Patents

Literature

89results about How to "Reduce grinding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microspheres prepared from composition containing zirconium oxide and preparation method of microspheres

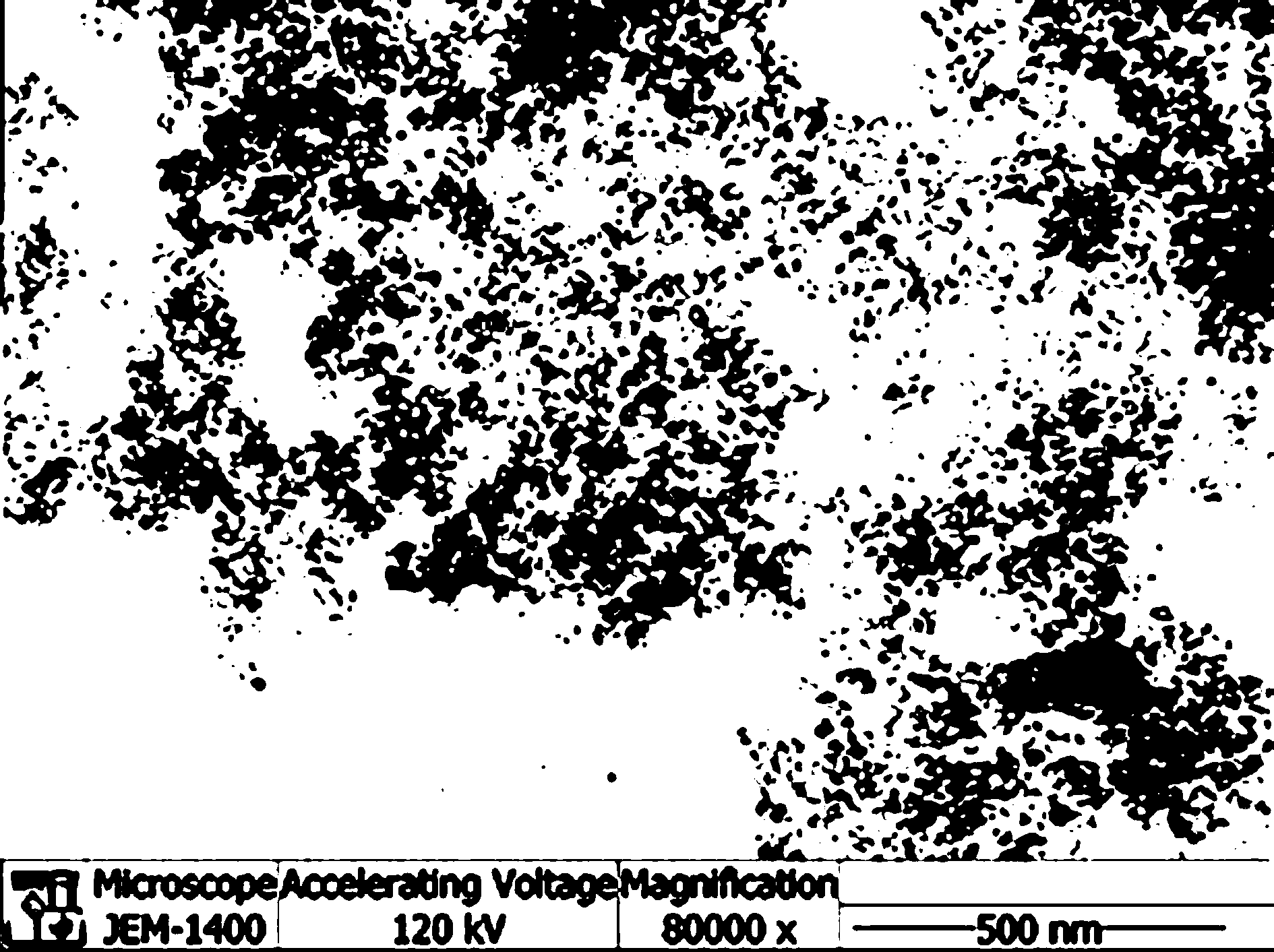

The invention relates to composite zirconium oxide microspheres and a preparation method thereof. The microspheres are prepared from yttrium oxide as a stabilizer of a zirconium oxide material. The microspheres comprises a doped system of third components including one or more of alumina, cerium oxide, copper oxide, magnesia, calcium oxide and silica, wherein the content of the yttrium oxide in the zirconium oxide is 0.1-8mol% while the total doping amount of the alumina, the cerium oxide, the copper oxide, the magnesia, the calcium oxide and the silica is 0-30wt%. According to the method, sediment dry gel is molded and further sintered to finish preparation of the composite zirconium oxide ceramic microspheres. The preparation method is simple in production technology, relatively low in cost, and applicable to industrialization. A lot of energy sources are saved for industrialization of the zirconium oxide ceramic microspheres. Meanwhile, the prepared ceramic microspheres disclosed by the invention have the characteristics of large density, durability, stability and the like.

Owner:YAAN YUANCHUANG CERAMIC

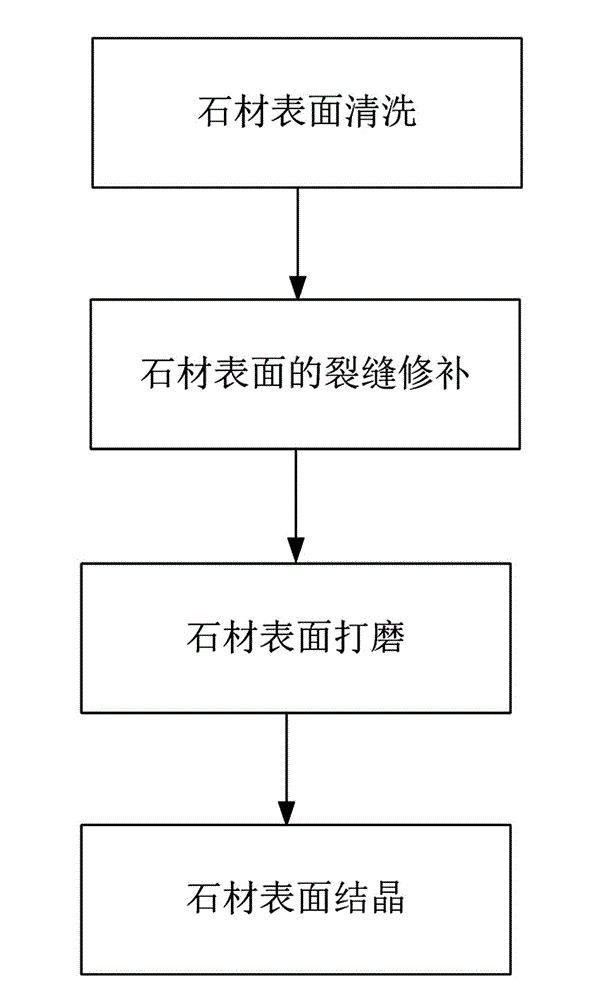

Method for maintaining stone surface of building

InactiveCN104652838AExtended service lifeNew appearanceBuilding repairsProtection layerBrightness perception

The invention relates to a method for maintaining the stone surface of a building, and belongs to the technical field of repairing of the building. The method for maintaining the stone surface of the building comprises the following steps of step 1, cleaning the stone surface, and removing dirt on the stone surface; step 2, repairing cracks in the stone surface, and caulking the cracks by using a healant; step 3, polishing the stone surface, enabling the healant caulked in step 2 to be flush with the stone surface through polishing, and renovating the stone surface in non-crack positions through polishing; step 4, enabling the the stone surface to be crystallized, and processing the stone surface by a crystallizing agent to form a crystallization protection layer. According to the method for maintaining the stone surface of the building, disclosed by the invention, the whole appearance of stone can be new, certain smoothness and brightness are obtained, meanwhile, the influence of external corrosion on the stone surface can be isolated by the crystallization layer, and the service life of the stone of the building is prolonged.

