Patents

Literature

110results about How to "Guaranteed curing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

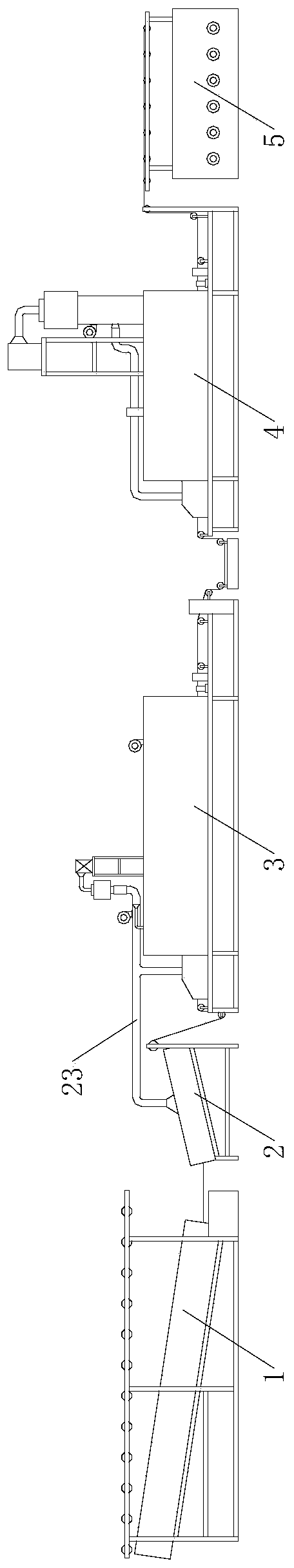

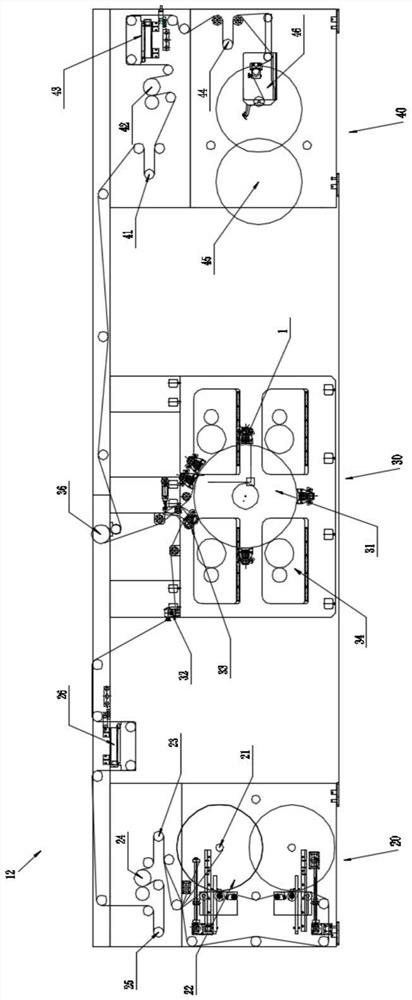

High-speed wire drawing device for optical fiber production process and high-speed wire drawing method thereof

ActiveCN101767930ASave spaceEasy to operateGlass making apparatusGlass productionUltraviolet lightsEngineering

