Patents

Literature

31results about How to "Less abrasive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibers, nonwovens and articles containing nanofibers produced from high glass transition temperature polymers

The present invention is directed to nonwoven webs and articles comprising nanofibers. The nanofibers are made from a polymer having a glass transition temperature about 25 C. The nanofibers, having a diameter of less than 1 micron, may comprise a significant number of the fibers in one layer of the web contained by the article. Preferably, the nanofibers are produced in a melt film fibrillation process. Articles include diapers, training pants, adult incontinence pads, catamenials products such as feminine care pads and pantiliners, tampons, personal cleansing articles, personal care articles, and personal care wipes including baby wipes, facial wipes, and feminine wipes.

Owner:PROCTER & GAMBLE CO

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

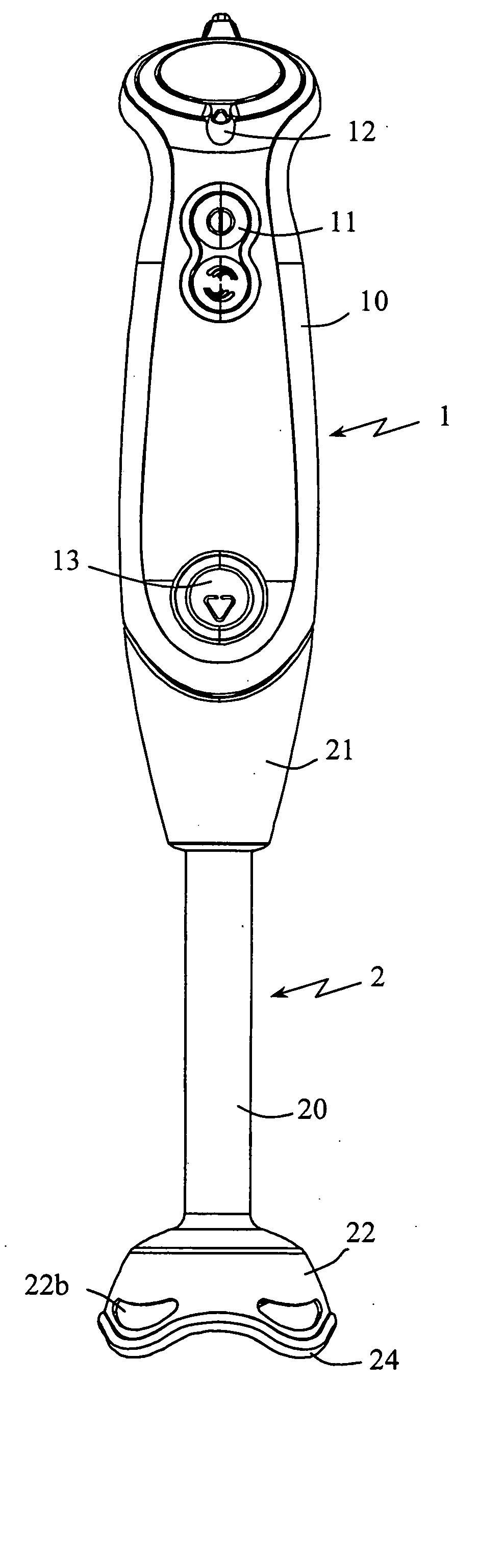

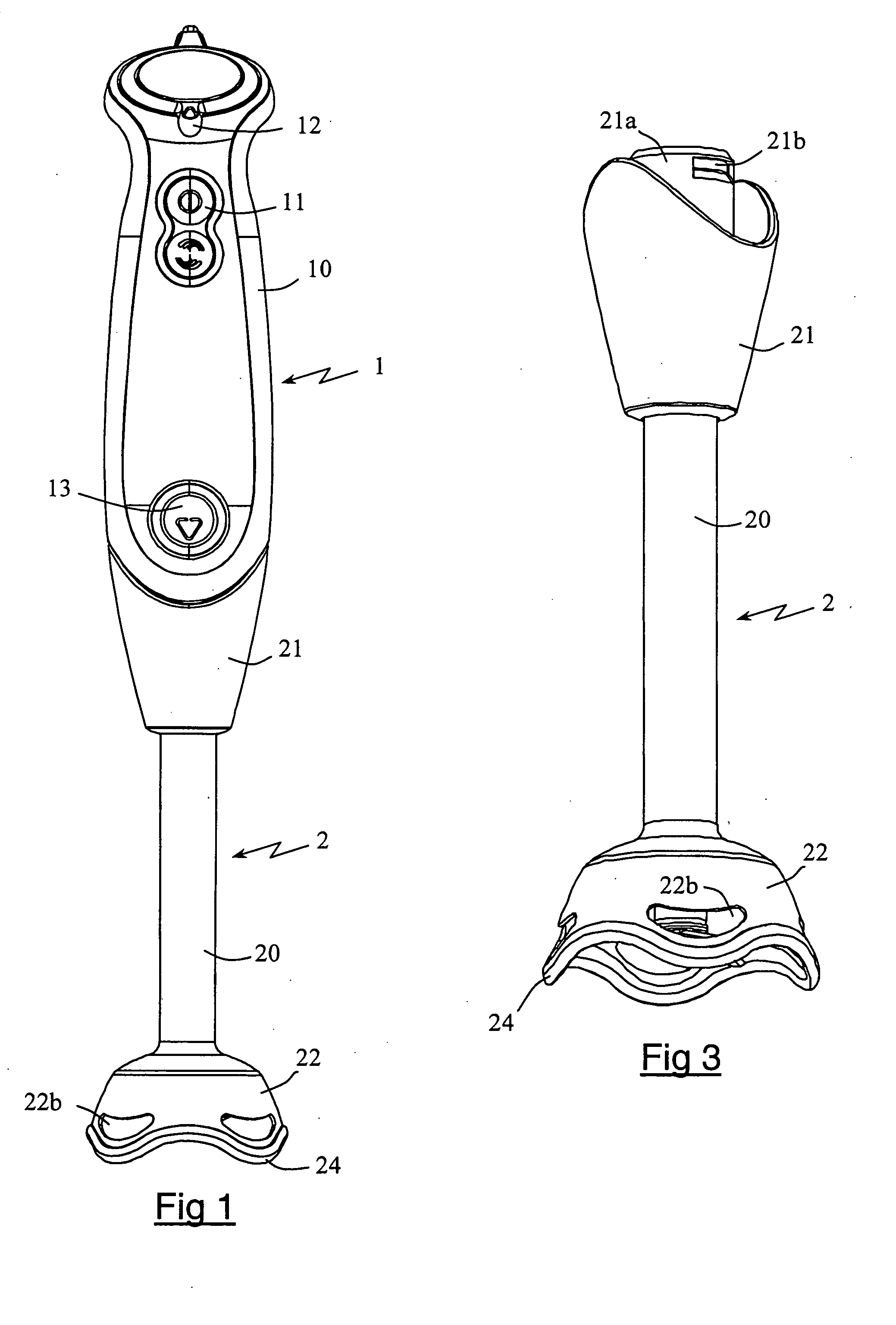

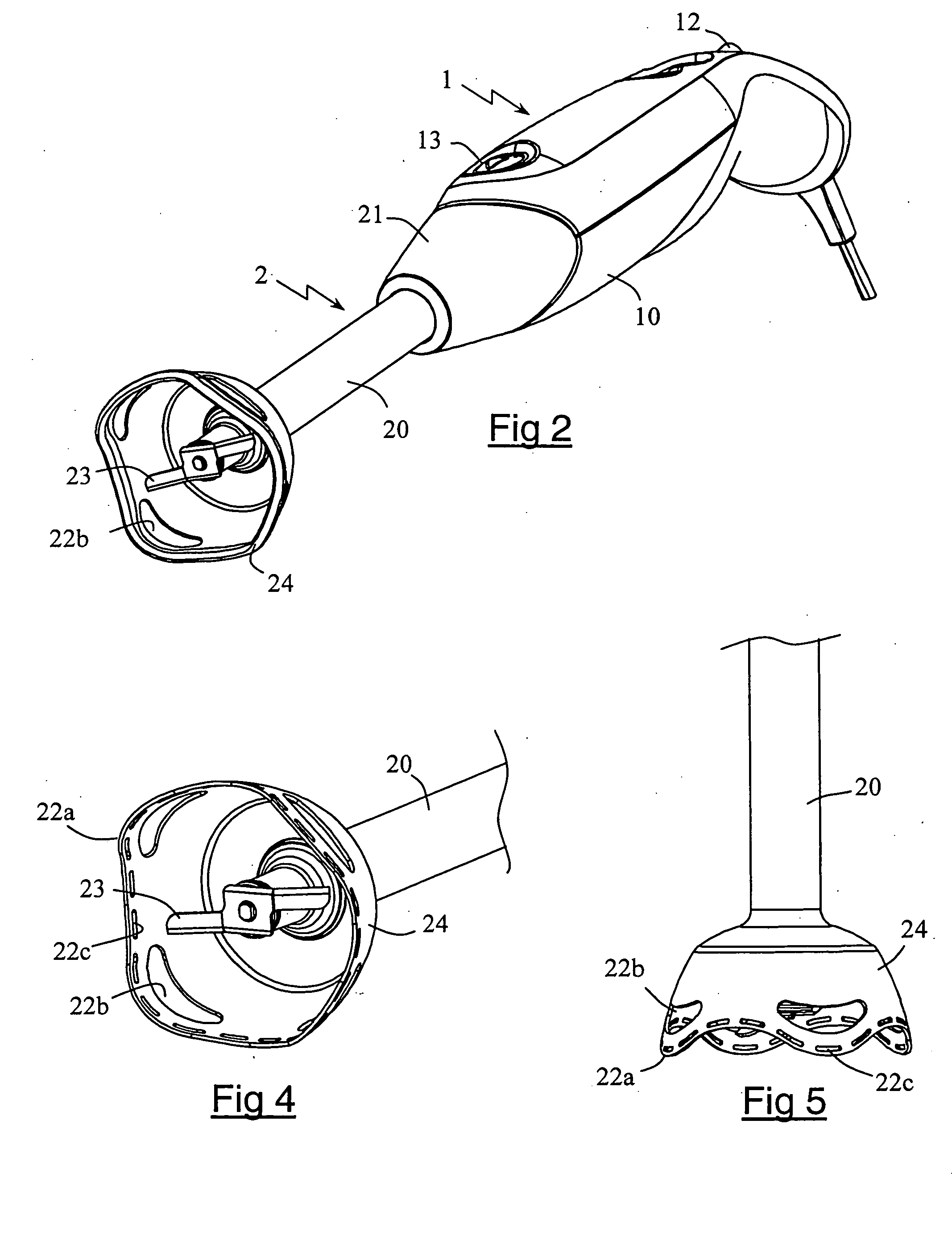

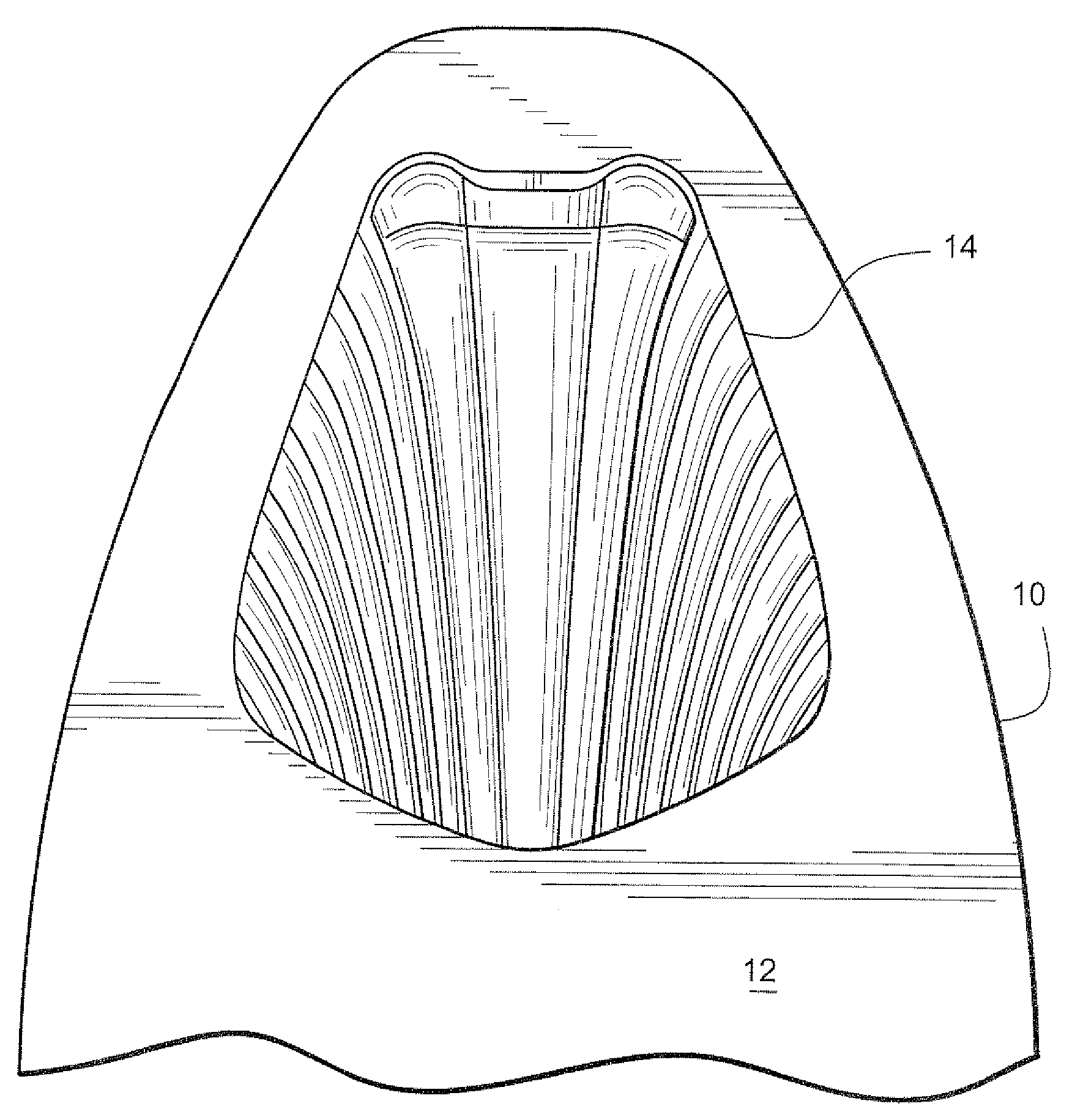

Mixer foot and hand held mixer equipped with the foot

InactiveUS20050078549A1Improve rigidityGood lookingMixer accessoriesKitchen equipmentHand heldEngineering

Owner:SEB SA

Nonabrasive sensory exfoliating system

InactiveUS20050169868A1Less abrasiveRemineralizes the skin surfaceCosmetic preparationsHair cosmeticsDermatologySilicone

The present invention relates to a method of exfoliating and warming the skin comprising the steps of topically applying a cosmetic or pharmaceutical composition. The composition comprises a physical exfoliating system of at least three insoluble particles of different materials, a heat generating agent and a silicone component.

Owner:E L MANAGEMENT

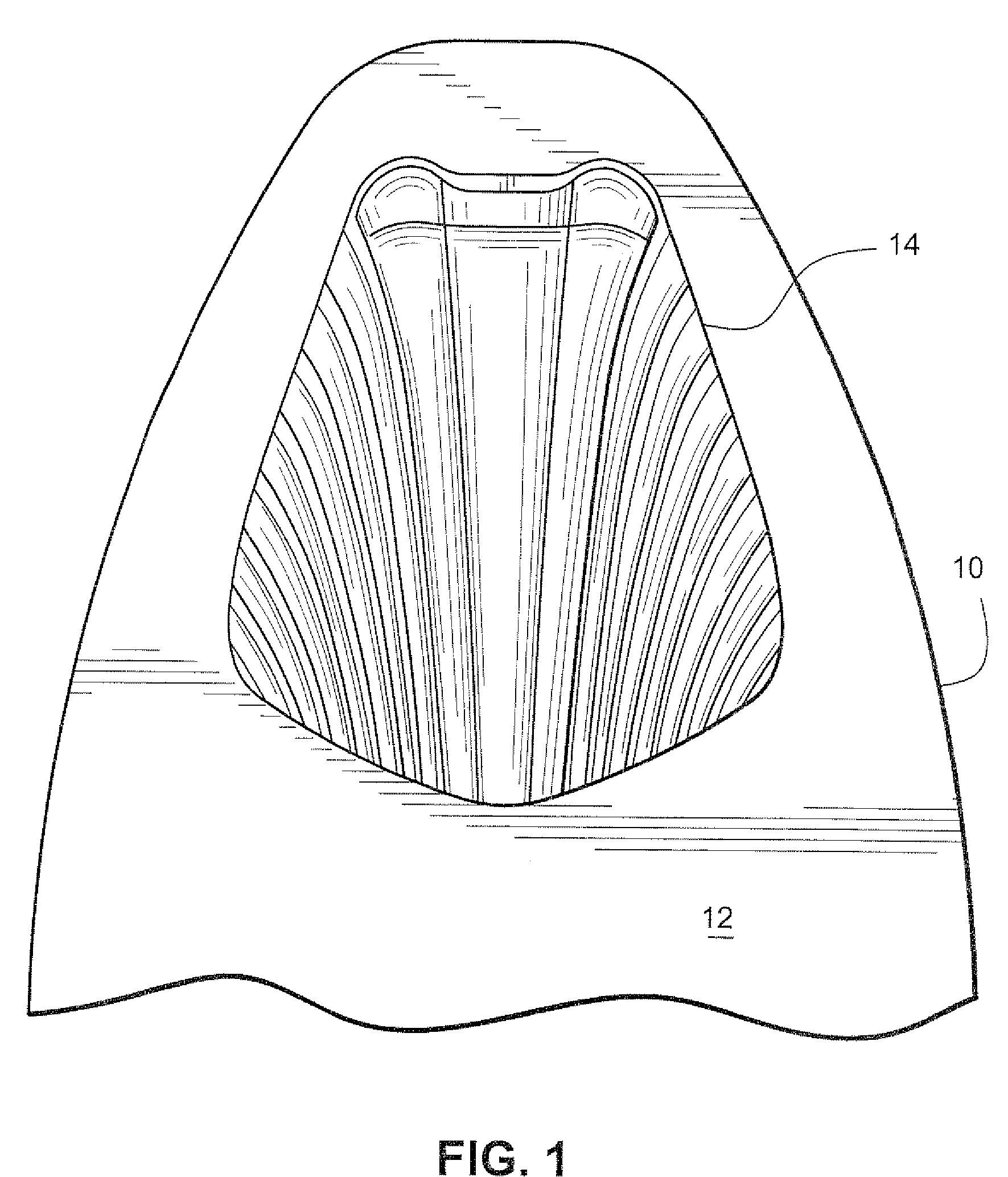

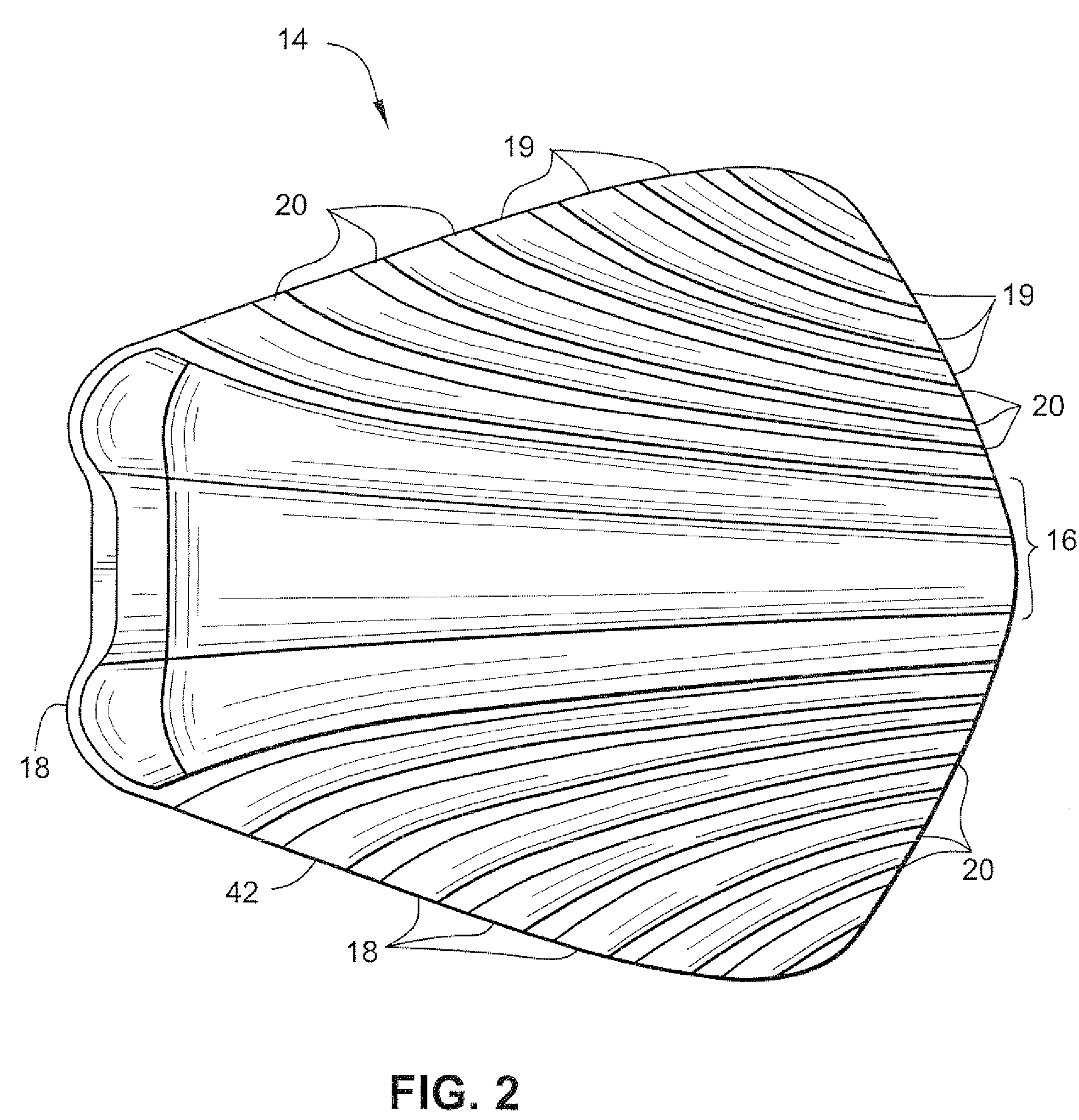

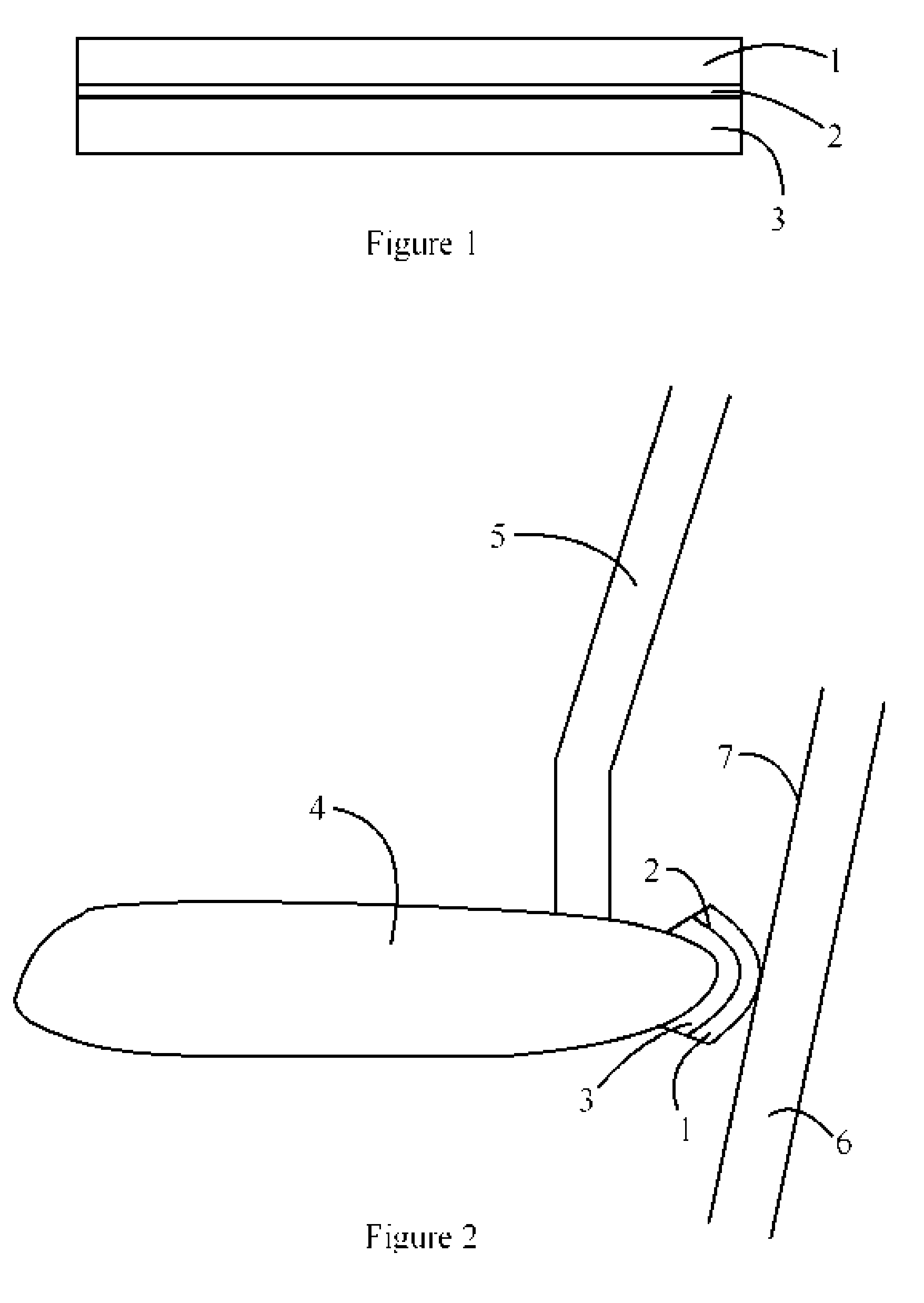

Traction pad for personal water board

InactiveUS7316597B2Less abrasiveCut skinWater sport boardsSnowboardsElastomerThermoplastic elastomer

