Metal slit-type ladle bottom blowing powder injection apparatus

A gap-type, metal-bottomed technology, applied in the field of steel refining, can solve problems such as strong abrasion and pressure loss, and achieve the effects of improving service life, being firm and not easily deformed, and having a large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

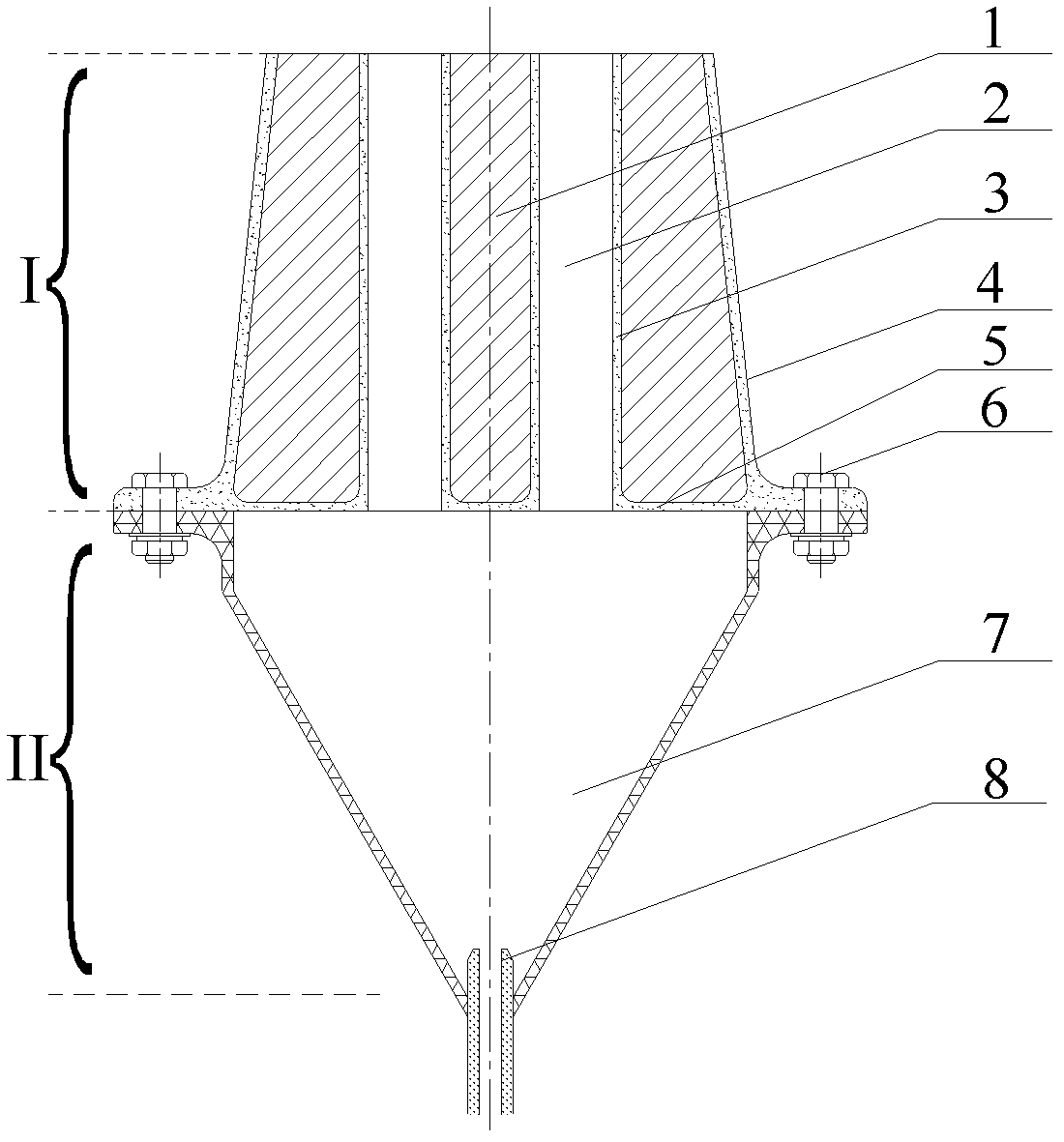

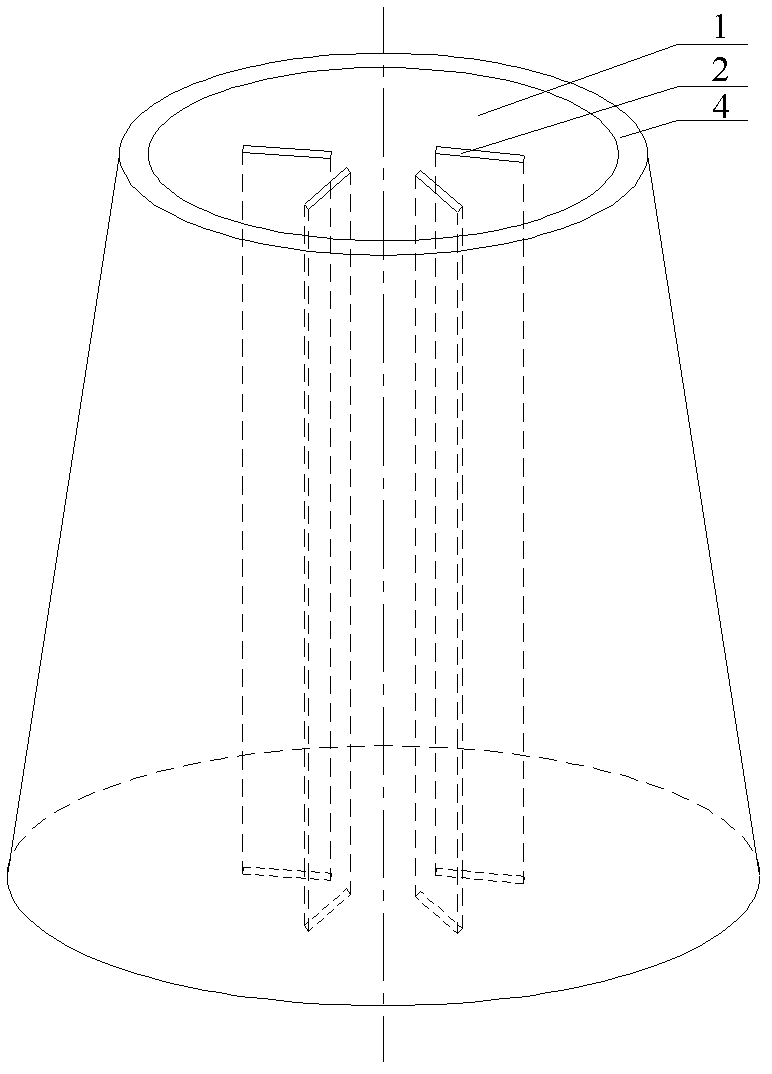

[0041] In this embodiment, a metal linear slit type powder spraying element is designed, and its shape is as follows figure 2As shown, the metal linear slit-type powder spraying element is in the shape of a circular table, with a metal shell 4 on the outside and a ventilating brick 1 inside, and a slit 2 is provided in the permeable brick 1. The slit 2 is rectangular, and the inner wall is provided with a The metal plate 3 is provided with a metal bottom surface 5 at the bottom of the breathable brick 1, and a through hole is provided on the metal bottom surface 5 to communicate with the gap 2. The periphery of the metal bottom surface 5 is connected to the metal shell 4, and the bottom of the metal plate 3 is connected to the metal bottom surface 5. top at the top of the gap;

