Automatic mineral oil water separation device and process method for solvent tail gas absorption system

A tail gas absorption and water separation device technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of many human factors and poor reliability of artificial discharge, so as to reduce environmental pollution, optimize work efficiency and quality, The effect of enhancing the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

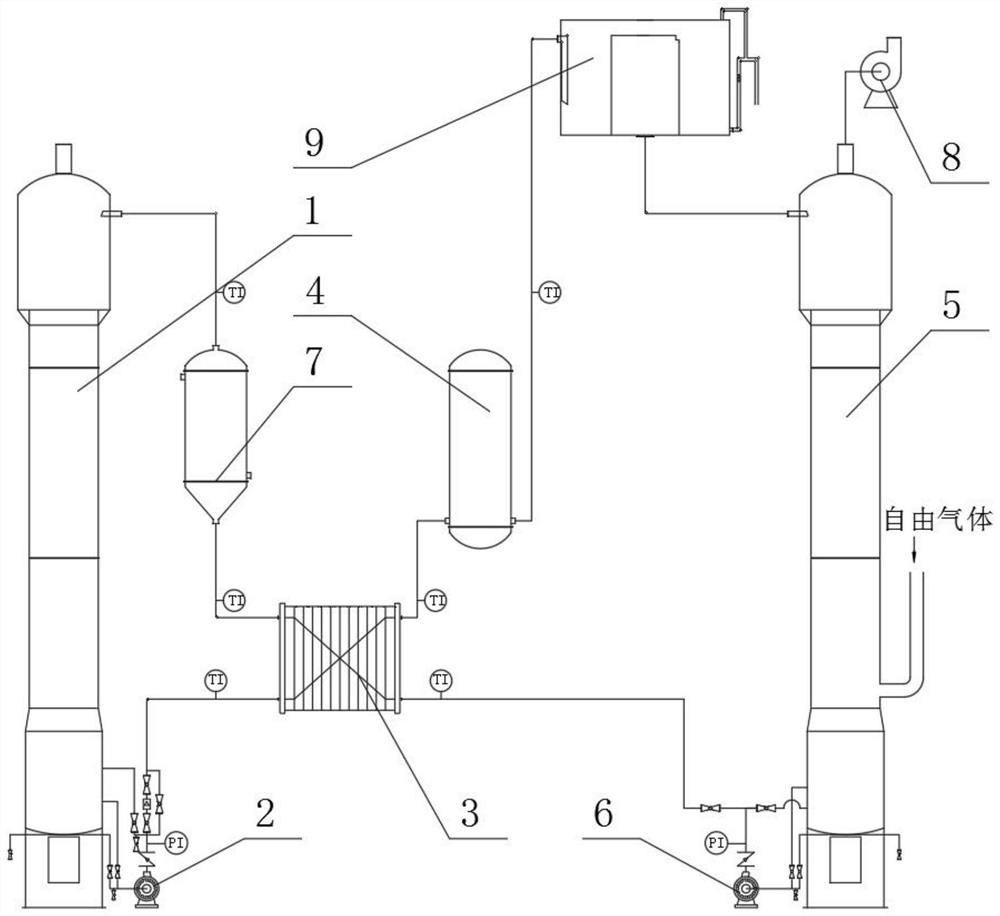

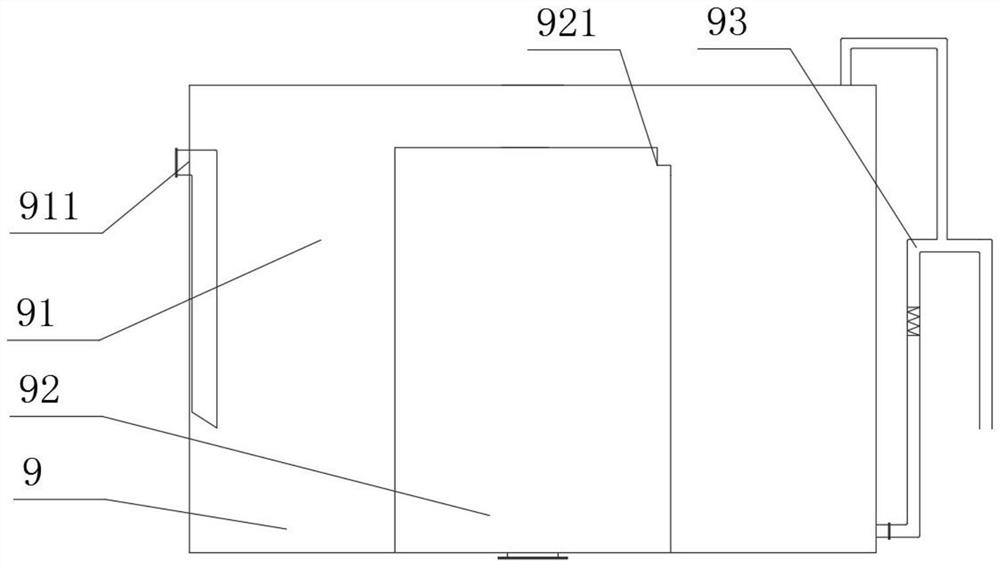

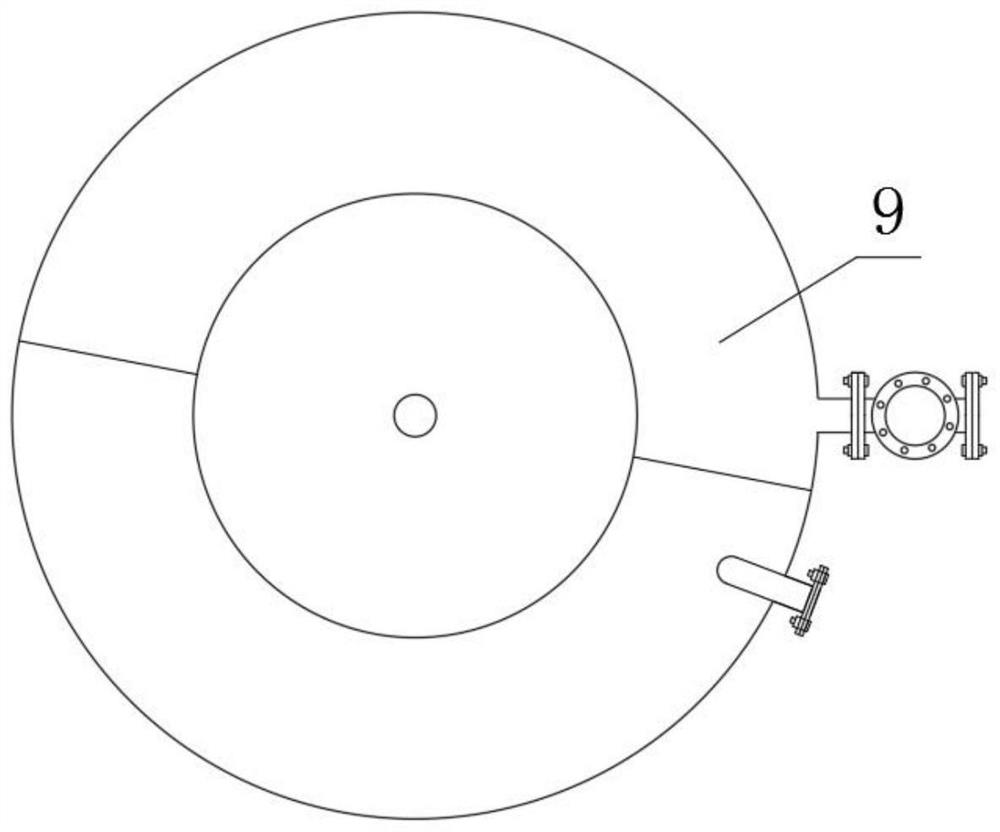

[0032] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a kind of solvent tail gas absorption system mineral oil automatic water separation device of this embodiment, comprise desorption tower 1, lean oil pump 2, heat exchanger 3, lean oil cooler 4, absorption tower 5, rich oil pump 6, Rich oil heater 7 and tail gas blower 8, the bottom of desorption tower 1 is connected to inlet d of heat exchanger 3 through lean oil pump 2, outlet b of heat exchanger 3 is connected to absorption tower 5 through lean oil cooler 4, and absorption tower 5 The bottom is connected to the c inlet of the heat exchanger 3 through the oil-rich pump 6, the outlet a of the heat exchanger 3 is connected to the top of the analysis tower 1 through the oil-rich heater 7, and the top of the absorption tower 5 is equipped with an exhaust fan 8, which is characterized in that: Including an automatic drainage box 9, an automatic drainage box 9 is arranged on the pipeline c...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination Figure 1-Figure 3 To illustrate this embodiment, based on specific embodiment one, a mineral oil automatic water separation process method of a solvent tail gas absorption system in this embodiment:

[0037] Step 1, the uncondensed free gas in the oil leaching process system enters the lower part of the absorption tower 5;

[0038] Step 2, the absorption tower 5 is a packed tower, the absorption tower 5 is operated under negative pressure, the paraffin oil is introduced from the upper part of the absorption tower 5, the paraffin oil and the free gas are countercurrently absorbed, and the principle of using the paraffin oil to dissolve with the solvent and not dissolve the air, Absorb solvent oil in free gas;

[0039] Step 3, the rich oil formed after the absorption of paraffin oil in step 2 is transported from the inlet c to the heat exchanger 3 through the rich oil pump 6, and after exchanging heat inside the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com