Patents

Literature

115results about How to "Ensure uniformity of dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Zinc acrylate particle composition, method for production thereof, and golf ball using the composition

InactiveUS6956128B2Difficult to scatterEasy to handleOrganic compound preparationConductive materialPolymer scienceActive agent

A zinc acrylate particle composition which is substantially fine and, even when kneaded with a rubber composition, is capable of being uniformly dispersed and kneaded in a state very rarely inducing fast adhesion or agglomeration, a method for the production thereof, and a golf ball using the composition are provided. The zinc acrylate particle composition contemplated by this invention comprises zinc acrylate satisfying the conditions that the proportion accounted for by the zinc acrylate particles measuring not less than 300 μm in particle size as determined by the dry type method be not more than 20% by mass of all the particles, that the median of particle sizes as determined by the dry type method be in the range of 10-300 μm, and that the ratio of the median (A) of particle sizes as determined by the dry type method to the median (B) of particle sizes as determined by the wet type method exceed 2, and an anionic surfactant.

Owner:BRIDGESTONE SPORTS +2

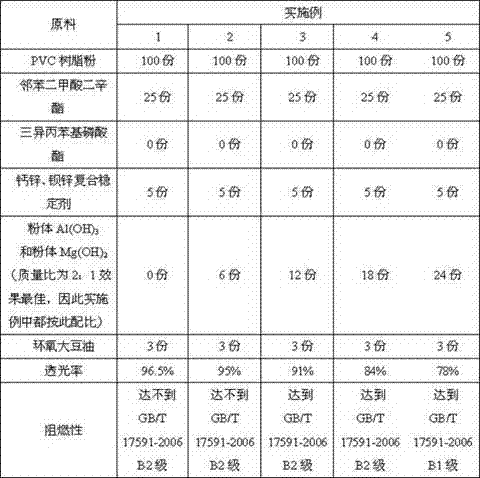

Flame-retardant transparent floor film and production technology thereof

The invention relates to a flame-retardant transparent floor film and a production technology thereof. The flame-retardant transparent floor film is prepared by treating the following main raw materials in parts by weight: 100 parts of PVC (Poly Vinyl Chloride) resin powder, 15 to 30 parts of a main plasticizer, 4 to 8 parts of a fire-retardant plasticizer, 4 to 6 parts of a stabilizer, 6 to 12 parts of an inorganic filler, and 2 to 4 parts of epoxidized soybean oil by a PVC die rolling technology. By adopting the flame-retardant transparent floor film and the production technology thereof, the conflict between the flame retardant performance, the transparence and the jet-printing performance is solved; the inorganic fillers are adopted, thus micromolecules separated by the liquid fire-retardant plasticizers are easily absorbed, and ideal transparence and the jet-printing performance can be provided for the product under efficient flame retardant performance; in addition, the generation of phenomena of wheel adhering, albinism and hard coiling can be effectively avoided by utilizing the flame-retardant transparent floor film; and simultaneously, the flame-retardant transparent floor film is excellent in wear resistance.

Owner:ZHEJIANG BOTAI PLASTIC

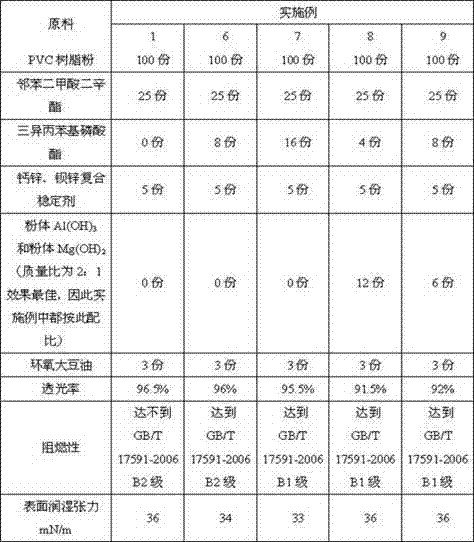

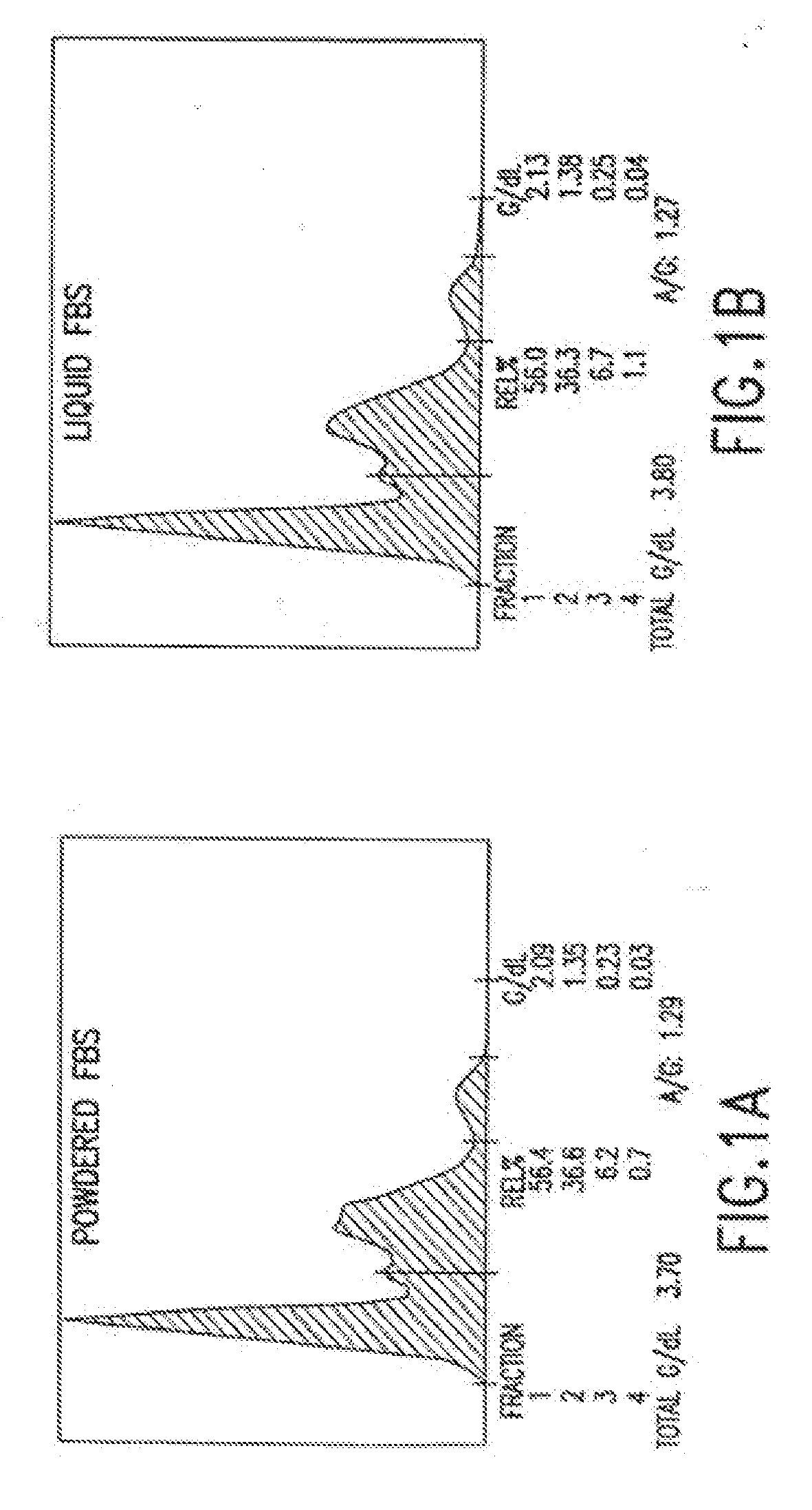

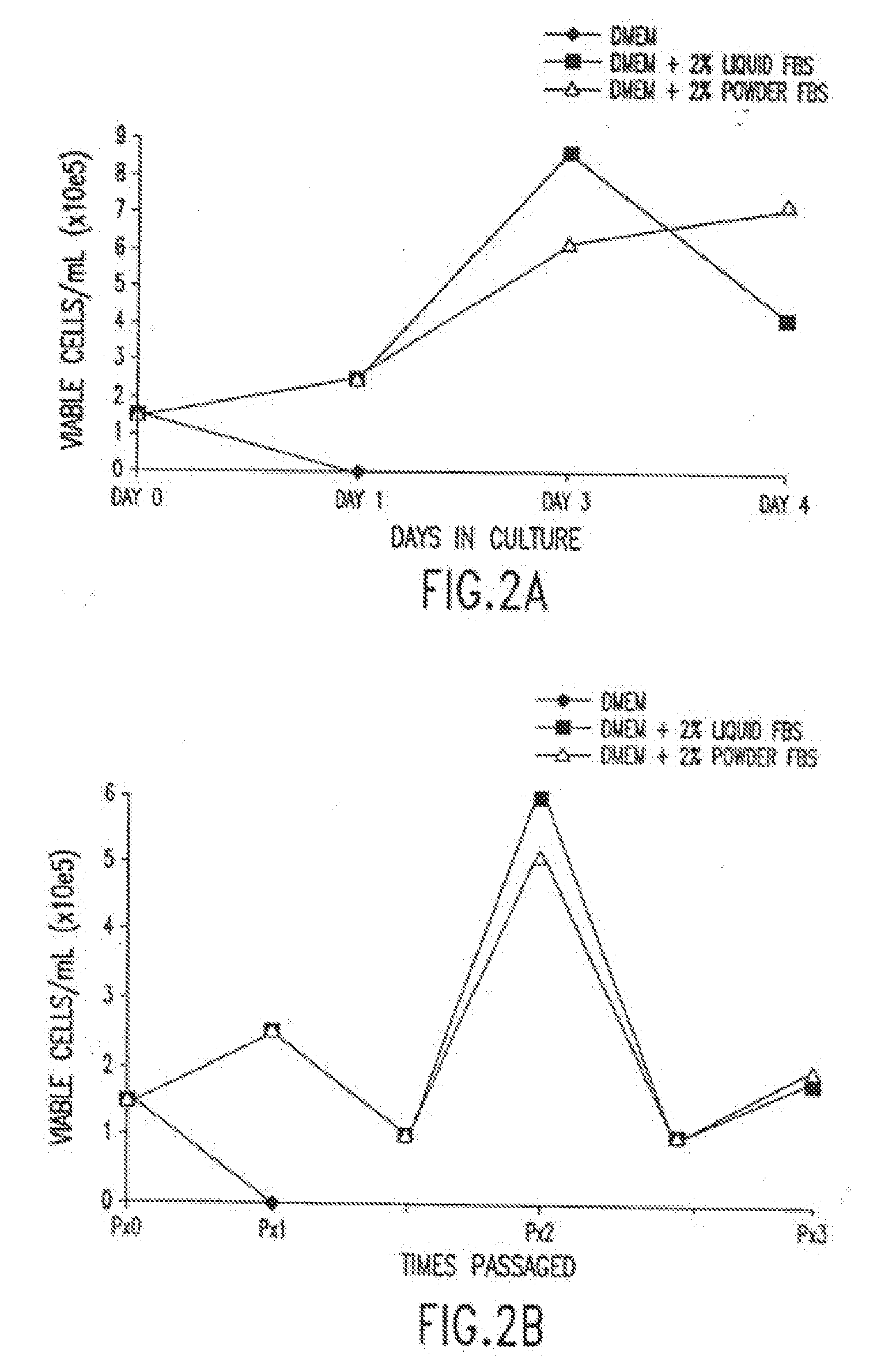

Dry powder cell culture products and methods of production thereof

InactiveUS20080019883A1Increase surface areaIncrease exposureMicroorganismsCulture processBiotechnologyPlant cell

The present invention relates to nutritive medium, medium supplement, media subgroup and buffer formulations. The present invention provides powder nutritive medium, medium supplement and medium subgroup formulations, e.g., cell culture medium supplements (including powdered sera such as powdered fetal bovine serum (FBS)), medium subgroup formulations and cell culture media comprising all of the necessary nutritive factors that facilitate the in vitro cultivation of cells. The invention further provides powder buffer formulations that produce particular ionic and pH conditions upon reconstitution with a solvent. The invention provides methods for production of media, media supplement, media subgroup and buffer formulations, and also provides kits and methods for cultivation of prokaryotic and eukaryotic cells, particularly bacterial cells, yeast cells, plant cells and animal cells (including human cells) using these dry powder nutritive media, media supplement, media subgroup and buffer formulations.

Owner:LIFE TECH CORP

Production technology of high stability asphalt by modification of waste tyre rubber powder

InactiveCN101381519AHomogeneous combined stateGuaranteed stabilityPlastic recyclingBuilding insulationsPolymer scienceAsphalt

The invention relates to a process for producing waste-tire rubber powder modified asphalt, in particular to a process for producing high-stability waste-tire rubber powder modified asphalt. The process is characterized in that the surface of waste-tire rubber powder is first activated; then the activated waste-tire rubber powder is added to hot asphalt, fully stirred, swollen, sheared, ground and then injected into a development tank for inoculation reaction, so as to obtain stable waste-tire rubber powder modified asphalt; the production course of the process belongs to chemical-physical action; the activated waste-tire rubber powder and the asphalt are subjected to crosslinking reaction and form a stably linked molecular structure; and the modified asphalt is stable in performance and capable of long-term storage. The high-stability waste-tire rubber powder modified asphalt has the characteristic of good stability.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

High tensile strength steel plate having excellent weld heat-affected zone low-temperature toughness and method for producing same

ActiveUS20150075682A1High tensile strengthImprove low temperature toughnessFurnace typesHeat treatment furnacesHeat-affected zoneChemical composition

The present invention provides a high tensile strength steel plate having a chemical composition containing, in percent by mass, 0.03% to 0.12% of C, 0.01% to 0.30% of Si, 0.5% to 1.95% of Mn, 0.008% or less of P, 0.005% or less of S, 0.015% to 0.06% of Al, 0.011% to 0.05% of Nb, 0.005% to 0.02% of Ti, 0.001% to 0.006% of N, 0.0005% to 0.003% of Ca, optionally, one or two or more of Cr, Mo, V, Cu, and Ni, in which Ceq is 0.44 or less, Ti / N is 1.5 to 3.5, and parameter formulas composed of specific elements for controlling the sulfide morphology and the degree of center segregation in the steel are satisfied, and the balance being Fe and incidental impurities, in which the hardness of the center segregation area of the steel sheet is further specified.