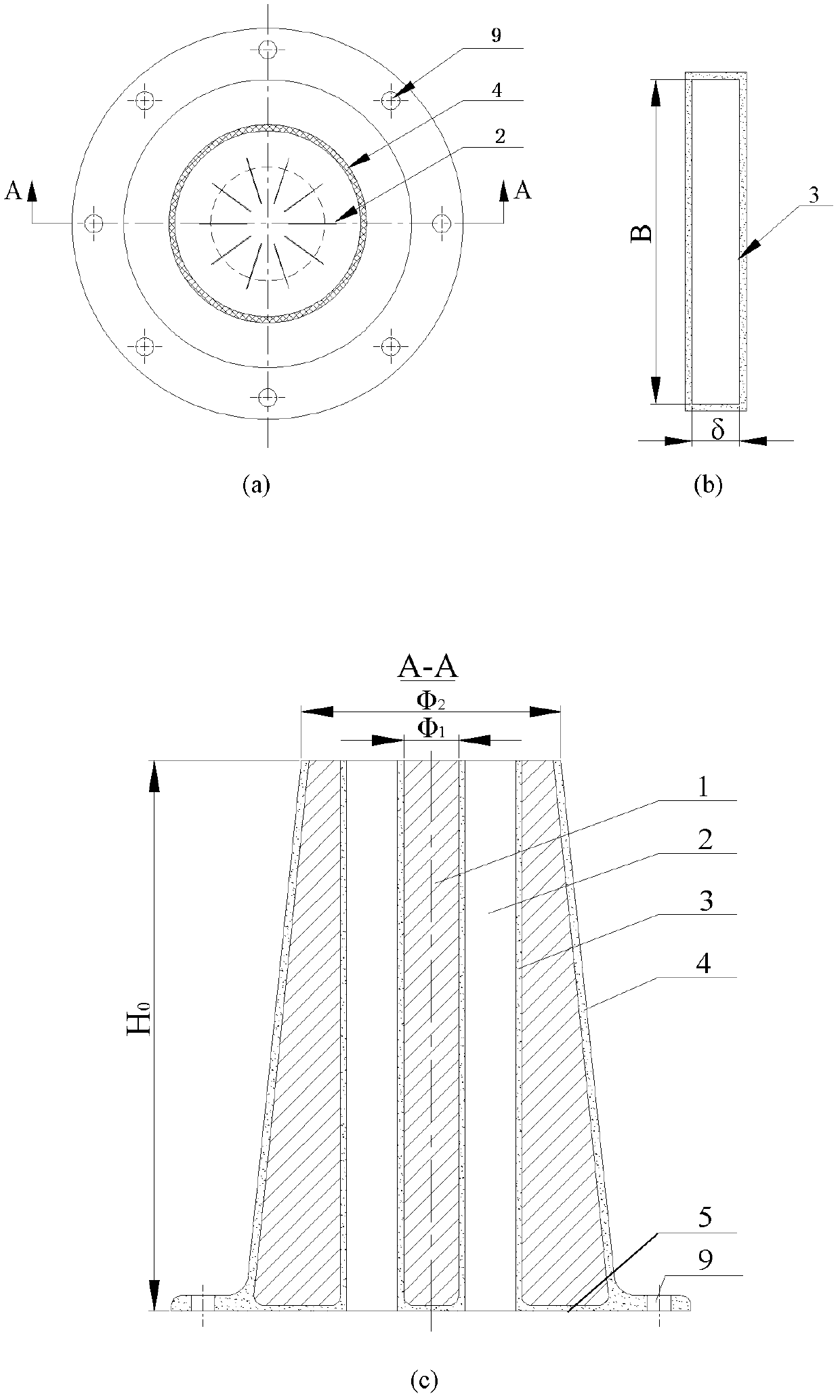

[0042] The metal gap is linear, such as image 3 As shown in (a)~3(c), the parameters are designed as follows:

[0043] (1) The inner diameter of the refractory material Φ 1 The choice is as follow...

Embodiment 2

[0050] In this embodiment, a metal annular gap type powder spraying element is designed, and its structure is as follows: Figure 4 (a), Figure 4 As shown in (b), the specific structure includes a refractory material 1, a gap 2, a metal plate 3, a metal shell 4 and a metal bottom surface 5, and a ventilating brick 1 is arranged inside, and a gap 2 is arranged in the ventilating brick 1, and the gap 2 is annular , the inner wall is provided with a metal plate 3, the bottom of the breathable brick 1 is provided with a metal bottom surface 5, the metal bottom surface 5 is provided with a through hole to communicate with the gap 2, the periphery of the metal bottom surface 5 is connected to the metal shell 4, and the bottom of the metal plate 3 is connected to the metal bottom surface 5 connection, the top of the metal plate 3 is on top of the gap;

[0051] Its specific parameters are designed as follows:

[0052] (1) The inner diameter of the refractory material Φ 1 The value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com