Owner:BEIJING URBAN CONSTR YATAI GRP +1

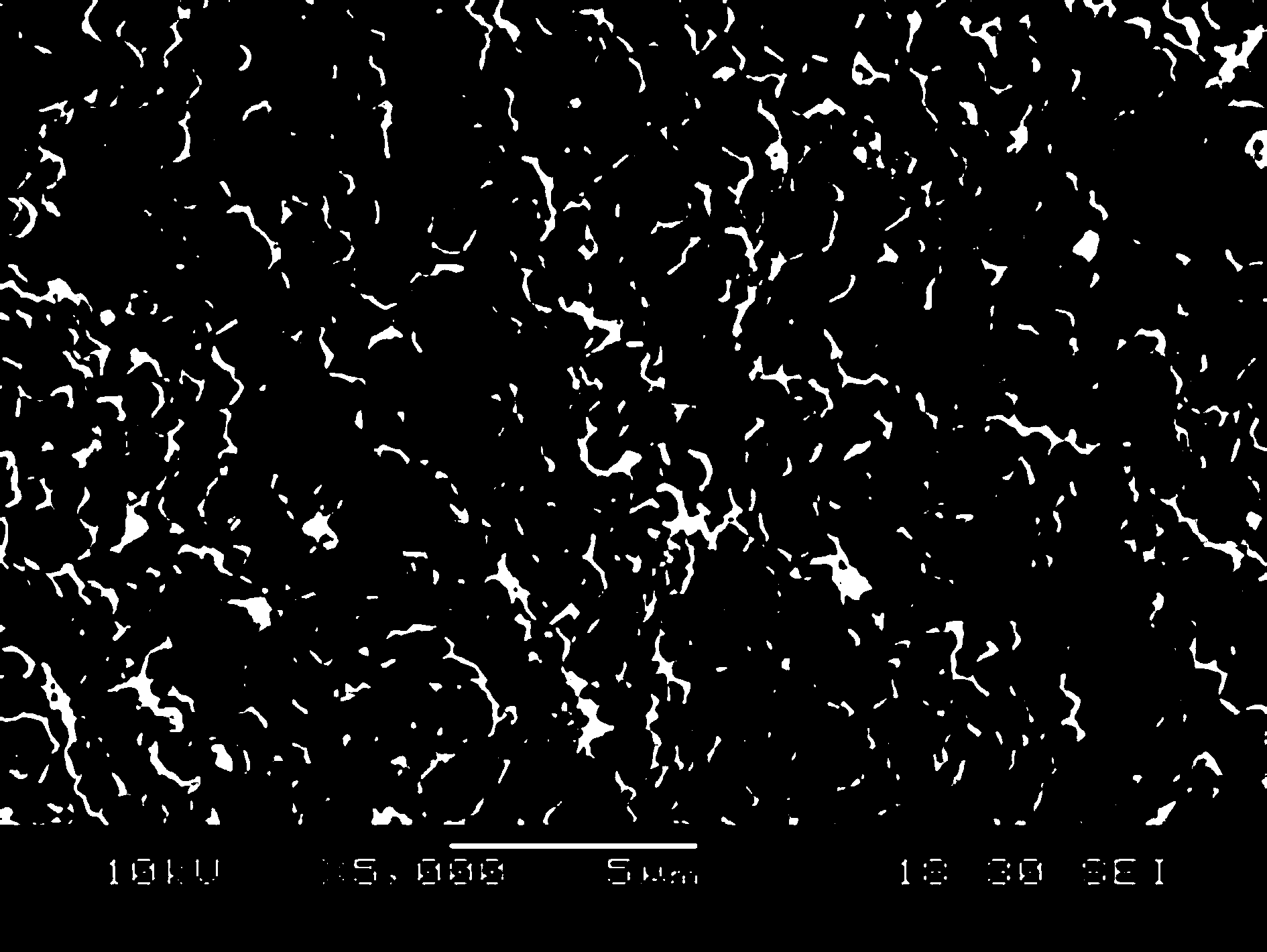

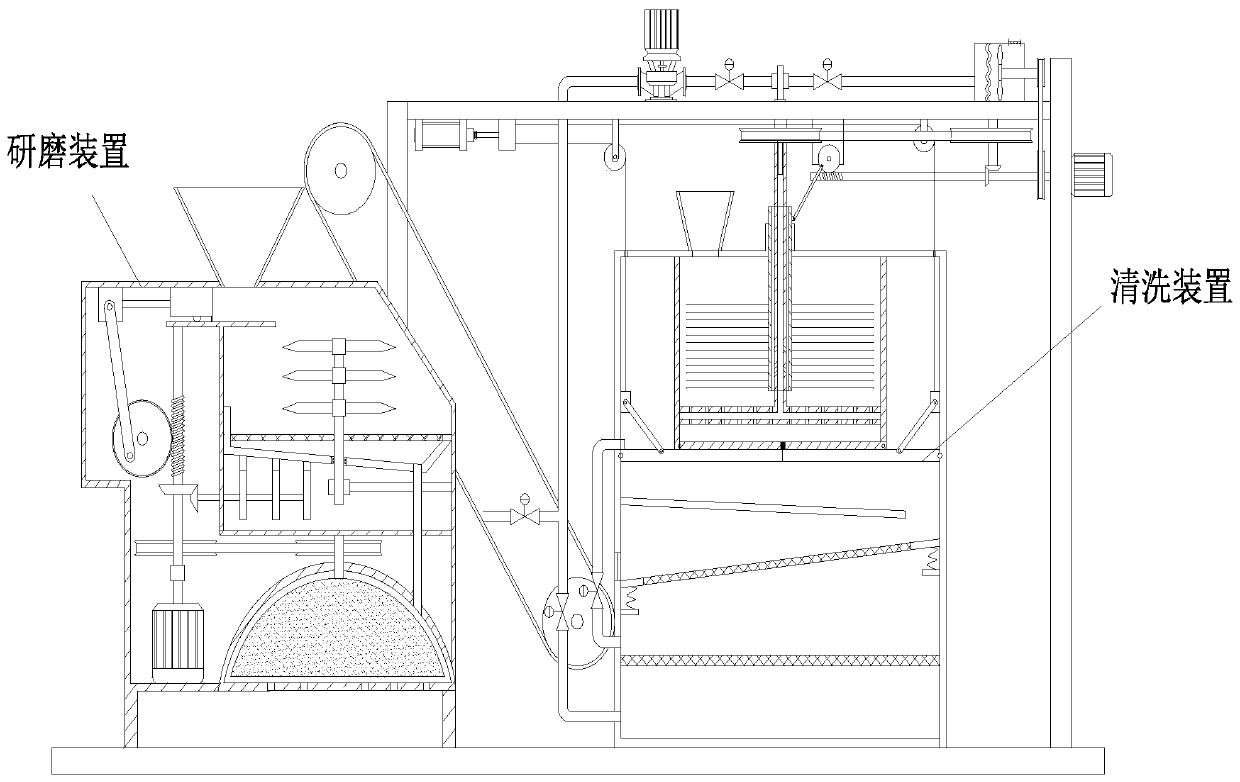

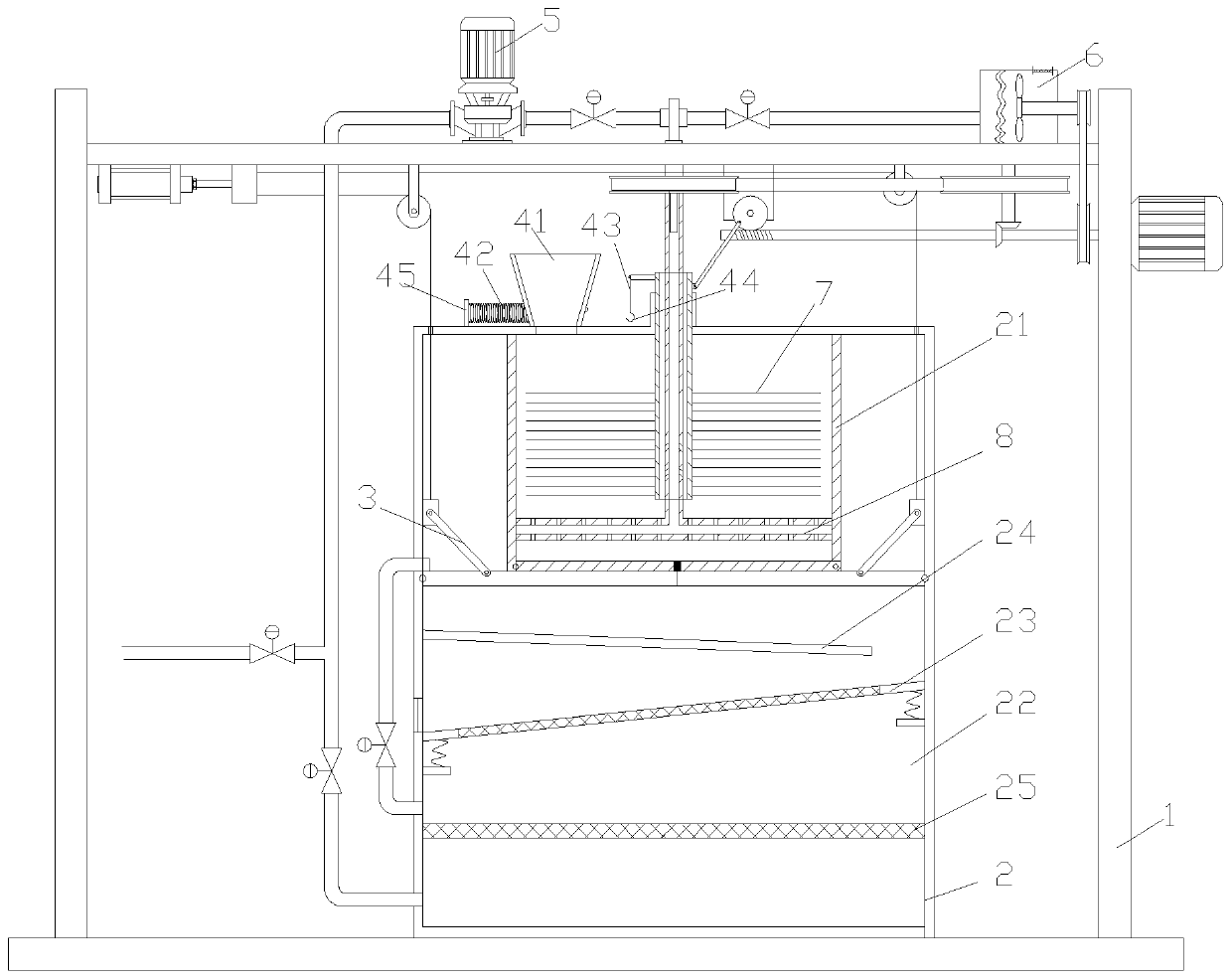

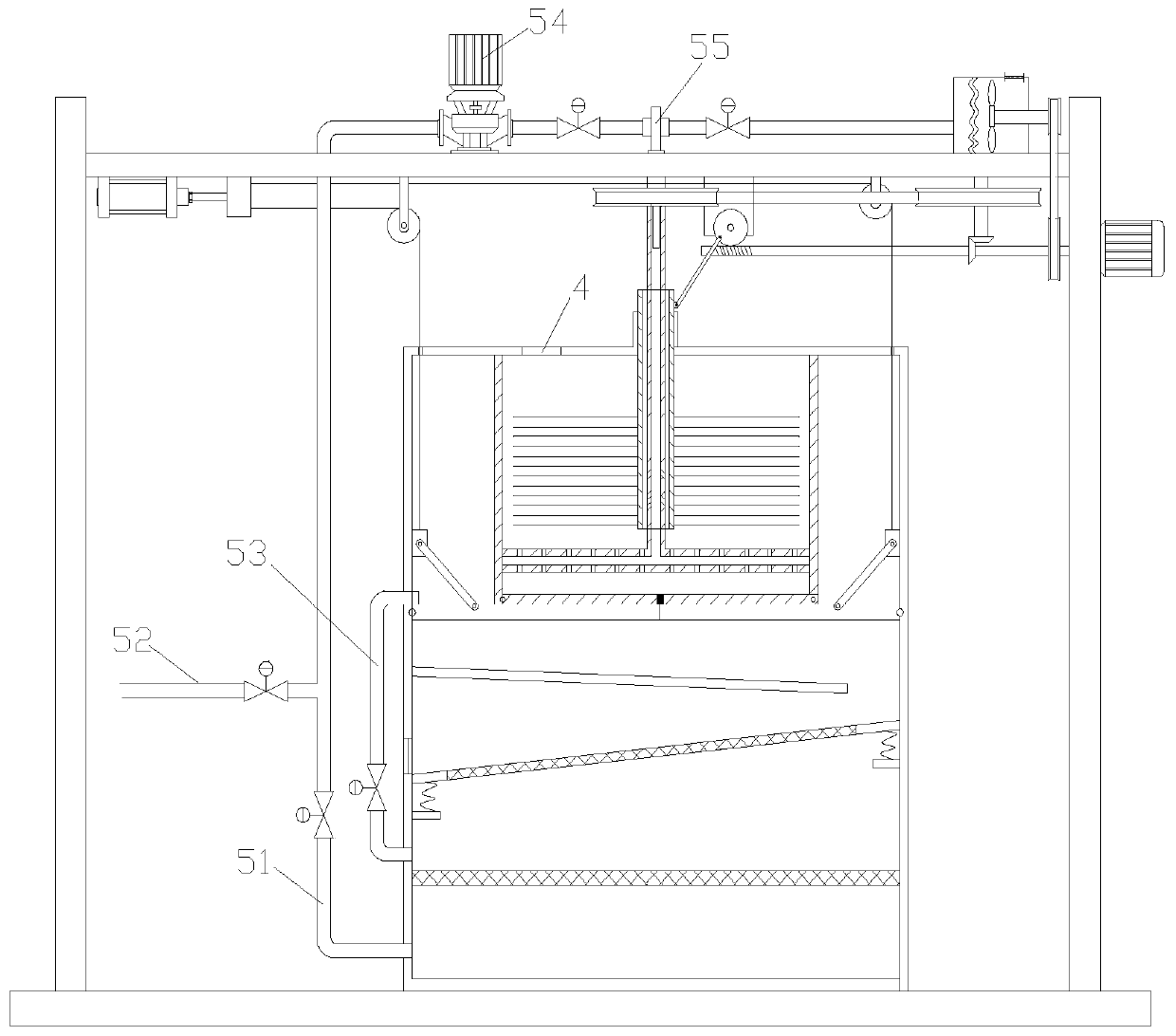

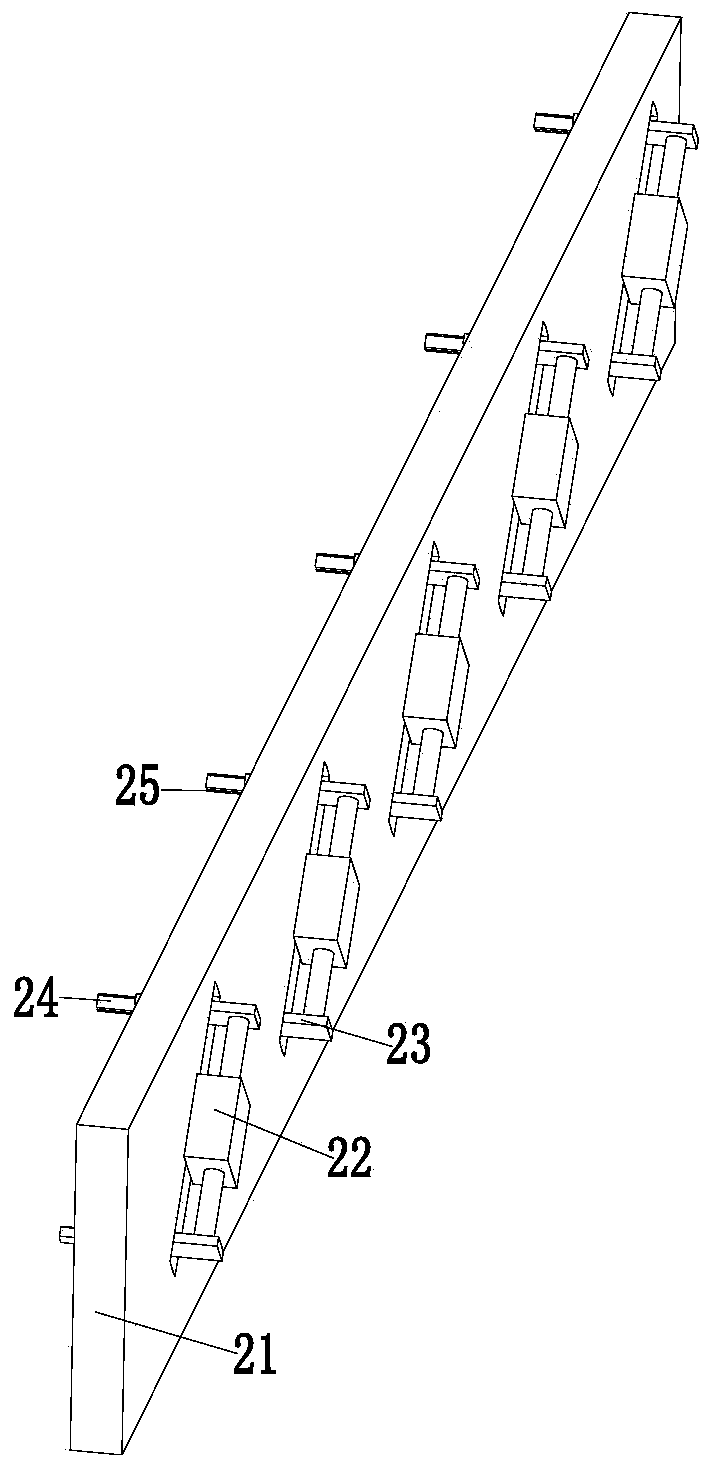

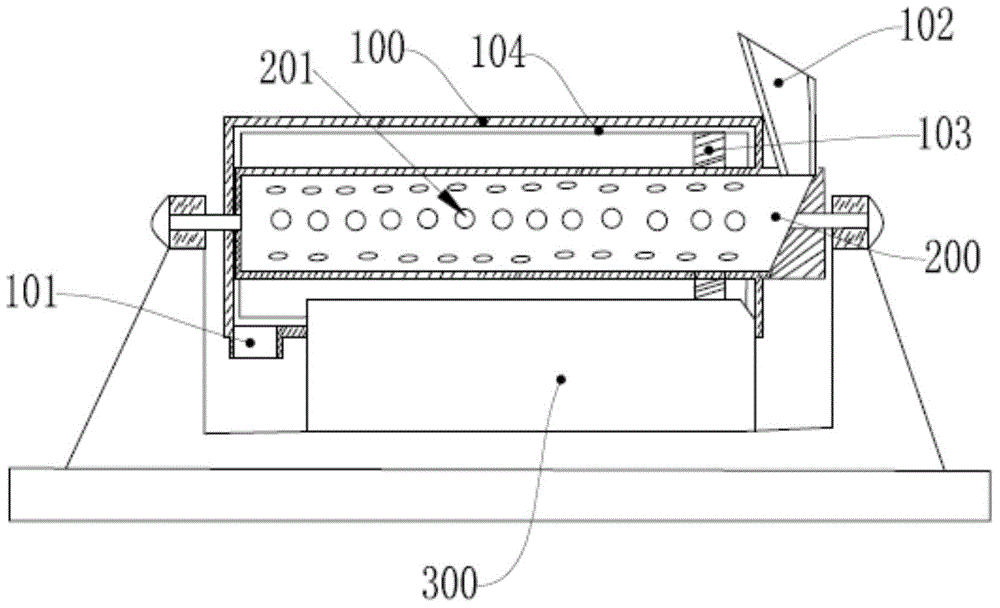

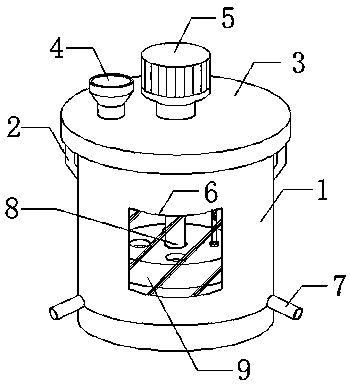

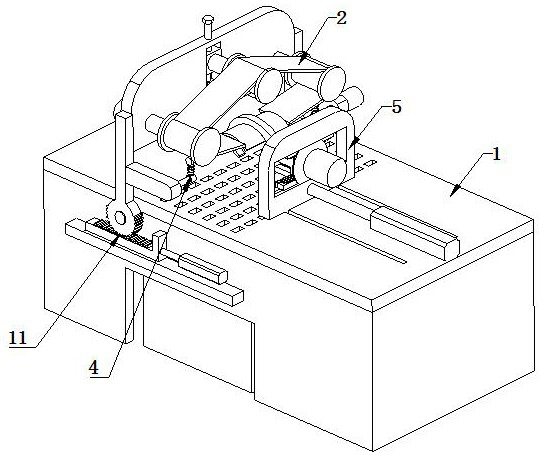

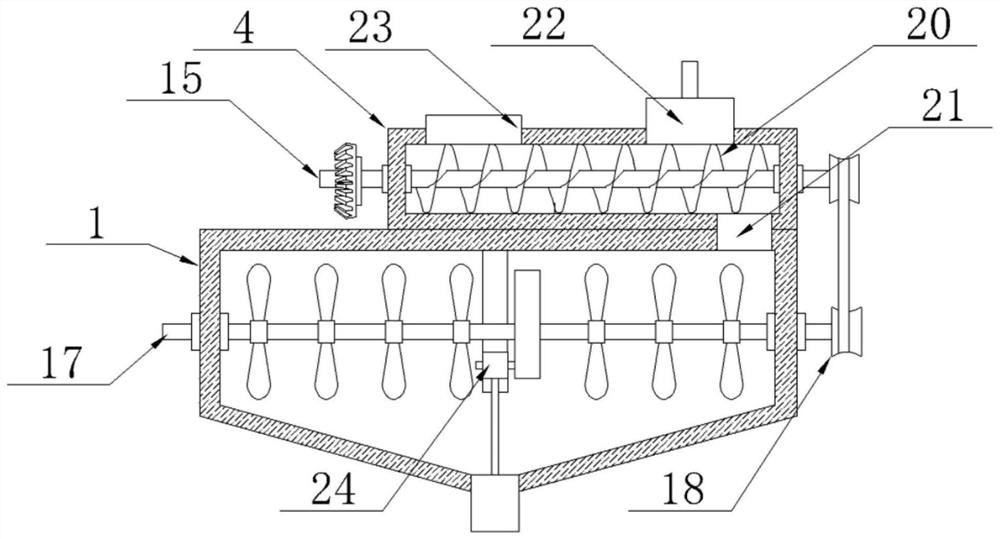

Medicinal material processing system

ActiveCN110180826AGuaranteed cleaning effectEasy drainage operationSievingDrying solid materials without heatEngineeringMaterials processing

The invention relates to medicinal material processing system. The medicinal material processing system comprises a cleaning device and a grinding device, wherein the cleaning device is used for cleaning and drying the medicinal materials, and the grinding device is used for refining the cleaned and dried medicinal materials. The medicinal materials processing system has the beneficial effects ofcompact structure, low manufacturing cost, high processing efficiency and the like.

Owner:天津市亨必达化学合成物有限公司

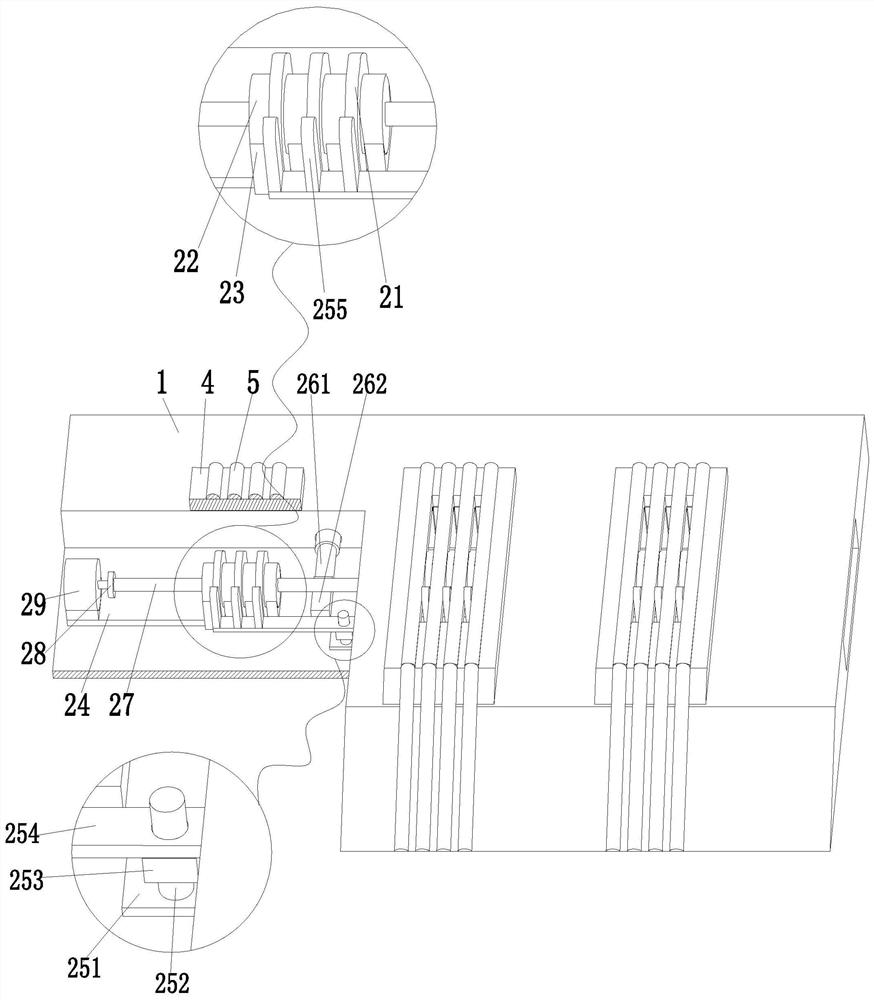

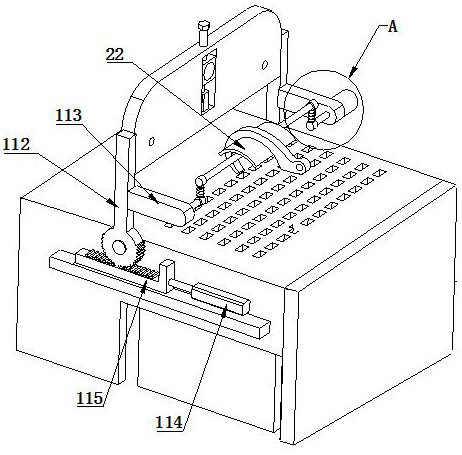

Board corner polishing device

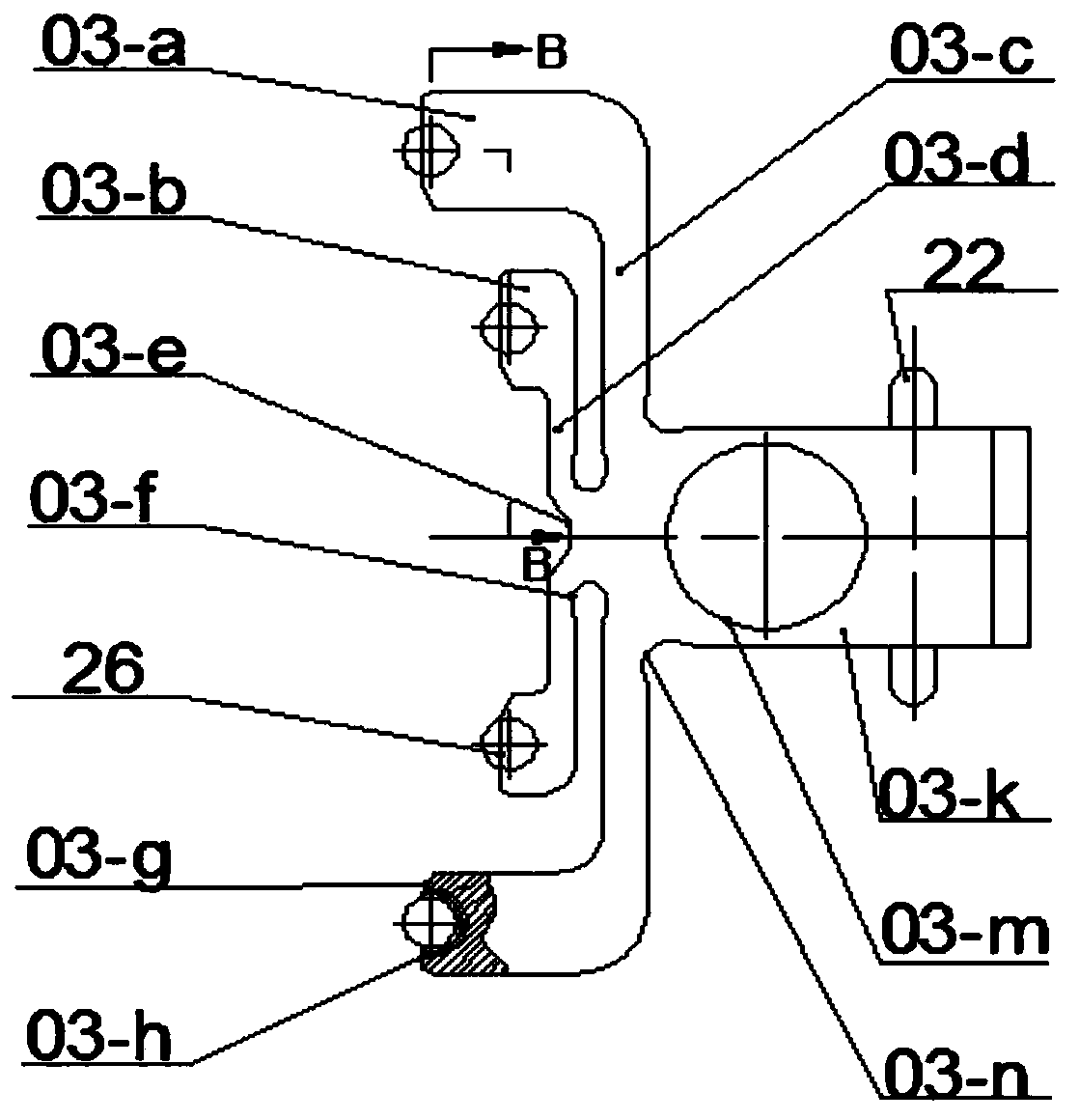

ActiveCN110614560AReduce grinding efficiencyAdjustable distanceGrinding drivesBelt grinding machinesEngineeringMachining

The invention discloses a board corner polishing device and relates to the technical field of board machining. Specific to the problems that manual operation is conducted during existing chamfer polishing of wood boards, thus polishing efficiency is low, much dust is produced during manual operation and is bad for the health of workers, and meanwhile, the boards need to be fixed manually during manual polishing operation, the following scheme is provided that an installation plate is included; a holding table is installed at the top of the installation plate; a driving mechanism is arranged above the holding table; a fixed device is arranged below the driving mechanism; and four polishing devices are arranged on the outer circle of the holding table in an array, are arranged at the top ofthe installation plate slidably and are connected with the driving mechanism. According to the board corner polishing device, the distance from a polishing belt to the holding table can be adjusted conveniently, thus boards of different sizes can be polished conveniently, the boards are also pressed and fixed during close polishing, time and labor are saved, no manual operation is needed, and health of workers is facilitated.

