Patents

Literature

38results about How to "Good fog effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

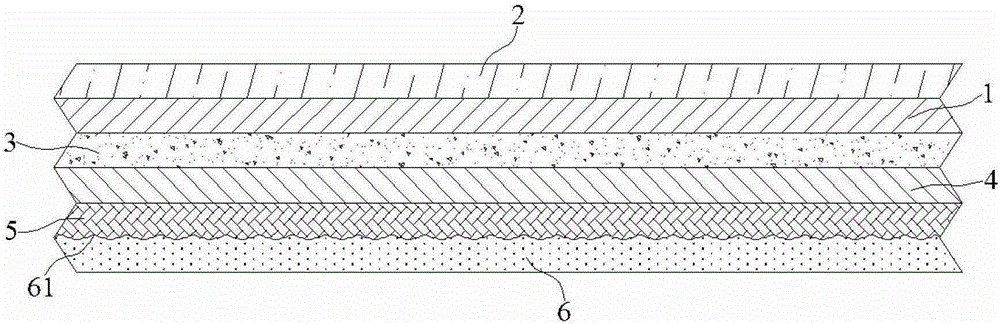

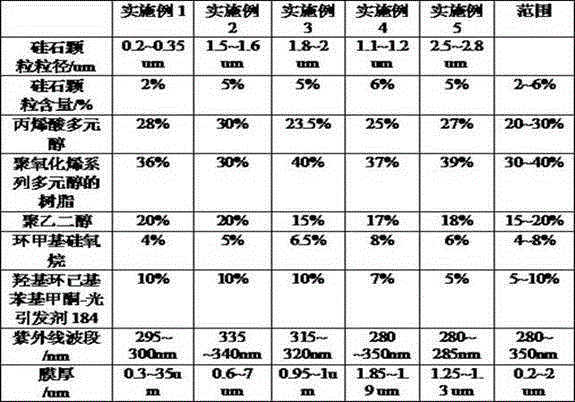

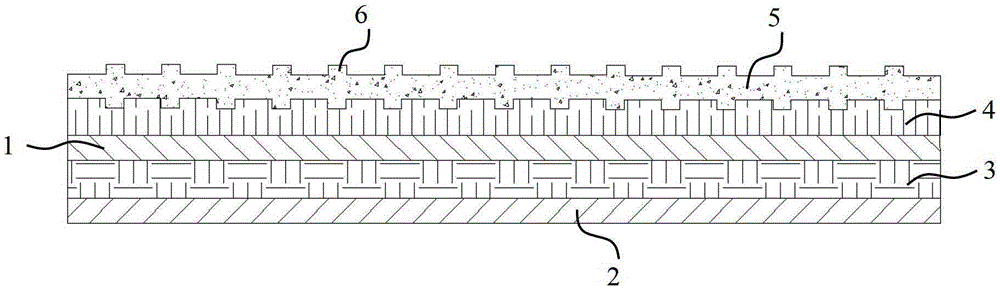

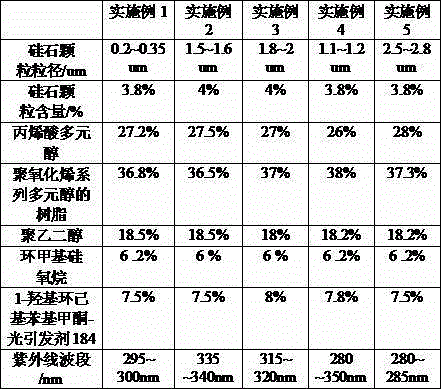

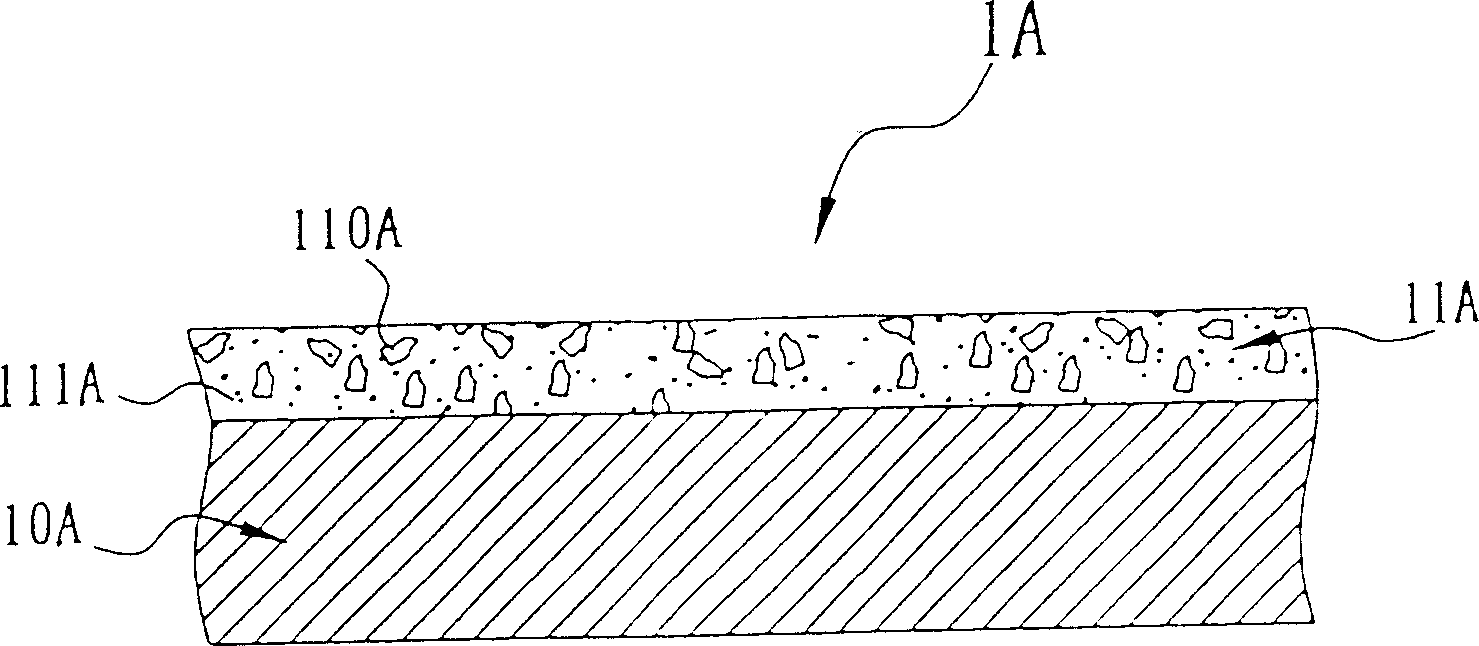

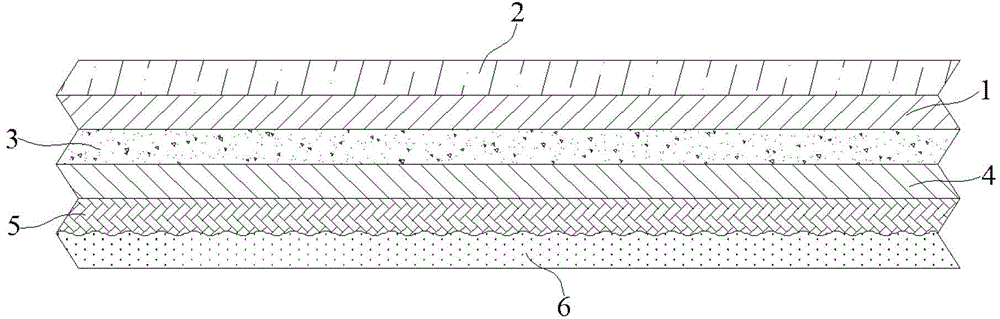

Anti-scuffing matt-surface antistatic release paper

ActiveCN103074819ALow wear resistanceImprove surface antistatic performanceNon-fibrous pulp additionSynthetic resin layered productsElectrostatic coatingPolyethylene glycol

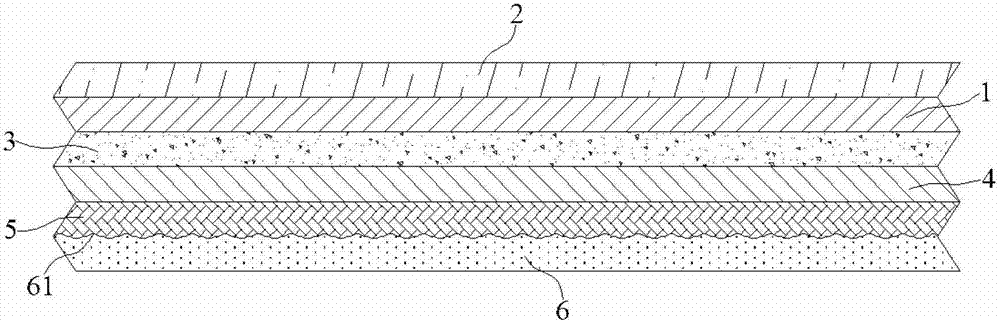

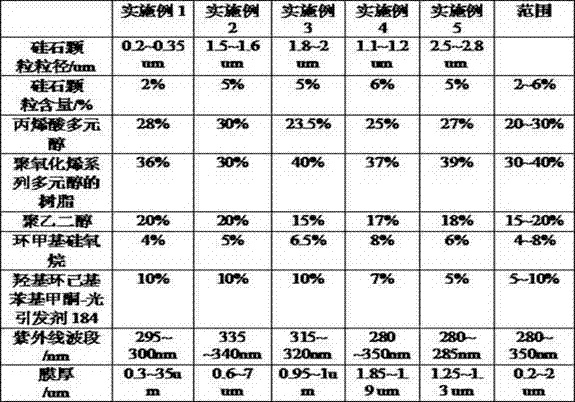

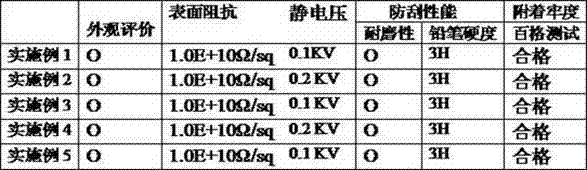

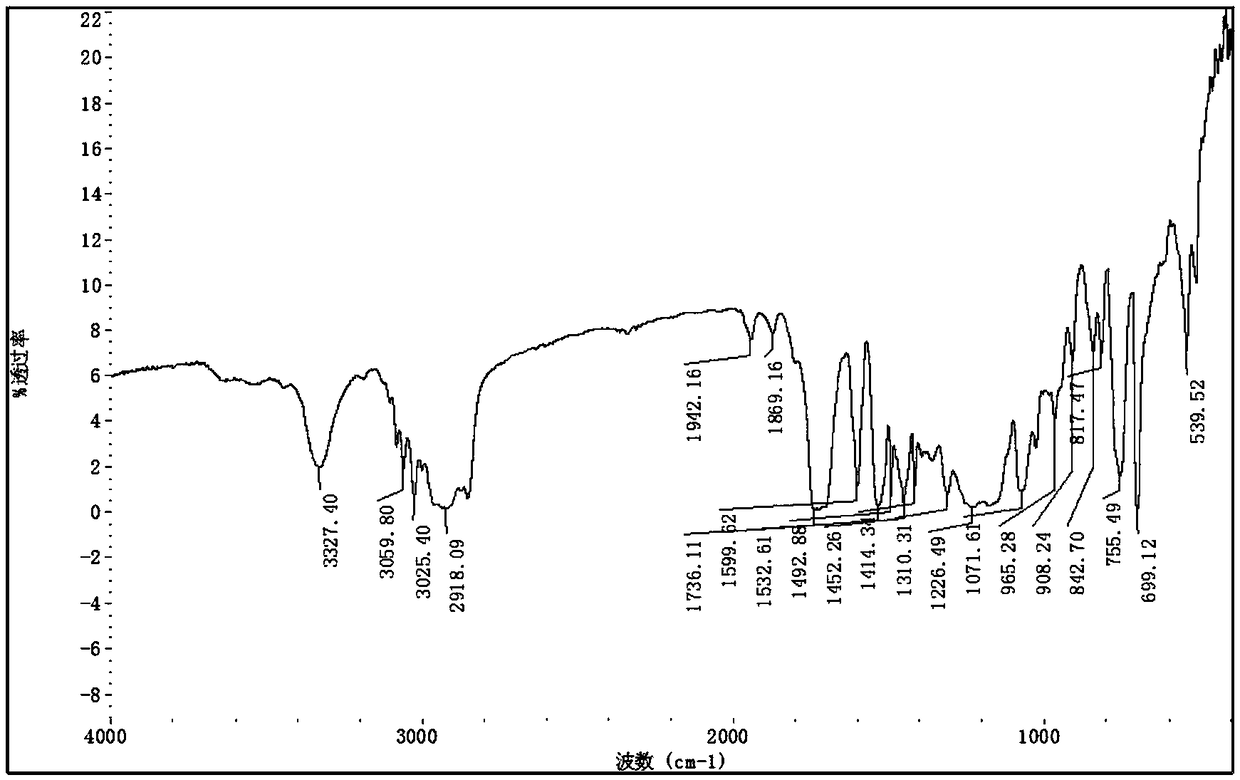

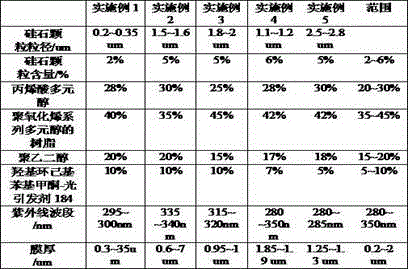

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

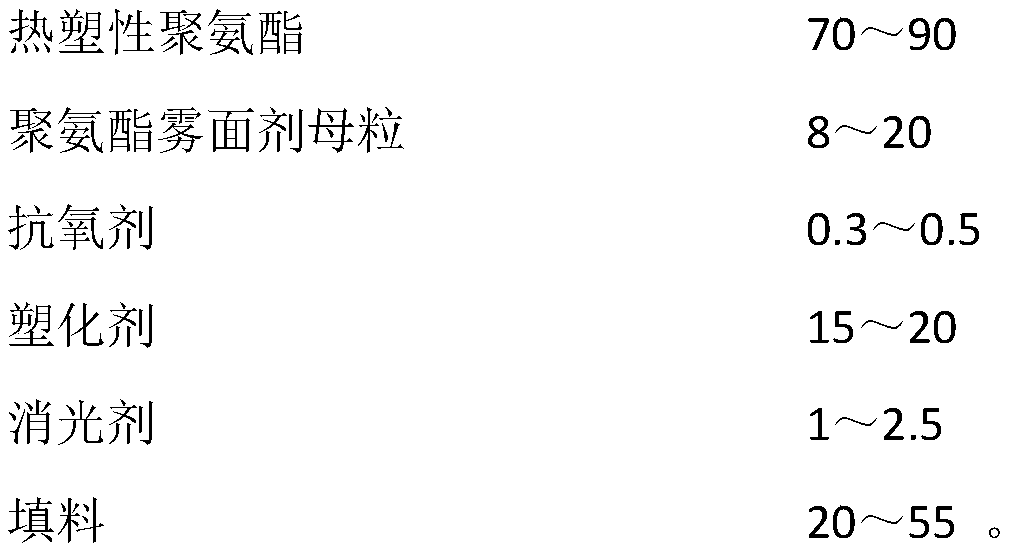

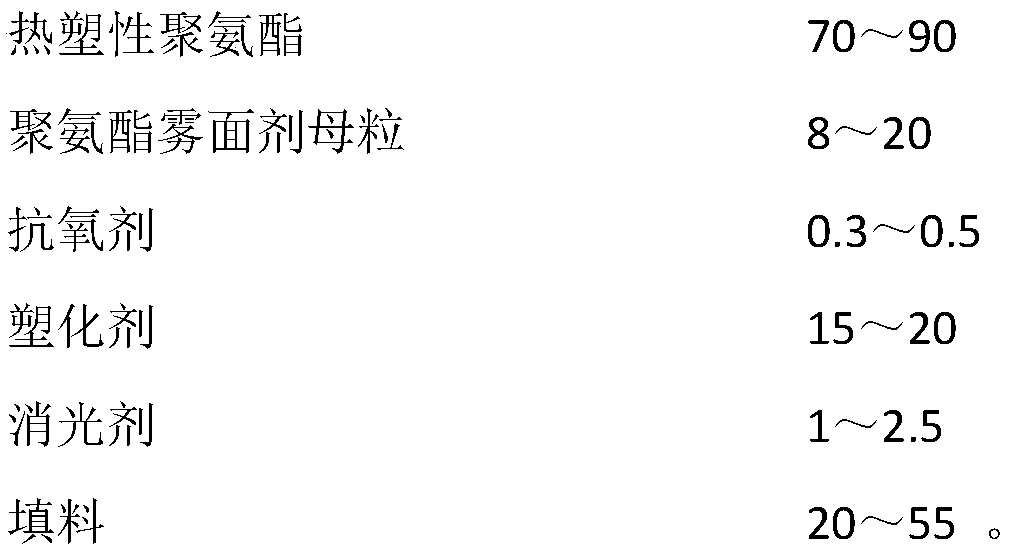

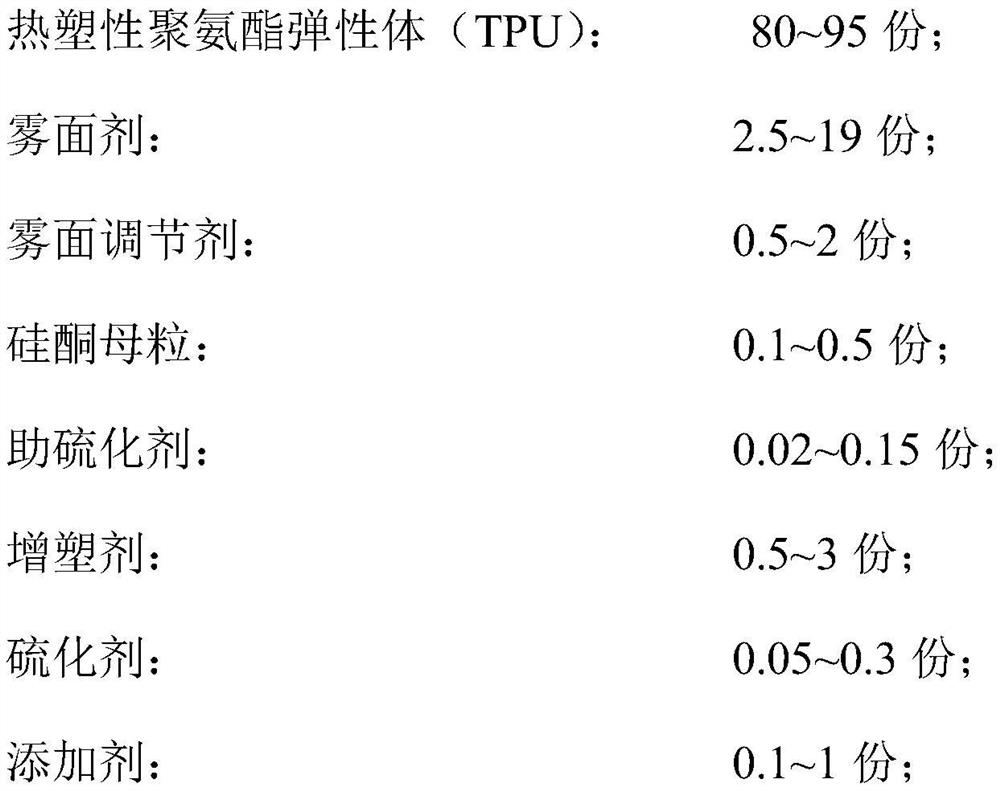

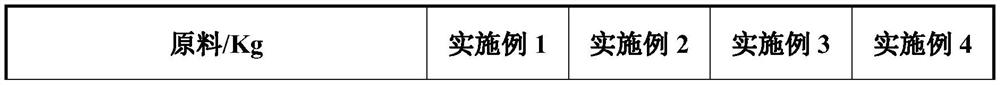

Matte TPU (Thermoplastic Polyurethane) material and preparation method thereof

ActiveCN109265967ADoes not affect mechanical propertiesLong-term retention of mechanical propertiesThermoplastic polyurethaneMechanical property

The invention relates to the field of high polymer materials and in particular relates to a matte TPU (Thermoplastic Polyurethane) material and a preparation method thereof. The invention provides a polyurethane matte agent master batch and a matte polyurethane composition, wherein preparation raw materials of the polyurethane matte agent master batch comprise polyurethane a styrene-ethylene-butadiene-styrene copolymer and an acrylate copolymer, wherein the weight ratio of the polyurethane to the styrene-ethylene-butadiene-styrene copolymer to the acrylate copolymer is (2 to 5) to (2 to 4) to1. The matte polyurethane composition has very good mechanical properties and matte effect.

