Complete drive control device set for oil-submersible screw pump

A submersible screw, drive and control technology, applied in the direction of pump control, isolation device, electric heating device, etc., can solve the problems of high failure rate of oil production, low system life, etc., to solve low-temperature wax deposition, reduce fault maintenance, and reduce overall vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

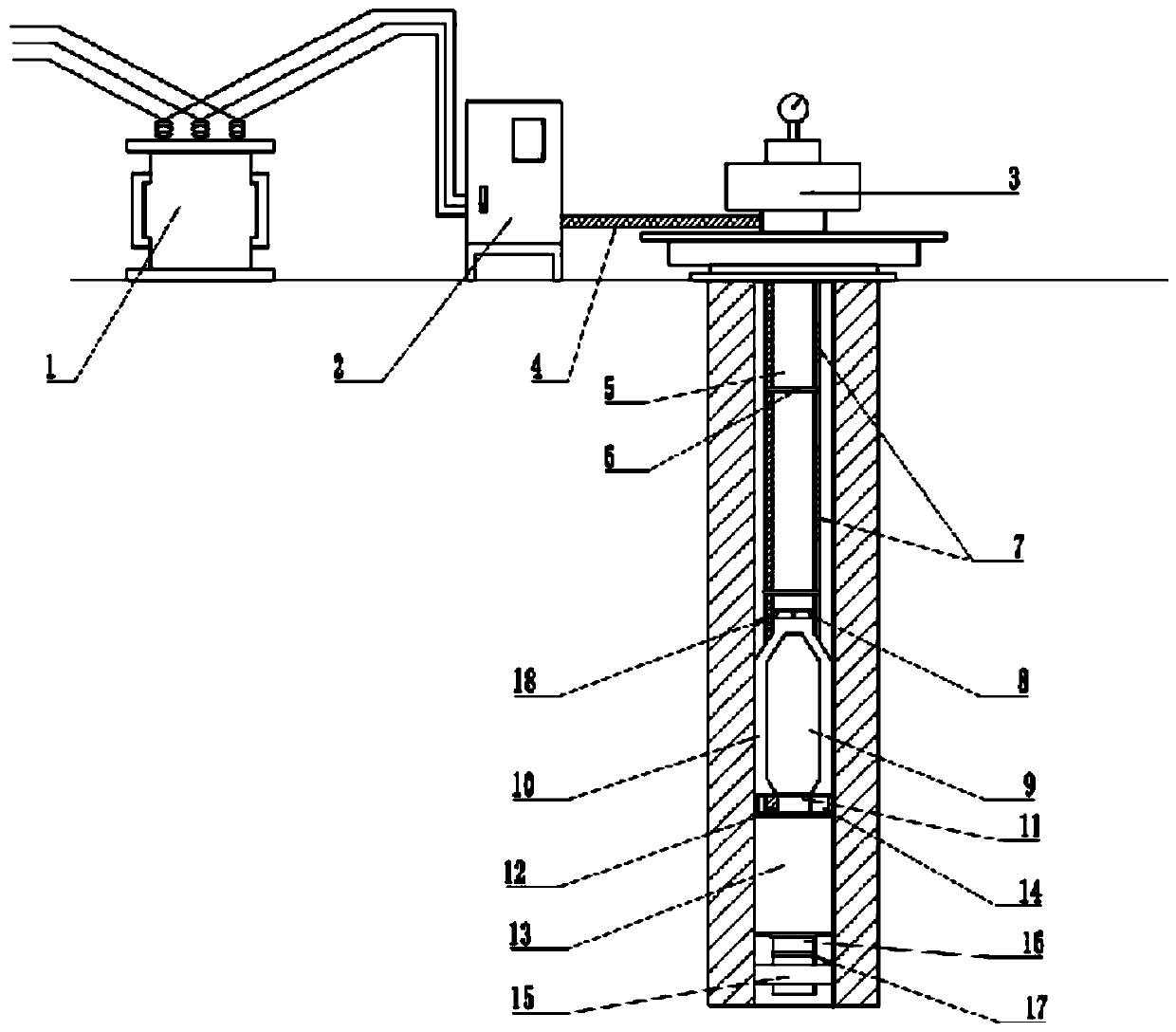

[0030] Such as figure 1 As shown, the embodiment of the present invention provides a complete set of drive and control device for submersible screw pump, which is characterized in that it includes: a control module, an oil production mechanism module and a downhole detection module;

[0031] A complete set of drive and control device for a submersible screw pump, comprising: a control module, an oil production mechanism module and a downhole detection module;

[0032] The oil production mechanism module includes a submersible screw pump, an oil submersible permanent magnet motor positioned above it, and a composite oil pipe; a coupling is installed below the oil submersible permanent magnet motor to connect with the oil submersible screw pump; the composite oil pipe is Three-layer structure, the outer layer is hot-dip galvanized steel wire or carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com