Efficient ball mill with annular grooves

A ring groove and ball mill technology, which is applied in the field of ceramic machinery, can solve the problems of determining the grinding time of the ball mill, ensuring the quality of the grinding material, the problems of increasing the grinding time, and delaying the progress of the process, so as to shorten the grinding time and improve the quality of the grinding material. High efficiency and the effect of increasing volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

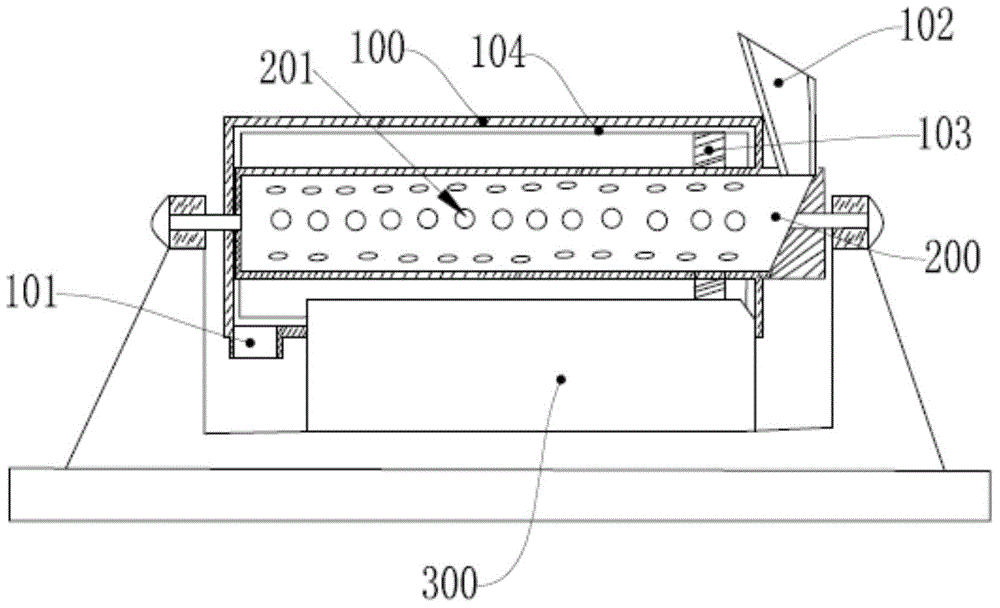

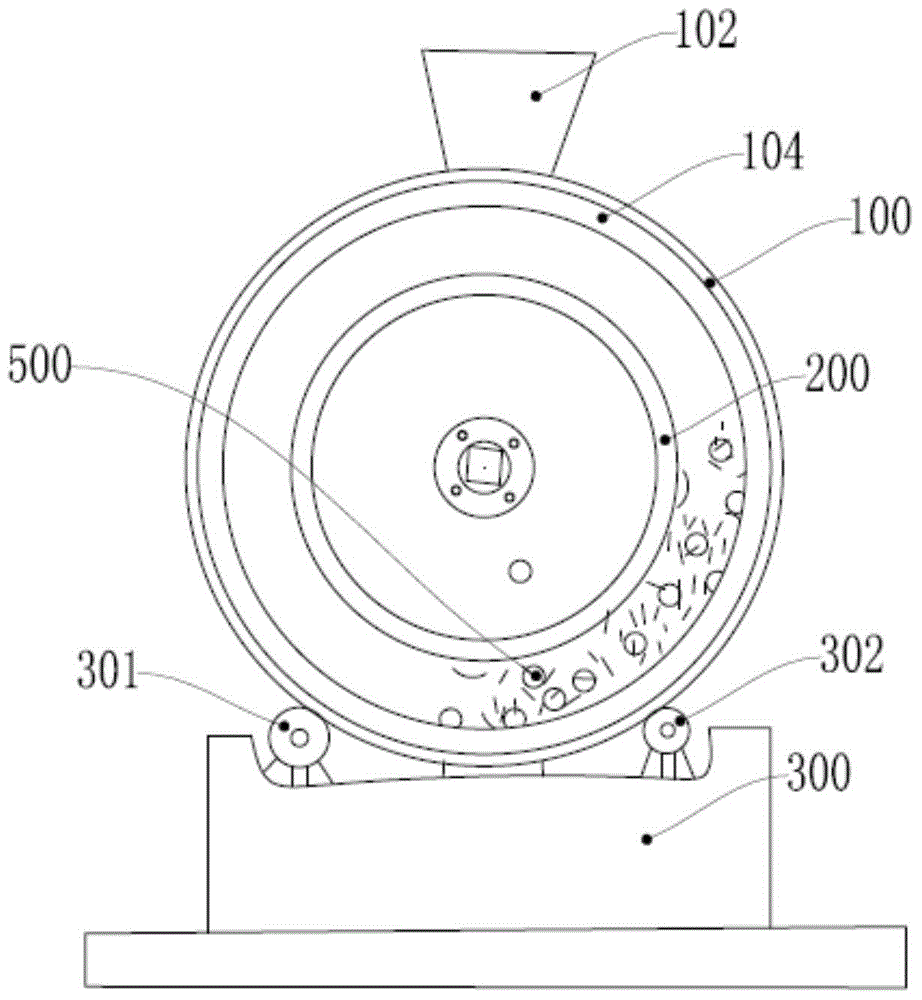

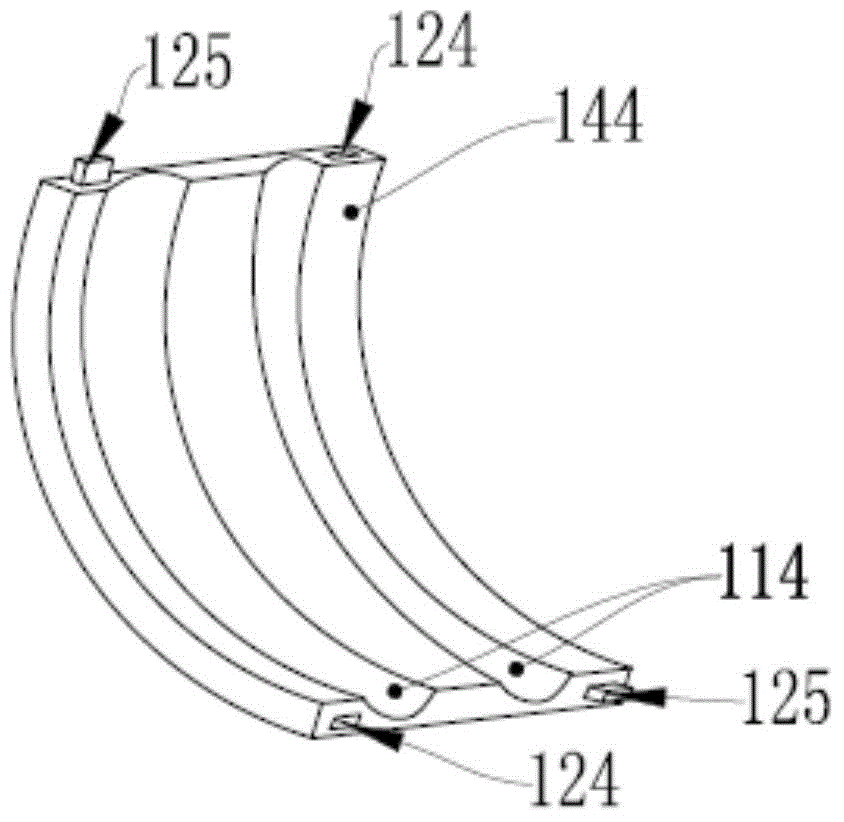

[0027] Such as Figure 1-3 As shown, a high-efficiency ball mill with an annular groove includes a cylinder 100 provided with a feed inlet 102 and a discharge opening 101 and a drive device 300, the drive device 300 drives the cylinder 100 to rotate, and the cylinder The body 100 is divided into two layers of tubular structure, the first layer is the shell of the cylinder body, the second layer is the primary sieve grinding network pipe 200 with sieve holes 201, which is made of non-magnetic copper alloy material, and the cylinder body 100 has two layers structure, the two-layer structure of the cylinder body 100 is equipped with grinding balls, the grinding balls are magnetic steel balls 500, the feeding port 102 is connected with the cavity of the primary screen grinding network pipe 200, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com