Owner:JFE STEEL CORP

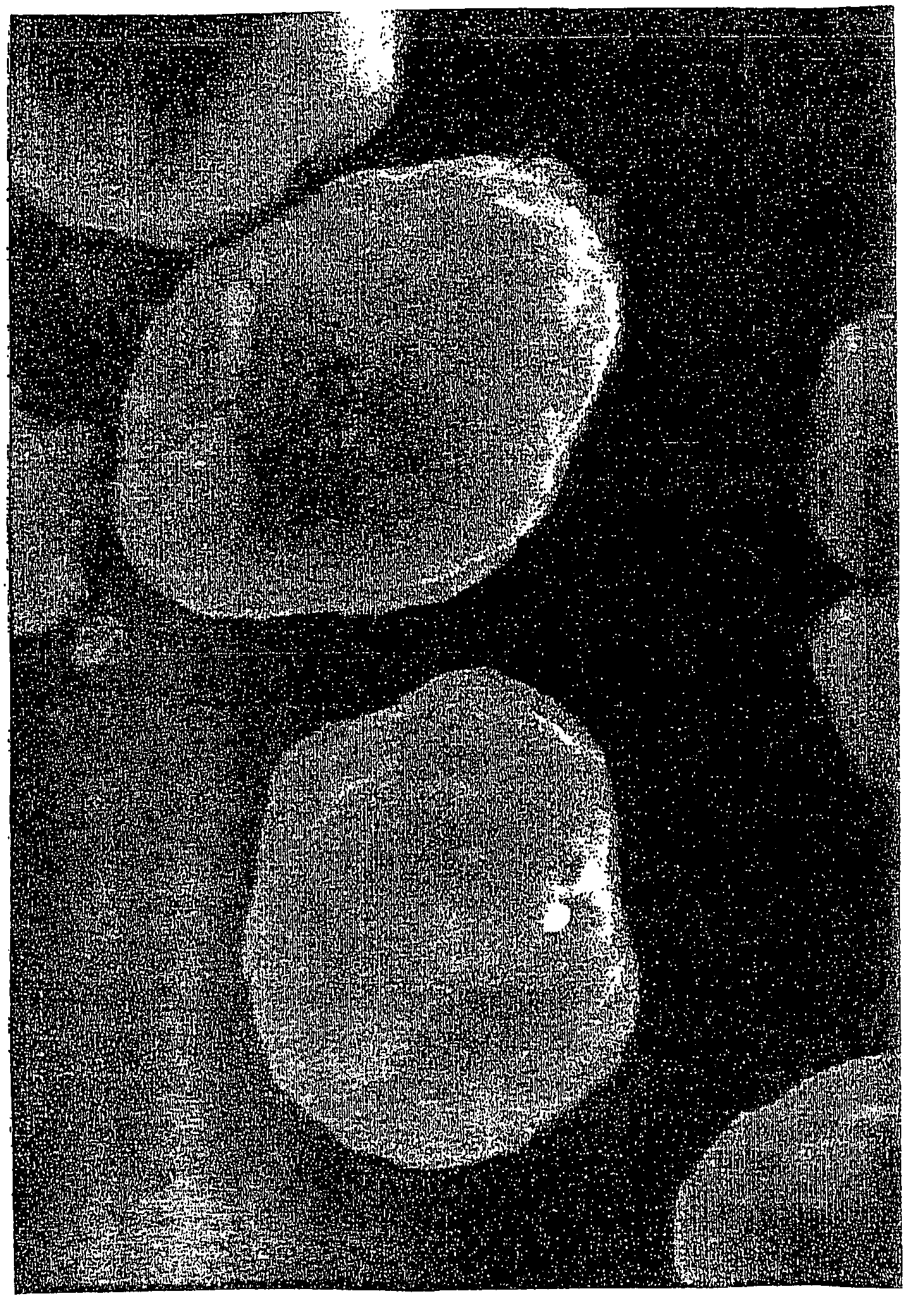

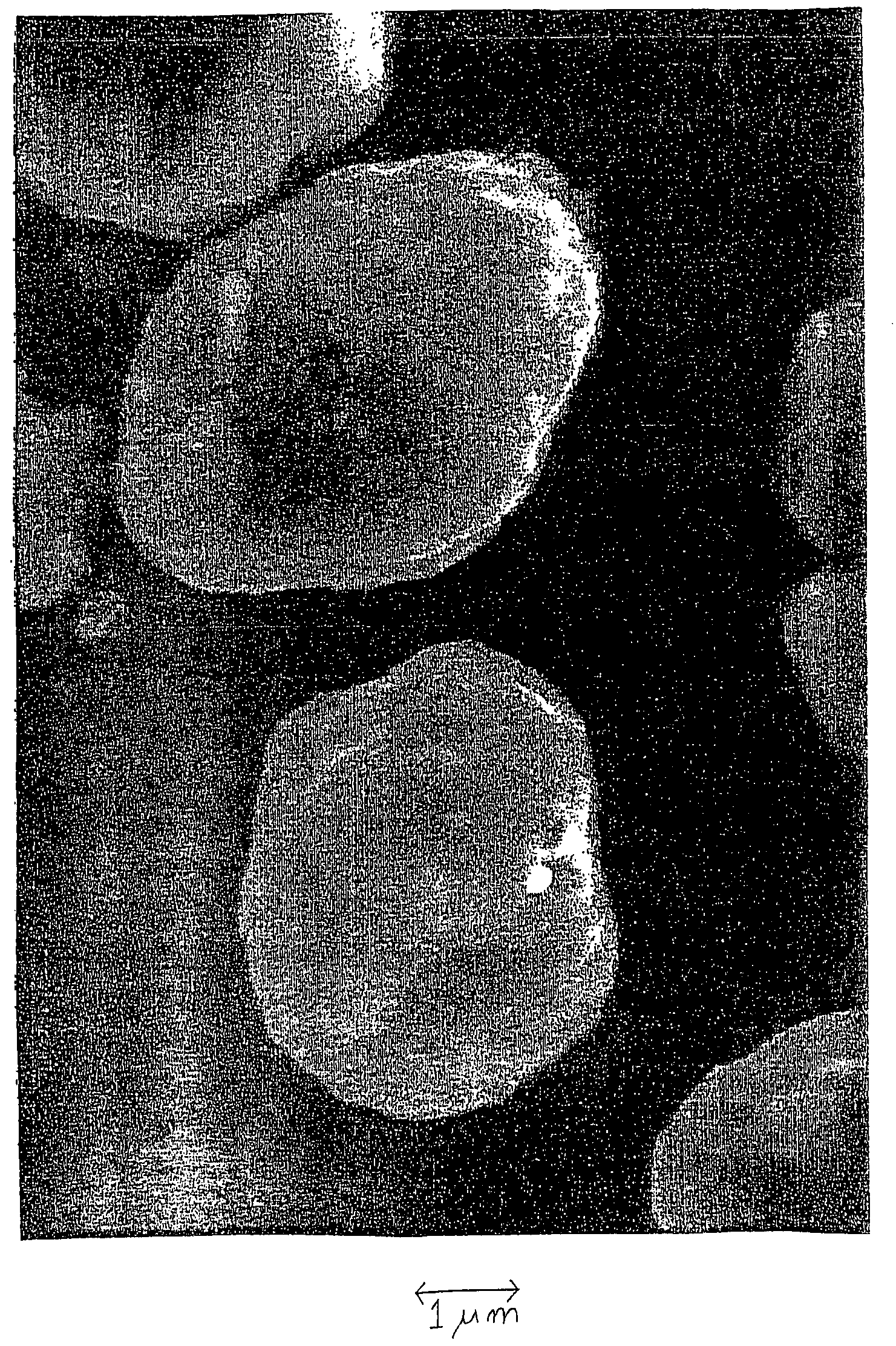

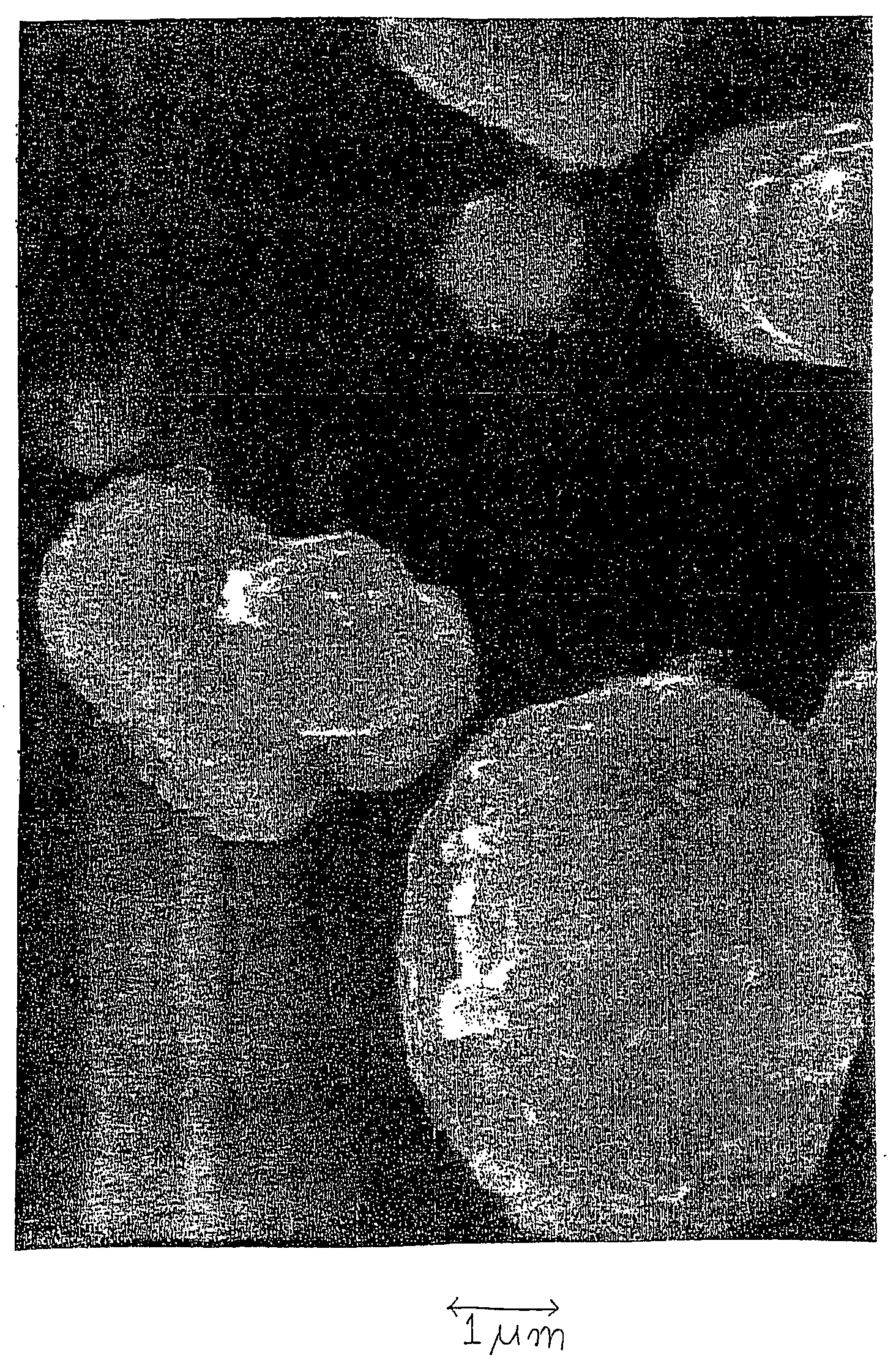

Carbon-covered lithium transition metal oxide, secondary cell positive electrode material and secondary cell

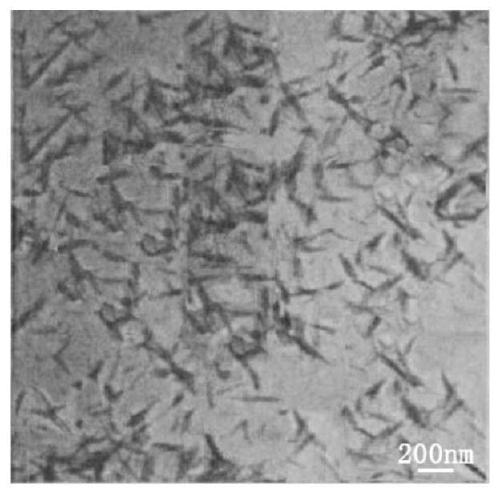

InactiveUS20050153205A1Low resistivityGood dispersionPositive electrodesCobalt compoundsFiberLithium

A carbon-covered lithium transition metal oxide which comprises a lithium transition metal oxide and carbon black attached on the surface thereof, wherein the carbon black covers 80% or more of the lithium transition metal oxide; a carbon-covered lithium transition metal oxide which comprises a lithium transition metal oxide and carbon fiber attached on the surface thereof; and a positive electrode material for a secondary cell which comprises the carbon-covered lithium transition metal oxide.