Owner:广州增城市大发塑胶颜料有限公司

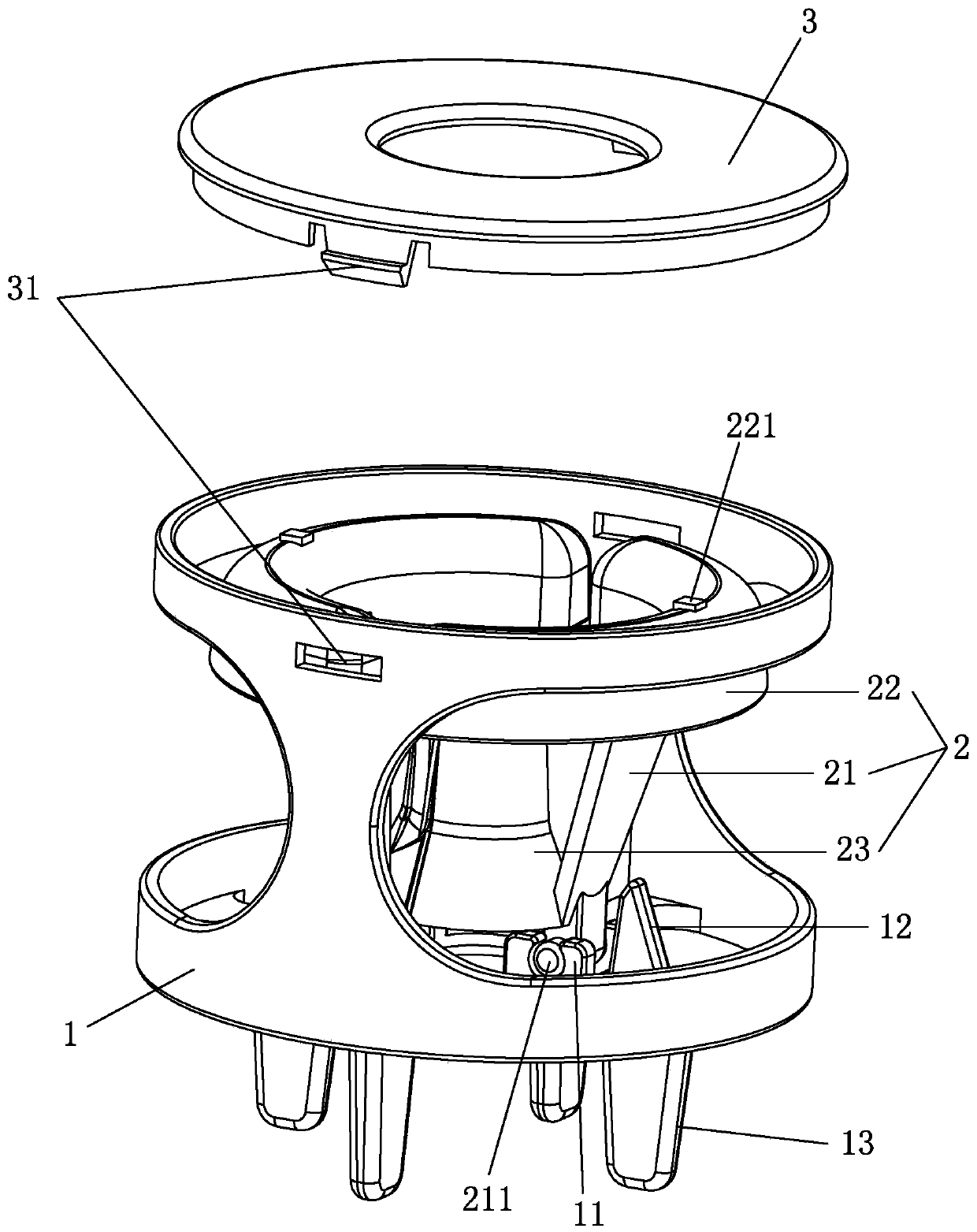

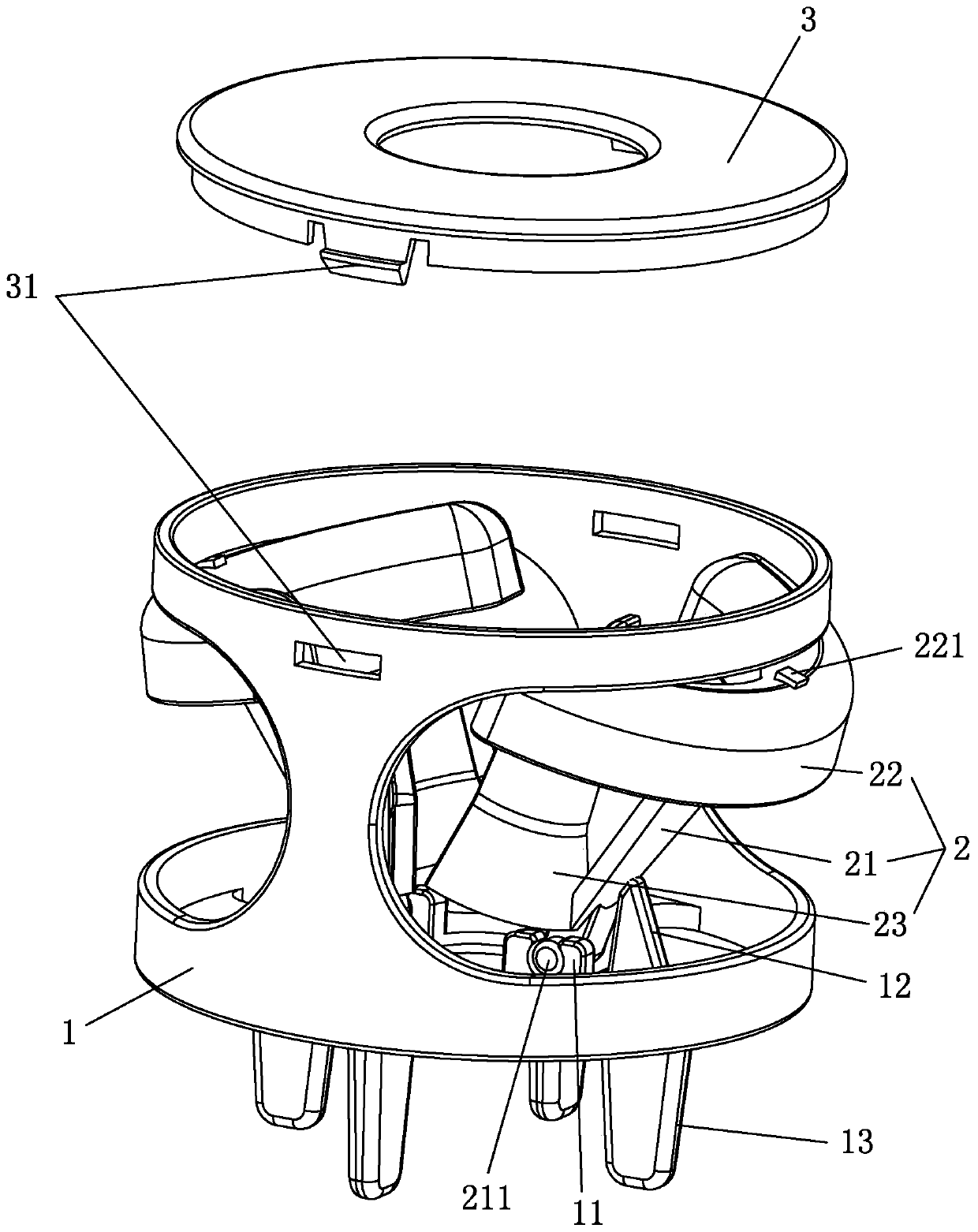

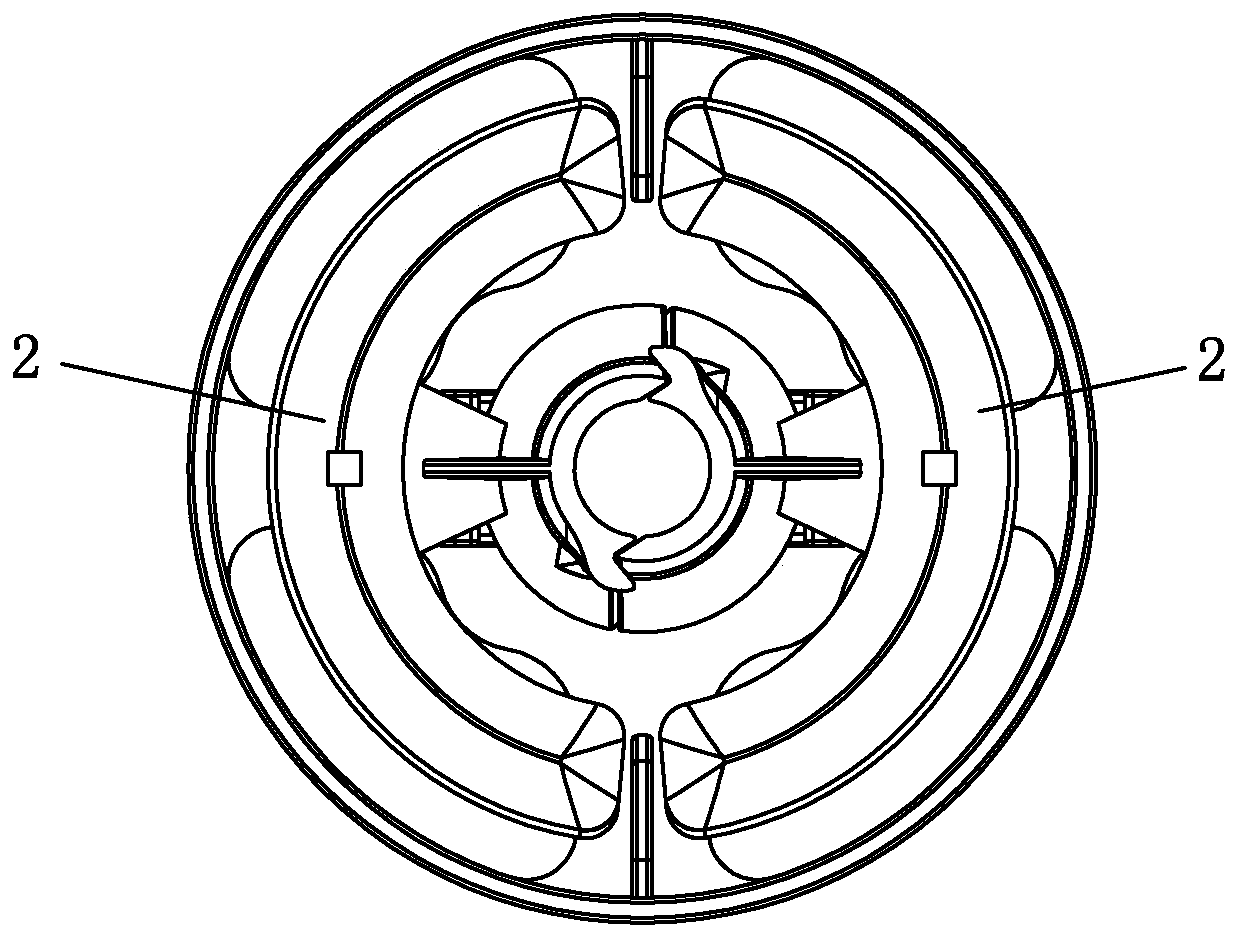

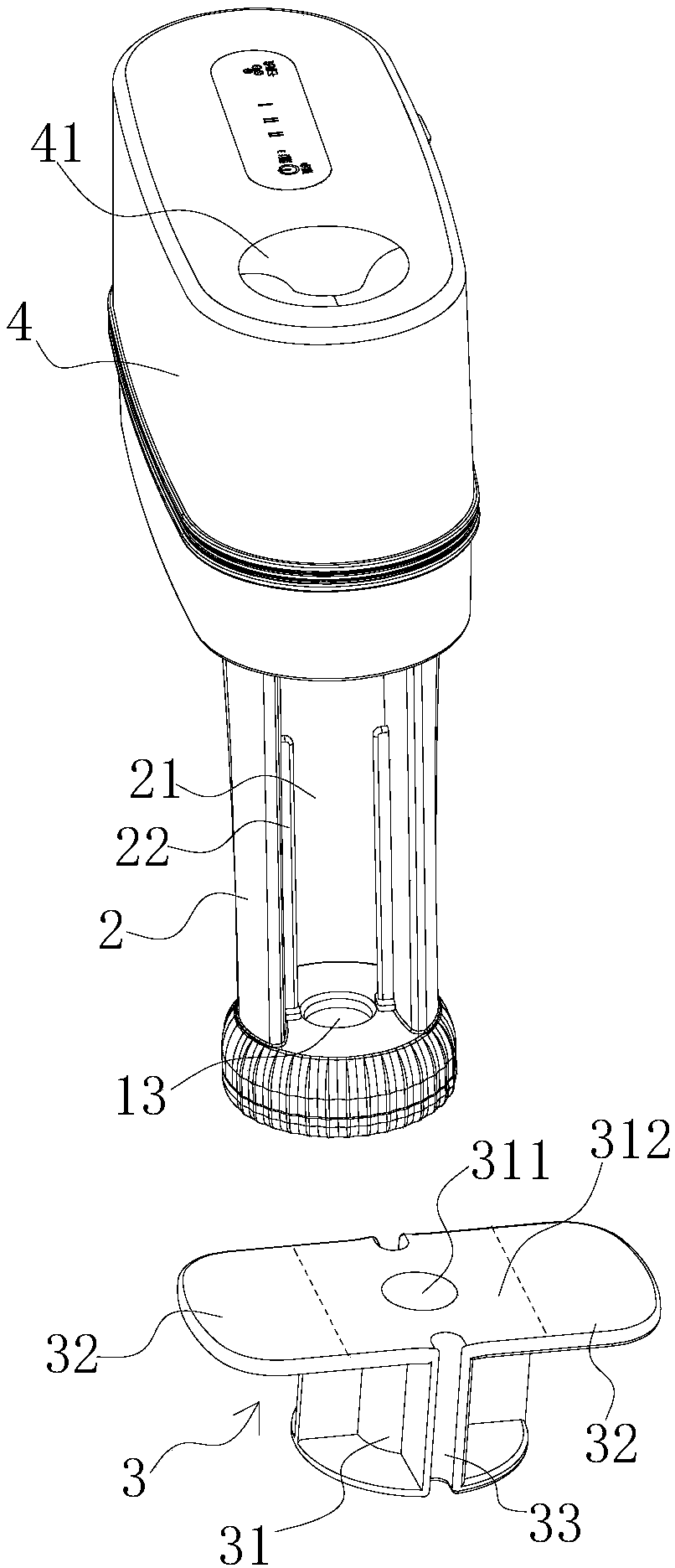

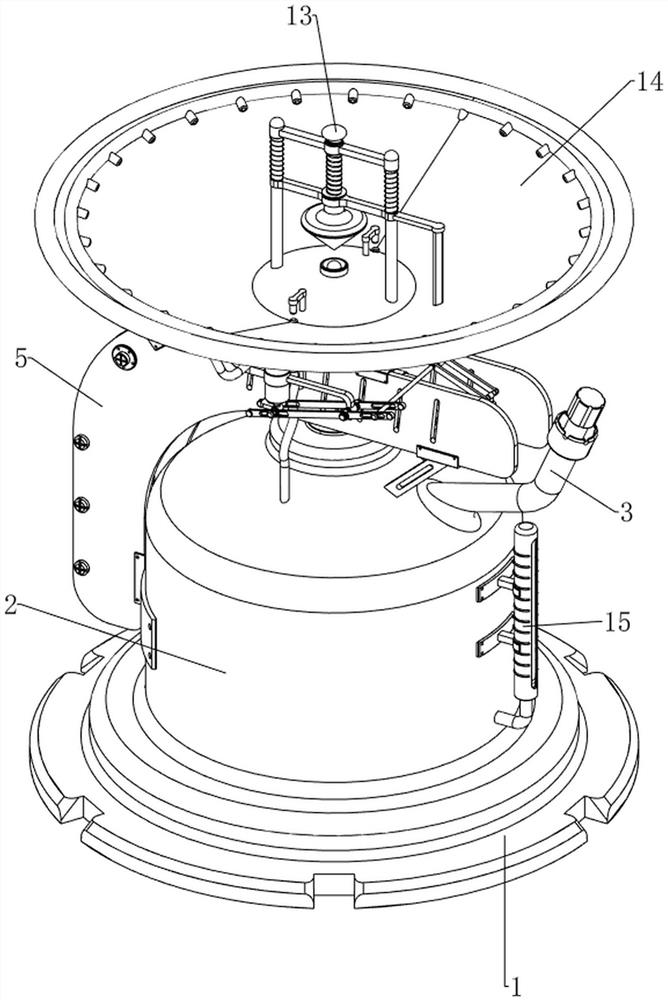

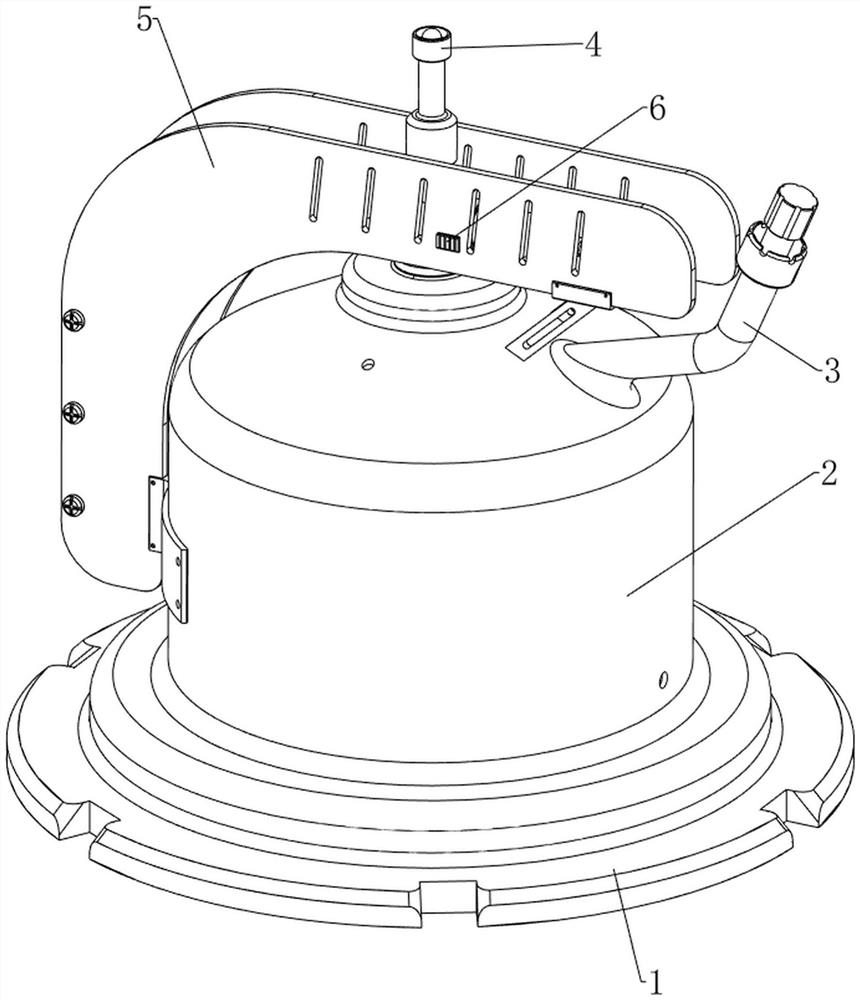

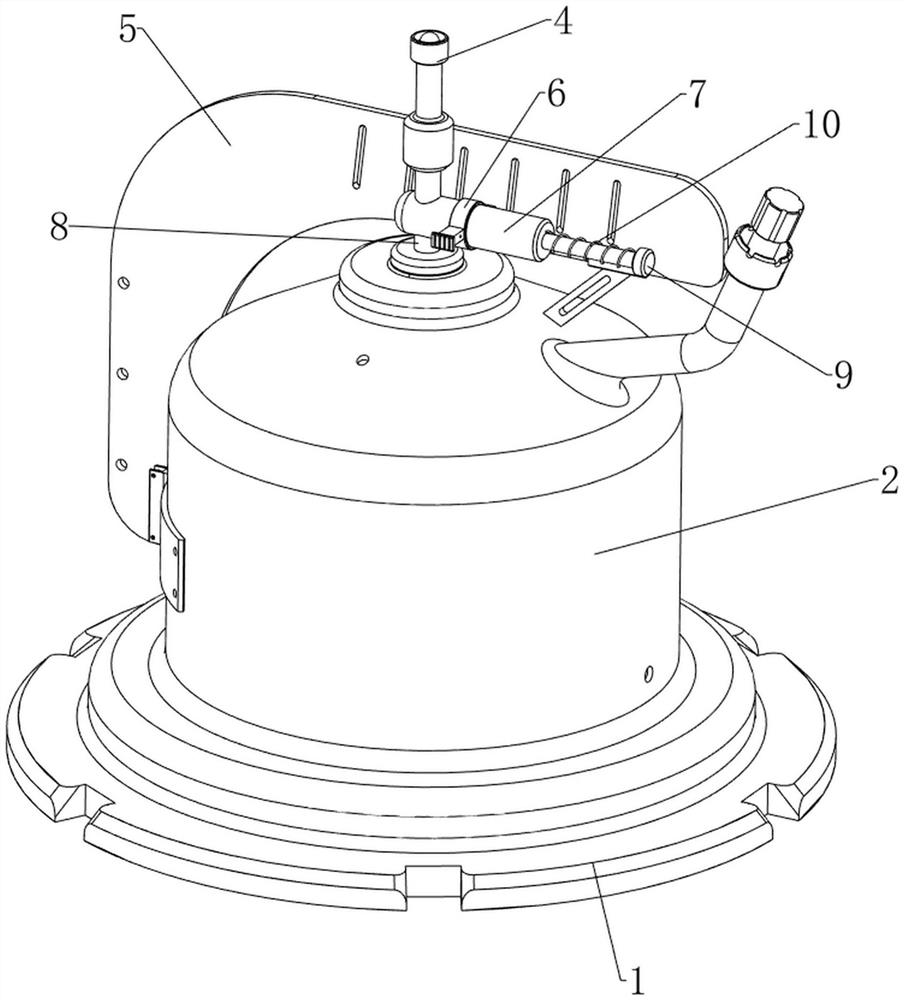

Novel humidifier atomization energy-gathering device

PendingCN110887149AIncrease fog outputGood fog effectLighting and heating apparatusAir humidification systemsBuoyant flowEngineering

The invention relates to a novel humidifier atomization energy-gathering device which comprises a base, wherein a plurality of energy-gathering floating arms are connected onto the base; each of the energy-gathering floating arms comprises a connecting part and an energy-gathering part; the upper end of the connecting part is fixedly connected with the energy-gathering part and the connecting partis obliquely arranged outwards from bottom up; the lower end of the connecting part is hinged to the base; all energy-gathering parts in low water level state mutually open outwards under the actionof gravity, or the energy-gathering parts in high water level state mutually close inwards under the action of buoyancy. The novel humidifier atomization energy-gathering device can form different energy-gathering part opening-closing states in high and low water level states; in the high level state, the energy-gathering parts mutually close to realize the effect of increasing the atomization quantity; and in the low water level state, the energy-gathering parts mutually open to avoid water mist blockage; and the novel humidifier atomization energy-gathering device can automatically adjust according to the water level height to ensure that the humidifier has an excellent atomization effect both in high water level state and low water level state.