Owner:HUZHOU TEACHERS COLLEGE

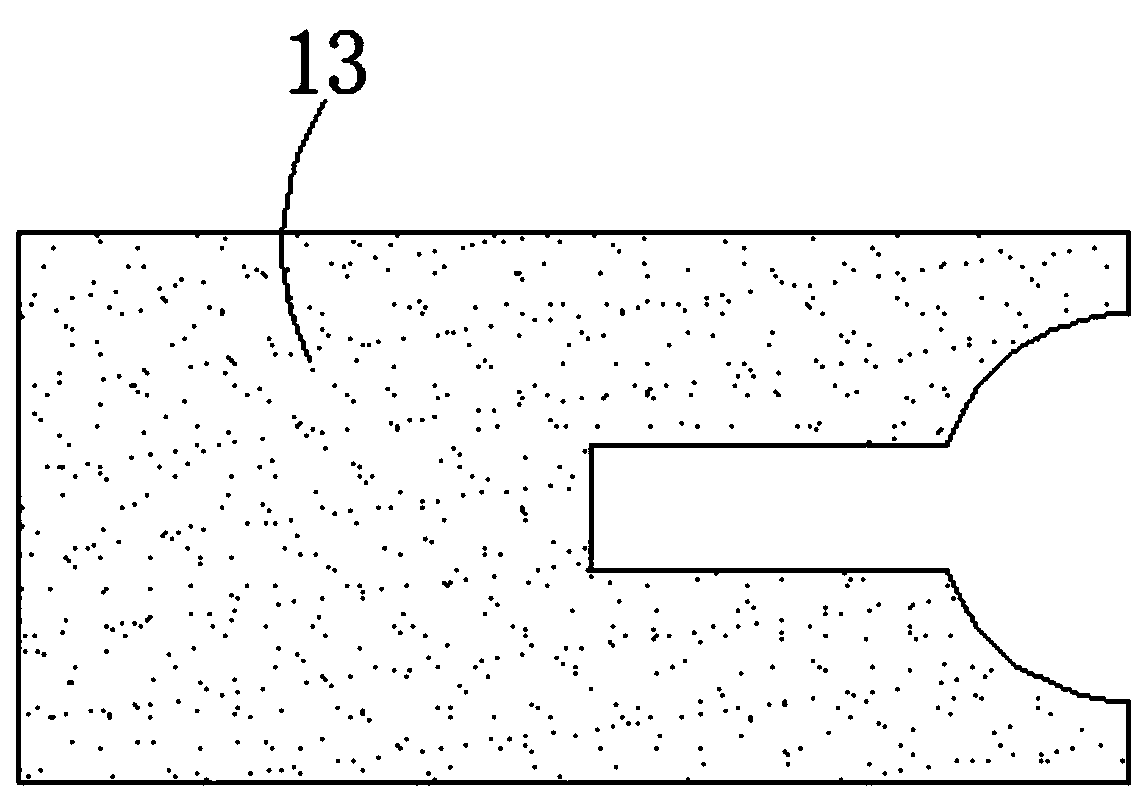

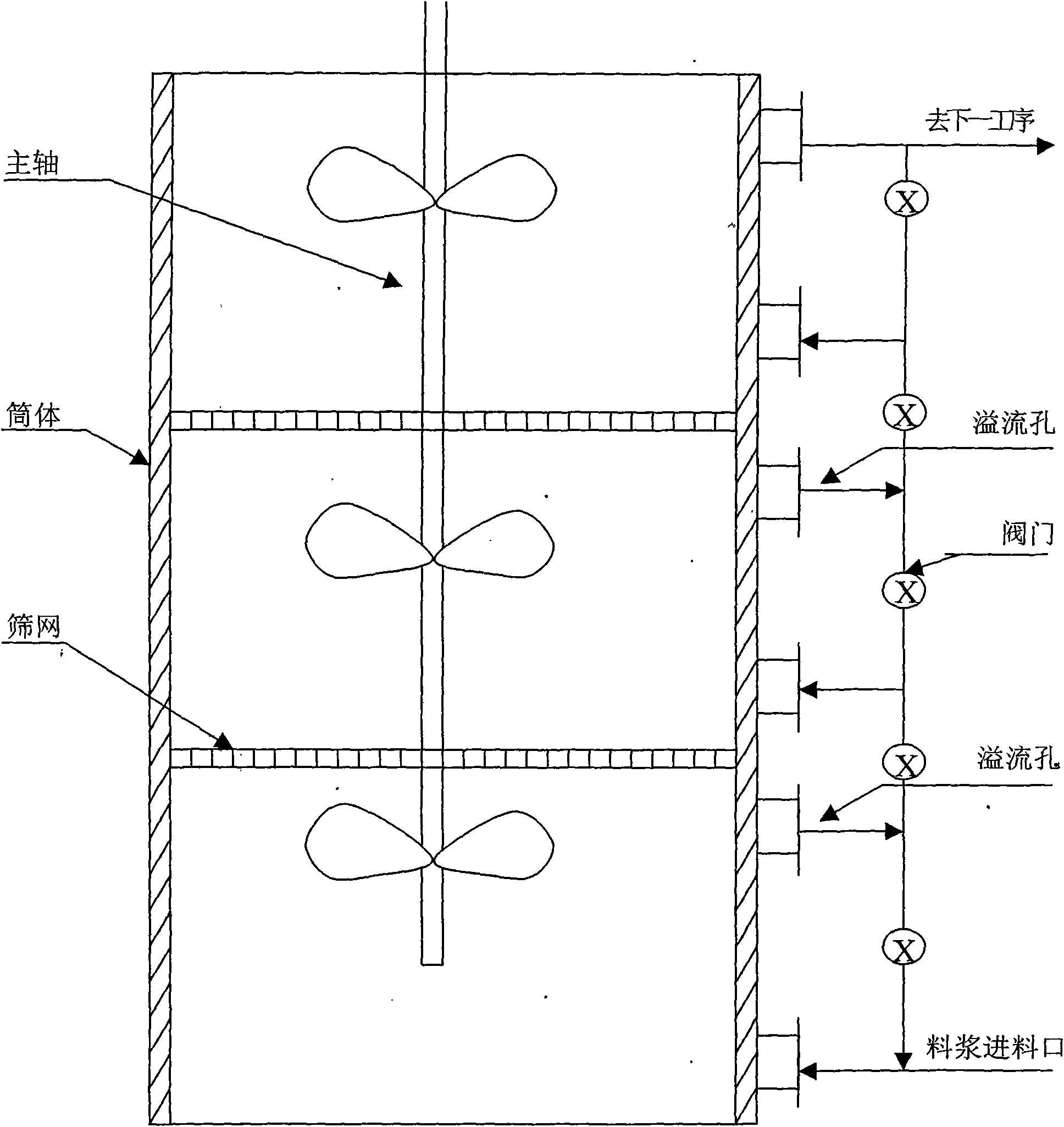

Coal-measure hard kaolin wet method stripping monocular tertiary circular grinding method

The invention discloses a coal-measure hard kaolin wet method stripping monocular tertiary circular grinding method, the process of which is as follows: ground paste coming from an upper working procedure is thrown into from the bottom of a stripping grinding machine by a pump, is processed by the three-level grinding from bottom to top; the grinding and retention time of material at all levels is controlled by overflowing pipes at all levels; the three-level circular grinding with different mixture ratios is carried out in the same vertical cylinder; a switch of valve gate at all levels is automatically controlled by a computer; grinding bodies at all levels of the three-grinding comprise zirconia grinding bodies, ceramic grinding bodies, and glass grinding bodies. In the premise of not adding the energy consumption, the method increases grinding efficiency and is characterized by adjustable grain diameters.

Owner:内蒙古嘉宾饮品有限公司

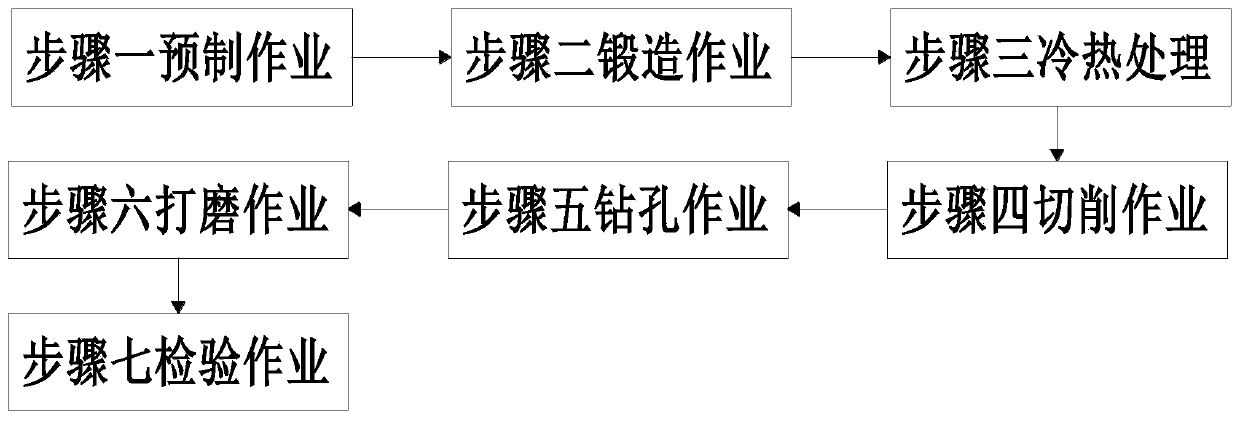

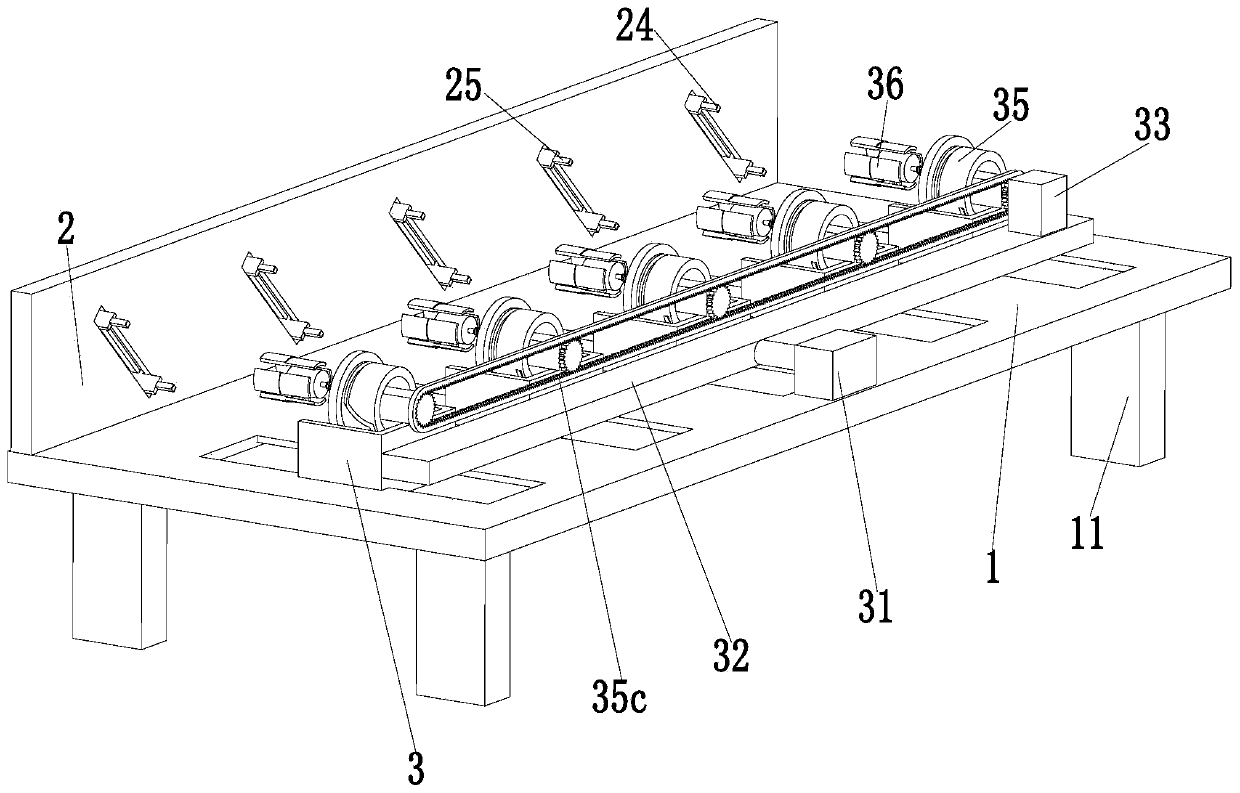

Batch treatment method for stainless steel flanges

ActiveCN111376119AReduce sanding qualityImprove grinding efficiencyGrinding carriagesRevolution surface grinding machinesGrindingDrill hole

The invention relates to a batch treatment method for stainless steel flanges. The batch treatment method for the stainless steel flanges mainly comprises the following process steps of prefabricationoperation, forging operation, cooling and heat treatment, cutting operation, drilling operation, grinding operation, inspection operation and the like. Stainless steel flange grinding equipment usedin the method comprises a bottom plate, a clamping device and a grinding device. The method can solve the following problems, existing when stainless steel flanges are ground by adopting an existing method, that a, when flange plates are ground by adopting the traditional method, abrasive paper generally needs to be manually held by hand for grinding, so that such grinding wastes time and labor, or when a small electric grinding machine is adopted for grinding, uneven grinding is frequently caused, the low grinding speed is low, the grinding quality of the stainless steel flanges is reduced, and subsequent use of the stainless steel flanges is influenced; and b, when an existing stainless steel flange grinding device is used for grinding different stainless steel flanges, different grinding heads need to be replaced, so that time is wasted, and the efficiency is low. The batch treatment method can improve the stainless steel flange grinding efficiency and quality.