Owner:MIKUNI SHIKISO

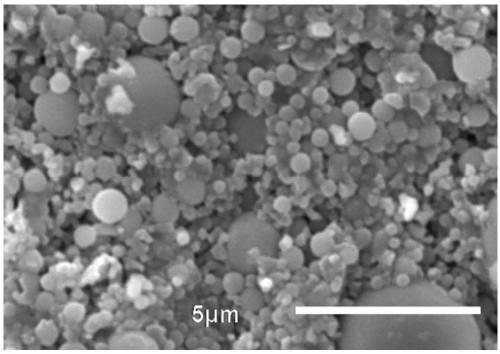

Hard alloy coating matrix added with rare earth

The invention provides a hard alloy coating matrix added with rare earth and relates to the technical field of rare earth hard alloy processes. The hard alloy coating matrix is prepared through the following steps: proportioning the components of 81-86.8% of WC (Wolfram Carbide) powder, 6-8% of cobalt powder, 3-4% of TiCN, 4-6% of tantalum-niobium solid solution (TaC:NbC=6:4) and 0.2-1% of the rear earth, and then adding the components into a rolling ball mill by using a hard alloy as a grinding body; meanwhile, adding a molding regent which is 4.0-4.5% of a total mass of raw materials and a surfactant which is 0.5-1.0% of the total mass of the raw materials, wherein the accumulated ball-milling time is 72-120 hours; atomizing and drying ball-milled slurry through spray drying; and sintering atomized granules which meet requirements and are formed in a pressure sintering furnace through a precise press. The hard alloy coating matrix is added in a state of rear earth-cobalt intermediate alloy powder, so that not only can the rear earth be ensured to achieve dispersible uniformity in a hard alloy, but also the rear earth can be effectively prevented from being oxidized. The purposes of purifying an interface with the rear earth and strengthening the alloy can be achieved.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

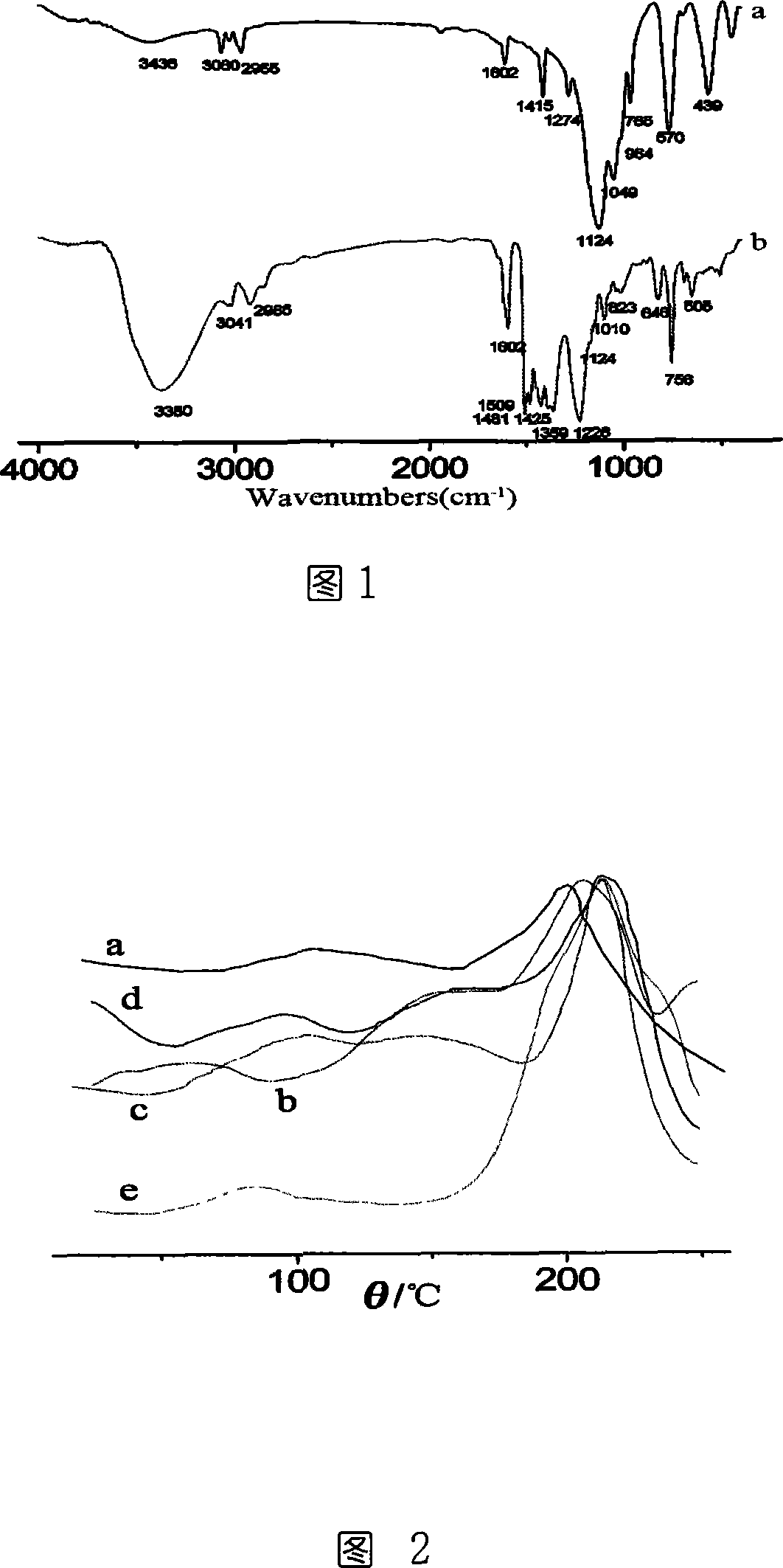

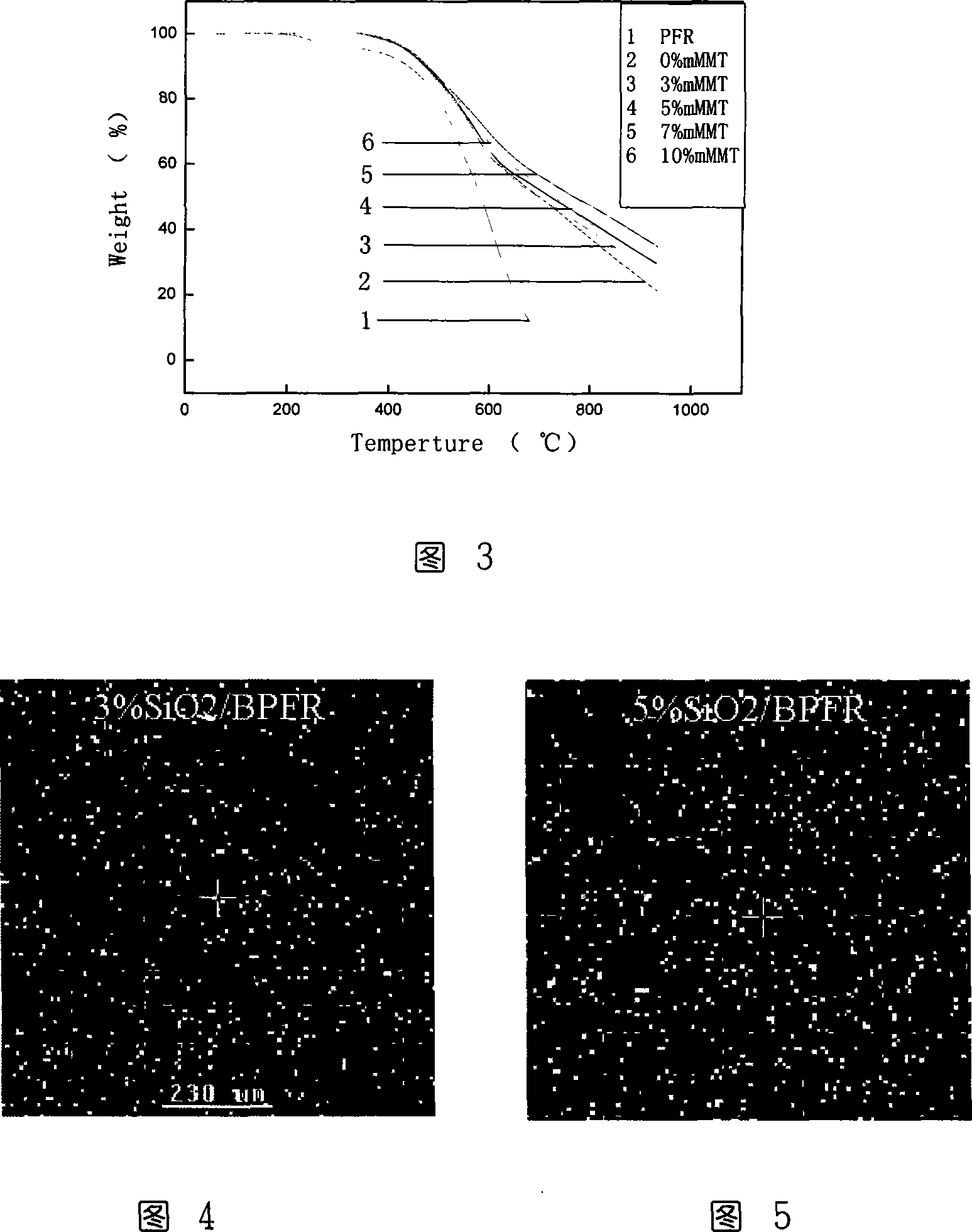

Method for preparing boron phenolic/in-situ nano hybrid compound resin

InactiveCN101177517AEnsure uniformity of dispersionImprove thermal stabilityNano hybridResin-Based Composite

The invention relates to a preparation method of boron phenolic / in-situ nano-hybrid composite resin, wherein the boron content in boron phenolic is calculated as 3.0:0.3-1.0 according to the molar ratio of phenolic hydroxyl group to boric acid, and is characterized in that: in the preparation of boron phenolic After 30-60 minutes of resin resinization reaction, add organic montmorillonite or tetramethoxysilane with 5-30% phenol weight of the reaction raw material to the solution, and react at a temperature of 105-130°C for 40-90 minutes. The gelation time is 60-120s / 200°C to control the reaction end point, and the reaction solvent is removed under reduced pressure to obtain boron phenolic / in-situ intercalation or in-situ generated nano-hybrid composite solid resin. The present invention uses in-situ intercalation or in-situ generation to prepare nano-composite materials, which ensures the dispersion uniformity of inorganic nano-materials in resins; compared with non-hybrid composite resins, the obtained resins have better thermal stability and high temperature Residual rate, mechanical properties and stability against hydrolysis; the preparation process is simple, convenient, easy to operate and control.

Owner:HEBEI UNIVERSITY

Preparation method of lithium-ion battery slurry

ActiveCN104393230ASave mixing process timeReduce mixing timeElectrode manufacturing processesSolventMicrometer

The invention provides a preparation method of lithium-ion battery slurry and relates to manufacturing of the lithium-ion battery. The preparation method of the lithium-ion battery slurry is characterized by comprising the steps of dry-blending, gluing, high-viscosity stirring and solvent diluting. According to the preparation method of the lithium-ion battery slurry, the dry blending method is used so that active materials are more uniformly mixed with a conductive agent, and the time of slurry combination is saved; during the high-viscosity stirring, a high-speed shearing superfine dispersion machine performs high-speed shearing superfine dispersion on slurry added with a nanometer-micrometer composite conductive agent, and performs instant micromixing dispersion on each ingredient of the nanometer-micrometer composite conductive agent, so that the dead corners of the slurry in a conventional mixing machine are avoided, and the effect of superfine dispersion uniformity is realized; the slurry combination is finished with higher viscosity, and water is added to the slurry for diluting to a required viscosity before the slurry is coated, so that the dispersion uniformity of the slurry during slurry combination is ensured, and the time of slurry combination can be shortened. The preparation method of the lithium-ion battery slurry has the advantages that the time of slurry combination is shortened and the superfine dispersion uniformity is ensured.

Owner:SHANDONG SACRED SUN POWER SOURCES

Culture medium for jonquil and preparation method thereof

InactiveCN104472327AImprove developmentPromotes robust growthGrowth substratesCulture mediaPeatOperability

The invention discloses a culture medium for jonquil. The culture medium is prepared from the mixture of the following components in parts by weight: 10 to 20 parts of peat, 20 to 30 parts of perlite, 20 to 30 parts of leaf mold, 5 to 10 parts of diatomaceous earth, 1 to 5 parts of bone meal, 10 to 20 parts of hush carbon, 0.5 to 1 part of superphosphate, 0.5 to 1 part of particular slow release fertilizer, and 0.01 to 0.05 part of humic acid. The culture medium for jonquil has the advantages that the formula is scientific and reasonable, the component sources are rich, the components are coordinated and matched to achieve outstanding water permeability, air permeability, water-retaining performance and fertilizer-retaining performance; the culture medium is beneficial for the root development and healthy and strong growth. The invention also discloses a preparation method of the culture medium for jonquil. The preparation method is characterized in that different components are respectively mixture to obtain the culture medium for jonquil. With the adoption of the preparation method, the dispersing uniformity and particle uniformity of the components in the culture medium can be ensured; in addition, the process is simple, large devices are saved, the operability is high, the investment is decreased, and mass production can be performed.

Owner:广东百艺园林科技有限公司

Micro-carbon casting powder for high-carbon steel in square and rectangular billets and preparation method thereof

ActiveCN110976797ASolve the problem of carbon increaseImprove insulation effectProcess efficiency improvementSteelmakingLithium carbonate

The invention discloses micro-carbon casting powder for high-carbon steel in square and rectangular billets and a preparation method of the micro-carbon casting powder, and belongs to the technical field of steelmaking metallurgical auxiliary materials. The invention discloses micro-carbon casting powder for the high-carbon steel in the square and rectangular billets is prepared from following rawmaterials in cluding, 40-65 parts of a special pre-melting material, 0-30 parts of wollastonite, 3-8 parts of quartz, 1-5 parts of bentonite, 0-3 parts of magnesia, 2-7 parts of albite, 2-6 parts offluorite, 1-4 parts of sodium carbonate, 1-4 parts of sodium fluoride, 1-3 parts of lithium carbonate, 2-6 parts of sodium nitrate, 0-1.5 parts of medium-carbon graphite, 0-1.5 parts of high-carbon amorphous graphite, 1-2.5 parts of superfine color black and 1.8-3.8 parts of a binding agent. The casting powder is low in carbon content, high in pre-melting ratio, not prone to generating a slag ring, capable of generating heat automatically and capable of being applied to the high carbon steel in special steel in the square and rectangular billets, capable of avoiding local recarburization of the high carbon steel in the special steel, meanwhile, low in fluorine content and capable of avoiding erosion to nozzle slag lines.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Graphene/silver nanowire-based cellulose/silk magnetic porous composite material

InactiveCN107603240AWell formedMild reaction conditionsLayer by layer self assemblyBiological materials

The invention discloses a graphene / silver nanowire-based cellulose / silk magnetic porous composite material and a preparation method of same. The method includes the following step: supporting nano Fe3O4 particles on supporters being modified cellulose and silk protein, and performing crosslinking, liquid nitrogen treatment and freeze drying to form a cellulose / silk magnetic porous composite material; performing layer by layer self-assembly on the surface of the cellulose / silk magnetic porous composite material with silver nanowires and graphene oxide; reducing the graphene oxide to prepare thegraphene / silver nanowire-based cellulose / silk magnetic porous composite material. Structural stability and mechanical strength of the cellulose / silk porous material are guaranteed and dispersion uniformity of the graphene and silver nanowires in a cellulose / silk base body is ensured. The composite material has potential application value in the fields such as photoelectric materials, adsorption materials, medical materials, biomaterials, etc.