Owner:佛山市顺德区巨科电器有限公司 +1

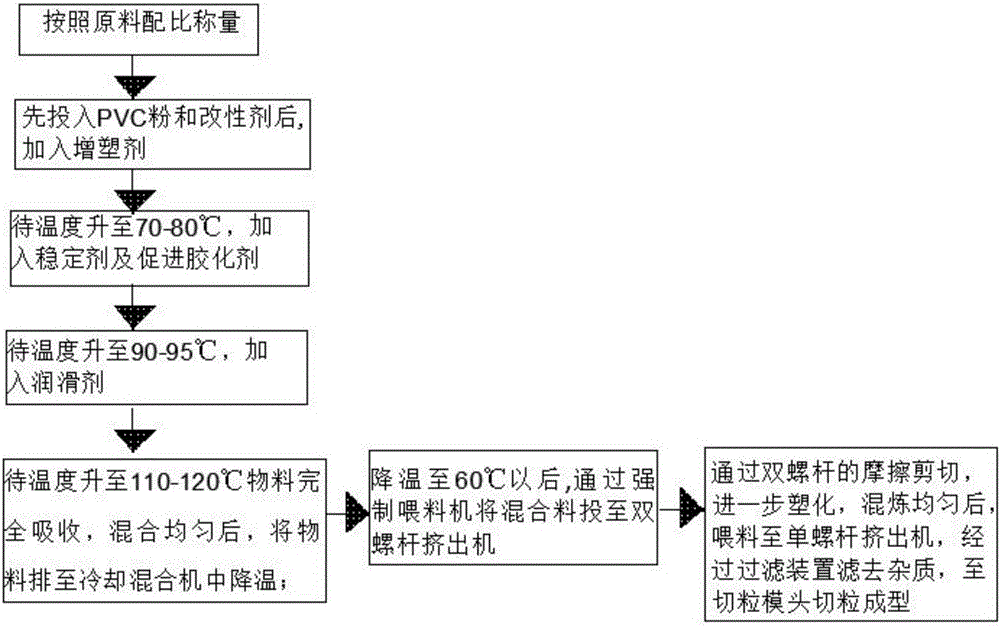

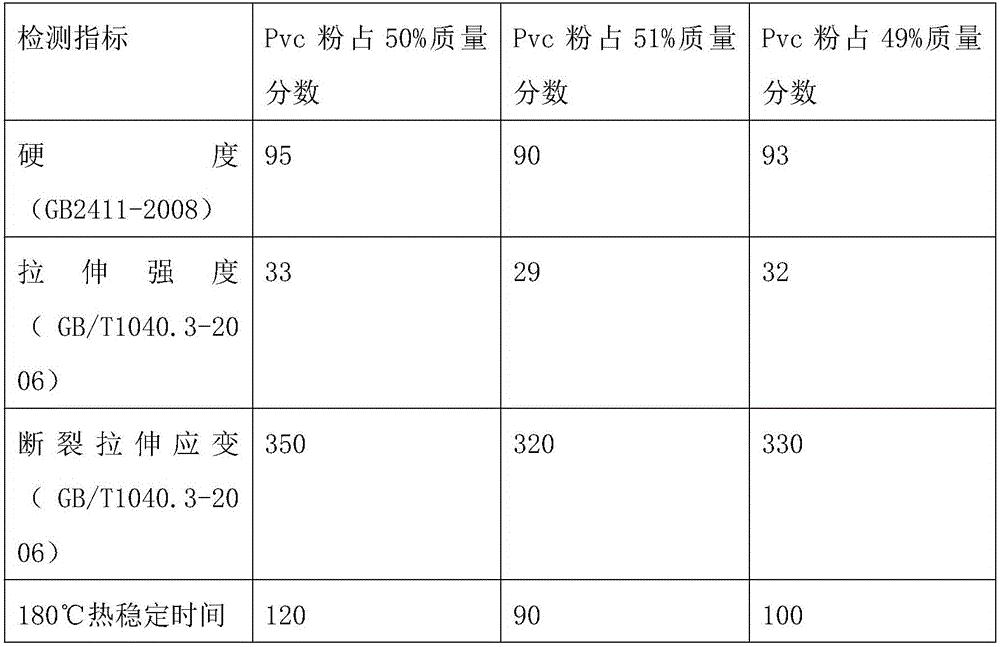

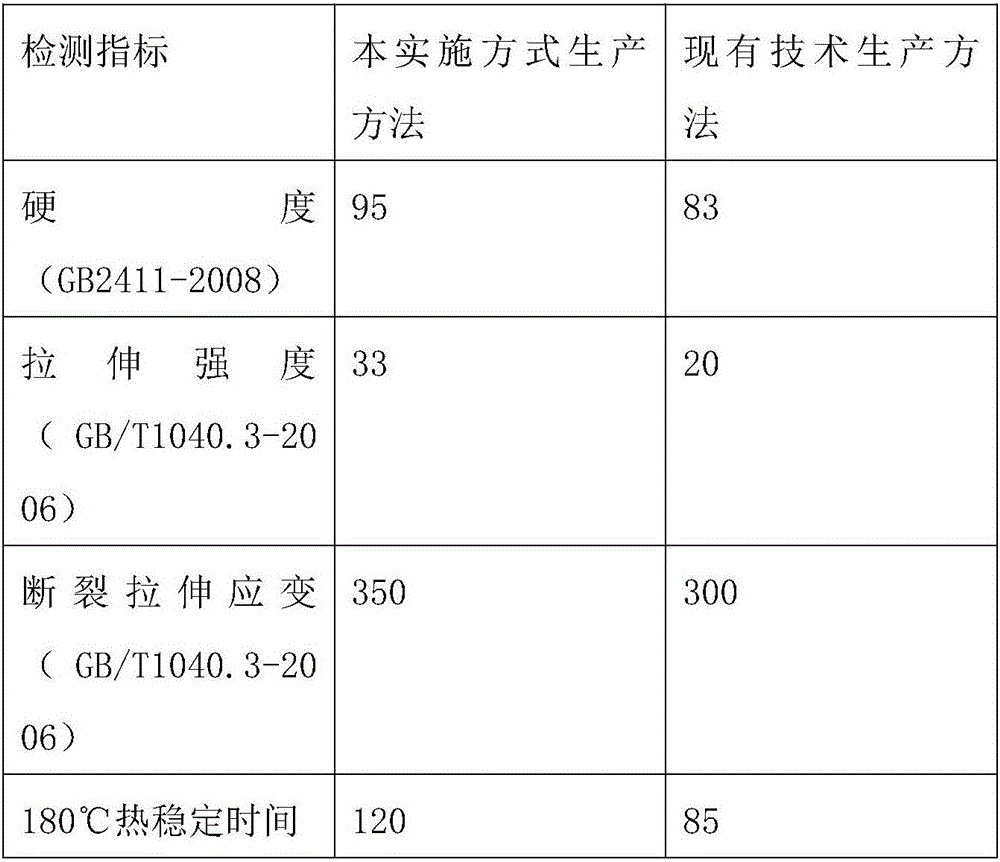

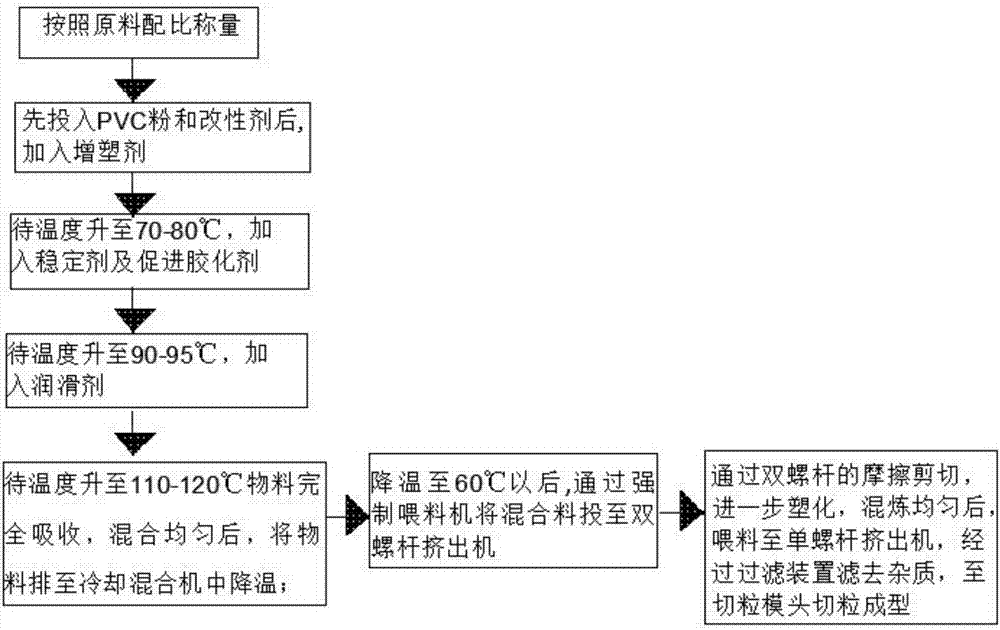

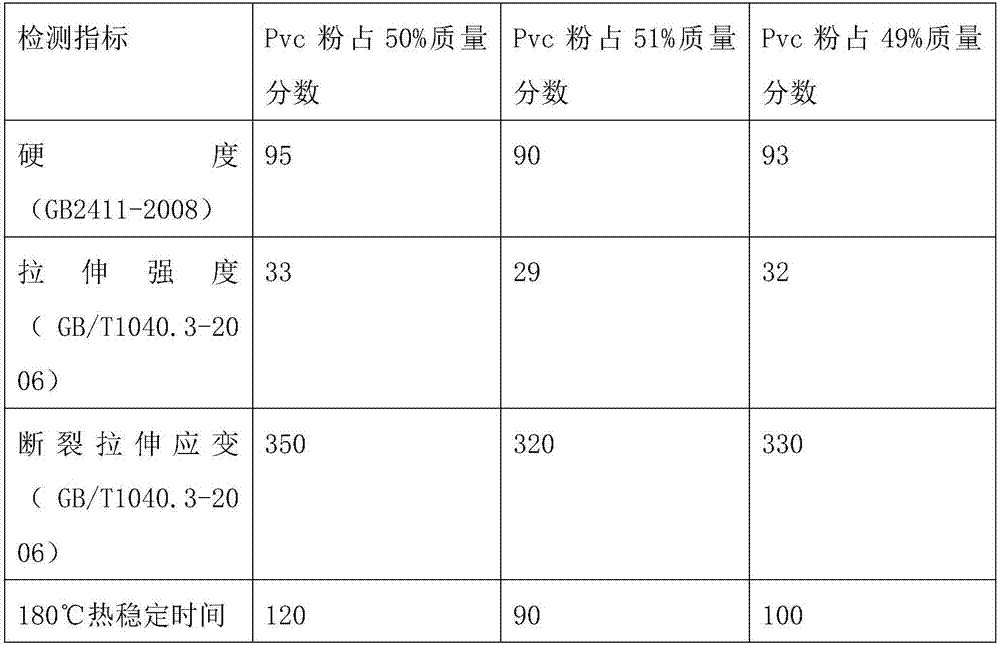

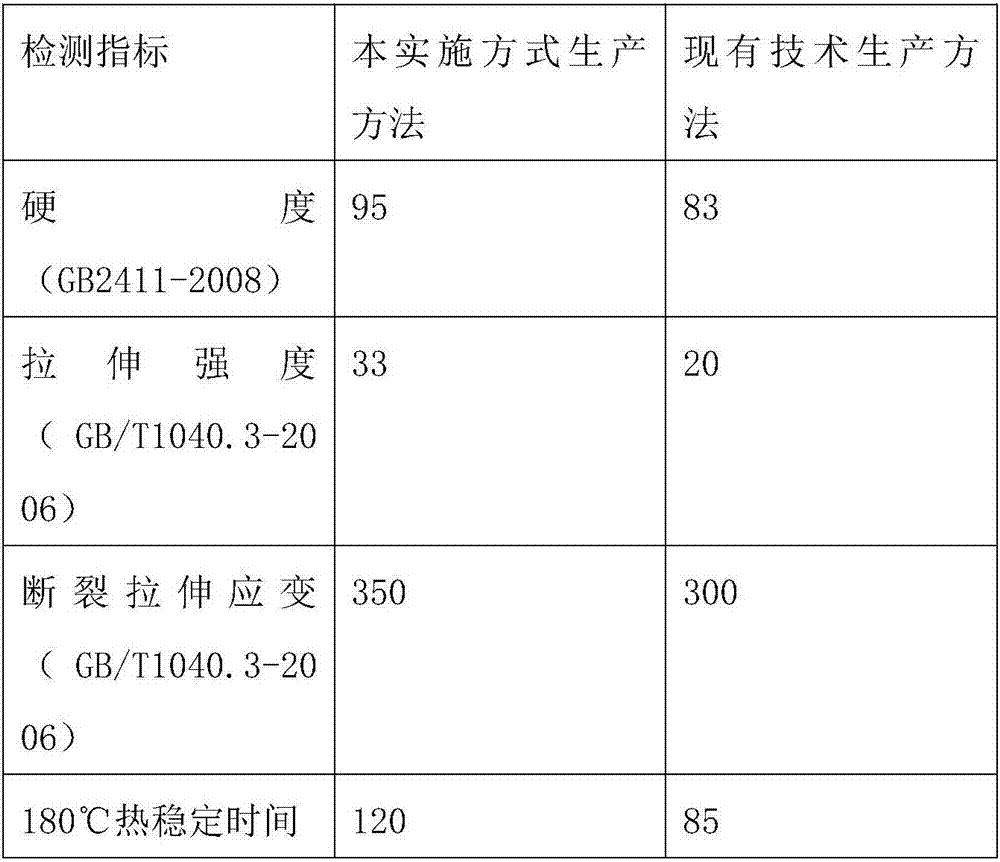

Non-phthalic PVC aggregate and preparation method thereof

The invention provides a non-phthalic PVC aggregate and a preparation method thereof. The non-phthalic PVC aggregate comprises, by mass, 49-51% of PVC powder and is characterized by further comprising, by mass, 19-21% of a modifier and the balance of a regulator. The non-phthalic PVC aggregate comprises, by mass, 49-51%, preferably 50% of the PVC powder and 19-21%, preferably 20% of the modifier, matting resin is selected as the modifier, and calcium carbonate does not need to be added, so that specific gravity of the non-phthalic PVC aggregate is not increased; performance indexes like hardness and tensile strength can be guaranteed when the non-phthalic PVC aggregate is properly proportioned. Matting effect can be improved, and characteristics of the non-phthalic PVC aggregate are unaffected. Both a formulation and the preparation method of the non-phthalic PVC aggregate can ensure high quality and good performance, and the non-phthalic PVC aggregate has wide application range.

Owner:JIANGSU DAHAI PLASTIC

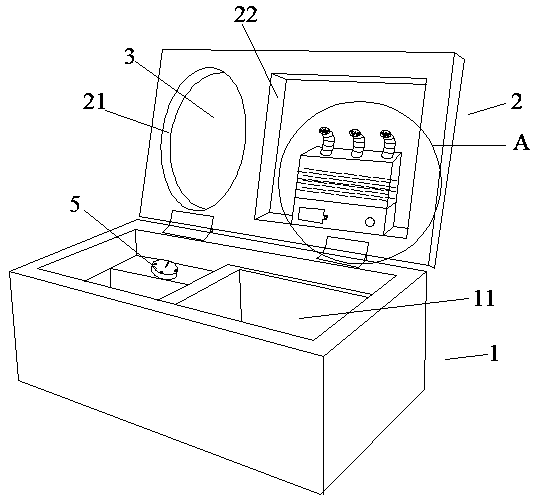

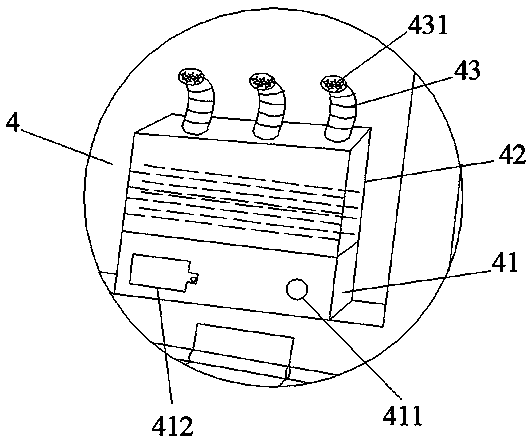

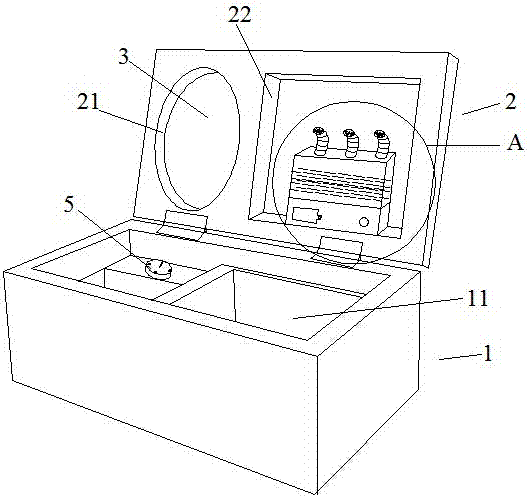

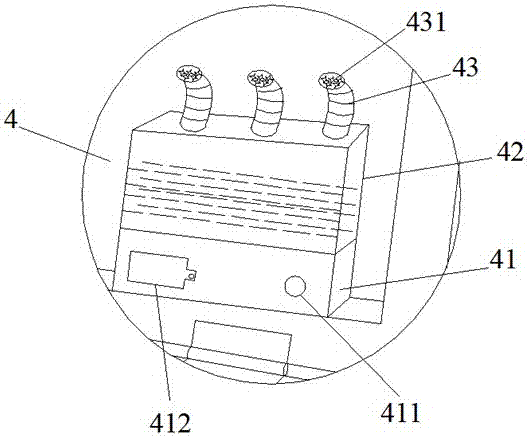

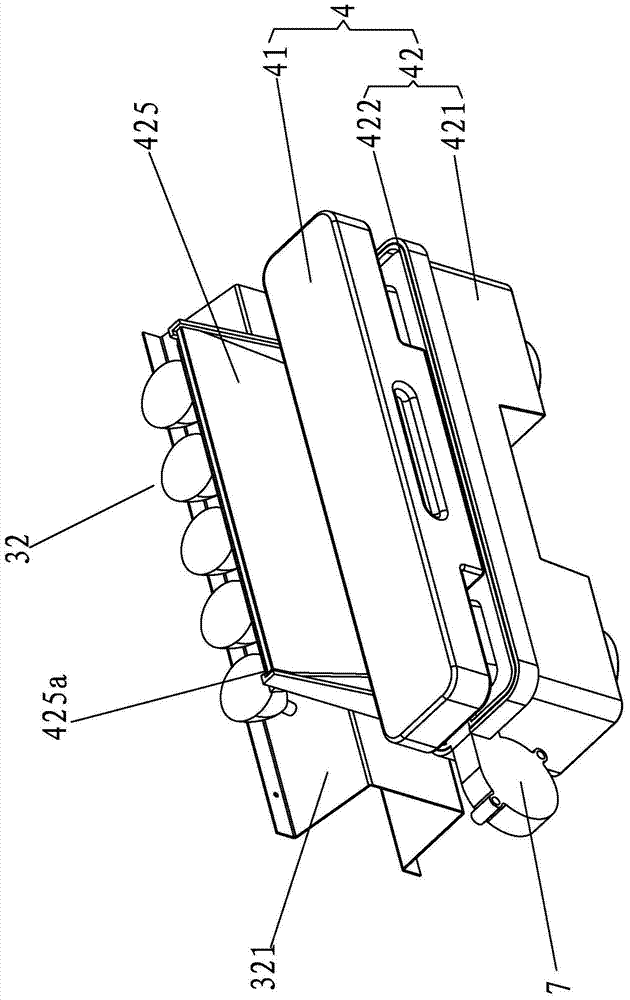

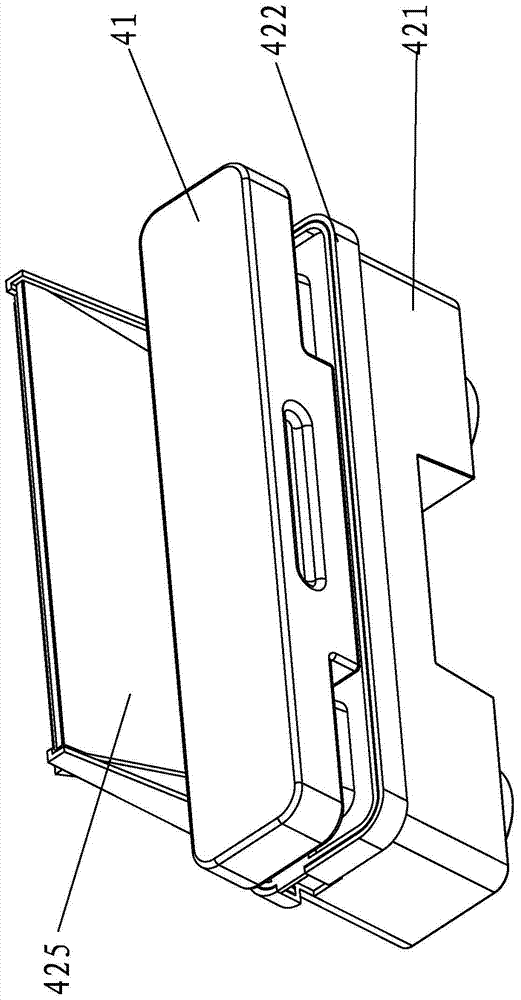

Novel dressing case

ActiveCN104223731AInnovativeIngenious structurePackaging toiletriesPackaging cosmeticsEngineeringMechanical engineering

The invention discloses a novel dressing case. The interior of a case body is separated into a plurality of storage spaces; the inner wall of a cover body is at least provided with a first accommodating groove and a second accommodating groove; a cosmetic mirror is arranged in the first accommodating groove; a moisturizing device is arranged in the second accommodating groove and comprises an atomizing mechanism and a container arranged above the atomizing mechanism and used for accommodating tonner; the top of the container is provided with a plurality of openings; the openings are rotationally connected with an atomizing channel; the end part of the atomizing channel is provided with a fine spray outlet; the fine spray outlet consists of a plurality of four-angle stars. The novel dressing case is novel in creativity and skillful in structure; the moisturizing device arranged in the second accommodating groove is used for moisturizing before dressing to achieve the better dressing effect; the novel dressing case is particularly suitable for households or offices; the atomizing channel of the moisturizing device is made of a hose which can stretch and be bent freely, and is convenient to adjust according to the position of a user; moreover, the fine spray outlet of the atomizing channel consists of four-angle stars, and the fine spray outlet effect is better.