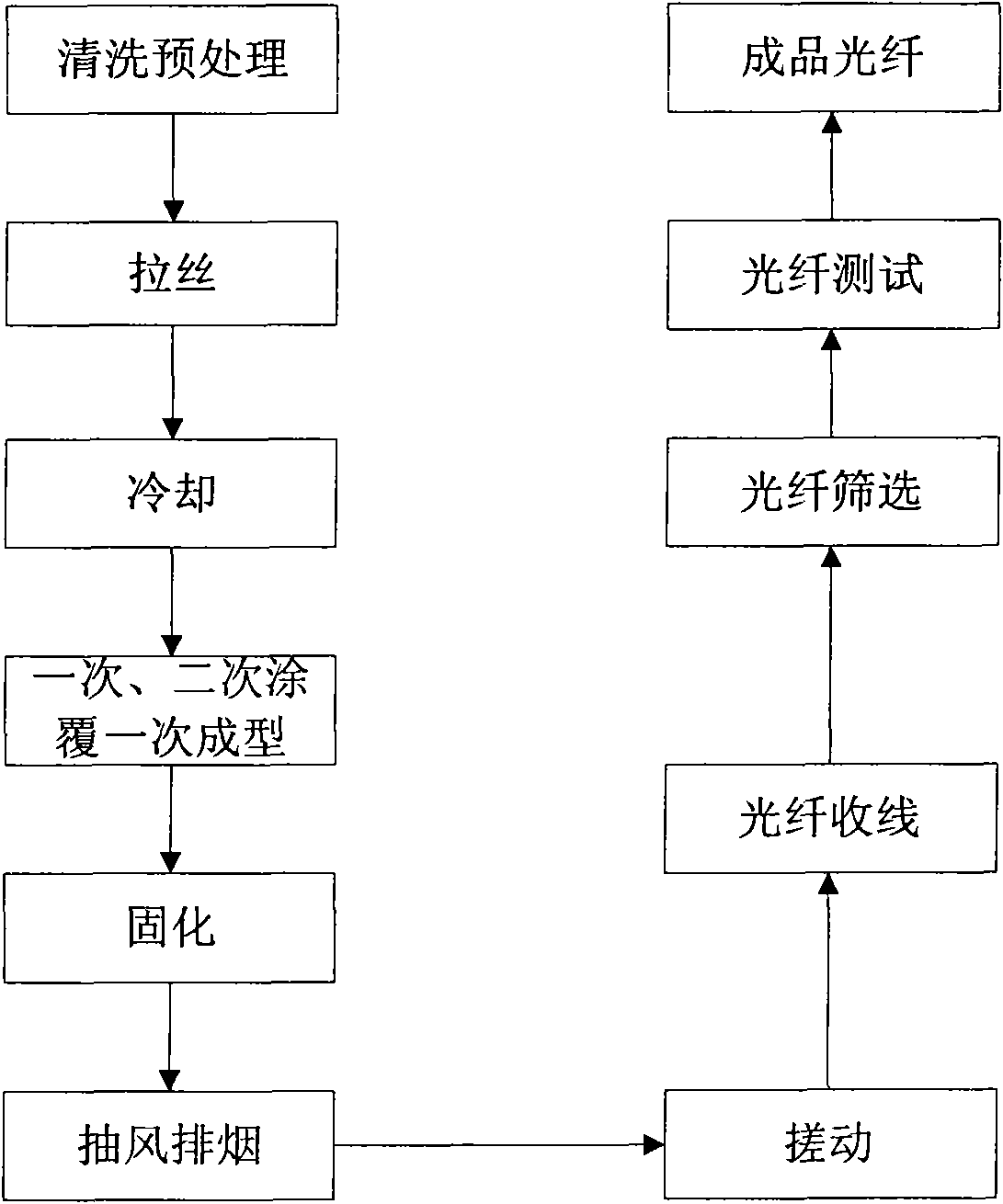

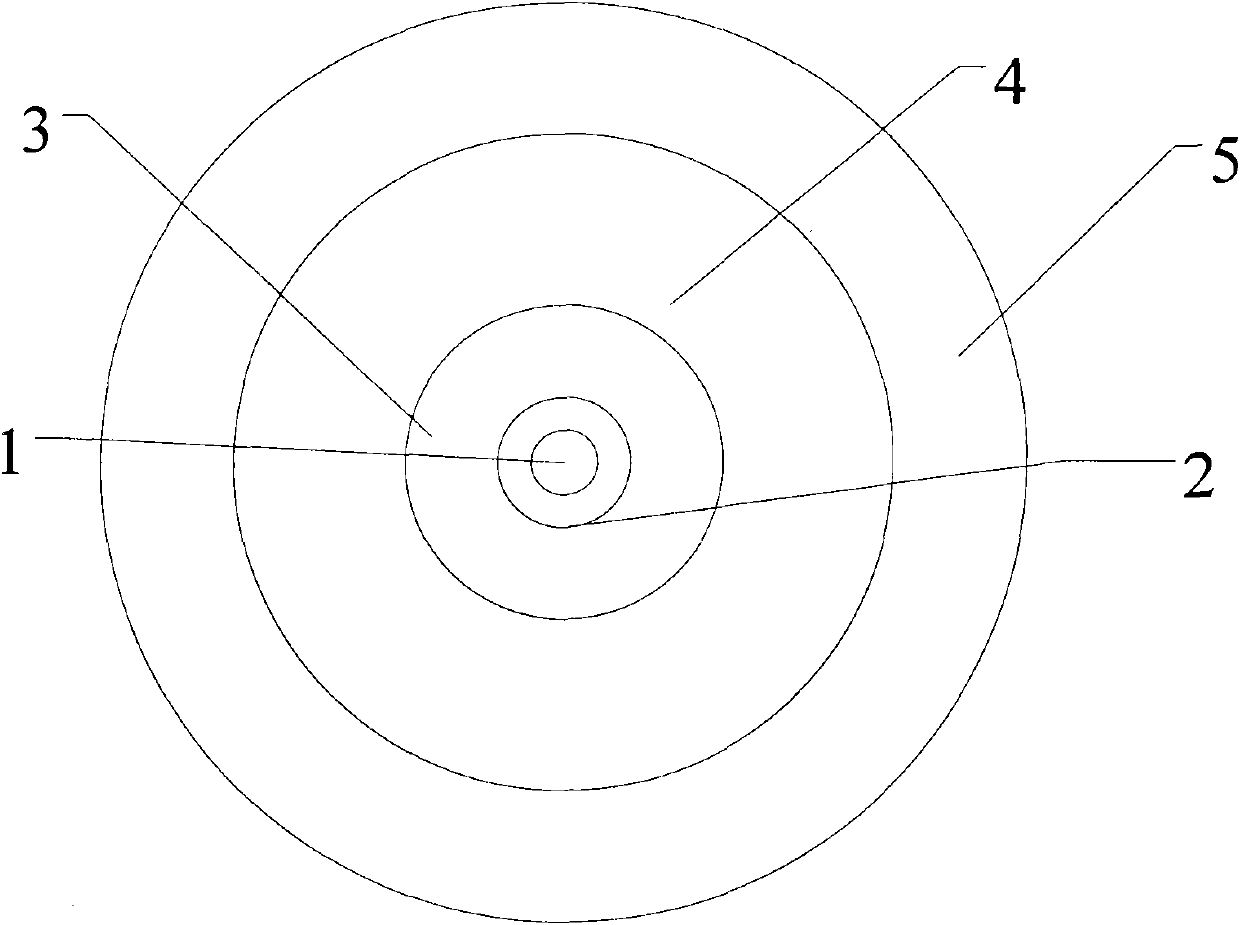

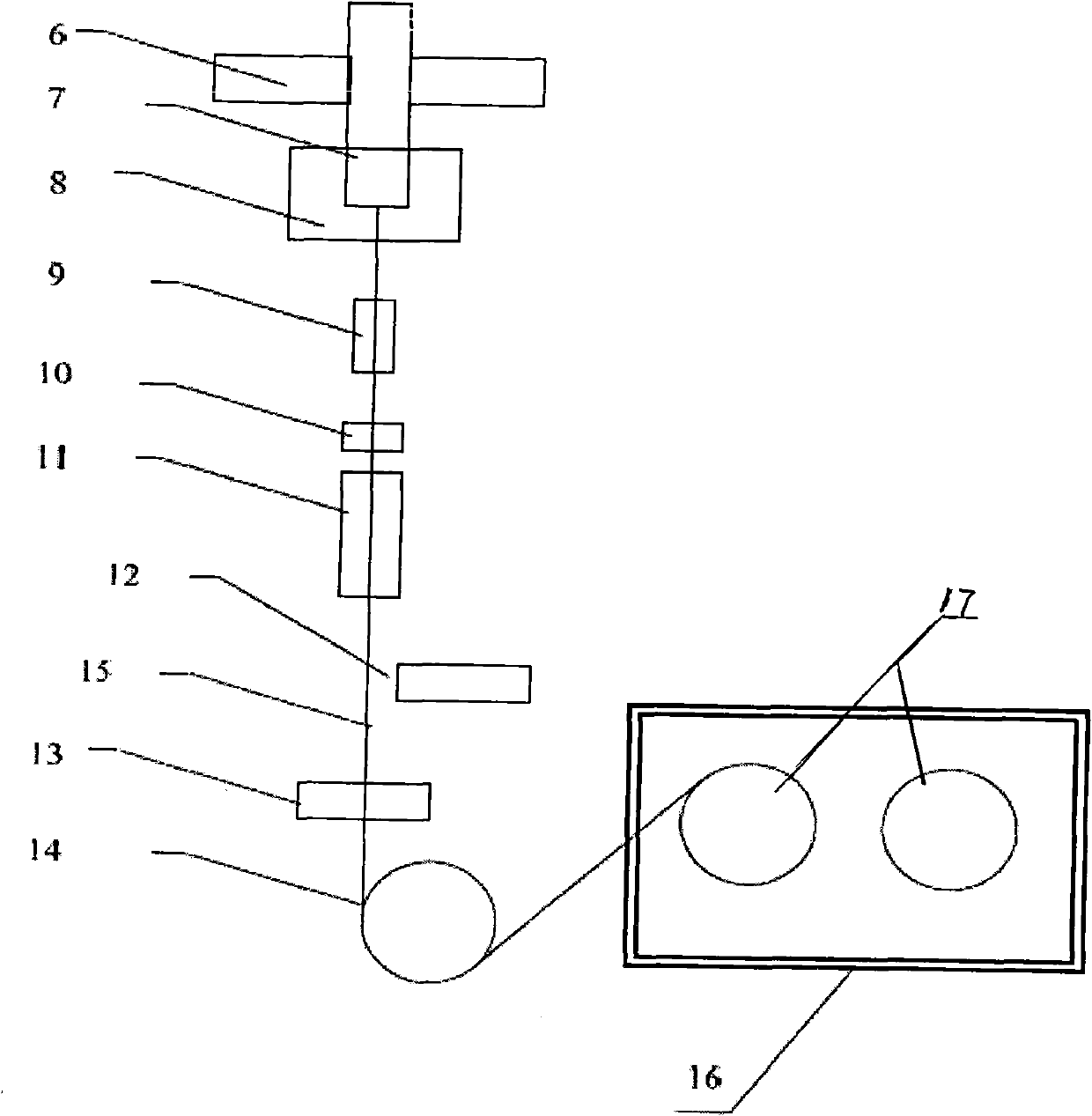

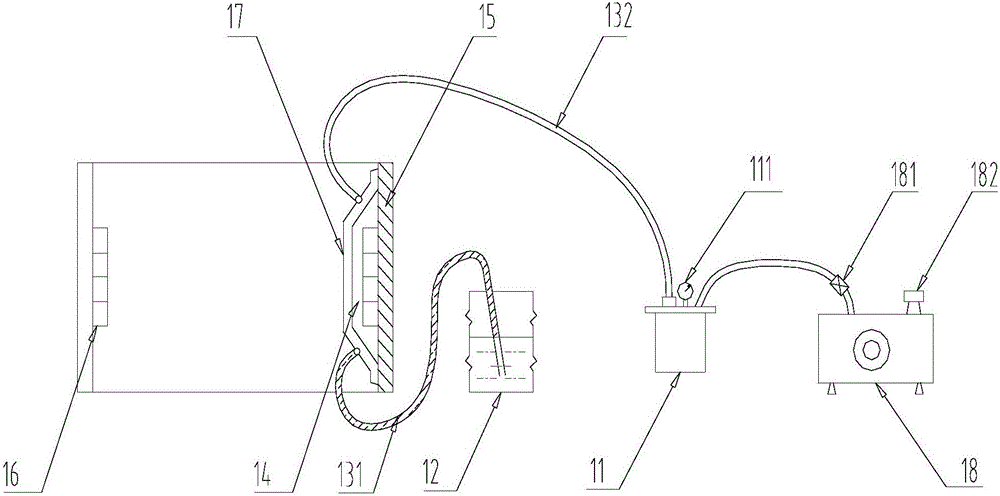

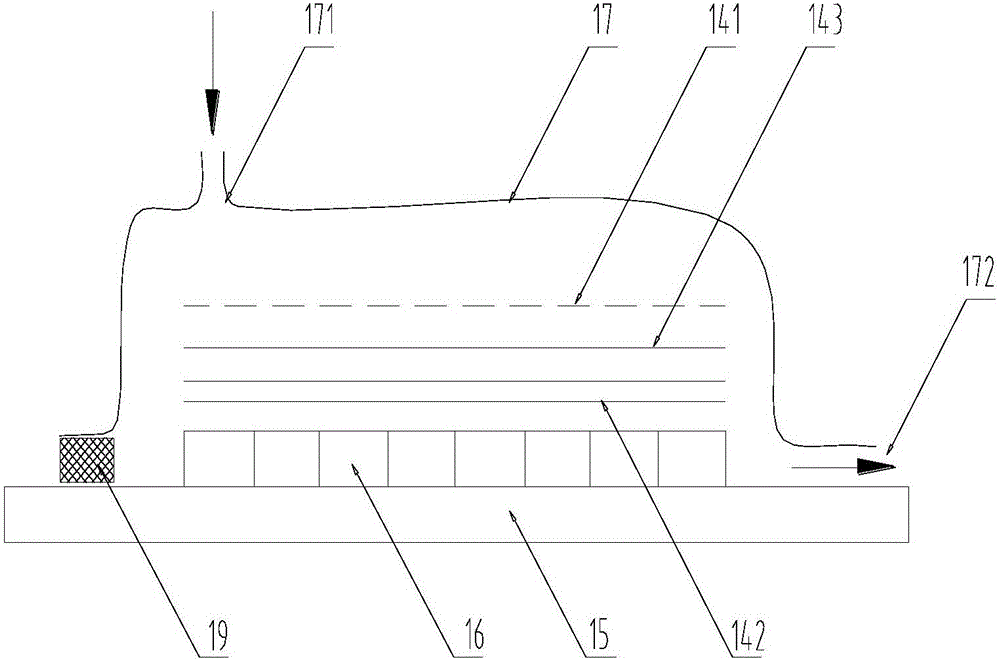

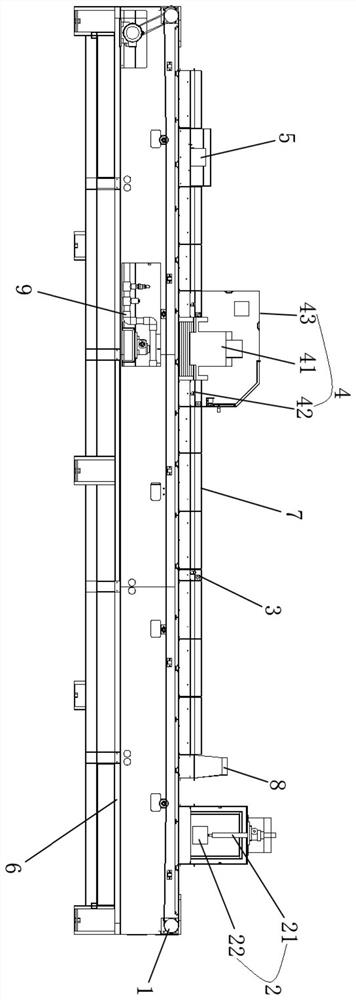

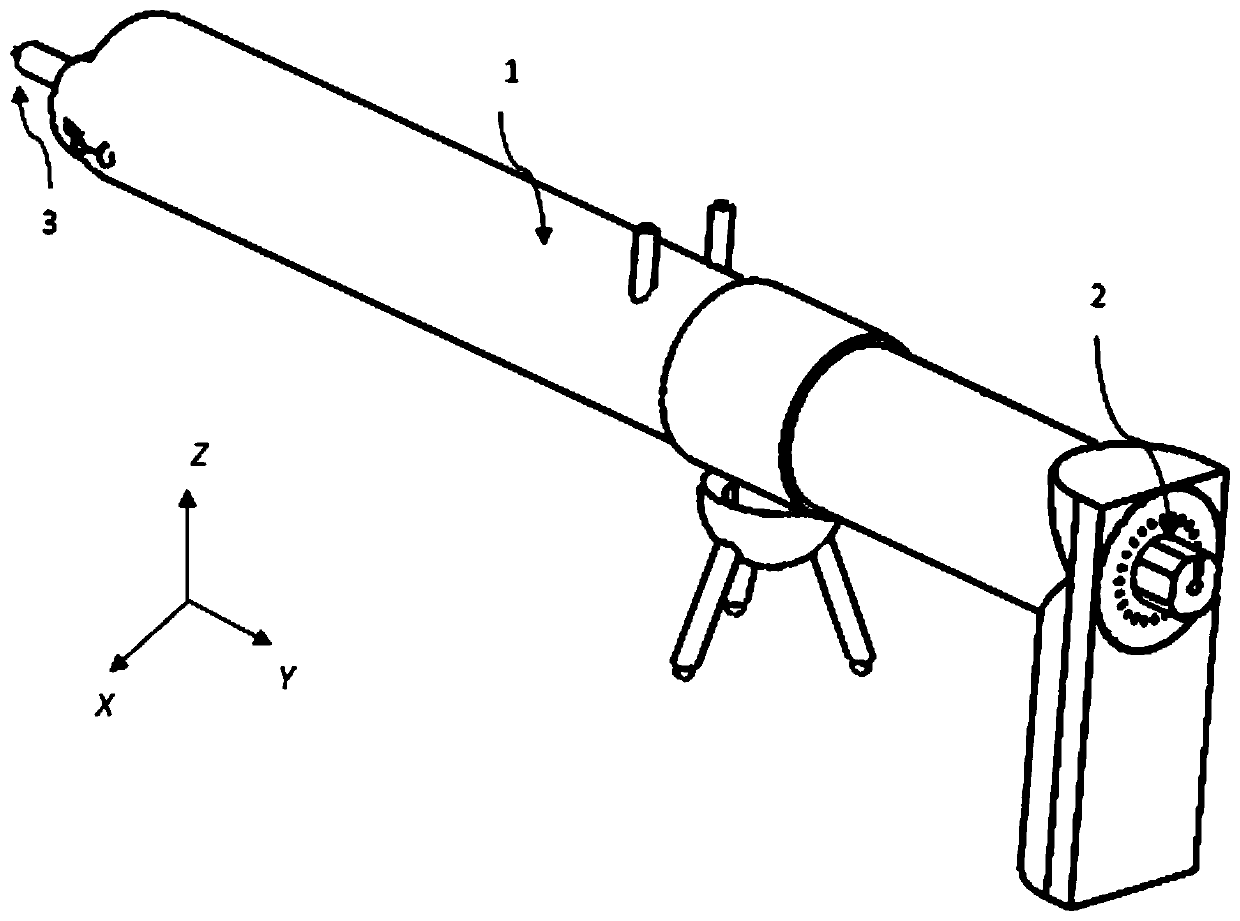

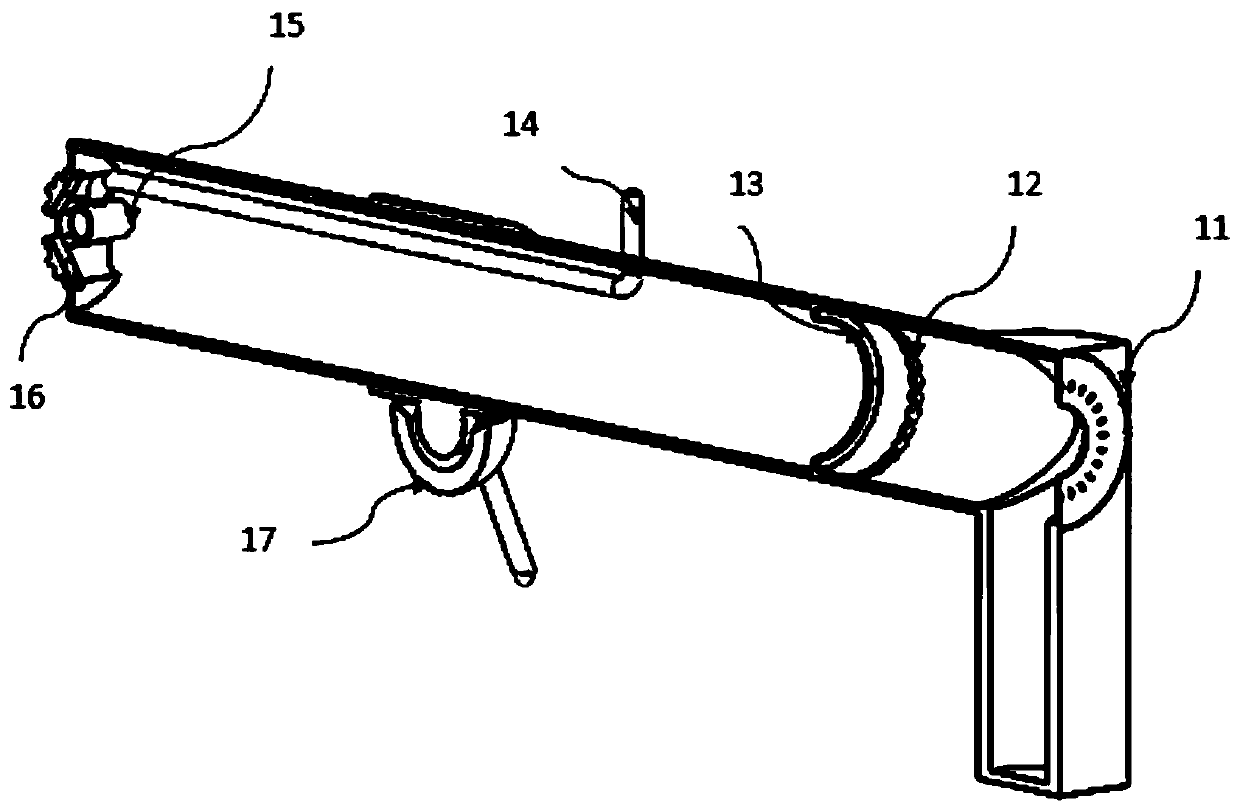

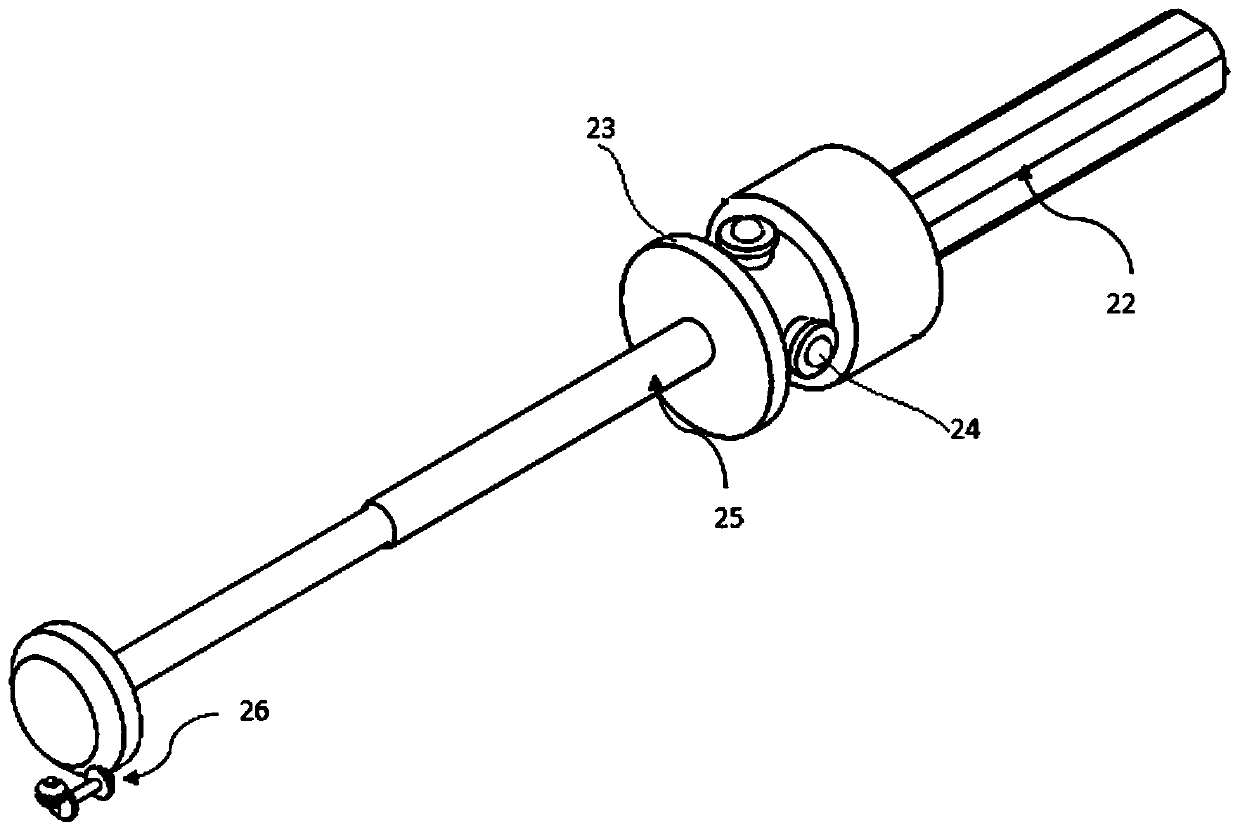

The invention relates to a high-speed wire drawing device for an optical fiber production process and a high-speed wire drawing method thereof, in particular to a wire drawing method for communication G. 652 optical fiber, particularly relates to a high-speed wire drawing method (with the speed higher than 1500m / min) and a high-speed wire drawing device thereof. The high-speed wire drawing device comprises a rod delivery device, a wire drawing furnace, a cooling pipe, a coating device, a curing device, an air draft device, a rubbing device, a traction wheel and a collecting device, wherein the rod delivery device is arranged on the upper part of the wire drawing furnace, the wire drawing furnace part consists of a graphite heating component and a stainless steel furnace body component, the coating device is arranged at the outlet of the cooling pipe, the curing device is arranged in front of the coating device, and the traction wheel and the collecting device are arranged in front of the rubbing device. The high-speed wire drawing method comprises the following steps: (1) surface pretreatment of a prefabricated rod; and (2) wire drawing: hanging the prefabricated rod after surface pretreatment on the rod delivery device, feeding the prefabricated rod into the wire drawing furnace for wire drawing, adopting ultraviolet light to cure a coating, rubbing an optical fiber through the rubbing device after curing, and after rubbing, collecting the optical fiber through the traction wheel and the collecting device.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

Magnetic pole protective layer flexible molding process and system

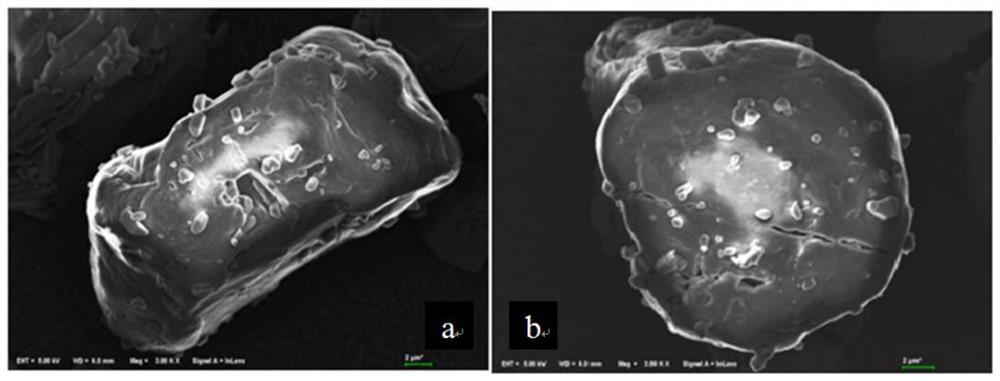

ActiveCN106426978AReduce hole positionExcellent impregnationManufacturing stator/rotor bodiesDomestic articlesMagnetic polesUltrasonic vibration

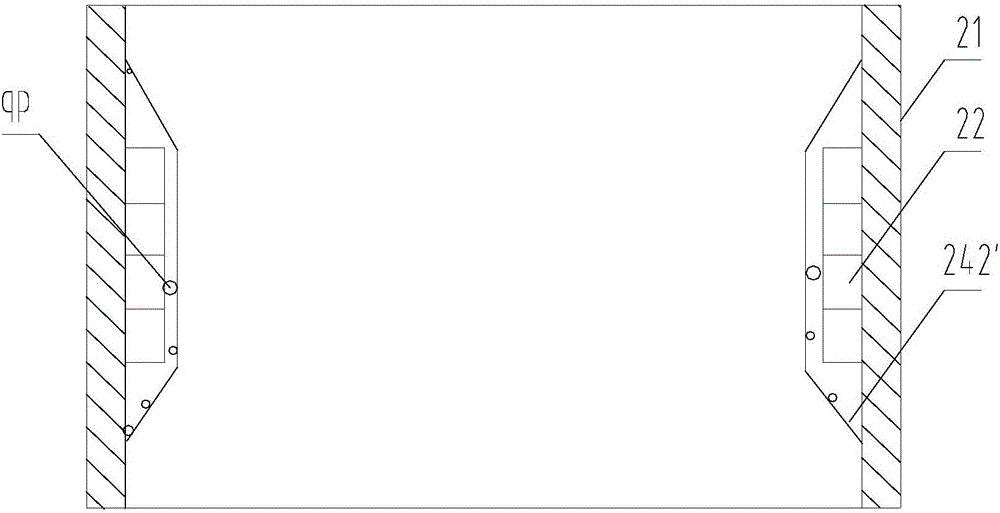

The invention discloses a magnetic pole protective layer flexible molding process and system; the process comprises: fitting magnet steel to corresponding position of one side wall of a magnet yoke, applying reinforcing material and a vacuum bag sequentially to the sidewall of the magnet steel and magnet yoke, such that the vacuum bag, along with the sidewall of the magnet steel and magnet yoke, forms a closed system; impregnating, to be specific, evacuating the closed system to inject an impregnating liquid to the closed system to implement wetting and impregnating; heating and / or transmitting ultrasonic to the closed system during impregnating; after impregnating, carrying out curing, to be specific curing the impregnating liquid to form a protective layer. By heating, it is possible to reduce the angle of contact; by ultrasonic vibration, mechanical wave is transmitted to the impregnating liquid; both facilitates full wetting and impregnating of the impregnating liquid; therefore, holes in the formed protective layer are decreased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

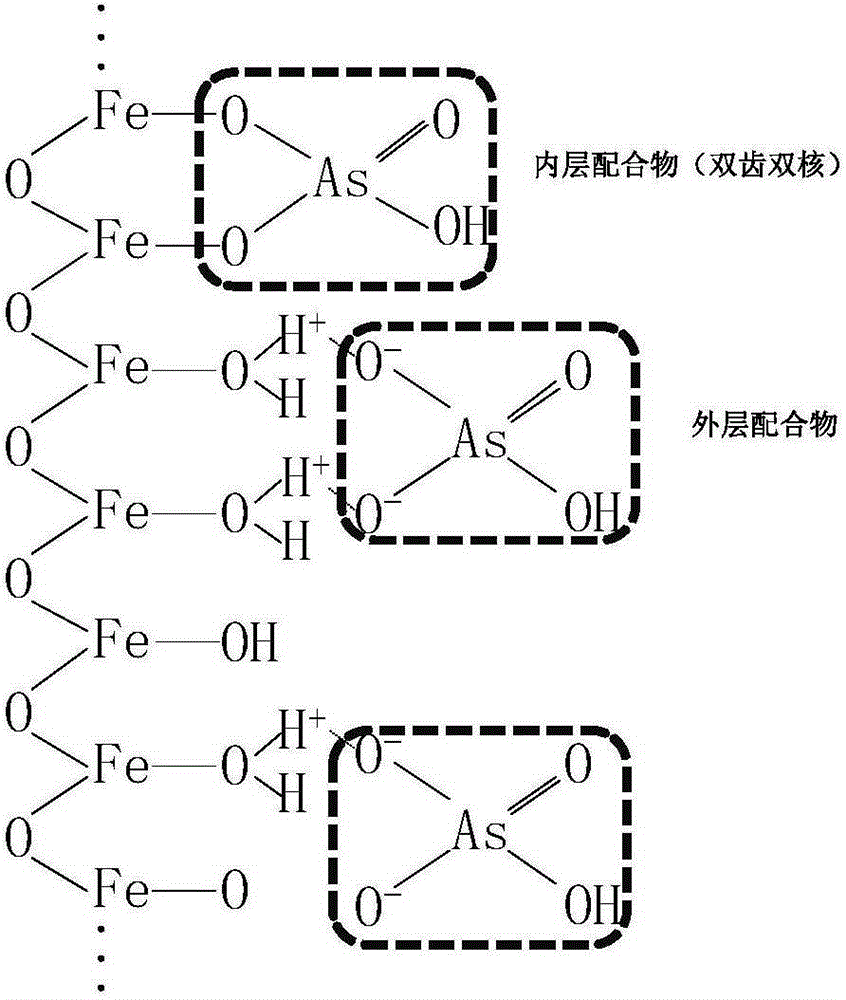

Steel slag-desulfurized gypsum based soil solidification agent applicable to arsenic contaminated soil

InactiveCN106467745AReduce the amount of blendingSmall increase ratioContaminated soil reclamationOrganic fertilisersSlagGypsum

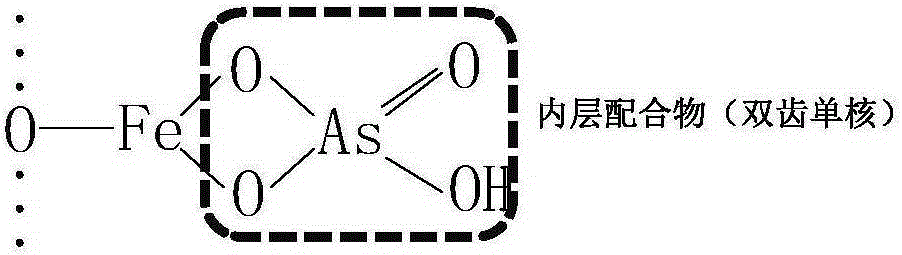

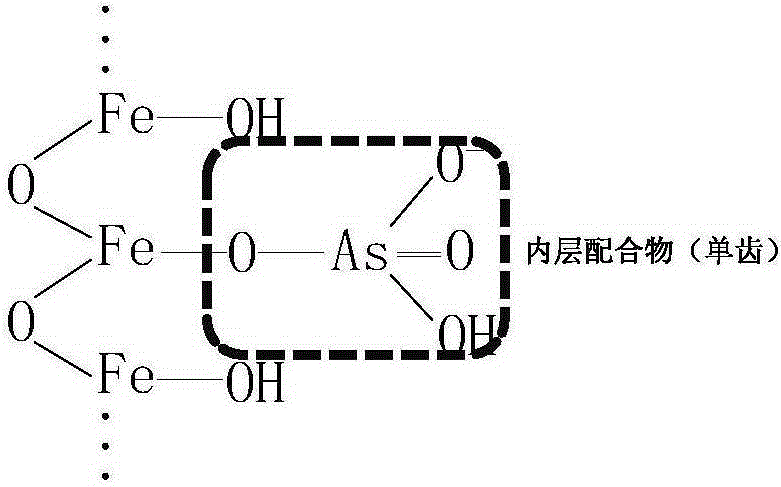

The invention discloses a steel slag-desulfurized gypsum based soil solidification agent applicable to arsenic contaminated soil. The soil solidification agent contains the ingredients in percentage by weight: 40% to 45% of steel slag, 15% to 25% of desulfurized gypsum, 22% to 30% of slag, 7% to 10% of cement clinker and 3% of excitant. According to the soil solidification agent disclosed by the invention, arsenic is solidified and stabilized mainly by means of chemical wrapping and in-phase replaced solidifying, and the age of a solidifying reaction can be shortened and the mixed amount of the solidification agent and solidified volume increase ratio in engineering applications can be lowered while a solidifying effect is guaranteed, so that the solidifying efficiency is increased greatly.