Owner:赵兵

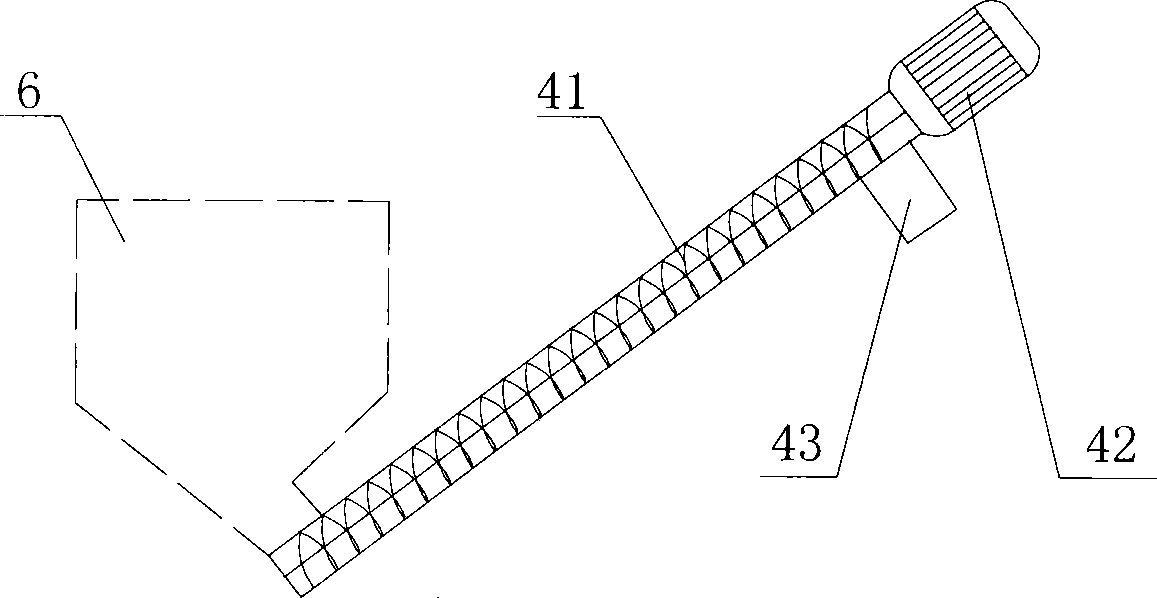

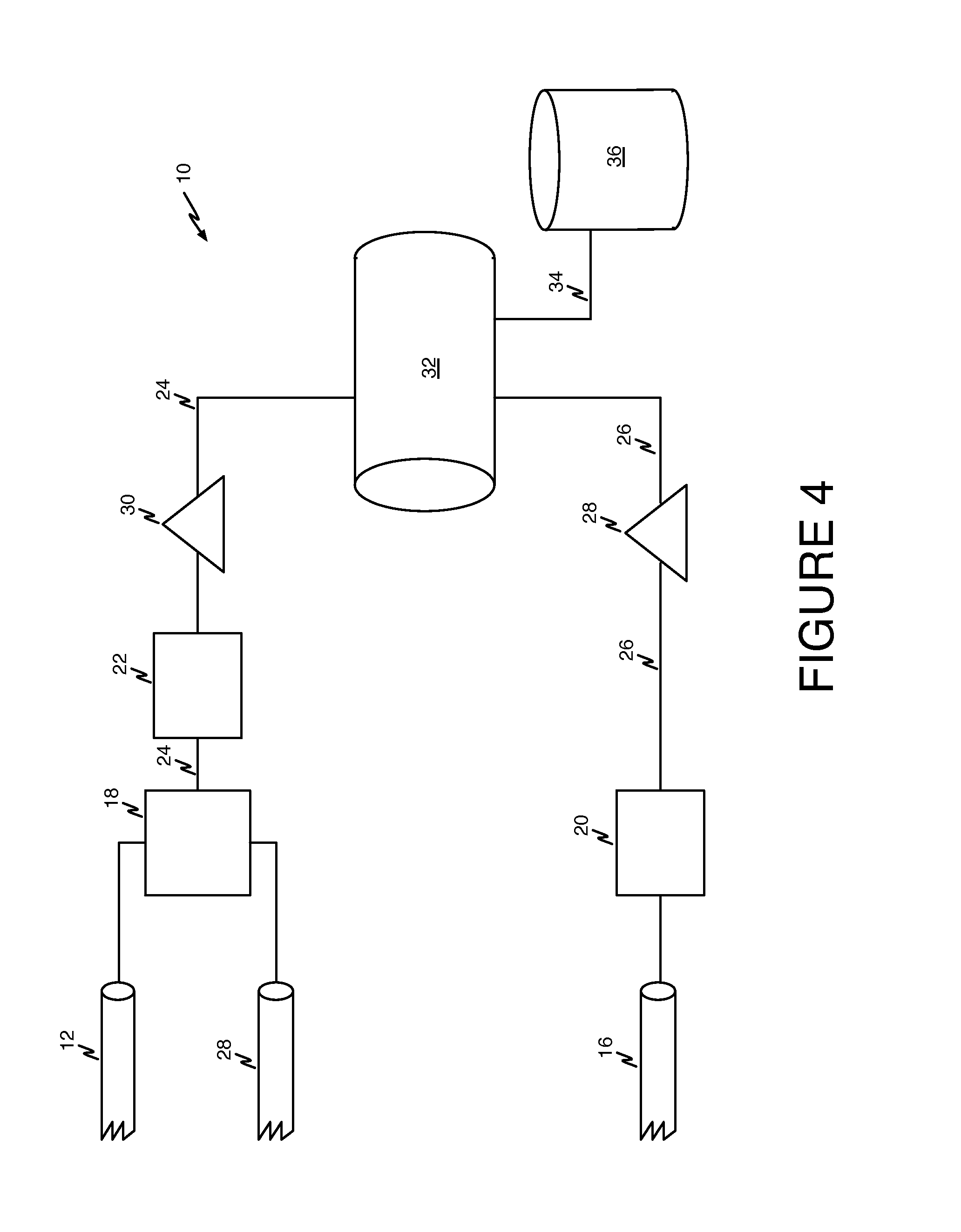

Mixing apparatus and method for manufacturing an emulsified fuel

ActiveUS8192073B1InexpensiveEnsure uniformity of dispersionFlow mixersTransportation and packagingProcess engineeringEmulsified fuel

Owner:TALISMAN CAPITAL TALON FUND

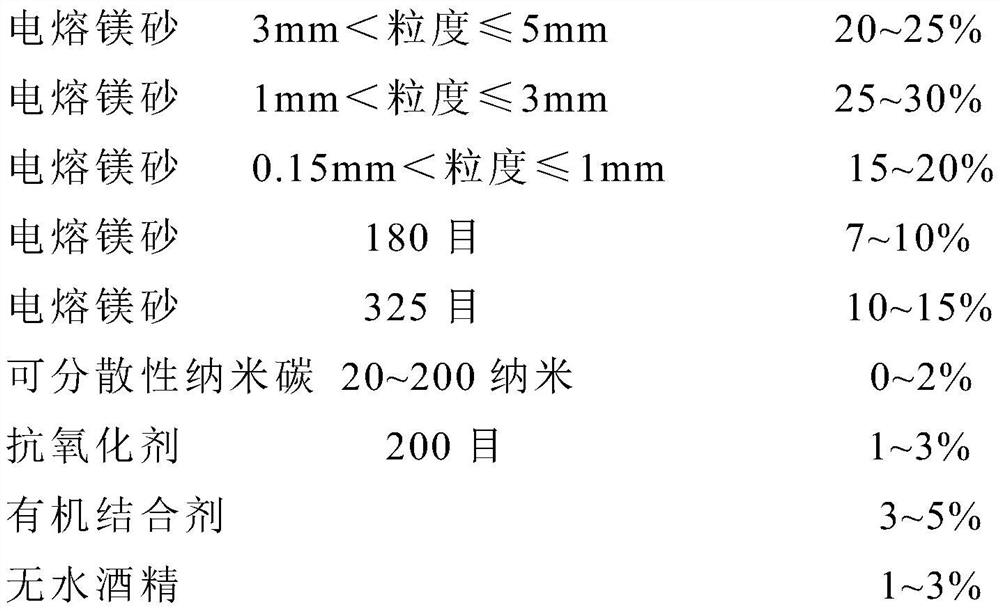

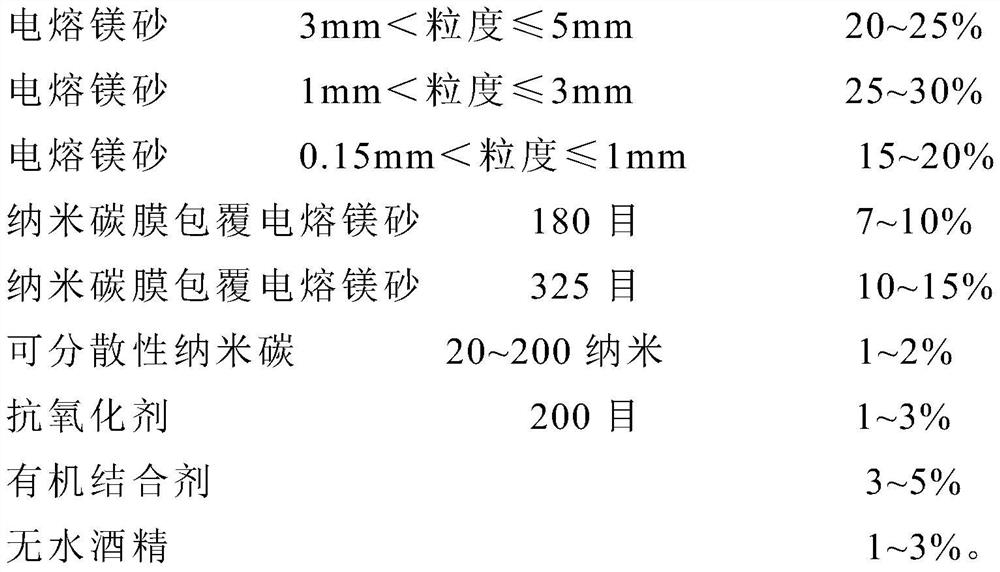

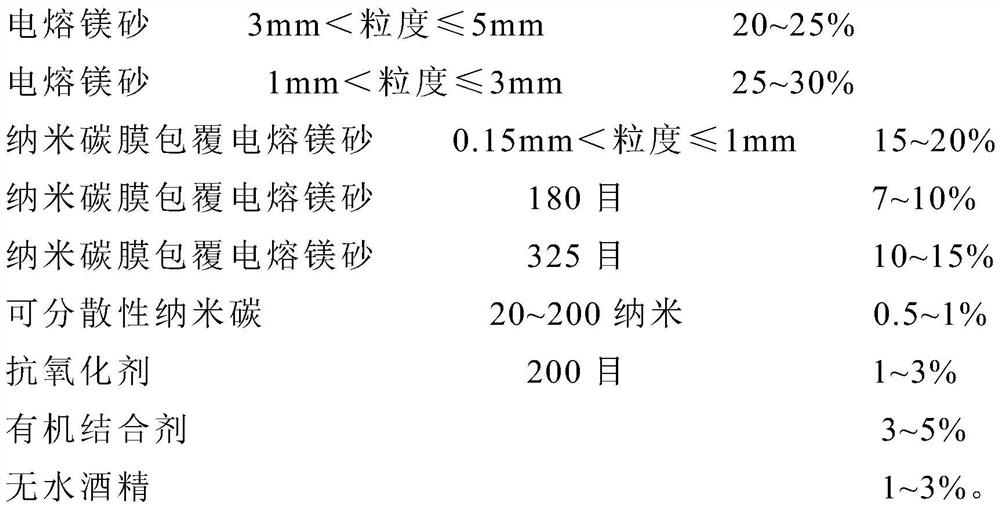

Nano-carbon low-carbon magnesia carbon brick for ladle slag line and preparation method

The invention discloses a nano-carbon low-carbon magnesia-carbon brick for ladle slag lines and a preparation method, wherein the magnesia-carbon brick comprises fused magnesia with five particle sizes, dispersible nano-carbon and an antioxidant, and through coating of nano-carbon films on the surfaces of fused magnesia particles with different particle sizes and application of the dispersible nano-carbon, the nano-carbon low-carbon magnesia-carbon brick can be used for ladle slag lines. By utilizing the characteristics that the nano carbon film and the dispersible nano carbon are mainly amorphous carbon, contain a small amount of graphite young crystals, can be infiltrated by a solvent and the like, infiltration and adsorption of the nano carbon film and the dispersible nano carbon to anorganic binding agent are improved, and uniform dispersion of the nano carbon in the magnesia carbon brick is realized; in addition, the size of carbon particles in the magnesia carbon brick is greatly reduced by controlling the sizes of the nanocarbon film and the dispersible nanocarbon with the thickness of 20-200 nanometers, the contact frequency of a refractory raw material of the magnesia carbon brick and the carbon particles is remarkably improved, the performance of the carbon particles is exerted under the condition of low carbon content, and the anti-erosion permeability of the magnesia carbon brick is improved.

