Organic adhesive for electrode paste of silicon solar cell and preparation method thereof

A technology for silicon solar cells and organic binders, applied in the direction of binder types, cellulose binders, aldehyde/ketone condensation polymer binders, etc., can solve problems such as casting, and achieve large aspect ratios Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below:

[0023] An organic binder for a silicon solar cell electrode paste and a preparation method thereof, comprising the following basic steps:

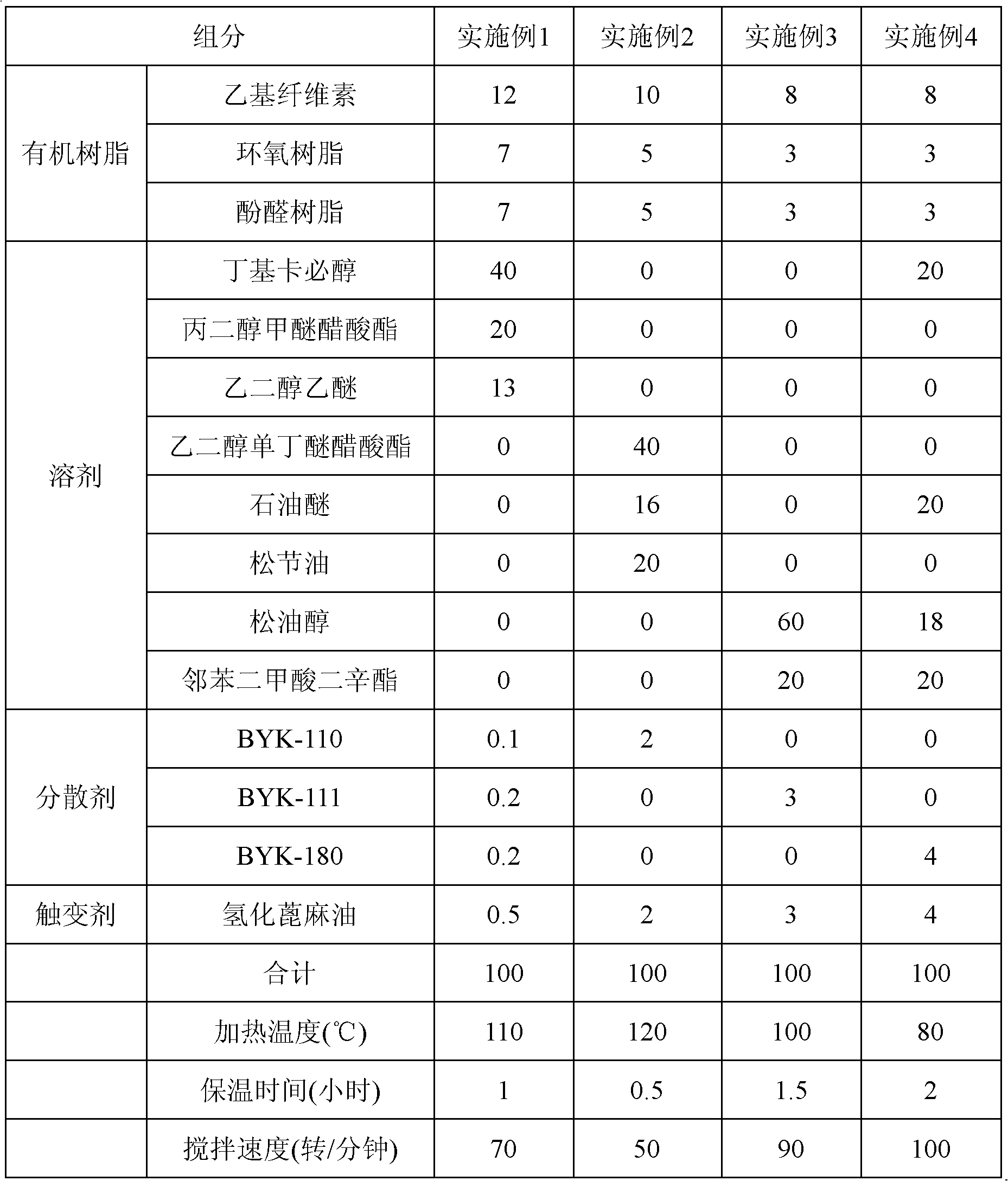

[0024] (1) Weigh the components of the organic binder according to mass percentage: ethyl cellulose 8-12%, epoxy resin 3-7%, phenolic resin 3-7%, organic solvent 68-82%, dispersant 0.5-4% and 0.5-4% thixotropic agent, the total mass percentage of each component is 100%;

[0025] (2) Add the weighed components into the oil bath reactor, heat and stir until the resin powder is completely dissolved to form a yellowish transparent solution, and then keep it warm;

[0026] (3) After cooling the pale yellow transparent solution in the step (2), filter through a 200-350 mesh screen to obtain an organic binder for silicon solar cell electrode paste.

[0027] Described organic solvent is butyl carbitol, propylene glycol methyl ether acetate, ethylene glycol ethyl ether, ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com