Owner:浙江大隆特材有限公司

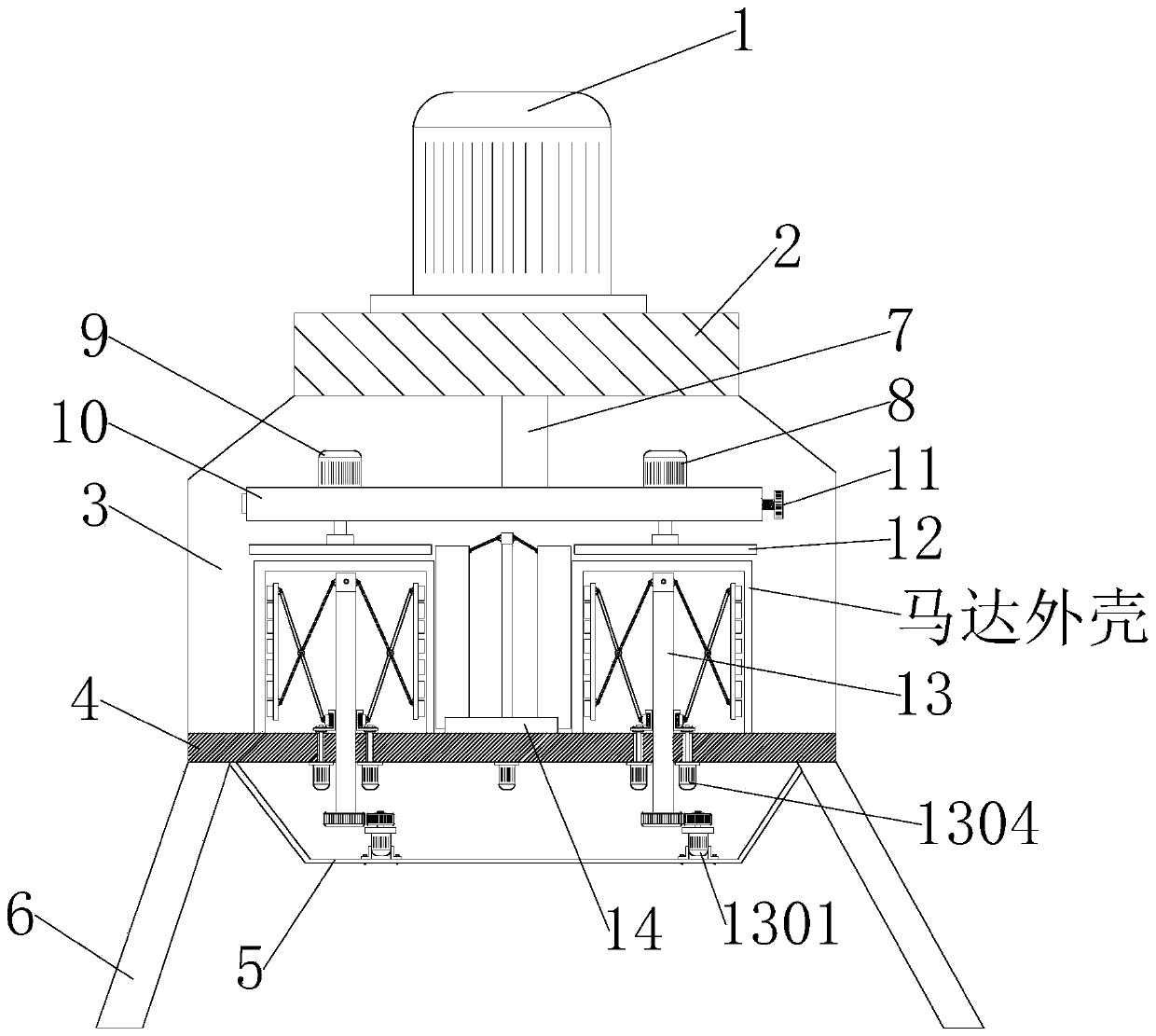

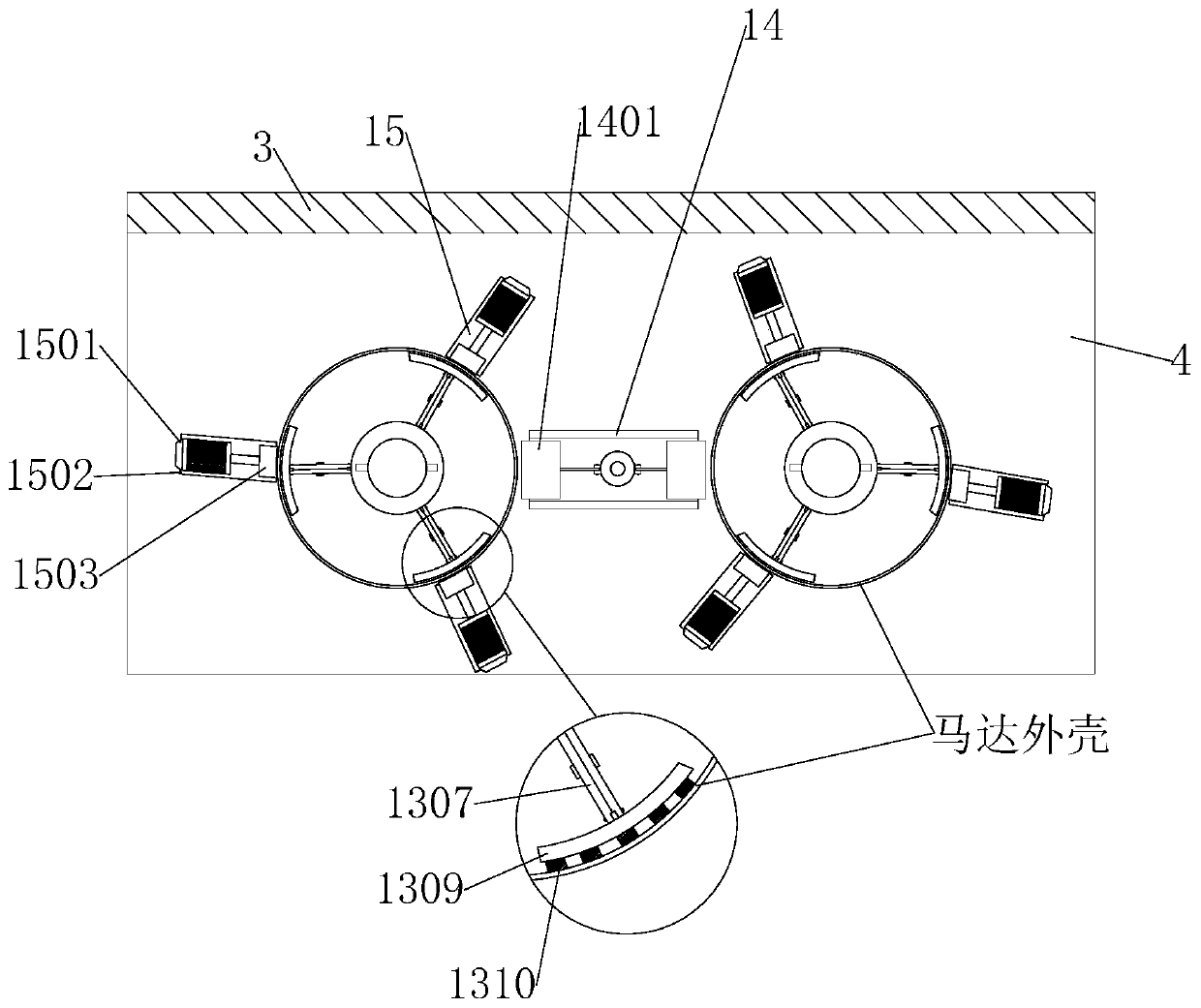

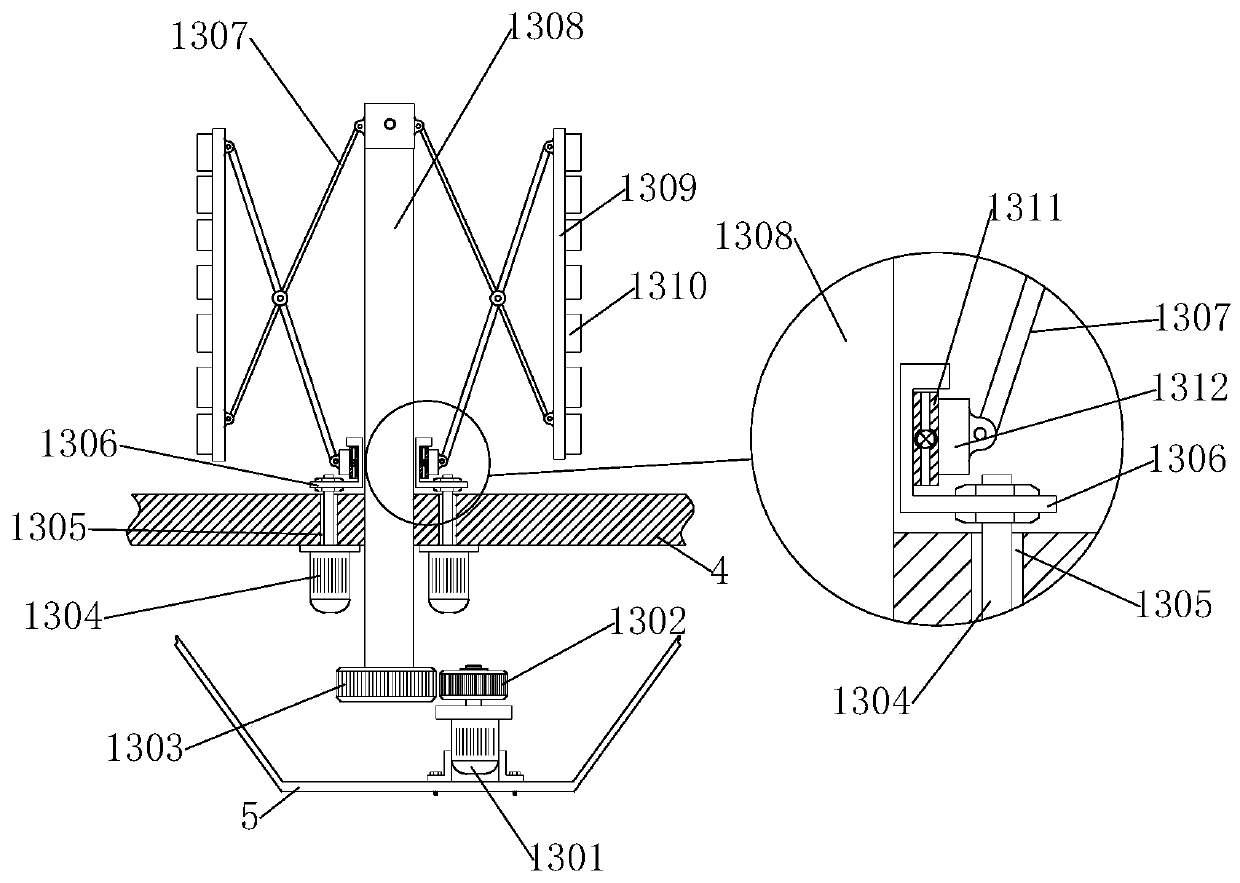

Motor shell drawing part surface finishing treatment process

ActiveCN111300176AReduce wearReduce grinding efficiencyRevolution surface grinding machinesGrinding drivesSurface finishingPolishing

The invention discloses a motor shell drawing part surface finishing treatment process and relates to the technical field of machining. A motor shell drawing part surface finishing treatment device isadopted to finish the motor shell drawing part surface finishing treatment process in a cooperative manner and comprises a bottom support plate horizontally placed, wherein a support ribbed plate erected at the top end of the bottom support plate is arranged at the top end of the bottom support plate; a top support plate horizontally fixed is arranged at the top end of the support ribbed plate; and a hydraulic cylinder is mounted at the top end of the top support plate. a cutting edge is mounted at the top end of an outer polishing block; when the outer polishing block polishes the inner wallof a motor shell, the cutting edge can scrape a projecting object on the inner wall of the motor shell to increase the polishing speed; and scraped chippings can be conveniently collected in a chipping falling groove 1408, so that the situation that the scraped chippings fall into a polishing surface to scratch the inner wall of the motor shell is avoided.

