Preparation method of wear-resistant coating

A wear-resistant coating and hard coating technology, applied in the field of preparation of wear-resistant coatings, can solve problems such as the decline of wear resistance, and achieve reduced residual stress, less adhesion and wear debris, and good tribological properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

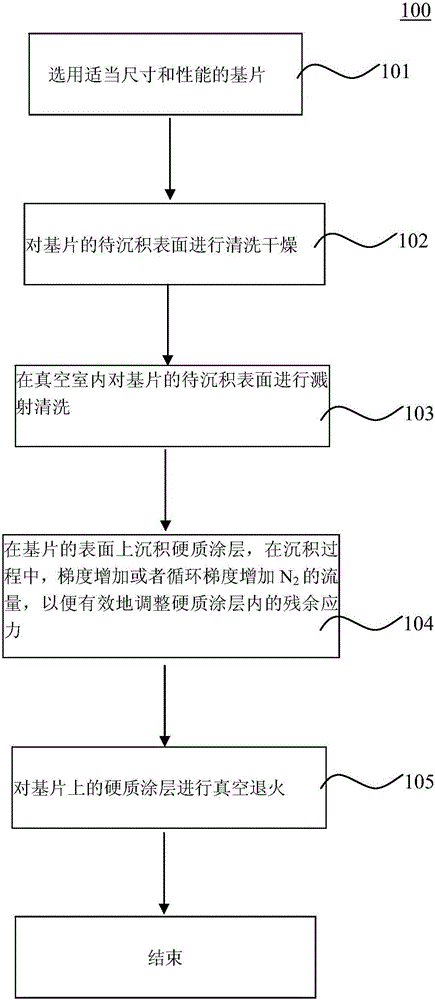

[0034] figure 1 is a flow chart of the preparation method 100 of the wear-resistant coating of the present invention. Such as figure 1 As shown, in the present invention, the preparation method 100 of the wear-resistant coating mainly includes the following steps:

[0035] Step 101, select a substrate with predetermined proper size and performance. The substrate is the cutting tool, mold and parts to be deposited wear-resistant coating, usually steel;

[0036] Step 102: cleaning and drying the surface of the substrate to be deposited. Specifically, alcohol, metal detergent and deionized water are usually used in sequence for ultrasonic cleaning for 3-8 minutes, and then dry N 2 Dry the surface to make the surface of the substrate to be deposited clean and easy to combine with the coating. After that, put the substrate into the vacuum chamber of the arc ion coating equipment;

[0037] Step 103: Perform sputter cleaning on the surface of the substrate to be deposited in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com