A traction surface for a water board has been developed comprising: a traction pad formed of a molded clear thermo plastic elastomer (TPE) material, and an upper surface of the pad having a roughened texture. The upper surface of the pad may include a center ridge extending a length of the pad and substantially parallel to a centerline of the board. Further, the upper surface may include a back step at a rear of the pad and a plurality of interlaced ribs and grooves extending substantially parallel to a centerline of the board. The grooves may be spaced apart at substantially the spacing of the toes of a foot of an adult male. In addition, the pad may include a bottom surface having a lip extending around a perimeter of the bottom surface. Moreover, injection molding may form the pad.

Owner:SURFCO HAWAII

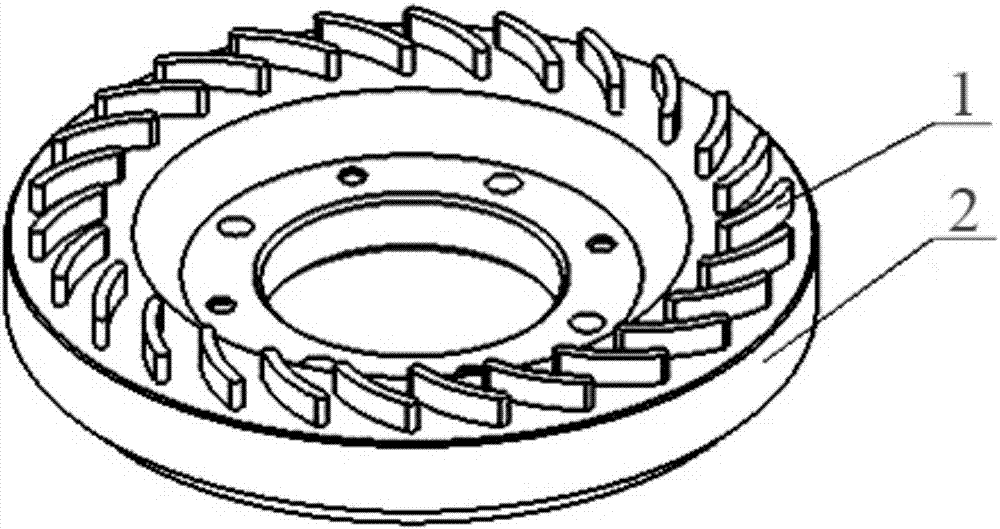

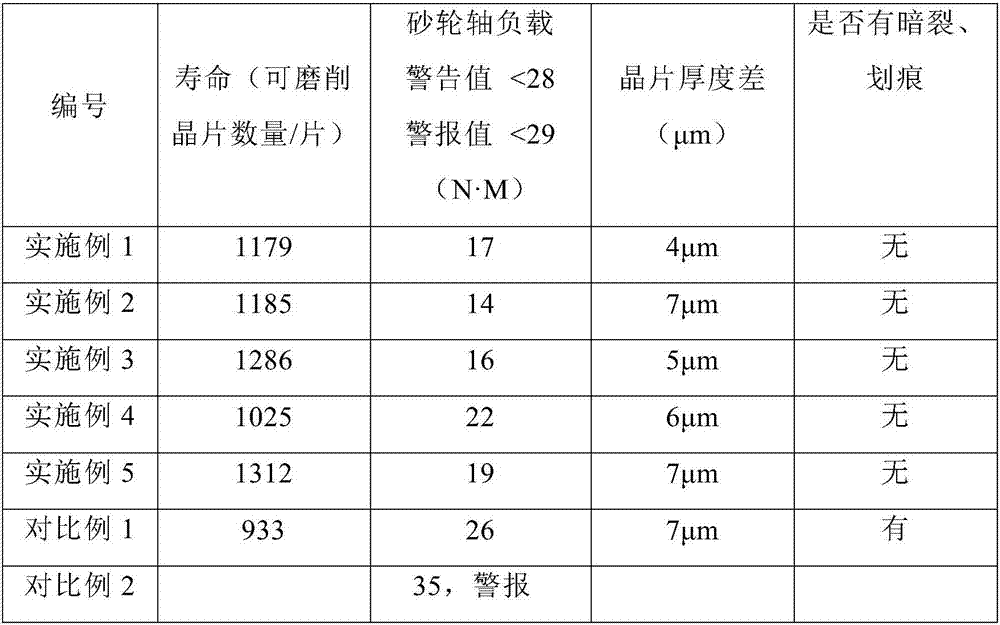

Metallic bond, diamond grinding wheel prepared through bond and preparation method of diamond grinding wheel

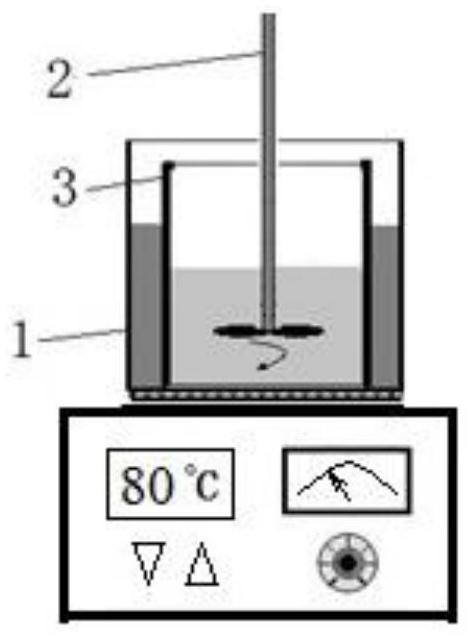

The invention relates to a metallic bond, a diamond grinding wheel prepared through the bond and a preparation method of the diamond grinding wheel. The metallic bond comprises, by weight percent, 95%-99% of copper-tin prealloyed powder, 0.5%-3% of graphite powder and 0.5%-2% of nanometer alpha-Al2O3. The copper-tin prealloyed powder, the graphite powder, the nanometer alpha-Al2O3 and diamond are taken according to a certain proportion, procedures of burdening and material mixing, pelletizing, compression, sintering and aftertreatment are carried out in sequence, and tool bits can be prepared. The multiple tool bits are arranged on a matrix at equal distance in the circumferential direction, the cambered surfaces of the tool bits are perpendicular to the matrix, and the diamond grinding wheel is prepared. The above tool bits are uniform in ingredient and good in density, diamond distribution is uniform, and the control effect of the metallic bond on the diamond is good. The grinding wheel has the beneficial effects of being good in ground workpiece surface quality, free of dark cracks and scratches, sharp in grinding and long in service life, facilitating large-scale production and the like and is especially suitable for producing sapphire wafers with the thinning thickness ranging from 100 micrometers to 700 micrometers.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Fibers, nonwovens and articles containing nanofibers produced from broad molecular weight distribution polymers

The present invention is directed to articles comprising nanofibers. The nanofibers, having a diameter of less than 1 micron, may comprise a significant number of the fibers in one layer of the web contained by the article. Preferably, the nanofibers are produced in a melt film fibrillation process. The articles include diapers, training pants, adult incontinence pads, catamenials products such as feminine care pads and pantiliners, tampons, personal cleansing articles, personal care articles, and personal care wipes including baby wipes, facial wipes, and feminine wipes.