Owner:武汉钢铁有限公司

High-performance composite phase-change material and preparation method thereof

ActiveCN108251063AShape stableUniform structureHeat-exchange elementsIndustrial wasteHigh power lasers

The invention discloses a high-performance composite phase-change material, belonging to the technical field of composite materials. The high-performance composite phase-change material comprises liquid alloy with high latent heat of phase change and a modified carbon nanotube sponge skeleton, wherein the modified carbon nanotube sponge skeleton is filled with the liquid alloy with high latent heat of phase change. The high-performance composite phase-change material comprises the liquid alloy with high latent heat of phase change and a melting point adjustable in a range of 20 to 130 DEG C and the modified carbon nanotube sponge skeleton with high thermal conductivity, wherein the liquid alloy uses InSnBi alloy as a substrate and one or more selected from a group consisting of high-enthalpy elements Ga, Cd, Zn and Sb as additives. The high-performance composite phase-change material has high latent heat of volume phase change, high thermal conductivity, low expansion and a melting point adjustable in a range of 20 to 130 DEG C; and the material has excellent and stable thermophysical characteristics and shows good application prospects in fields with high requirements for high-grade heat dissipation, e.g., heat dissipation of high-power lasers, the utilization of industrial waste heat, solar power generation, cooling of fuel cells, photoelectric devices, micro-nano-electronicmechanical systems.

Owner:GRIMAT ENG INST CO LTD

Titanium dioxide/nanosilver/cocoon fiber magnetic porous composite material and preparation method thereof

The invention discloses a titanium dioxide / nanosilver / cocoon fiber magnetic porous composite material and a preparation method thereof. The preparation method comprises the following steps: modifying salix psammophila cellulose by using polydopamine; carrying out freeze-drying treatment by using liquid nitrogen to obtain the magnetic porous composite material; immersing the magnetic porous composite material into a mixed solution with a silver-ammonia solution and titanium dioxide nanotubes for reacting for 60-300 minutes, taking the magnetic porous composite material out of the mixed solution, then repeatedly washing the magnetic porous composite material with deionized water, and carrying out vacuum drying to obtain the magnetic porous composite material. According to the magnetic porous composite material, salix psammophila and cocoon fibers are used as base materials, so that raw materials are abundant and the cost is low; then magnetic nano ferroferric oxide, nanosilver and titanium dioxide nanotubes are effectively and synergistically self-assembled to obtain a porous nanocomposite material; the porous nanocomposite material has important application values in the fields such as adsorption materials, photocatalysis, biological materials and medical materials and the like.

Owner:钱景

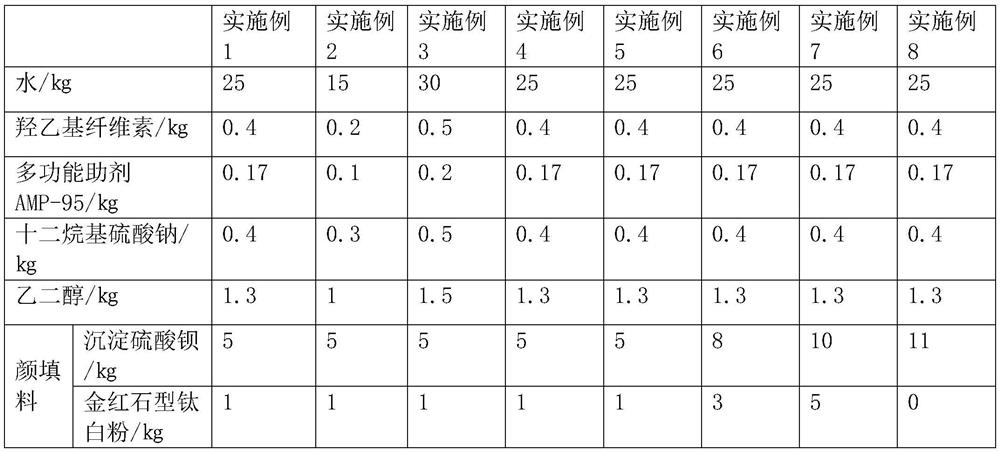

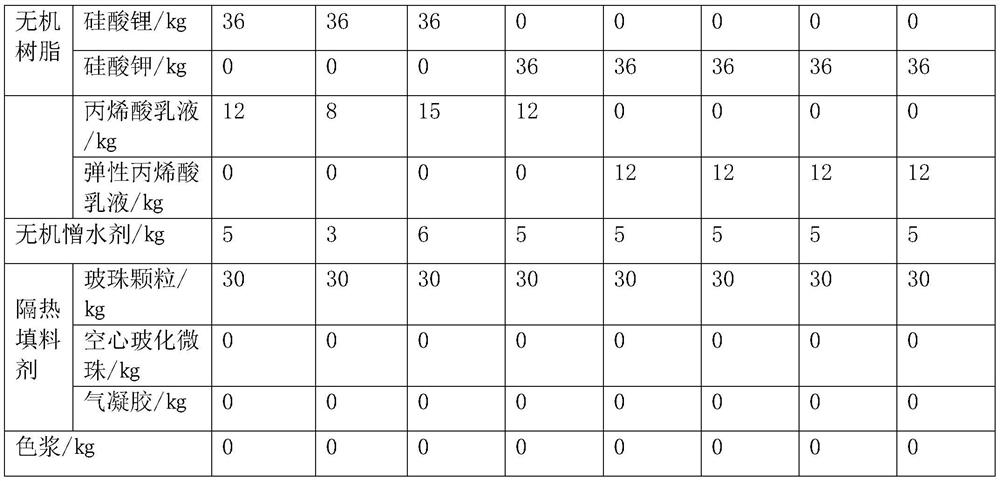

External wall thermal insulation coating as well as preparation method and application thereof

InactiveCN112126291AGood weather resistanceLow thermal conductivityFireproof paintsAlkali metal silicate coatingsCellulosePolymer science

The invention discloses an external wall thermal insulation coating as well as a preparation method and application thereof, and belongs to the field of external wall coatings. The external wall thermal insulation coating comprises the following components by weight: 15-30 parts of water; 0.2-0.5 parts of hydroxyethyl cellulose; 1-1.5 parts of ethylene glycol; 30-40 parts of inorganic resin; 8-15parts of an acrylic emulsion; 0.3-0.5 parts of lauryl sodium sulfate; 3-6 parts of an inorganic water repellent; 6-15 parts of pigment and filler; 23-38 parts of a thermal insulation filler; and 0.1-0.2 parts of a multifunctional auxiliary agent. The coating disclosed by the invention can be directly applied to a cement mortar wall reinforced by seal primer, and has the advantages of good thermalinsulation property, high fireproof grade, good hydrophobicity and good comprehensive performance.

Owner:HUBAO NEW MATERIAL TECH SHANGHAI CO LTD

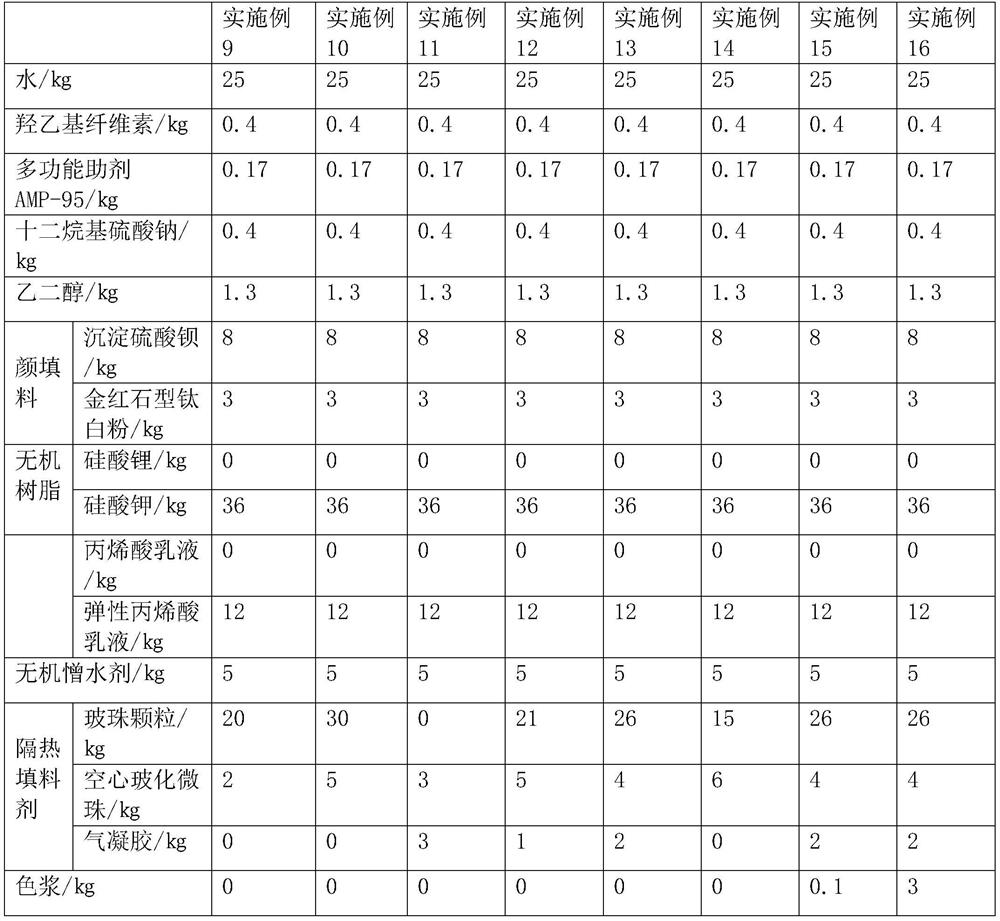

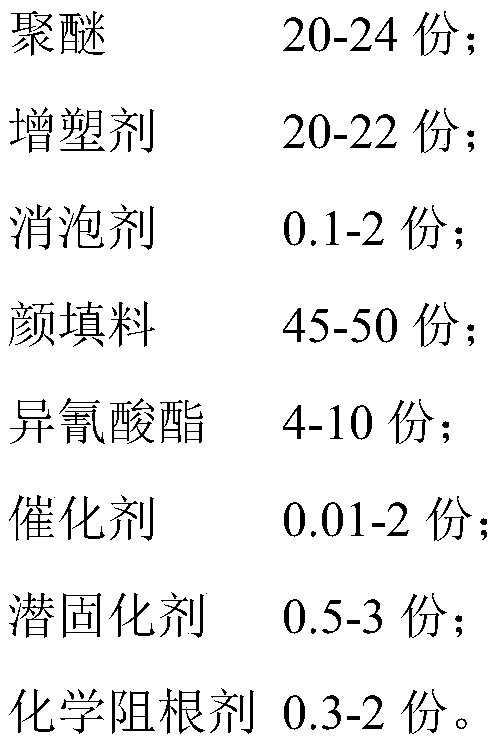

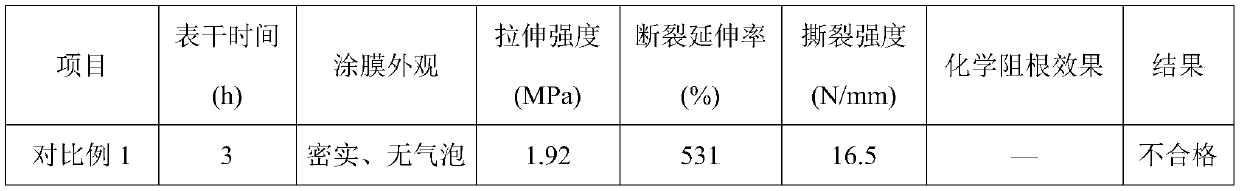

Reactive single-component polyurethane root-puncture-resistant waterproof coating material and preparation method thereof

ActiveCN110903751ANo significant effect on conventional physical propertiesNormal physical propertiesPolyurea/polyurethane coatingsPolymer scienceChemical reaction

The invention belongs to the field of waterproof coating materials, and discloses a reactive single-component polyurethane root-puncture-resistant waterproof coating material and a preparation methodthereof, wherein the waterproof coating is added with a chemical root-retardant agent capable of carrying out a chemical reaction with isocyanate in a coating material, and the molecular structure ofthe chemical root-retardant agent contains a root-retardant active group and one or two hydroxyl groups capable of carrying out a chemical reaction with the main component isocyanate in a polyurethanecoating material. According to the invention, the root-puncture-resistant waterproof coating material has excellent physical properties; the root-retardant agent of the root-puncture-resistant waterproof coating material directly participates in a chemical reaction, so that the root-puncture-resistant waterproof coating material has reliable and durable root-puncture-resistant effect compared with traditional physical addition, and is a real reactive single-component polyurethane root-puncture-resistant waterproof coating material; and the root-puncture-resistant waterproof coating material is suitable for planting roofs in various environments.