Owner:WUHAN UNIV

Carbonatite oil well density selectivity water shutoff agent and preparation process thereof

InactiveCN102746835AStrong stabilityExpand the blocking radiusDrilling compositionChemistryProcess engineering

A carbonatite oil well density selectivity water shutoff agent comprises, by weight, 100 parts of cement, 60-75 parts of coal ash, 50-58 parts of clay, 52-62 parts of micro silicon, 5-8 parts of early strength agents, 16-28 parts of fluid loss agents and 1100-1200 parts of water. A preparation process of the carbonatite oil well density selectivity water shutoff agent includes: weighing the fluid loss agents and the early strength agents according to the formula ratio, dissolving the weighed fluid loss agents and the weighed early strength agents into the water obtained according to the formula ratio, and then adding the cement, the coal ash, the clay and the micro silicon according to the formula ratio so as to obtain the carbonatite oil well density selectivity water shutoff agent. The carbonatite oil well density selectivity water shutoff agent has the advantages of capability of staying among oil-water interfaces to set up a water shutoff partition, guarantee of solidification effects, safety in injection, expansion of shutoff radius, high compression strength after solidification, easiness to prepare, good injection performance, simplicity in construction process and high construction efficiency.

Owner:XINJIANG HUAYOU TECH SERVICE

Mold bag curing soil for sea filling and cofferdam, preparation method and application method thereof

The invention discloses a mold bag curing soil for sea filling and cofferdam, a preparation method and an application method thereof, and belongs to the technical field of marine materials. The mold bag curing soil is prepared from the following raw materials: waste mud, a composite flocculant, a mud structure agent and biomass fibers, wherein by adopting the dry weight of the waste mud as the reference, the dry weight of the waste mud accounts for 40-60% of the total weight of the slurry during the slurry injection of the mold bag curing soil, the composite flocculant accounts for 6-9% of the dry weight of the waste mud, the mud structure agent accounts for 3-4.5% of the dry weight of the waste mud, and the biomass fibers accounts for 0-2.5% of the dry weight of the waste mud. With the technical scheme of the present invention, the curing effect of the mold bag filling material for the sea filling and cofferdam can be effectively improved, and the product can be directly used for the reclamation project after the curing treatment, and can meet the use requirements of the cofferdam construction project.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD +1

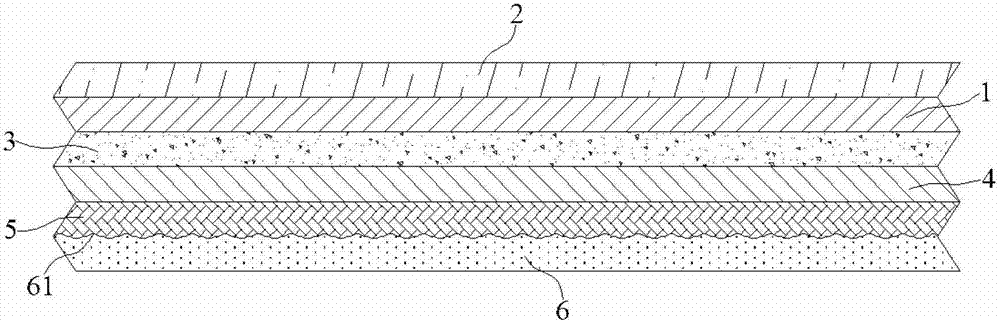

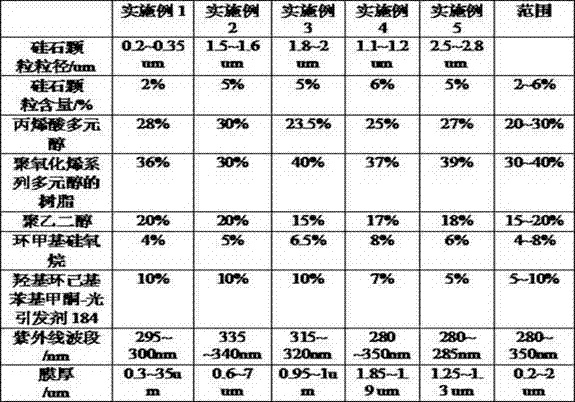

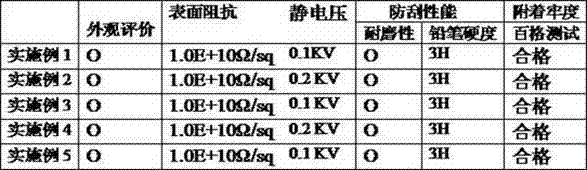

Anti-scuffing matt-surface antistatic release paper

ActiveCN103074819ALow wear resistanceImprove surface antistatic performanceNon-fibrous pulp additionSynthetic resin layered productsElectrostatic coatingPolyethylene glycol

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

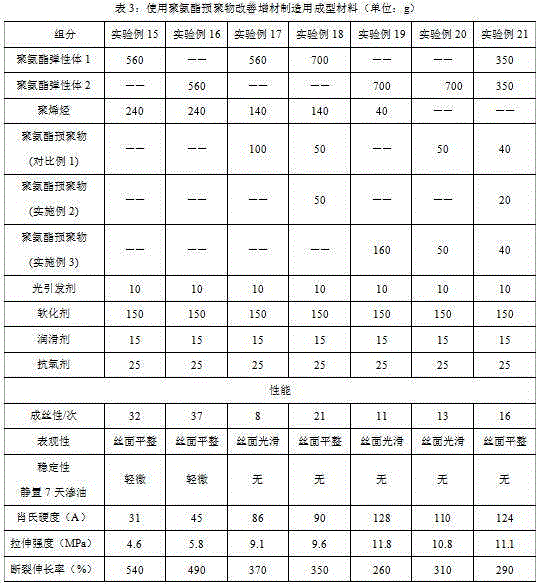

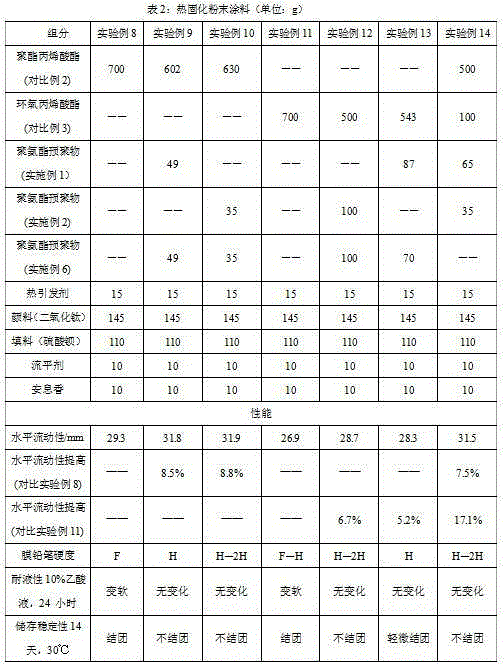

Solid-state hypocrystalline unsaturated polyurethane prepolymer and preparation method thereof

ActiveCN105294986AImprove adhesionIncrease silkinessPolyurea/polyurethane coatingsPolymer scienceAlcohol

The invention discloses a solid-state hypocrystalline unsaturated polyurethane prepolymer and a preparation method thereof. The melting range of the polyurethane prepolymer ranges from 50 DEG C to 145 DEG C, the melt viscosity is smaller than or equal to 100 mpa*s, the number-average molecular weight ranges from 250 to 5000, the unsaturation degree is 0.3-6 mmol / g, and the solid-state hypocrystalline unsaturated polyurethane prepolymer is prepared through reaction with alkyl-chain-base dihydric alcohol, polyisocyanate and unsaturated alcohol and ether stop ends being reaction substances and NCO / OH equivalence ratio being 0.8-1.2. The prepolymer is a solid-state polyurethane prepolymer meeting the construction characteristic requirement, the melting range of the solid-state polyurethane prepolymer is 50-145 DEG C, the prepolymer has good stability in the storage process and has low enough melt viscosity, and therefore when the prepolymer and resin components containing the prepolymer are applied to the surface of a base material, excellent levelling property is achieved, and the unsaturation degree of a resin system is effectively compensated for in the light / heat curing process.

Owner:GUANGZHOU KINTE IND

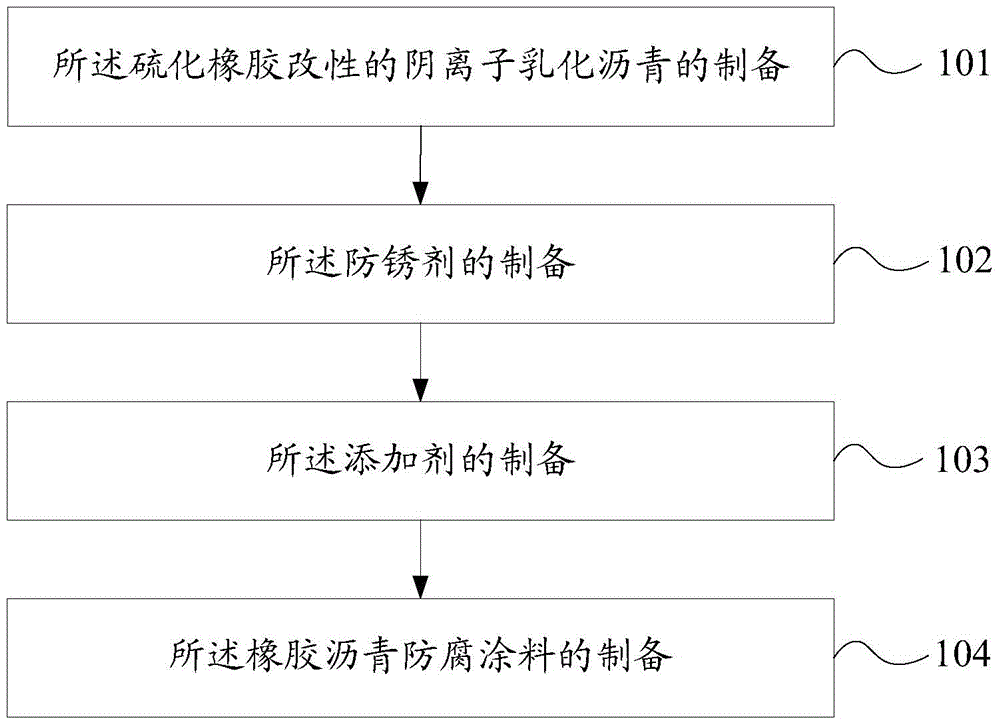

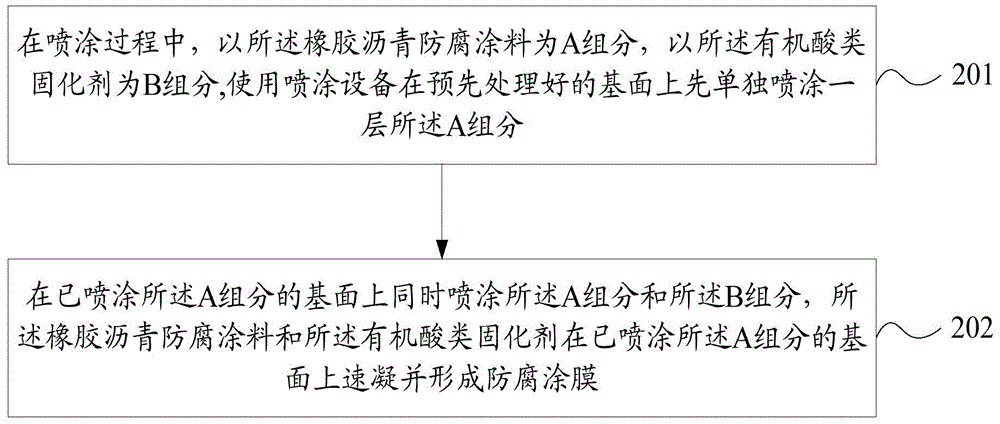

Anticorrosive material for metallic equipment and preparation and construction methods thereof

InactiveCN104893578AAccelerateSmall construction environmentUnspecified rubber coatingsAnti-corrosive paintsIonOrganic acid

The invention provides an anticorrosive material for metallic equipment. The material comprises a rubber-asphalt anticorrosive coating material and an organic acid type curing agent, wherein the organic acid type curing agent consists of one or more of citric acid type curing agent, sorbic acid, amino naphthalene disulfonic acid and tartaric acid, and an anti-rusting agent is added in the rubber-asphalt anticorrosive coating material and is prepared from one or more of zinc phosphate, modified zinc phosphate and zinc molybdate, a surfactant, a wetting agent, a dispersing agent and deionized water. According to the anticorrosive material for the metallic equipment and the preparation and construction methods thereof, the anti-rusting agent is innovatively added in the anticorrosive material for the metallic equipment, so that the anticorrosive material for the metallic equipment, prepared by using the anti-rusting agent, has more excellent corrosion resistance while guaranteeing environmental friendliness; meanwhile, the weather resistance is very excellent, and the service life of the metallic equipment is greatly prolonged; the organic acid type curing agent, of which the corrosiveness to metal can be neglected, is used innovatively, and the required curing performance can be effectively guaranteed by the organic acid type curing agent.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

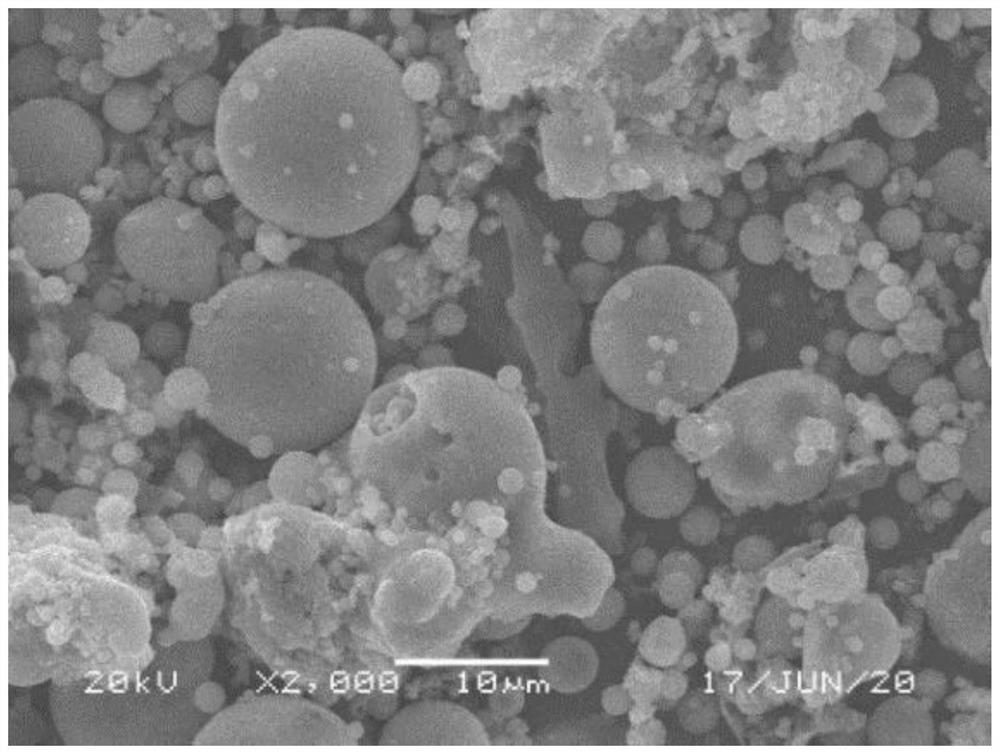

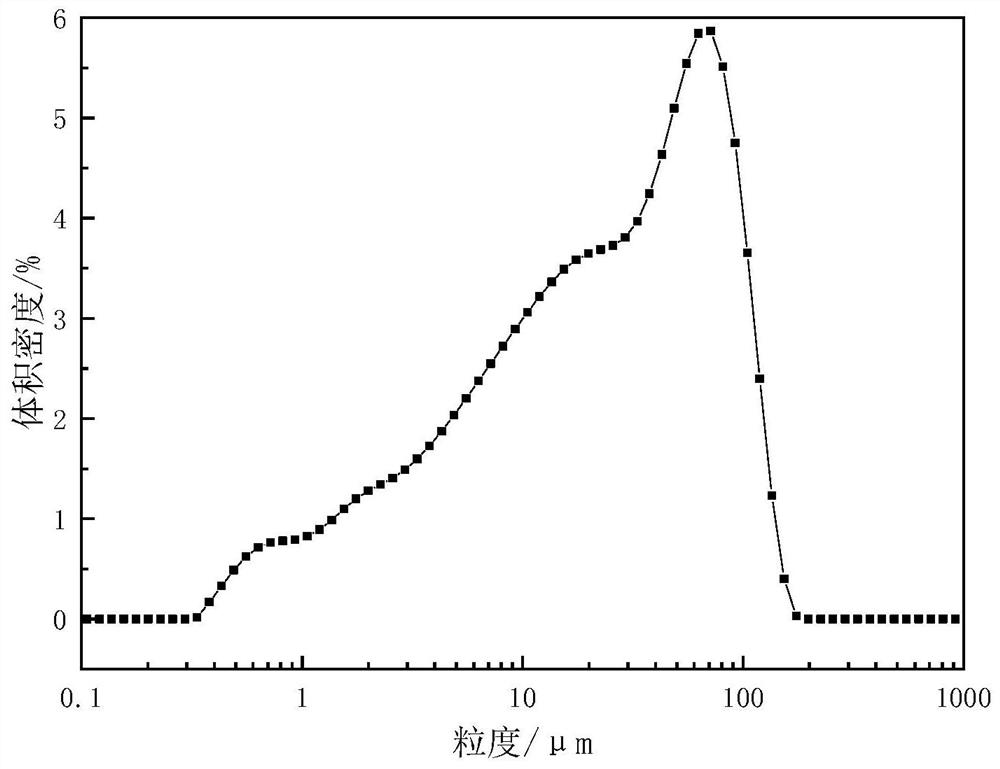

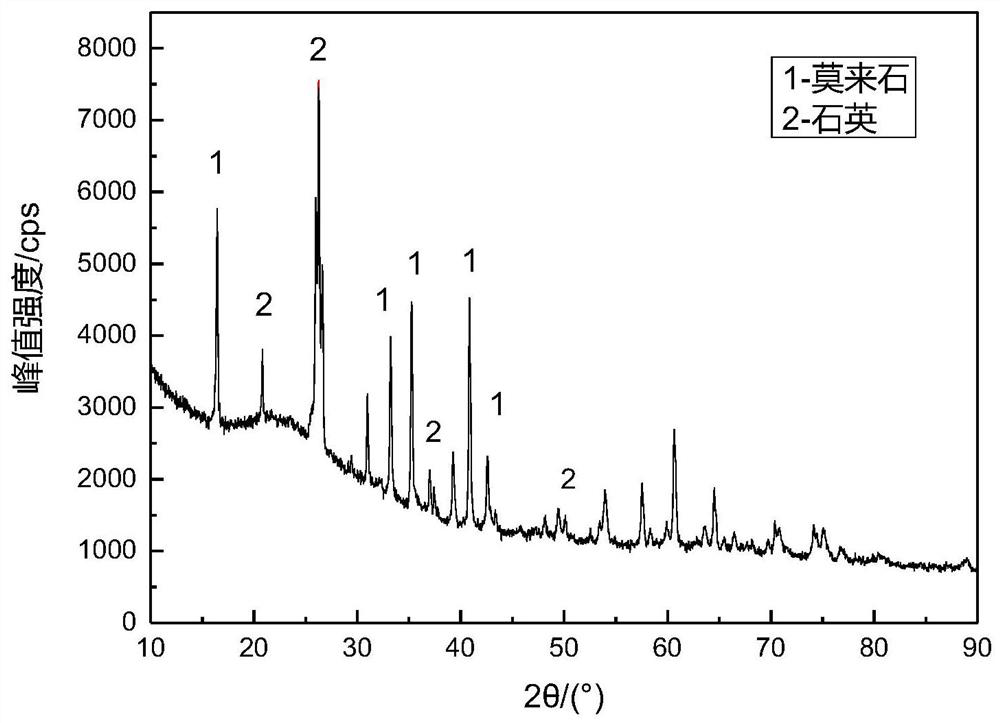

Preparation method and application of slag-fly ash geopolymer

The invention discloses a preparation method and application of a slag-fly ash geopolymer, and the preparation method comprises the following steps: (a) using sodium silicate, sodium hydroxide solid and water to prepare an alkali activator through magnetic stirring, and conducting sealing and standing; (b) grinding and sieving the furnace slag, and uniformly stirring the ground furnace slag and low-calcium fly ash, stirring and mixing the slag and low-calcium fly ash mixture and an alkali activator to prepare slurry; (c) uniformly smearing Vaseline in a triple mold, injecting the slurry in three times, and after filling is completed, performing strickling and vibration treatment to prepare a prototype sample; and (d) sealing the prototype sample with a preservative film, conducting curing at normal temperature, and conducting demolding to obtain a finished product. The preparation method is simple in process and low in production cost, and the effect of treating waste with waste is achieved; and meanwhile, the prepared geopolymer has the characteristics of high compressive strength and good curing and repairing effect on heavy metal polluted soil, and is beneficial to solving the problem of heavy metal pollution of the soil.