Owner:PROCTER & GAMBLE CO

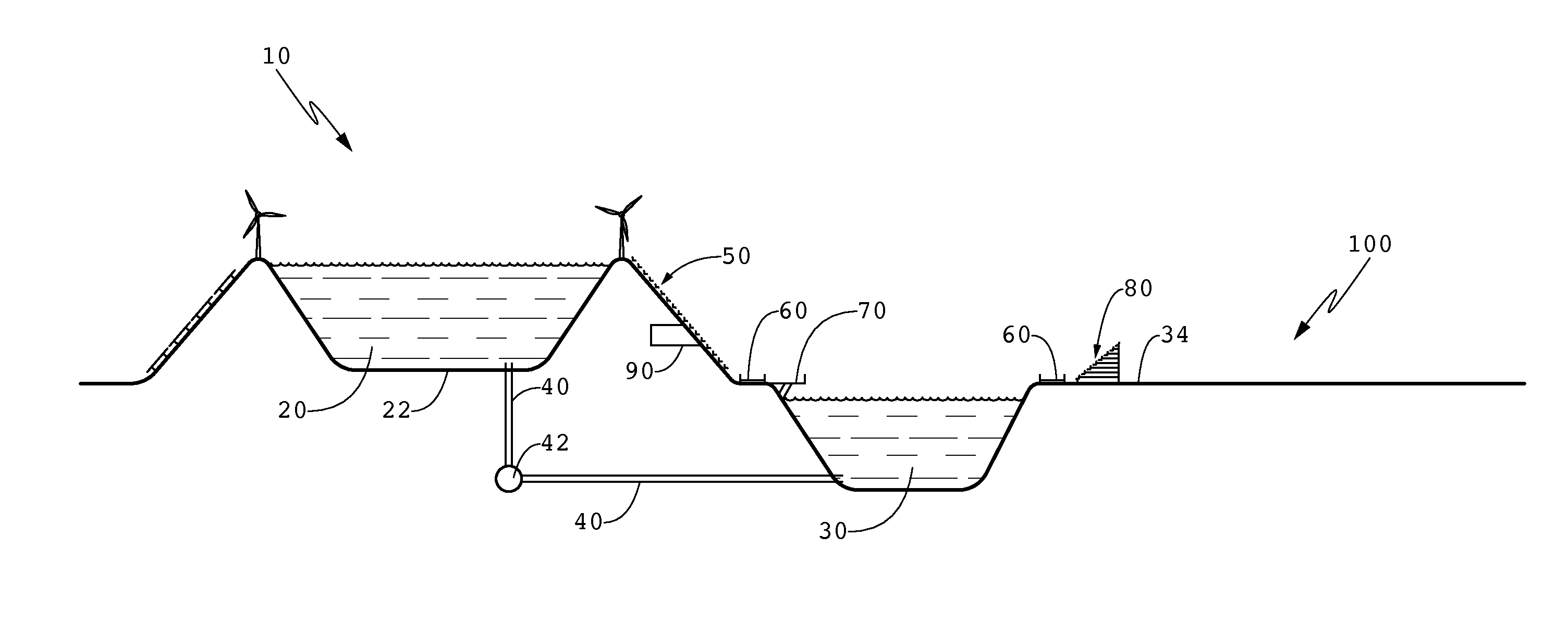

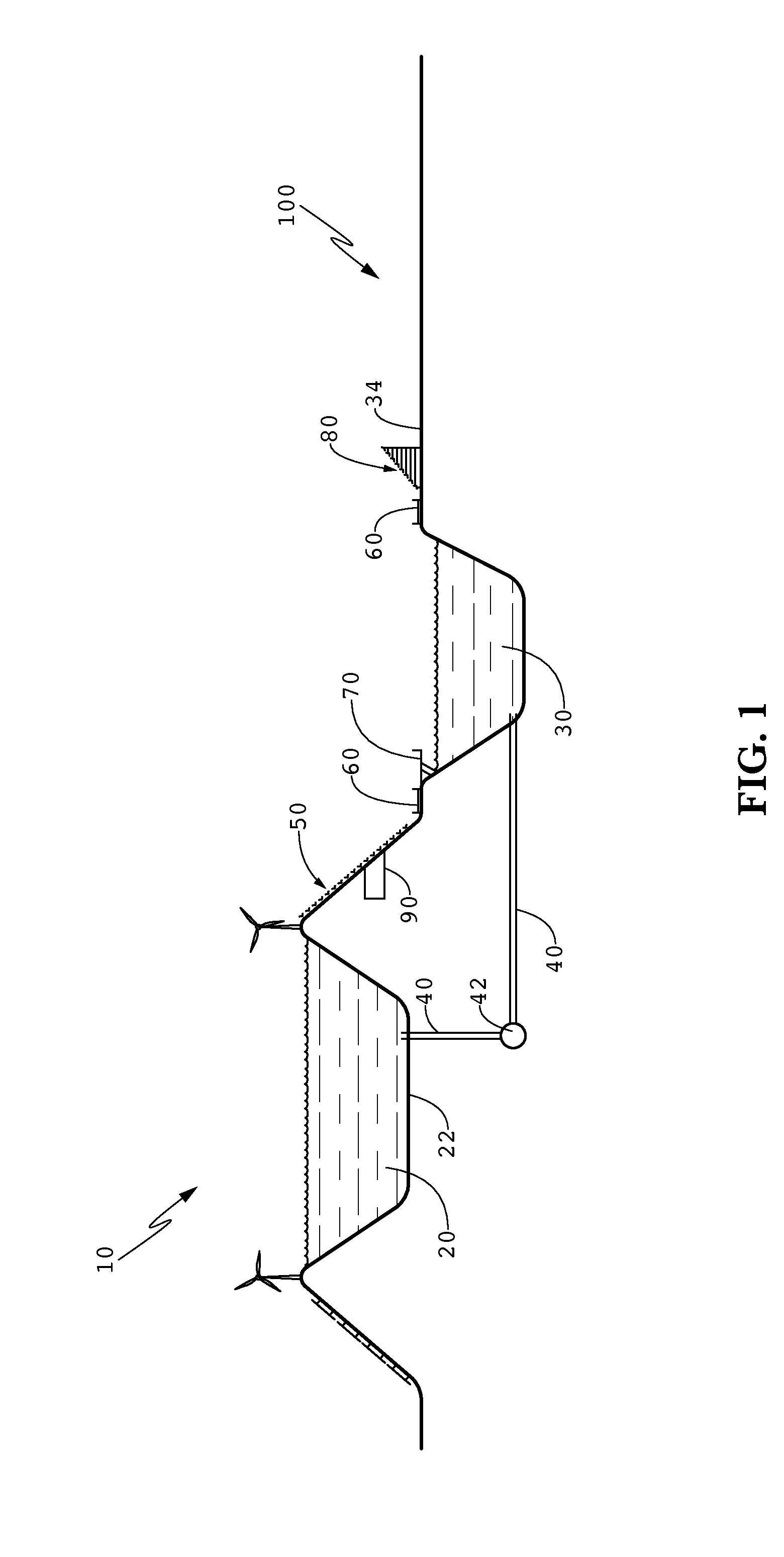

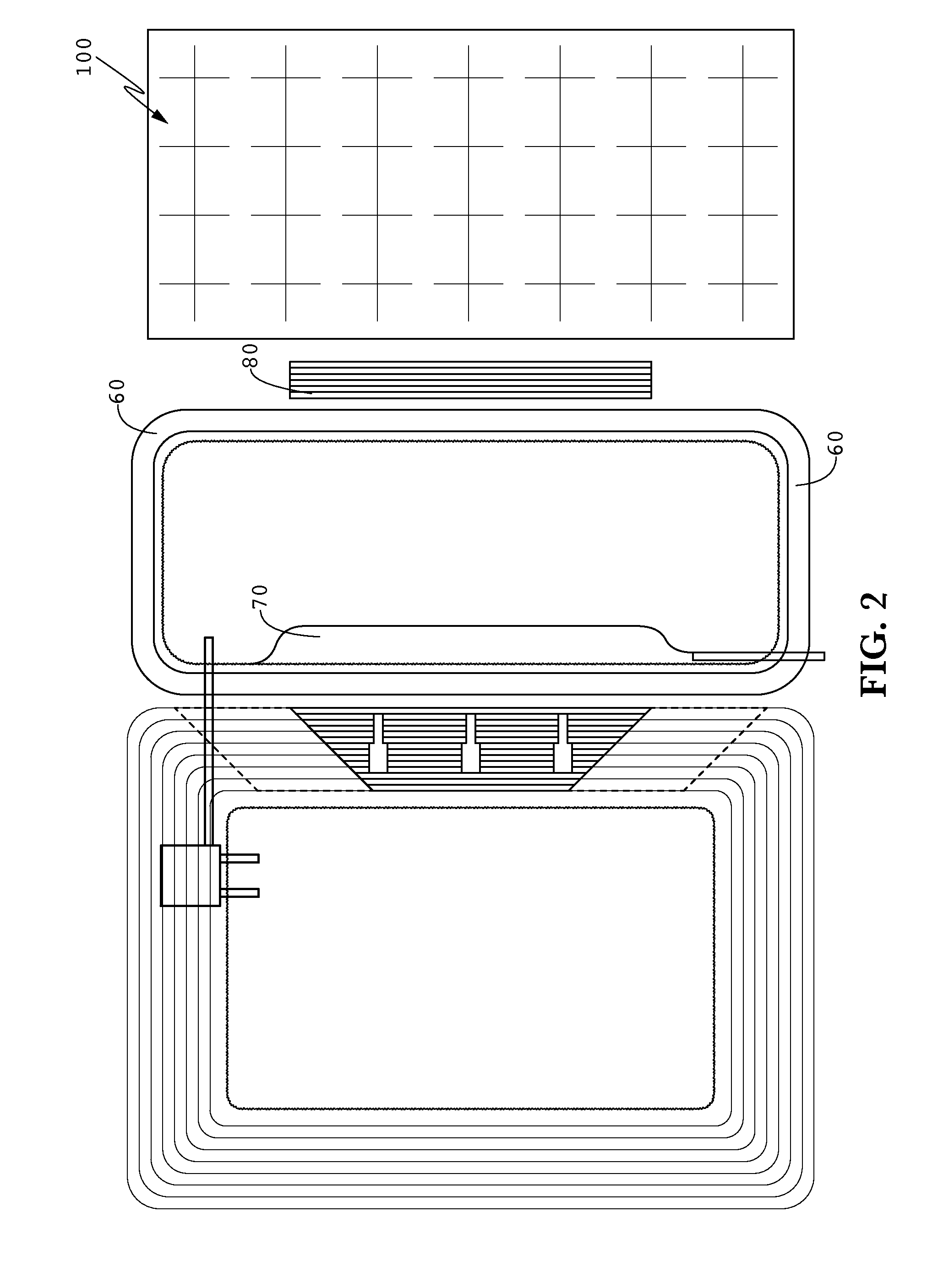

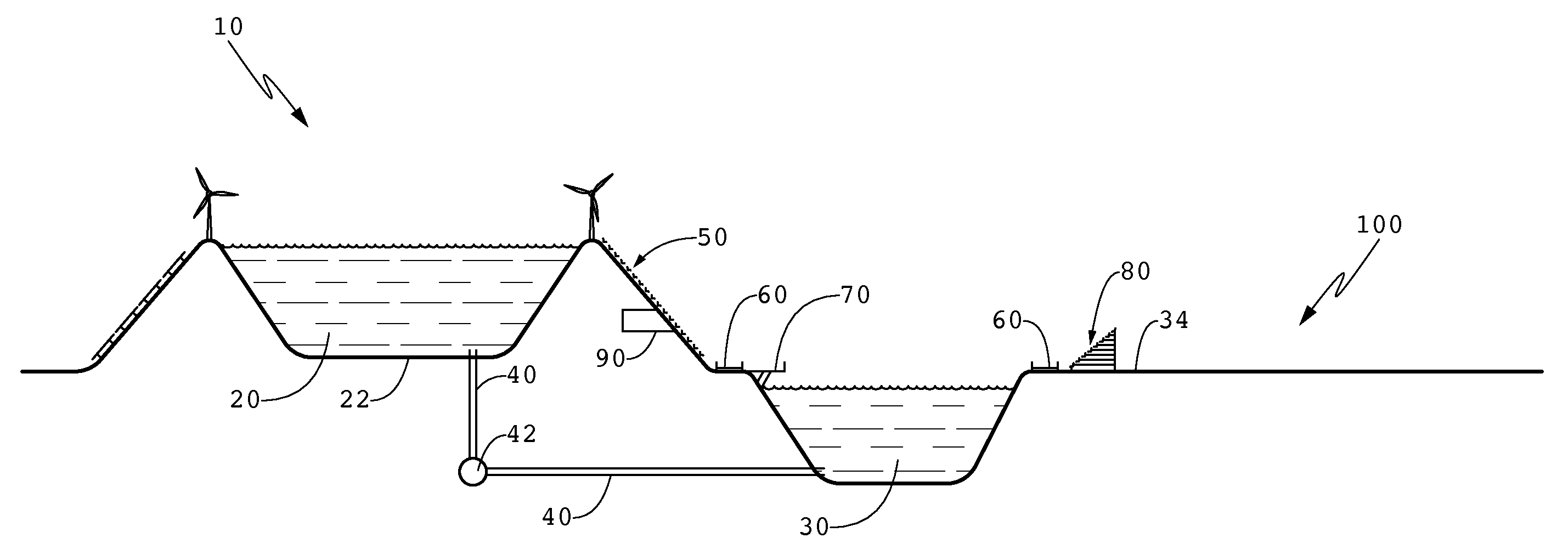

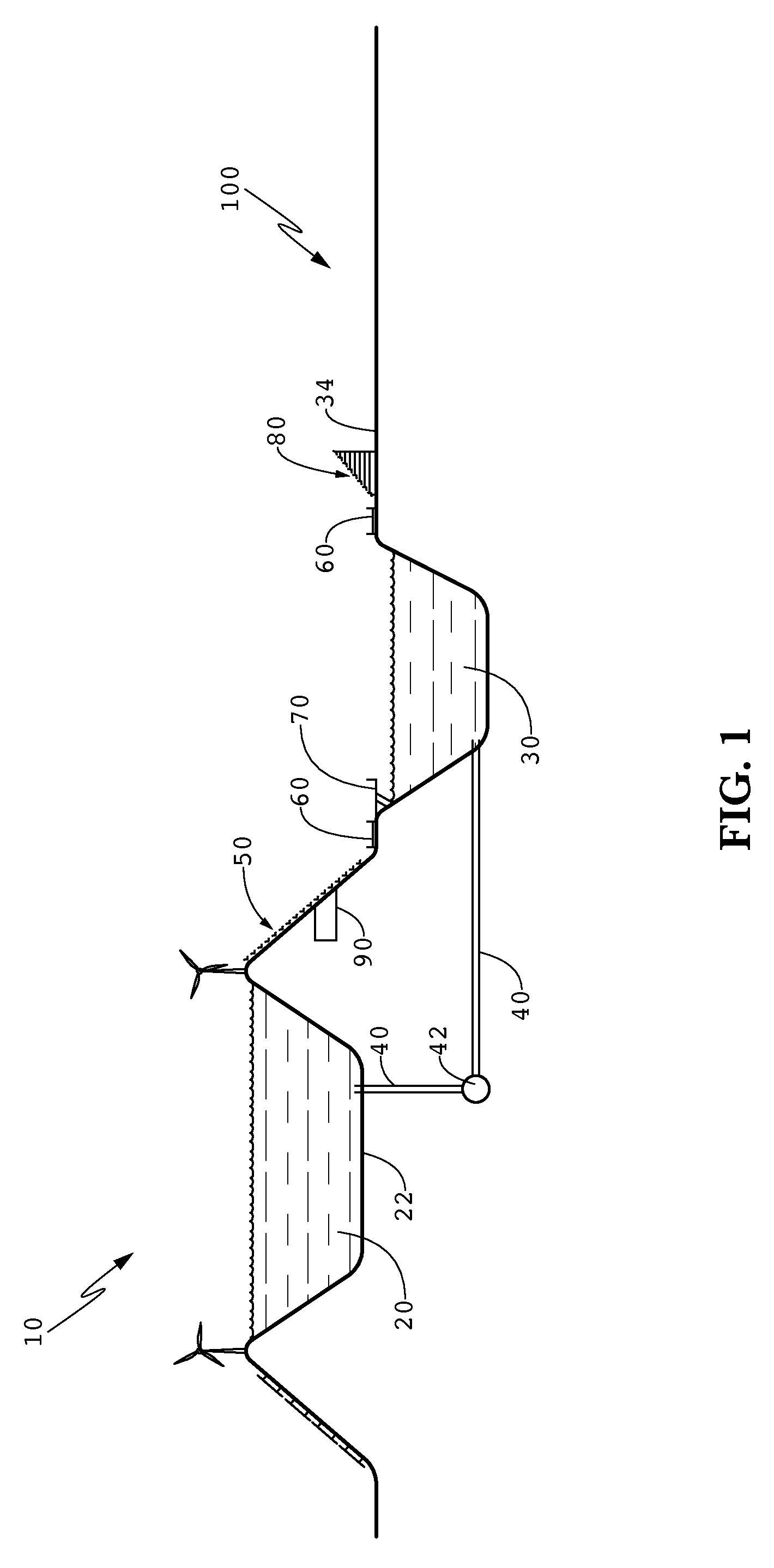

Multi-purpose pumped storage facility

ActiveUS20140270965A1Optimize head availableEasy to operateMining devicesWater-power plantsEngineeringShore

A pumped storage facility combined with at least a seating area constructed on a bank of an upper reservoir facing a lower reservoir. The lower reservoir includes a track around the shore thereof so that spectators in the seating area can view the track. A performance area is constructed adjacent the track along the lower reservoir, and can be built over the water on piers if needed. Thus, racing events can take place on the track and be viewed by spectators in the seating area. A parking lot drains water into the lower reservoir.