Owner:KESHUN WATERPROOF TECH CO LTD

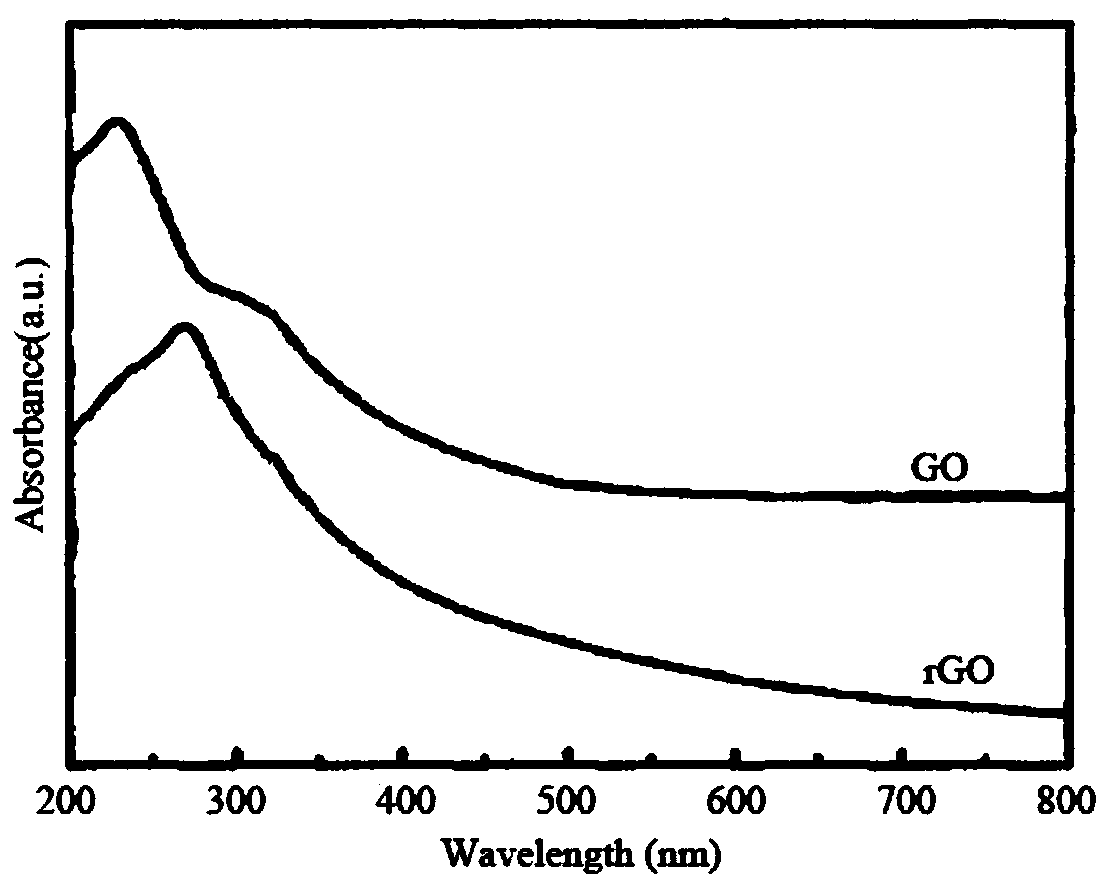

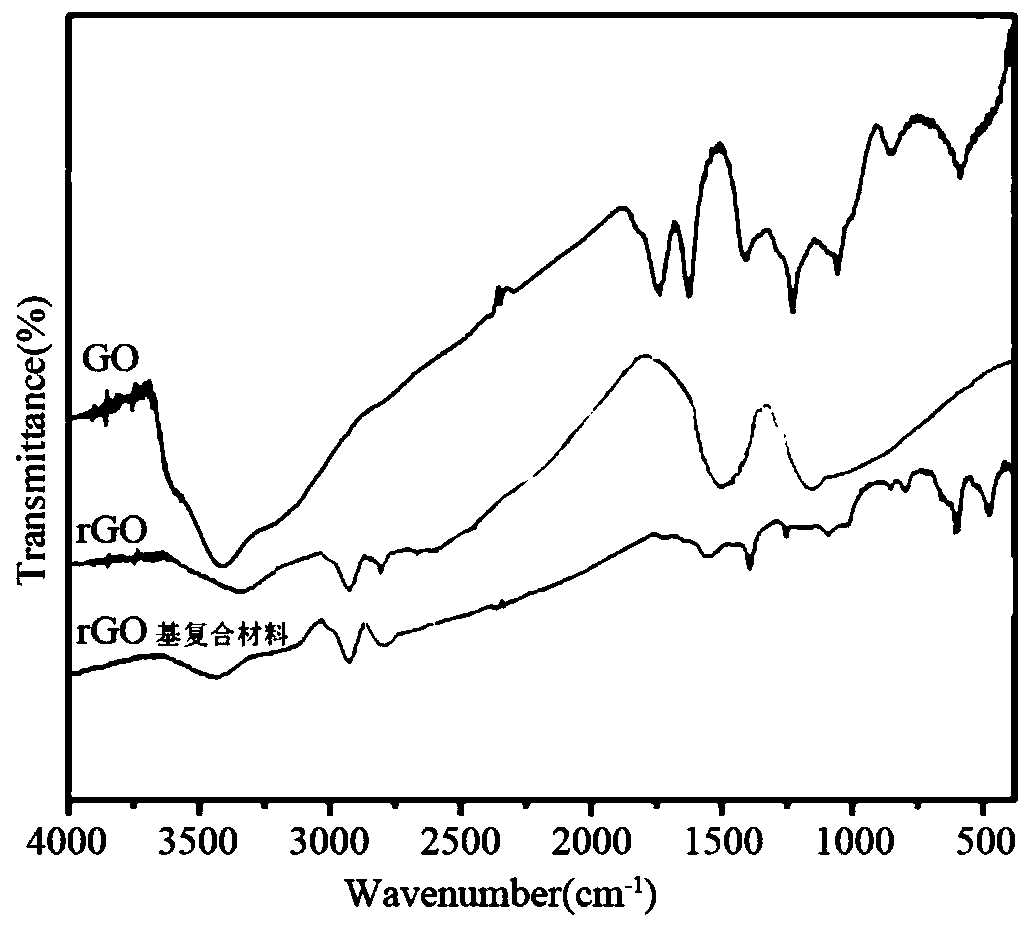

Production and application of nano-hybrid material

ActiveCN110252267AEasy to stackImprove lipophilicityOther chemical processesWater treatment compoundsFiberGallic acid ester

The invention provides production and application of a nano-hybrid material, and belongs to the technical field of water treatment. Production of the nano-hybrid material comprises the following steps of modifying GO with benzoicacid,3,4-dihydroxy-5-methoxy- to obtain rGO; coating a rGO slice layer with a MnFe2O4 composite material through a chemical co-precipitation method to produce a rGO-based composite material; and after the rGO-based composite material and a fiber raw material are mixed, conducting electrostatic spinning to obtain the nano-hybrid material. The nano-hybrid material can be used for sewage treatment. According to the production method of the nano-hybrid material, not only is the GO reduced, but also graphene is modified with gallic acid to make the anti-oxidation activity and the stability of nanoparticles, which are evenly dispersed on the surface of the rGO and coat the rGO slice layer, excellent, and the produced nano-hybrid material can effectively adsorb heavy metal ions in sewage, has high anti-pollution performance, and can avoid organic pollution and biological pollution.

Owner:ZHEJIANG OCEAN UNIV

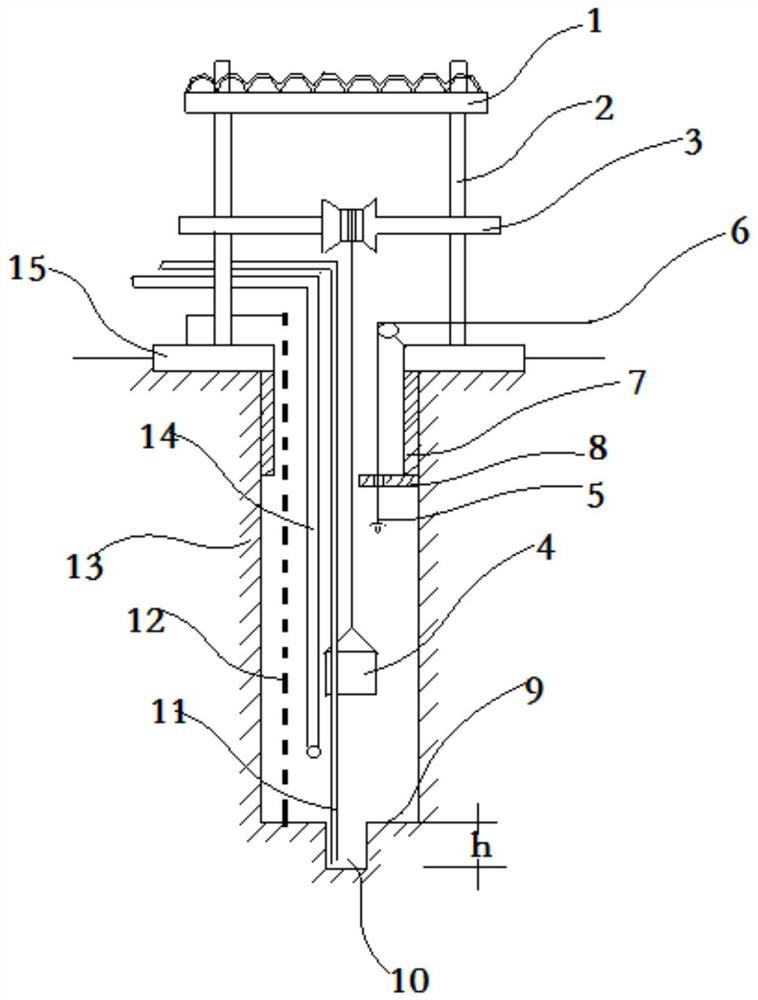

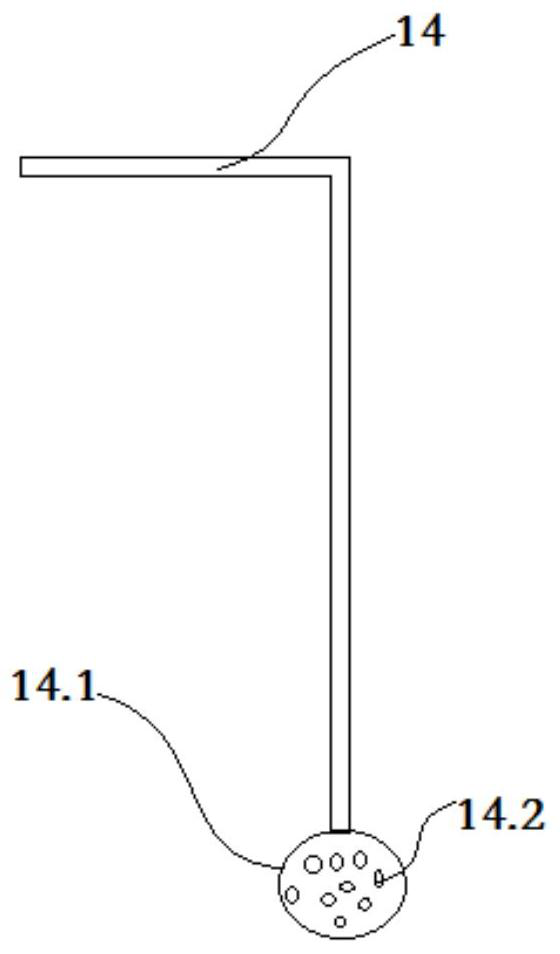

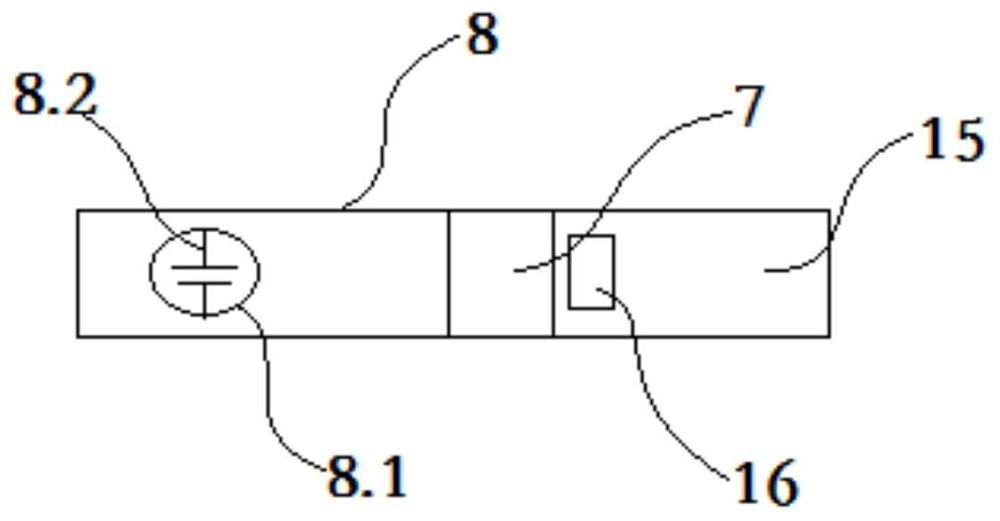

Manual hole digging pile hole mechanical high-pressure grouting construction protection device and manual hole digging pile hole construction method

InactiveCN111749239APrevent fallingEnsure safetyBulkheads/pilesArchitectural engineeringDrainage tubes

The invention relates to the technical field of pile foundation hole digging, in particular to a manual hole digging pile hole mechanical high-pressure grouting construction protection device and a manual hole digging pile hole construction method. By combing selection and installation of a to-be-dug pile foundation site of the manual hole digging pile, and by combining the arrangement of the connecting relation among stand columns, a protective shed, a winch, a soil container, a telescopic retaining wall, a protective end plate, a well bottom, a water collecting pit, a drainage pipe, a crawling ladder, an air supply pipe, the front end of a retaining wall and other components, rainwater and falling objects can be effectively prevented from falling into a manual hole digging pile hole in the construction process of the manual hole digging pile, the safety of constructors is ensured, meanwhile, the device is simple in structure and good in wall protection effect, the excavated well wallis protected through fixed connection between the front end of the protection wall and the telescopic protection wall and telescopic protection wall operation of the telescopic protection wall, the defects that in the traditional concrete pouring process, the difficulty is large, and the pouring protection period is long are overcome, and the protective security is improved.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP SAIDE CONSTR CO LTD

Graphene oxide-sodium alga acid magnetic composite material and preparation method thereof

InactiveCN107474304AMagnetic hasEnsure uniformity of dispersionOrganic/organic-metallic materials magnetismBiological materialsGraphite oxide

The invention discloses a graphene oxide-sodium alga acid magnetic composite material and a preparation method thereof. The preparation process comprises the following steps: modifying sodium alginate using polyamidoamine (PAMAM); performing freeze-drying treatment using liquid nitrogen so as to obtain a sodium alga acid / silk magnetic porous composite material; dipping the sodium alga acid / silk magnetic porous composite material in a graphene oxide solution, taking out the composite material, repeatedly cleaning the material with ethanol and deionized water, and drying in vacuum, thereby obtaining the graphene oxide-sodium alga acid magnetic composite material. According to the method disclosed by the invention, the sodium alga acid and silk are taken as base materials, graphene oxide is effectively self-assembled, and the prepared graphene oxide-sodium alga acid magnetic composite material has huge application value in the fields of adsorption materials, biological materials, medical materials and the like.

