Room temperature self-crosslinking type PUA-SiO2 hybrid emulsion and preparation method thereof

A self-crosslinking, room temperature technology, applied in the direction of coating, etc., can solve the problems of coating film performance and construction, cost, high glass transition temperature, low hardness, etc., to improve storage stability and simplify the preparation process , Excellent reinforcing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

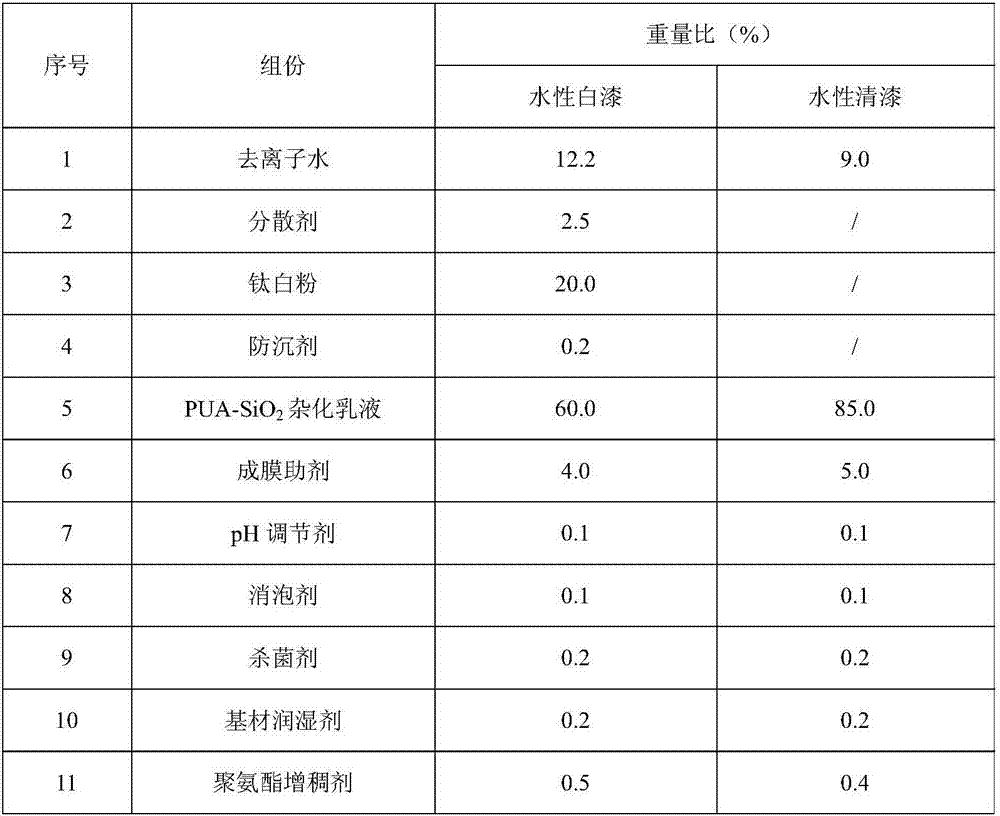

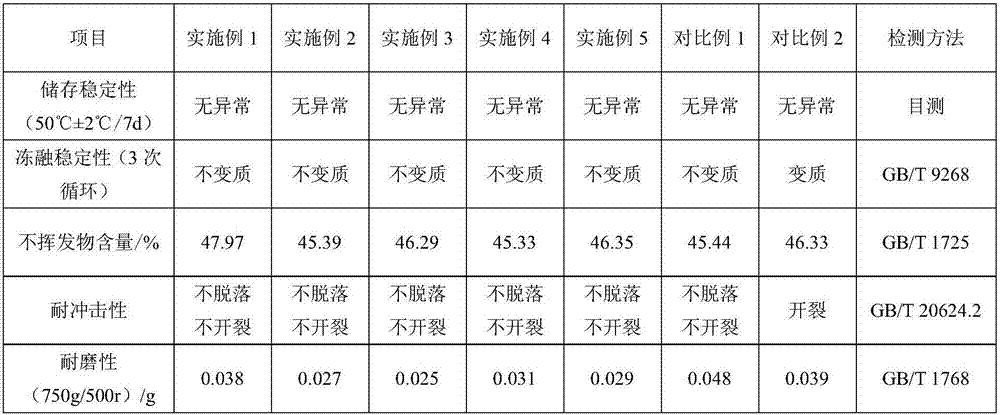

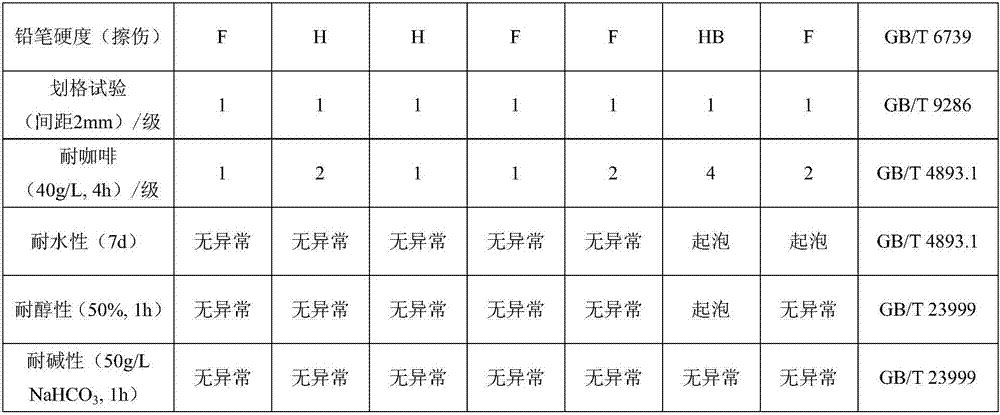

Examples

Embodiment 1

[0029] (1) Preparation of polyurethane macromonomer aqueous dispersion: Add 80 mass parts of molecular weight to 500 hydroxyl polypropylene glycol, 2 mass parts of 1,4-butanediol, 8 mass parts of dihydroxypolypropylene glycol in the nitrogen-protected reactor Methylpropionic acid was dehydrated under vacuum at 105°C for 1.5h. The temperature was lowered to 55° C., 10 parts by mass of N-methylpyrrolidone and 160 parts by mass of acetone were added and stirred until the raw materials were dissolved. 70 parts by mass of isophorone diisocyanate was diluted with 140 parts by mass of acetone, and then slowly dropped into the reactor. Subsequently, 0.5 parts by mass of di-n-butyltin dilaurate was added, and the reaction was stirred for 3 h. Cool to 50° C., add 0.3 parts by mass of hydroquinone, dropwise add 17.2 parts by mass of β-hydroxyethyl acrylate, drop it in 20 minutes, and continue the reaction for 3 hours. Add 35 parts by mass of acetone and 8 parts by mass of triethylamine...

Embodiment 2