Owner:WINDMARKET

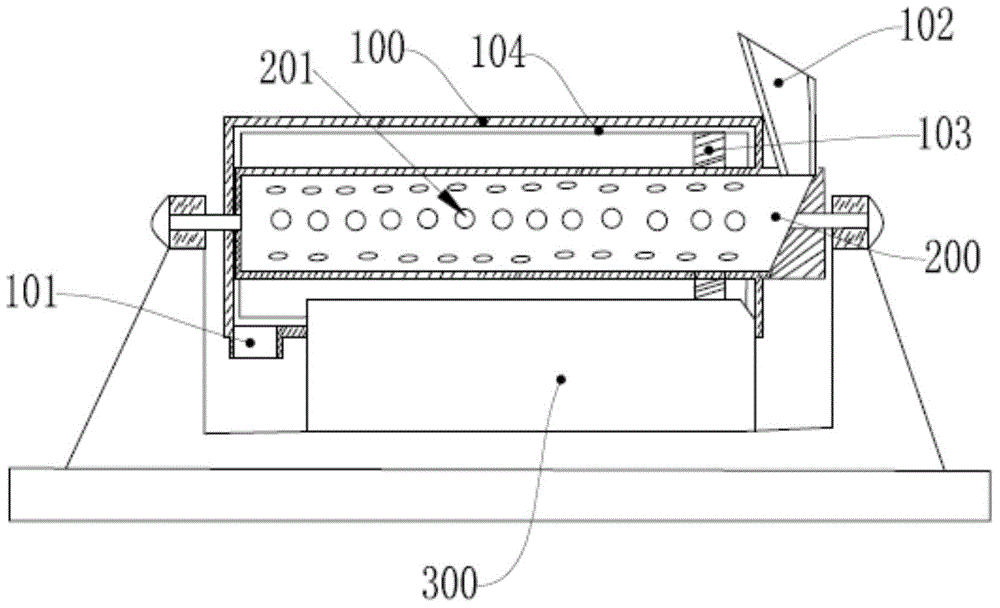

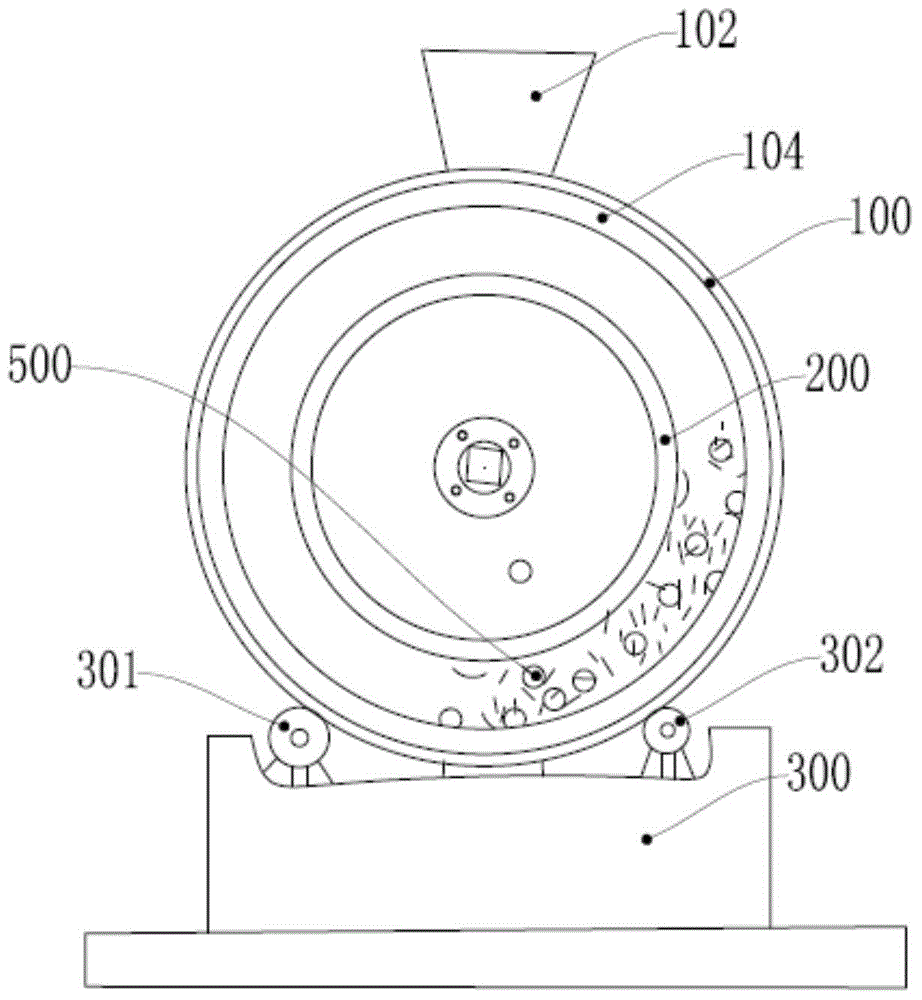

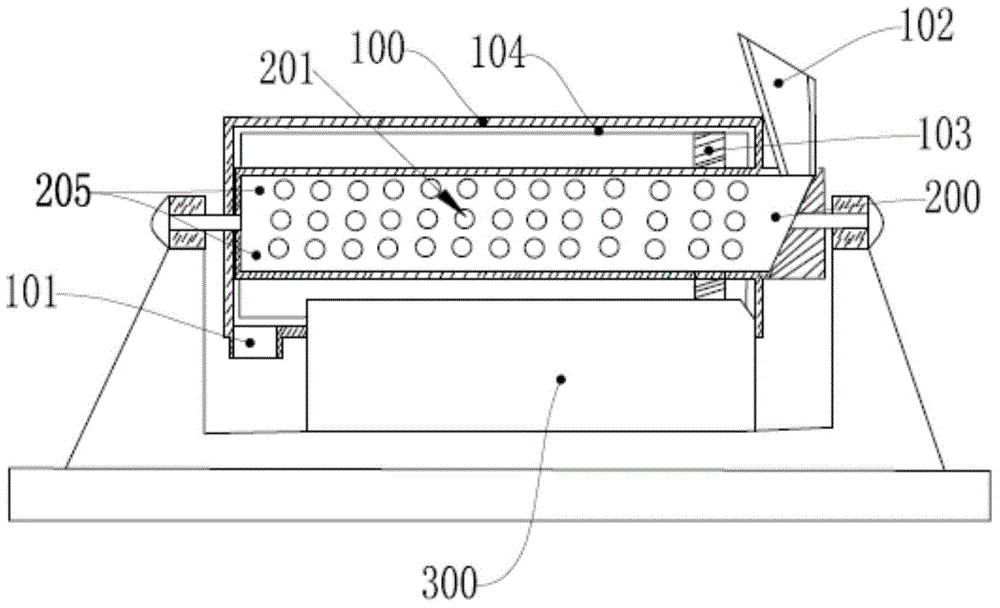

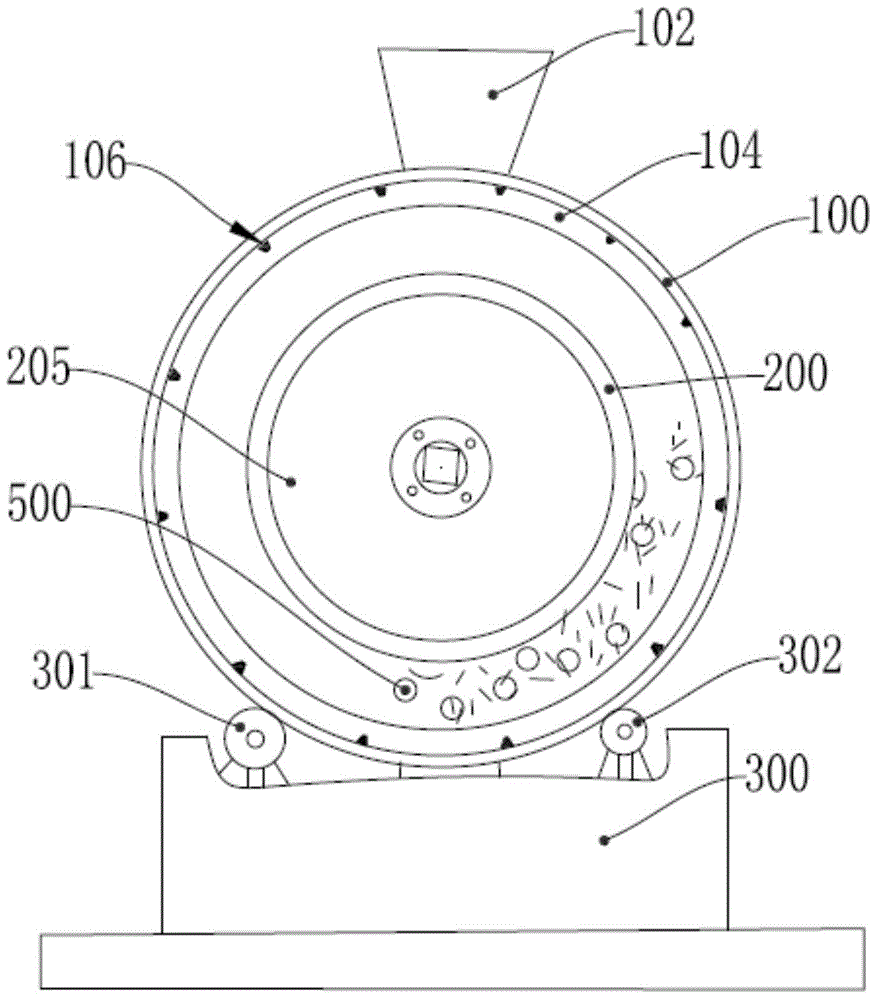

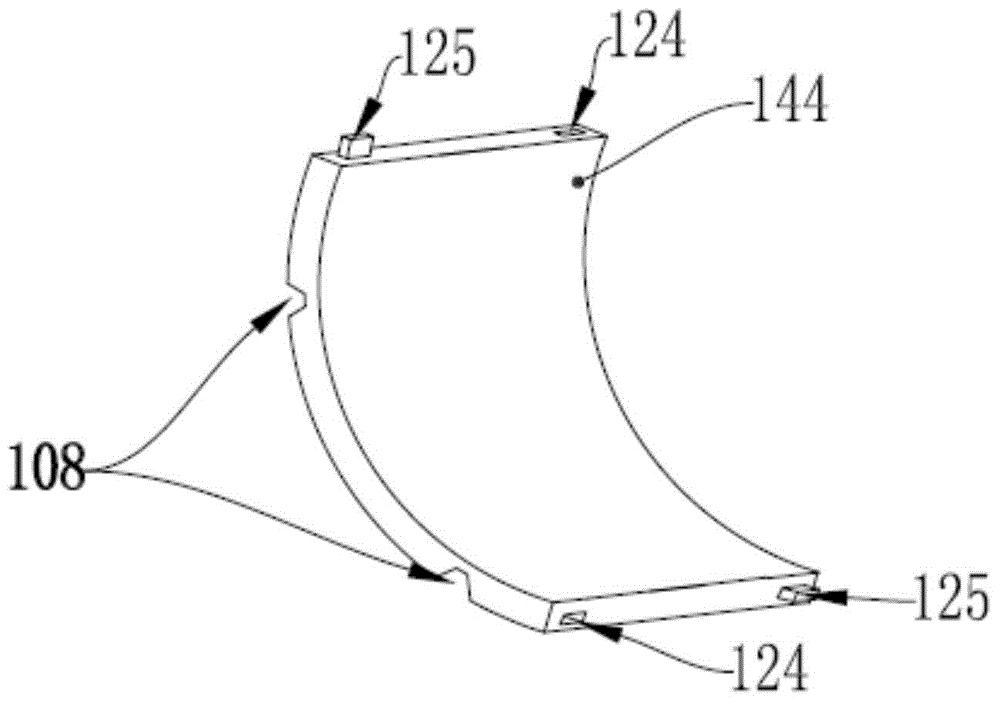

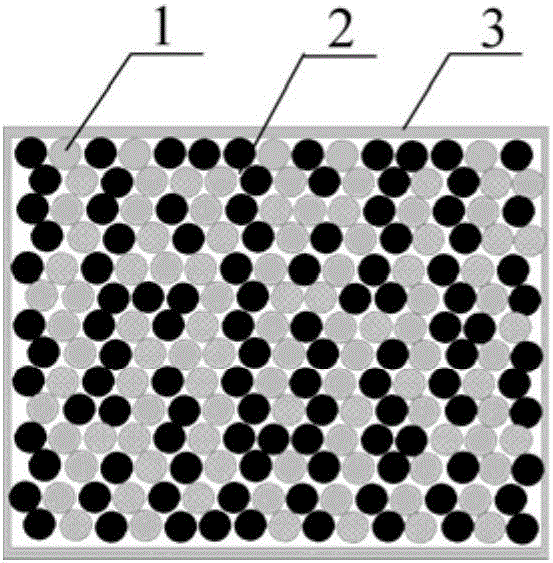

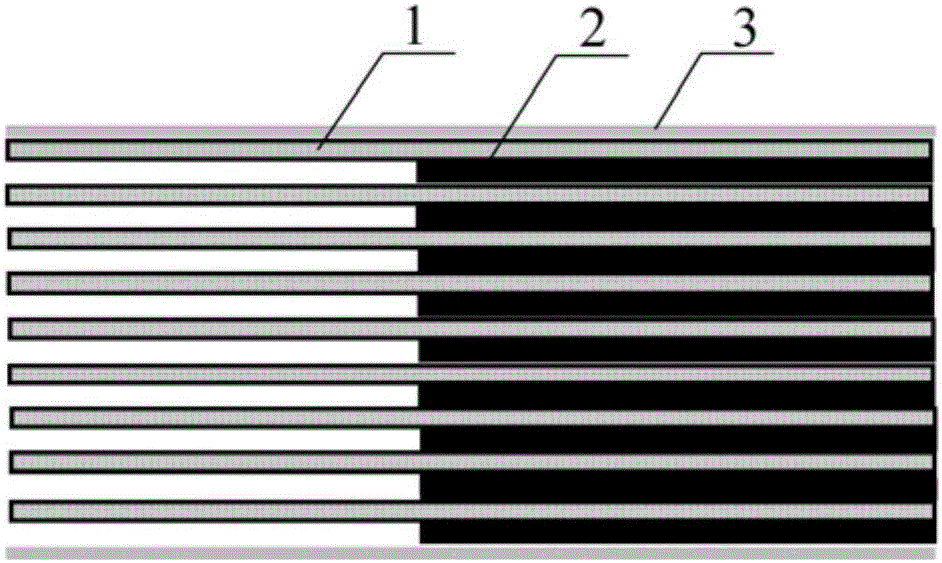

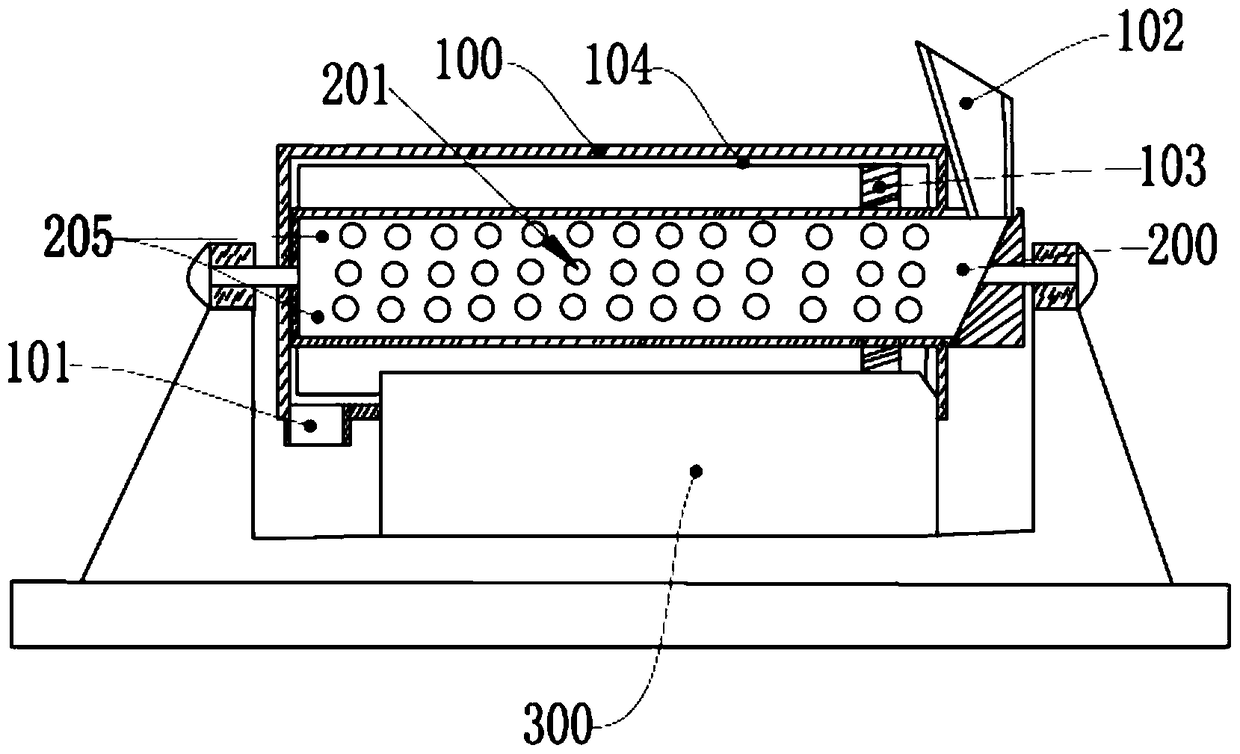

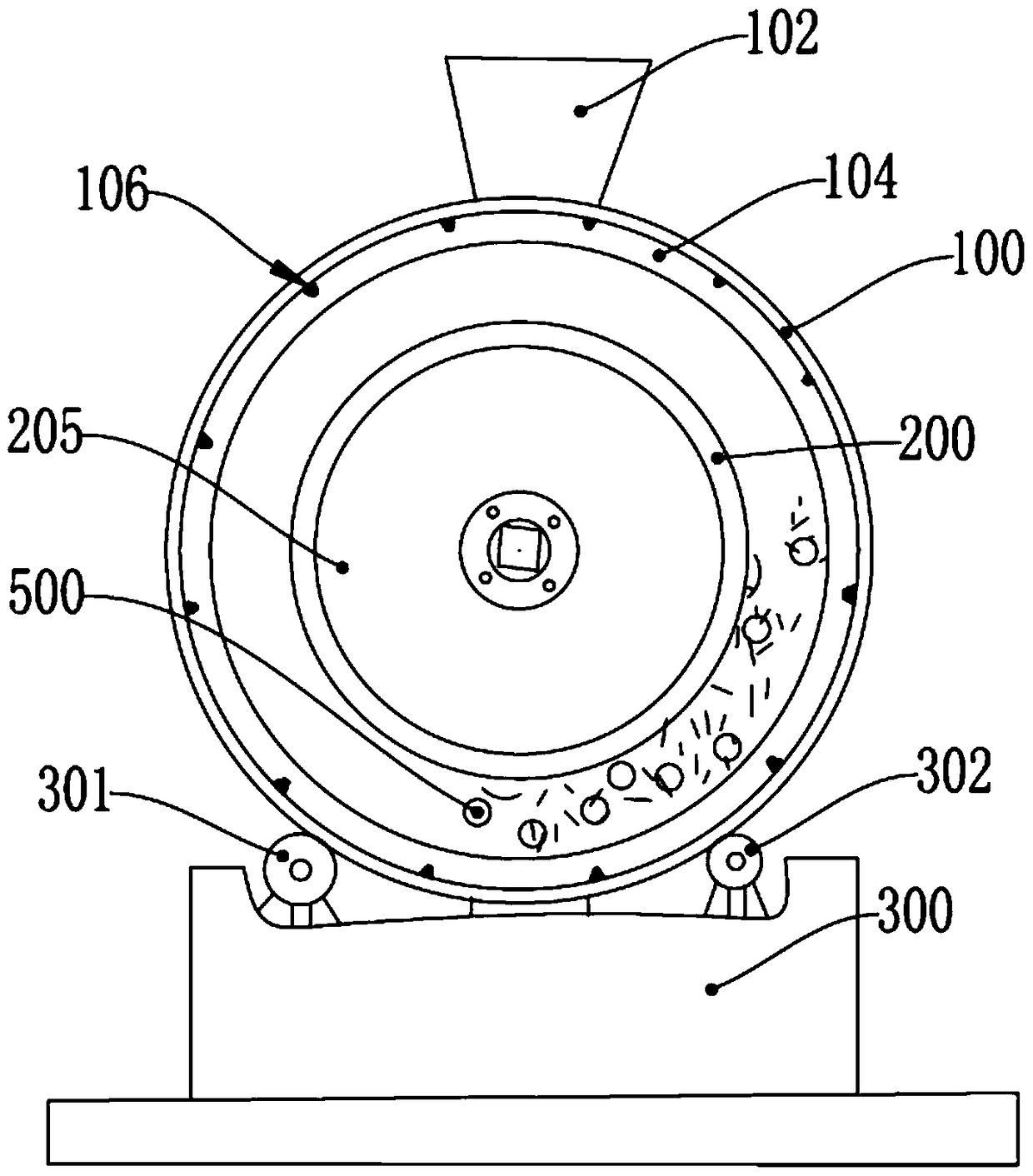

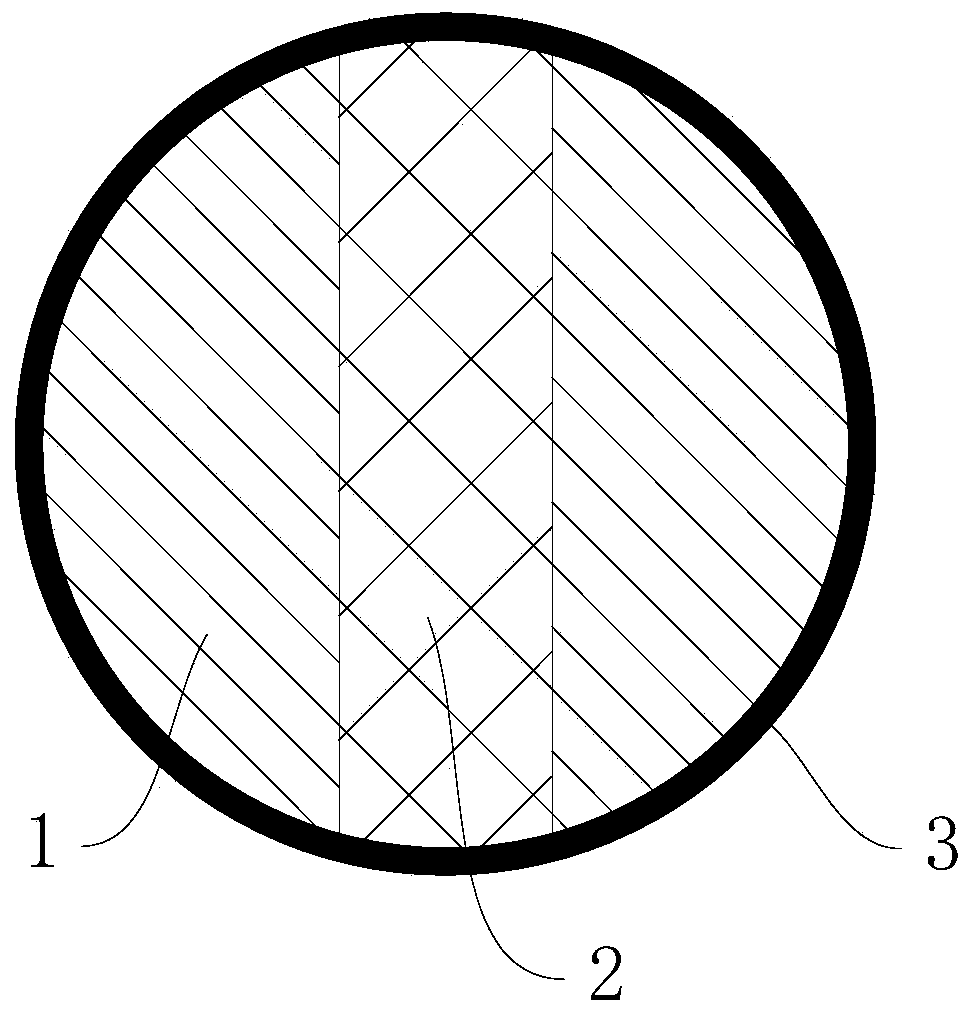

Efficient ball mill with annular grooves

InactiveCN105772170AEasy dischargeImprove grinding efficiencyGrain treatmentsPrimary screeningEngineering

The invention relates to the field of ceramic machinery, in particular to an efficient ball mill with annular grooves. The efficient ball mill comprises a cylinder provided with a feed port and a discharge port, and a driving device; the driving device drives the cylinder to rotate; the cylinder is divided into two layers of tubular structures; the first layer is a cylinder outer shell; the second layer is a primary screening and grinding net pipe with sieve holes; grinding balls are respectively put in accommodating cavities between the inner surface of the cylinder outer shell and the outer surface of the primary screening and grinding net pipe; the feed port is connected with the accommodating cavity of the primary screening and grinding net pipe; the discharge port is connected with the accommodating cavities between the inner surface of the cylinder outer shell and the outer surface of the primary screening and grinding net pipe; lining plates are arranged in the cylinder outer shell; the contact surfaces between the back surfaces of the lining plates and the inner wall of the cylinder of the ball mill are corresponding arc surfaces; multiple grooves with arc sections are formed in the working surfaces of all the lining plates; and the connecting surfaces of the adjacent grooves are arc surfaces. The ball mill is an efficient ball mill capable of improving the grinding efficiency and quality.

Owner:FOSHAN BAOHANG MACHINERY EQUIP IND INTPROP SERVICES

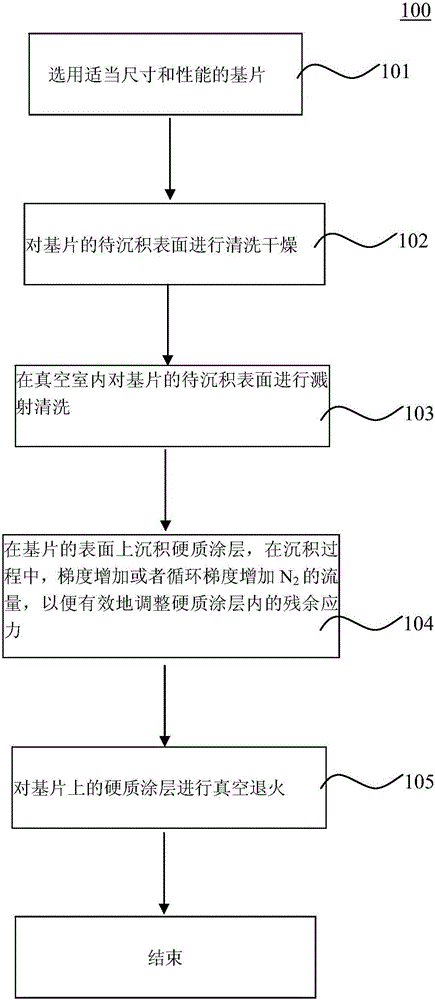

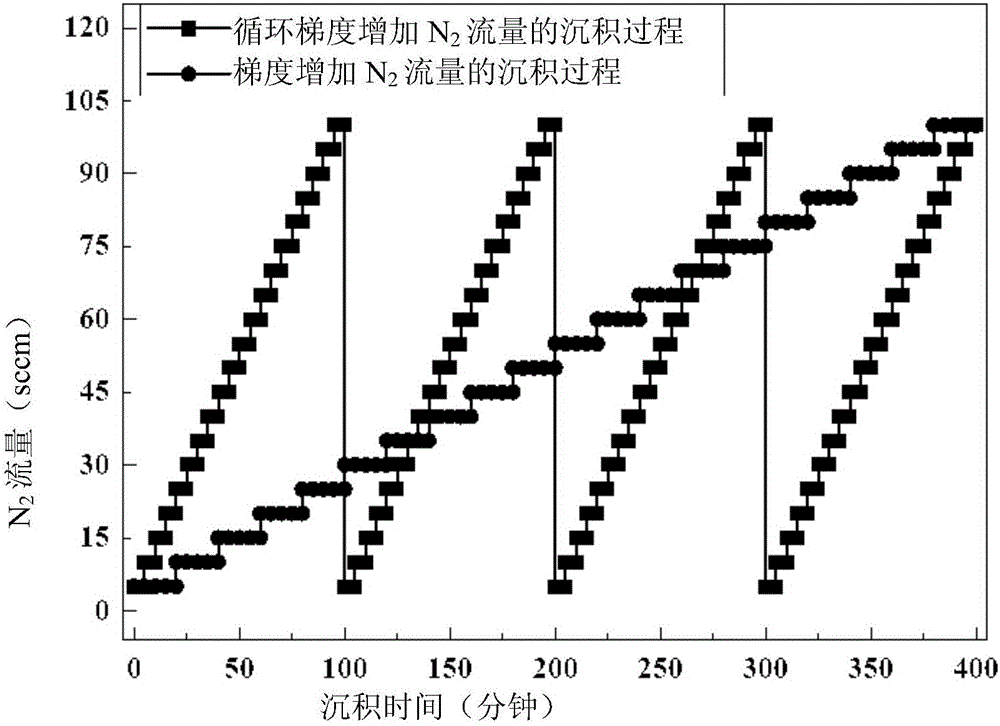

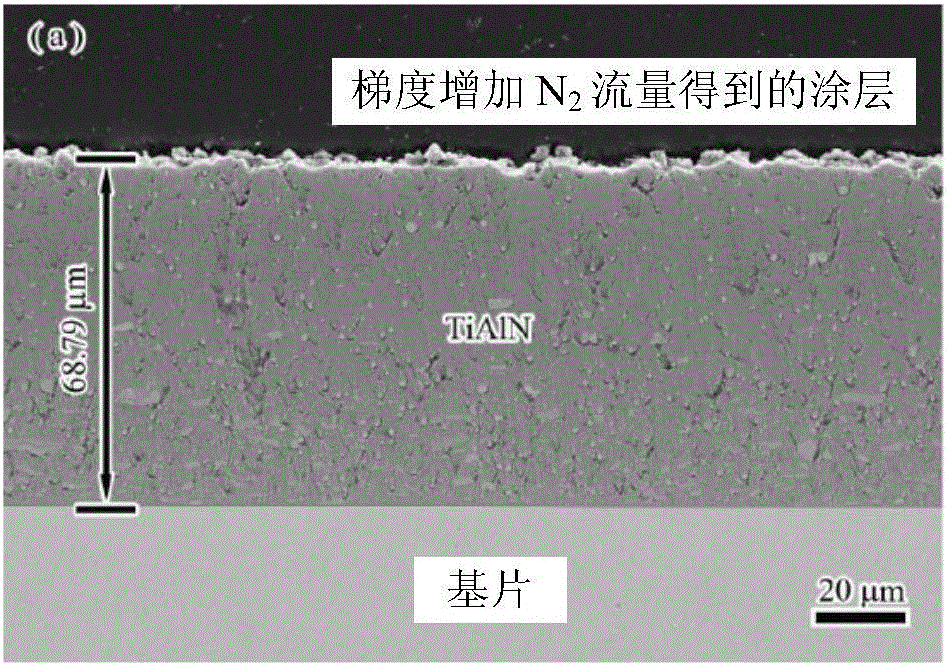

Preparation method of wear-resistant coating

InactiveCN106191790AReduce residual stressImprove scratch resistanceVacuum evaporation coatingSputtering coatingSputter cleaningWear resistant

The invention relates to a preparation method of a wear-resistant coating. The preparation method is used for preparing a hard coating on the surface of a substrate and comprises the following steps: selecting the substrate with predetermined size and performance; cleaning and drying a to-be-deposited surface of the substrate; performing sputter cleaning on the to-be-deposited surface of the substrate in a vacuum room of arc ion plating equipment; injecting inert gases and N2 into the vacuum room; depositing a nitride hard coating on the surface of the substrate by adoption of the arc ion plating technology, and in the deposition process, enabling gradient increase or circular gradient increase of the flowrate of N2 to facilitate adjusting the residual stress in the hard coating; and performing vacuum annealing on the hard coating on the substrate to finally obtain the wear-resistant coating with large thickness. Through gradient increase or circular gradient increase of the flowrate of N2, the residual stress of the coating with large thickness is effectively reduced, and the coating has better scratch resistance and fracture toughness.

Owner:SHENZHEN POLYTECHNIC

Multi-purpose pumped storage facility

ActiveUS8899873B2Limit evaporation lossConstruction costMining devicesWater-power plantsEngineeringRace track

A pumped storage facility combined with at least a seating area constructed on a bank of an upper reservoir facing a lower reservoir. The lower reservoir includes a track around the shore thereof so that spectators in the seating area can view the track. A performance area is constructed adjacent the track along the lower reservoir, and can be built over the water on piers if needed. Thus, racing events can take place on the track and be viewed by spectators in the seating area. A parking lot drains water into the lower reservoir.

Owner:WINDMARKET

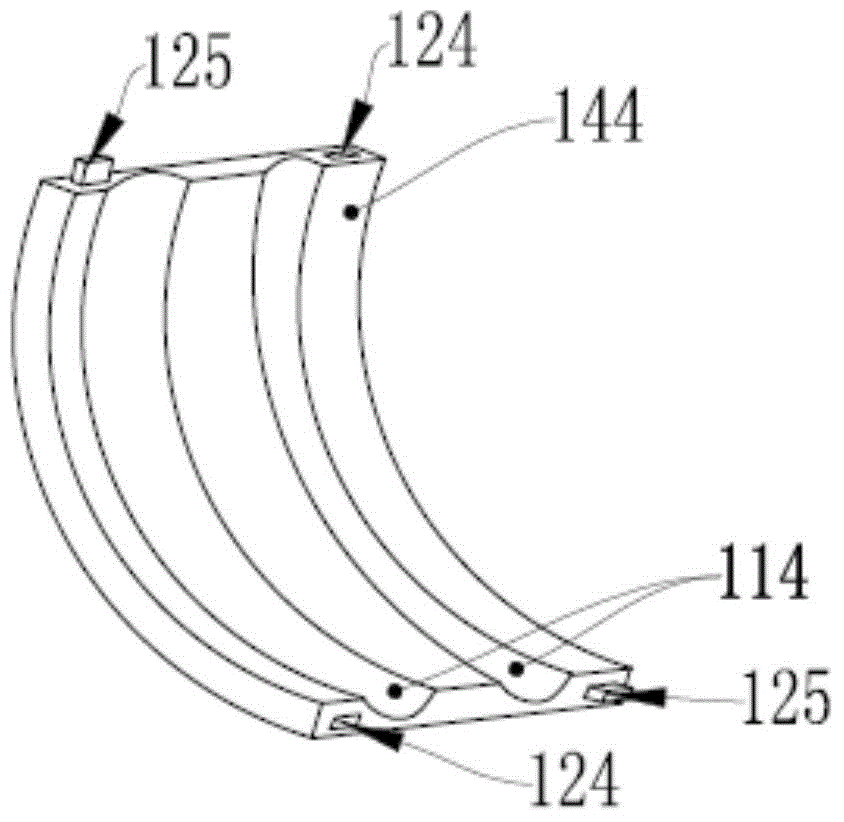

Efficient ball grinding mill with reinforcing ribs

The invention relates to the field of ceramic machinery, in particular to an efficient ball grinding mill with reinforcing ribs. A cylinder body is of a two-layer tubular structure, the first layer is a cylinder body shell, the second layer is a preliminary screening and grinding mesh tube with screening holes, grinding balls are placed inside the cylinder body, a feed port of the cylinder body is connected to a cavity of the preliminary screening and grinding mesh tube, and a discharge port of the cylinder body is connected to a cavity between the inner surface of the cylinder body shell and the outer surface of the preliminary screening and grinding mesh tube; a lining plate is arranged inside the cylinder body shell, is formed by splicing a plurality of lining bricks and is cylindrical, the reinforcing ribs and the lining plate are arranged on the inner surface of the cylinder body shell, grooves are formed in the back surfaces of the lining bricks and cover the reinforcing ribs, the back surface of the lining plate is attached and fixed to the inner surface of the cylinder body shell, and every two adjacent lining bricks are spliced and fixed through mortises and tenons of the lining bricks. The efficient ball grinding mill is convenient to install and stable in structure.

Owner:佛山市铖罡机械制造有限公司

Opaque water-based inks

Described herein are opaque water-based inks that include water and an opacity-providing polymer component. In one aspect, the opacity providing polymer component is a hollow sphere polymer material. The opacity-providing polymer material may replace all or part of white opacifying pigment material, such as titanium dioxide. Also described herein is a method of opacifying a printing ink by adding hollow sphere resin particles and a colorant to a printing ink that comprises water as a volatile component.

Owner:SUN CHEM CORP

Modified calcium carbonate-filled adhesive compositions and methods for use thereof

ActiveUS8530573B2Less abrasiveImprove rheologyOther chemical processesSynthetic resin layered productsThermal expansionChemistry

The invention is based on the discovery that modified calcium carbonates can be used as fillers for the preparation of non-abrasive adhesive formulations that are useful in microelectronic applications. The modified calcium carbonate fillers possess functional groups, which form strong bonds to the thermoset matrix. Invention compositions display excellent rheological properties, in addition to a low coefficient of thermal expansion.

Owner:DESIGNER MOLECULES

A kind of metal fiber electric brush and preparation method thereof

ActiveCN104332795BCompact structureImprove current carrying capacityRotary current collectorBrushes manufactureMetallurgyMetal fibers

The invention discloses a metal fiber brush and a preparation method thereof. The brush comprises conductive metal fibers and filling metal fibers. The length of the filling metal fibers is shorter than the length of the conductive metal fibers, one end of each filling metal fiber is flush with one end of each conductive metal fiber, the conductive metal fibers and the filling metal fibers are uniformly arranged along a length direction, and after compacting molding, the filling metal fibers and the conductive metal fibers are integrally wrapped by a metal wrapping sleeve. The preparation method comprises: winding the conductive metal fibers and the filling metal fibers together on a wire reel to form a metal fiber ring; and cutting the metal fiber ring, after the compacting molding, immersing one end of the metal fiber ring in an acid solution or aqueous alkali, and dissolving the filling metal fibers to obtain the metal fiber brush. The metal fiber brush is compact and reasonable in structure, high in fiber bonding strength, simple in preparation process, large in current carrying capability, small in contact resistance, long in service life, fast in sliding speed, small in heat productivity and small in debris amount, is suitable for industrial production, can replace a conventional carbon brush or a conventional metal fiber brush, and can satisfy the application demand for a large-power high-precision conductive slip ring.

Owner:CENT SOUTH UNIV

Polyethylene spunbond nonwoven date-bunch covers

InactiveUS20190261578A1Improve microclimateProtect from rainDomestic articlesPlant protective coveringsYarnMold spores

Polyethylene spunbond nonwoven date-bunch covers are an urgently needed, price-competitive alternative to mesh covers made of synthetic monofilament yarn. They are the first improvement to the ideal date-bunch cover that USDA researchers theorized seventy years ago, by adding dust and mold spore exclusion, yet providing sufficient shade and vapor transmission for proper ripening. Black mold is insignificant even under close tree spacing and “wet summer” conditions. The lowered temperature and increased humidity inside the cover promotes pliable, smooth skin instead of dry and brittle as commonly occurs with covers made of monofilament mesh fabric. Covers made of polyethylene spunbond nonwoven fabric are lighter, less abrasive, compress easier, and thus are far more user-friendly. Ripe dates can be held on-tree longer than was ever possible before without accumulating dust or losing quality, which renders unnecessary the labor-intensive practice of multiple pickings, and saves cold storage costs.

Owner:DENIS STEPHEN PAUL

Environment-friendly coconut charcoal fiber composite friction material and manufacturing method for brake pad

InactiveCN105299112AImprove thermal stabilityStable coefficient of frictionOther chemical processesFriction liningCarbon fibersRoom temperature

The invention discloses a method for manufacturing a brake pad through an environment-friendly coconut charcoal fiber composite friction material. The method includes the steps that aramid fibers and coconut charcoal fibers which are in the formulation with 5-15 parts of resin, 15-40 parts of steel fibers, 1-8 parts of aramid fibers, 5-35 parts of coconut charcoal fibers and 3-18 parts of petroleum coke are evenly stirred in a high-speed stirrer; then, the steel fibers are put into the high-speed stirrer to be stirred with the mixture of the aramid fibers and the coconut charcoal fibers which are evenly mixed; after even stirring is conducted and the temperature is lowered to the room temperature, the petroleum coke is added to be stirred; after even stirring is conducted, the resin is added to be stirred; after even stirring is conducted, the mixture is taken out; different brake pad molds are selected according to the occasions on which the brake pad is used; the prepared friction material is put into a brake pad mold, and the brake pad mold is put into a mold press to be subjected to mold pressing, wherein the mold pressing pressure ranges from 15 Mpa to 16 Mpa, the temperature ranges from 150 DEG C to 160 DEG C, the conditions are maintained for 12-15 minutes, pressure is relieved, and heating is stopped; and the brake pad mold is taken out, and the brake pad is poured out and corrected and polished on a grinding machine.

