Low-temperature high-efficiency crude oil pour point depressant

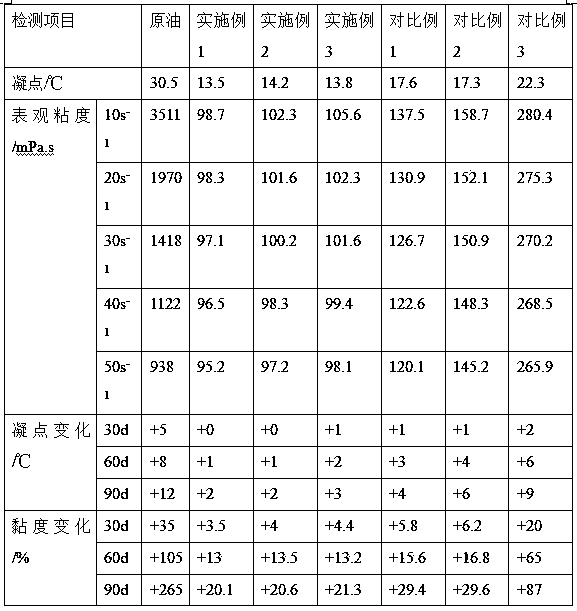

A crude oil pour point depressant and low-temperature technology, which is applied in the field of petroleum industry, can solve the problems of poor viscosity reduction effect and poor storage stability, and achieve the effect of improving stable storage, improving dissolution and spreading performance, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of composite pour point depressing base material comprises the following steps:

[0034](1) Mix sepiolite and reagent A through a 120-mesh sieve at 50-60°C in a mass ratio of 1:5-8, mix them in a reactor, stir at a constant temperature of 400-700r / min for 1-3h, filter, and collect the filter residue After washing with water for 3~5 times, transfer to an oven and dry at 60~80°C for 4~8h to obtain the dry matter, take the dried matter in a tube furnace, roast at 300~500°C for 3~5h, cool to room temperature with the furnace, and heat up to 550~700°C, roast for 1~3h, cool naturally to room temperature, and discharge to obtain roasted product;

[0035] (2) At 50~75°C, take sodium humate and add reagent B to mix at a mass ratio of 1:8~13, stir at 400~700r / min for 45~65min, heat up to 100~120°C, keep stirring for 30~50min , to obtain the mixture, take the mixture according to the mass ratio of 14~20:3, add the formaldehyde solution with a mass fraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com