Owner:QINGDAO BAIRUIJI BIOTECH

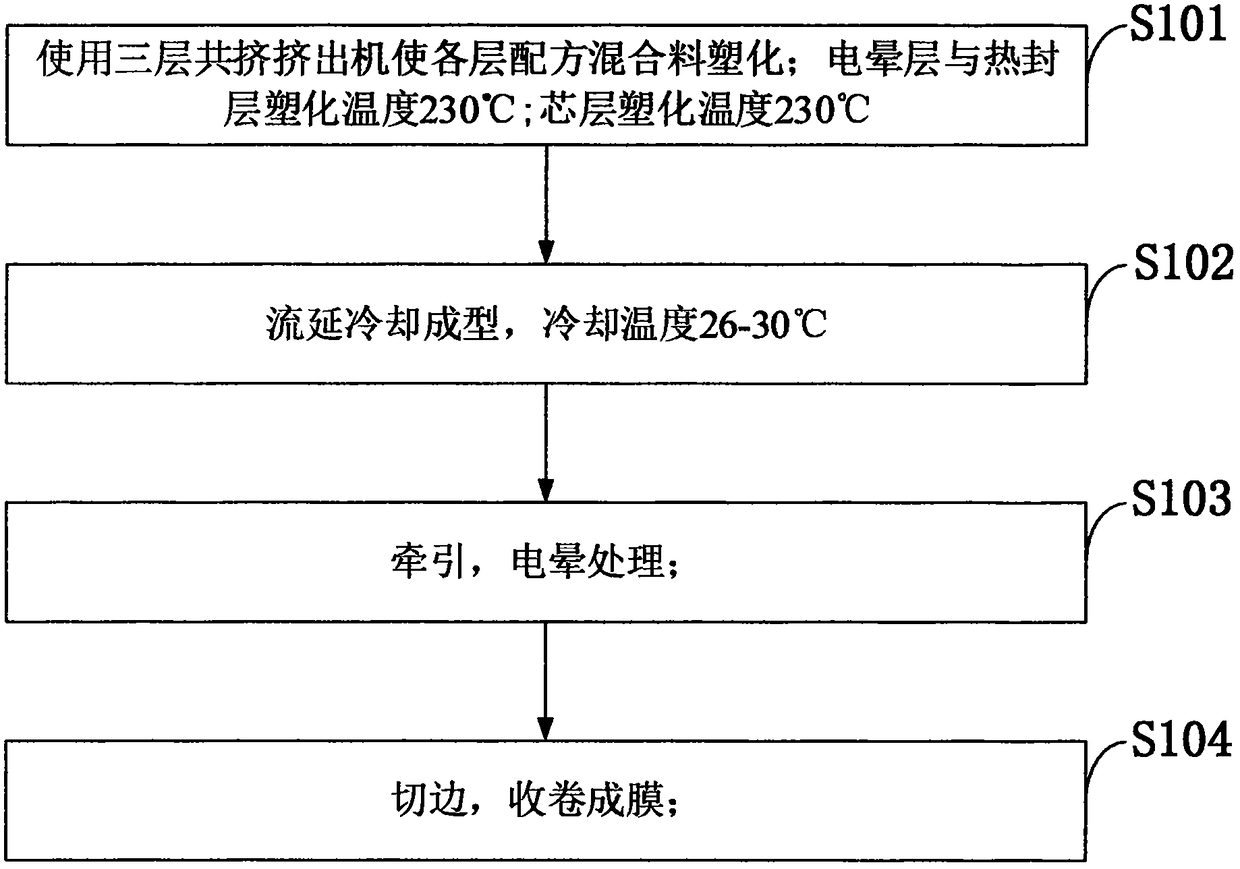

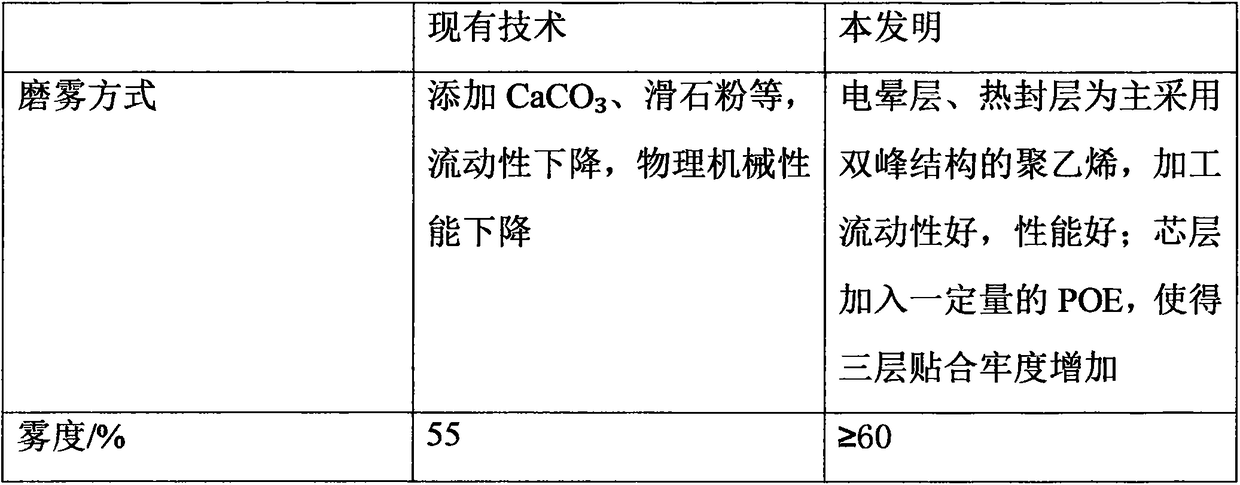

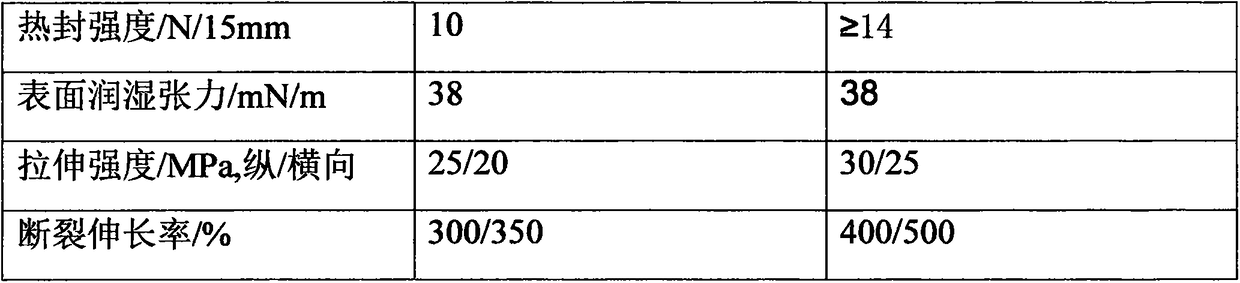

Grinding fog type PP film which has easiness in heat seal and can be internally printed and preparation method

ActiveCN108454207AGood fog effectGood heat sealingFlexible coversWrappersAntistatic agentEngineering

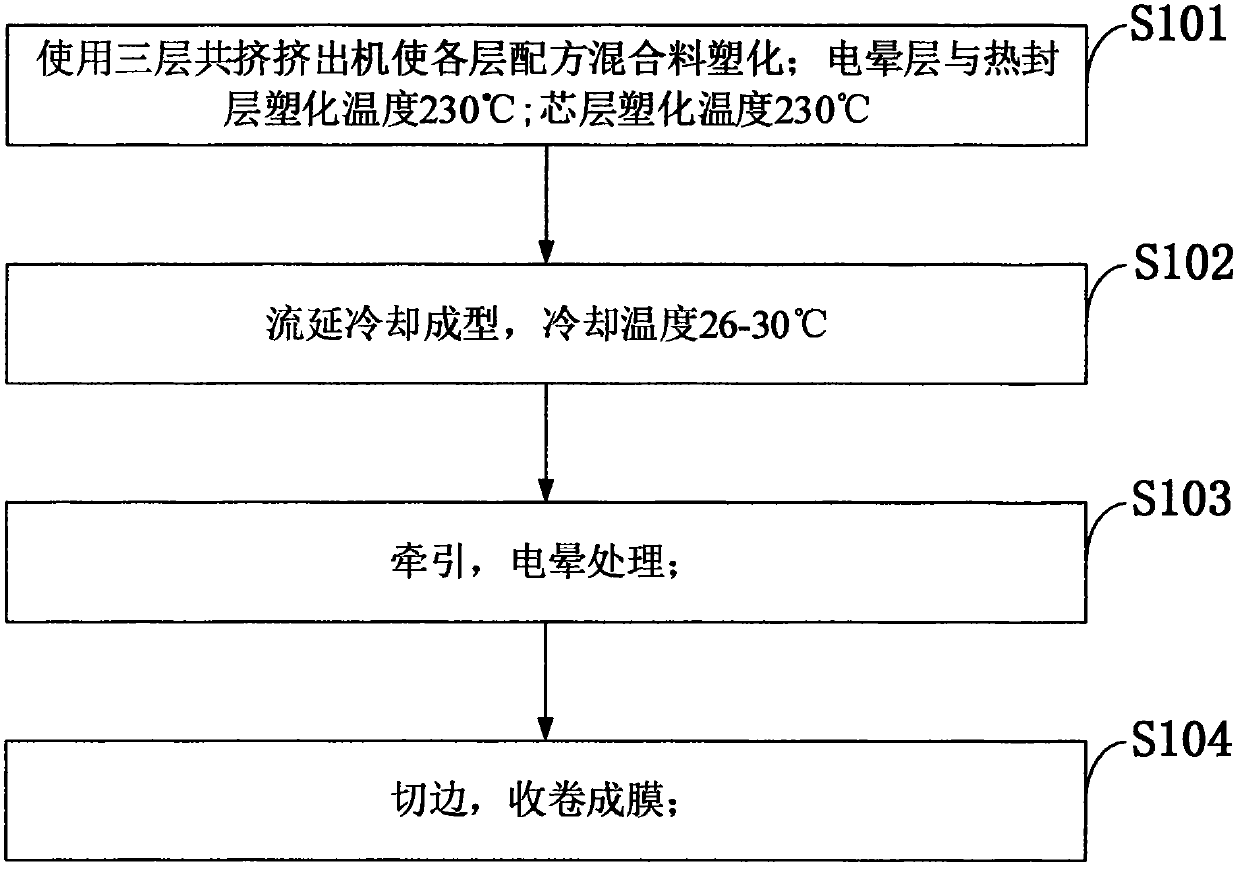

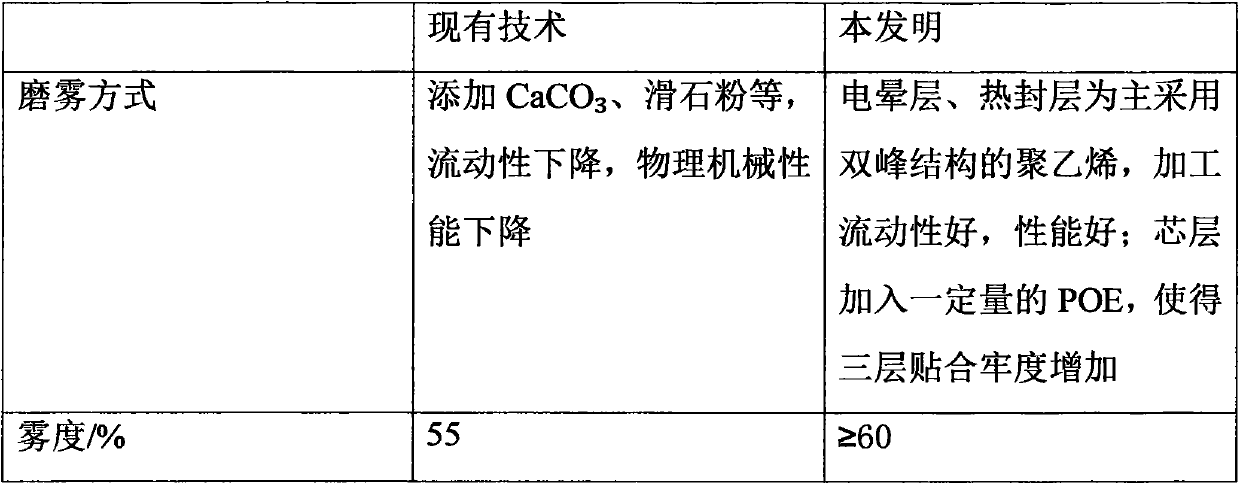

The invention belongs to the technical field of packaging materials and discloses a grinding fog type PP film which has easiness in heat seal and can be internally printed and a preparation method. The PP film is composed of a corona layer, a core layer and a heat seal layer, wherein the corona layer is prepared from ingredients in mass fraction: 0 to 85 parts of bimodal PE, 15 to 100 parts of binary co-polypropylene, 0 to 1.5 parts of slip agent, 0 to 1.5 parts of opening agent and 0 to 1.5 parts of antistatic agent; the core layer is prepared from ingredients in mass fraction: 85 to 100 parts of homo-polypropylene and 0 to 15 parts of POE; the heat seal layer is prepared from ingredients in mass fraction: 100 parts of bimodal PE, 0 to 1.5 parts of slip agent, 0 to 1.5 parts of opening agent and 0 to 1.5 parts of antistatic agent. The preparation method comprises the steps: utilizing a three-layer co-extrusion extruding machine to plastify all layers of formula mixtures; casting, cooling and forming, wherein a cooling temperature is 26 to 30 DEG C; drawing, performing corona treatment, cutting edges, rolling and forming films. The grinding fog type PP film disclosed by the invention has the advantages of very good grinding fog effect, good heat seal performance and application to high-speed package.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

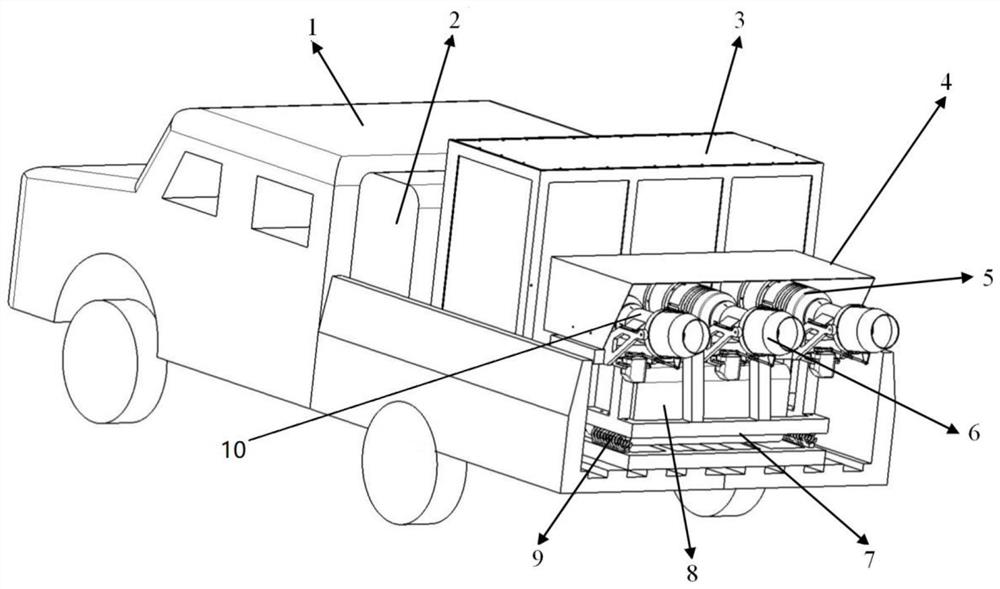

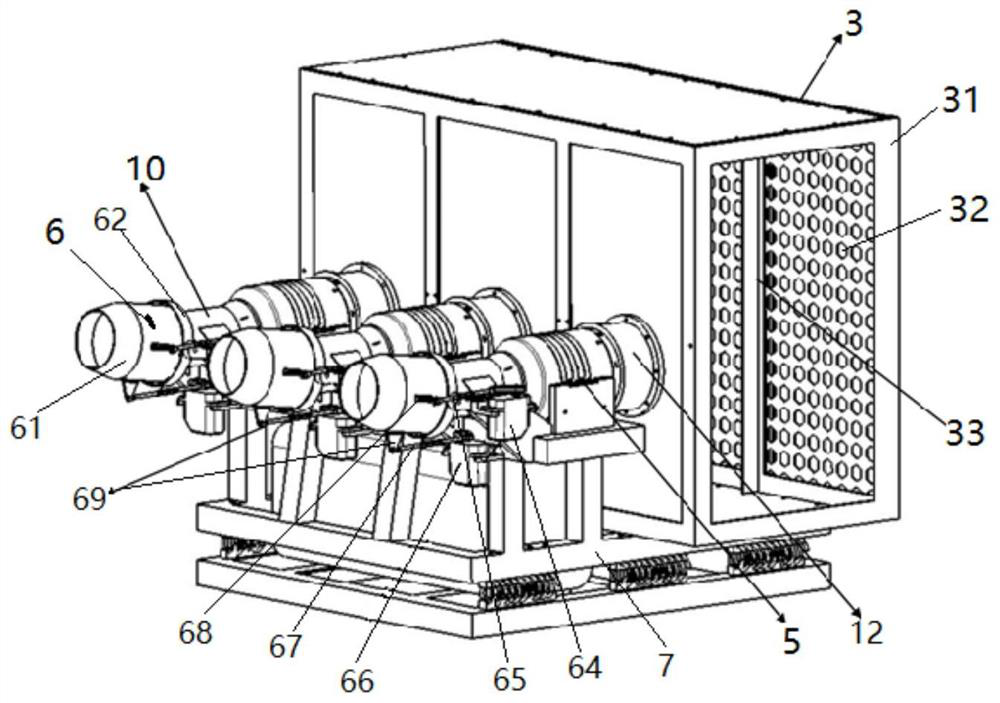

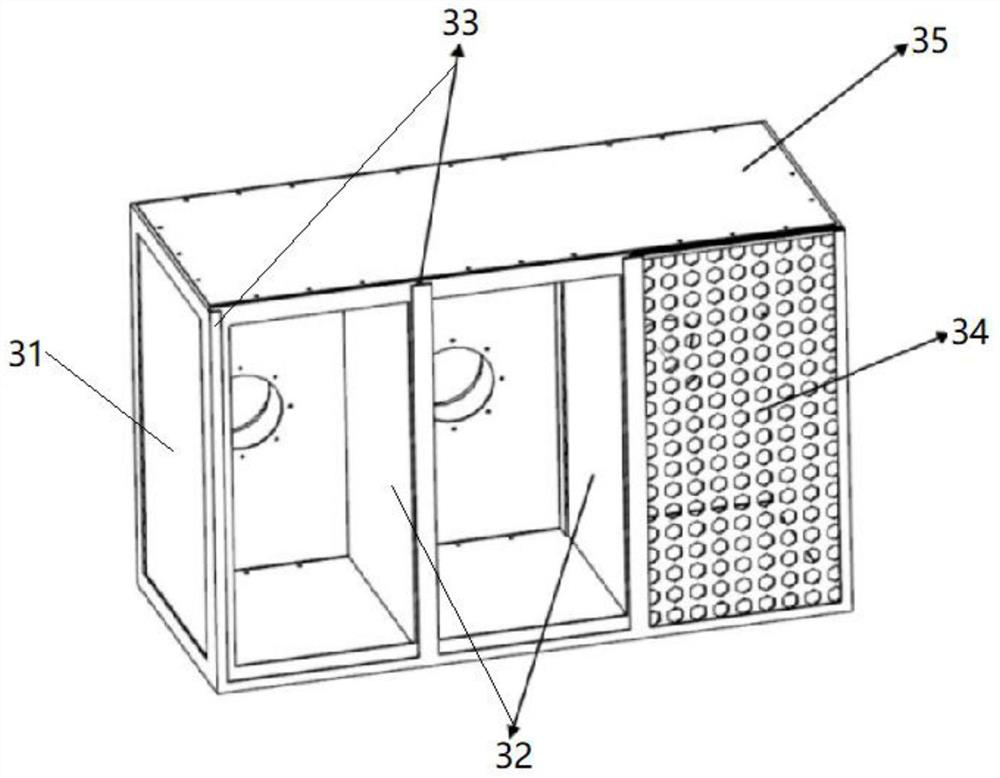

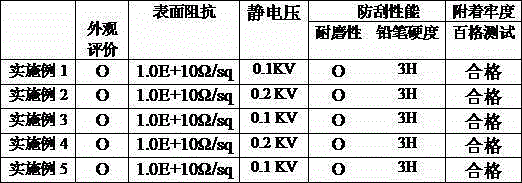

Micro turbojet atomizing device for ground

PendingCN113882950ASolve the problem of combined fog makingImprove efficiencyGas turbine plantsTurbine/propulsion air intakesEngineeringTurbojet engine

The invention relates to a micro turbojet atomizing device for ground. The device comprises an atomizing agent box and at least two micro turbojet engines, and the air inlet ends of the micro turbojet engines are communicated with an air inlet dustproof device through air inlet adapter pipes. An atomizing agent spraying pipe, an atomizing agent mixing cavity and a vector spraying pipe are sequentially arranged at the outlet end of a tail spraying pipe of each micro turbojet engine, high-temperature and high-pressure gas of the tail spraying pipes of the micro turbojet engines is sprayed into the atomizing agent mixing cavities, the temperature in the atomizing agent mixing cavities is increased, and high-temperature and high-pressure spraying flow is formed in the atomizing agent mixing cavities. An atomizing agent in the atomizing agent box enters the atomizing agent spraying pipes through a pump and a guide pipe, the atomizing agent spraying pipes spray the atomizing agent into the atomizing agent mixing cavities, the atomizing agent is heated in the atomizing agent mixing cavities to form mist, and then the mist is sprayed out of the vector spraying pipe at different spraying angles through the spraying flow. According to the device, the problem of combined atomization of multiple micro turbojet engines is solved for the first time, and the combined atomization of multiple micro turbojet engines can be carried out, so that the atomization efficiency is greatly improved.