Owner:绍兴越创岩土科技有限公司

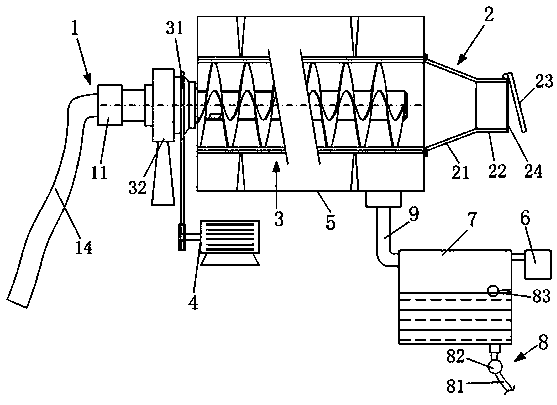

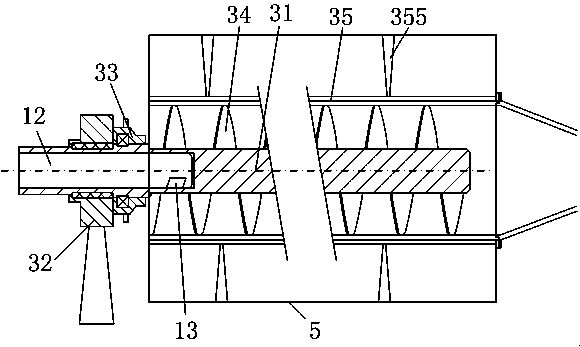

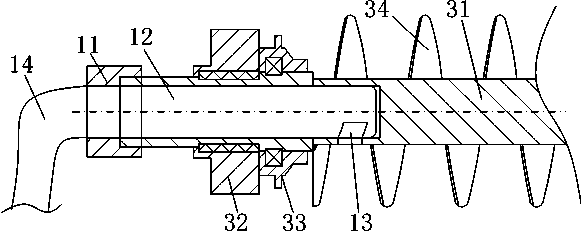

Vacuum suction-type screw-extrusion solid-liquid separation system

ActiveCN103641289AReduce processing timeSave time and costSludge treatment by de-watering/drying/thickeningSuction forceSlag

The invention discloses a vacuum suction-type screw-extrusion solid-liquid separation system. The vacuum suction-type screw-extrusion solid-liquid separation system comprises a screw extruding mechanism, a driving mechanism, a sealing box body, a vacuumizing machine, an airtight water tank and a continuous liquid discharging mechanism, wherein the screw extruding mechanism is connected with a continuous feeding mechanism and a continuous solid discharging mechanism, the driving mechanism is used for providing the rotation power, the screw extruding mechanism is sealed inside the sealing box body, the vacuumizing machine is communicated with the sealing box body through a pipeline and used for providing vacuum suction force to the vacuum suction-type screw-extrusion solid-liquid separation system, the airtight water tank is connected onto a pipeline between the sealing box body and the vacuumizing machine and used for collecting the liquid discharged from the screw extruding mechanism, and the continuous liquid discharging mechanism is arranged on the airtight water tank. By utilizing the integral vacuum suction principle, the vacuumizing machine which is arranged at the rear end is used for providing the vacuum suction force to the entire internal space, the reliability is high, the flow is optimized, the continuous suction function, the continuous solid / slag discharging function and the continuous liquid discharging function can be realized, the sewage waste treatment time is effectively saved, and the time cost and the labor cost can be greatly saved.

Owner:CHENGDU XINCHAOSHUN ENVIRONMENTAL TECH

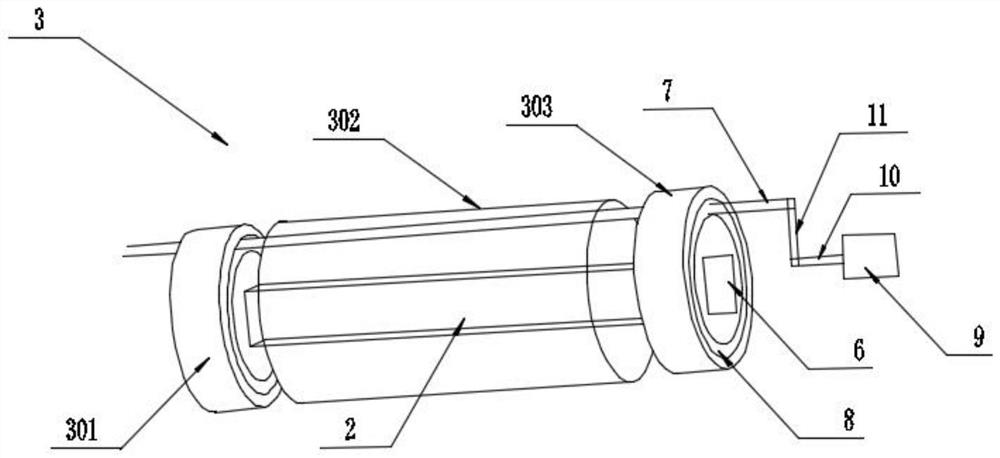

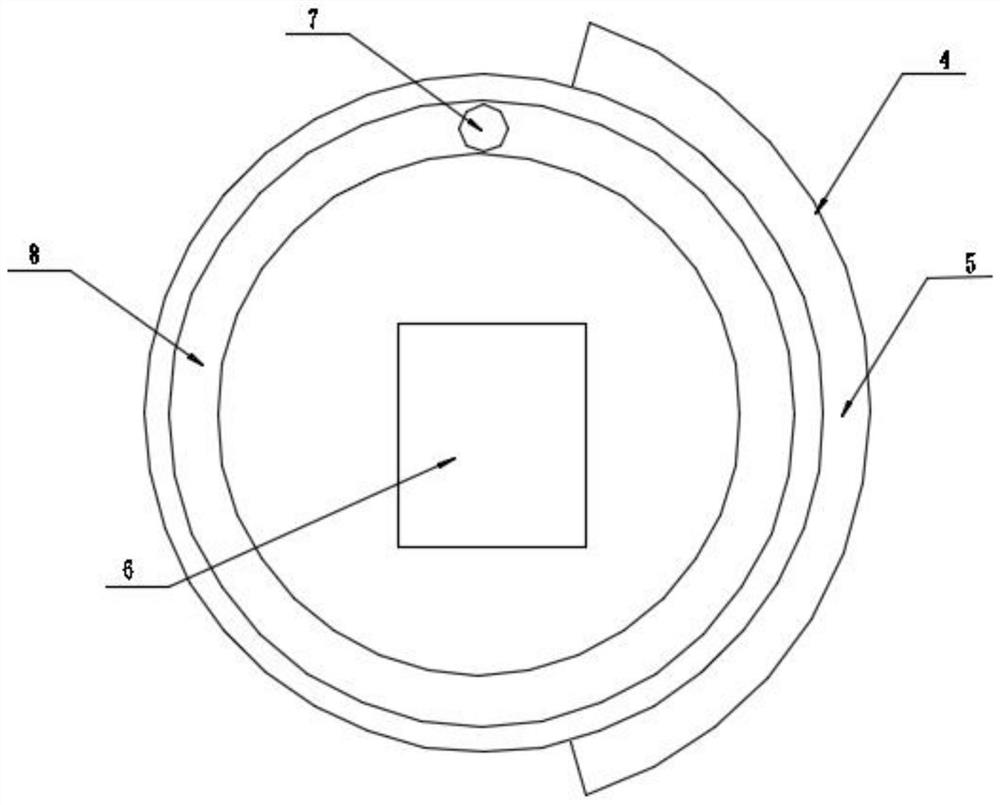

An enamelled wire and a production process thereof

InactiveCN109065260AGuaranteed environmental protectionGuaranteed curing effectPolyurea/polyurethane coatingsInsulating conductors/cablesEnvironmental resistanceEmulsion

The invention discloses an enameled wire and a production process thereof, includes the following steps: S1, preparing a blank, S2, medium drawing, S3, Cleaning, S4, medium and small wire drawing, S5,annealing, S6, Cooling, S7, painted, S8, Lubrication, S9, take-up, The invention provides an enameled wire and a production process thereof. The enameled wire and the production process thereof can prepare an insulating paint by combining a sleeping polyester resin emulsion with an additive, which can ensure environmental protection characteristics and at the same time can ensure curing effect, avoid falling off, improve corrosion resistance, reduce corona phenomenon, ensure service life and reduce production and use cost by improving the treatment process.

Owner:瑞安市中德电工器材有限公司

Carbonatite oil well density selectivity water shutoff agent and preparation process thereof

A density-selective water shutoff agent for carbonate rock oil wells, its component formula is by weight, 100 parts of cement, 60-75 parts of fly ash, 50-58 parts of clay, 52-62 parts of micro silicon, early strength 5-8 parts of agent, 16-28 parts of fluid loss reducer, and 1100-1200 parts of water. A preparation process of density-selective water shutoff agent for carbonate rock oil wells. The fluid loss reducer and early strength agent are weighed according to the above-mentioned formula quantity, dissolved in the water of the formula quantity, and then cement and fly ash are added into the formula quantity , Clay, and micro-silicon are fully dissolved to obtain the product. The beneficial effects of the density-selective water shutoff agent for carbonate rock oil wells provided by the present invention are: it is easy to stay between the oil-water interface, and a water shutoff partition is established; the curing effect is guaranteed; the injection is safe and the radius of water shutoff is expanded; High compressive strength; easy to prepare, good injectability, simple construction process and high construction efficiency.

Owner:XINJIANG HUAYOU TECH SERVICE

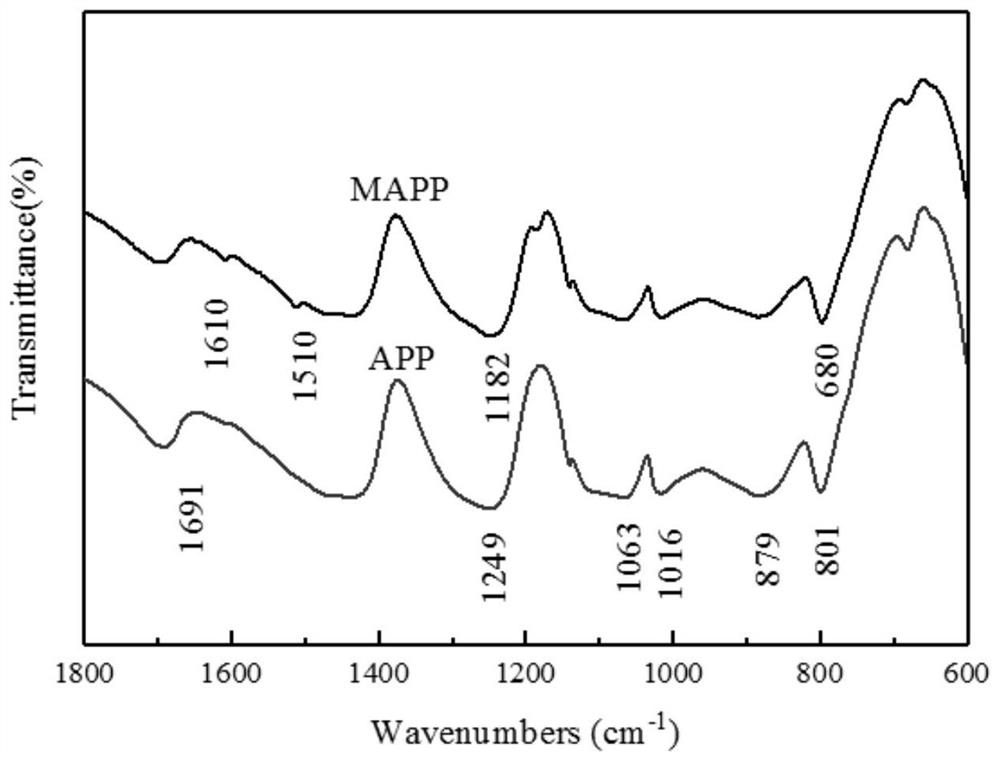

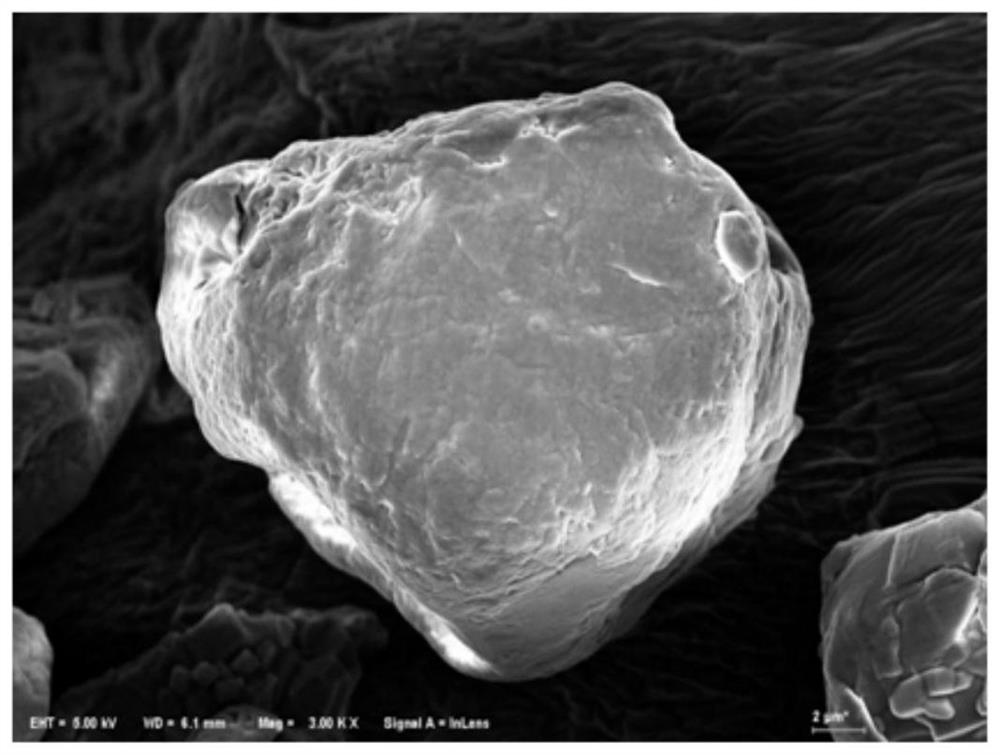

Method for preparing flame-retardant polypropylene by in-situ coating of modified ammonium polyphosphate

PendingCN111704769AFully curedEnsure uniformity of dispersionMicroballoon preparationMicrocapsule preparationEpoxyPolymer science

The invention relates to a method for preparing flame-retardant polypropylene by in-situ coating of modified ammonium polyphosphate. The method comprises the following steps: taking epoxy resin as a wall material and ammonium polyphosphate as a core material; carrying out in-situ polymerization in a step heating mode to obtain epoxy resin coated ammonium polyphosphate microcapsules, compounding the epoxy resin coated ammonium polyphosphate microcapsules with pentaerythritol and other carbon sources to obtain an intumescent flame retardant, and finally mixing and molding polypropylene and the flame retardant to obtain the flame-retardant polypropylene product with excellent properties. Experiments show that the prepared ammonium polyphosphate microcapsules are more completely cured, the flame retardant property and charring performance of the final polypropylene product are greatly improved, and the dripping phenomenon is prevented.

Owner:WUHAN UNIV OF TECH

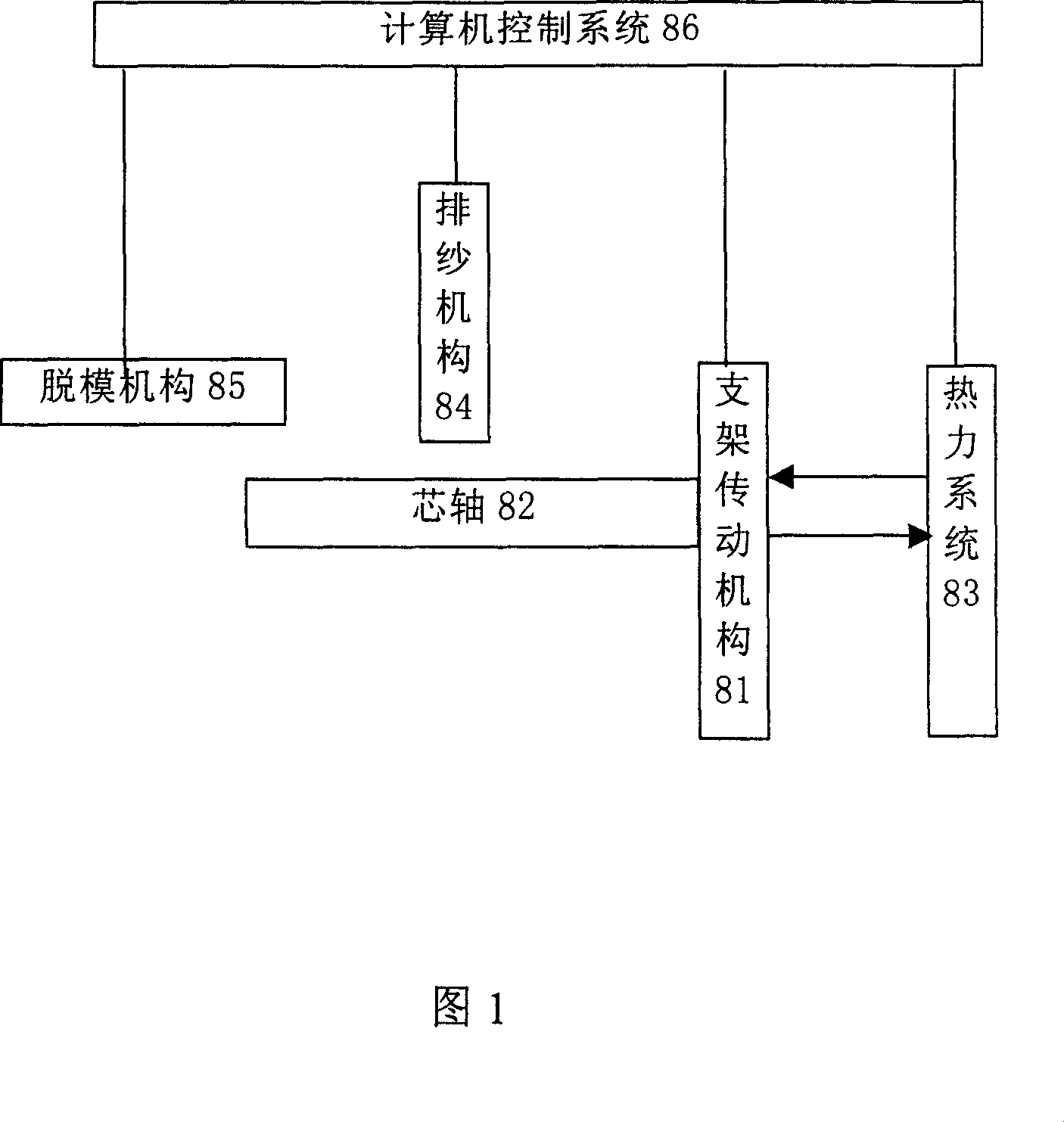

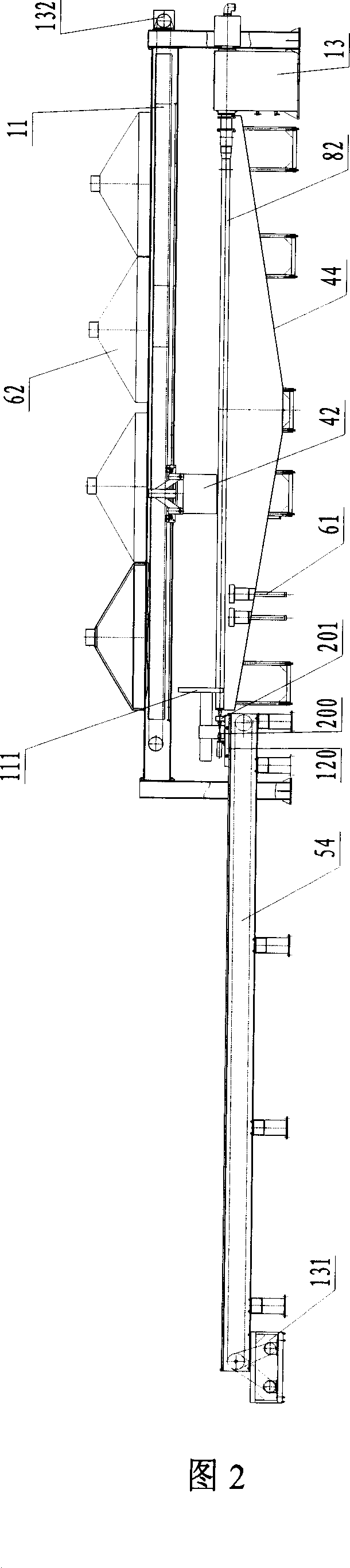

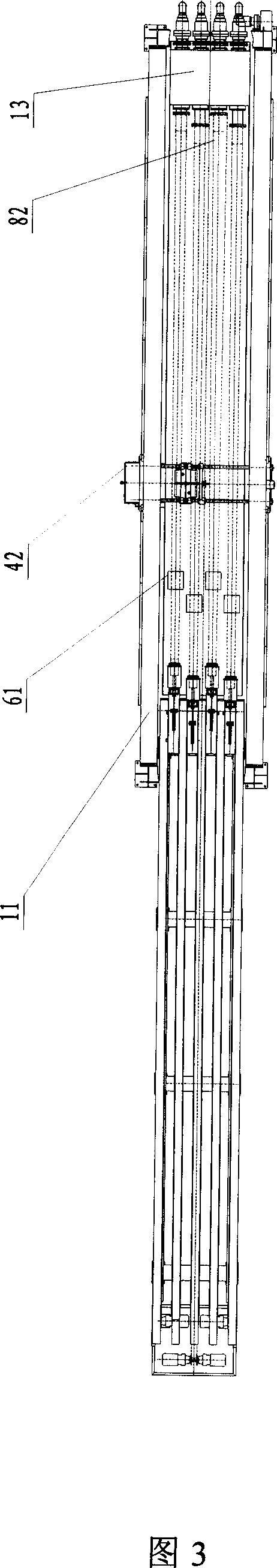

Producing system of internally-heating curing glass fibre reinforced plastic controlled by programm

InactiveCN1982037AImprove product qualityIncrease productivityProgramme controlComputer controlYarnGlass fiber

A program controlled system with internal heating and solidifying for preparing the glass fiber reinforced plastic pipe is composed of a supporting frame-drive mechanism, a dual-layer metallic mandrel for delivering high-temp steam, a steam system, a yarn arranging system, a demoulding unit and computer control system.

