Production technology of high stability asphalt by modification of waste tyre rubber powder

A technology of waste tire rubber powder and modified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve problems such as poor stability, large discrete performance, and uneven distribution, so as to speed up uniformity and ensure stability , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

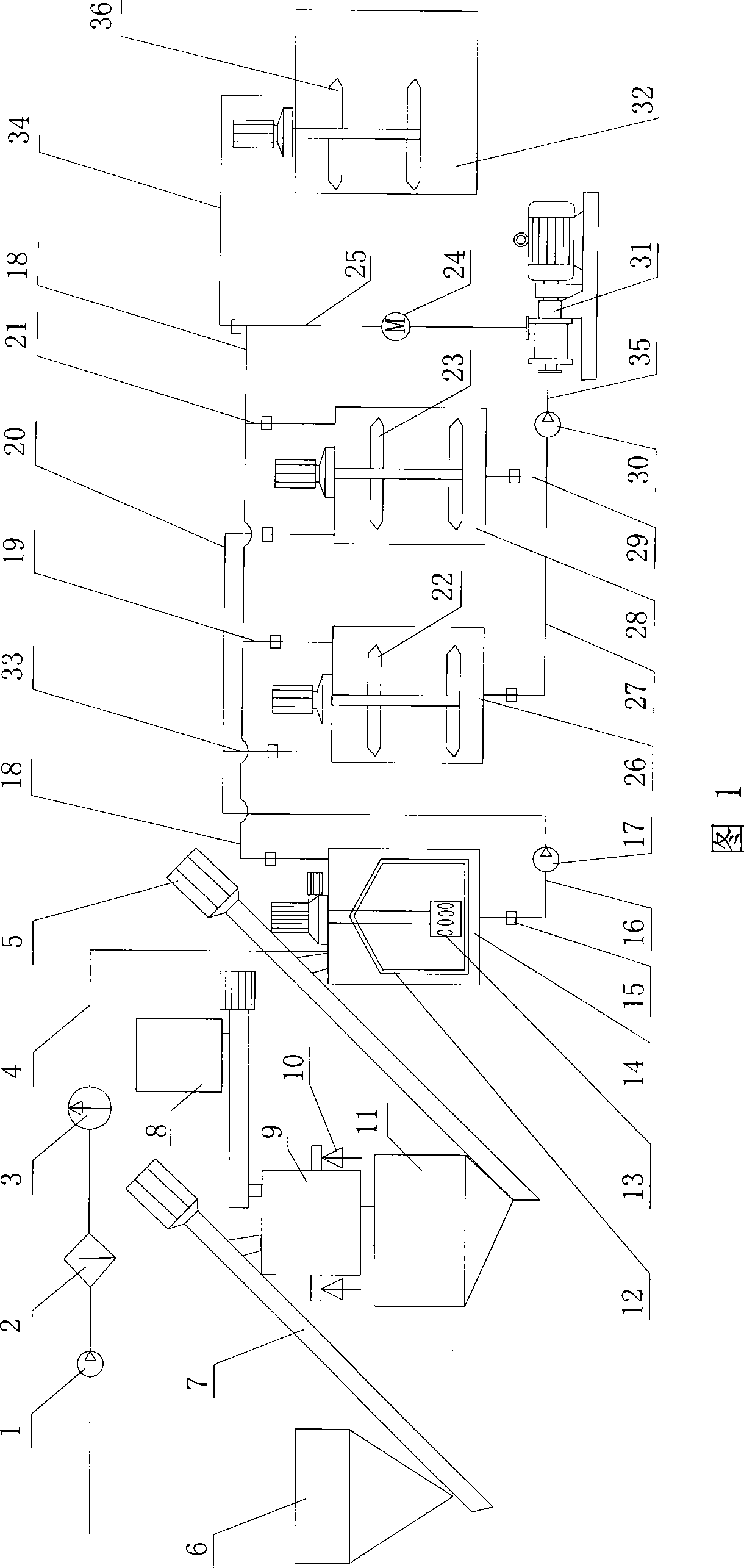

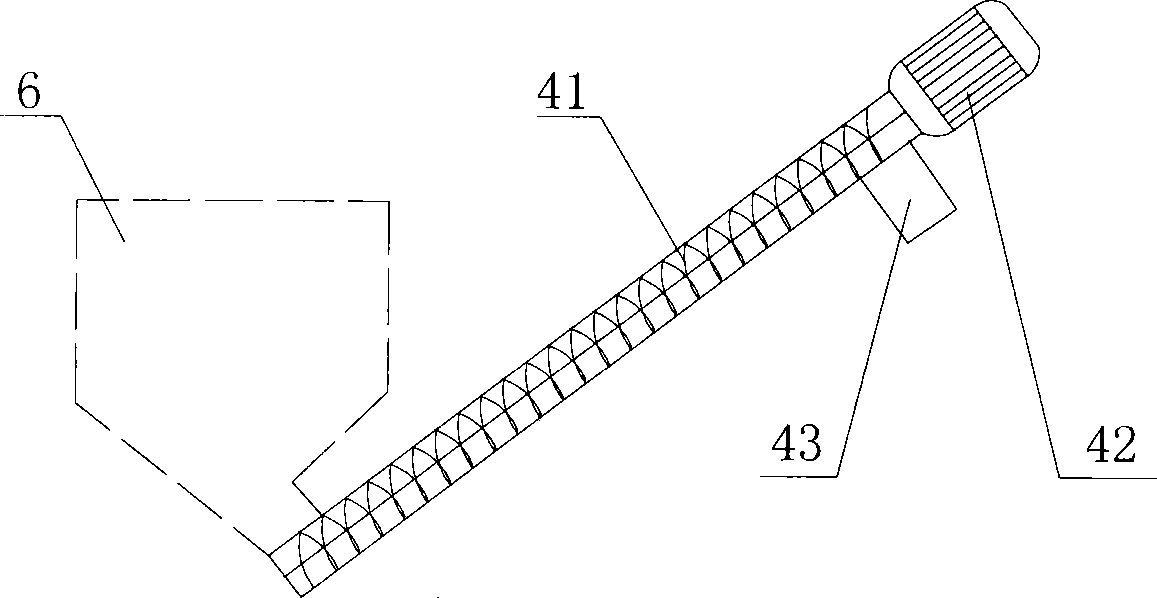

[0032] A production process for high-stability waste tire rubber powder modified asphalt, which comprises the following steps:

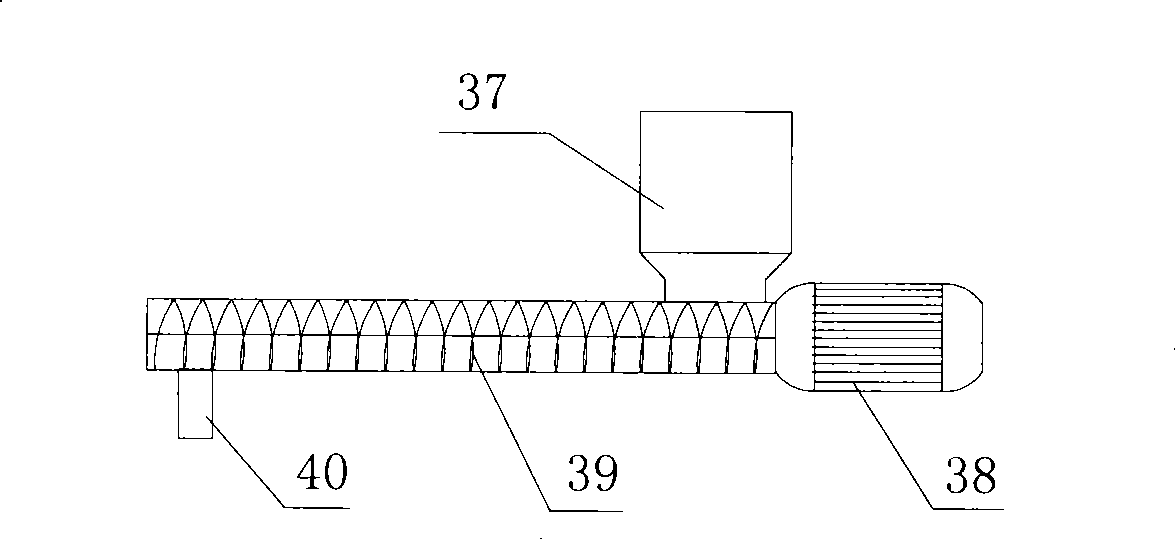

[0033] 1).Activate waste tire rubber powder: select RV rubber regenerant and waste tire rubber powder with 30-100 mesh fineness as 0.3-10% of the weight of waste tire rubber powder with RV rubber regenerant Tire rubber powder, spare; feed waste tire rubber powder with a fineness of 30 to 100 mesh and RV rubber regeneration agent into a high-speed mixer at normal temperature and pressure;

[0034] The high-speed mixer performs mixing and stirring at a speed greater than 800 rpm for 1.5 to 10 minutes, and the temperature is controlled at 20°C to 100°C, so that the surface of the waste tire rubber powder in the high-speed mixer is activated to obtain activated waste tire rubber powder;

[0035] 2). According to the activated waste tire rubber powder being 10-20% of the asphalt weight, select the activated waste tire rubber powder and asphalt, melt the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com