Owner:DONGYING RUIZHI YOULIANG PETROLEUM EQUIP

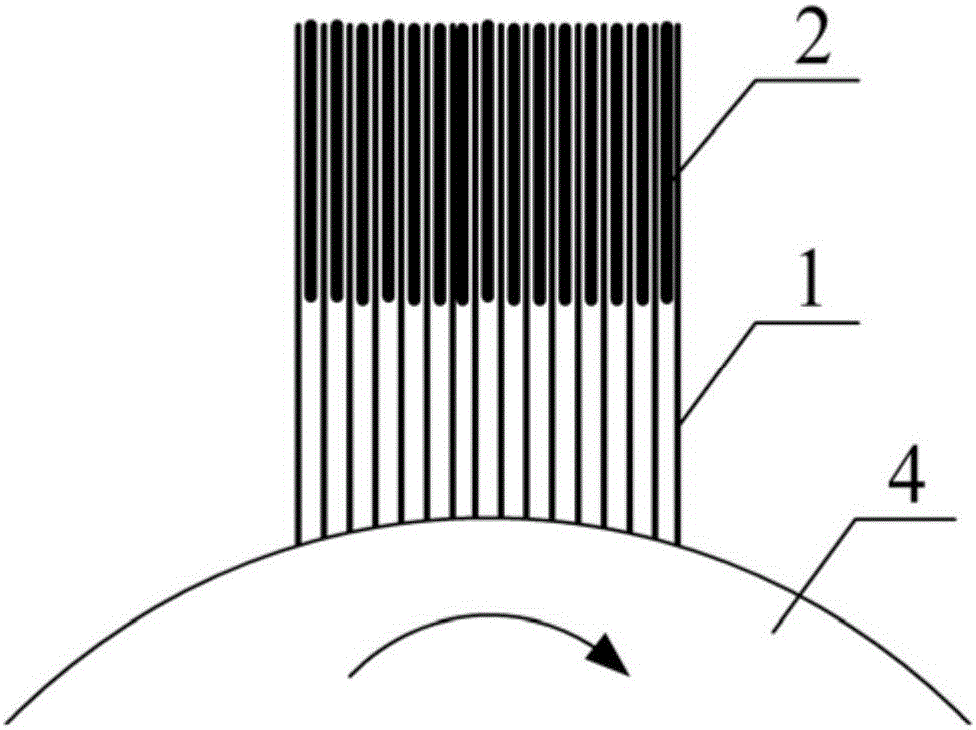

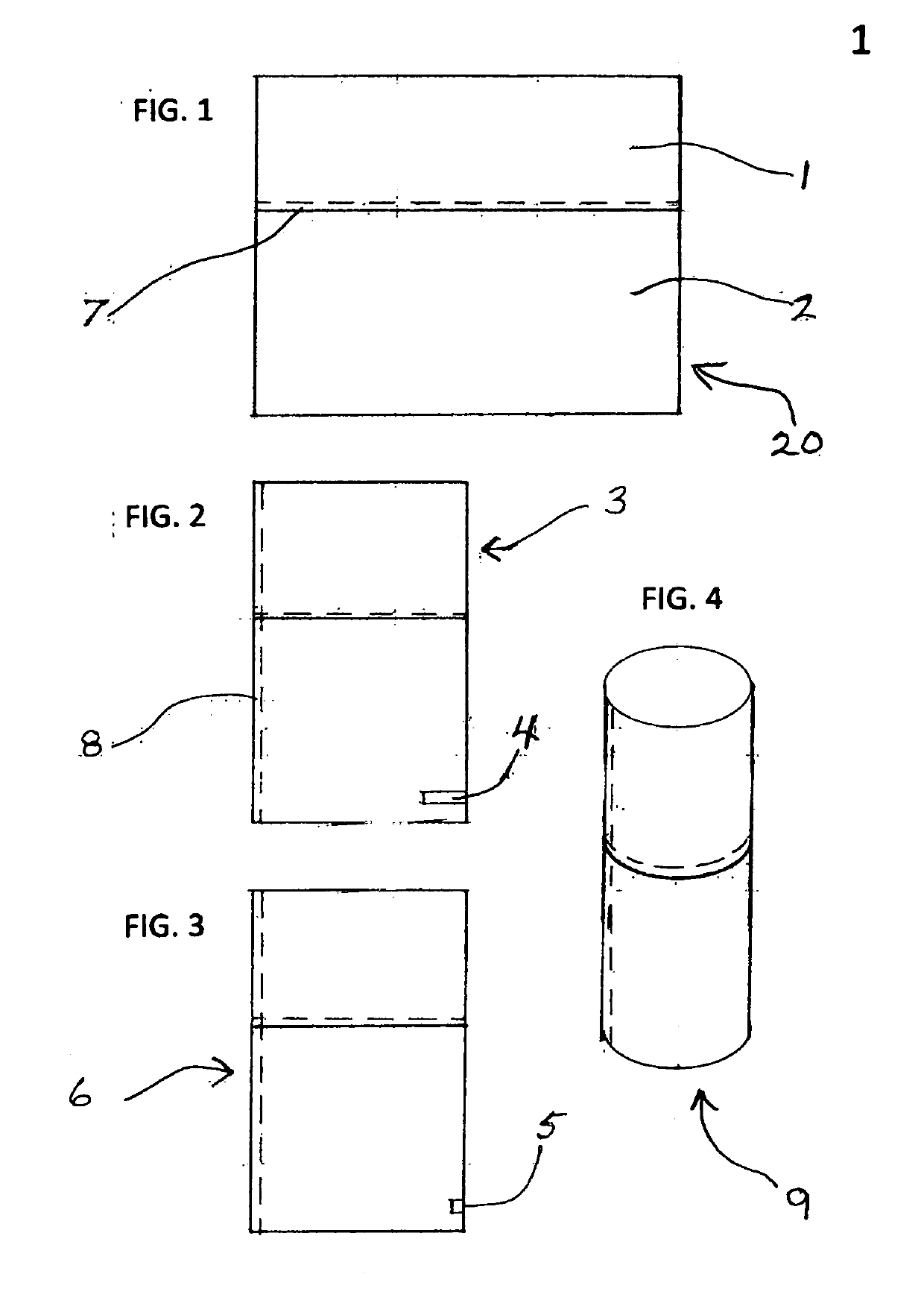

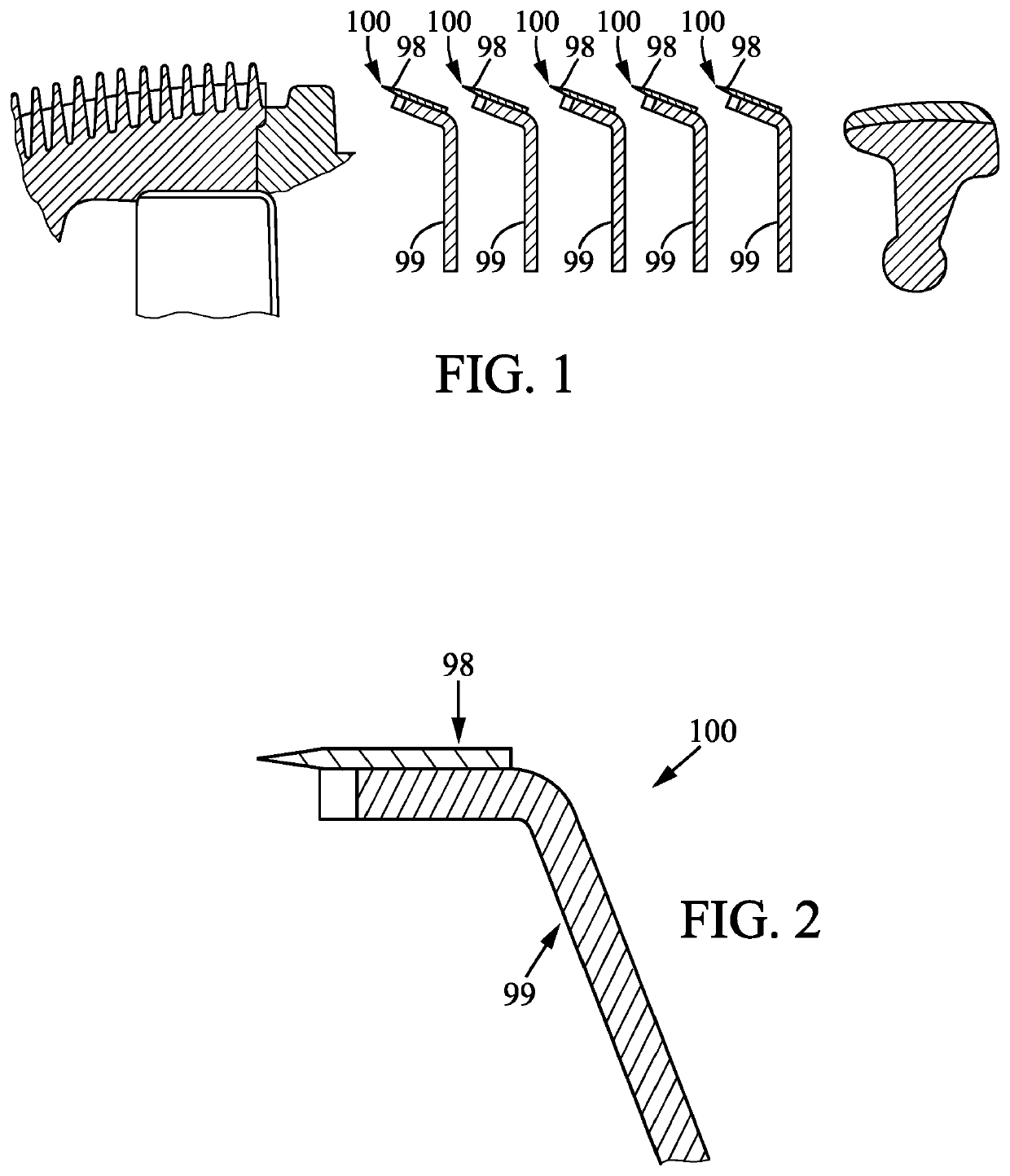

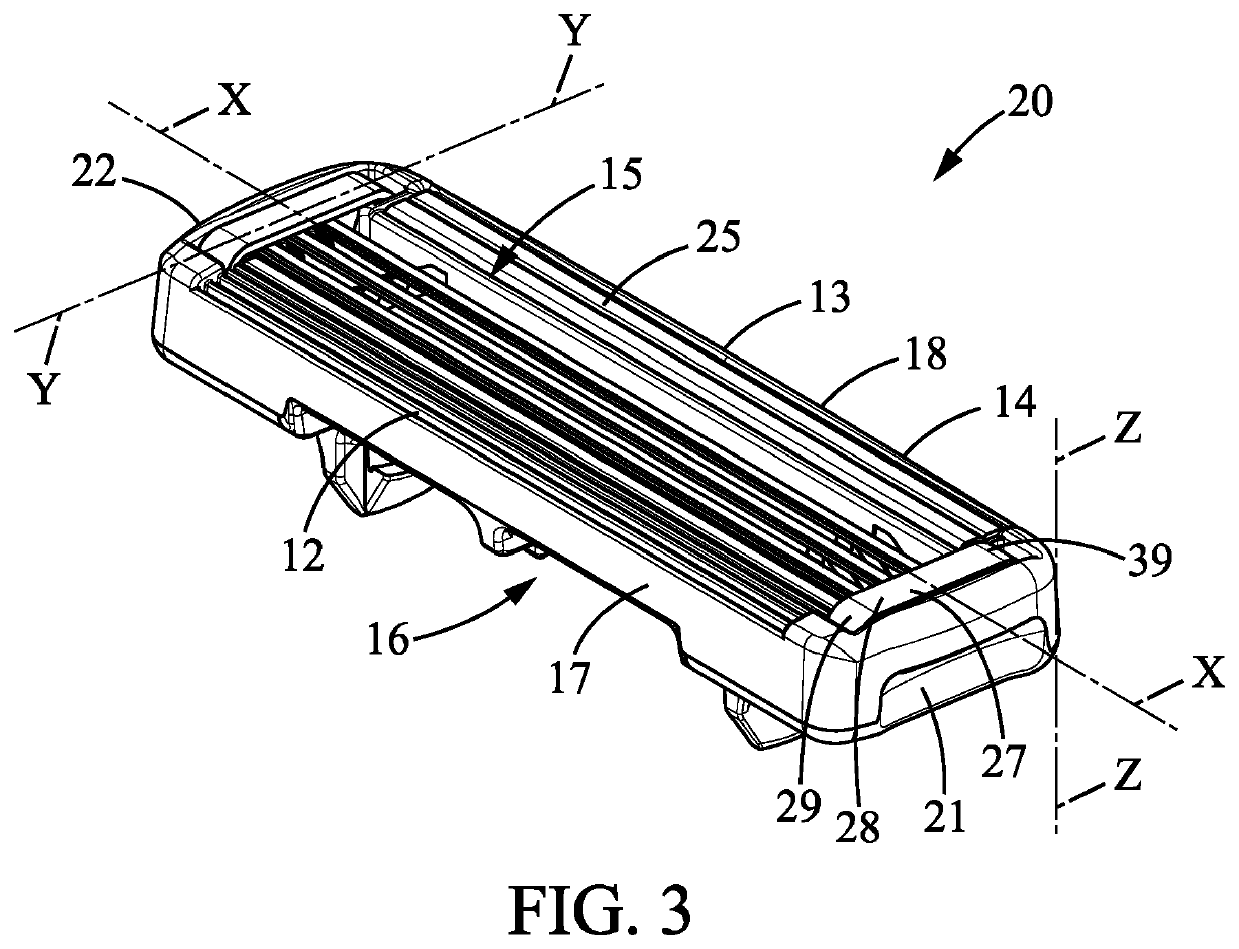

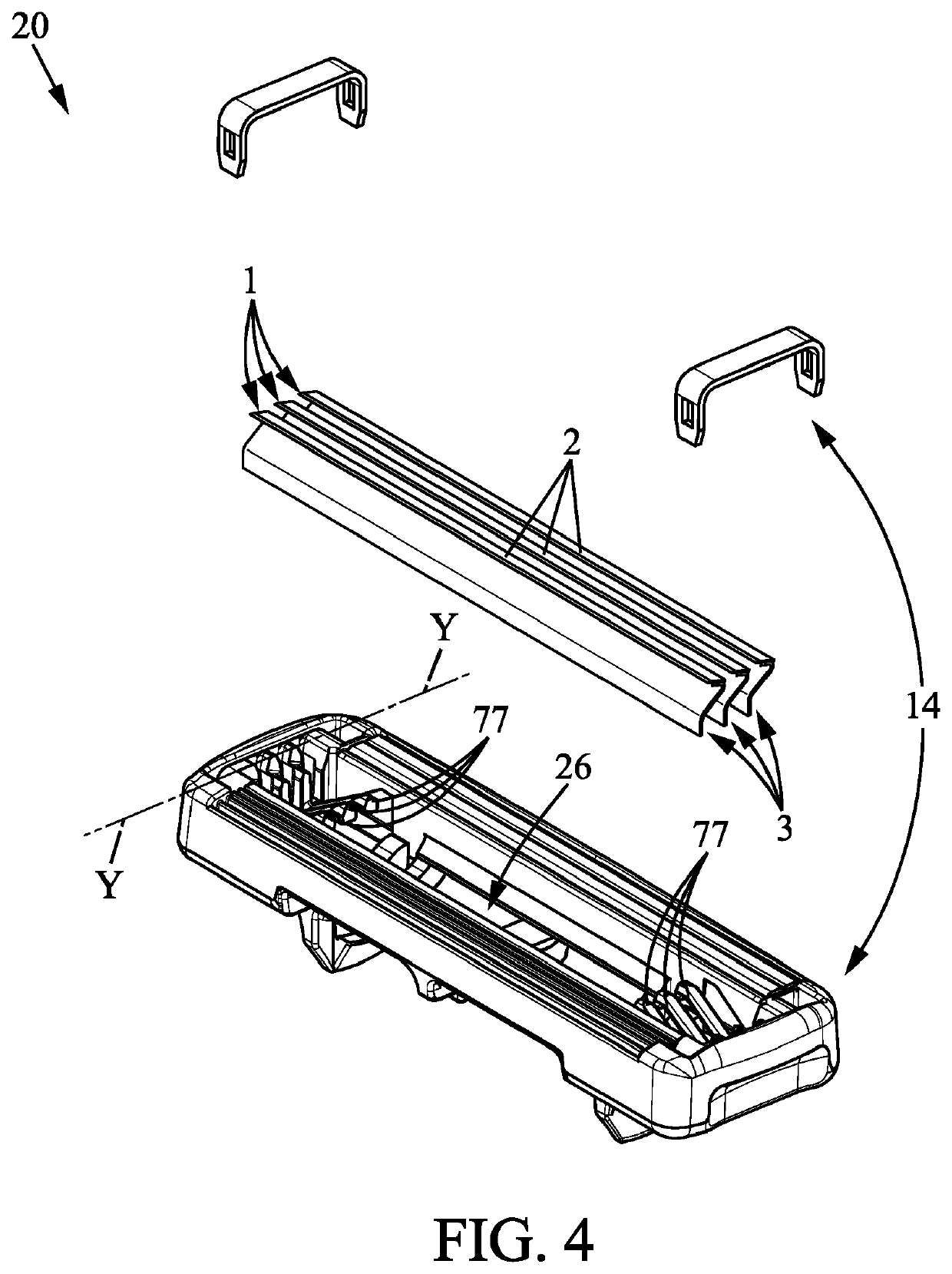

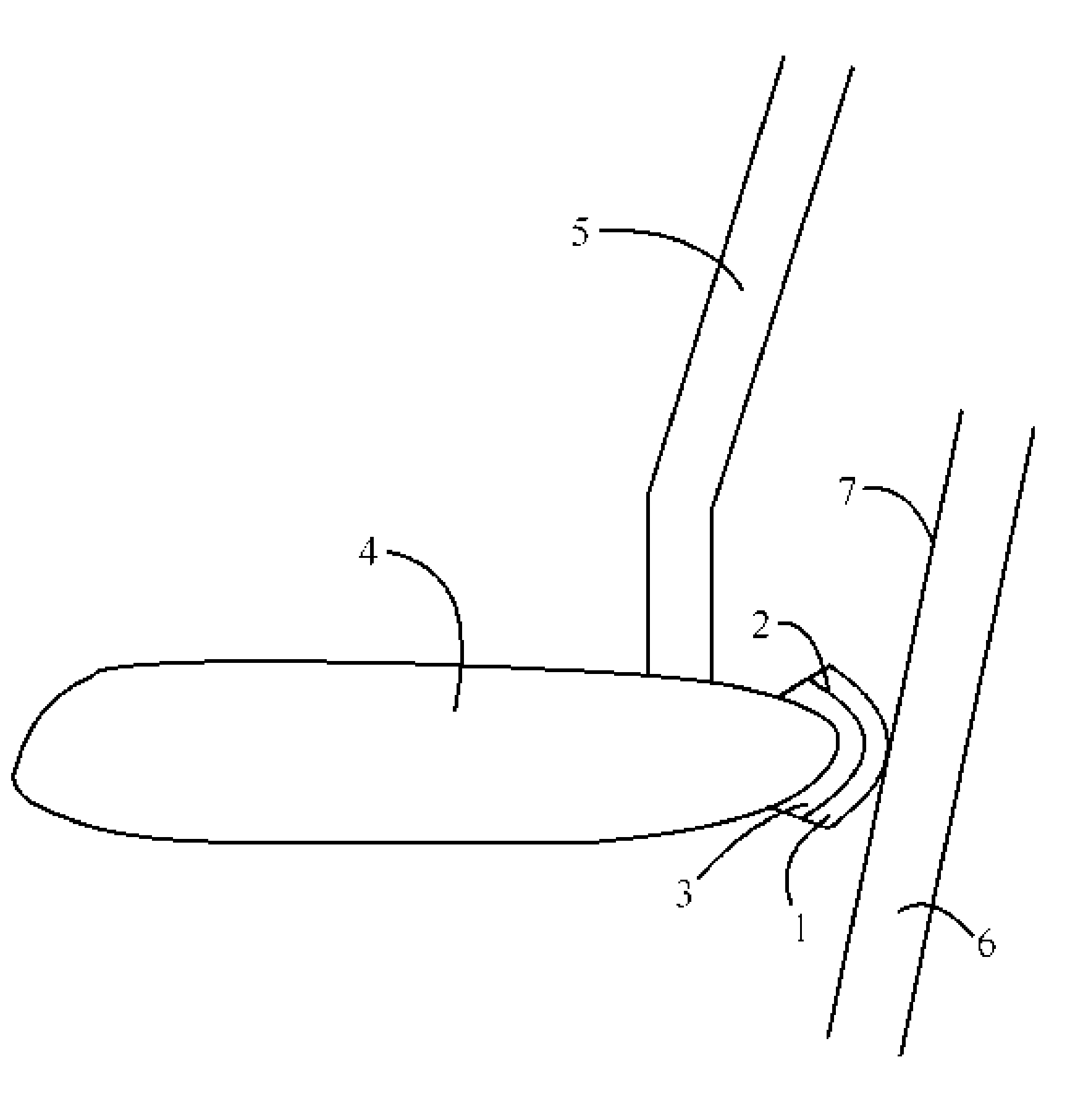

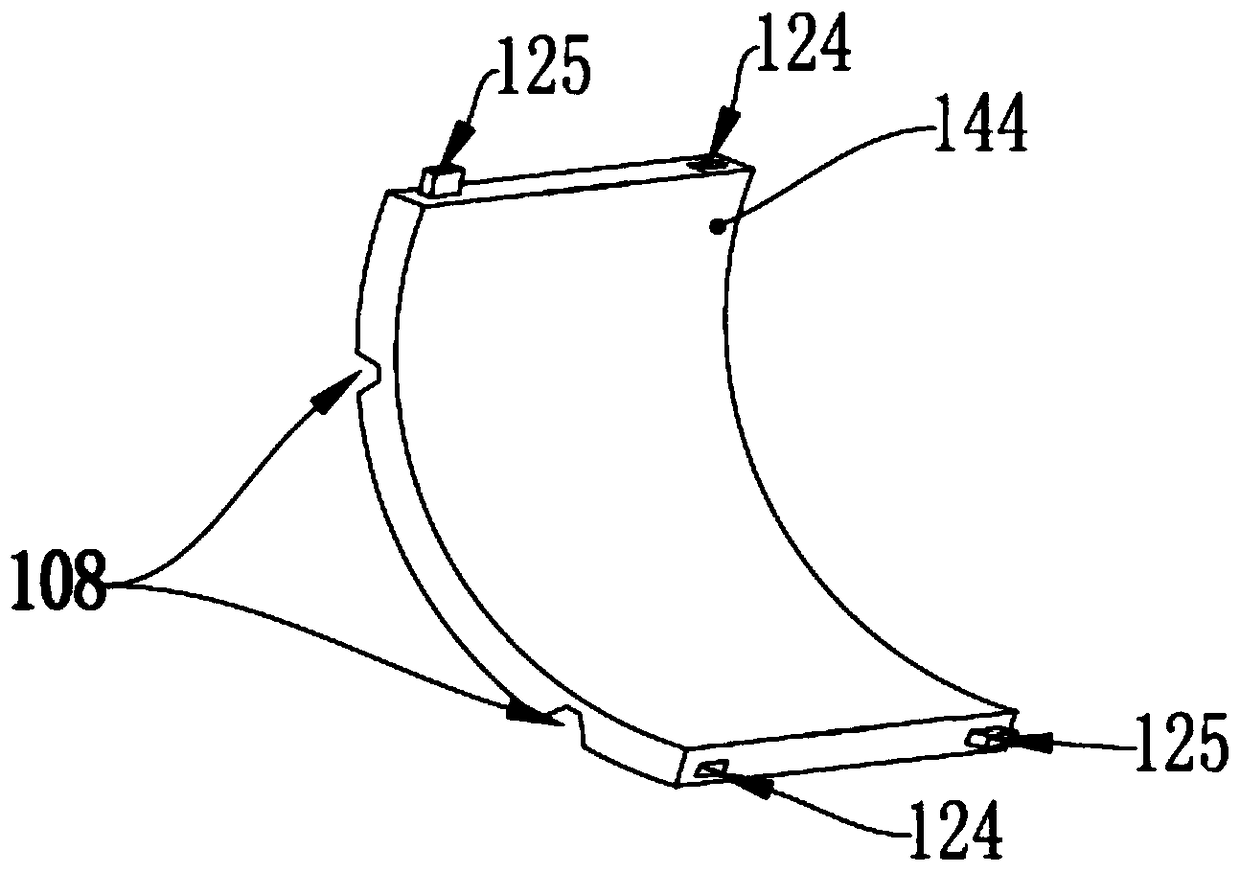

Razor system

PendingUS20210206010A1Improve shaving effectImprove performanceMetal working apparatusStructural engineeringMechanical engineering

A cutting member (1) for a shaving cartridge includes a front side, a back side opposing the front side, and a flat cutting portion (2) with a cutting edge portion (4). Further the cutting member includes a first bent portion (8), an intermediate portion (11), a second bent portion (9) and a base portion (10) that are made out of one single piece of material. The first bent portion is integral with the flat cutting portion. The first bent portion is convex on the back side of the cutting member, and the second bent portion is concave on the back side of the cutting member. The proposed shape of the cutting member resembles an “S” shape or a question mark shape.