Owner:钱景

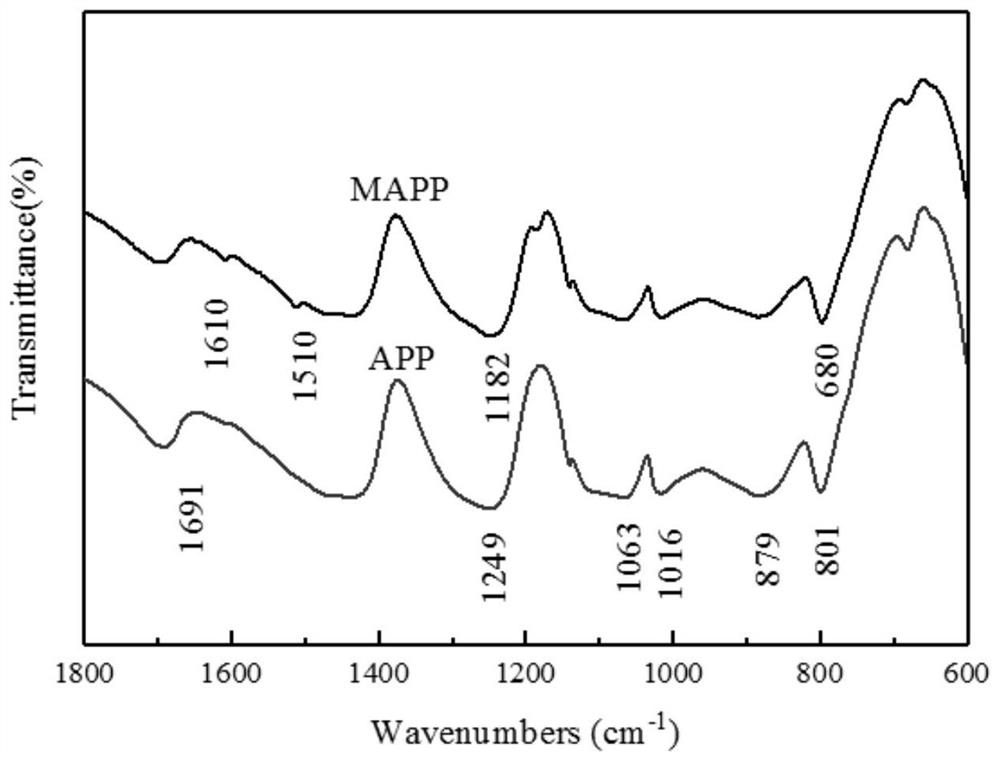

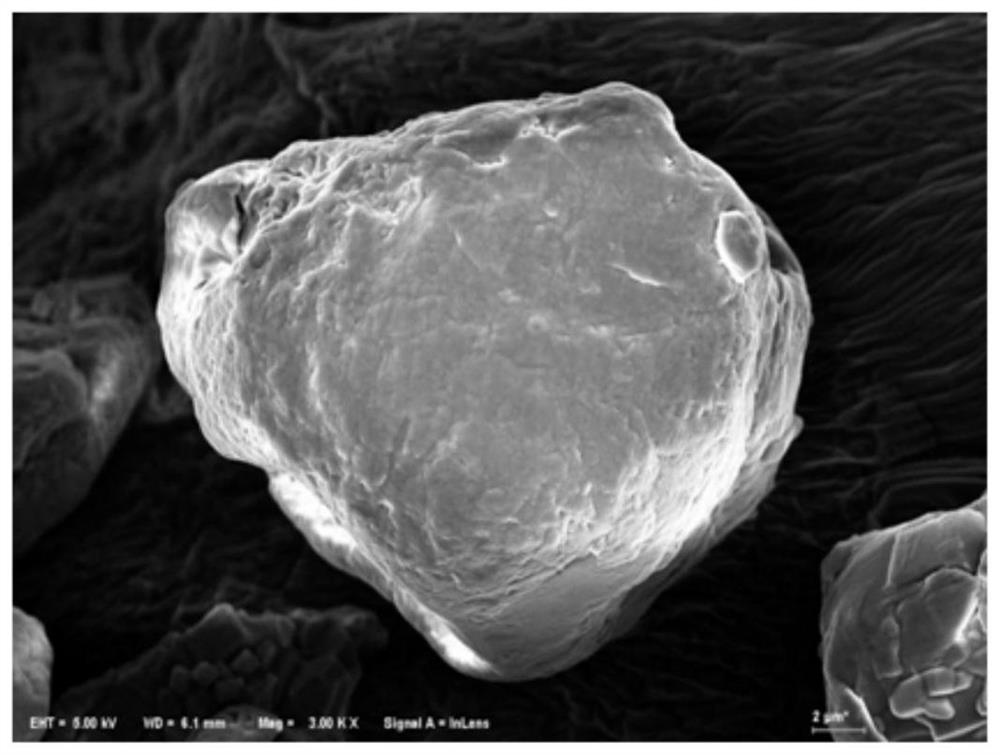

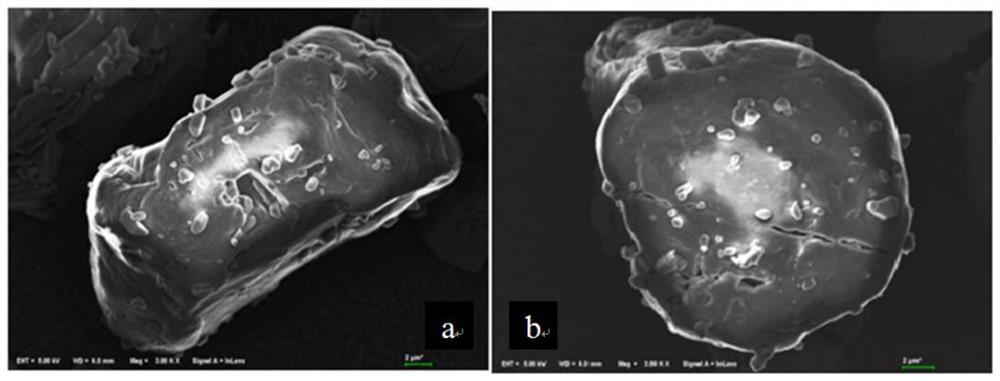

Method for preparing flame-retardant polypropylene by in-situ coating of modified ammonium polyphosphate

PendingCN111704769AFully curedEnsure uniformity of dispersionMicroballoon preparationMicrocapsule preparationEpoxyPolymer science

The invention relates to a method for preparing flame-retardant polypropylene by in-situ coating of modified ammonium polyphosphate. The method comprises the following steps: taking epoxy resin as a wall material and ammonium polyphosphate as a core material; carrying out in-situ polymerization in a step heating mode to obtain epoxy resin coated ammonium polyphosphate microcapsules, compounding the epoxy resin coated ammonium polyphosphate microcapsules with pentaerythritol and other carbon sources to obtain an intumescent flame retardant, and finally mixing and molding polypropylene and the flame retardant to obtain the flame-retardant polypropylene product with excellent properties. Experiments show that the prepared ammonium polyphosphate microcapsules are more completely cured, the flame retardant property and charring performance of the final polypropylene product are greatly improved, and the dripping phenomenon is prevented.

Owner:WUHAN UNIV OF TECH

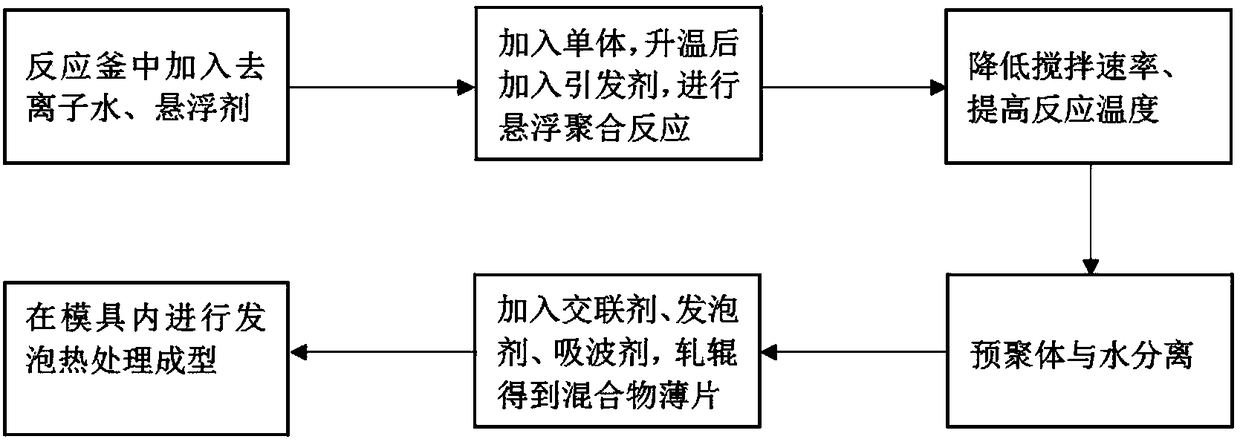

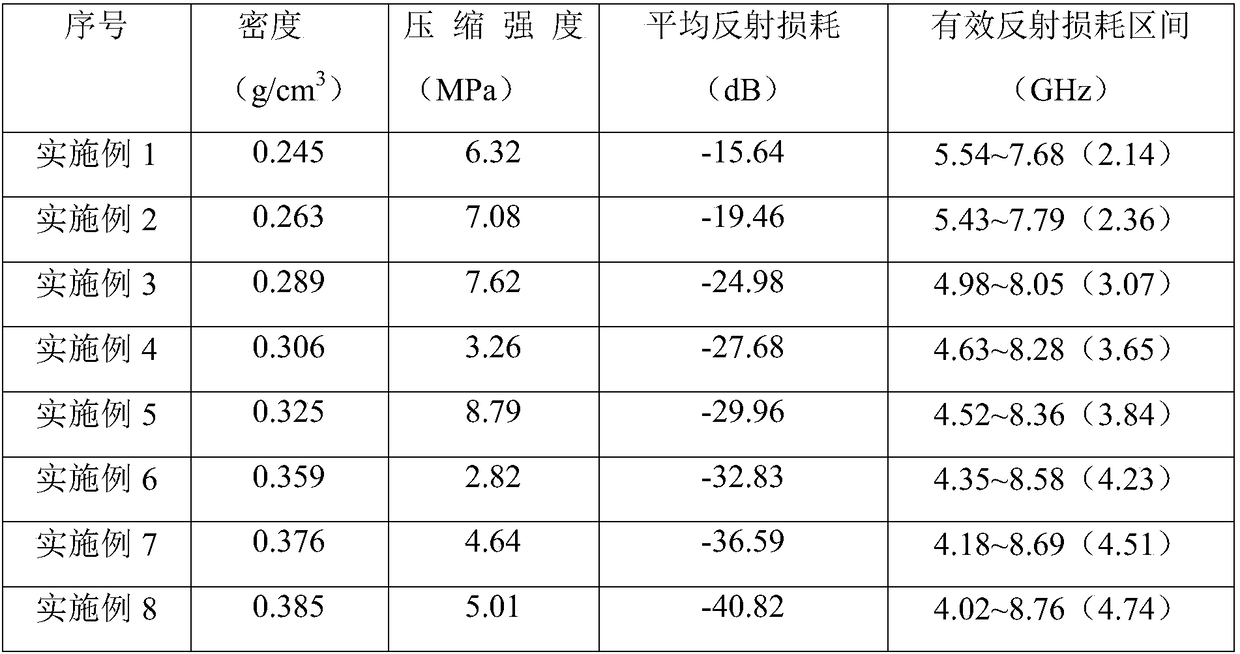

Preparation method of high-density ultra-thick wave-absorbing polymethacrylimide (PMI) foam composite material

The invention discloses a preparation method of a high-density ultra-thick wave-absorbing polymethacrylimide (PMI) foam composite material. (Methyl) acrylonitrile and (methyl) acrylic acid are taken as comonomers; free radical suspension polymerization is carried out in a form of small liquid drops in presence of a suspending agent, and a microwave absorbing agent is introduced into the reaction system, so that the wave-absorbing PMI foam composite material is prepared. The foam composite material prepared by using the method can be directly prepared into a molding part by being foamed in a specific mould; furthermore, the preparation method is high in production efficiency and simple and convenient to operate. The high-density ultra-thick wave-absorbing PMI foam composite material can beapplied to the military field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Polyurethane foam with organosilicon modified expanded graphite as flame retardant

The invention relates to a polyurethane foam, especially to a polyurethane foam with organosilicon modified expanded graphite as a flame retardant. The polyurethane foam must contains organosilicon modified expanded graphite. The polyurethane foam further comprises polyester polyol, 1,4-cyclohexane diisocyanate, hydroxyl-terminated fluorosilicone resin, stannous octoate, triethylenediamine, a surfactant, an antioxidant and a drier. The polyurethane foam of the invention has the following beneficial effects: (1) good flame retardant effect; (2) low addition amount of the flame retardant; (3) good heat preservation effect; (4) no residual raw material inside the foam and no harm to the human body.

Owner:德清顾舒家华高分子材料有限公司

Graphene and silver nanowire loaded silk/sodium alginate porous composite material

The invention discloses a graphene and silver nanowire loaded silk / sodium alginate porous composite material and a preparation method. The preparation process comprises the following steps: modifyingsodium alginate with PAMAM; preparing a silk / sodium alginate porous composite material through liquid nitrogen and freeze drying treatment; soaking the silk / sodium alginate porous composite material in a graphene oxide solution for sufficient adsorption; reducing with a reducing agent to obtain a graphene loaded silk / sodium alginate three-dimensional porous composite material; finally, performinglayer-by-layer self-assembly of a silver nanowire on the surface of the graphene loaded silk / sodium alginate three-dimensional porous composite material by use of electrostatic attraction, to finallyobtain the graphene and silver nanowire loaded silk / sodium alginate porous composite material. According to the invention, the sodium alginate and the silk are adopted as base materials, and the graphene and the silver nanowire are subjected to effective self-assembly to obtain the graphene and silver nanowire loaded silk / sodium alginate porous composite material which has huge application value in the fields such as photoelectric material, adsorption materials, biological materials and medical materials.

