Hot press-formed article and method for its manufacture

A technology of hot stamping forming and manufacturing method, which is applied in the direction of manufacturing tools, hot-dip coating process, transportation and packaging, etc. It can solve the problems of insufficient judgment standards, achieve excellent corrosion resistance after spraying, not easy to damage the mold, and combine excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0032] In the hot stamped product according to the first embodiment of the present invention, an iron-zinc solid solution phase exists on the surface of the steel sheet. In addition, substantially the entire plating layer may be composed of this solid solution phase.

[0033] In the present invention, the so-called iron-zinc solid solution phase has the same lattice structure as the base material α-Fe, but the lattice constant is relatively large, and it is considered to be a phase in which iron is mixed with zinc. The presence of this phase can be confirmed by using an X-ray diffractometer in combination with an elemental analysis device such as an X-ray microprobe (referred to as EPMA or XMA).

[0034] When the galvanized steel sheet is heated, zinc in the plating layer and iron in the base steel sheet diffuse into each other, and an iron-zinc intermetallic compound phase is first formed in the plating layer. When the aforementioned interdiffusion proceeds by increasing the...

no. 2 approach

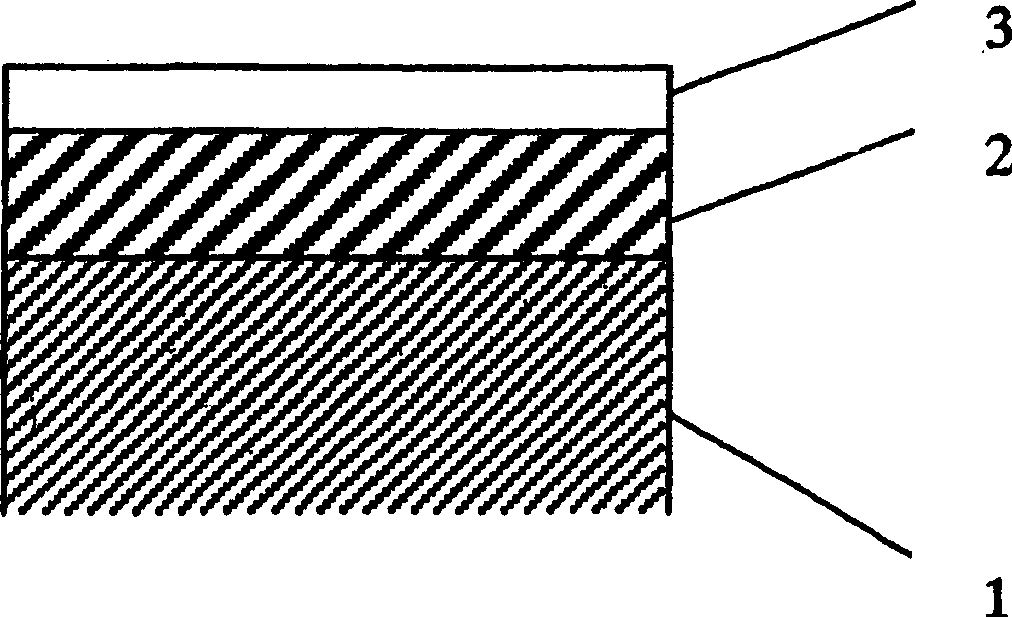

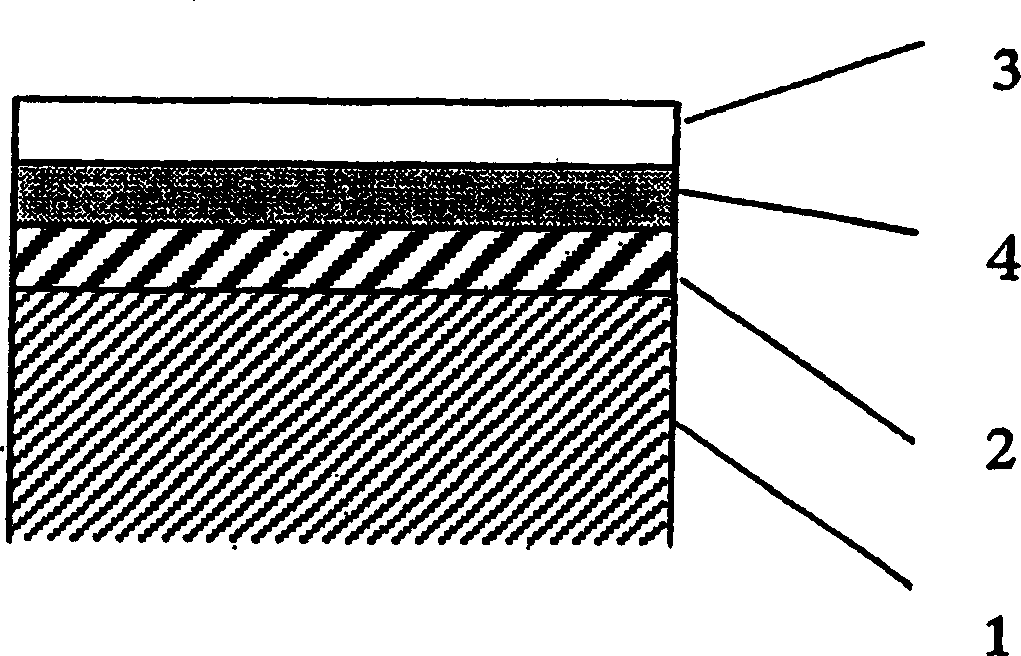

[0068] The hot stamped product of the second embodiment of the present invention, such as figure 1 As shown in the schematic diagram of , there is an iron-zinc solid solution layer (hereinafter, simply referred to as a solid solution layer) that is essentially formed by an iron-zinc solid solution phase shown in 2 near the surface layer, and zinc oxide 3 forming the surface layer is formed on its upper part. the existing surface structure. That is, on the steel 1 as the base material, the iron-zinc solid solution layer 2 and the zinc oxide layer 3 thereon are sequentially formed. like figure 2 As shown, there is no surface structure in which there is a layer 4 containing a substantial amount of iron-zinc intermetallic compound between the iron-zinc solid solution layer 2 and the zinc oxide layer 3 as is generally seen. The iron-zinc solid solution layer 2 and the zinc oxide layer 3 are formed by heating the galvanized steel sheet in an oxidizing atmosphere.

[0069] In the...

Embodiment 1

[0111] This example illustrates the first embodiment of the present invention.

[0112] As a galvanized steel sheet for hot stamping, an alloyed hot-dip galvanized steel sheet is used. The characteristics are as follows, and the sheet thickness is 2mm containing C: 0.2%, Si: 0.3%, Mn: 1.3%, and P: 0.01%. The cold-rolled steel plate is used as the base steel plate, and the coating weight is 45-75g / m on one side 2 And the iron content in the coating film is 13-15%. However, in Example No. 5 of Table 1, an unplated cold-rolled steel sheet was used as a comparative example.

[0113] The thus-prepared galvanized steel sheet is heated in an atmospheric furnace at a furnace temperature of 850-950° C. for 3-10 minutes. By changing the heating conditions (combination of temperature x time), test materials for hot stamping were produced in which the thickness of the zinc oxide layer, the thickness of the iron-zinc solid solution phase, and the amount of zinc in the solid solution phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com