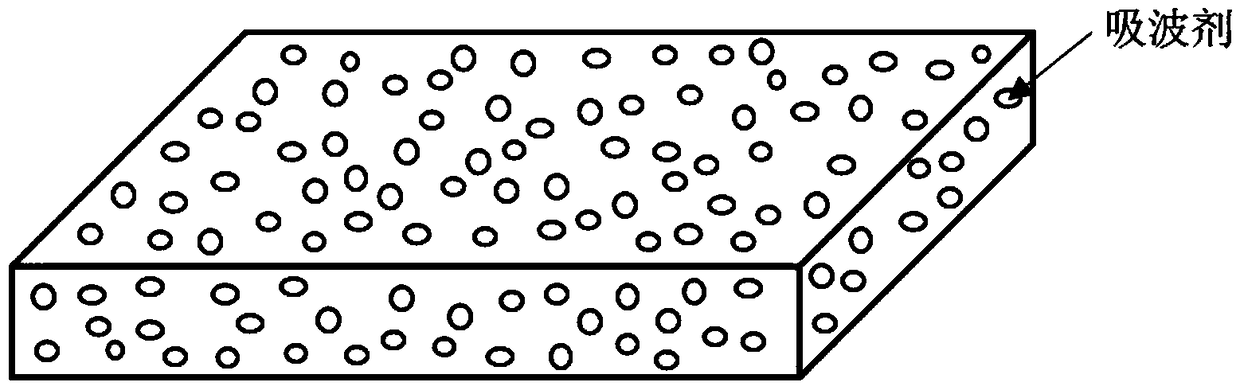

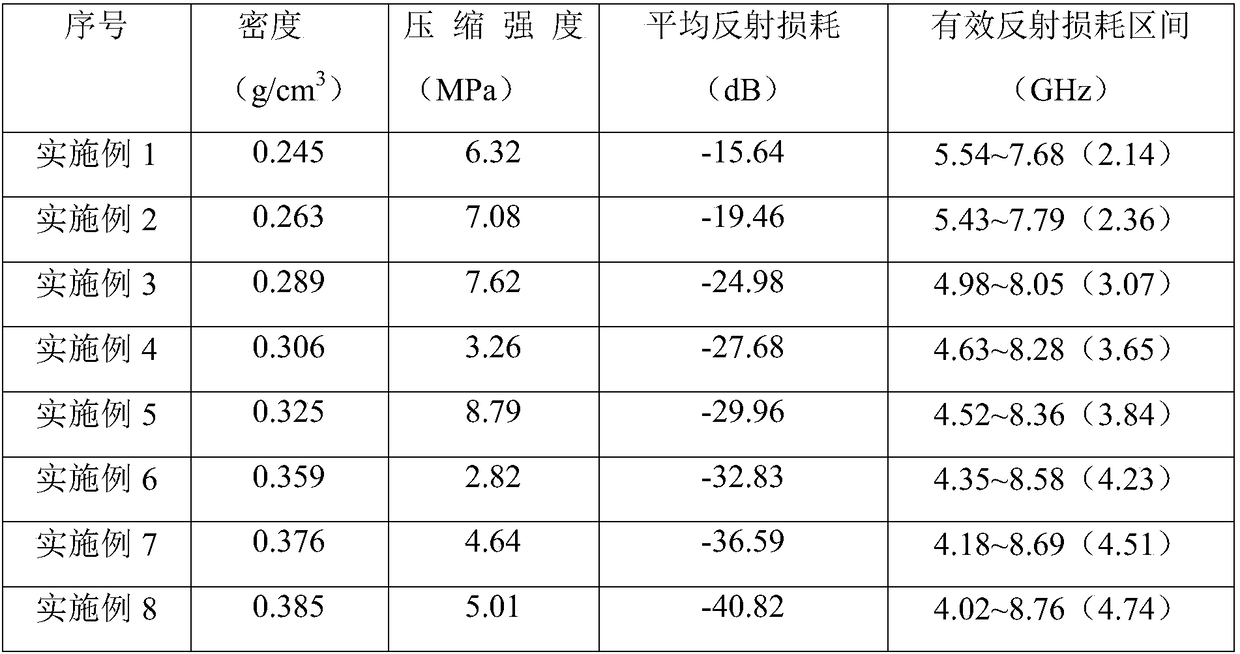

Preparation method of high-density ultra-thick wave-absorbing polymethacrylimide (PMI) foam composite material

A composite material and foam technology, applied in the field of preparation of functional composite foam, can solve the problems of low material utilization, long reaction time, sedimentation of wave absorbing agent, etc., and achieve the effect of improving wave absorbing performance, easy operation, and increasing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