Owner:深圳市可高机电有限公司

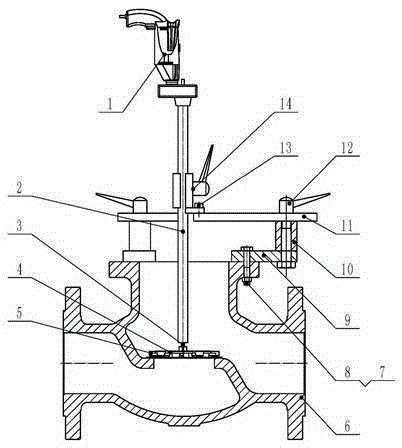

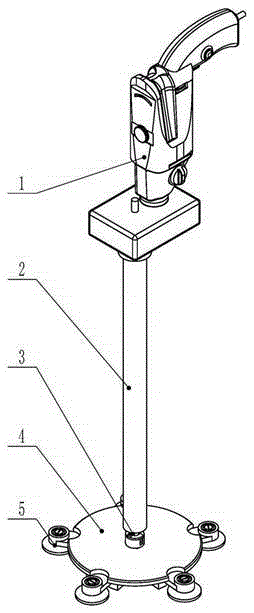

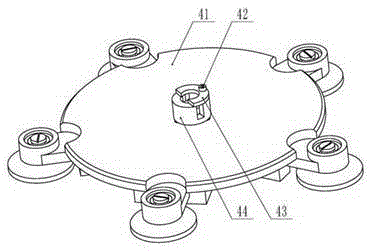

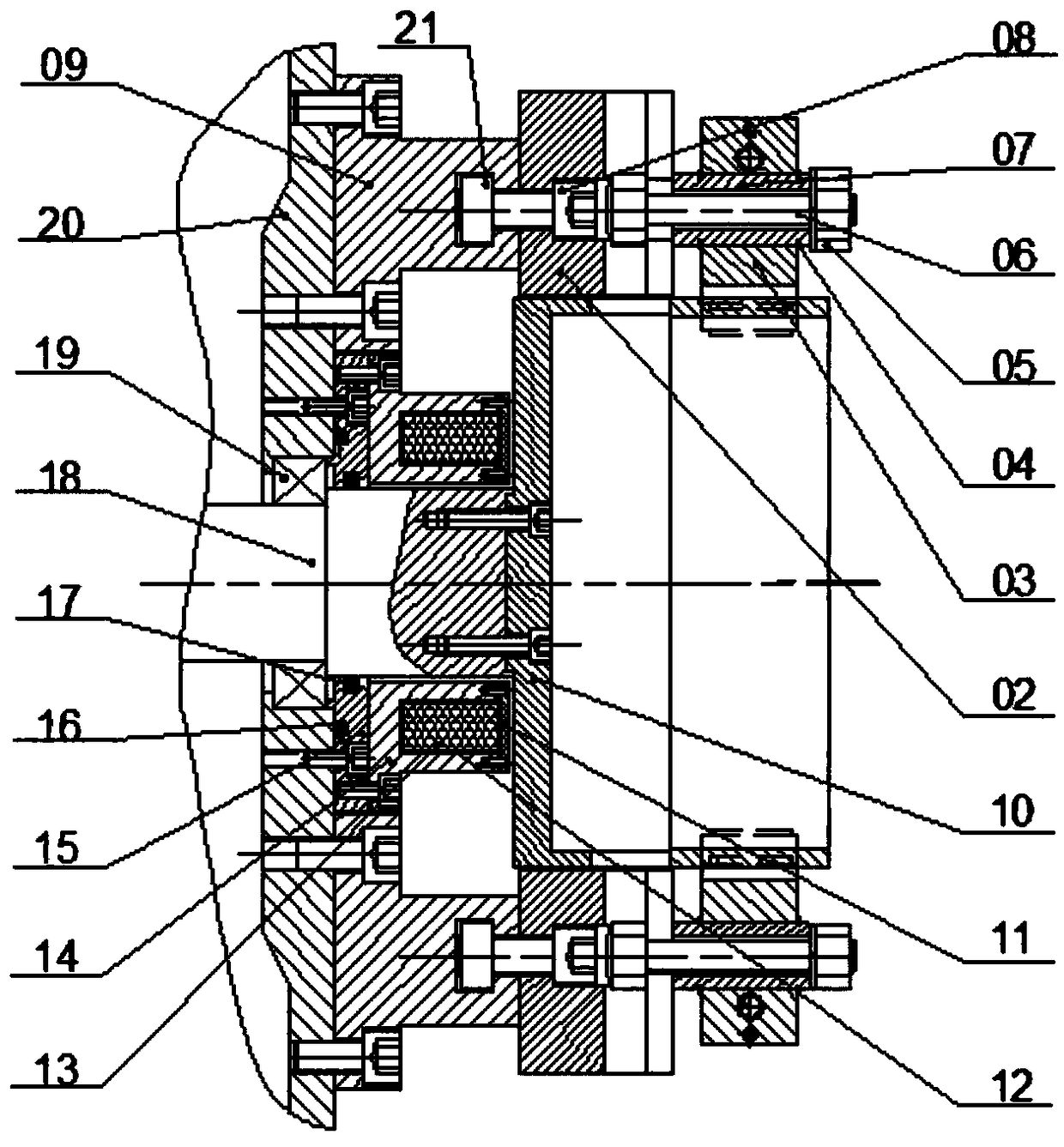

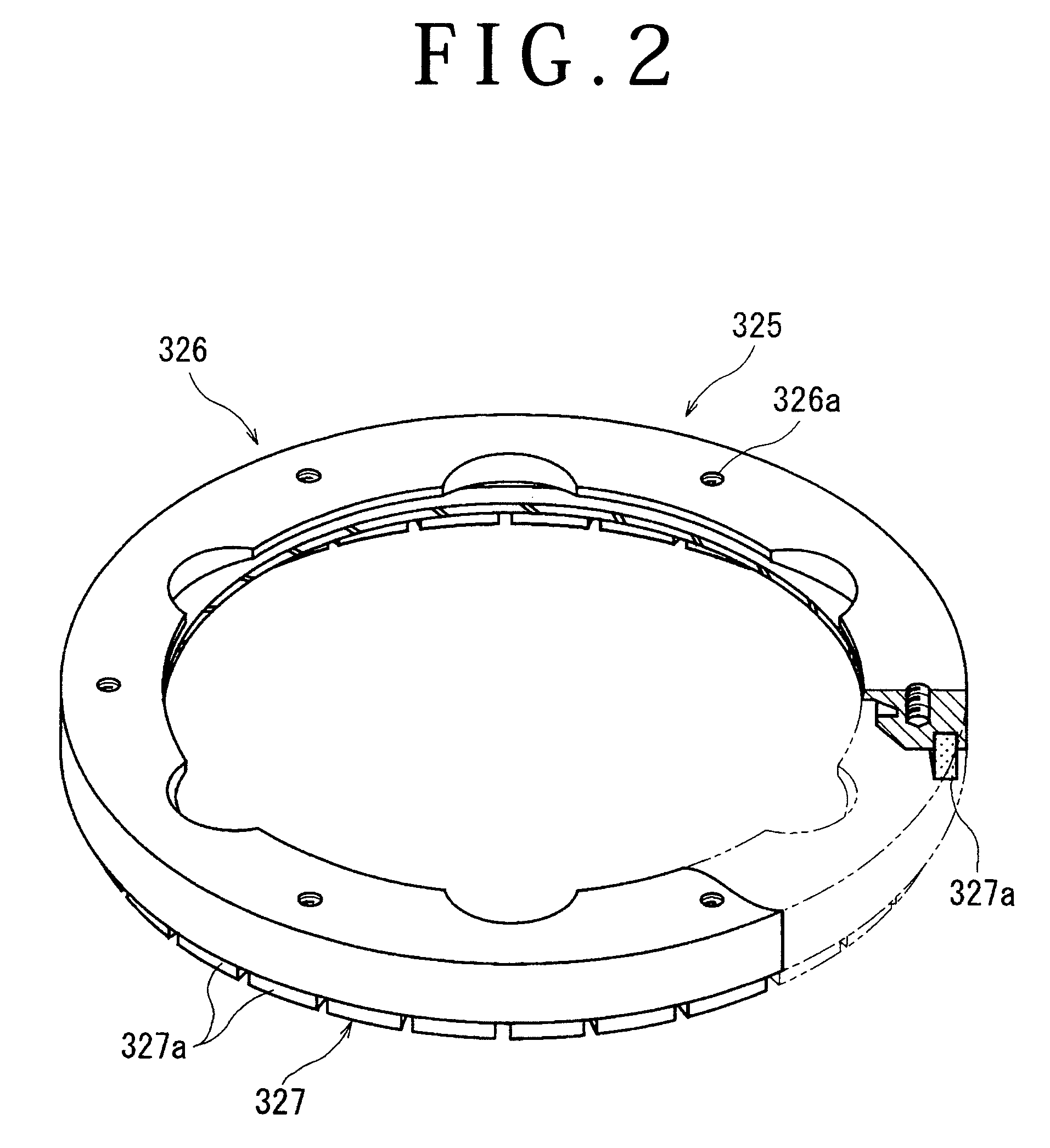

Floating type uniform load planet grinding head

The invention provides a floating type uniform load planet grinding head suitable for a field valve sealing face grinding machine. The floating type uniform load planet grinding head is characterized by comprising a clamping arm, bearings, planet grinding head bodies, springs, limiting screws and pressing screws. The clamping arm is used for being fixed to a sun shaft grinding disc of the grinding machine. The bearings are installed in bearing holes in the clamping arm and provide radial supporting and axial guiding for the planet grinding head bodies. Shaft necks of the planet grinding head bodies and the inner rings of the bearings are in movable fit. The springs are arranged in two arrangement manners, according to one manner, the springs are arranged on the shaft necks of the planet grinding head bodies in a sleeving manner; and according to the other manner, the plate type springs are fixed to the clamping arm. The limiting screws and the planet grinding head bodies are in threaded connection, and the pressing screws are used for fixing the plate type springs to the clamping arm. After the grinding pressure is set, the floating type planet grinding head bodies automatically compensate for the machining and installing errors of the planet grinding head bodies through deformation of the springs, and the problem that all the planet grinding head bodies hardly uniformly load and make contact with grinded faces is solved.