Owner:北京朗瑞达管道技术有限公司

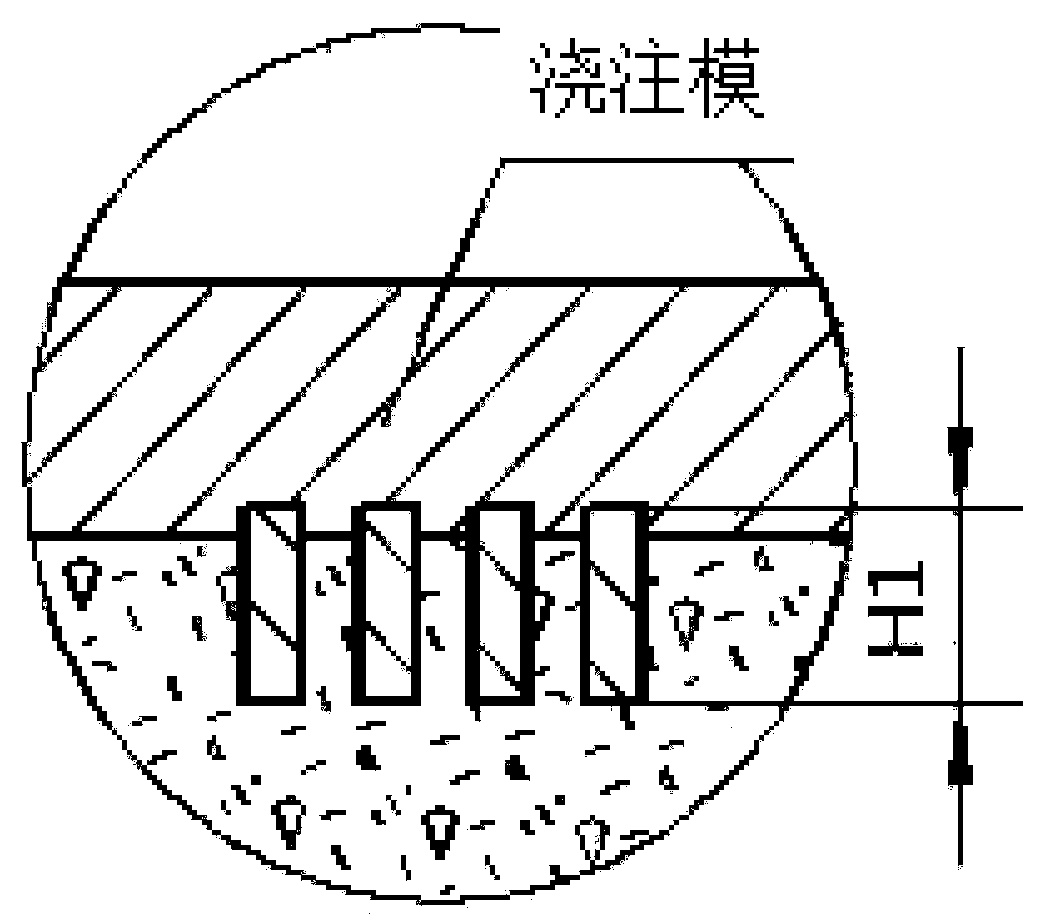

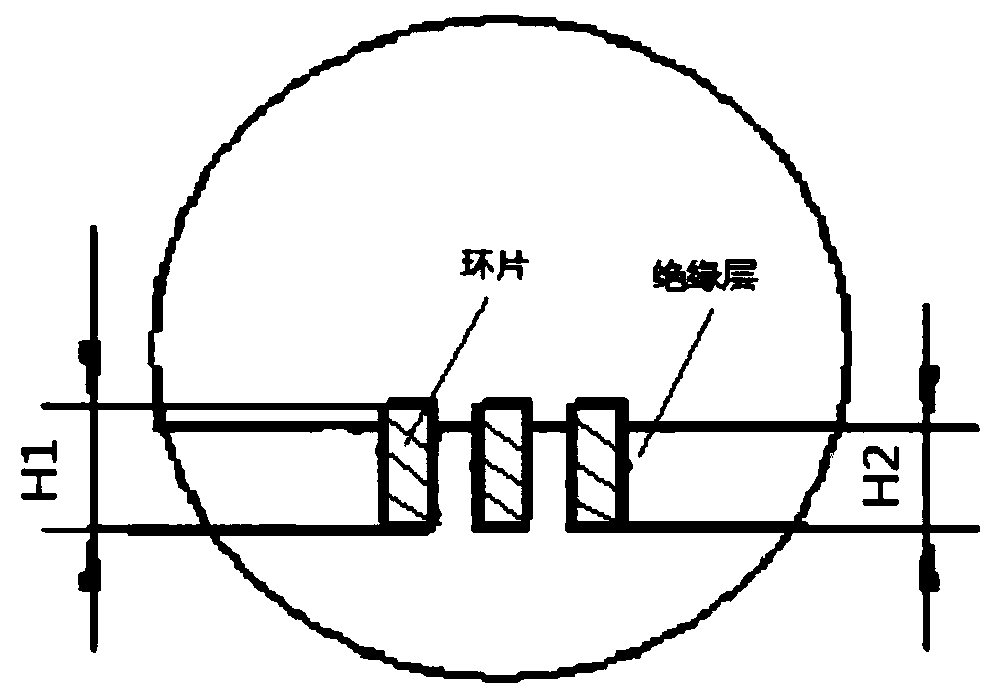

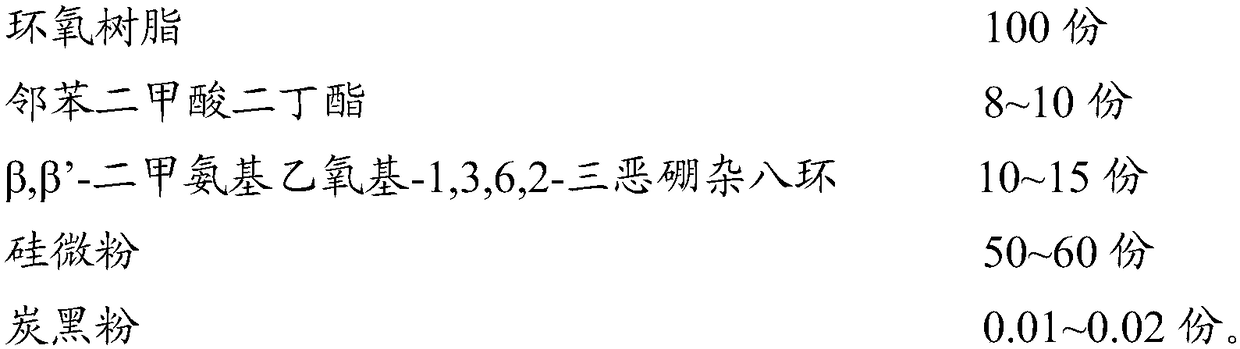

Glue for pouring conductive sliding ring body, conductive sliding ring body and pouring method thereof

InactiveCN108373582AIncreased compressive strength and insulation resistanceImprove insulation performanceDomestic articlesInsulation resistanceCarbon black

The invention provides glue for pouring a conductive sliding ring body. The glue is prepared from the following components: 100 parts of epoxy resin, 8 to 10 parts of dibutyl phthalate, 10 to 15 partsof beta,beta'-dimethylaminoethoxy-1,3,6,2-trioxaborocane, 50 to 60 parts of silicon micro-powder and 0.01 to 0.02 part of carbon black powder. According to the glue for pouring the conductive slidingring body, provided by the invention, the insulating resistance and compressive strength of the conductive sliding ring body are effectively improved. The invention further provides a pouring methodof the conductive sliding ring body; the pouring method is simple to operate and has strong operability.

Owner:张洁琦

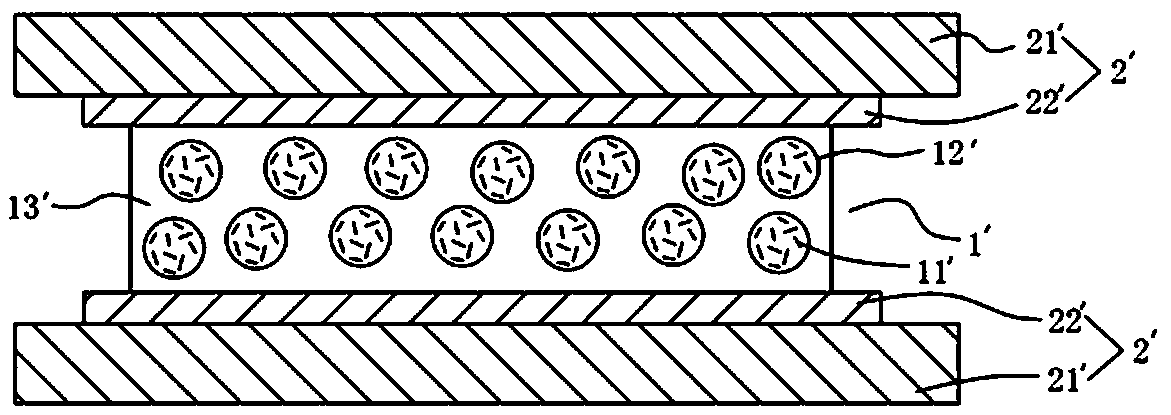

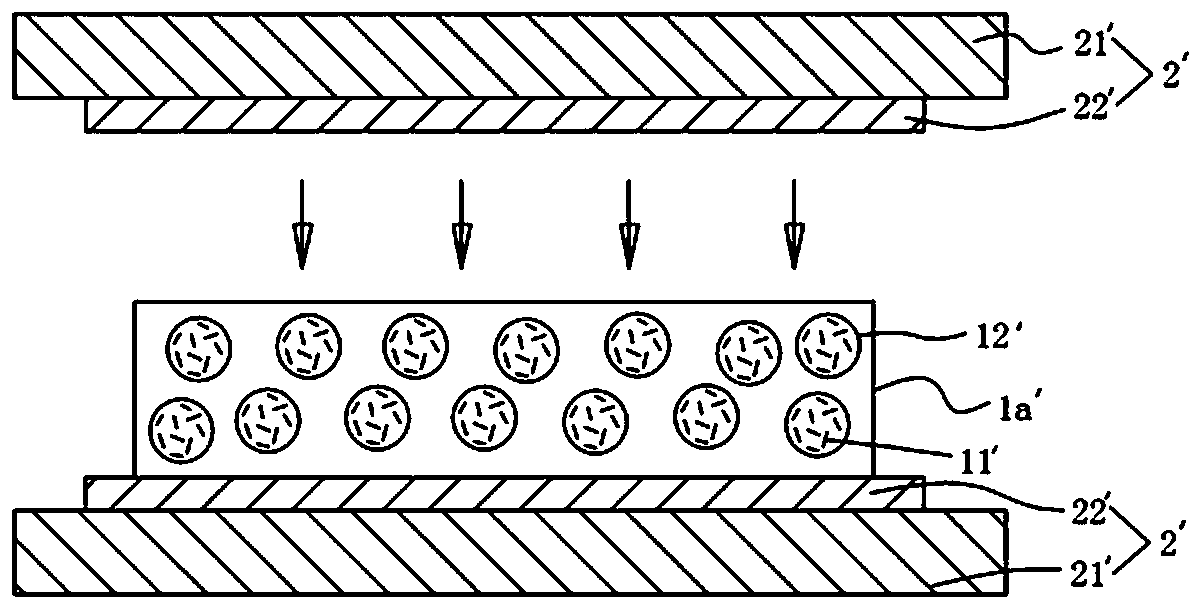

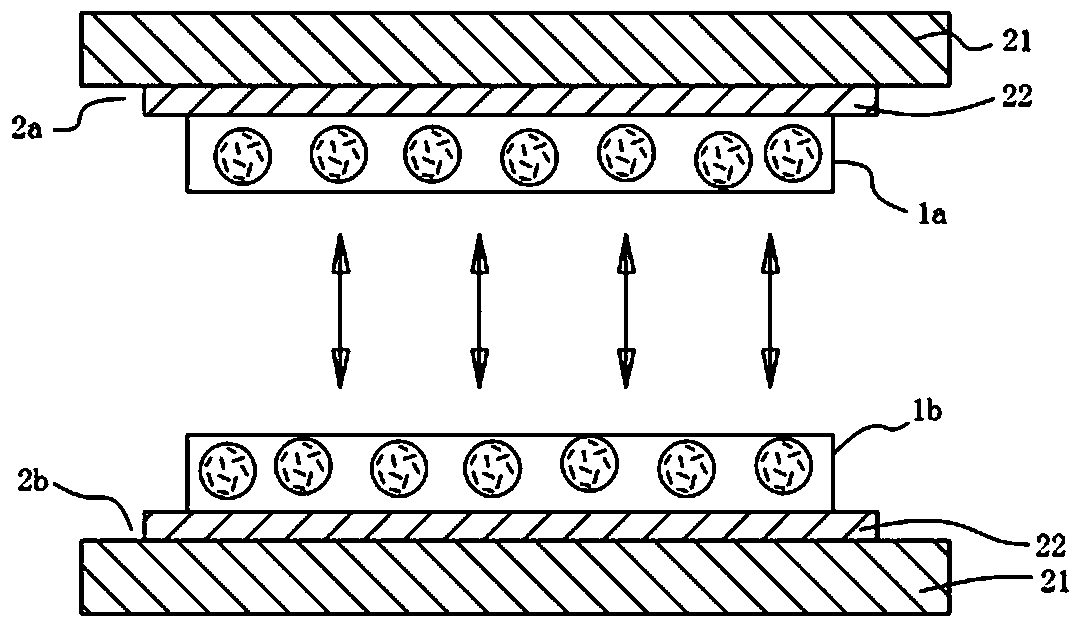

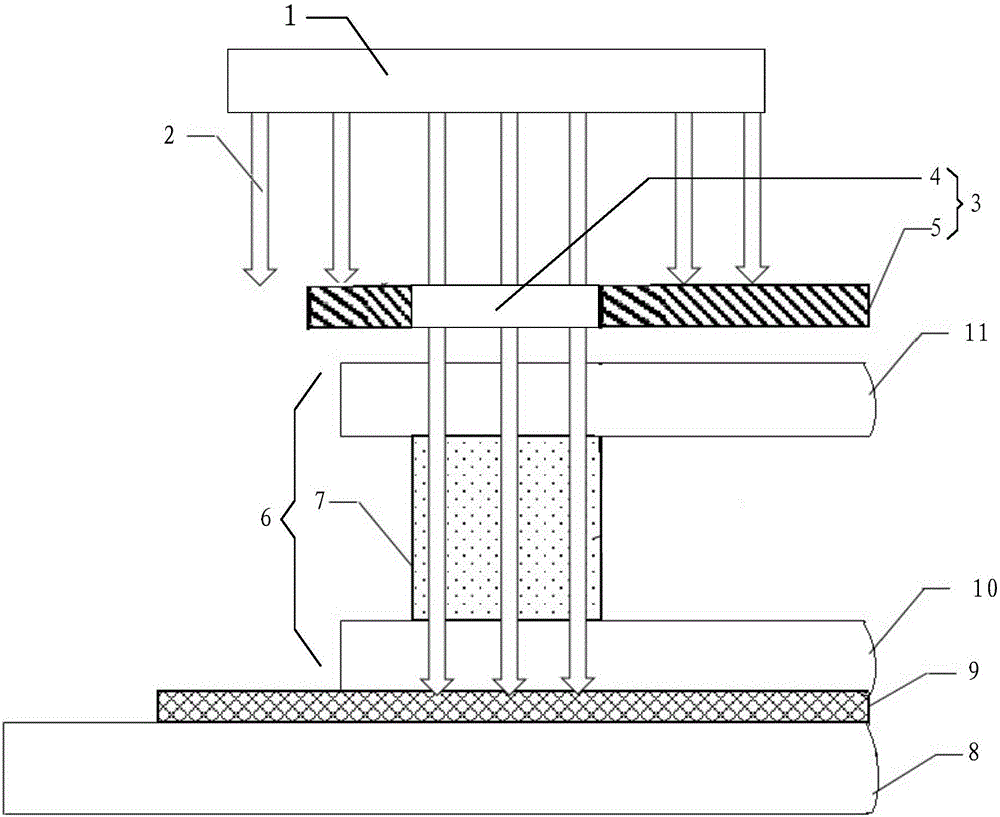

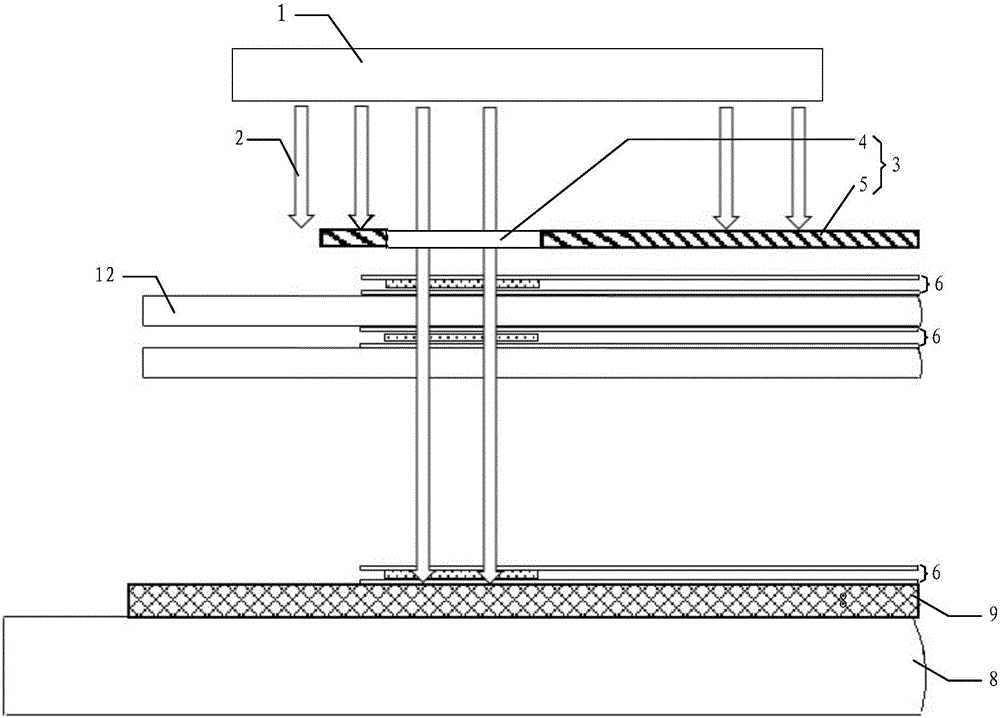

Preparation method of suspended particle controllable light valve

InactiveCN109856884AImprove curing effectGuaranteed curing effectNon-linear opticsSuspended particlesEmulsion

The invention discloses a preparation method of a suspended particle controllable light valve. The light valve comprises an upper transparent electrode and a lower transparent electrode. The light valve matrix emulsion containing a polymerization precursor PPM, a suspension medium SM, light-controlled particles LCP and a photoinitiator PI is divided into two parts which are applied to the inner sides of the two transparent electrodes to form light valve matrix emulsion layers. The light valve matrix emulsion layers on the two transparent electrodes are solidified by ultraviolet UV radiation toform an upper light-controlled layer and a lower light-controlled layer. The upper transparent electrode and the upper light-controlled layer constitute an upper stacking assembly. The lower transparent electrode and the lower light-controlled layer constitute a lower stacking assembly. The upper and lower stacking assemblies are laminated together in a face-to-face manner through the upper and lower light-controlled layers to obtain a complete light control layer. The technical method of the invention reduces the thickness of the light valve matrix emulsion layer on each side to half and increases the penetration performance of UV exponentially. The curing effect of the light valve matrix can be improved, and the dark light transmittance of the light valve is reduced. Moreover, the dosage of photoinitiator in the light valve matrix emulsion can be reduced.

