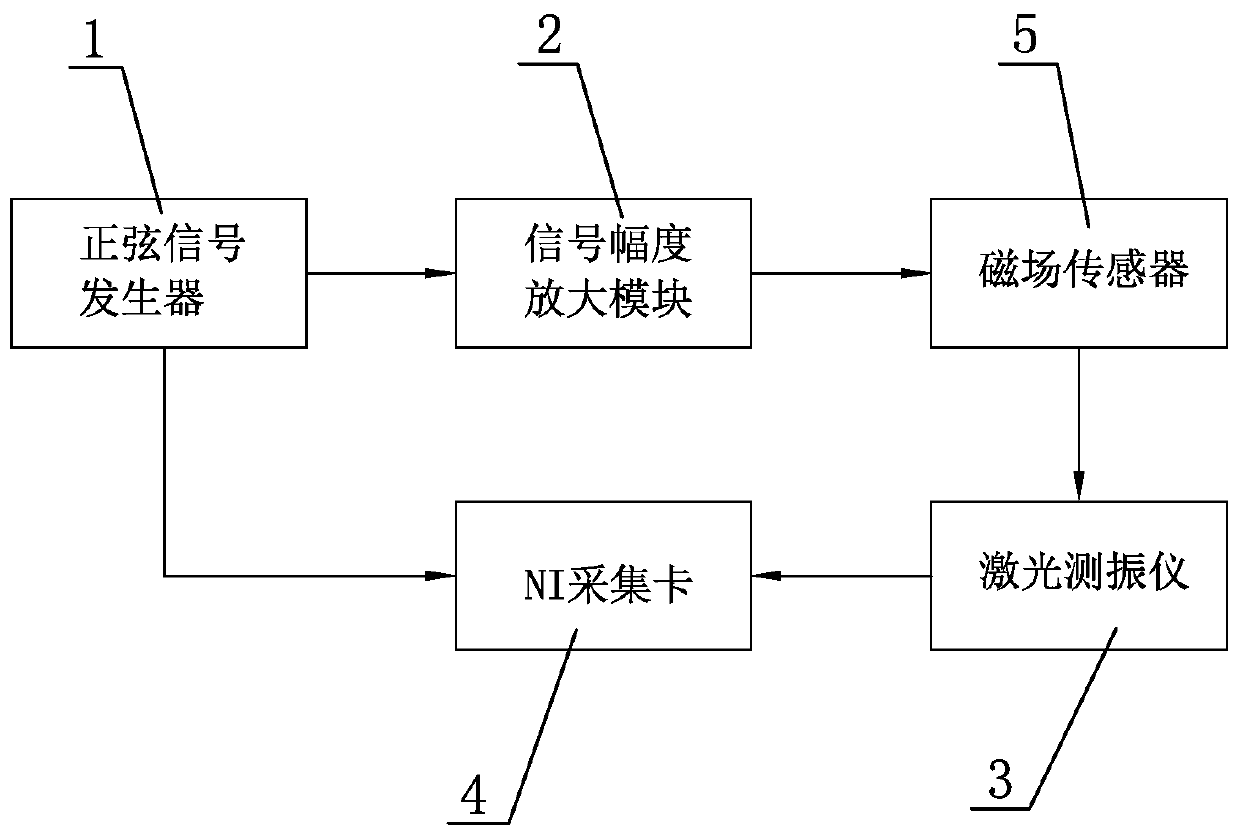

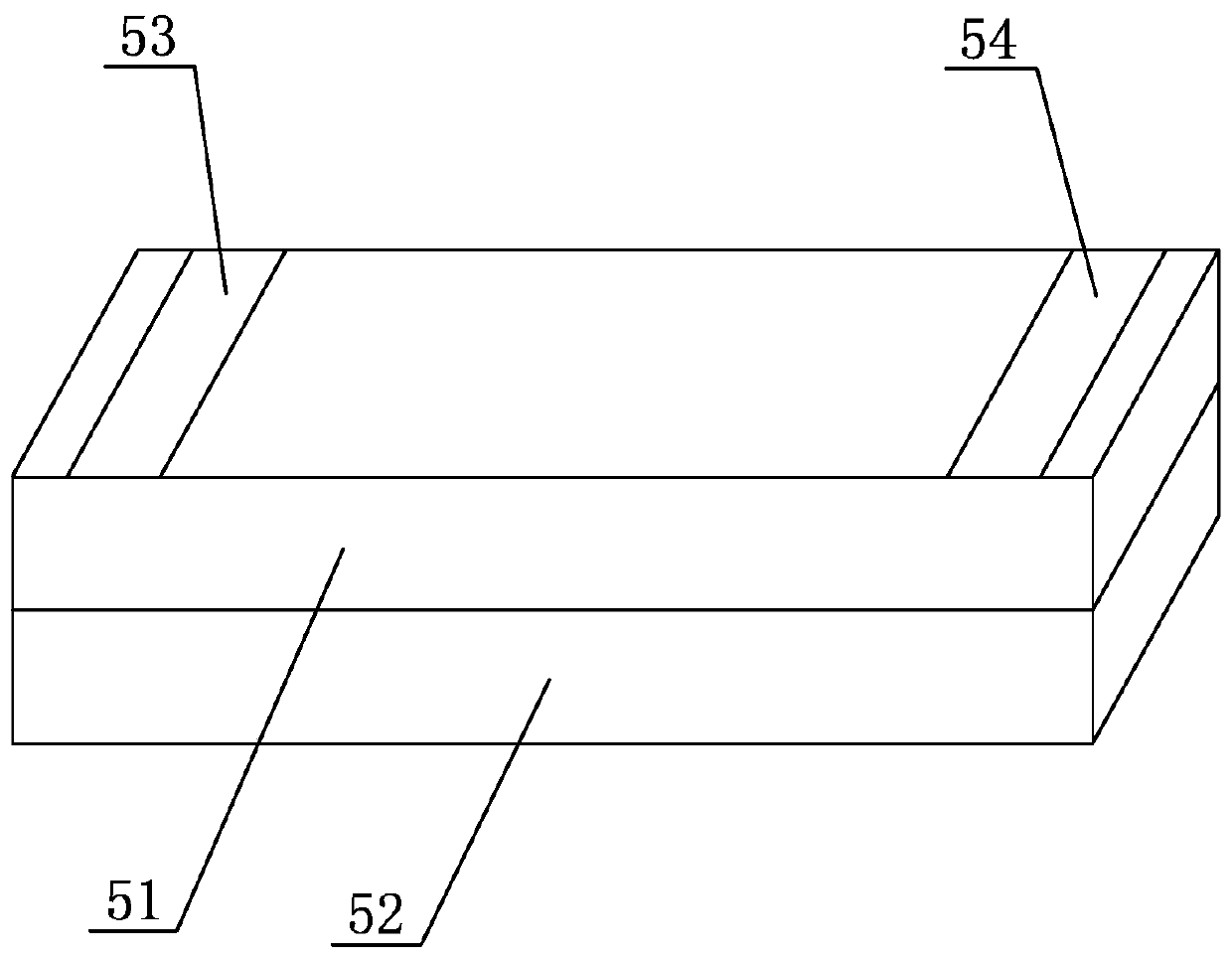

[0023] As shown in the figure, a test method for DC magnetic field strength, the test system used includes a sinusoidal signal generator 1, a signal amplitude amplification module 2, a laser vibrometer 3, an NI acquisition card 4, and a magnetic field sensor excited by a transverse field 5. The magnetic field sensor 5 includes a piezoelectric material layer 51 and a piezoelectric material layer 52 bonded and fixed to each other. A positive electrode 53 and a negative electrode 54 are arranged on one surface of the piezoelectric material layer 51, where the positive electrode 53 and the negative electrode 54 are located. The surface of the piezoelectric material layer 51 and the bonding surface of the piezoelectric material layer 52 are opposite to each other, so as to realize the transverse field excitation of the magnetic field sensor 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com