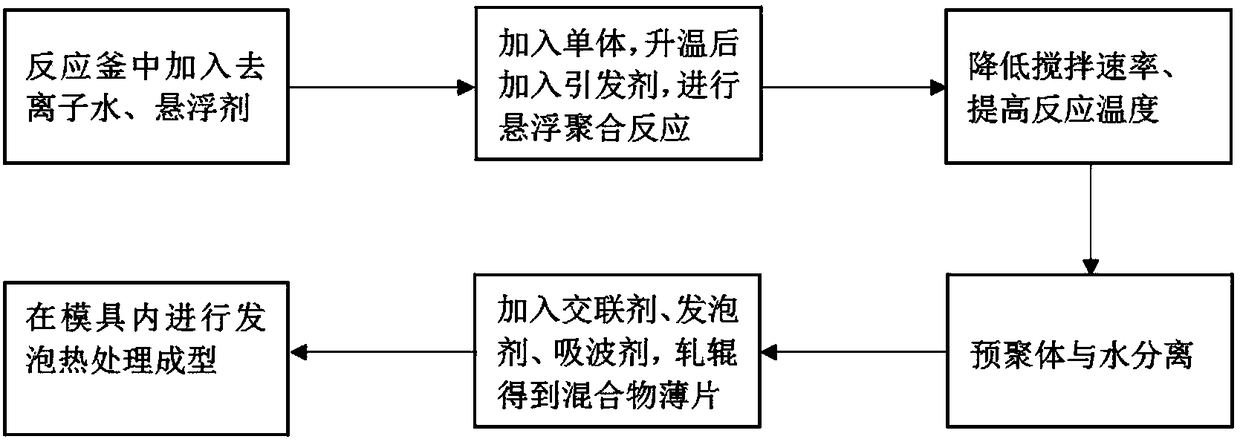

Method used

Image

Examples

Embodiment 1

[0037] Monomer: the molar ratio of acrylonitrile (AN) to methacrylic acid (MAA) is 1:1, and the total mass fraction is 100 parts.

[0038] Dispersion medium: the amount of deionized water is 100 parts, and the amount of suspending agent PVA1788 is 0.5 parts.

[0039] Initiator: azobisisobutyronitrile (AIBN), the dosage is 0.1 part.

[0040] Crosslinking agent: acrylamide (AM), the dosage is 0.5 parts.

[0041] Foaming agent: expanded microsphere foaming agent, the consumption is 1 part.

[0042] Wave absorbing agent: ferrite, the dosage is 10 parts.

[0043] Steps: first dissolve the suspending agent PVA in deionized water to prepare a suspending agent solution, put the solution into the reaction kettle, and turn on the stirring device at the same time. Add two kinds of reaction monomers in sequence, start heating, raise the temperature to 65°C, then add the initiator to the reaction kettle, adjust the rotation speed to 150r / min, and the viscosity of the suspension in the rea...

Embodiment 2

[0045] Monomer: The molar ratio of methacrylonitrile (MAN) to acrylic acid (AA) is 1:1, and the total mass fraction is 100 parts.

[0046] Dispersion medium: the amount of deionized water is 200 parts, and the amount of suspending agent PAAS is 2 parts.

[0047] Initiator: azobisisoheptanonitrile (ABVN), the dosage is 0.5 parts.

[0048] Cross-linking agent: acrylamide (AM), the dosage is 1 part.

[0049] Foaming agent: expansion microsphere foaming agent, consumption is 5 parts.

[0050] Wave absorbing agent: modified ferrite, the dosage is 15 parts.

[0051] Steps: first mix the suspending agent PAAS and deionized water, stir to obtain a colloid, and put the colloid into the reaction kettle, and the rest of the implementation process is similar to Example 1.

Embodiment 3

[0053] Monomer: the molar ratio of acrylonitrile (AN) to acrylic acid (AA) is 1.5:1, and the total mass fraction is 100 parts.

[0054] Dispersion medium: 150 parts of deionized water, suspending agent MgCO 3 The dosage is 3 servings.

[0055] Initiator: dibenzoyl peroxide (BPO), the dosage is 1 part.

[0056] Cross-linking agent: magnesium oxide (MgO), the dosage is 1.5 parts.

[0057] Foaming agent: azodicarbonamide (AC), the dosage is 8 parts.

[0058] Wave absorbing agent: ferrite, the dosage is 20 parts.

[0059] Steps: first add deionized water and suspending agent into the reaction kettle, adjust the stirring rate to 150r / min, add the monomer after stirring for 0.5h, and the rest of the implementation process is similar to that of Example 1. However, the follow-up foaming process is 180 ° C for 30 minutes, and the hot blowing process is 215 ° C for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com