Owner:ZHEJIANG JINGYI NEW MATERIAL TECH CO LTD

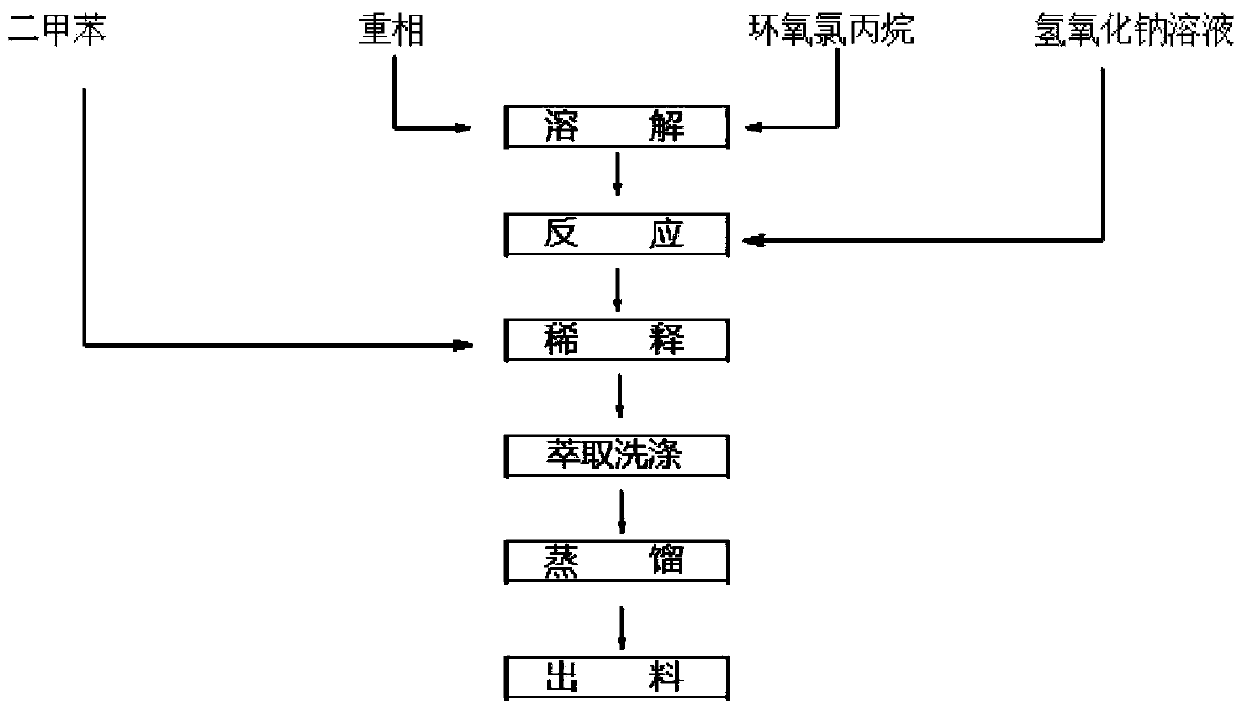

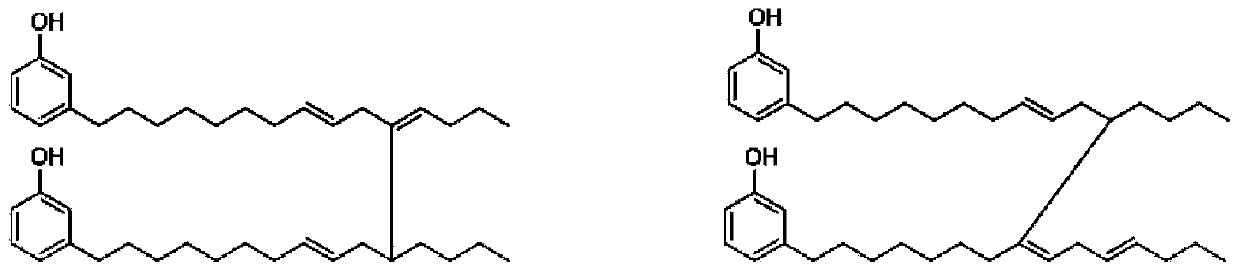

Method for preparing epoxy resin by heavy-phase materials in cardanol production

The invention relates to a method for preparing epoxy resin by heavy-phase materials in cardanol production. The method includes weighing substances according to mass that a molar ratio, among the cardanol heavy-phase materials, epichlorohydrin and alkali, is 1:1-10:1-10, then adding the cardanol heavy-phase materials into a reaction vessel, stirring, feeding in nitrogen and exhausting air, adding the epichlorohydrin after 1-5 minutes, continuing stirring, controlling the temperature within a range of 40-50 DEG C, adding an alkali solution, finishing dropwise adding prior to increasing the temperature to 70-100 DEG C, keeping the temperature for 2-9 hours, adding organic solvent for dissolution prior to washing with hot water, and performing reduced pressure distillation to obtain black oily liquid, namely a prepared product. The epoxy resin obtained through the method is 0.10-0.35eq / 100g in epoxy value, good in curing performance and convenient to use.

Owner:上海美东生物材料股份有限公司

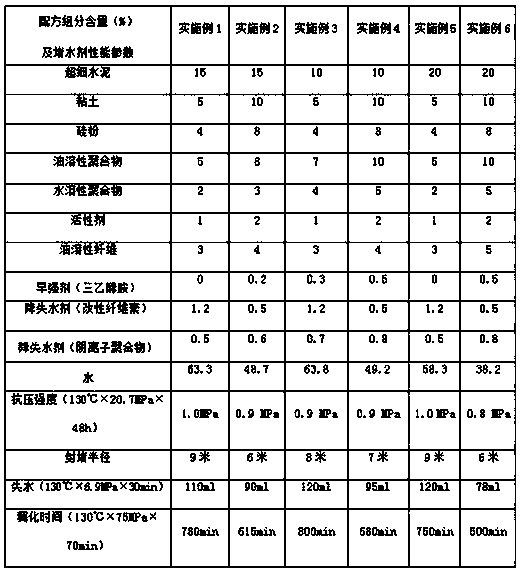

Large-pore-path plugging compound water shutoff agent for sandstone reservoir and preparation method of large-pore-path plugging compound water shutoff agent

InactiveCN108147730AImprove stabilityGuaranteed curing effectDrilling compositionMicrofine cementFiber

The invention provides a large-pore-path plugging compound water shutoff agent for a sandstone reservoir. The large-pore-path plugging compound water shutoff agent comprises the following components by mass percent: 10-20% of superfine cement, 5-10% of clay, 4-8% of silica powder, 0-0.5% of an early strength agent, 1-2% of a fluid loss agent, 5-10% of an oil-soluble polymer, 3-5% of oil-soluble fibers, 2-5% of a water-soluble polymer, 1-2% of an active agent and 35-70% of water, wherein the total mass percent of the components is 100%. The invention further provides a preparation method of thelarge-pore-path plugging compound water shutoff agent. The large-pore-path plugging compound water shutoff agent for the sandstone reservoir has the following beneficial effects: the strength is high, the erosion resisting effect is excellent, and the construction effect is guaranteed; the components can be appropriately adjusted to adapt to different well conditions; safe injection is ensured, and the water plugging radius is increased; and the preparation is easy, the pump injection performance is favorable, the construction process is simple and the construction efficiency is high.

Owner:XINJIANG HUAYOU TECH SERVICE

Processing technology of special self-adhesive enameled wire for household motor and device

ActiveCN110310782AImprove processing stabilityGood coating effectInsulating conductors/cablesCopper wireSelf adhesive

The invention discloses a processing technology of a special self-adhesive enameled wire for a household motor and a device. The processing technology comprises the steps of softening a copper bare wire through an annealing oven to obtain a copper wire A; sensing the copper wire A into a drying furnace for drying to obtain a copper wire B; coating the surface of the copper wire B with primer, sending the copper wire B into a first enamelling furnace, and drying the copper wire B for the first time in different temperature environments through the first enamelling furnace to obtain an enameledwire C; coating the surface of the enameled wire C with finish paint, then sending the enameled wire C into a second enamelling furnace, and drying the enameled wire C for the second time in differenttemperature environments through the second enamelling furnace to obtain an enameled wire D; and winding the enameled wire D to obtain a finished enameled wire. The working stability and the bondingeffect of the self-adhesive paint after being coated can be effectively improved according to the invention.

Owner:浙江郎立电工器材有限公司

Frame sealing adhesive composition, to-be-cure display panel, curing device and display panel

The invention provides a frame sealing adhesive composition, a to-be-cure display panel, a curing device and a display panel and relates to the technical field of display. When the frame sealing adhesive composition is cured, external ultraviolet irradiation can be avoided, and a curing effect is ensured. The frame sealing adhesive composition comprises an adhesive body and further comprises X-ray fluorescent powder doped in the adhesive body. The X-ray fluorescent powder can produce light so as to cure the adhesive body after being exposed to X-ray irradiation. The frame sealing adhesive composition is suitable for manufacturing of the to-be-cure display panel, the curing device and the display panel.

Owner:BOE TECH GRP CO LTD +1

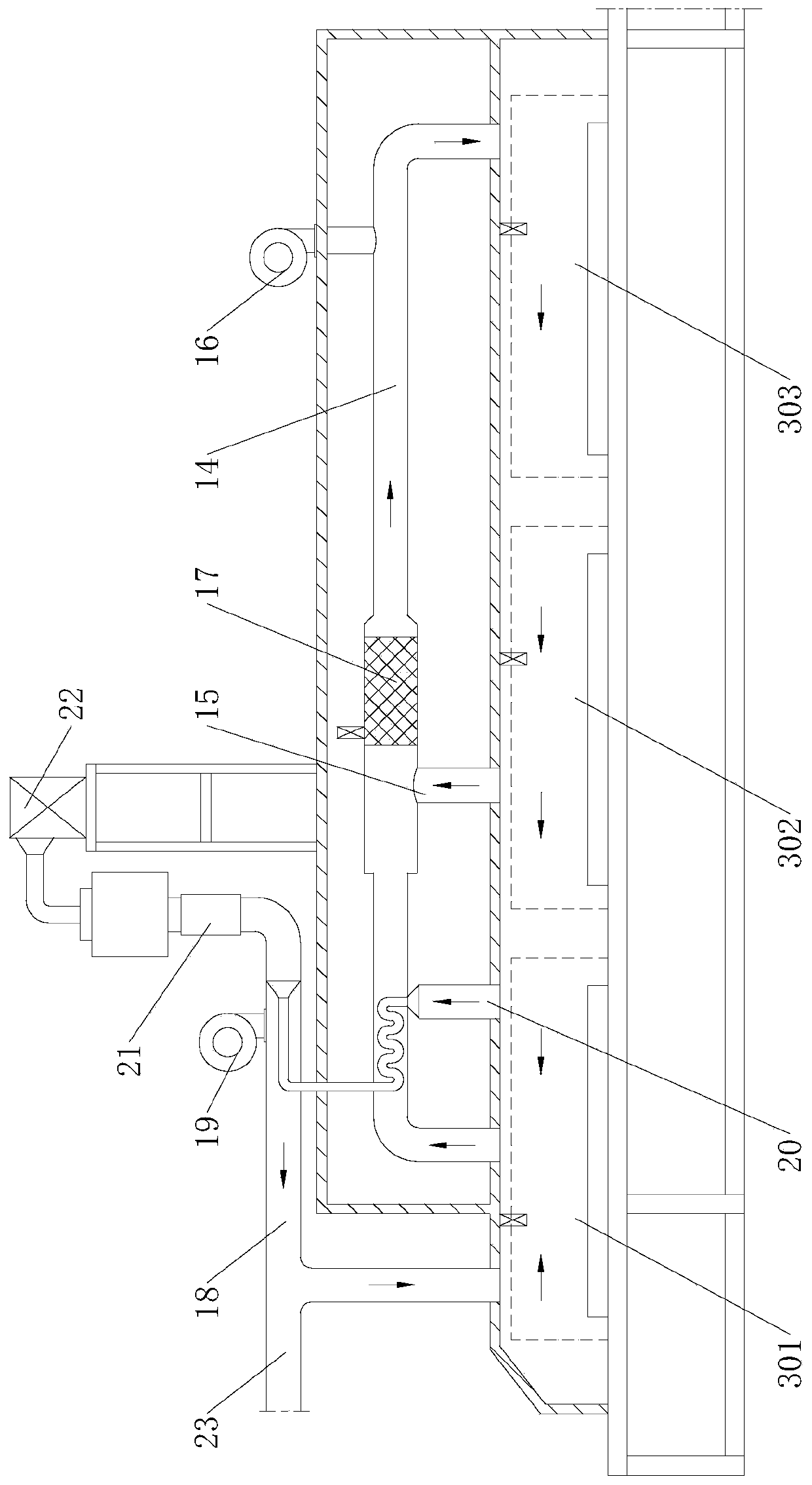

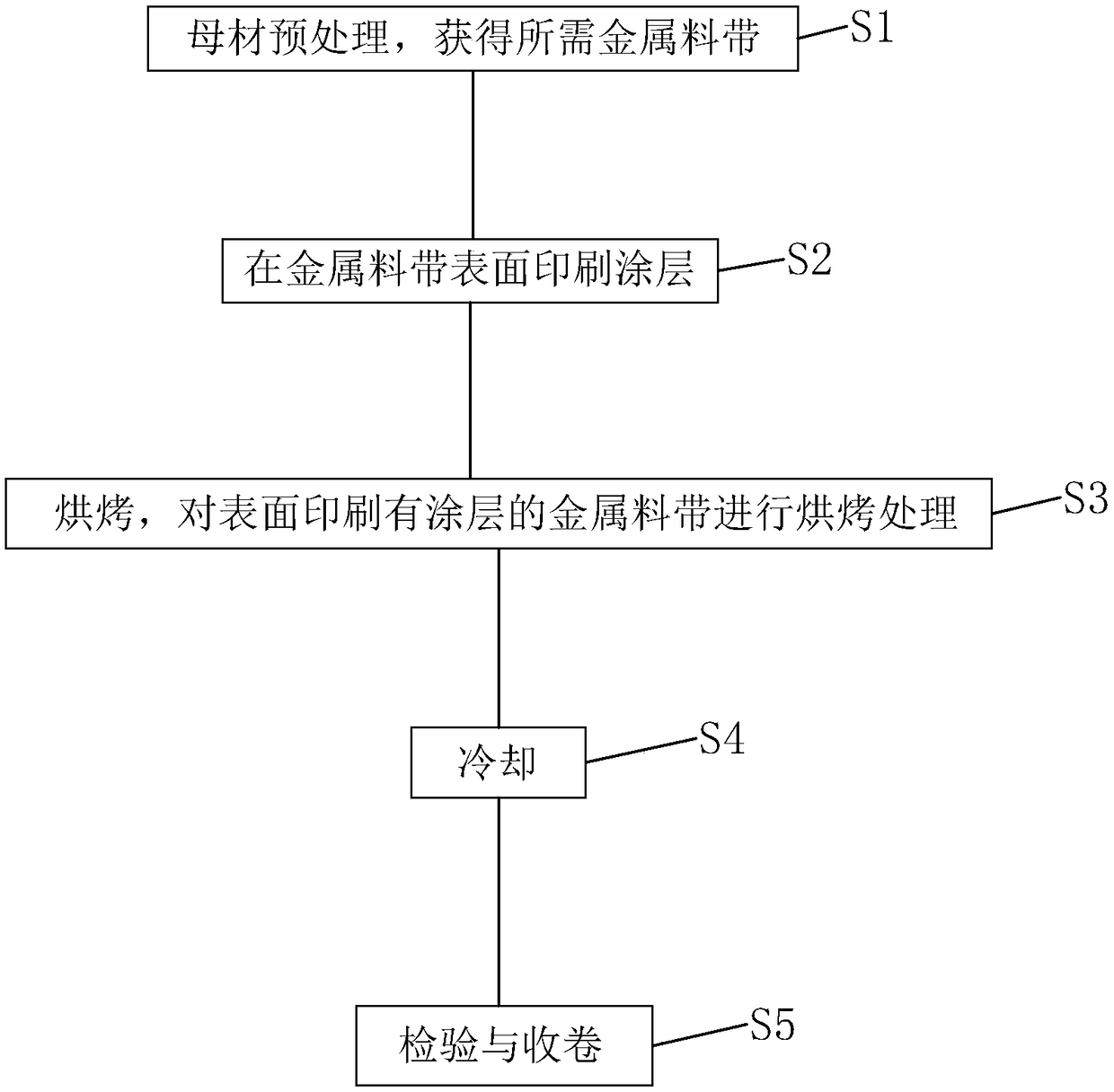

Production process of shielding cover for electronic products

ActiveCN109348697AGuaranteed curing effectReduce the likelihood of disengagementLocalised screeningTemperature differenceElectromagnetic shielding

The invention discloses a production process of a shielding cover for electronic products, and relates to the technical field of electromagnetic shielding. The production process comprises the steps of base metal preprocessing, coating printing, baking, cooling and the like; in the baking process, the baking temperature is 180-220 DEG C and the baking time length is 3-5 min; from the beginning tothe end, the baking process comprises four stages in sequence: a first intermediate temperature stage, a high temperature stage, a second intermediate temperature stage and a secondary high temperature stage; and a baking temperature difference between any two adjacent stages is at least 10 DEG C. The production process of the shielding cover for electronic products is not only capable of improving the using performance of the metal shielding cover and prolonging the service life of the metal shielding cover, but also beneficial for improving the production efficiency and the product outgoingquality.

