Method for performing nondestructive detection on distribution transformer winding material with two ends heated

A technology for distribution transformers and non-destructive testing, applied in the field of distribution transformers, can solve the problems of low accuracy, inability to accurately measure the thermoelectric potential at winding contacts, and large human body radiation, so as to avoid damage and simplify the test method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

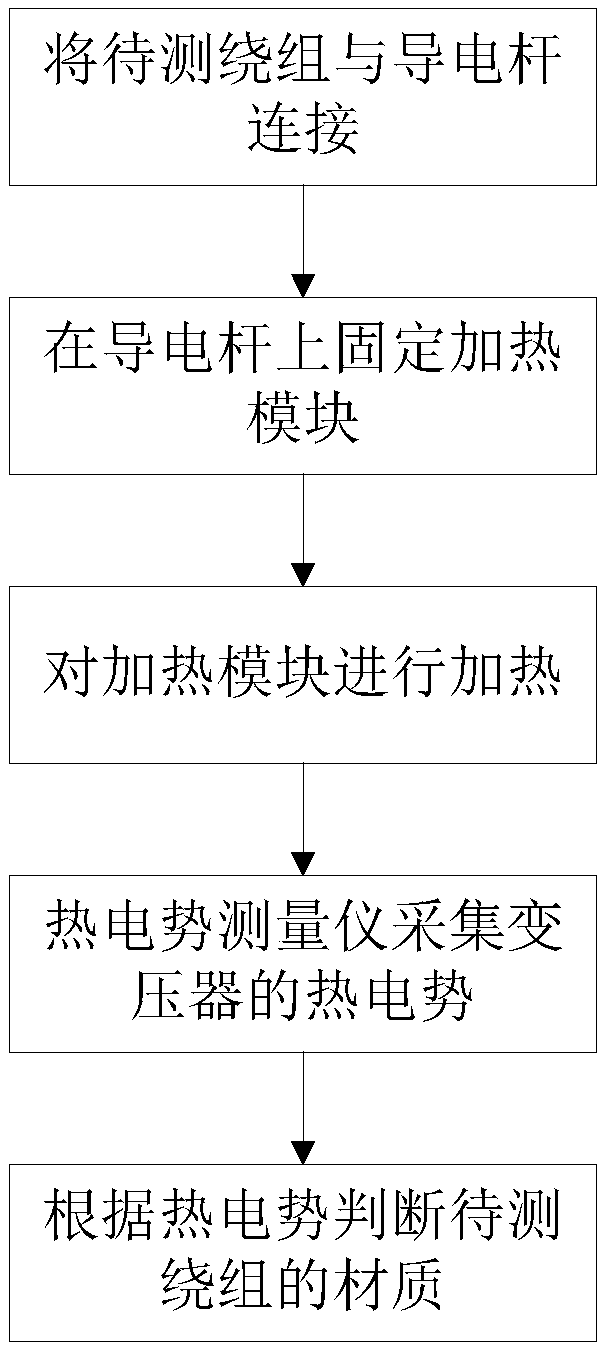