Owner:BEIJING RAYMOND CBE MECHANICAL & ELECTRIC TECH

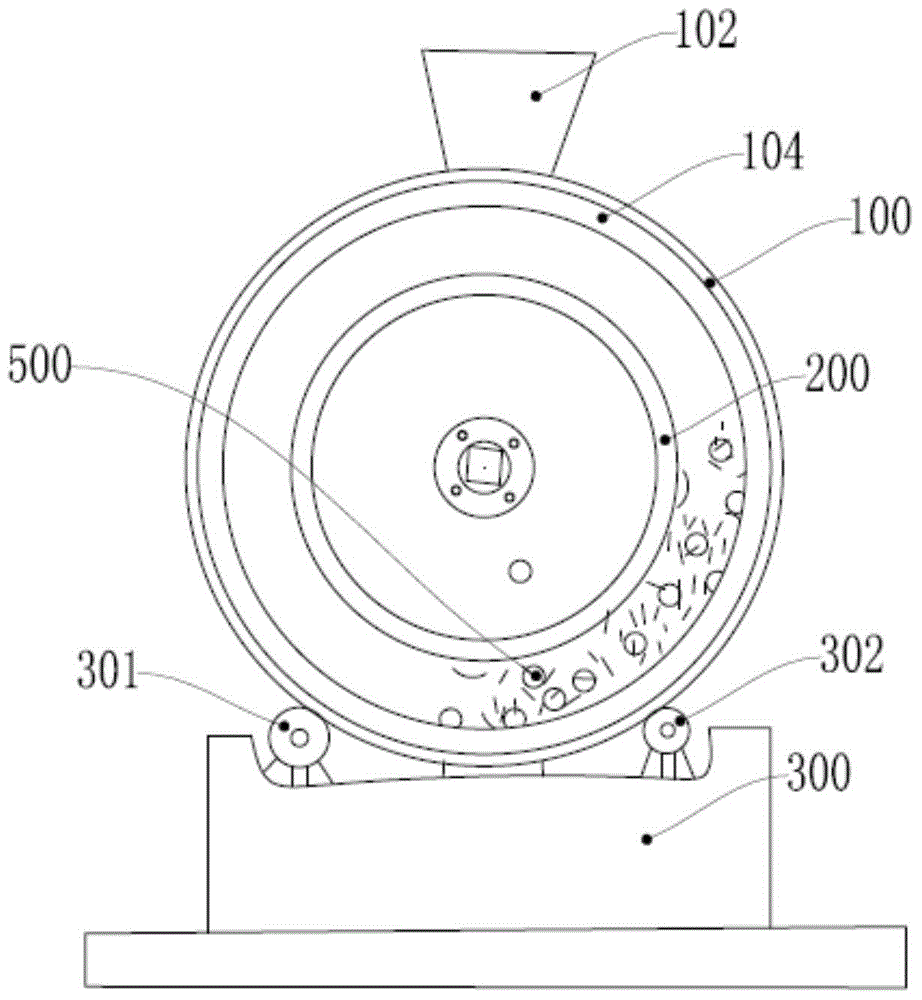

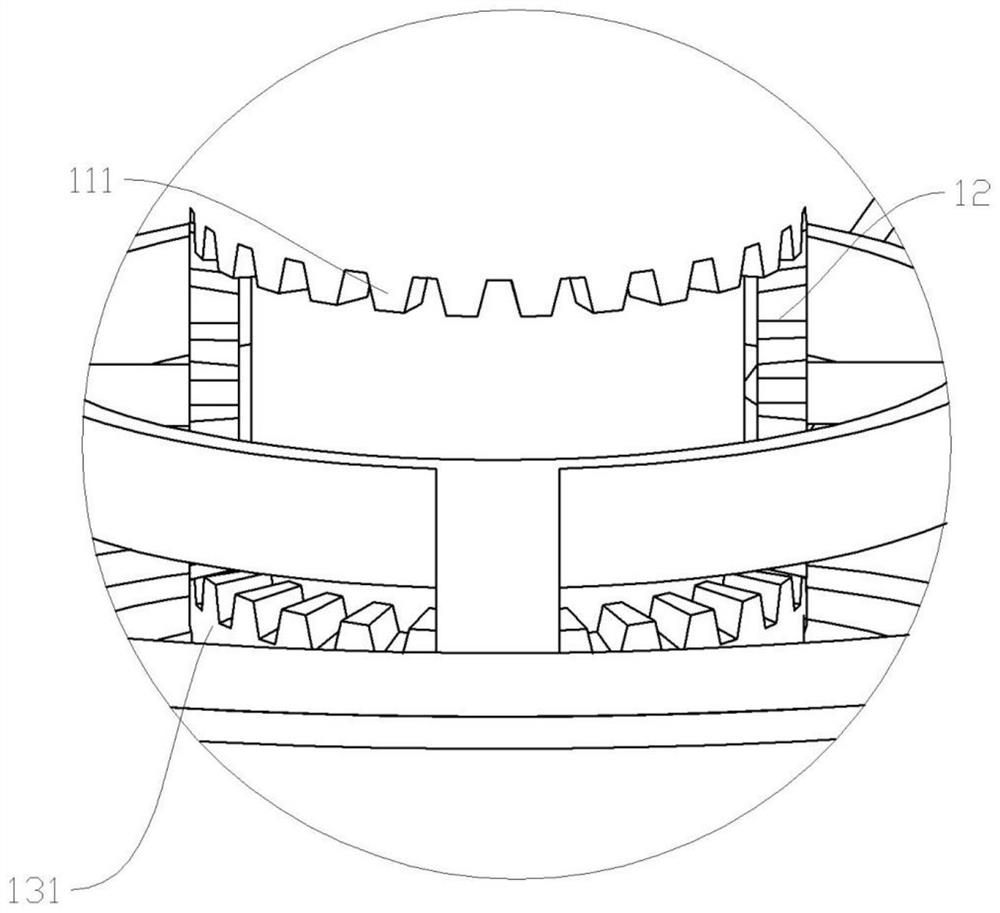

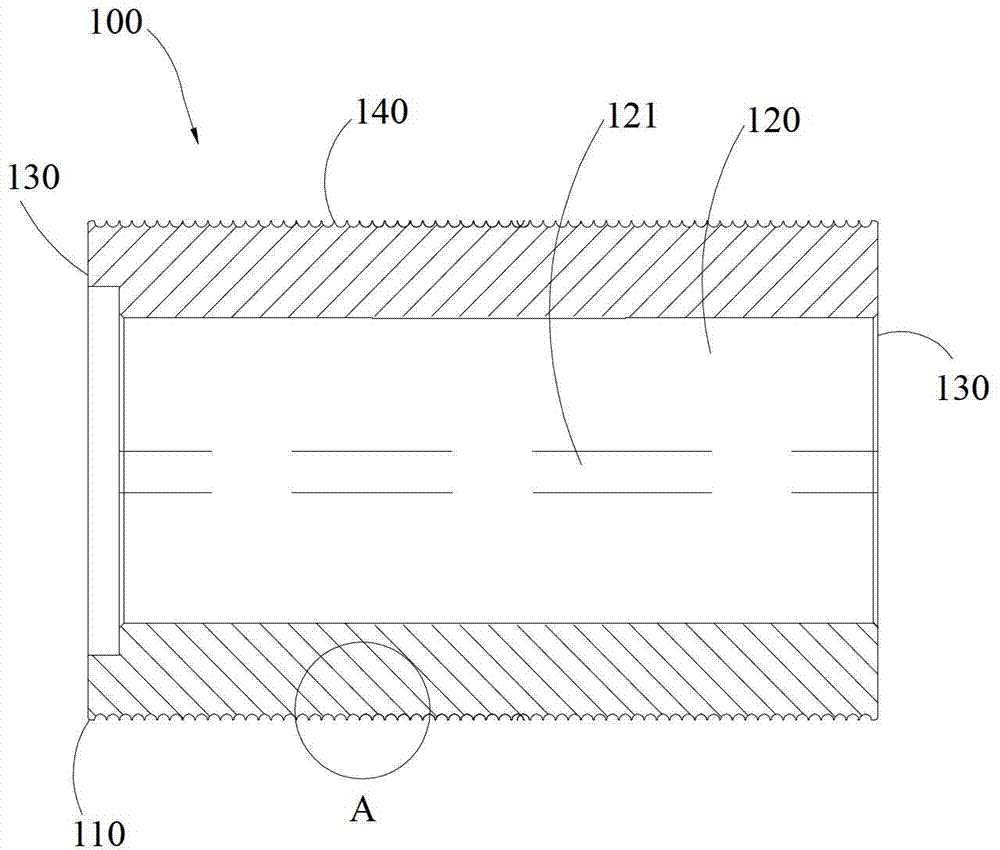

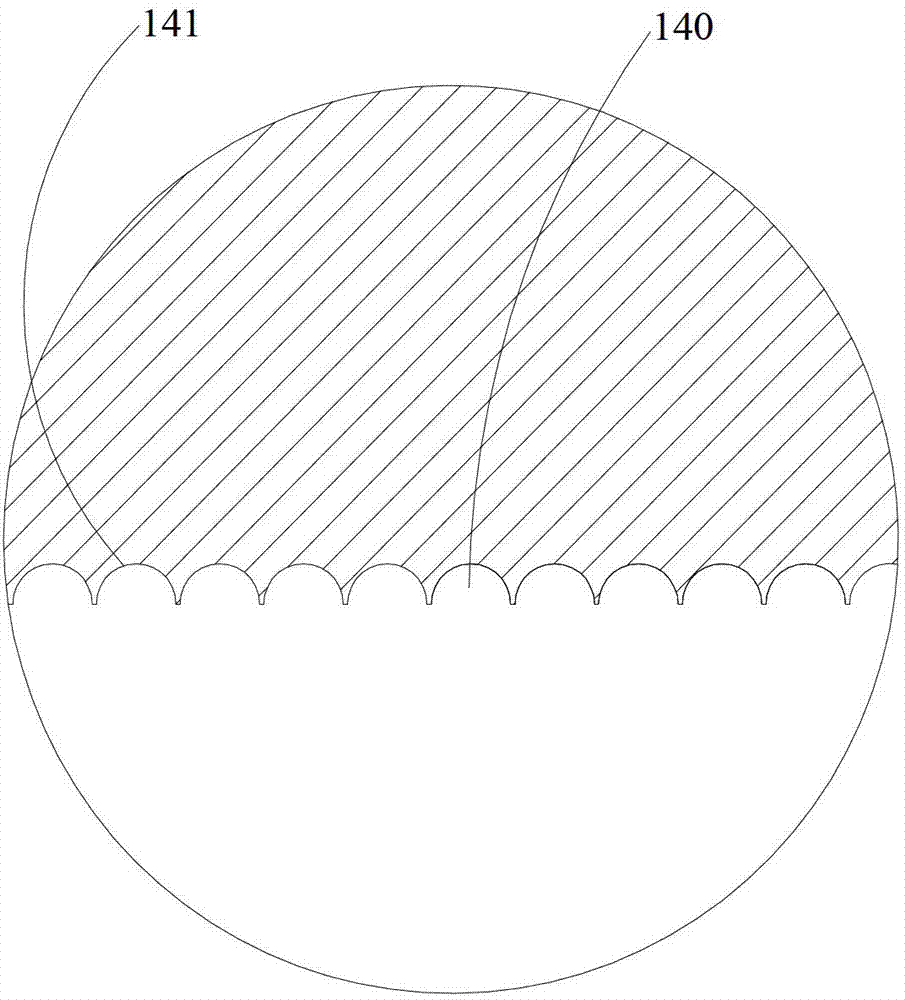

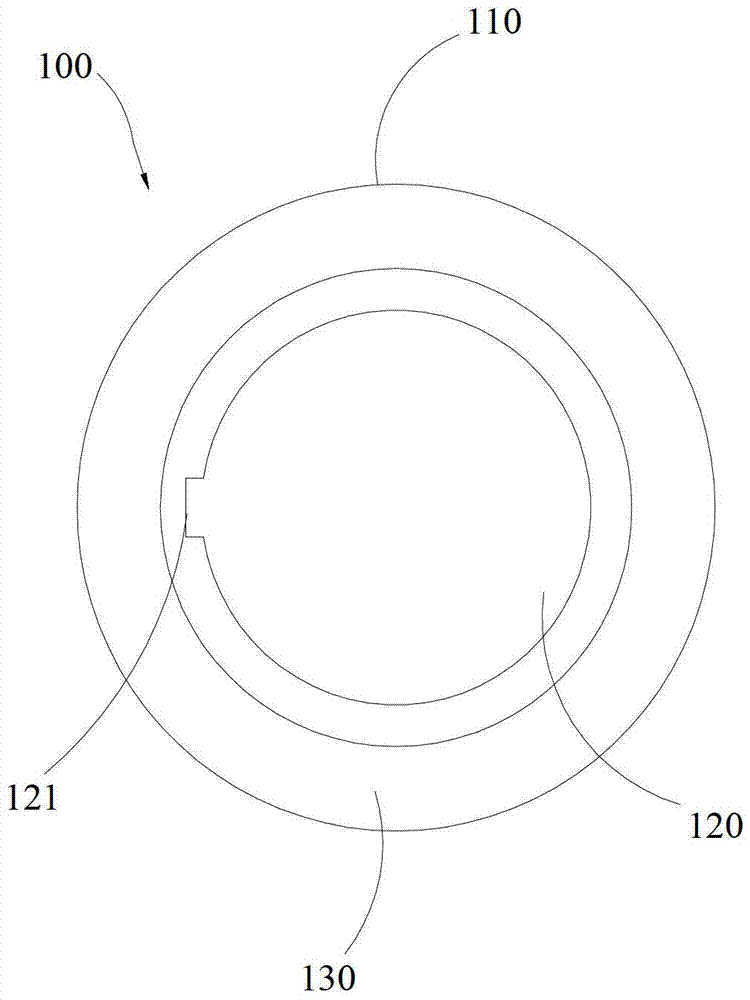

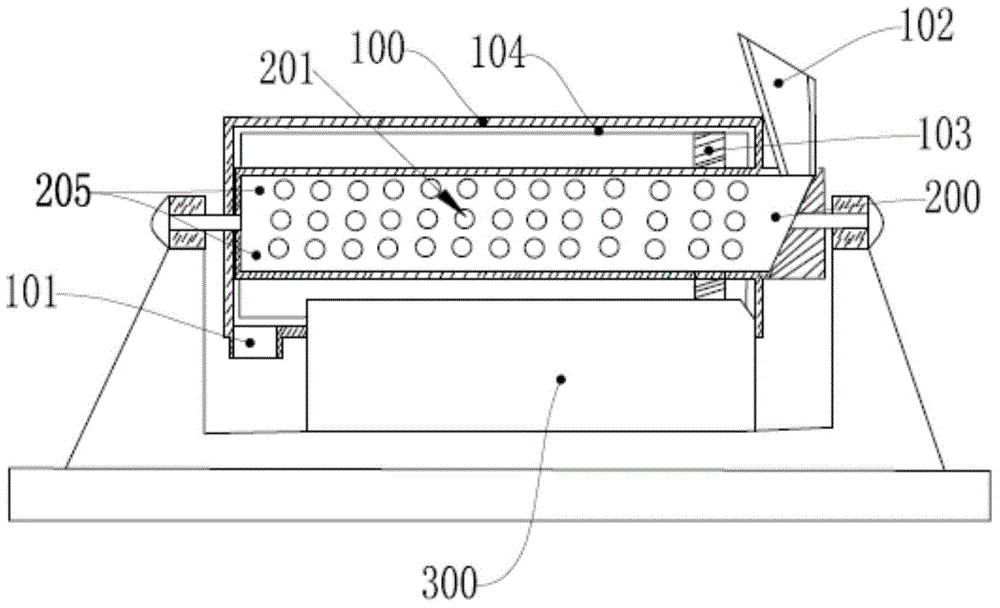

Efficient ball mill with annular grooves

InactiveCN105772170AEasy dischargeImprove grinding efficiencyGrain treatmentsPrimary screeningEngineering

The invention relates to the field of ceramic machinery, in particular to an efficient ball mill with annular grooves. The efficient ball mill comprises a cylinder provided with a feed port and a discharge port, and a driving device; the driving device drives the cylinder to rotate; the cylinder is divided into two layers of tubular structures; the first layer is a cylinder outer shell; the second layer is a primary screening and grinding net pipe with sieve holes; grinding balls are respectively put in accommodating cavities between the inner surface of the cylinder outer shell and the outer surface of the primary screening and grinding net pipe; the feed port is connected with the accommodating cavity of the primary screening and grinding net pipe; the discharge port is connected with the accommodating cavities between the inner surface of the cylinder outer shell and the outer surface of the primary screening and grinding net pipe; lining plates are arranged in the cylinder outer shell; the contact surfaces between the back surfaces of the lining plates and the inner wall of the cylinder of the ball mill are corresponding arc surfaces; multiple grooves with arc sections are formed in the working surfaces of all the lining plates; and the connecting surfaces of the adjacent grooves are arc surfaces. The ball mill is an efficient ball mill capable of improving the grinding efficiency and quality.

Owner:FOSHAN BAOHANG MACHINERY EQUIP IND INTPROP SERVICES

Stainless steel flange manufacturing and machining treatment system

ActiveCN111468999AReduce sanding qualityImprove grinding efficiencyGrinding wheel securing apparatusGrinding carriagesSS - Stainless steelEmery paper

The invention relates to a stainless steel flange manufacturing and machining treatment system. The stainless steel flange manufacturing and machining treatment system comprises a bottom plate, a clamping device and a polishing device, wherein the clamping device is installed at the rear end of the bottom plate, and the polishing device is installed at the front end of the bottom plate. Accordingto the stainless steel flange manufacturing and machining treatment system, the difficulty problems existing in the stainless steel flange polishing process can be solved, and specifically, a. when atraditional flange is polished, generally, abrasive paper needs to be held manually for polishing, so that polishing wastes time and labor, or a small electric polisher is adopted for polishing and when the small electric polisher is used for the polishing, uneven polishing and low polishing speed are often caused, the polishing quality of the stainless steel flange is reduced, and follow-up use of the stainless steel flange is affected; and b, when an existing stainless steel flange polishing device polishes different stainless steel flanges, different grinding heads need to be replaced, timeis wasted, efficiency is low; and the stainless steel flange manufacturing and machining treatment system can improve stainless steel flange polishing efficiency and quality.