Owner:上海亿尚金属有限公司 +1

Method, system and device for eliminating influence on photocuring by oxygen and photocuring equipment

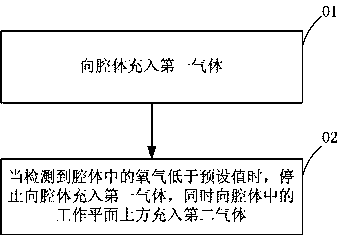

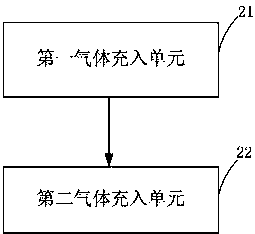

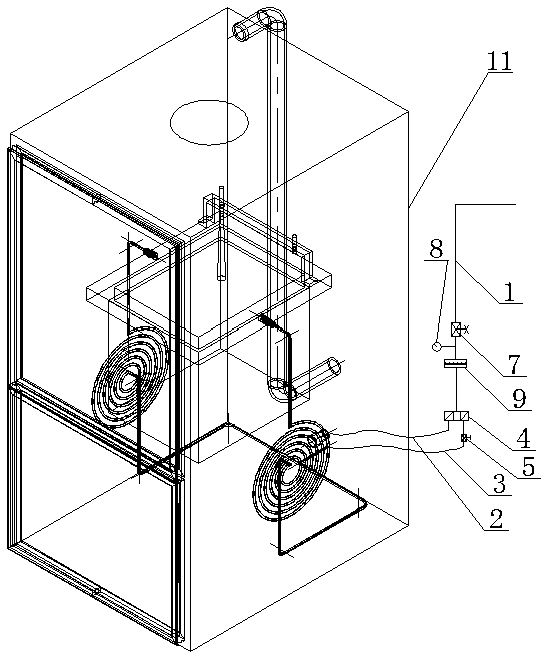

InactiveCN108081597AGuaranteed curing effectTake advantage ofAdditive manufacturing apparatusManufacturing environment conditioningNitrogenEngineering

The invention discloses a method, a system and a device for eliminating influence on photocuring by oxygen and photocuring equipment. The method comprises the following steps: first gas is filled in acavity; when the oxygen in the cavity is detected to be lower than a preset value, the first gas is stopped from filling in the cavity, and meanwhile, second gas is filled above a working plane in the cavity; the first gas and the second gas are both gas capable of eliminating influence on the photocuring reaction process by the oxygen; and the second gas is lower in filling flow value compared with the first gas. In the method, the system and the device for eliminating the influence on photocuring by the oxygen and the photocuring equipment, the oxygen is totally eliminated to the greatest extent through filling of the first gas with higher flow value; and in subsequent working process, the second gas with lower flow value is directly filled above the working plane in the cavity to prevent the oxygen from influencing the surfaces of photosensitive resins, so that the photocuring effect is guaranteed, nitrogen is fully used, and meanwhile, the use level of the nitrogen is saved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

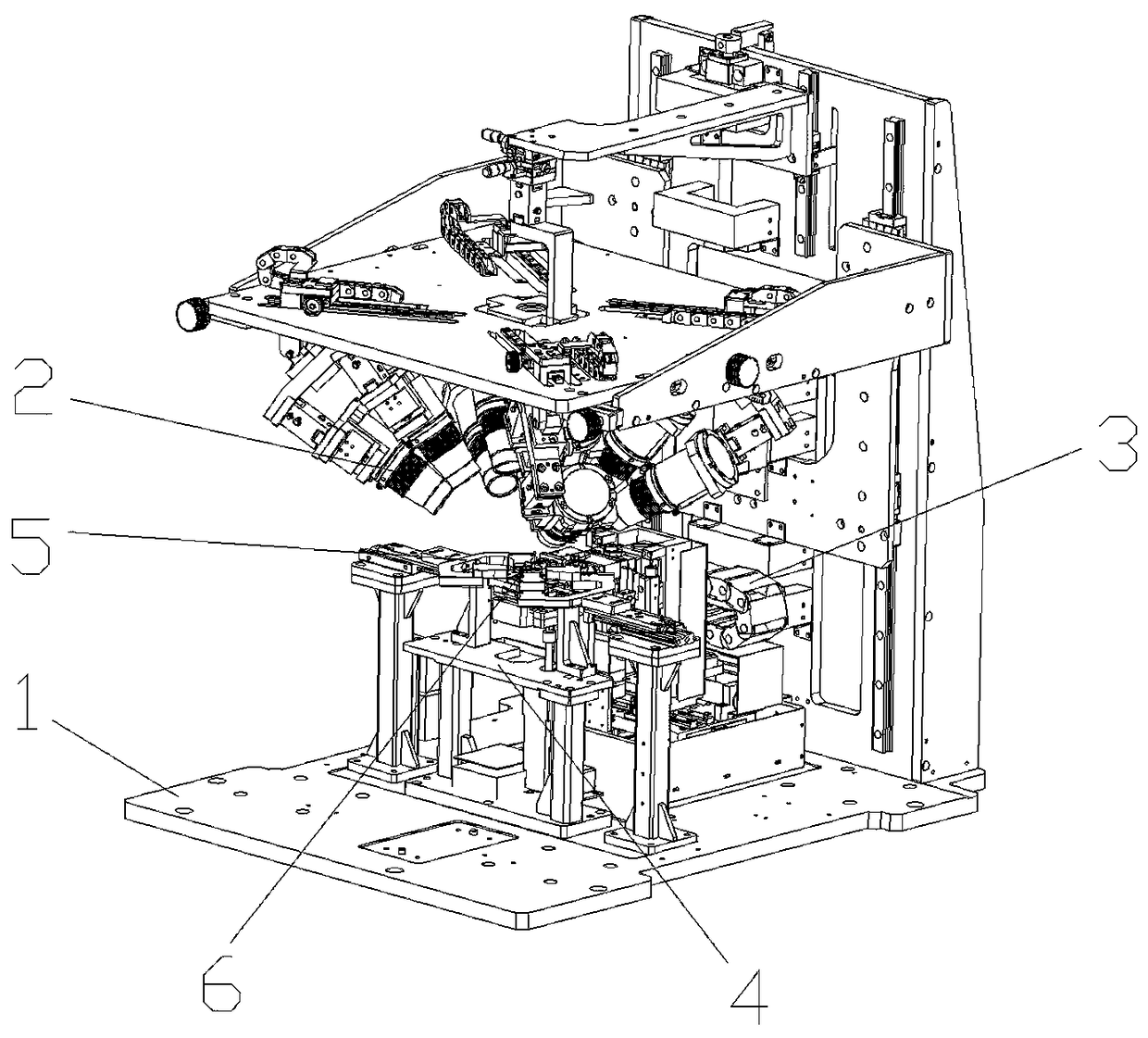

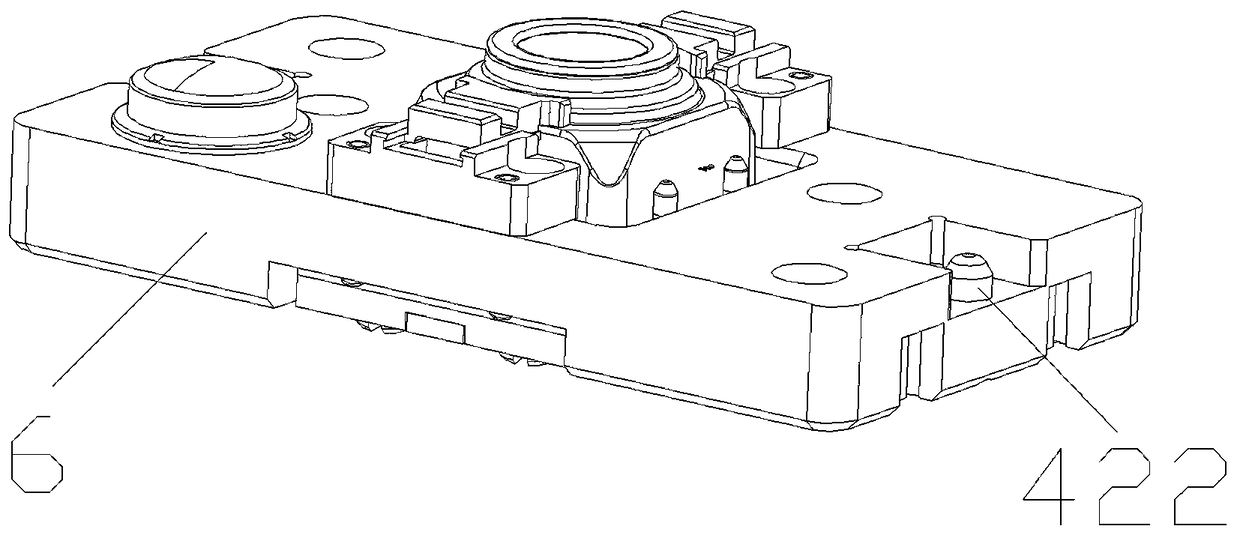

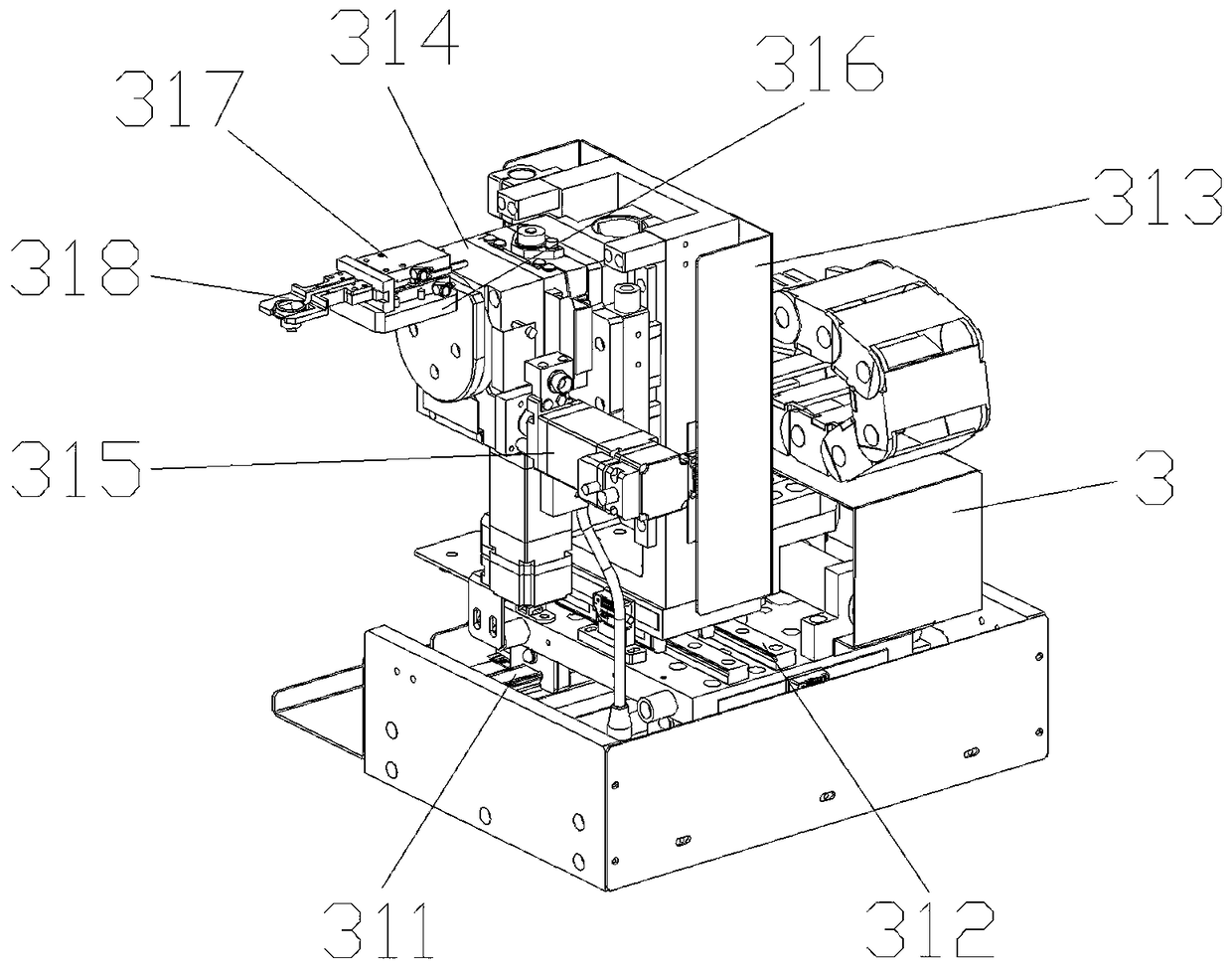

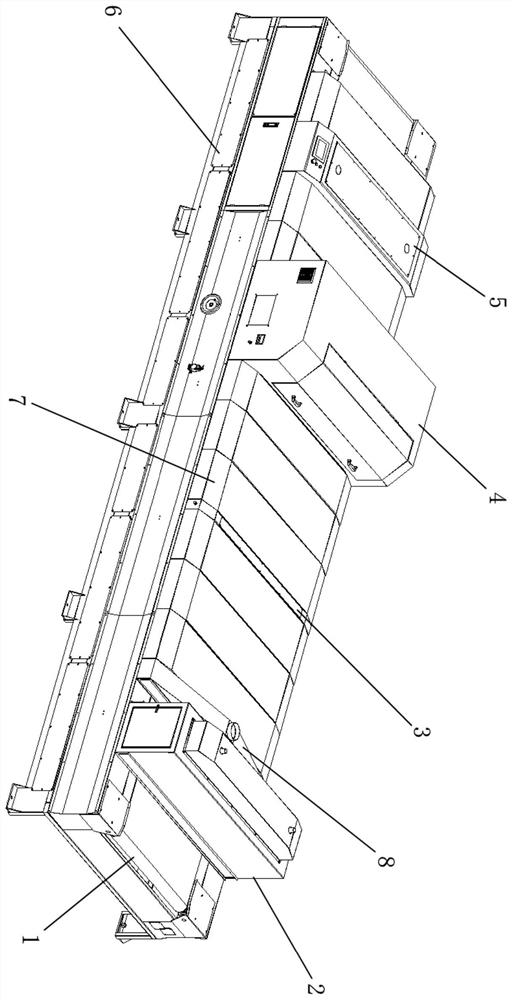

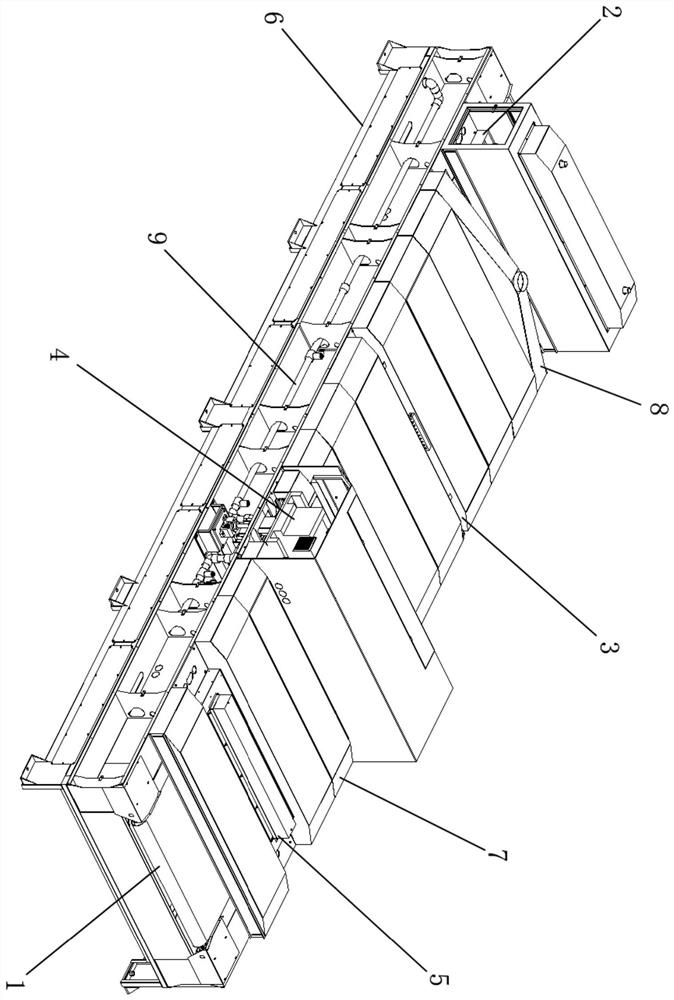

High-definition camera precise focusing platform and focusing method

PendingCN108919456AGuaranteed Alignment AccuracyHigh positioning accuracyMountingsComputer scienceHigh definition

The invention discloses a high-definition camera precise focusing platform and a focusing method, and aims at providing the high-definition camera precise focusing platform and the focusing method, which have excellent solidifying effect of dispensed glue and improve focusing efficiency and focusing precision. The high-definition camera precise focusing platform comprises a mounting plate, and anoptical device adjusting module, a five-axis motion module, a jacking and aligning module and a UV curing module are arranged on the mounting plate; a cooperative product carrier is arranged on the jacking and aligning module; the optical device adjusting module, the five-axis motion module and the UV solidifying module all cooperate with the product carrier; and the optical device adjusting module is located right above the product carrier. The platform and the method provided by the invention are applied to the technical field of camera assembling.