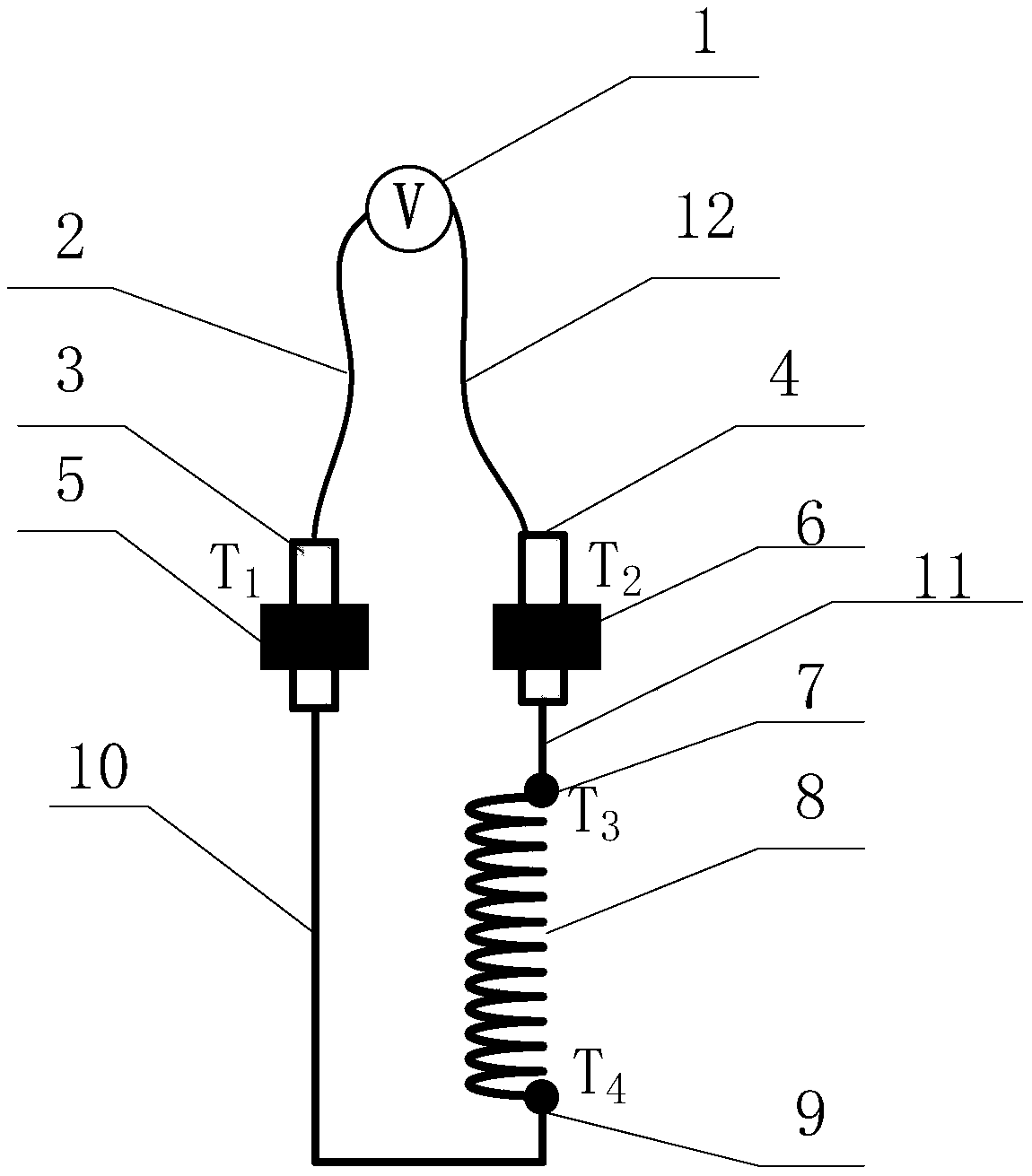

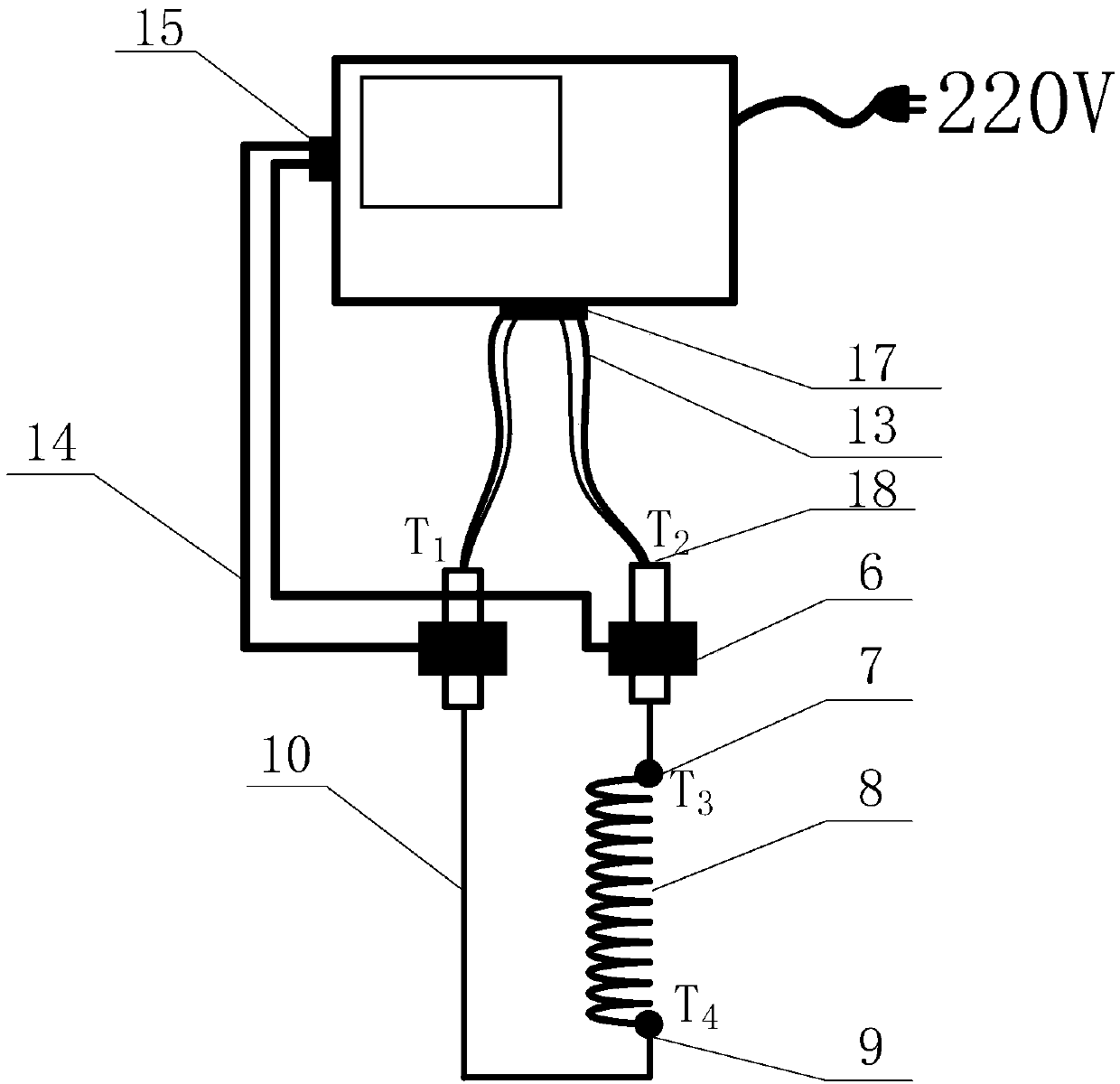

[0046] Example: such as figure 1 with figure 2 Shown; A non-destructive testing method for the winding material of distribution transformers heated at both ends, which includes:

[0047] S1: the winding 8 to be tested is connected to the first conductive rod 3 and the second conductive rod 4 through the first copper bar connecting wire 10 and the second copper bar connecting wire 11 respectively;

[0048] S2: Fixing the first heating module 5 and the second heating module 6 on the first conductive rod 3 and the second conductive rod 4 respectively;

[0049] S3: Control the heating of the first heating module 5 and the second heating module 6, so that the first conductive rod 3 and the second conductive rod 4 are heated in the same way;

[0050]S4: The thermoelectric potential measuring instrument 1 connects the first thermoelectric potential measurement line 2 and the second thermoelectric potential measurement line 12 with the first conductive rod 3 and the second conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com