Owner:赵兵

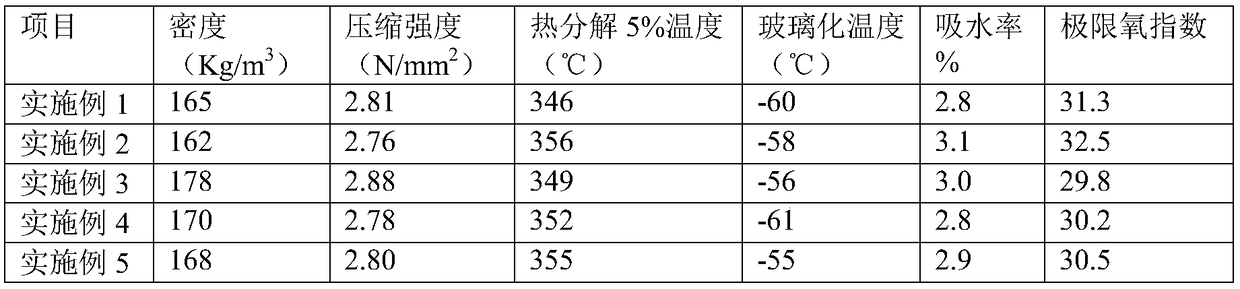

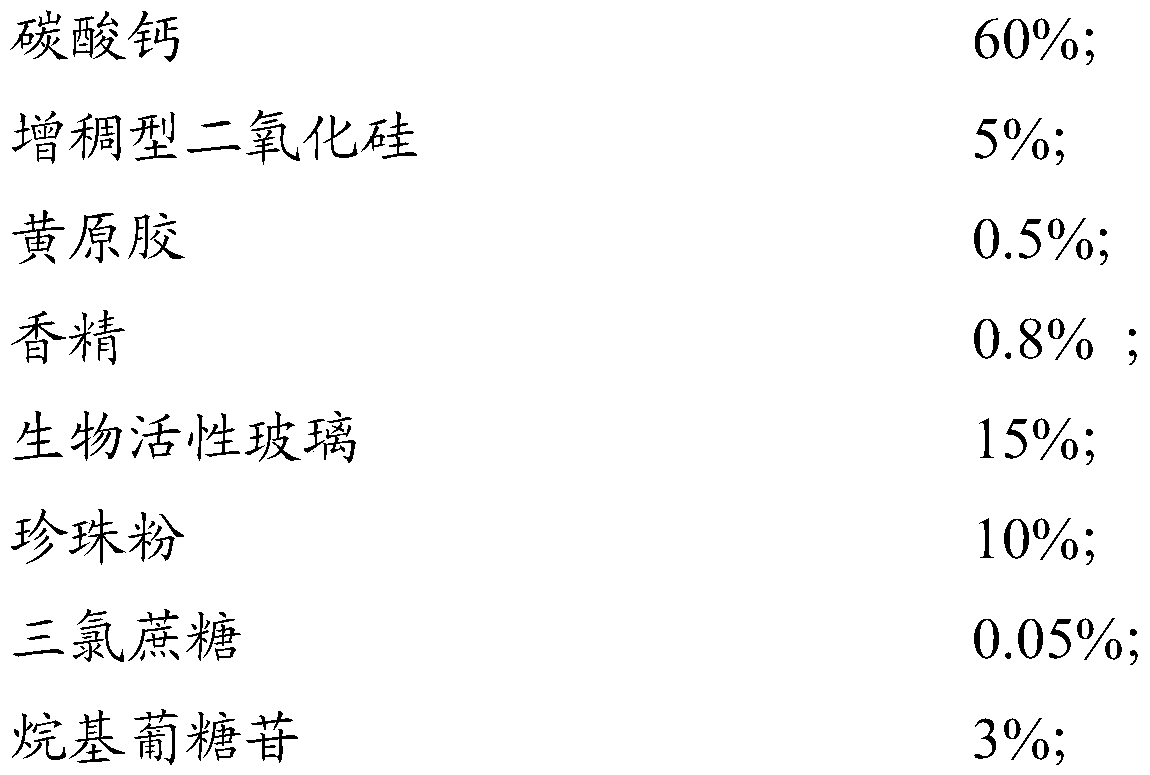

Tooth powder having function of repairing oral mucosa and preparation method of tooth powder

ActiveCN110623848AHas low free water propertiesHas cell repair functionCosmetic preparationsToilet preparationsFoaming agentBioactive glass

The invention discloses tooth powder having function of repairing oral mucosa and a preparation method of the tooth powder, and belongs to the technical field of oral care products. The tooth powder having function of repairing oral mucosa is mainly prepared from the following raw materials of an abrasive, a mouth feel adjusting agent, edible essence, a foaming agent, active components and water,wherein the active components comprise bioactive glass. The tooth powder has the characteristics of being stable in active matter content, and prominent in efficacy, can solve the difficult problem that conventional bioactive glass has poor stability in oral care products, and the tooth powder has the effects of repairing oral mucosa and protecting gum.

Owner:GUANGZHOU LIBY

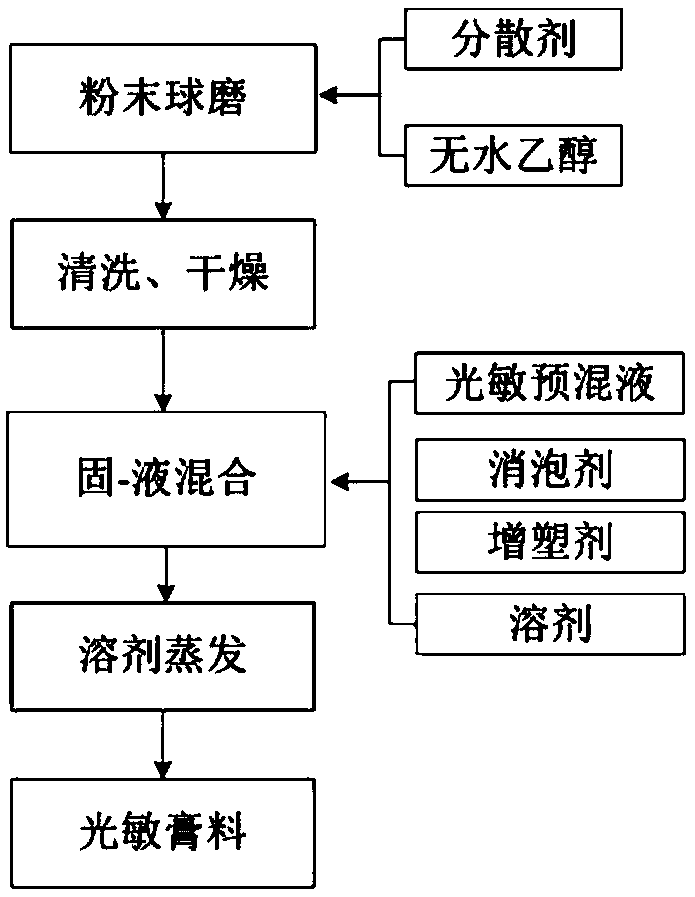

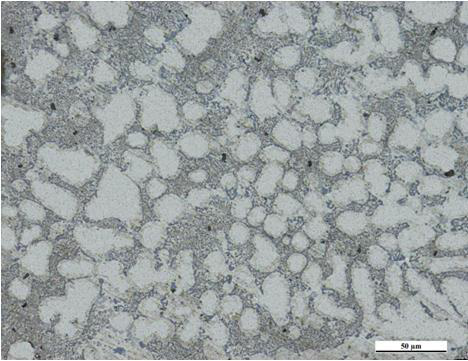

Homogenizing preparation technique of zirconium oxide/aluminum oxide composite photo-sensitive paste based on SLA-3D (stereo lithography apparatus-three dimensional) printing

ActiveCN109456041ATo achieve toughening and reinforcementImprove mechanical propertiesAdditive manufacturing apparatusComposite ceramicPlasticizer

The invention belongs to the technical field of preparation of photo-sensitive ceramic paste, and particularly relates to a homogenizing preparation technique of a zirconium oxide / aluminum oxide composite photo-sensitive paste based on SLA-3D (stereo lithography apparatus-three dimensional) printing. The homogenizing preparation technique comprises the following steps of (1) adding a composite ceramic powder containing aluminum oxide and zirconium oxide into an ethanol solution containing a dispersant, performing ball milling and dispersing, drying, and screening, so as to obtain the zirconiumoxide / aluminum oxide composite ceramic powder; (2) mixing an active thinner, a pre-polymer and a photo-initiator to obtain a photo-sensitive premix solution; mixing the photo-sensitive premix solution and a plasticizer, so as to obtain an organic solution; (3) uniformly mixing the prepared composite ceramic powder in step (1) and the organic solution in step (2), slowly evaporating the solution,and finally obtaining the homogenizing composite ceramic photo-sensitive paste. The prepared homogenizing composite ceramic photo-sensitive paste has the advantages that the content of solid is greater than 75 wt%, and the dispersing uniformity of the composite ceramic powder in organic resin is effectively guaranteed.

Owner:SHANDONG UNIV

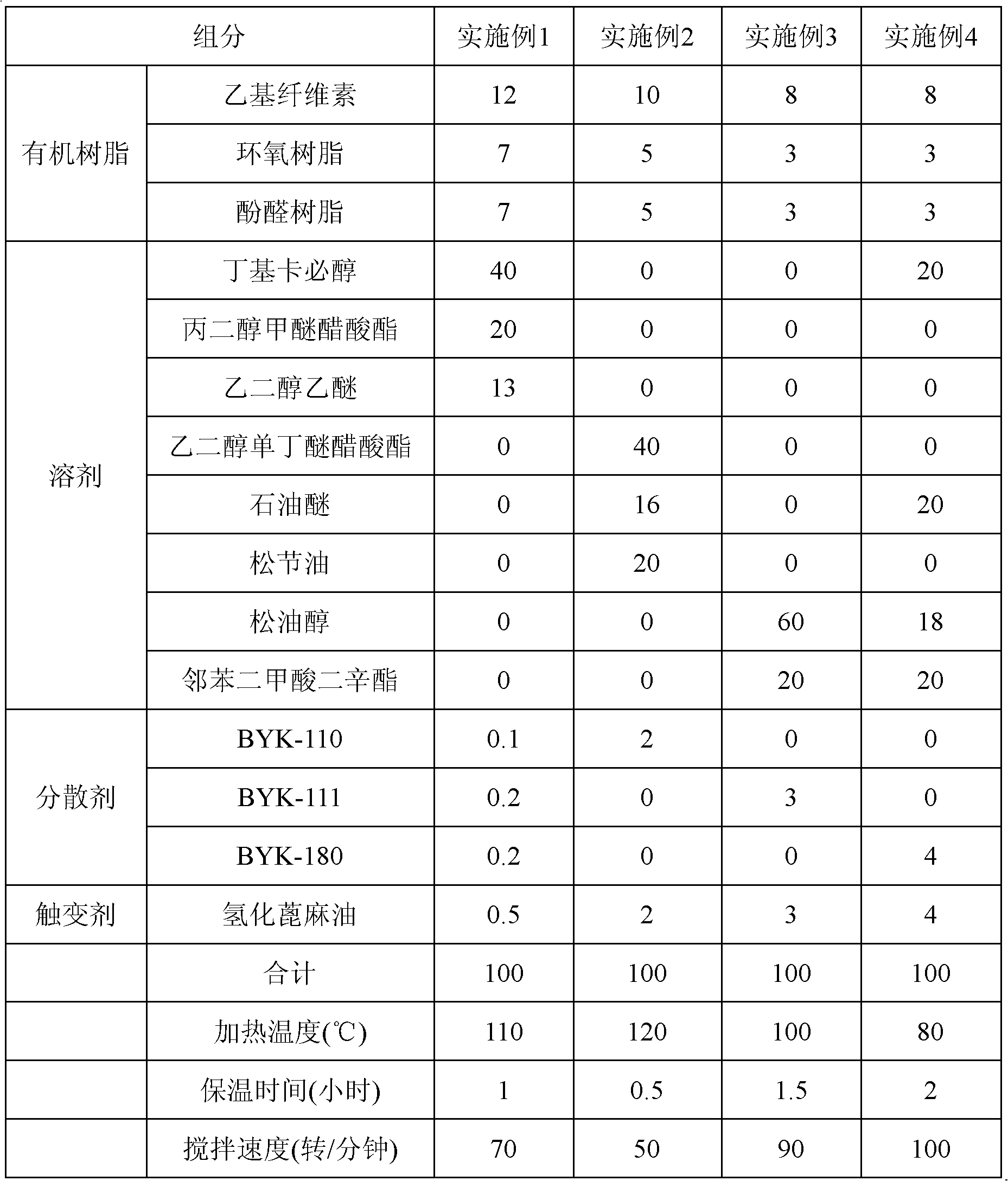

Organic adhesive for electrode paste of silicon solar cell and preparation method thereof

InactiveCN101864251AEnsure uniformity of dispersionIncrease aspect ratioAldehyde/ketone condensation polymer adhesivesCellulose adhesivesWater bathsGrating

The invention discloses an organic adhesive for the electrode paste of a silicon solar cell and a preparation method thereof. The preparation method comprises the following steps: (1) weighting the raw materials of the organic adhesive according to the raw material composition and weight percentages thereof; (2) adding the weighted components in a reaction tank using water bath, heating and stirring to ensure that resin powder is completely dissolved to form a yellowish and transparent solution, then keeping the temperature; and (3) cooling the yellowish and transparent solution, using a silkscreen to filter, and obtaining the organic adhesive for the electrode paste of the silicon solar cell. By using the paste prepared from the organic adhesive, the dispersion uniformity of solid powder material can be maintained, the paste can be stored for long time without layering, and the printed grating has larger height-width ratio and can not cause casting.

Owner:IRICO

Method for preparing aluminum matrix composite material through synergism of alterant and carbon nano-materials

The invention provides a method for preparing an aluminum matrix composite material through synergism of alterant and carbon nano-materials. The method comprises the following steps of: putting a matrix alloy in a crucible, heating to 740 to 750 DEG C, adding Al-Sr intermediate blocks in batches after melting, wherein the addition amount of Sr accounts for 0.04 to 0.06 wt.% of the total weight ofa melt, simultaneously applying ultrasound, causing an ultrasonic probe to stretch into the melt by about 3 to 5mm, wherein the ultrasonic power is 1.4 to 2.8kW, the frequency is 20kHZ, and the time is 5 to 10min; and after completing ultrasound, heating the melt to 770 DEG C to 780 DEG C, and carrying out heat preservation for 30 to 40 minutes; then adding Al-C intermediate blocks to the melt inbatches at different angles under the protection of argon, wherein the addition amount of the carbon accounts for 0.5-1.0wt.% of the total weight of the melt, simultaneously applying ultrasound for 10to 15 minutes, and after completing ultrasound, when the temperature of the melt drops to 700 DEG C, casting to obtain the aluminum matrix composite material. The method is stable, safe and reliablein process; the prepared material has uniform and refined structure; and the performances of the aluminum matrix composite material are greatly improved.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com