[0034] (1) Preparation of polyurethane macromonomer water dispersion: add 80 mass parts of molecular weight to 1500 hydroxypolyethylene glycol, 4 mass parts of 1,6-hexanediol, 4 mass parts of Dimethylolbutyric acid was vacuum dehydrated at 105°C for 2h. Cool down to 75°C, add 200 parts by mass of butanone and stir until the raw materials are dissolved. 35 parts by mass of isophorone diisocyanate was diluted with 80 parts by mass of methyl ethyl ketone, and then slowly dropped into the reactor. Subsequently, 1.5 parts by mass of di-n-butyltin dilaurate was added, and the reaction was stirred for 3 hours. Cool to 50° C., add 0.2 parts by mass of hydroquinone, dropwise add 8 parts by mass of β-hydroxyethyl acrylate, drop it in 20 minutes, and continue the reaction for 3 hours. Add 70 parts by mass of butanone and 3 parts by mass of triethylamine, and neutralize for 20 minutes. Add 310 parts by mass of distilled water and disperse at high speed for 20 minutes. A thin film evap...

Embodiment 3

[0039] (1) Preparation of polyurethane macromonomer aqueous dispersion: Add 80 mass parts molecular weight to 1000 hydroxyl polyethylene glycol, 8 mass parts of 1,6-hexanediol, 6 mass parts of Dimethylolpropionic acid was dehydrated under vacuum at 110°C for 1h. The temperature was lowered to 75° C., 10 parts by mass of N-methylpyrrolidone and 120 parts by mass of methyl ethyl ketone were added and stirred until the raw materials were dissolved. Dilute 50 parts by mass of toluene diisocyanate with 100 parts by mass of butanone, and then slowly drop it into the reactor. Subsequently, 1 mass part of di-n-butyltin dilaurate was added, and the reaction was stirred for 3 hours. Cool to 50° C., add 0.5 parts by mass of hydroquinone, dropwise add 23 parts by mass of β-hydroxyethyl acrylate, drop it in 20 minutes, and continue the reaction for 3 hours. Add 50 parts by mass of butanone and 6 parts by mass of triethylamine, and neutralize for 20 minutes. Add 400 parts by mass of dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com