Owner:BIC VIOLEX SA

Lightweight imitation stone particles and water-based imitation stone coating prepared therefrom

The invention provides a light stone-imitating particulate matter and a water-based stone-imitating coating prepared by adopting same, and belongs to the technical field of water-based architectural coatings. The preparation method comprises the following steps: smashing or cutting waste or a leftover material of rubber, resin and engineering plastics or reclaimed rubber into particles, coating a colored film on the surface to prepare the light stone-imitating particulate matter. The water-based stone-imitating coating prepared by adopting the stone-imitating particulate matter comprises the following ingredients in percentage by weight: 8-30% of emulsion, 30-80% of a light stone-imitating particulate matter, 1-40% of an inorganic pigment filler, 1-8% of a wetting dispersant, 0.5-8% of a thickening agent, 0.1-5% of an antifoaming agent, 0.5-5% of a film coalescing aid, 0.1-1% of a mildew inhibitor, 1-10% of an anti-freezing agent, and proper amount of water, wherein the pH value is regulated to be 8-9.5 with a pH regulator. The imitated stone is life-like, and presents strong artistic feeling. As the specific weight of the light stone-imitating particulate matter is low, the flexibility is good, and the abrasiveness to a mixing plant is low; a lot of thickening agents or anti-setting agents are not required to be added, and the prepared stone-imitating coating has high stability, long storage life, and convenience in construction. Moreover, the technology avoids black pollution such as waste tires, and is beneficial to environment protection.

Owner:HEBEI UNIV OF ENG

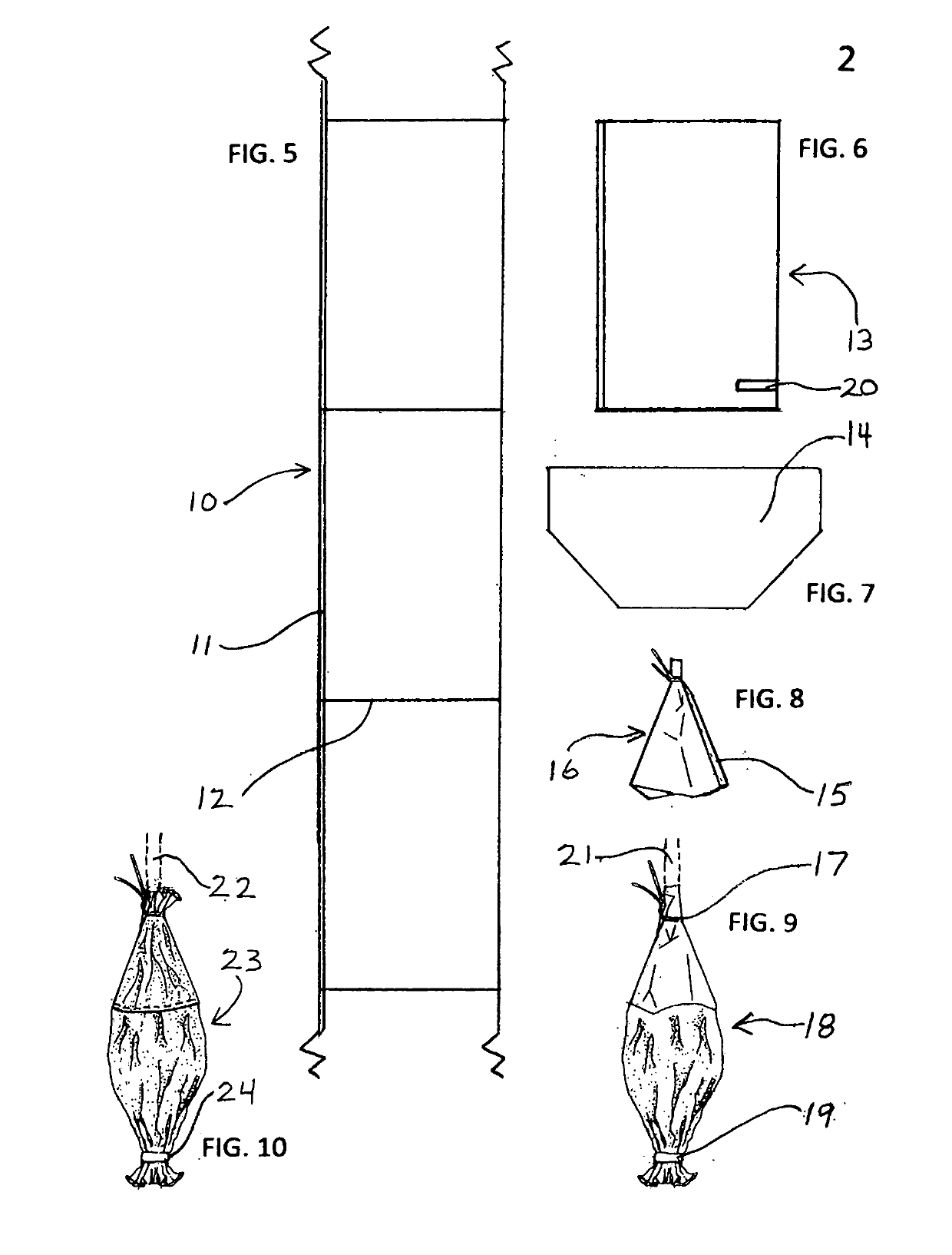

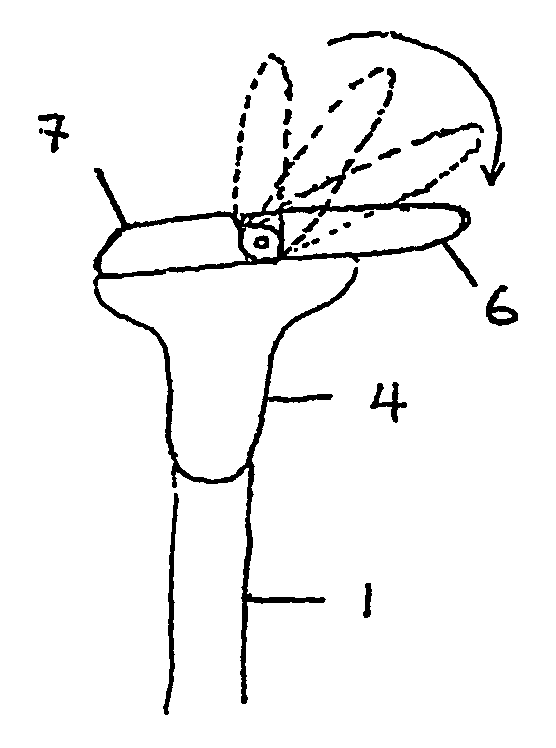

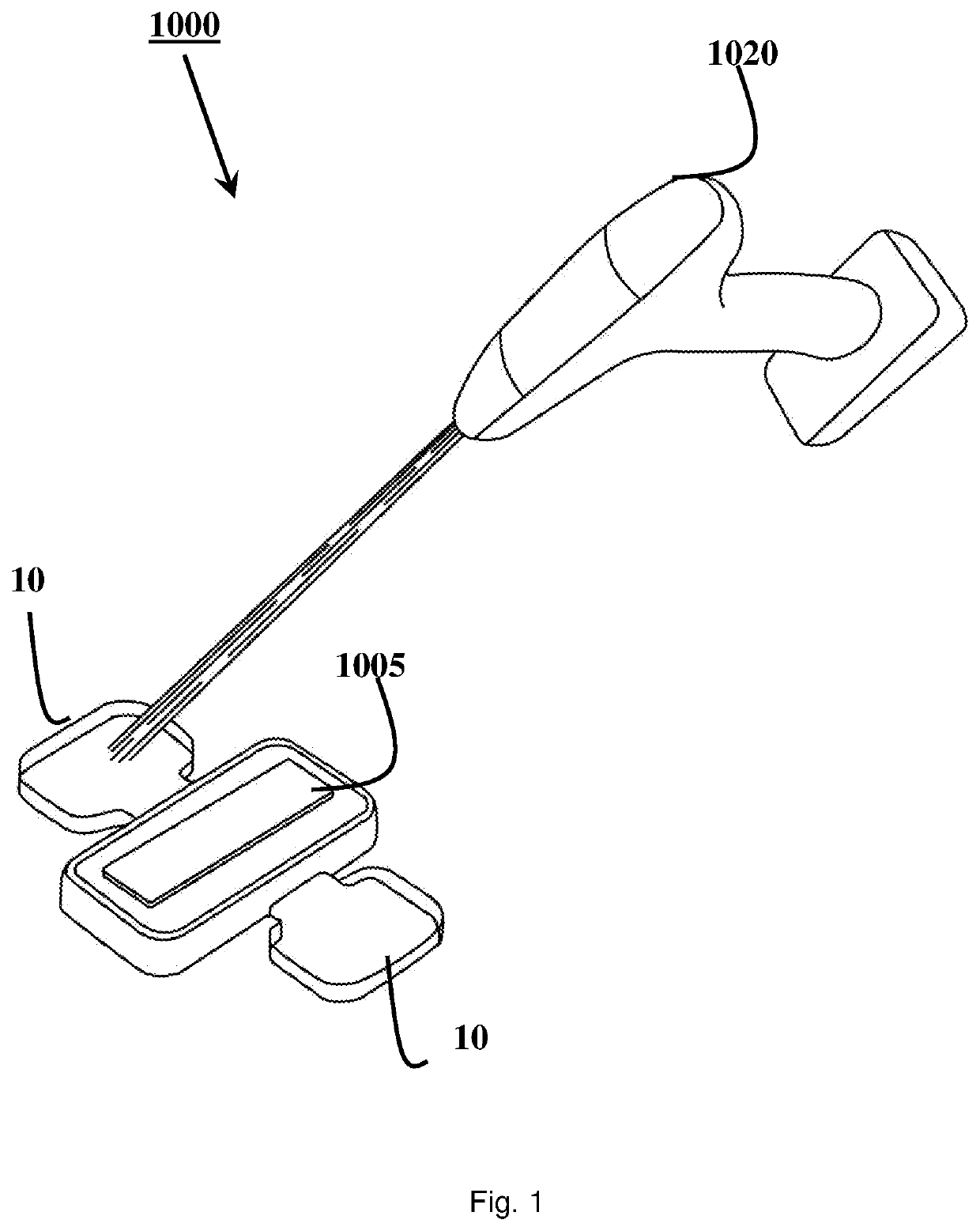

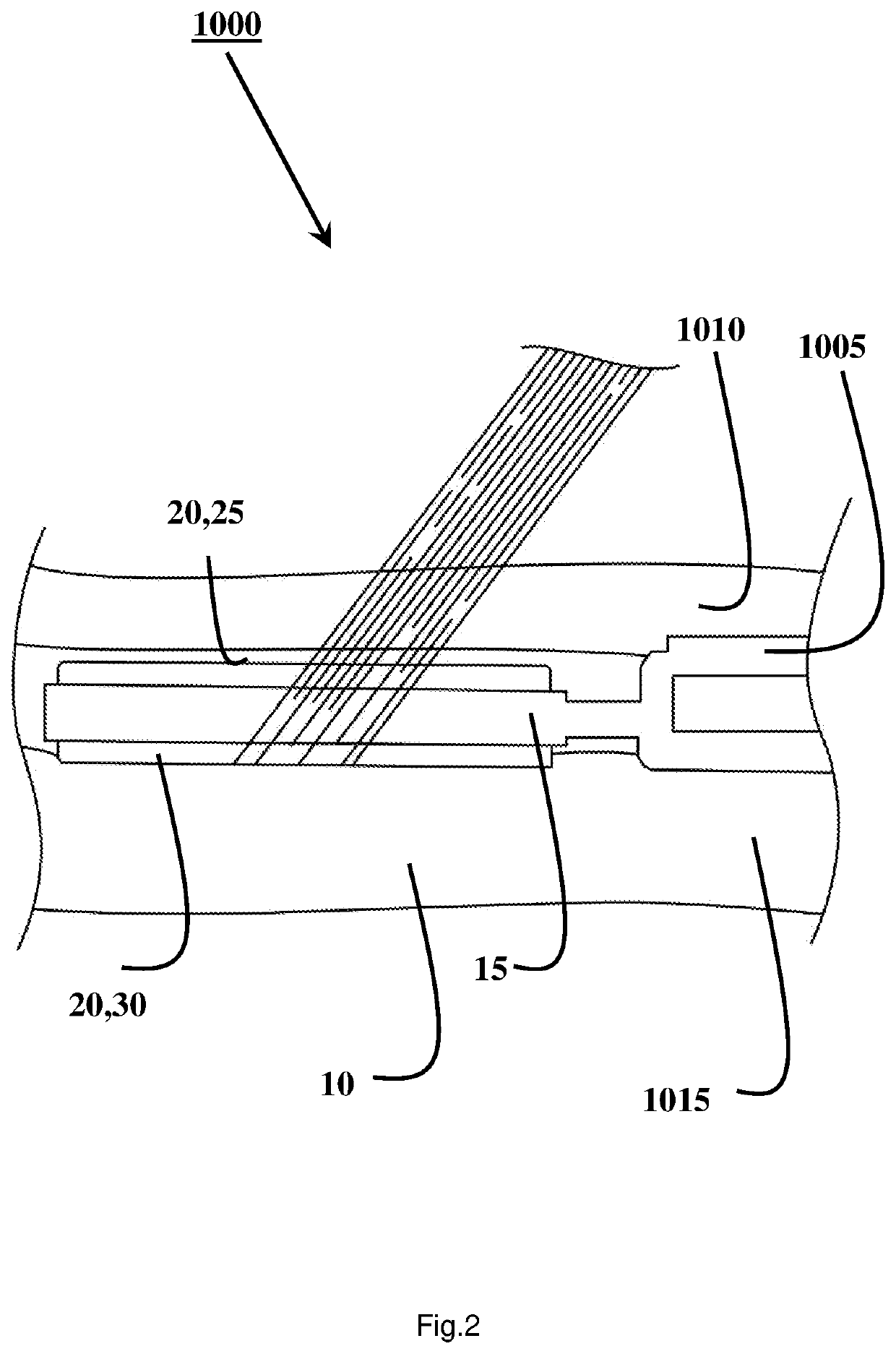

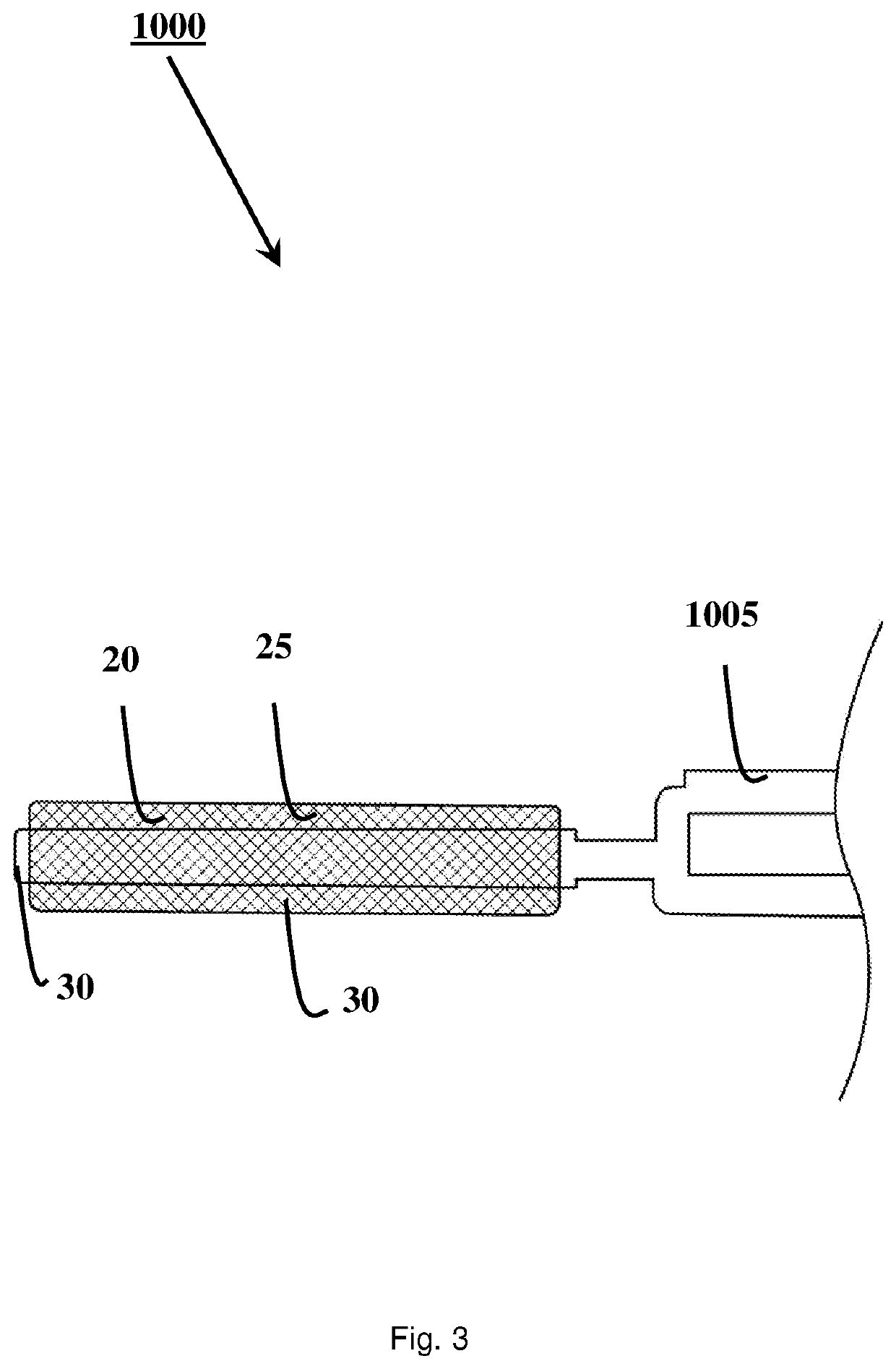

Precision contoured exo/endocervical cell sampler

InactiveUS20050256427A1Prevent excessive penetrationSecurely holdSurgical needlesPreparing sample for investigationMicroscope slideCervix

An L-shaped, precision contoured EXO / ENDOcervical cell sampler for collecting representative cells is invented for pre-malignant and malignant diagnosis. The said cell sampler comprises of an elongated and rounded stick-shaped stem with a slightly thickened handle means at one end, and a flattened connecting means havig two protrusions at the other end. An L-shaped configuration at the root of said connecting means has one vertical ENDOcervical contact portion and one horizontal EXOcervical contact portion, which directly hug to the transformation zone thereby allowing a through and complete 360 DEG rotatinal sweeping-up of all the truly representatives cells. When said cell sampler is withdrawn from the cervix, the vertical ENDOcervical contact portion is subsequently bent and both the EXO- and ENDOcervical portions are swept across a microscope slide for cytological microscopic examination.

Owner:MOO YOON NGEN +1

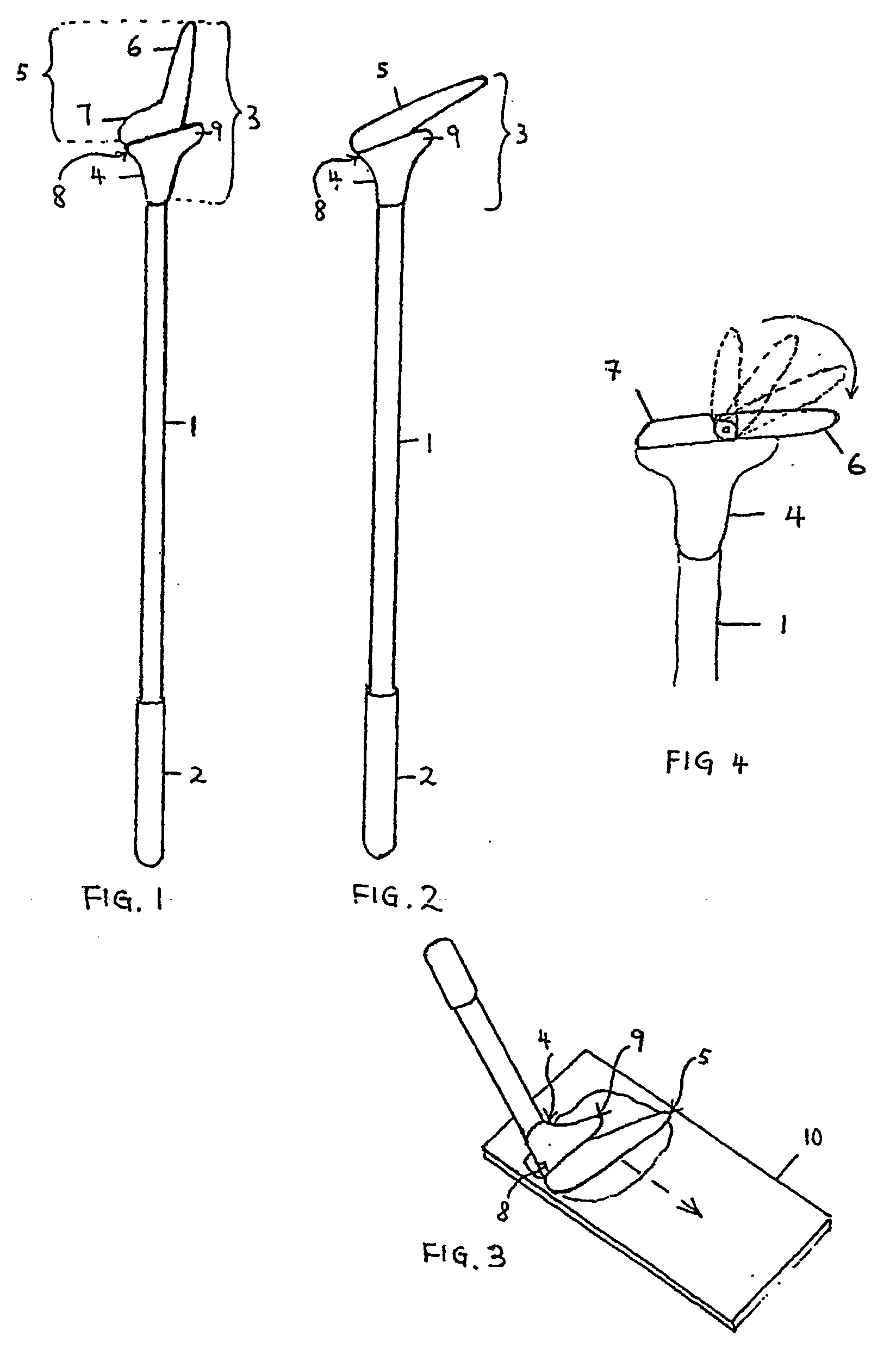

Golf Training Accessory

A golf training accessory for improving the effectiveness of exercises of sliding a golf club along a guide surface is disclosed. The accessory includes a suitable contact material along with a method of removably attaching the material to a golf club. In use, the contact material rather than the golf club contacts the guide surface. Preferably the method of attachment is a layer of re-useable adhesive. Preferably the contact material is a material that causes a low level of abrasion when it slides against a hard smooth surface. Preferably the contact material is a material that causes low friction when it slides against a hard smooth surface. Preferably the contact material is a material that causes a low level of noise when it slides against a hard smooth surface. Suitable materials may include a soft cloth material such as cotton or felt.