Owner:西安觉天动力科技有限责任公司

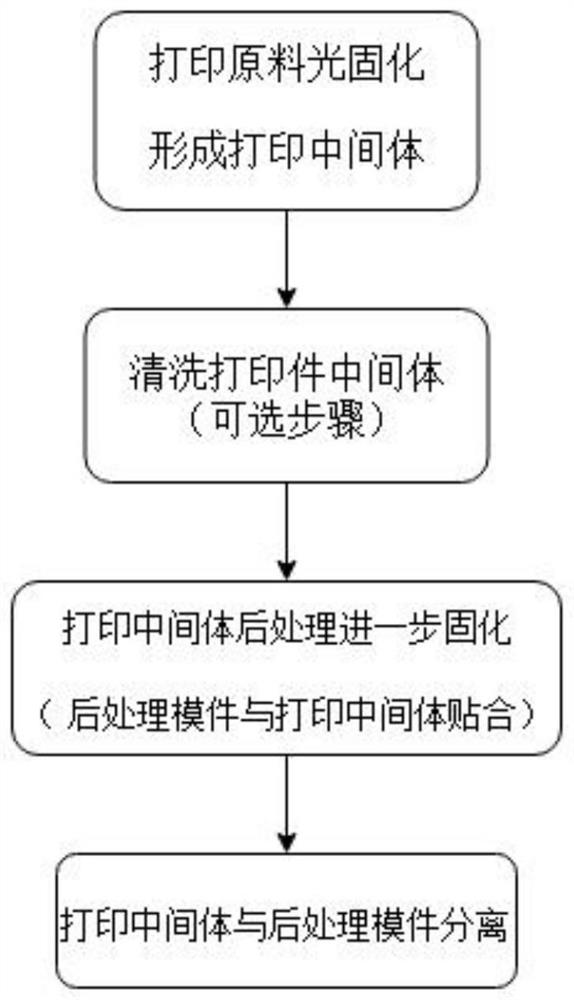

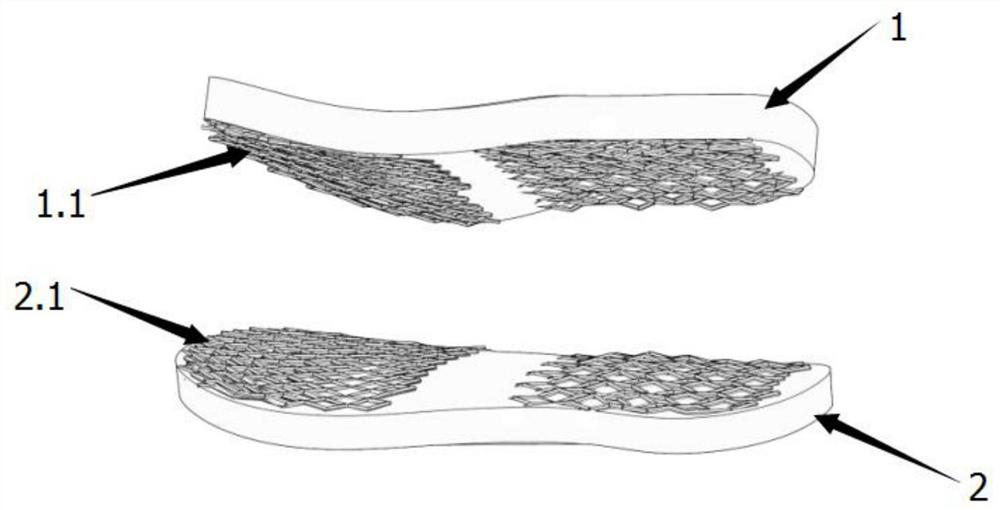

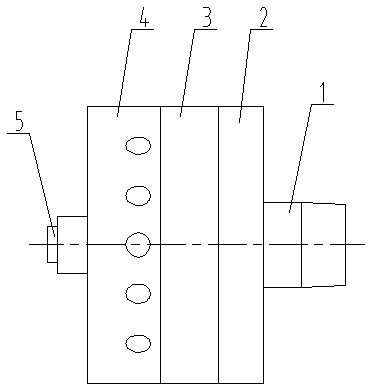

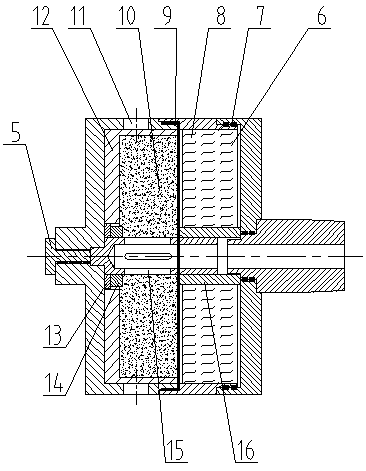

Post-treatment method for printed intermediate of stereo lithography appearance 3D printed piece

PendingCN112976577AChange surface featuresEasy to processAdditive manufacturing apparatus3D object support structures3d printEngineering

The invention discloses a stereo lithography appearance 3D printing post-treatment method. The method has the advantages that operation is simple, the characteristics of the printed intermediate which is not completely cured after stereo lithography appearance 3D printing are utilized, in the post-treatment process, namely in the process of completely curing the printed intermediate, the printed intermediate is attached to a post-treatment module, so that a surface structure on the post-treatment module can be formed on the surface of the printed piece, the texture and roughness of the surface of the printed piece are increased, or the surface characteristics are changed, subsequent processing of the printed piece is facilitated, or the predetermined design function of the printed piece is achieved, in addition, the shape and the surface structure of the post-treatment module are customized according to the printed piece, and different production requirements are met.

Owner:3D FAB LTD

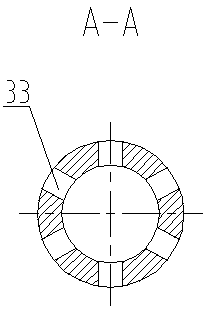

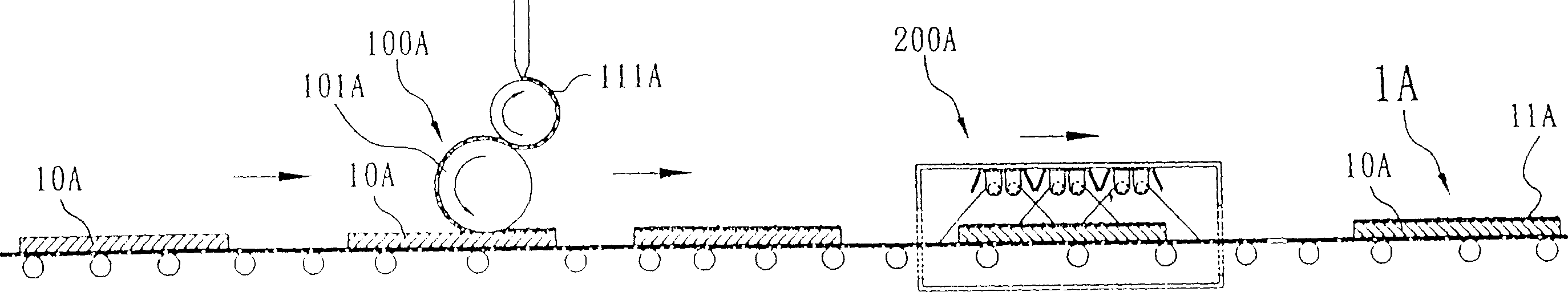

Wire coiling type electronic cigarette atomizer and wire coiling manufacturing tool thereof

PendingCN109512027AHighlight substantive featuresSignificant progressTobacco devicesElectricityEngineering

The invention relates to a wire coiling type electronic cigarette atomizer and a wire coiling manufacturing tool thereof. The wire coiling type electronic cigarette atomizer comprises an atomizer anda manufacturing tool for a coiled wire in the atomizer. The atomizer comprises an electric conductor connected with a battery, the other end of the electric conductor is connected with an atomizationcylinder, the other end of the atomization cylinder is sequentially connected with an oil storage cylinder, a sealing cover and a cigarette holder in a length direction, and an air guide pipe is further mounted in the center of the atomization cylinder. A jackscrew gas guide insulation disc is arranged on the outer circumference of the air guide pipe, the top end of the jackscrew air guide insulation disc is connected with a coiled wire which can conduct electricity and heat and is wound into a spiral shape, the coiled wire comprises a positive electrode and a negative electrode, the positiveelectrode is mounted in a wire coiling clamping groove formed in the right end of the air guide pipe, and the negative electrode is clamped on the outer circumference of the atomization cylinder. Sealing rings are arranged at the connecting position of the cigarette holder and the sealing cover and also at the connecting position of the oil storage cylinder and the sealing cover, and air amount adjusting holes are further formed in the outer circumference of the cigarette holder. The advantages are that the wire coiling type electronic cigarette atomizer has a simple structure, is convenient to operate, is easy in coiled wire manufacturing, good in atomization effect and stable in smoke output, etc.

Owner:陆峰

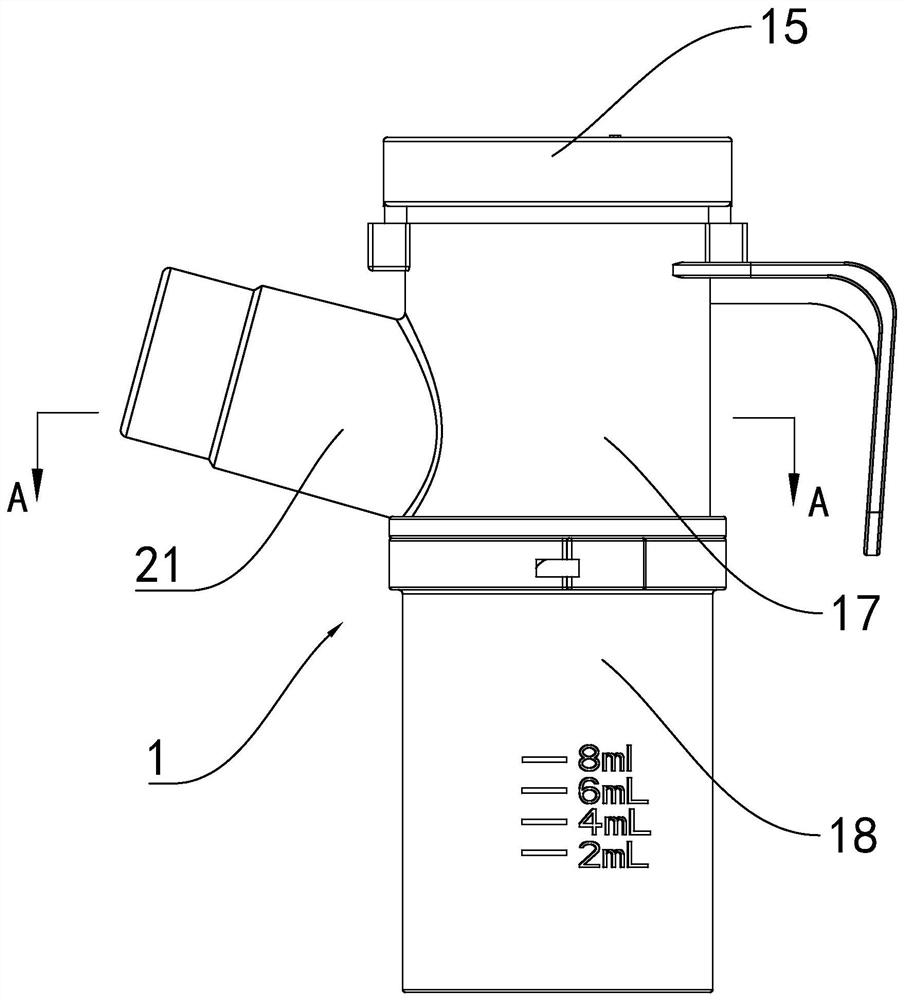

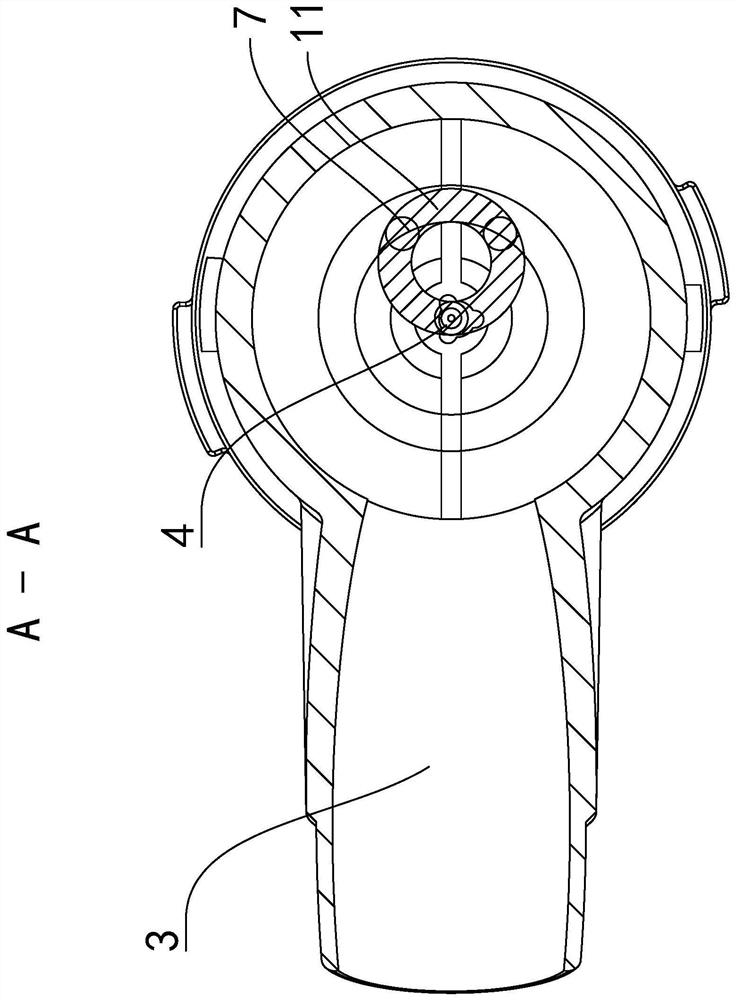

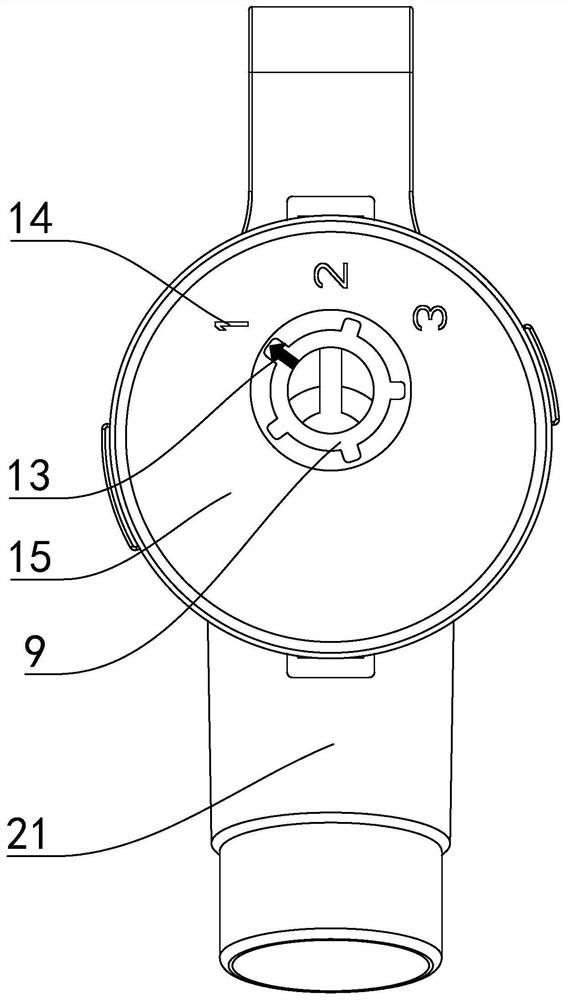

Atomizing cup with adjustable collision distance

The invention discloses an atomizing cup with the adjustable collision distance. The cup comprises a cup shell and a collision assembly, wherein a jet flow opening is formed in a containing cavity ofthe cup shell; the collision assembly is of an integrated structure formed by fixedly connecting an adjusting part and a plurality of collision bodies in an up-down manner; and the adjusting part is positioned in the cup shell in a rotating or sliding mode. An operator rotates or moves the adjusting part, and the collision surfaces on the collision bodies below the adjusting part are driven to rotate around the jet flow direction or move in the direction perpendicular to the jet flow direction, so that different collision surfaces are switched to directly face the jet flow opening, and the purpose of adjusting the collision distance is achieved.

Owner:JIANGSU YUYUE MEDICAL EQUIP&SUPPLY CO LTD +4

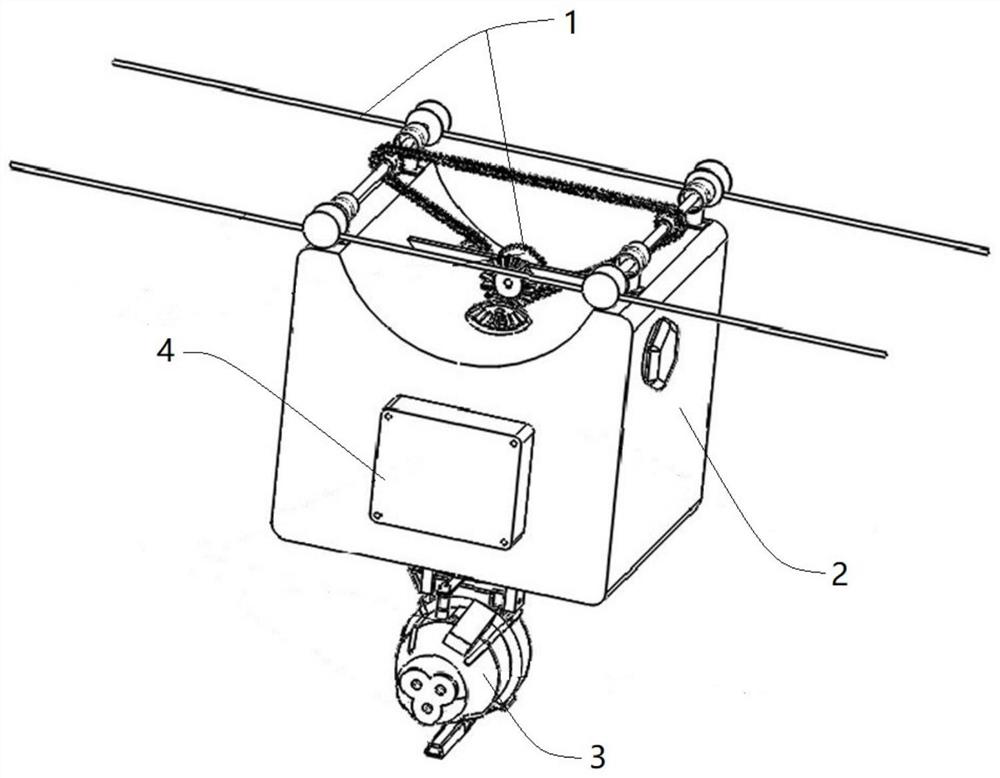

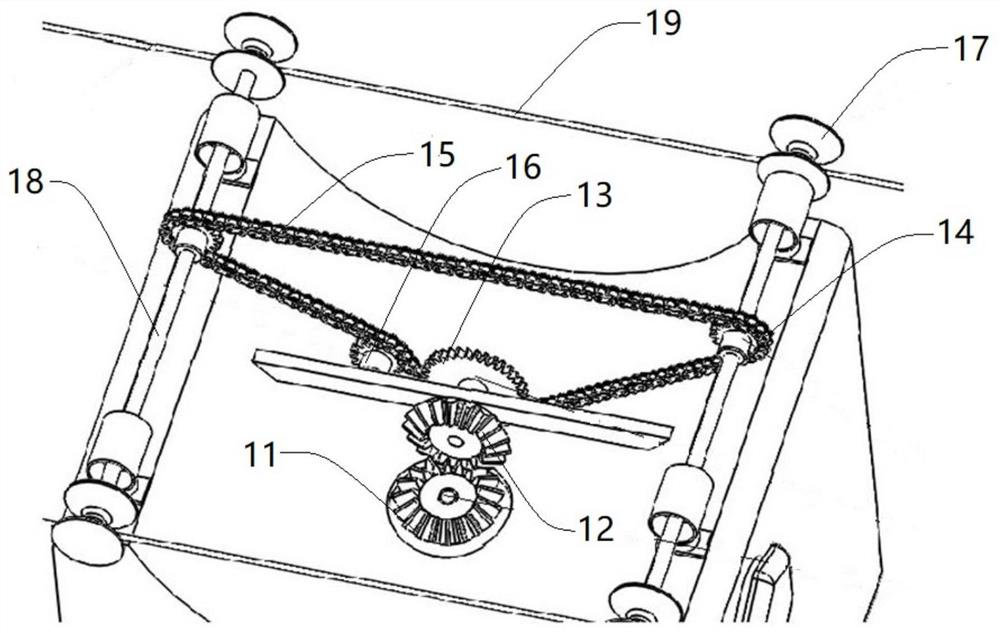

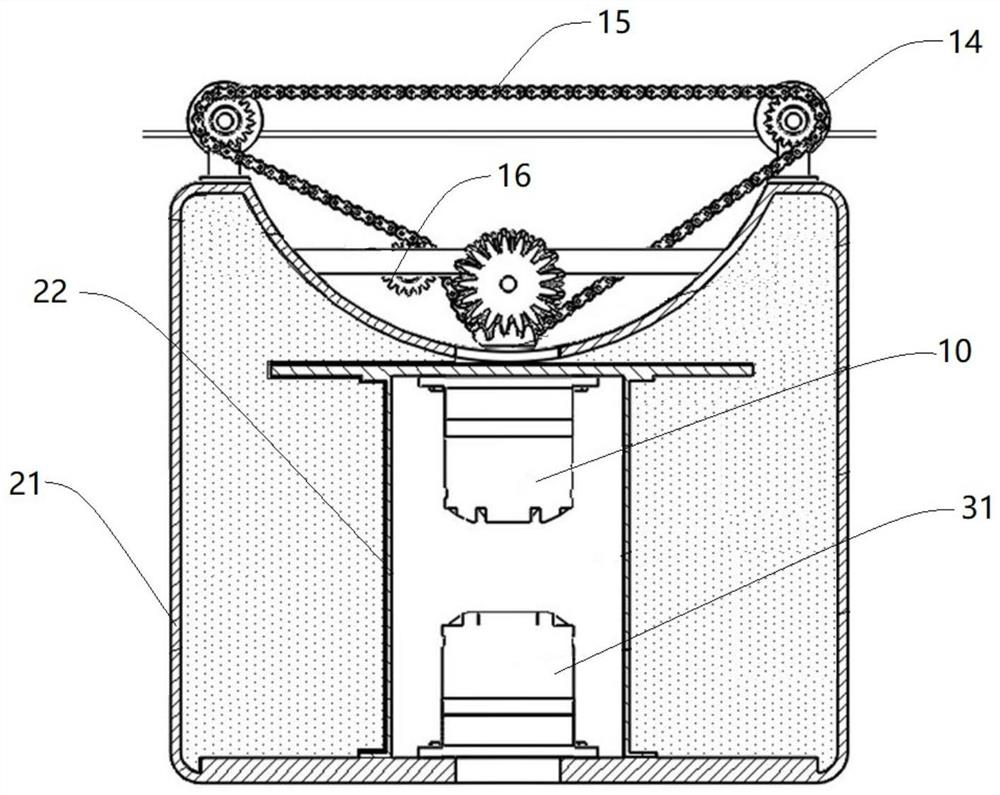

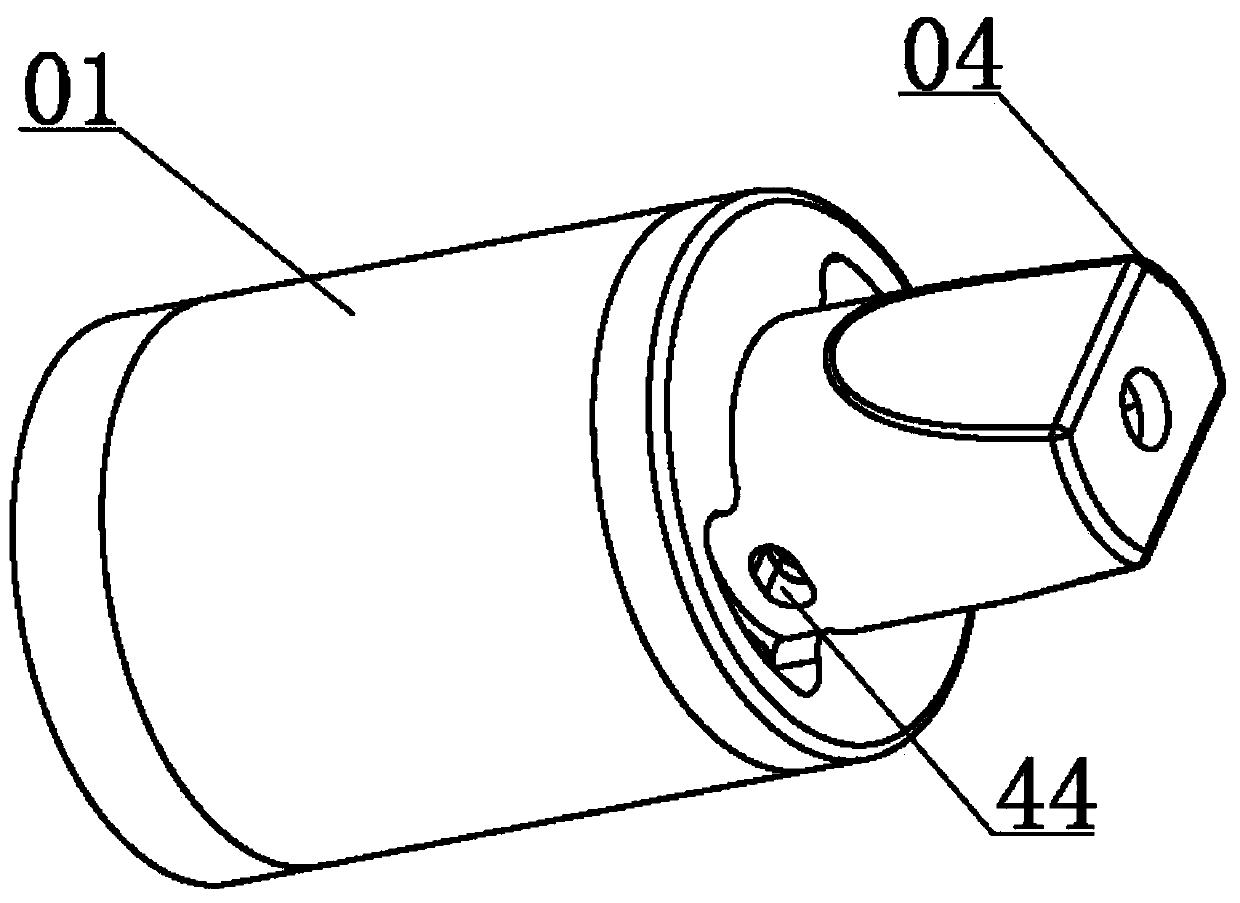

Rail self-propelled electrostatic mist sprayer

PendingCN112335636AImprove adsorption capacityHelp atomizationClimate change adaptationLiquid fertiliser regulation systemsSprayerElectric machine

The invention belongs to the technical field of spraying equipment, and particularly relates to a rail self-propelled electrostatic mist sprayer. The mist sprayer comprises an automatic walking device, a liquid storage device located below the automatic walking device and a mist spraying device located below the liquid storage device. The automatic walking device comprises a first motor, a transmission assembly connected with the first motor and a guide rail in rolling connection with the transmission assembly, and the first motor is fixed in the liquid storage device; the mist spraying devicecomprises a second motor, a rotary controller connected with the second motor and a mist spraying assembly connected with the second motor, and the second motor is fixed in the liquid storage device;and an electrostatic generator is mounted below the mist spraying assembly. The rail self-propelled electrostatic mist sprayer is simple in structure and complete in function, has the suspension typerail self-walking function, achieves unmanned spraying and all-around spraying, and has the electrostatic adsorption capacity of fog drops.

