Single-component polyurethane waterproof coating

A polyurethane waterproof, single-component technology, which is applied in the field of building waterproof materials, can solve the problems of slow sedimentation of powder particles, inability to thickly coat during construction, and uneven coating film, so as to prevent the sedimentation of powder components and improve storage stability , Improve the effect of film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

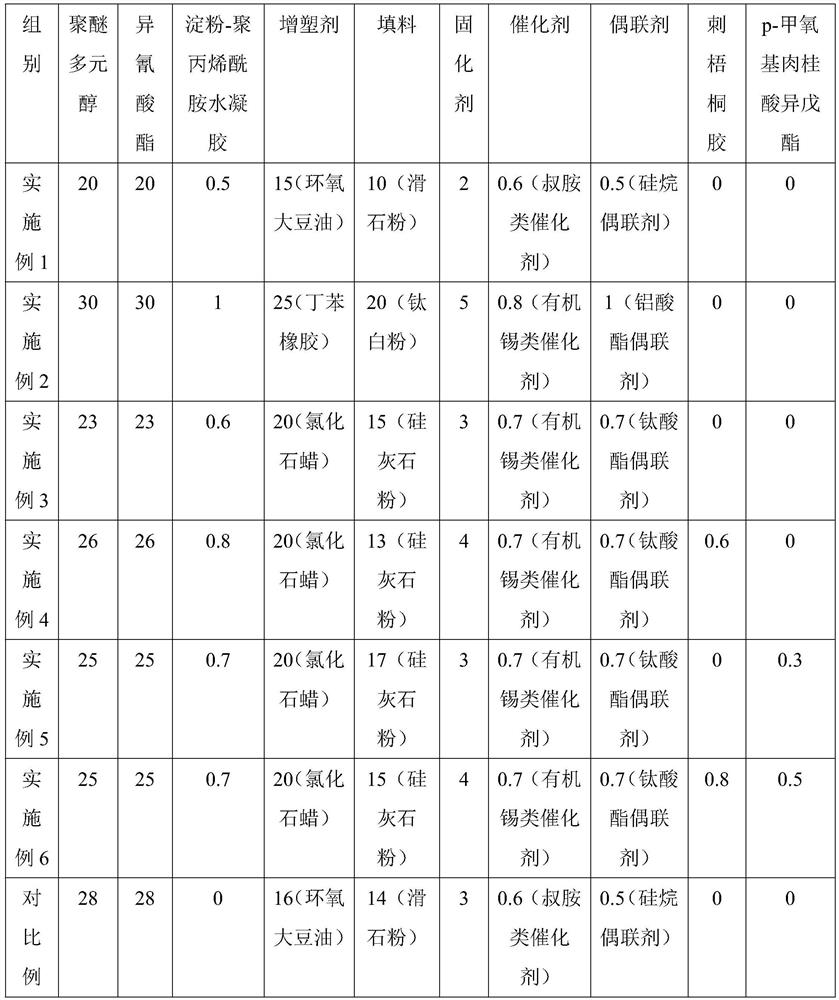

Embodiment 1

[0028] A kind of one-component polyurethane waterproof coating, the raw material components are as shown in Table 1, and all components are in parts by weight. It is prepared by the following steps: (1) at room temperature, add isocyanate and polyether polyol into the reaction kettle, feed nitrogen into the reaction kettle, and stir at a constant temperature of 100 ° C for 3 hours; (2) put the reaction kettle When the temperature drops to 80°C, add epoxidized soybean oil and talc powder to the reactor in sequence, and stir and mix for 2 hours; (3) Lower the temperature of the reactor to 60°C, add 4-phenyl-2-oxazole to the reactor Alkanone, N-methyl-2,4-dinitroaniline, and tertiary amine catalysts were stirred and mixed for 30 minutes, the temperature in the reactor was lowered to below 50°C, and the material was discharged under nitrogen protection to obtain a single-component polyurethane Waterproof paint precursor; (4) adding step (3) gained single-component polyurethane wat...

Embodiment 2

[0030] A kind of one-component polyurethane waterproof coating, the difference from Example 1, the components in the raw materials are shown in Table 1.

Embodiment 3

[0032] A kind of one-component polyurethane waterproof coating, the difference from Example 1, the components in the raw materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com