Owner:珠海市运泰利自动化设备有限公司

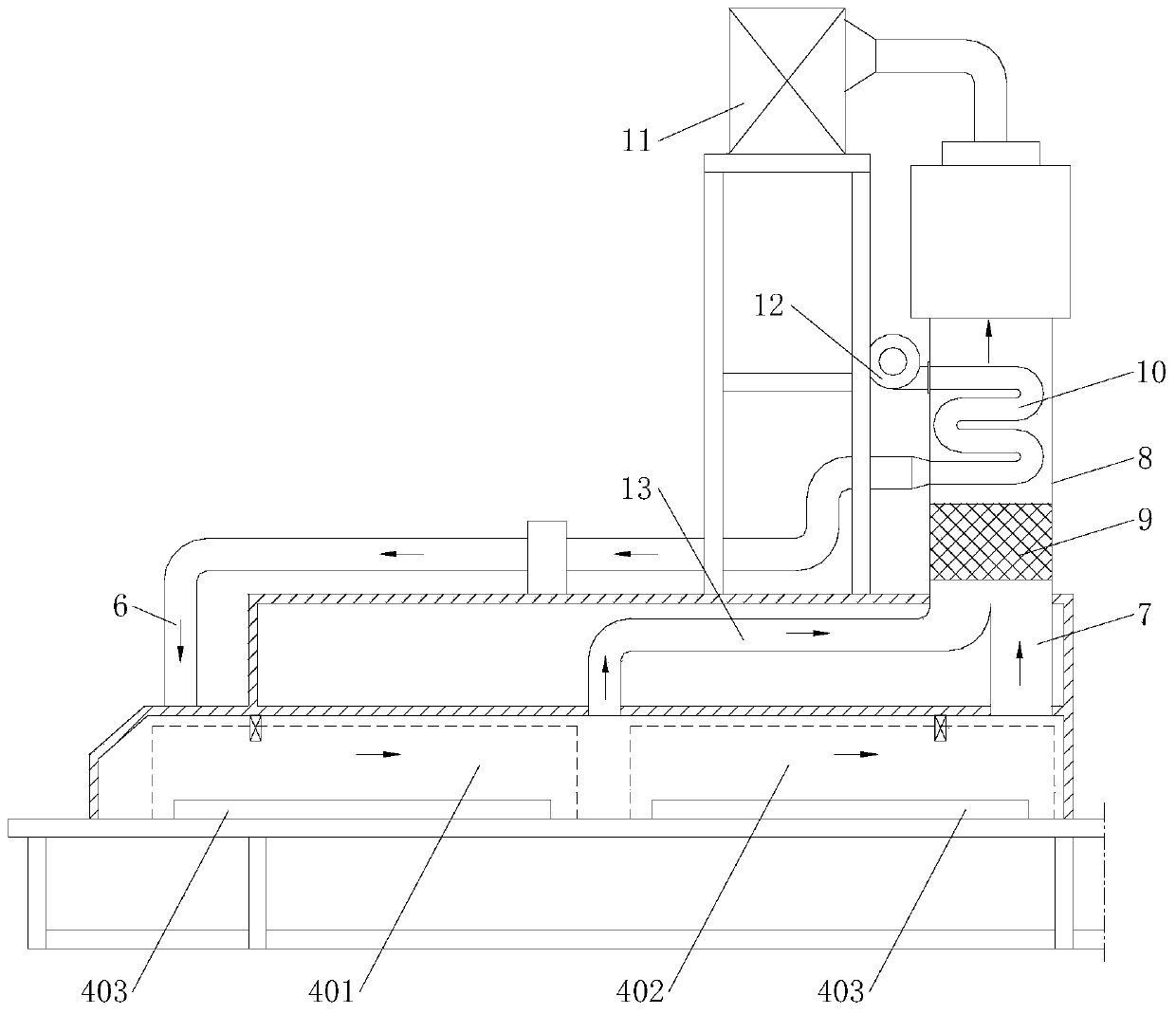

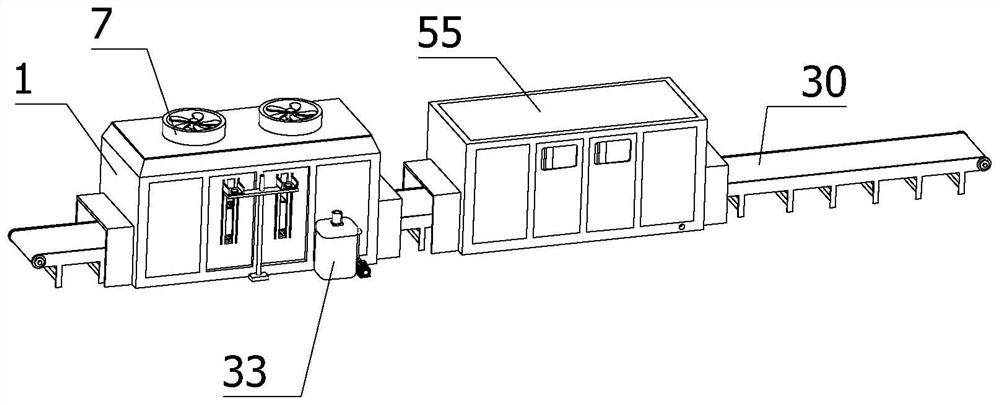

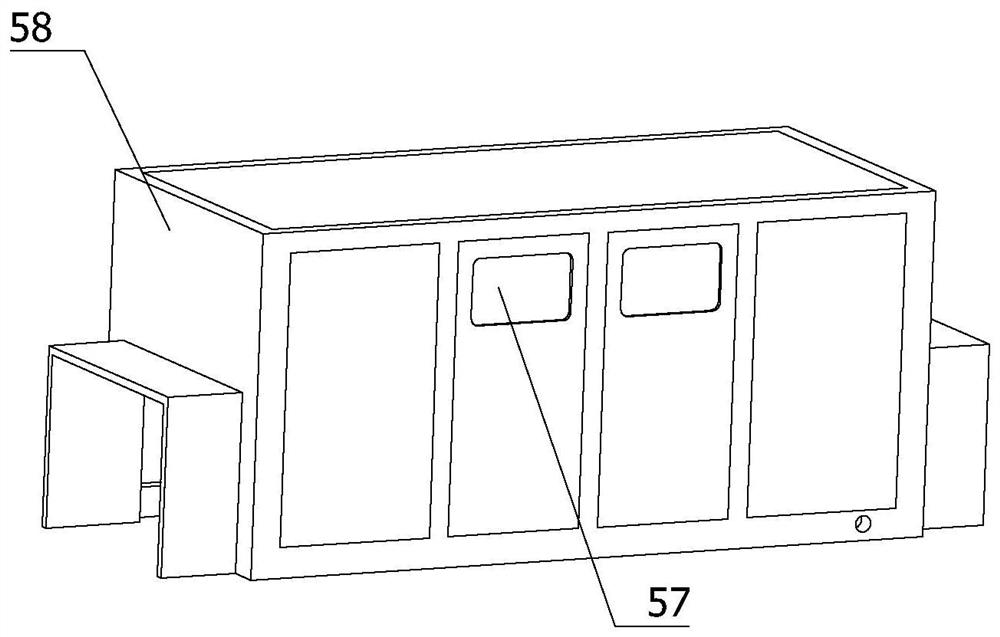

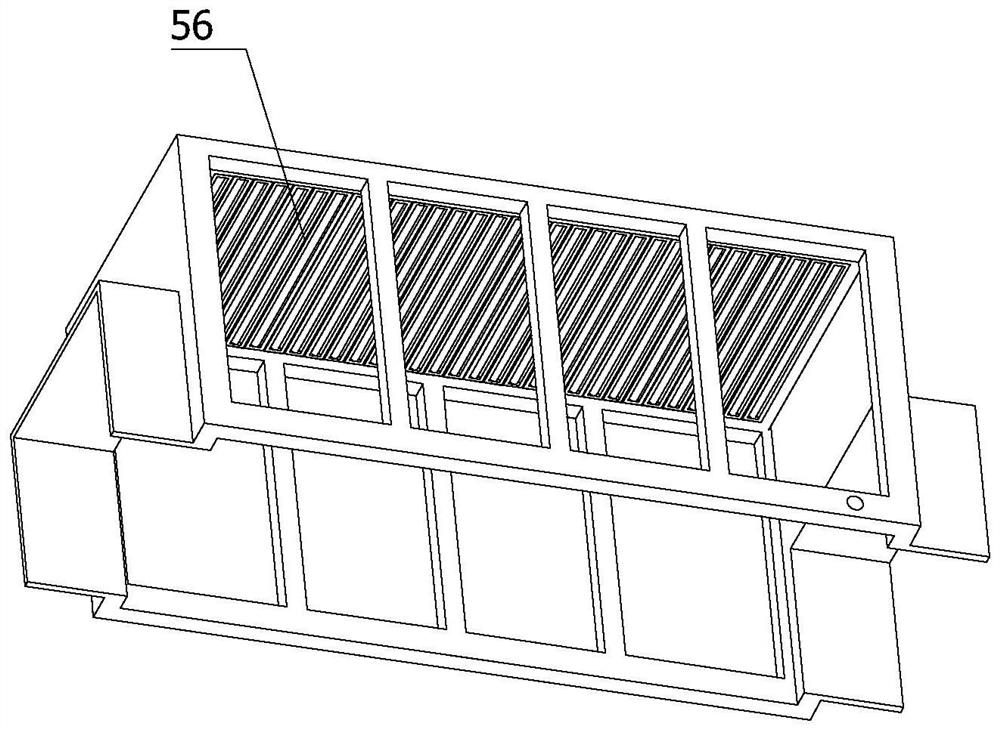

MEC curing and drying machine for material surface layer and using method of MEC curing and drying machine

The invention discloses an MEC curing and drying machine for a material surface layer and a using method of the MEC curing and drying machine. The MEC curing and drying machine comprises a conveying line, an initial curing assembly, a first air knife, an MEC curing assembly and a terminal curing lamp tube, and the initial curing assembly, the first air knife, the MEC curing assembly and the terminal curing lamp tube are sequentially arranged in the conveying direction of the conveying line; the initial curing assembly comprises a lifting structure and an initial LED lamp tube capable of ascending and descending along with the lifting structure, and the initial LED lamp tube can conduct initial curing on the material surface layer; the first air knife blows out inert gas to conduct secondary curing on the material surface layer; the MEC curing assembly comprises an MEC lamp tube and second air knives located on the two sides of the MEC lamp tube, the MEC lamp tube is used for conducting curing on the material surface layer for the third time, and the second air knives blow out the inert gas; and the terminal curing lamp tube adopts an LED lamp tube to conduct curing on the material surface layer for the fourth time. With the MEC curing and drying machine for the material surface layer and the using method thereof, a UV coating is rapidly cured, the curing effect is guaranteed while the curing efficiency is improved, energy consumption is reduced, and pollution is reduced.

Owner:SUZHOU KISINHOM MACHINERY EQUIP CO LTD

Photo-cured hydrogel conveying device for minimally invasive surgery and in-situ printing method

ActiveCN110101448AReduce wound areaReduce the risk of cross-infectionOsteosynthesis devicesEngineeringInvasive surgery

The invention discloses a photo-cured hydrogel conveying device for minimally invasive surgery and an in-situ printing method. The device comprises a shell, a rotary steering structure and a coaxial spraying nozzle, wherein the rotary steering structure and the coaxial spraying nozzle are installed in the shell, the coaxial spraying nozzle is installed in the shell, and the outlet of the coaxial spraying nozzle is located outside. The posture is changed and adjusted through the transmission of an internal bevel gear group, the rotation of a handle around the Y axis is converted into the rotation of the coaxial spraying nozzle around the X axis, and the rotating range of the coaxial spraying nozzle is 0-180 degrees. The posture is indicated by scale lines on the outer handle, the rotating angle of the handle is indicated by the outer circle, and the rotating angle of the coaxial spraying nozzle at the tail end is indicated by the inner circle. The coaxial spraying nozzle is in a round tube shape. The outlet of the coaxial spraying nozzle is located on the longitudinal axis of a round tube. An embedded curing light source is adopted for one part of the coaxial spraying nozzle. The outer circle of the coaxial spraying nozzle has a material outlet effect and a light shielding effect. Illumination light sources are evenly distributed on the periphery of the coaxial spraying nozzle.By means of the continuous illumination and interval feeding segmented curing strategy, the material curing uniformity is ensured, and efficiency is improved.

Owner:XI AN JIAOTONG UNIV

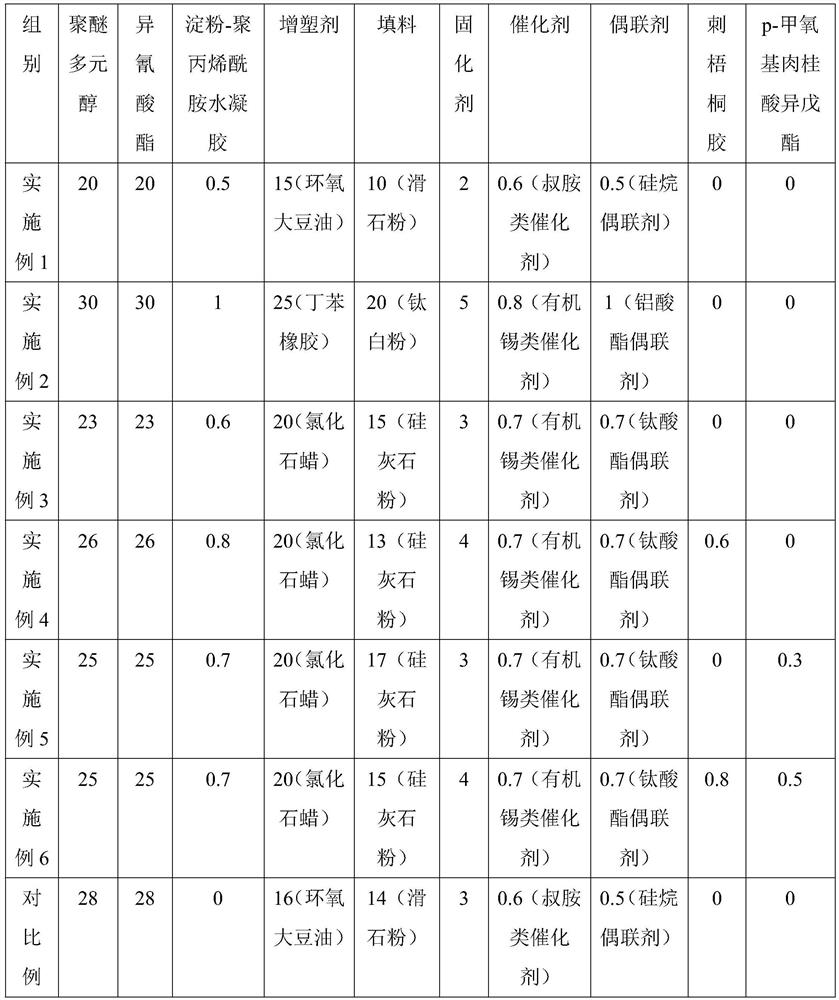

Single-component polyurethane waterproof coating

InactiveCN111763475AImprove storage stabilityImprove compactnessPolyurea/polyurethane coatingsRadiation-absorbing paintsStarch solutionPlasticizer

The invention belongs to the technical field of building waterproof materials, and discloses a single-component polyurethane waterproof coating. The coating comprises the following raw materials in parts by weight: 20-30 parts of polyether polyol, 20-30 parts of isocyanate, 0.5-1 part of starch-polyacrylamide hydrogel, 15-25 parts of a plasticizer, 10-20 parts of a filler, 2-5 parts of a curing agent, 0.6-0.8 part of a catalyst and 0.5-1 part of a coupling agent. A preparation process of the starch-polyacrylamide hydrogel comprises the following steps: sequentially adding a potassium persulfate initiator, an acrylamide monomer and a polyethylene glycol acrylate cross-linking agent into a starch solution, carrying out uniform mixing after each component is added, and carrying out heating for a sufficient reaction so as to obtain the starch-polyacrylamide hydrogel. According to the single-component polyurethane waterproof coating disclosed by the invention, CO2 released in the process ofcuring and film-forming is effectively removed, the phenomena of uncompactness, bubbles and pinholes of a cured coating film are avoided, the precipitation of powder of the waterproof coating in a storage process is effectively reduced, and the storage stability of the single-component polyurethane waterproof coating is improved.

Owner:湖北九阳防水材料科技有限公司

Paint spraying line capable of recycling UV ink

InactiveCN112588497ASpray evenlyGuaranteed curing effectPretreated surfacesCoatingsProcess engineeringSpray painting

The invention relates to the technical field of paint spraying, in particular to a paint spraying line capable of recycling UV ink. The paint spraying line comprises a spraying mechanism, a conveyor belt, a recycling mechanism and a curing box body, wherein the spraying mechanism comprises a paint spraying box body, a ventilator, a paint spraying frame and a spray gun; the recycling mechanism comprises an ink pump, a filter box, an ink filter pipe, an ink receiving groove and an ink receiving hopper; and the curing box body comprises an ultraviolet lamp, a box body and an observation window. According to the paint spraying line, a workpiece is conveyed into the paint spraying box body through the conveyor belt, the spray gun on the paint spraying frame sprays the workpiece, and the ventilator is started at the same time to be used for exhausting harmful gas in the spraying process; and in the spraying process, the spray gun sprays the position outside the workpiece and is filtered by the ink filter pipe to flow into the ink receiving groove, redundant ink sprayed to the conveyor belt by the spray gun is collected by the ink receiving hopper and poured into the ink receiving groove,the ink in the ink receiving groove is pumped by the ink pump and conveyed to the filter box, the filter box filters the pumped ink through the ink pump for secondary use, the height is adjusted to spray different workpieces, the redundant ink can be recycled and reutilized, and the working efficiency is improved.

Owner:毛爱聪

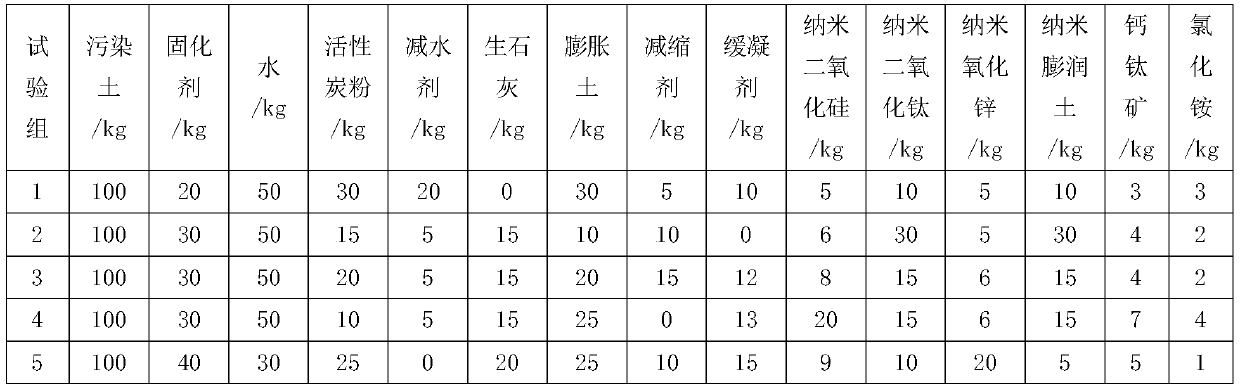

Fluidized pit backfill soil adopting contaminated soil as raw material and construction method

PendingCN110282923ALarge specific surface areaStrong surface adsorptionMaterial fill-upSodium BentoniteSilicon dioxide

The invention discloses a fluidized pit backfill soil adopting contaminated soil as a raw material and a construction method. The backfill soil is prepared from 95-105 parts of contaminated soil, 20-40 parts of a solidifying agent, 30-50 parts of water, 10-30 parts of activated carbon powder, 0-20 parts of a water reducer, 0-20 parts of quick lime, 10-30 parts of expansive soil, 0-10 parts of a shrinkage reducing agent, 0-15 parts of a retarder, 5-20 parts of nanometer silicon dioxide, 10-30 parts of nanometer titanium dioxide, 5-20 parts of nanometer zinc oxide, 5-30 parts of nanometer bentonite, 3-7 parts of perovskite and 1-4 parts of ammonia chloride. The raw materials are mixed, stirred and the like to prepare the backfill soil. The utilization rate of the contaminated soil is remarkably increased, the backfill soil and the air environment are purified, and the high flowability (capable of reaching 157), the unconfined compressive strength (capable of reaching 825 kPa) and the volume shrinkage rate (capable of reaching 2%) are achieved.

Owner:JIANGSU UNIV OF SCI & TECH

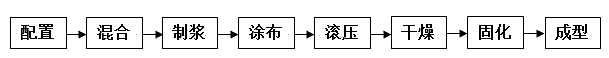

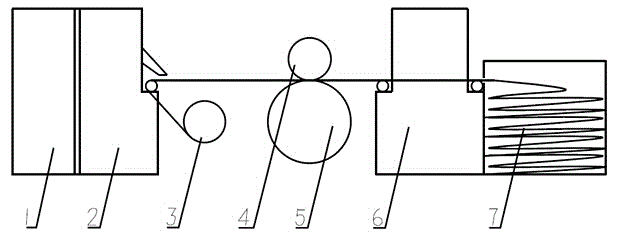

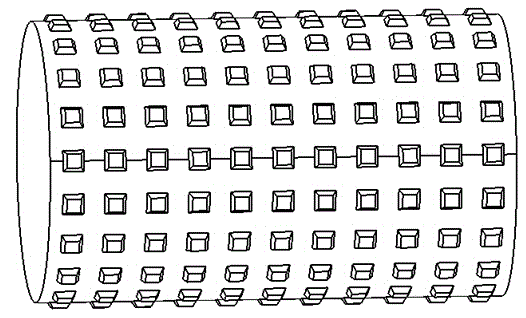

Manufacturing method for trapezoid microflute polishing thin film

ActiveCN104552043AGuaranteed curing effectExtended service lifeAbrasion apparatusGrinding devicesProduction lineContinuous/uninterrupted

The invention discloses a manufacturing method for a tapezoid microflute polishing thin film. The method comprises the steps of configuring, mixing, pulping, coating, rolling, drying, solidifying and cutting. A production line for implementing the manufacturing method comprises a ball mill, a stirring machine, a rotating drum rack, a rolling wheel, an idler wheel and a drying box, a thermostat, wherein the micron-order protruded regular prismoids are uniformly engraved in the axial direction and radial direction of the surface of the rolling wheel; the distance between the adjacent micron-order protruded regular prismoids in the axial direction and radial direction of the surface of the rolling wheel is equal to the width of the bottom surface of each regular prismoid. All the working procedures of the manufacturing method are completed on one production line, so that the production efficiency is high; furthermore, the production process is continuous and uninterrupted, and microflute molding time is strictly controlled, so that the post-solidifying performances, after follow-up drying, of the polishing thin film are ensured, a grinding layer of the trapezoid microflute polishing thin film is prevented from generating cracks; the polishing thin film manufactured by the method disclosed by the invention has the characteristics of long service life, good polishing effect and the like.

Owner:QUZHOU UNIV

Curing device and method and flexible printing machine comprising curing device

ActiveCN111619203AAvoid Contaminated SituationsClean thoroughlyRotary letterpress machinesPrinting after-treatmentElectric machineryControl cell

The invention discloses a curing and method and a flexible printing machine comprising the curing device. The technical problem that the curing effect is poor or the curing precision is not maximizedin a timely manner is solved. The curing method is characterized in that a micro-control unit controls a motor to be started up at a preset frequency, when the motor is started up, a rotary shaft of the motor drives a connecting rod to rotate, then the connecting rod is in transmission connection with a movement rod, thus the movement rod drives a center part of a fan-shaped protection case to rotate, so that friction occurs between the outer surface of the center part and a cleaning sponge mat on the inner surface of a semi-condensation shell. In this way, the cleaning effect is achieved, thecuring effect is guaranteed in a timely manner, the curing precision and efficiency are improved, and the situation that a curing lamp tube or protection shell is not replaced until the curing effectis poor, resulting in low production efficiency is avoided. In addition, the protection shell avoids the situation that the curing lamp tube is likely to be contaminated is avoided, and the protection shell can be cleaned in a timely manner, thereby reducing the production cost and increasing the production benefit.

Owner:佛山伟塔机械装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com