Owner:WEIFANG UNIV OF SCI & TECH +1

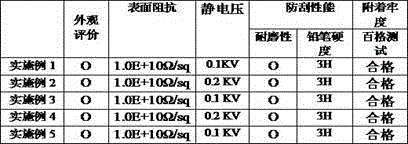

Earphone shell surface treatment method

The invention discloses an earphone shell surface treatment method. The earphone shell surface treatment method comprises the following steps that a, the surface of a plastic shell is polished; b, after polishing, the plastic shell is sprayed with first paint, wherein silica particles, polyethylene glycol and oil paint in the first paint are mixed according to the weight ratio of 2-5:16-25:95-110,the particle size of the silica particles is 8-15 mu, and after spraying, drying is conducted on the first paint at the temperature of 65-75 DEG C for 20-30 min; c, the plastic shell is then sprayedwith second paint, metal particles and oil paint in the second paint are mixed according to the weight ratio of 3-8:100-110, the particle size of the metal particles is 18-25 mu, and after spraying, drying is conducted on the second paint at the temperature of 65-75 for 20-30 min; d, the second paint is sprayed with a UV protective layer, the UV protective layer is dried, and then the treated earphone shell is obtained. The earphone shell surface treatment method has the beneficial effects that the obtained earphone shell is good in texture, communication performance and anti-static performance.

Owner:GUIZHOU XIANGYIN ELECTRONICS TECH CO LTD

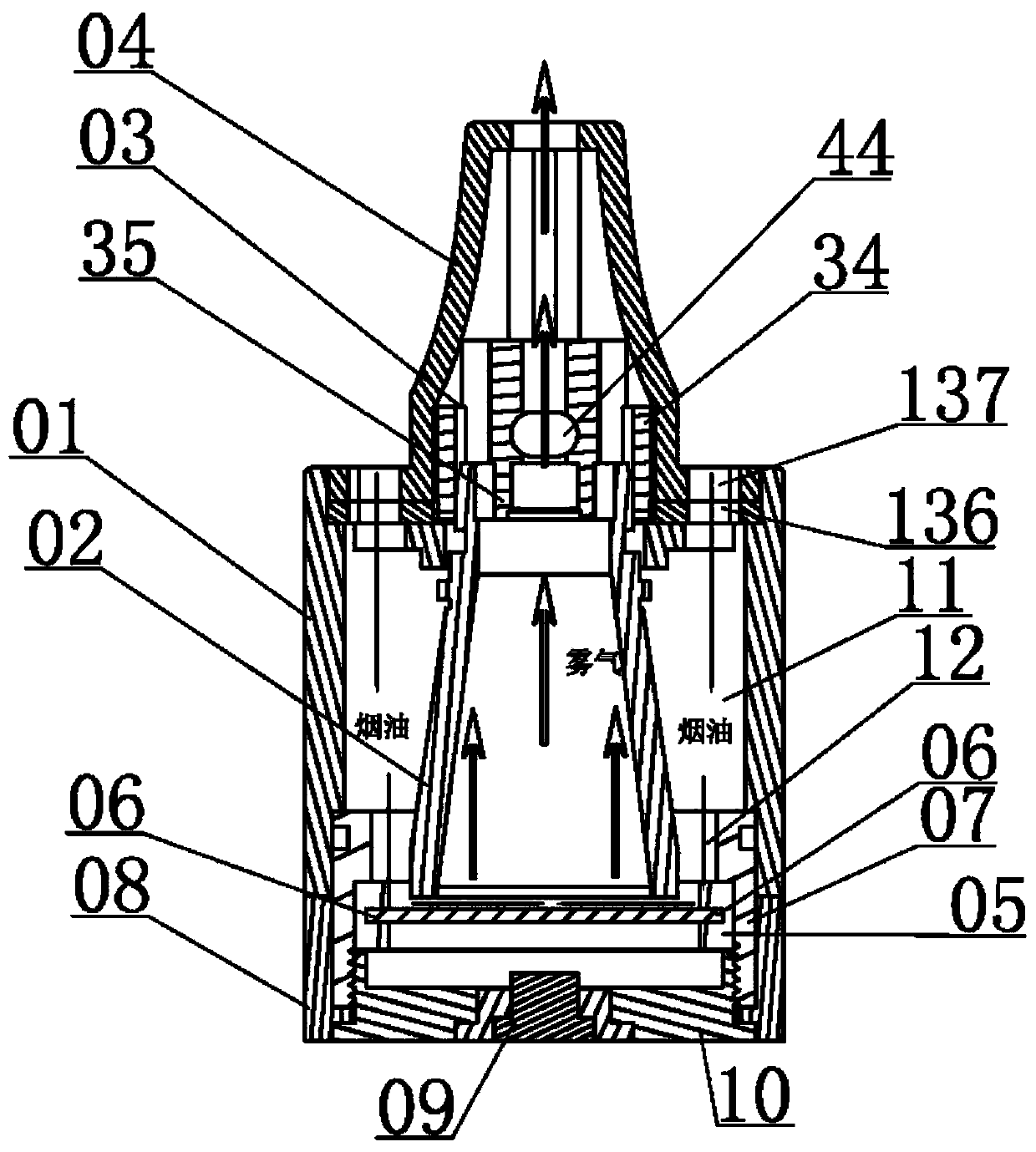

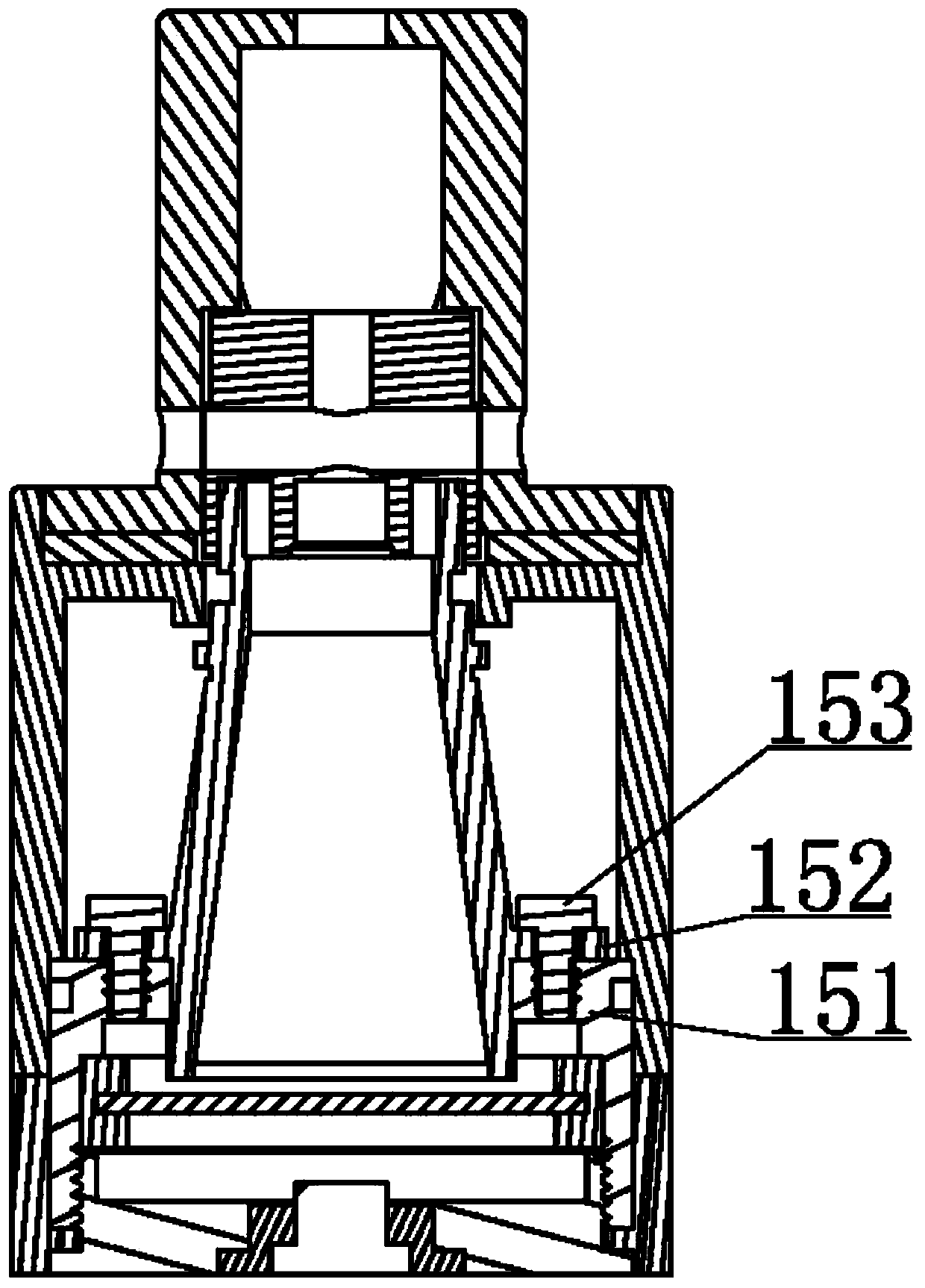

Energy concentrating ultrasonic atomizing device

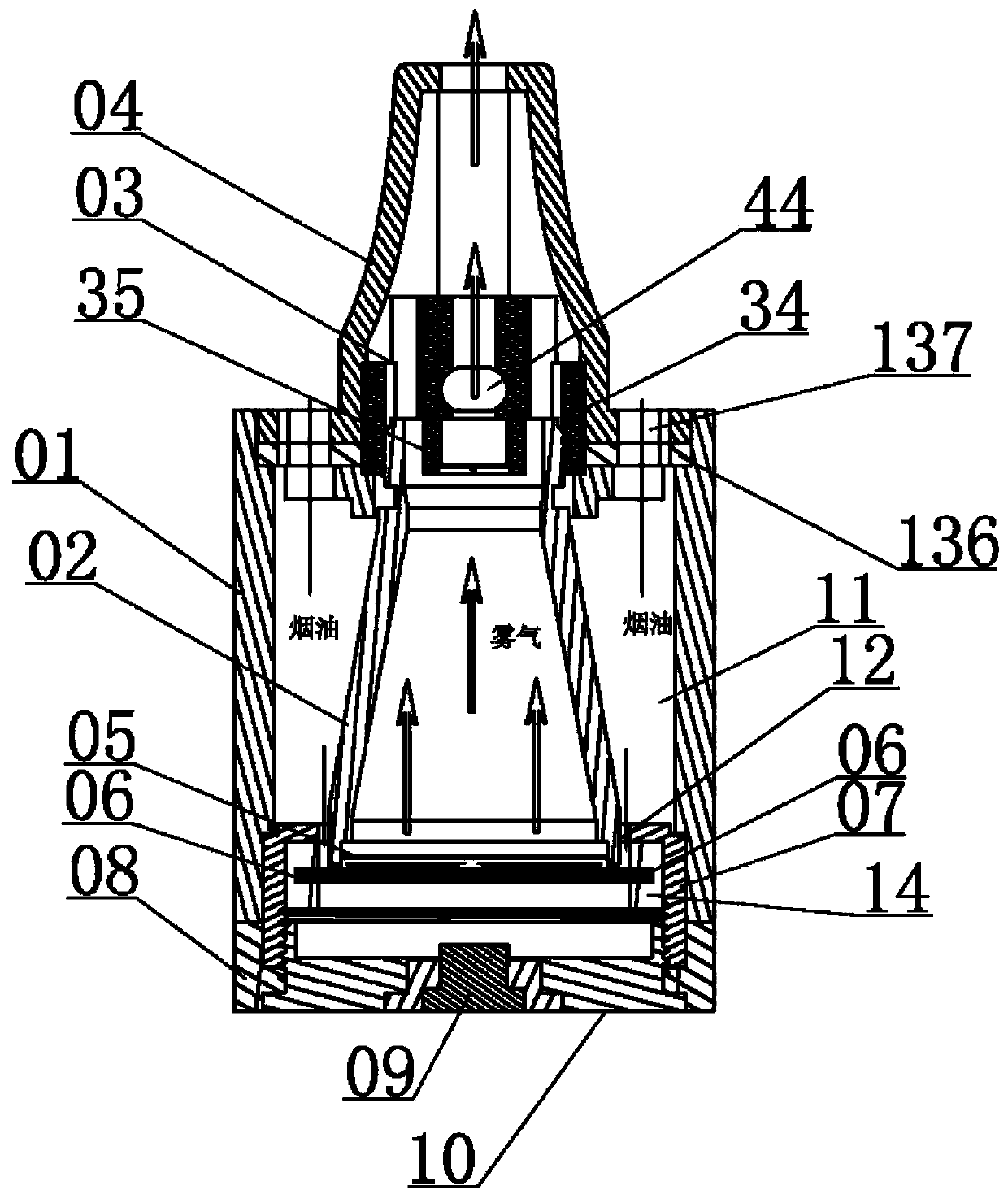

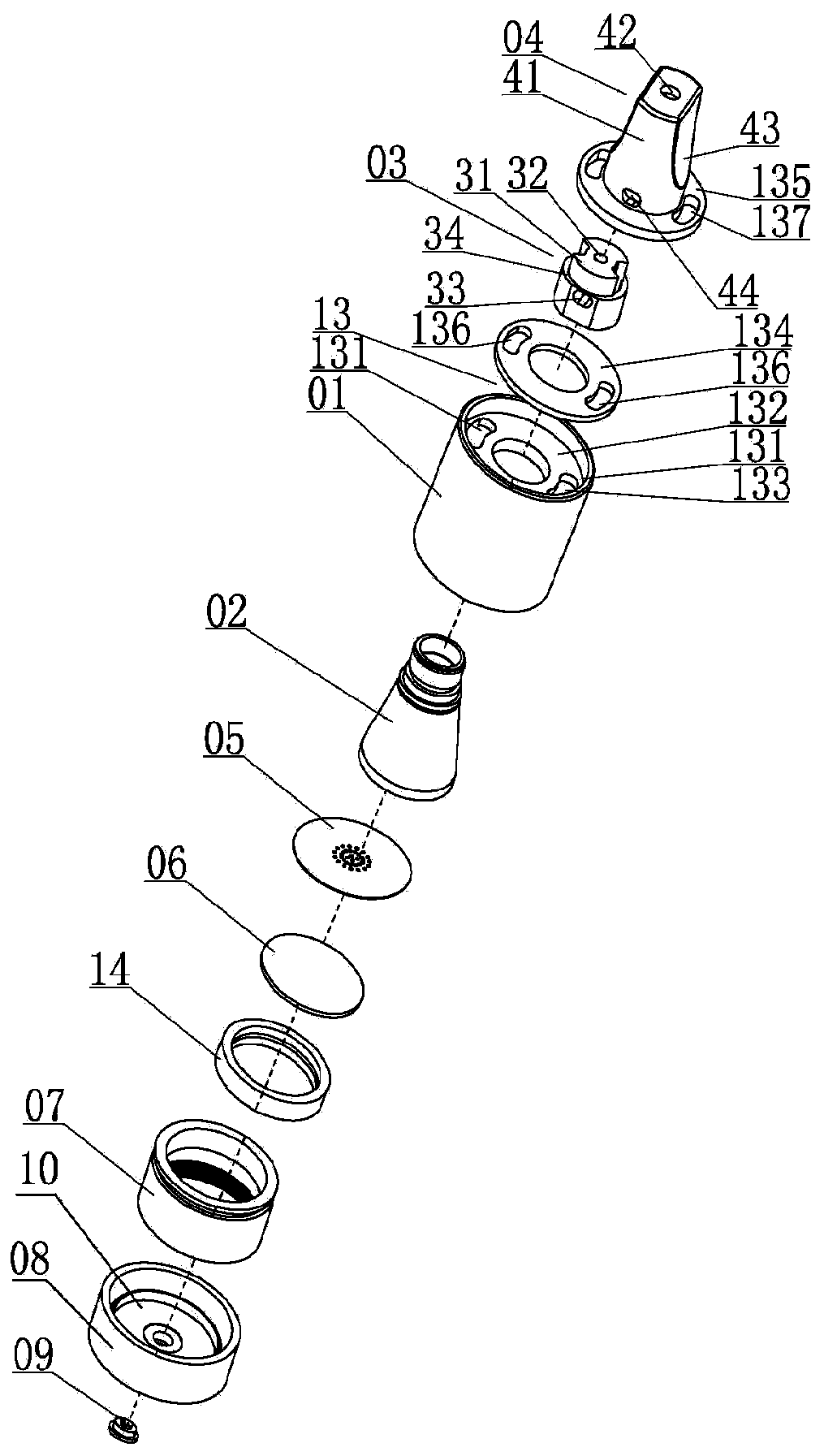

PendingCN109892705ASolve the problem of overheatingSolving Recycling ProblemsTobacco devicesElectricityEngineering

The invention discloses an energy concentrating ultrasonic atomizing device which comprises an outer shell, a conical cavity arranged on the outer shell and extending upwards to the outer upper portion of the outer shell, a connecting piece connected to the upper end of the conical cavity in a sleeved manner, an upper cover connected to the connecting piece, a metal substrate and a piezoelectric ceramic piece which are sequentially arranged at the bottom of the conical cavity, a fixing seat accommodating the metal substrate, the piezoelectric ceramic piece and the conical cavity is arranged under the piezoelectric ceramic piece and a bottom cover accommodating the fixing seat and connected with the outer housing is connected onto the fixing seat in a sleeving manner. A first electrode anda second electrode which are respectively connected with the piezoelectric ceramic piece are arranged on the bottom cover. By the non-heating working mode, the problem of overheating of fuselage is solved; liquid is atomized easily, and energy exchange efficiency is improved; meanwhile, metal substrates, piezoelectric ceramics and other parts can be easily recycled assuredly, and daily maintenanceis facilitated.

Owner:华健

Easy-to-process high-modulus matte thermoplastic polyurethane elastomer and preparation method thereof

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

Anti-scratch matte anti-static release paper

ActiveCN103074819BImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionSynthetic resin layered productsSilica particlePolyol

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

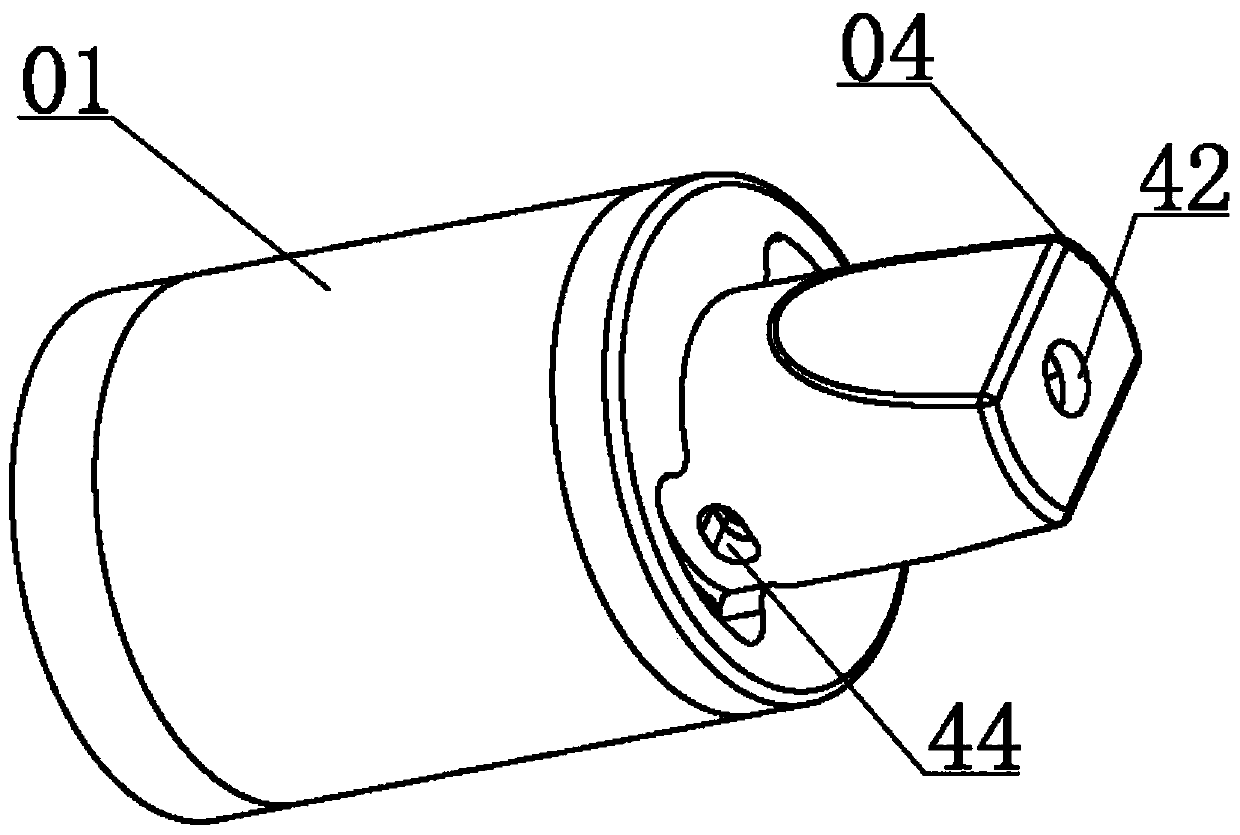

Energy-concentrating atomizer

PendingCN109892704ASolve the problem of overheatingSolving Recycling ProblemsTobacco devicesElectricityConical cavity

The invention discloses an energy-concentrating atomizer. The energy-concentrating atomizer comprises an outer housing, a conical cavity arranged in the outer housing and extending upward to the outerupper portion of the outer housing, a connecting piece connecting to the upper end of the conical cavity in a sleeved manner, an upper cover connected to the connecting piece, a piezoelectric ceramicpiece arranged at the bottom of the conical cavity, a fixing seat accommodating the piezoelectric ceramic piece and the conical cavity is arranged under the piezoelectric ceramic piece and a bottom cover accommodating the fixing seat and the outer housing is connected onto the fixing seat in a sleeving manner. A first electrode and a second electrode which are respectively connected with the piezoelectric ceramic piece are arranged on the bottom cover. By the non-heating working mode, the problem of overheating of fuselage is solved; liquid is atomized easily, and energy exchange efficiency is improved; meanwhile, metal substrates, piezoelectric ceramics and other parts can be easily recycled assuredly, and daily maintenance is facilitated.