Owner:BROOKS ROGER JOHN

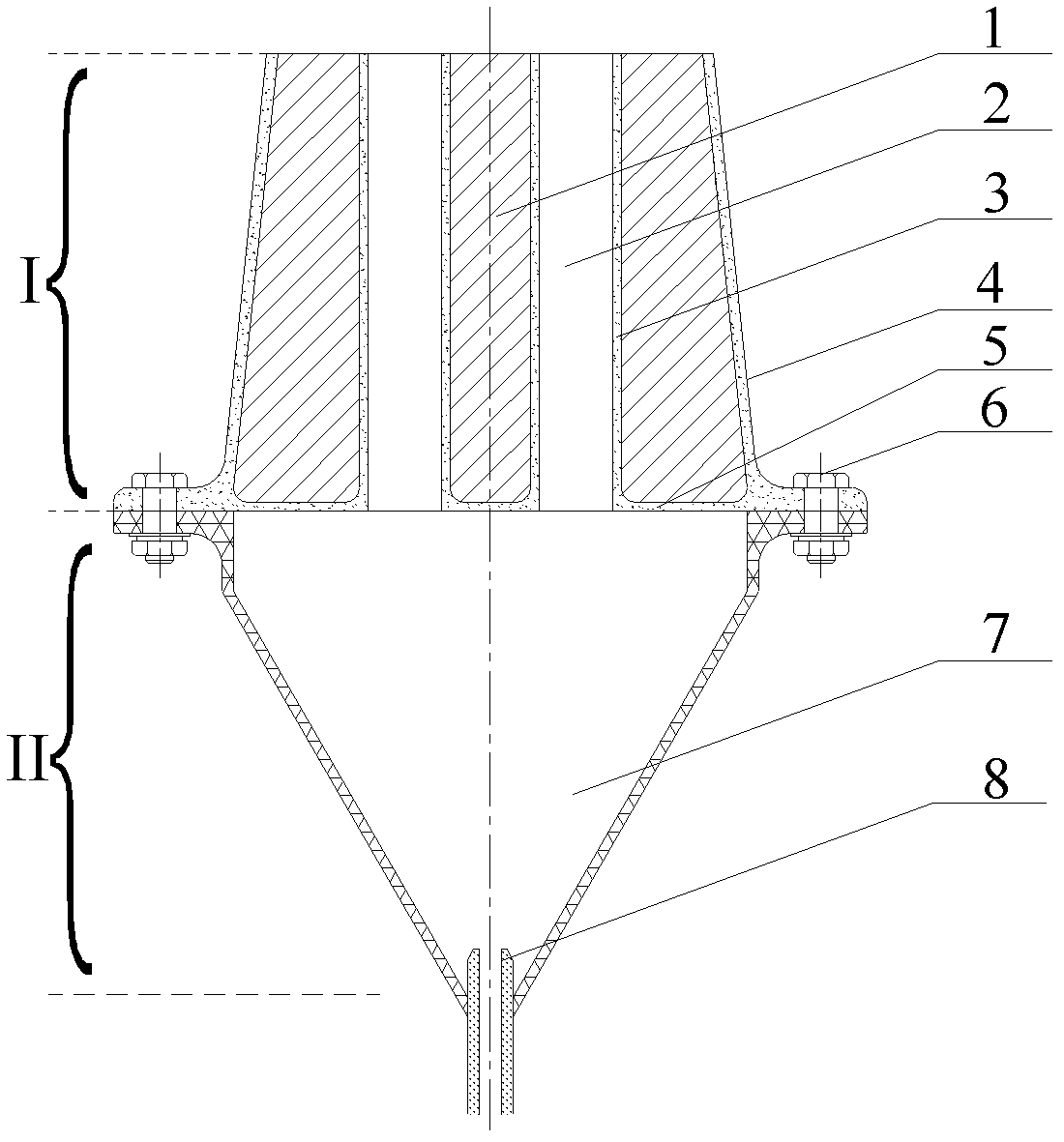

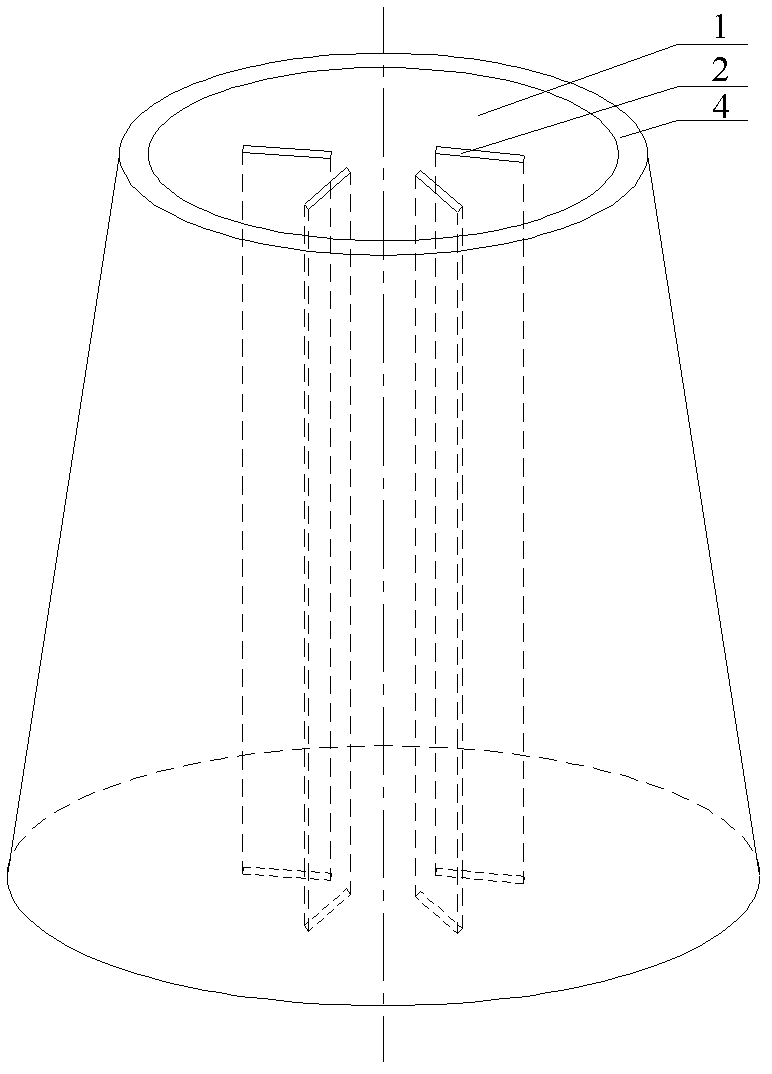

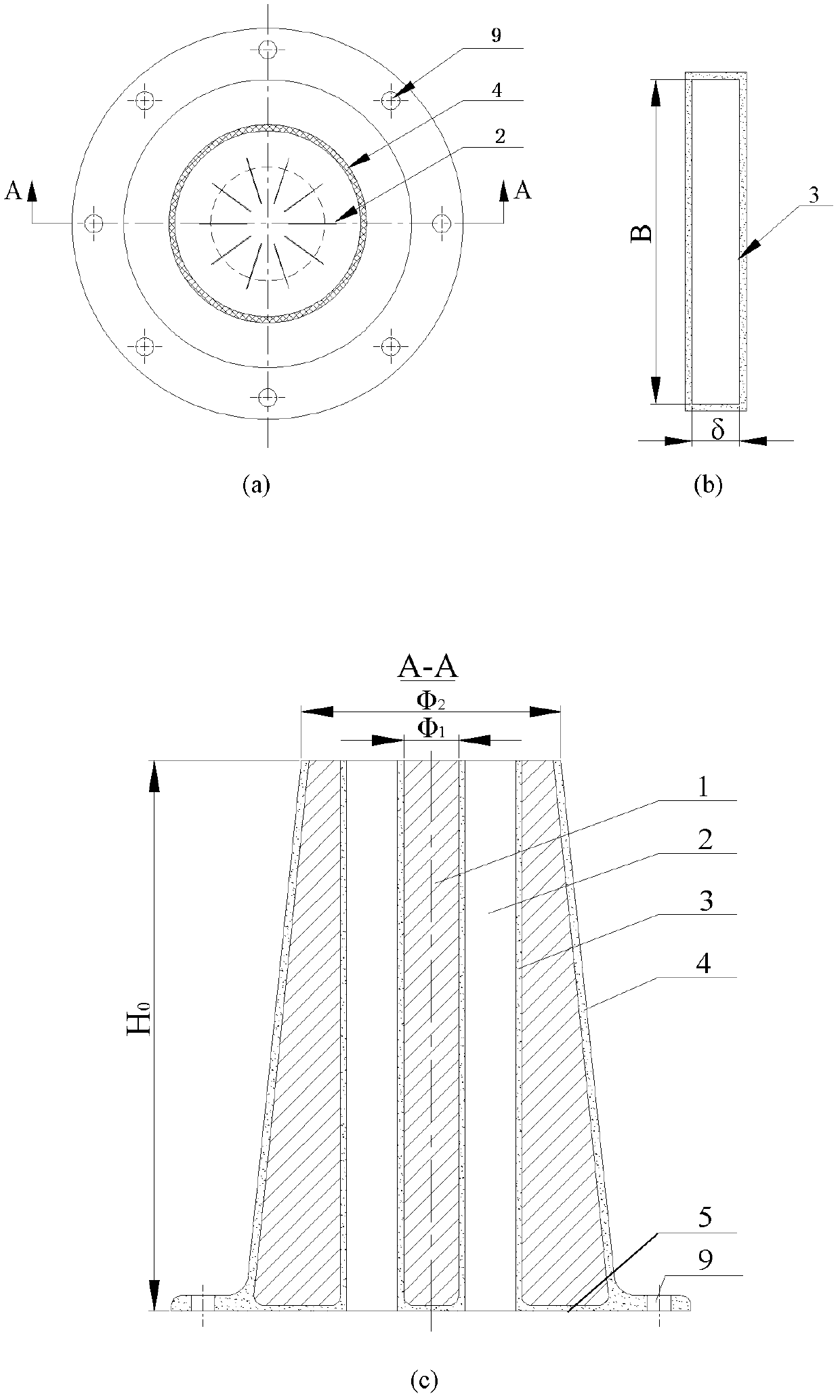

Metal slit-type ladle bottom blowing powder injection apparatus

The invention provides a metal slit-type ladle bottom blowing powder injection apparatus which belongs to the steel refining technical field. The apparatus comprises two parts of a metal slit-type powder injection element and an air accumulating chamber, the metal slit-type powder injection element is connected with the air accumulating chamber through flange bolts; wherein the metal slit-type powder injection element comprises an external metal shell and an refractory material which has slits inside, a metal plate is provided on an inner wall of the slit, a metal base plate is provided on the bottom of the refractory material, a through hole provided on the metal base plate is communicated with the slits, the circumference of the metal base plate is connected with the metal shell, the bottom of the metal plate is connected with the metal base plate, the top of the metal plate is positioned at the top of the slit. The invention has the advantages that the strength for powder injectionsmelting is enhanced, the strength is high at the high temperature, the metal slits are welded for difficult deformation, the apparatus of the invention has the advantages of good airtight, stable blowing, low manufacture cost, large adjustable scope of power and air amount, long usage life, safety and reliability.

Owner:NORTHEASTERN UNIV LIAONING

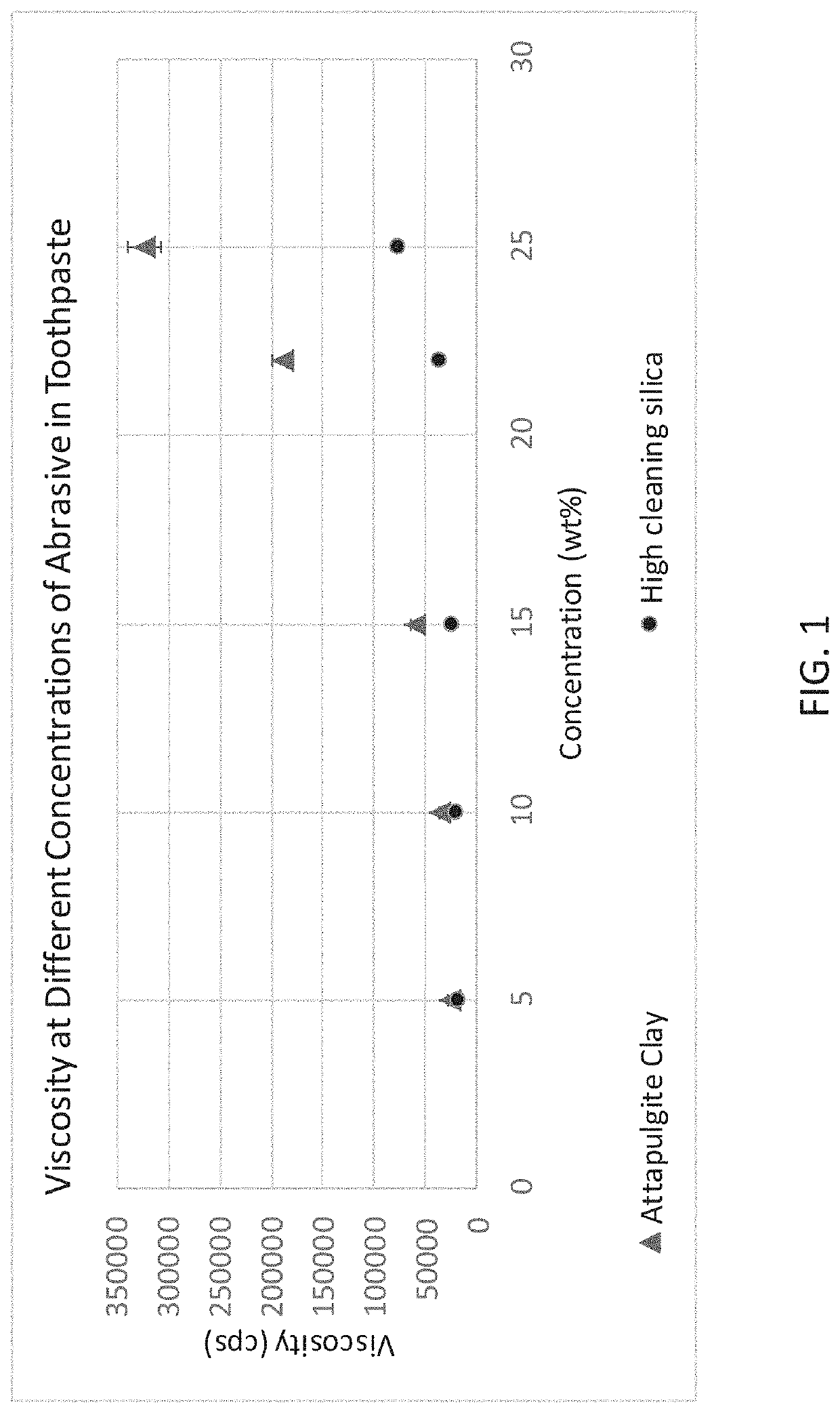

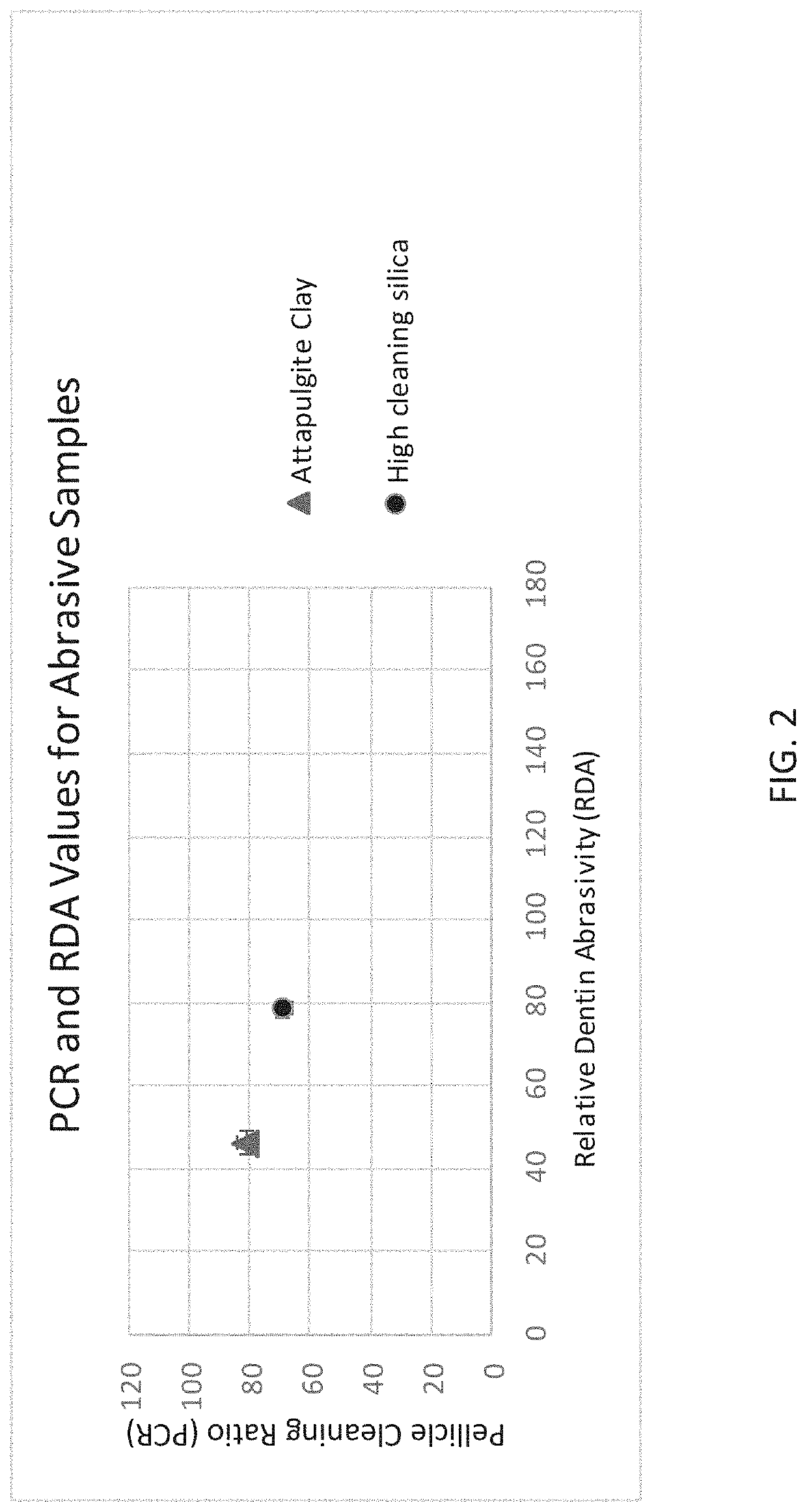

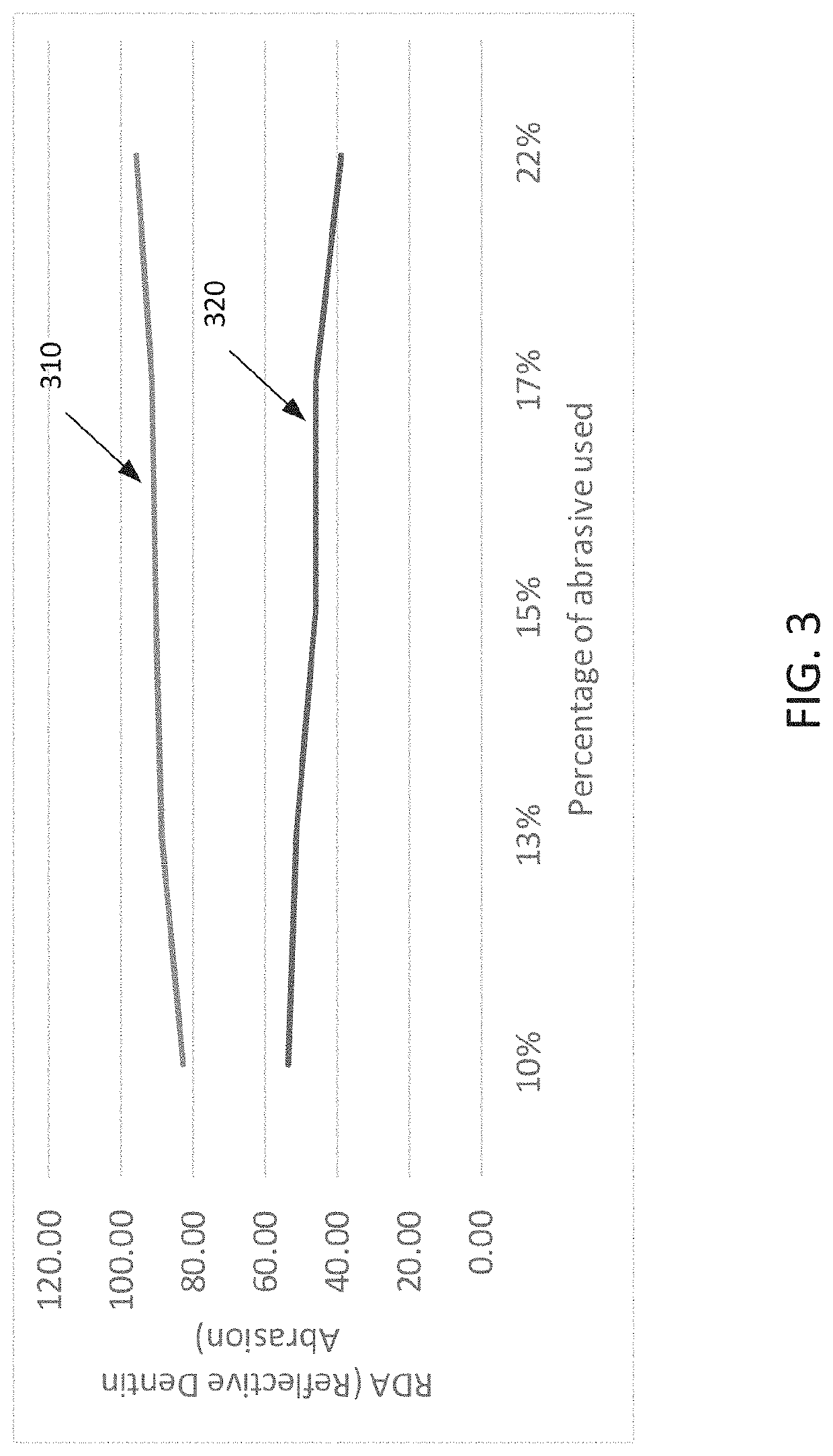

Oral care composition

PendingUS20220202666A1Reduce harmLess abrasiveCosmetic preparationsToilet preparationsMouth careDentin