Owner:华健

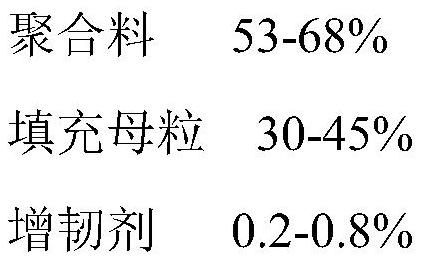

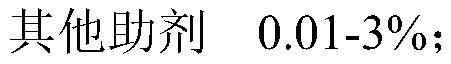

Weaving material and preparation method thereof

InactiveCN113150444AGood flexibilityEasy to weaveConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolymer sciencePolypropylene

The invention relates to the field of weaving materials, and particularly discloses a weaving material and a preparation method thereof. The weaving material comprises the following raw materials in percentage by weight: 53-68% of a polymer material, 30-45% of filling master batch, 0.2-0.8% of a flexibilizer and 0.01-3% of other auxiliaries, wherein the polymer material is a mixture consisting of polypropylene and polyethylene in a weight ratio of 5: (0.5-1.0); the preparation method of the weaving material comprises the following steps: mixing the polymer material, the filling master batch, the flexibilizer and the other auxiliary agents, and then performing extrusion, film forming and primary stretching to obtain a film sheet; cutting the membrane, stretching for the second time to obtain a woven material, and finally rolling the woven material. The prepared weaving material is low in refractive index, relatively low in glossiness and high in mist effect, has matte high-grade natural texture, has excellent softness and tensile strength and is good in processability.

Owner:东莞市三岱编织材料有限公司

Matte antistatic agent for release film

ActiveCN103103875BImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionRelease paperPolyethylene glycolEngineering

Owner:斯迪克新型材料(江苏)有限公司

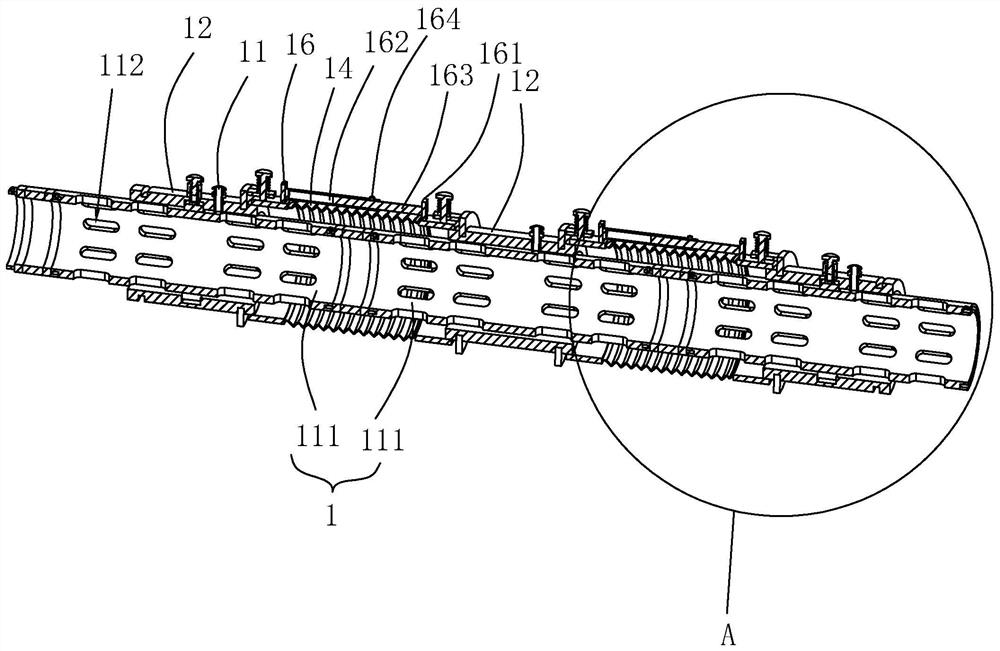

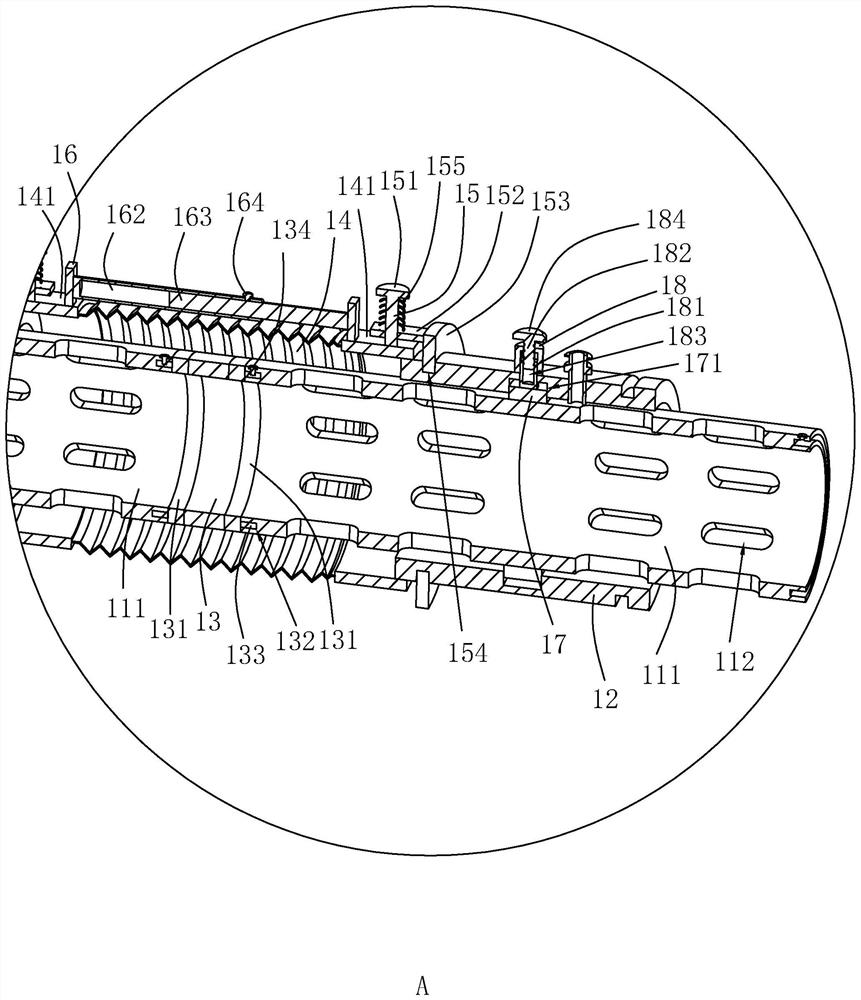

Spraying device for steel-wood combined shed frame

PendingCN114849953ASimple structureImprove adjustment effectClimate change adaptationSpraying apparatusStructural engineeringManufacturing engineering

The invention relates to a steel and wood combined shed frame spraying device which comprises a conveying pipe and a plurality of atomizing nozzles arranged on the conveying pipe in the length direction of the conveying pipe, the spraying device further comprises a water conveying device used for conveying water into the conveying pipe, and the conveying pipe comprises a plurality of splicing pipes formed by splicing. A plurality of strip-shaped holes are formed in each splicing pipe, a plurality of sliding cylinders are arranged on the conveying pipe in a sleeving and sliding mode, the multiple atomizing nozzles are arranged on the multiple sliding cylinders in a one-to-one correspondence mode, and telescopic sealing pieces used for sealing gaps between the adjacent sliding cylinders at different intervals are arranged between the adjacent atomizing nozzles; the sliding barrels at the two ends of the multiple sliding barrels are provided with sealing pieces used for sealing gaps between the sliding barrels and the conveying pipe. The device has the advantage that the mist effect formed by the multiple atomizing nozzles is improved.

Owner:BEIJING URBAN CONSTR ENG TENTH

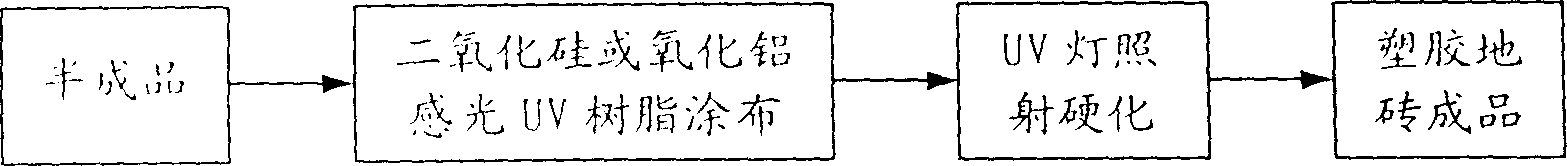

Process for coating aluminium oxide at surface of plastic floor tile

InactiveCN1273225CGood fog effectImprove wear resistanceLiquid surface applicatorsCoatingsHigh resistancePolymer science

A process for coating alumina on the surface of plastic floor tile includes such steps as goating UV-sensitive resin, spraying alumina sand, using UV lamp to rdiate it for hardening unit, coating UV-sensitive resin again, and using UV lamp to radiate it again. Its advantages are high resistance to abrasion, scraping, corrosion and compression, and stereoscopic grains.

Owner:NAN SING PLASTICS CORP

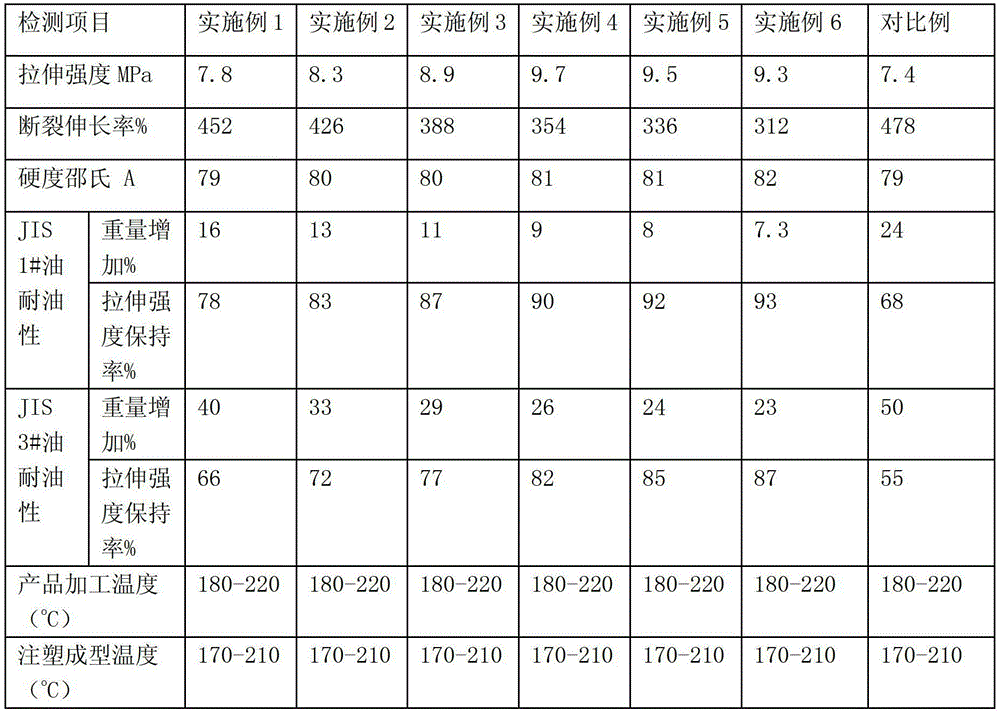

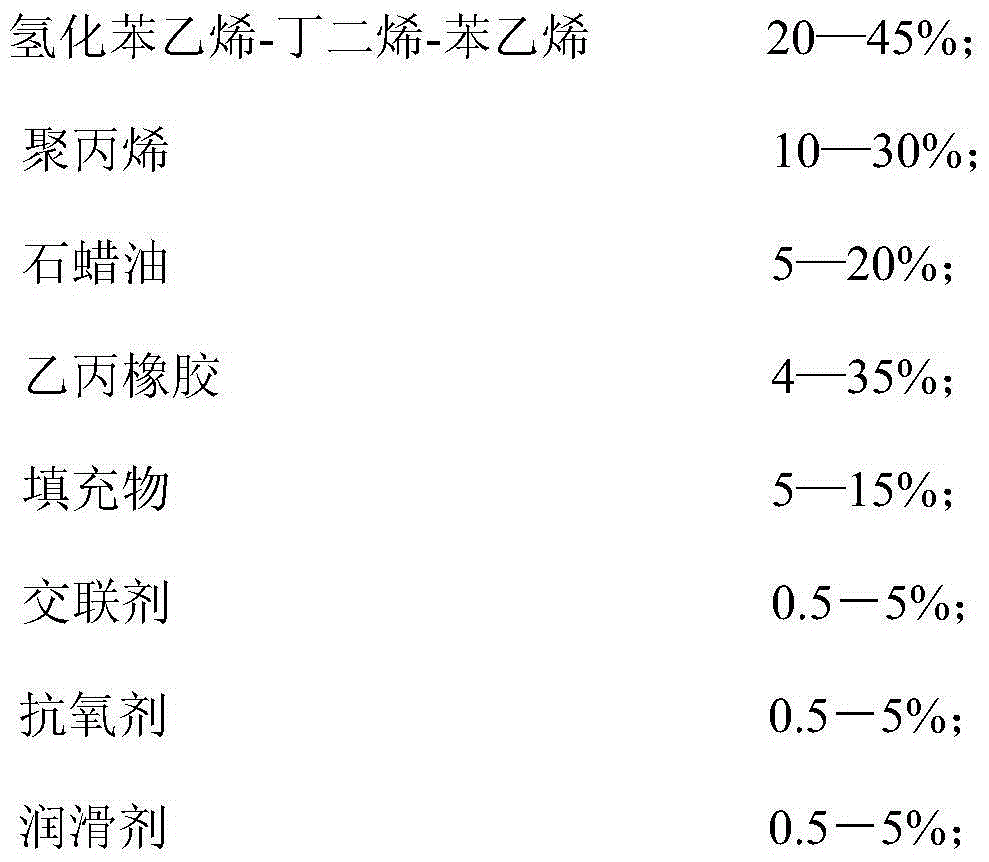

A kind of fog surface oil-resistant elastomer cable material and preparation method thereof

ActiveCN103172965BGood fog effectGood oil resistancePlastic/resin/waxes insulatorsElastomerAntioxidant

The invention provides a matted oil-resistant elastomeric cable material and a preparation method thereof. The cable material comprises the following components by weight percent: 20 to 45 percent of hydrogenated styrene-butadiene-styrene, 10 to 30 percent of polypropylene, 5 to 20 percent of paroline, 4 to 35 percent of ethylene propylene rubber, 5 to 15 percent of filler, 0.5 to 5 percent of a cross-linking agent, 0.5 to 5 percent of an antioxidant and 0.5 to 5 percent of a lubricant. The matted oil-resistant elastomeric cable material ensures that a cable has matted effect and also has good oil resistance and mechanical property, and can meet the requirements of oil resistant occasions.

Owner:深圳市益力盛电子有限公司

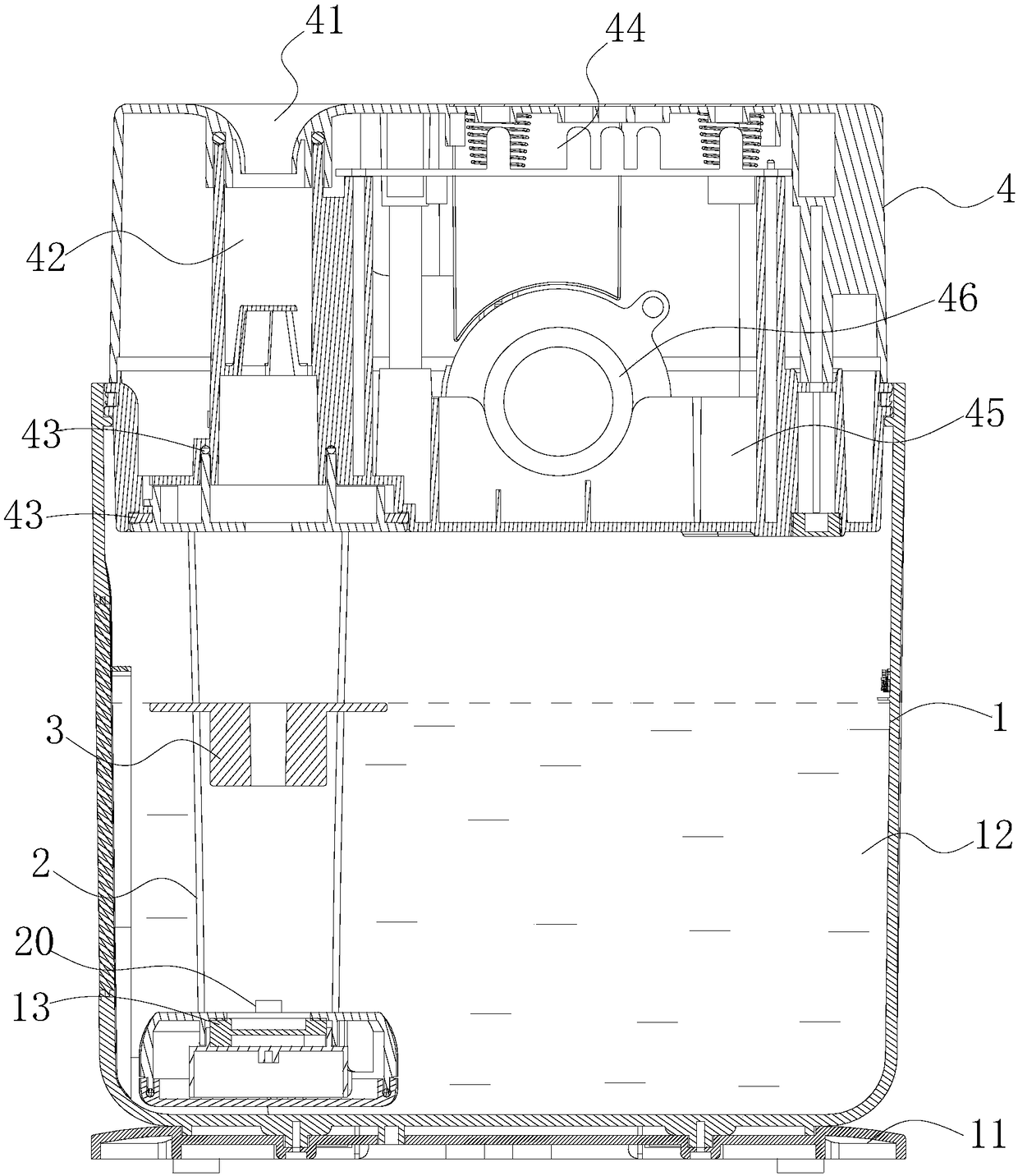

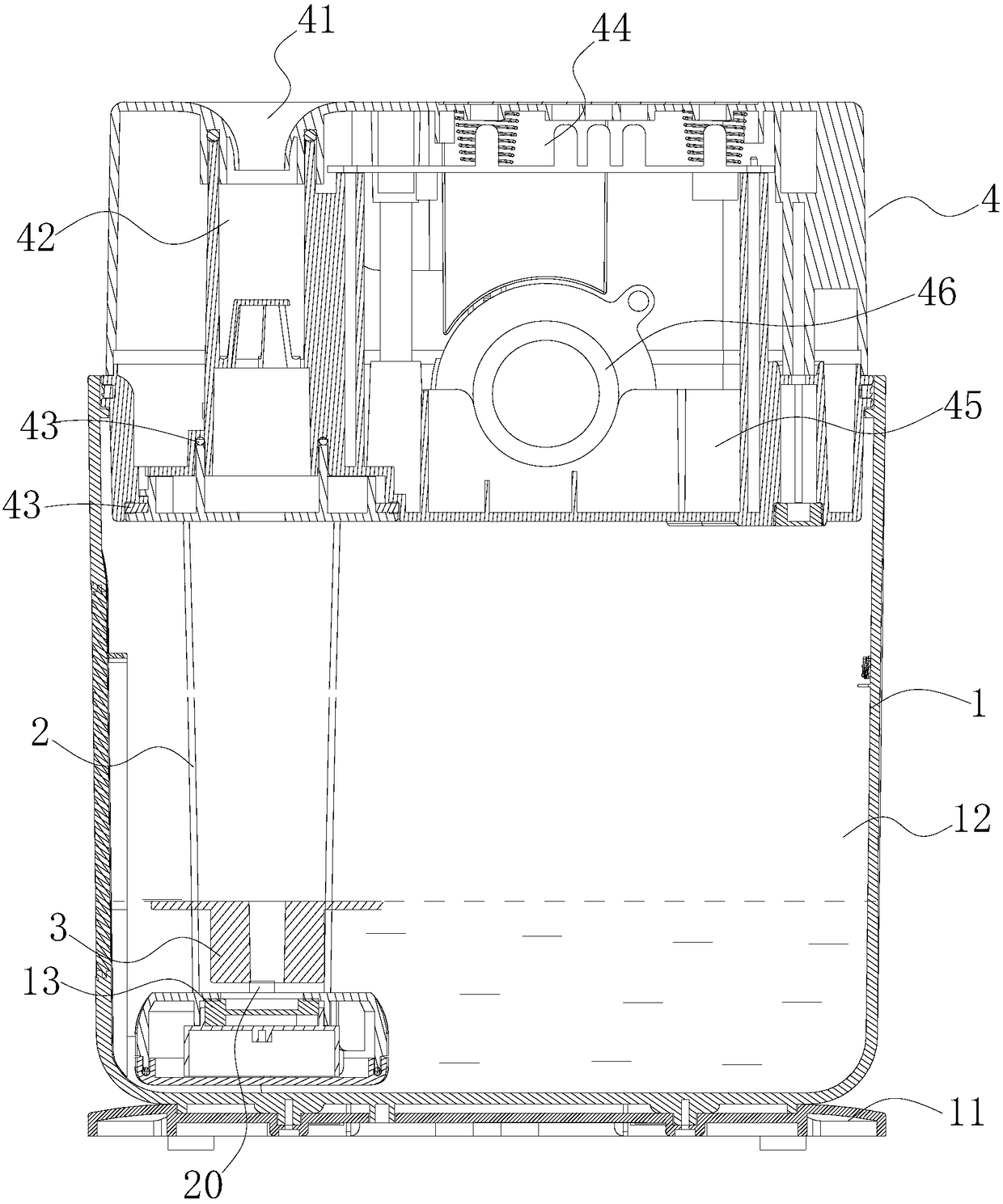

Atomization enhanced mute type upper water adding humidifier

ActiveCN108204648ADimensions will not be limitedDimensions do not affectLighting and heating apparatusNoise suppressionEngineeringUltrasonic atomization

The invention discloses an atomization enhanced mute type upper water adding humidifier. The humidifier comprises a humidifier body with a water tank arranged in the humidifier body, the bottom of thewater tank is provided with an ultrasonic atomization sheet; a mist outlet cover body is arranged at the upper end of the humidifier body, and a mist outlet channel is formed in the mist outlet coverbody; a mist guide pipe arranged between the ultrasonic atomization sheet and the mist outlet channel, and a mist guide groove is formed in the mist guide pipe, and vertical grooves are formed in theside wall of the mist guide pipe; the humidifier further comprises an energy gathering ring used for enhancing the atomization capability of the ultrasonic atomization sheet, the energy gathering ring comprises a guide cylinder and multiple baffles, wherein the guide cylinder floats on the liquid surface of the guide groove, and the multiple baffles extend outwards from the upper end of the guidecylinder; the guide cylinder is provided with an axial atomization hole, the tail end, far away from the axial atomization hole, of each baffle plate extends from one vertical groove to the outside of the mist guide pipe, and the vertical distance between the tail end, far away from the axial atomization hole, of each baffle and the axial center line of the axial atomization hole is at least twice the aperture of the axial atomization hole. The humidifier has the advantages of being large in mist outlet amount, stable in mist discharge and low in noise.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD +1

Preparation method of novel matte anti-static release paper

ActiveCN103061207BImprove surface antistatic performanceLow wear resistanceSpecial paperPaper coatingUltravioletPolyethylene glycol

The invention discloses a preparation method of novel matte anti-static release paper. One surface of release paper body paper is coated with a coating layer through a coating machine, and one surface of a thin film layer is coated with a matte anti-static coating with a thickness of 0.2-2 micrometres. Under the influence of the used ultraviolet rays which are of a wave band of 280-350nm and of an illumination of 1200mW / cm<2>, components, contained in the matte anti-static coating, including 2-6% of silica particles, 20-30% of acrylic polyol with the average molecular weight of 500-2000, 35-45% of resin of polyoxyalkylene polyols with the average molecular weight of 200-2500, 15-20% of polyethylene glycol and 5-10% of 1-1-hydroxy-cyclohexyl phenyl ketone-photoinitiator 184 react to obtain the matte anti-static coating. The thickness of the matte anti-static coating is 4-10 micrometres. The preparation method of the novel matte anti-static release paper not only solves the problems that the binding force between the coating layer and the release agent coating of the release paper is not strong and the release force between the coating layer and the release agent coating of the release paper is not stable, but also promotes the anti-static performance of the surface of the film, and meanwhile promotes the anti-scraping performance.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Foggy surface release material for high-reliability adhesive tape

InactiveCN108149518ALow wear resistanceImprove surface antistatic performanceSpecial paperNon-macromolecular organic additionElectrostatic coatingUltraviolet

The invention discloses a foggy surface release material for a high-reliability adhesive tape. The foggy surface release material is characterized by being used in release paper of the adhesive tape;the foggy surface release material consists of the following components in percentage by weight: 5 percent of silica particles, 27 percent of acrylic polyol with an average molecular weight of 500-2000, 39 percent of resin of polyoxylene series polyol with an average molecular weight of 200-2500, 18 percent of polyethylene glycol, 6 percent of cyclomethylsiloxane and 5 percent of 1-hydroxycyclohexylphenylketone photoinitiator 184; a foggy surface antistatic coating layer adopts an ultraviolet waveband of 280-350 nm, and the diameter of each of the silica particles is 2.5-2.8 micrometers. The foggy surface release material disclosed by the invention can eliminate influences caused by static electricity on the silicone oil coating instability, is stable in release peeling force and also avoids the generation of electrostatic sparks in the production process.

Owner:邓明

A kind of grinding fog type easy heat sealable PP film and preparation method thereof

ActiveCN108454207BGood fog effectGood heat sealingFlexible coversWrappersPolymer sciencePlasticulture

The invention belongs to the technical field of packaging materials and discloses a grinding fog type PP film which has easiness in heat seal and can be internally printed and a preparation method. The PP film is composed of a corona layer, a core layer and a heat seal layer, wherein the corona layer is prepared from ingredients in mass fraction: 0 to 85 parts of bimodal PE, 15 to 100 parts of binary co-polypropylene, 0 to 1.5 parts of slip agent, 0 to 1.5 parts of opening agent and 0 to 1.5 parts of antistatic agent; the core layer is prepared from ingredients in mass fraction: 85 to 100 parts of homo-polypropylene and 0 to 15 parts of POE; the heat seal layer is prepared from ingredients in mass fraction: 100 parts of bimodal PE, 0 to 1.5 parts of slip agent, 0 to 1.5 parts of opening agent and 0 to 1.5 parts of antistatic agent. The preparation method comprises the steps: utilizing a three-layer co-extrusion extruding machine to plastify all layers of formula mixtures; casting, cooling and forming, wherein a cooling temperature is 26 to 30 DEG C; drawing, performing corona treatment, cutting edges, rolling and forming films. The grinding fog type PP film disclosed by the invention has the advantages of very good grinding fog effect, good heat seal performance and application to high-speed package.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

new cosmetic box

The invention discloses a novel dressing case. The interior of a case body is separated into a plurality of storage spaces; the inner wall of a cover body is at least provided with a first accommodating groove and a second accommodating groove; a cosmetic mirror is arranged in the first accommodating groove; a moisturizing device is arranged in the second accommodating groove and comprises an atomizing mechanism and a container arranged above the atomizing mechanism and used for accommodating tonner; the top of the container is provided with a plurality of openings; the openings are rotationally connected with an atomizing channel; the end part of the atomizing channel is provided with a fine spray outlet; the fine spray outlet consists of a plurality of four-angle stars. The novel dressing case is novel in creativity and skillful in structure; the moisturizing device arranged in the second accommodating groove is used for moisturizing before dressing to achieve the better dressing effect; the novel dressing case is particularly suitable for households or offices; the atomizing channel of the moisturizing device is made of a hose which can stretch and be bent freely, and is convenient to adjust according to the position of a user; moreover, the fine spray outlet of the atomizing channel consists of four-angle stars, and the fine spray outlet effect is better.

Owner:QINGDAO BAIRUIJI BIOTECH

A kind of non-phthalic PVC pellets and preparation method thereof

Owner:JIANGSU DAHAI PLASTIC

Water dissolving and atomizing device for biological perfume

ActiveCN114534944AGood fog effectWell mixedLiquid spraying apparatusAir quality improvementPhysical chemistryEngineering

The invention relates to an atomization device, in particular to a biological spice water-dissolving atomization device. The invention provides a biological perfume water dissolving and atomizing device which assists in mist discharging in a pressurization mode. A biological spice water dissolving and atomizing device comprises a first frame, a mounting plate, a first support, a first pressurizing box, a water inlet pipeline, atomizing nozzles and the like, the mounting plate is arranged on the left side of the first frame, the first support is arranged on the right side of the upper portion of the mounting plate, the first pressurizing box is arranged in the middle of the first support, and the water inlet pipeline is communicated between the bottom of the first pressurizing box and the first frame. An atomizing nozzle is arranged at the top of the left side of the first pressurizing box. After an electric push rod is started, the electric push rod continuously stretches out and draws back to drive a third support to move left and right in a reciprocating mode, so that a push rod is driven to move left and right in a reciprocating mode, a biological perfume solution in a first pressurization box is atomized and sprayed out through an atomization nozzle, and under the pressurization cooperation effect of the push rod and the first pressurization box, the mist outlet effect of biological perfume mist is good.

Owner:SHENZHEN ITSUWA ELECTRON CO LTD

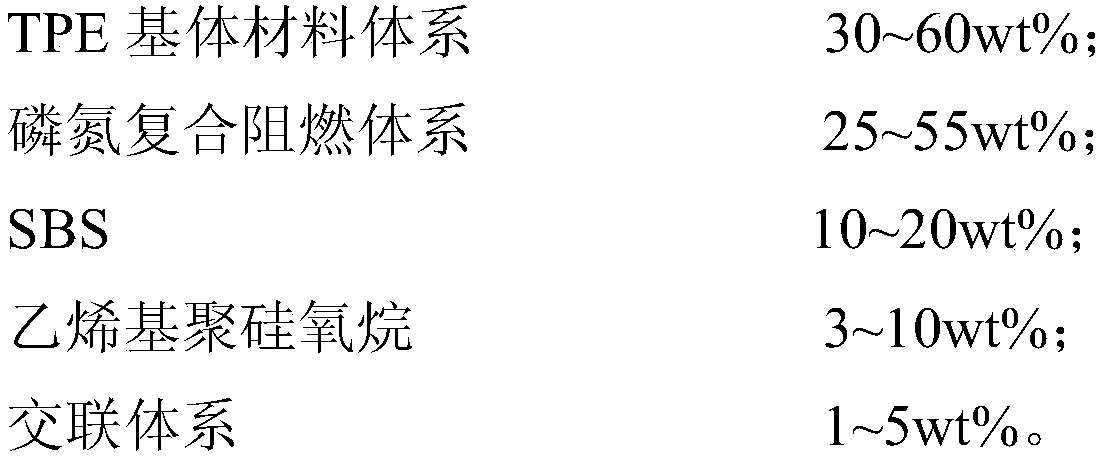

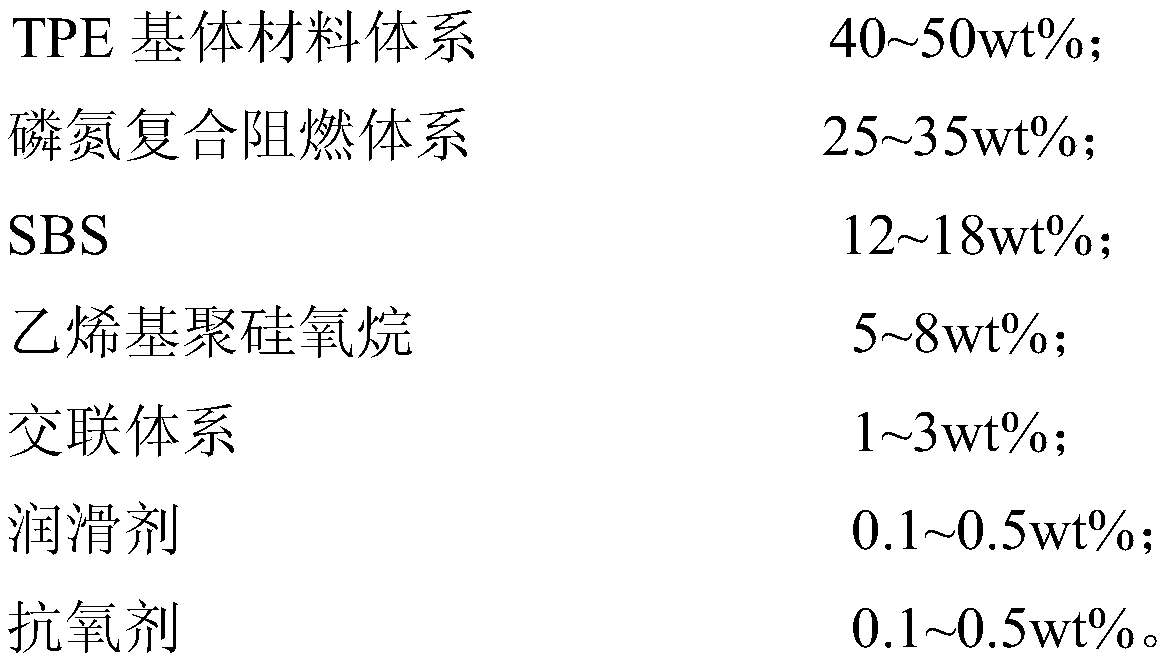

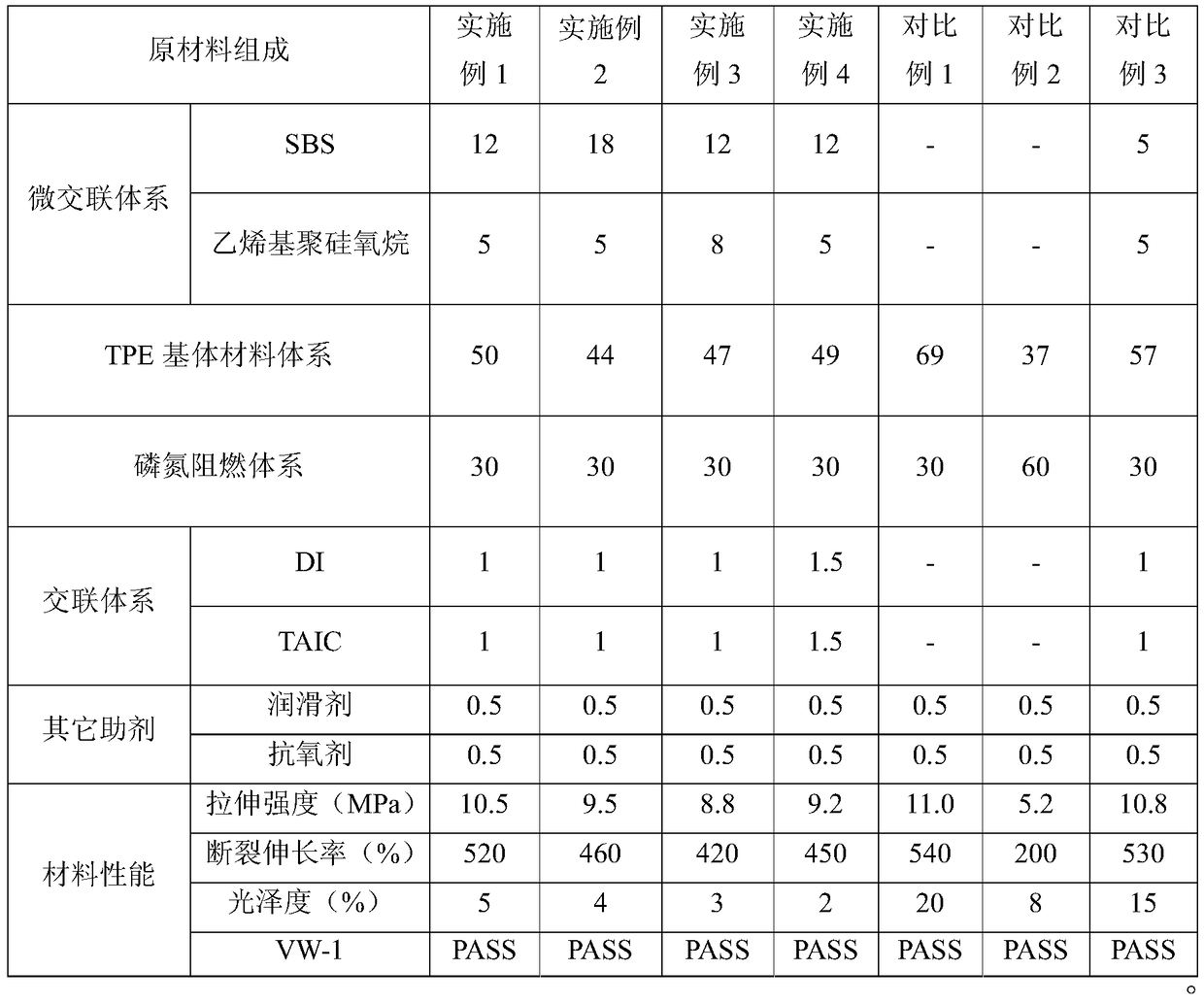

A high fog surface halogen-free flame-retardant thermoplastic elastomer for wire and cable and its preparation method

ActiveCN106751360BGood fog effectHigh strengthPlastic/resin/waxes insulatorsThermoplastic elastomerPolymer chemistry

The invention discloses a high-fogging halogen-free flame-retardant thermoplastic elastomer for electric wires and cables. The high-fogging halogen-free flame-retardant thermoplastic elastomer comprises the following raw materials in percentage by weight: 30-60wt% of a TPE base material system, 25-55wt% of a phosphorus-nitrogen composite flame-retardant system, 10-20wt% of SBS, 3-10wt% of vinyl polysiloxane and 1-5wt% OF A crosslinking system. In order to solve the problem of poor fogging effects of halogen-free flame-retardant TPE cable materials, the invention provides a halogen-free flame-retardant TPE cable material and a preparation method thereof, the appearance of the prepared cable has high fog surface effects, and other properties of the cable material can be maintained.

Owner:新疆天利高新石化股份有限公司

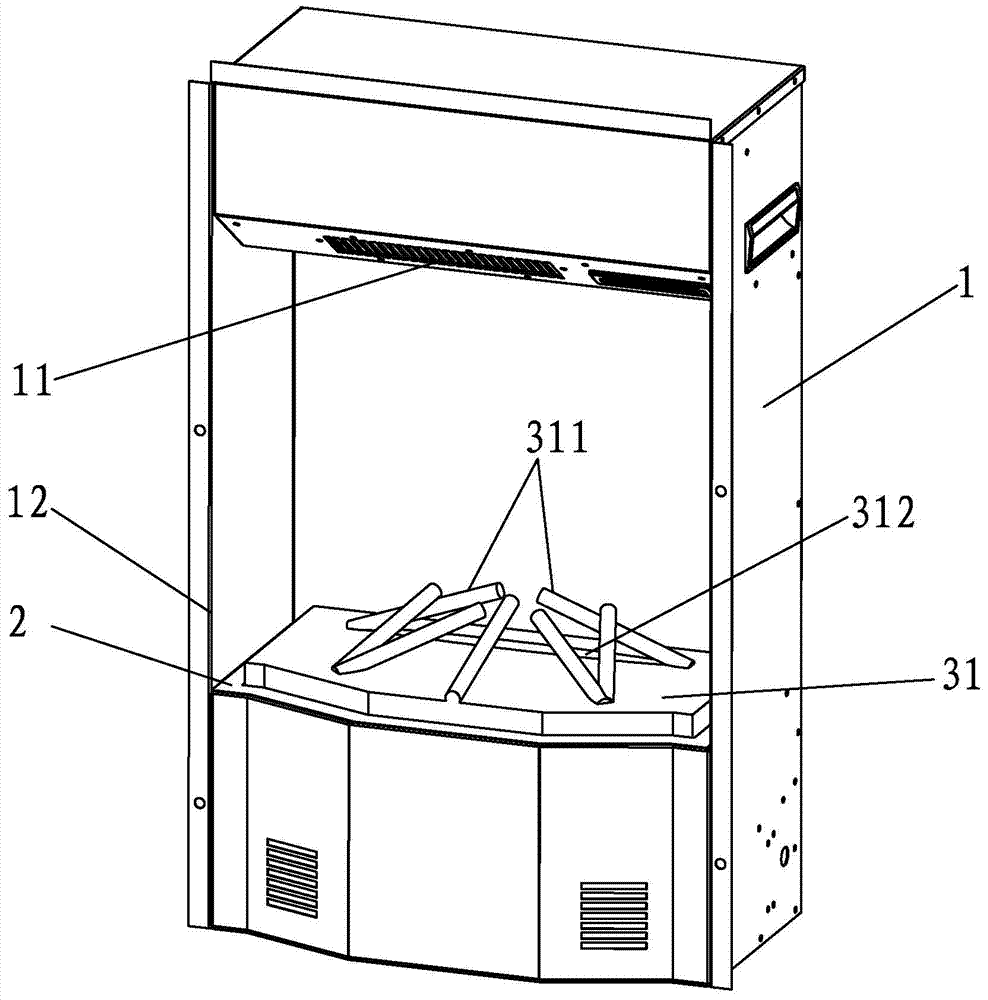

A fog-making simulated fireplace with 3D flame effect

ActiveCN104033949BEasy to viewPlay a role in humidificationLighting elementsElectric lightingLight-emitting diodeLight emitting device

The invention provides a fog-making simulated fireplace with a 3D (three-dimensional) flame effect. The fog-making simulated fireplace can be used for heating an indoor environment, can also be used for humidifying the indoor environment, and is high in fog-making effect. The fog-making simulated fireplace comprises a shell, a flame simulating device and a heater, wherein the shell is divided into an upper cavity and a lower cavity through a partition; the flame simulating device and the heater are arranged in the shell; the flame simulating device comprises a mounting plate and a light emitting device; the mounting plate is arranged on the partition and is a light transmitting plate; simulated wood charcoal strips are arranged on the upper surface of the light transmitting plate; a light transmitting hole is formed in the partition and corresponds to the mounting plate; light of the light emitting device is transmitted from the light transmitting hole; a fog-making device is arranged in the lower cavity and comprises a water tank and a fog-making machine; the water tank is provided with an upper water tank body and a lower water tank body; the fog-making machine is arranged in the lower water tank body; a fog discharging opening is formed in the lower water tank body; the mounting plate is provided with a fog outlet which is oppositely connected with the fog discharging opening; a water draining opening is formed in the bottom of the upper water tank body; a water inlet is formed in the top of the lower water tank body; and mechanical switch structures which are used for controlling make or break of the water draining opening are respectively arranged in the water draining opening and the water inlet.

Owner:FUJIAN ALLEN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com