Owner:BASF AG

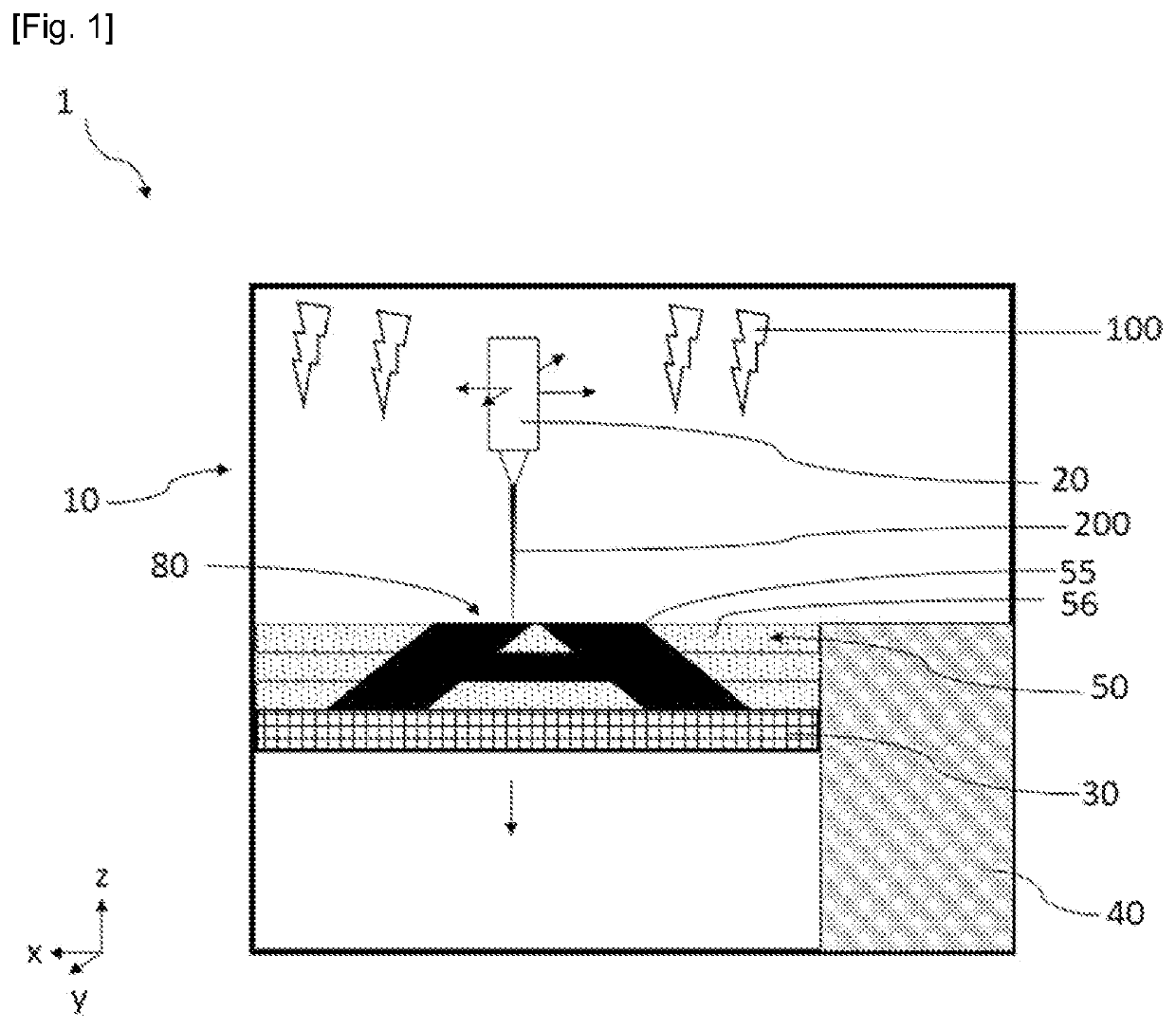

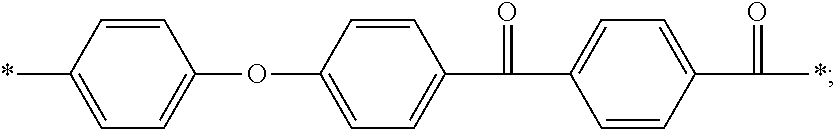

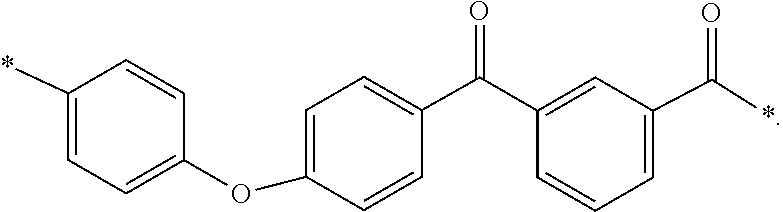

Filled polyaryl ether ketone powder, manufacturing method therefor and use thereof

PendingUS20220363842A1Improve mechanical propertiesHigh modulusAdditive manufacturing apparatus3D object support structuresPolymer scienceEther

A powder with a volume-weighted particle size distribution, with a median diameter D50 ranging from 40 to 120 micrometers, including at least one polyaryl ether ketone and at least one filler, in which: said at least one polyaryl ether ketone forms a matrix incorporating, at least partly, said at least one filler, and said filler has a Stokes equivalent spherical diameter distribution with a median diameter d′50 of less than or equal to 5 micrometers. Also a powder manufacturing process and the use thereof in a process for the layer-by-layer construction of objects by electromagnetic radiation-mediated sintering.

Owner:ARKEMA FRANCE SA

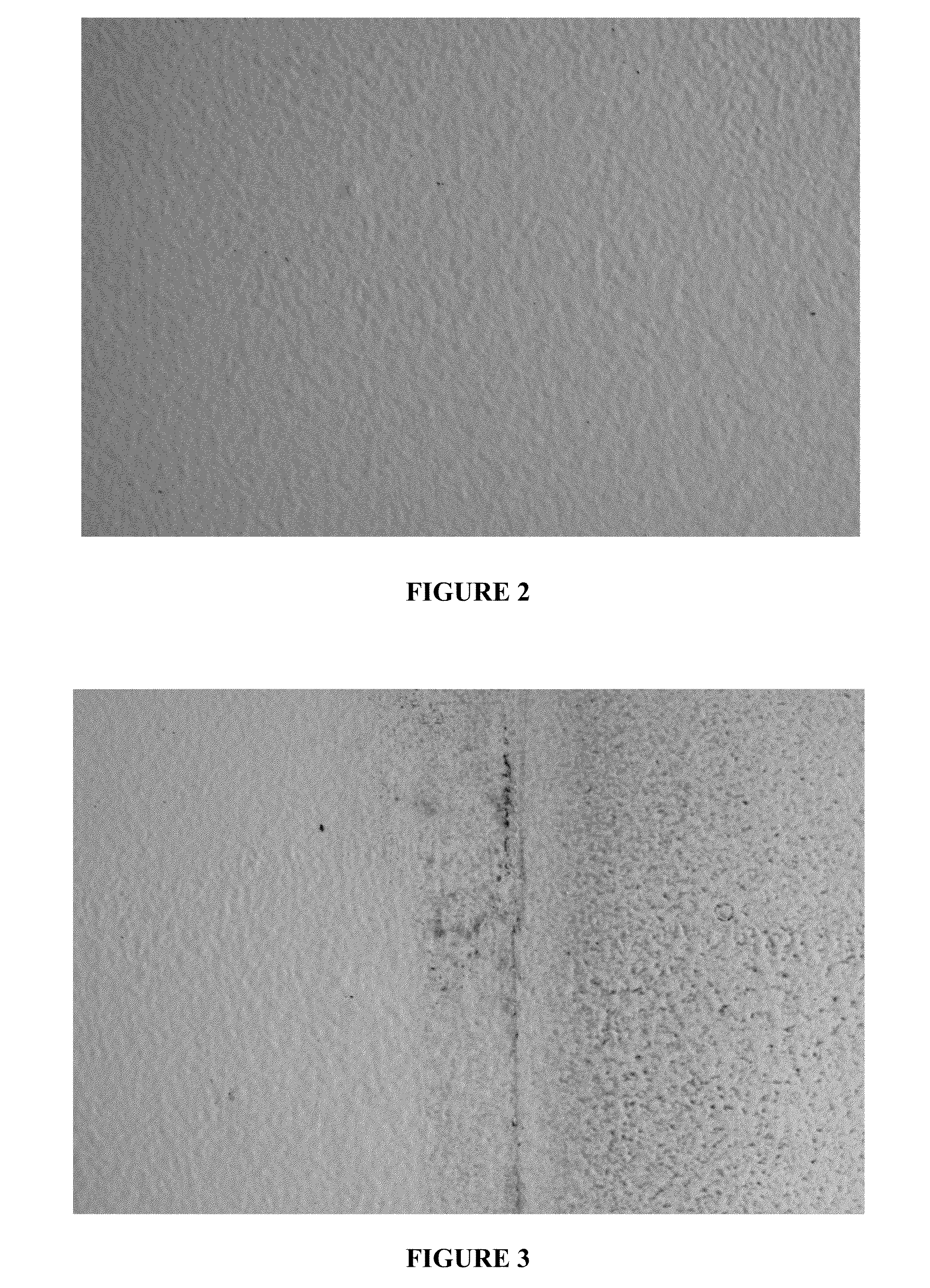

Composite material, manufacturing process therefor and uses thereof

InactiveUS20150037564A1Long lastingLess abrasiveSynthetic resin layered productsLaminationPolymer scienceAdhesive

A process for producing a composite material comprising the steps of: providing mm-sized particles comprising at least particles of a porous optionally at least partially compressed open-cell melamine formaldehyde resin and mm-sized particles of at least one non-rigid foamed resin; mixing said particles with at least one reactive adhesive in a concentration of 6 to 18 g of reactive adhesive per 100 g of mm-sized particles; reacting said reactive adhesive with said particles in the presence of aerial moisture thereby bonding said particles together during said mixing process; transporting said mixture into a mould; and irreversibly compressing said mixture to a block in a mould without additional heat to a density greater than 50 kg / m3 to form a block of said composite material; a composite material obtainable by this process; and the use of this composite material for polishing and / or cleaning applications with a liquid.

Owner:GO4HIT

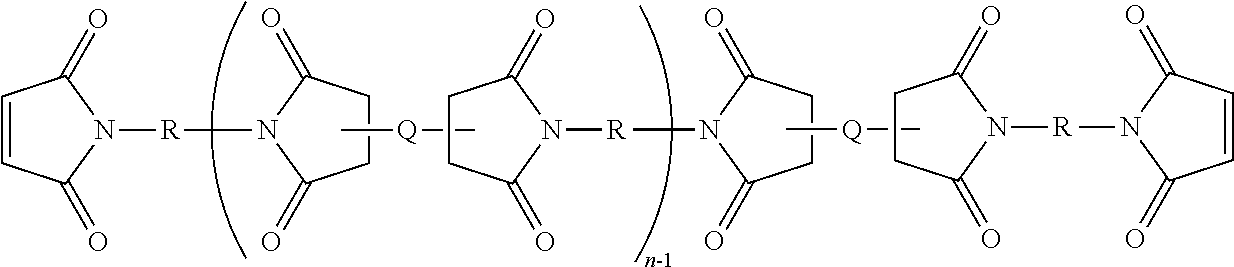

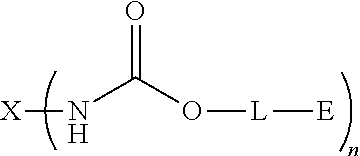

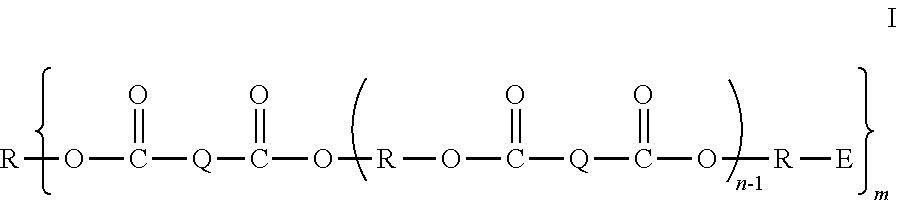

An attachment means for attaching a medical device to tissue, a system for attaching a medical device to tissue, a medical device having an attachment means, a method of attaching a medical device to tissue, and a method of manufacturing an attachment means

PendingUS20220160940A1Less abrasiveWeakening rangeSpinal electrodesHead electrodesPhoto irradiationCross linker

An attachment device for connecting a medical device to biological tissue of a subject includes a biocompatible scaffold including photoactive crosslinking agent and a photoactive dye to facilitate crosslinking of the scaffold with biological tissue of a subject when light is directed onto the scaffold. A conformable cover for a medical device made from the biocompatible scaffold includes strain crystallised, filaments which change shape at a predetermined temperature to conform the cover to an outer shape of the medical device. The conformable cover can be attached to biological tissue.

Owner:GLOBAL SURGICAL INNOVATIONS HLDG PTY LTD

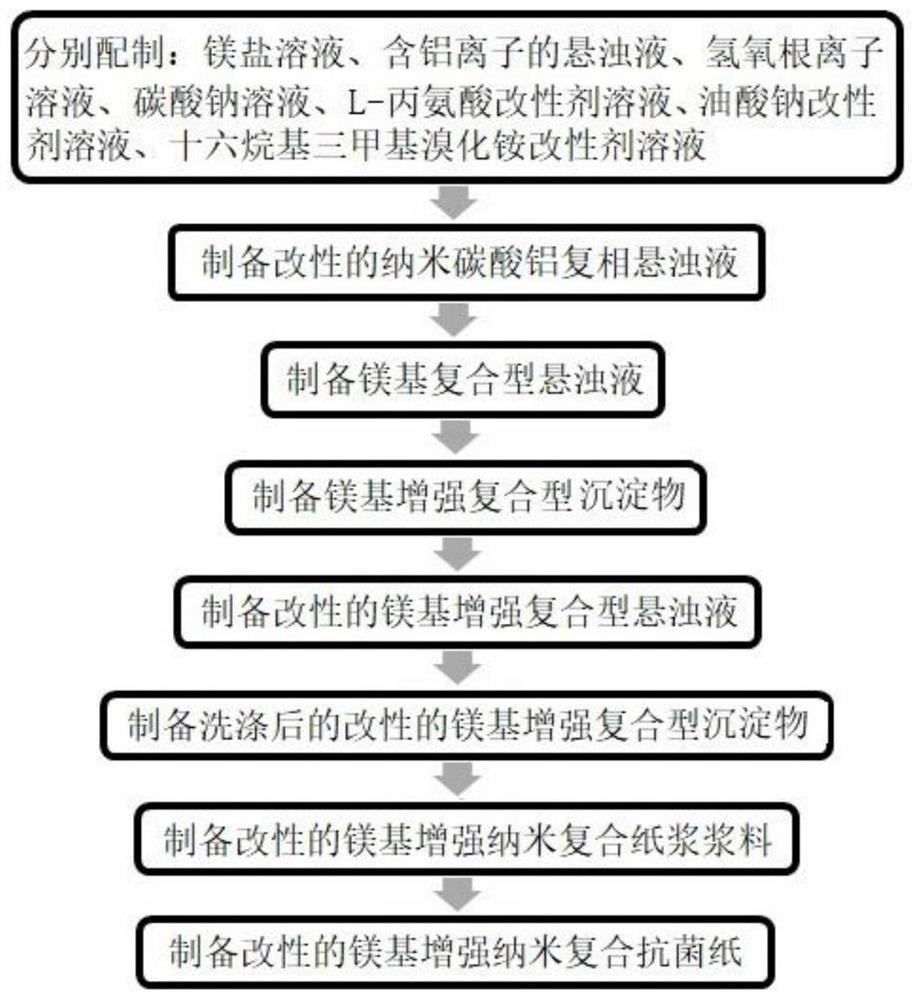

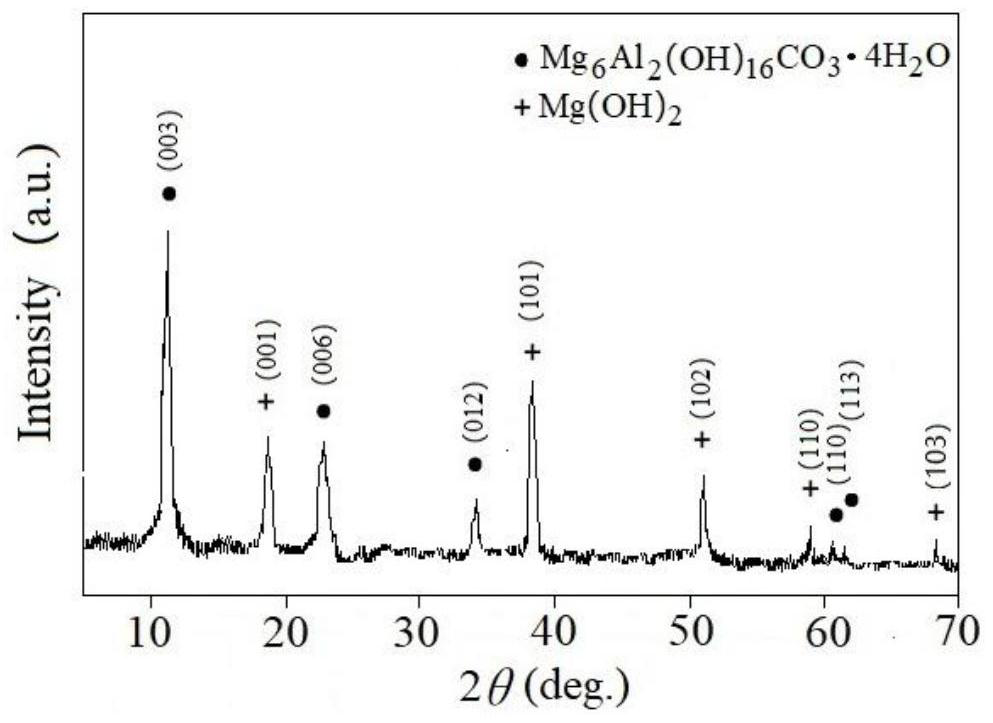

Preparation method of pseudomonas aeruginosa-resistant nano-composite paper

ActiveCN113026418ANon-corrosiveNo corrosionPaper/cardboardBiocidal agent additionAluminum IonMagnesium salt

The invention discloses a preparation method of pseudomonas aeruginosa-resistant nano composite paper, and mainly solves the problems of low pseudomonas aeruginosa killing rate, expensive raw materials and high preparation cost of antibacterial paper in the prior art. According to the implementation scheme, the method comprises the following steps: 1) respectively preparing a magnesium salt solution, a turbid liquid containing aluminum ions, a hydroxyl ion solution, a sodium carbonate solution, an L-alanine solution, a sodium oleate solution and a hexadecyl trimethyl ammonium bromide solution, performing mixing, heating and stirring to obtain a modified magnesium-based reinforced composite turbid liquid; 2) sequentially standing, filtering and washing the turbid liquid to obtain a precipitate; and (3) adding cut waste paper into the precipitate to obtain modified magnesium-based reinforced nano-composite paper pulp, and performing sieving and airing to obtain the antibacterial paper. The composite paper is non-toxic and non-corrosive; is obvious in antibacterial effect; and is low in preparation cost, simple in process, conducive to improvement of paper printing quality and toughness, and capable of being used for indoor decoration of large office occasions in the building industry.

Owner:XIDIAN UNIV

A high-efficiency ball mill with reinforcing ribs

The invention relates to the field of ceramic machinery, in particular to an efficient ball grinding mill with reinforcing ribs. A cylinder body is of a two-layer tubular structure, the first layer is a cylinder body shell, the second layer is a preliminary screening and grinding mesh tube with screening holes, grinding balls are placed inside the cylinder body, a feed port of the cylinder body is connected to a cavity of the preliminary screening and grinding mesh tube, and a discharge port of the cylinder body is connected to a cavity between the inner surface of the cylinder body shell and the outer surface of the preliminary screening and grinding mesh tube; a lining plate is arranged inside the cylinder body shell, is formed by splicing a plurality of lining bricks and is cylindrical, the reinforcing ribs and the lining plate are arranged on the inner surface of the cylinder body shell, grooves are formed in the back surfaces of the lining bricks and cover the reinforcing ribs, the back surface of the lining plate is attached and fixed to the inner surface of the cylinder body shell, and every two adjacent lining bricks are spliced and fixed through mortises and tenons of the lining bricks. The efficient ball grinding mill is convenient to install and stable in structure.

Owner:佛山市铖罡机械制造有限公司

Magnetic ball and production method thereof

PendingCN110310796AReserved functionLess abrasivePermanent magnetsPermanent magnet manufactureMagnetic tension forceEconomic benefits

The invention relates to the field of magnetic spheres, in particular to a magnetic ball comprising a spherical magnetic ball body. A magnetic core is arranged in a way of penetrating through the center of the magnetic ball body. The magnetic core is made of Nd-Fe-B material. The magnetic ball body is made of magnetic conducting material. When the magnetic ball body is filled with the magnetic core, the suction point is located at the two ends of the magnetic core in practical use, i.e. the N / S pole. Compared with the magnetic ball completely supported by aluminum, iron and boron, the magneticsuction force at the two ends is almost unaffected and the cost is greatly reduced and thus huge economic benefits are produced.

Owner:金华市新利磁业工贸有限公司

Nonabrasive Sensory Exfoliating System

InactiveUS20100003295A1Less abrasiveRemineralizes the skin surfaceCosmetic preparationsToilet preparationsDermatologySilicone

Owner:MOHAMMADI FATEMEH F +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com