Owner:无锡市麒啸机械有限公司

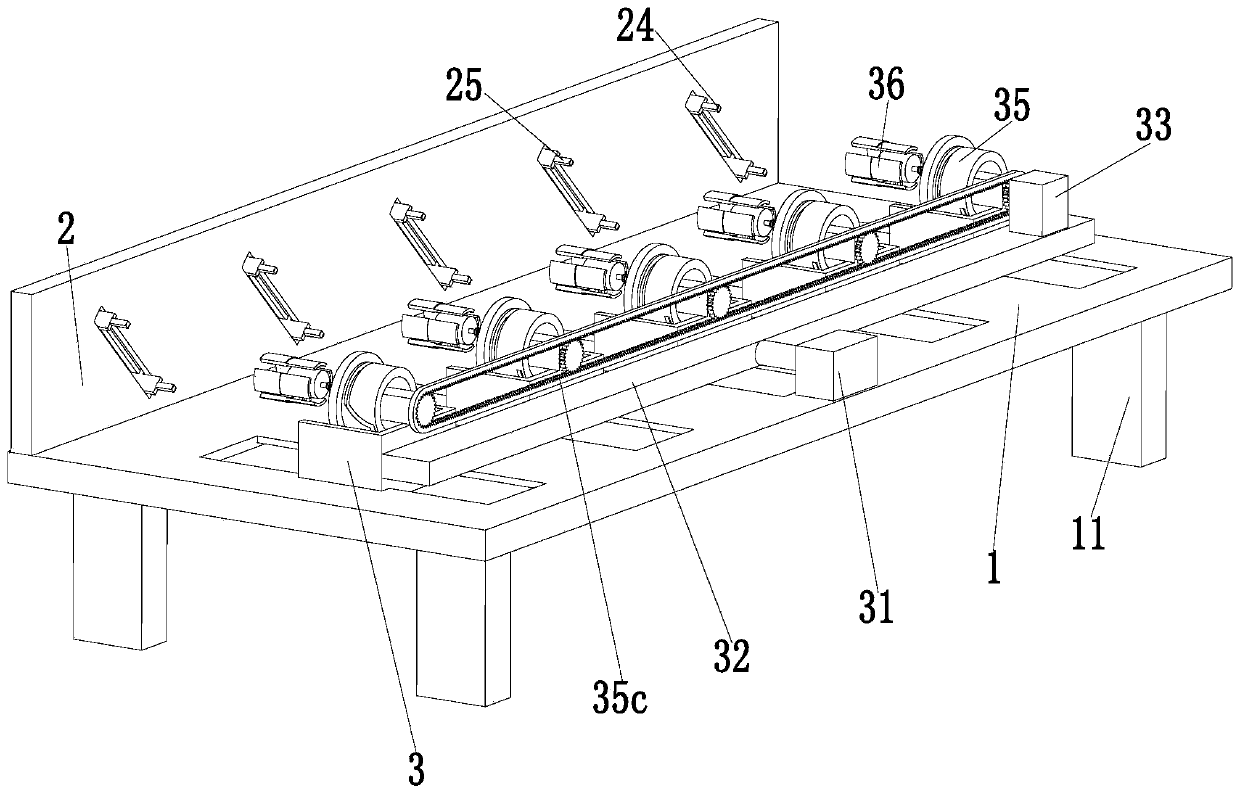

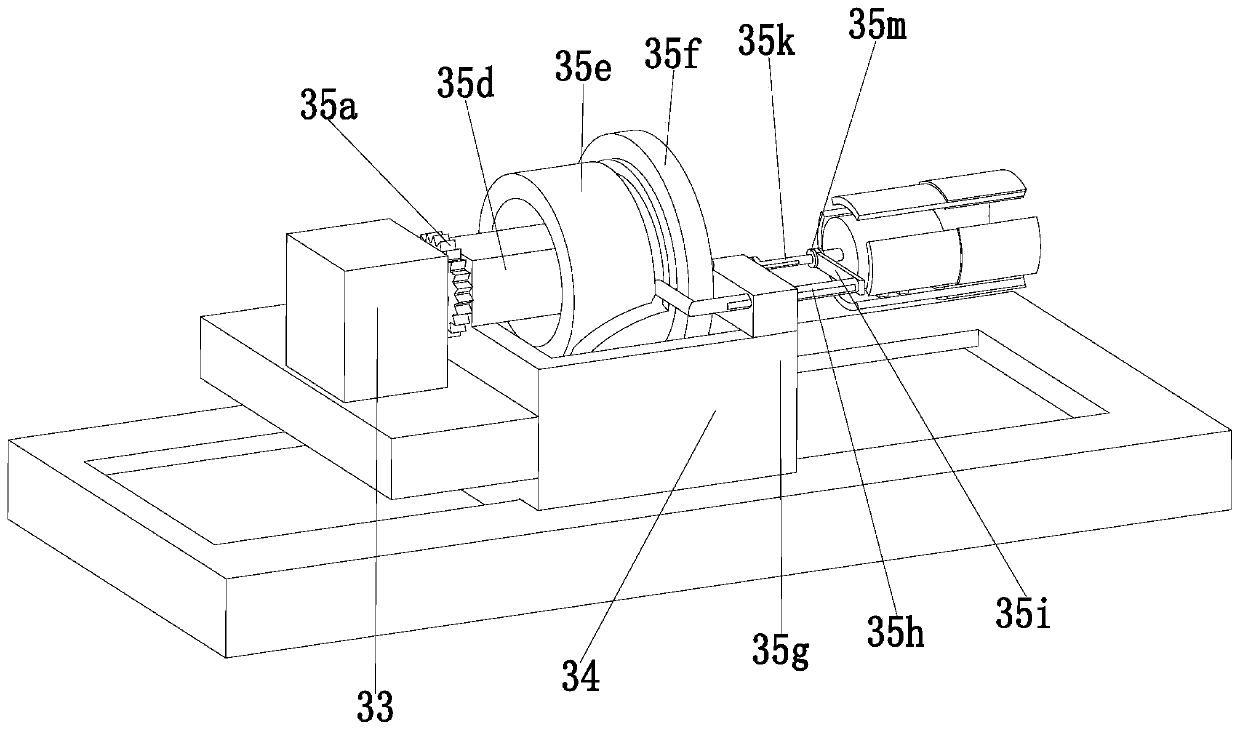

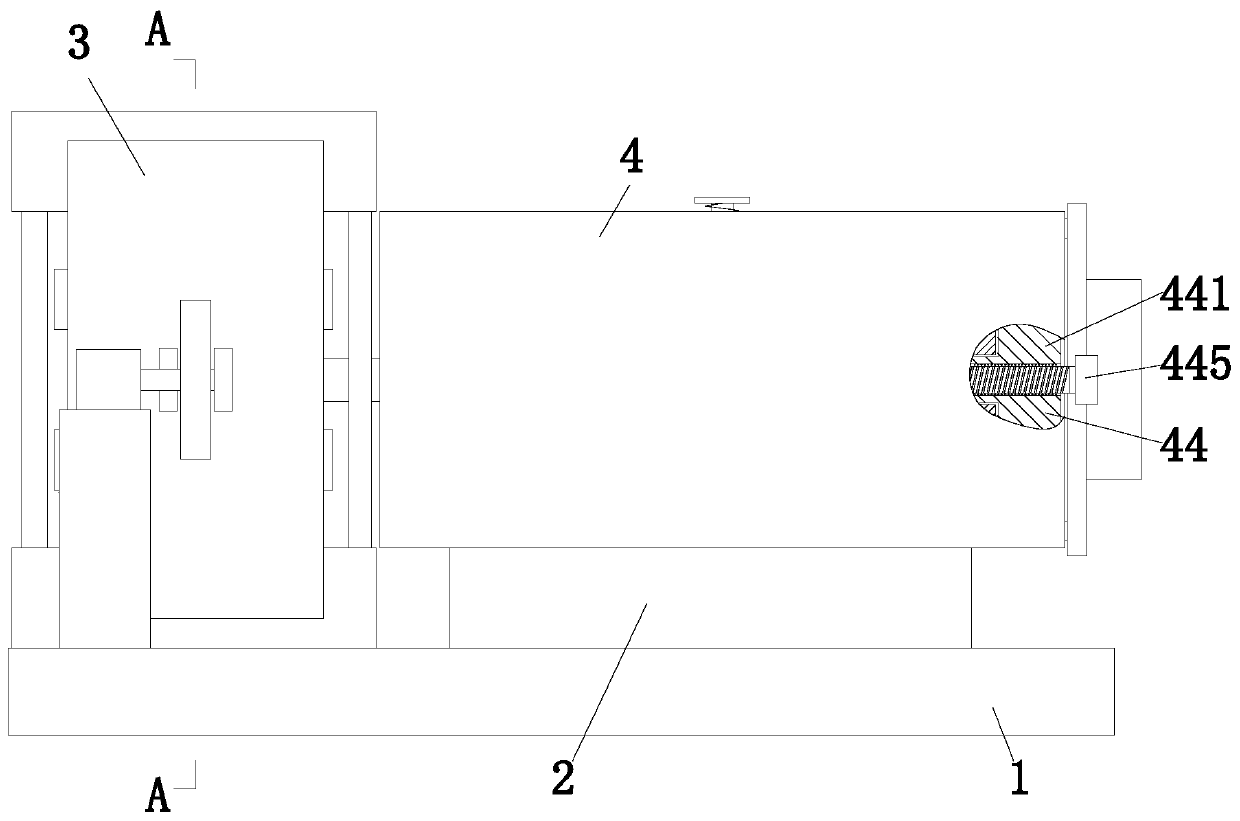

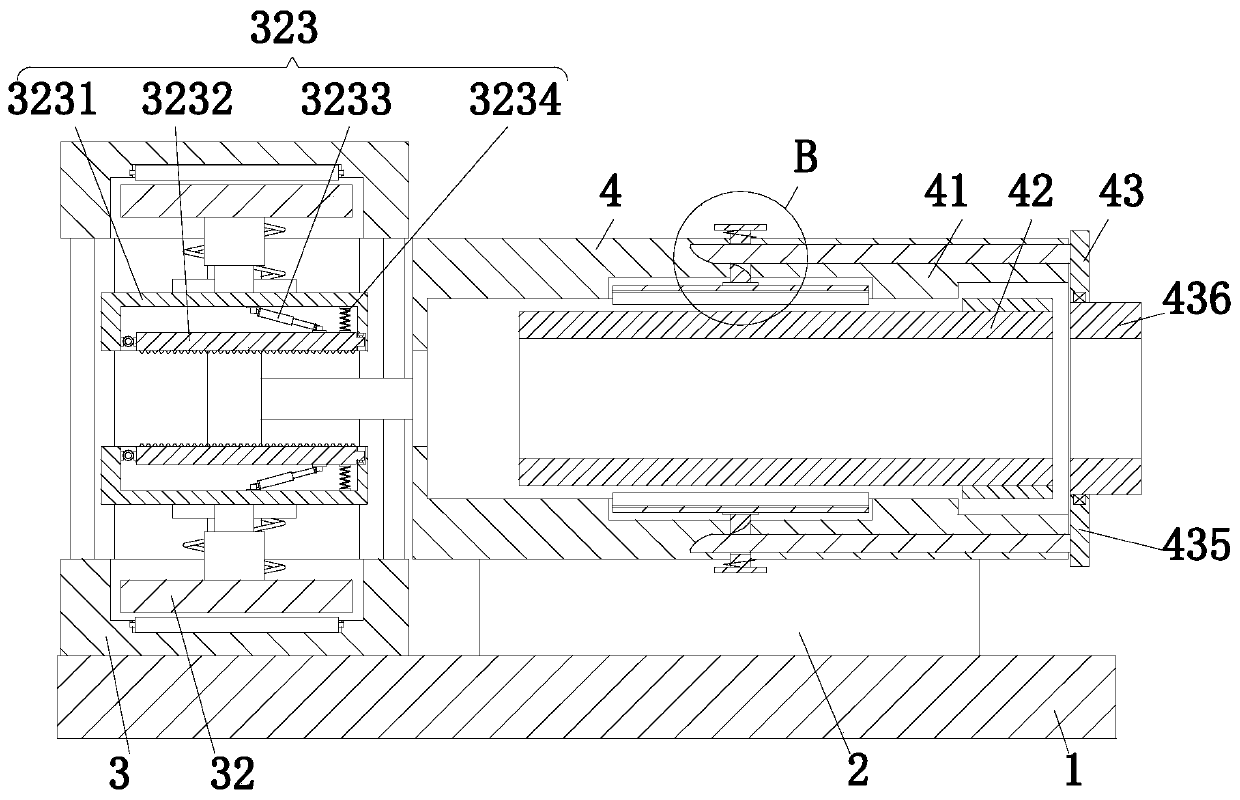

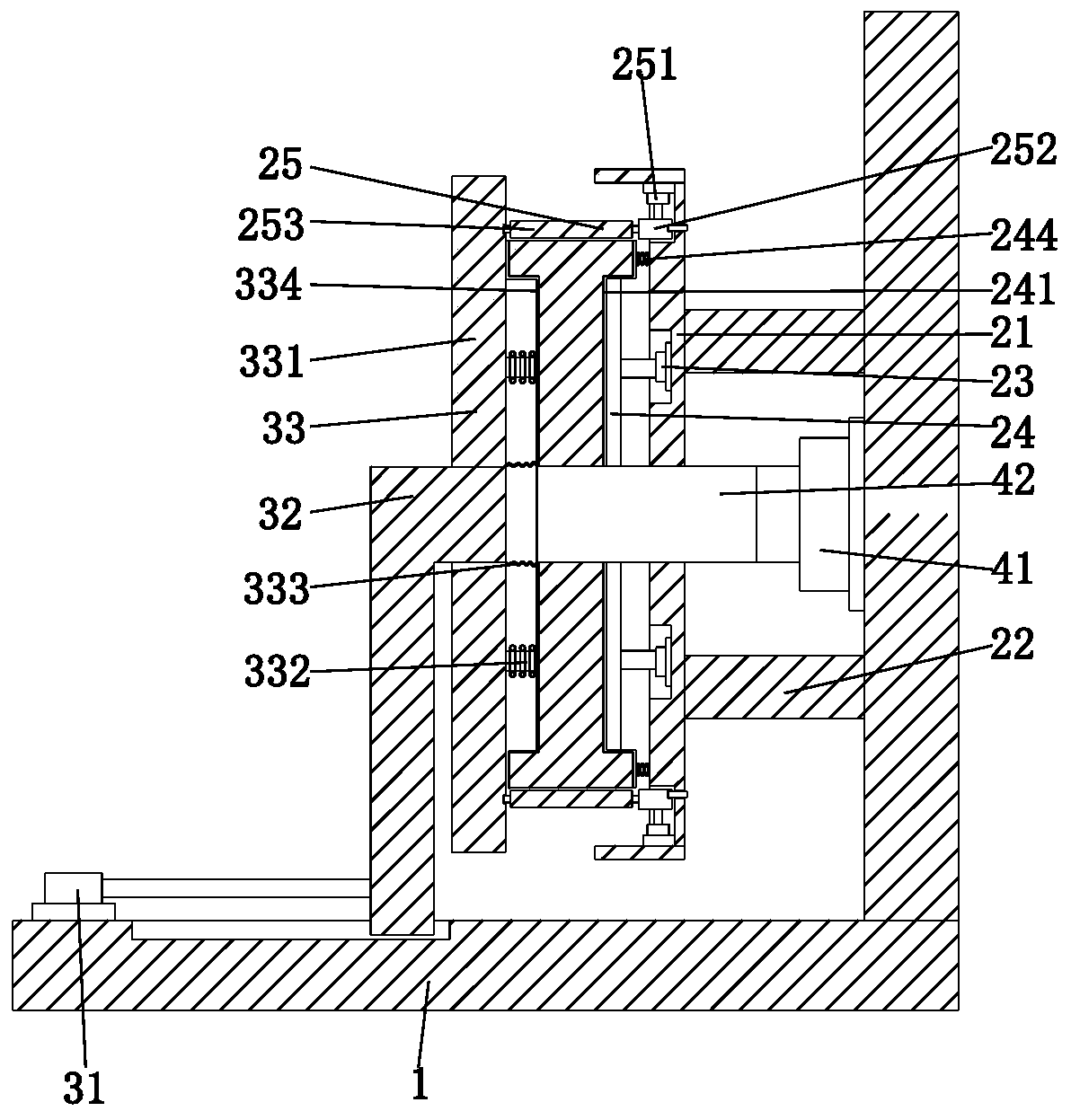

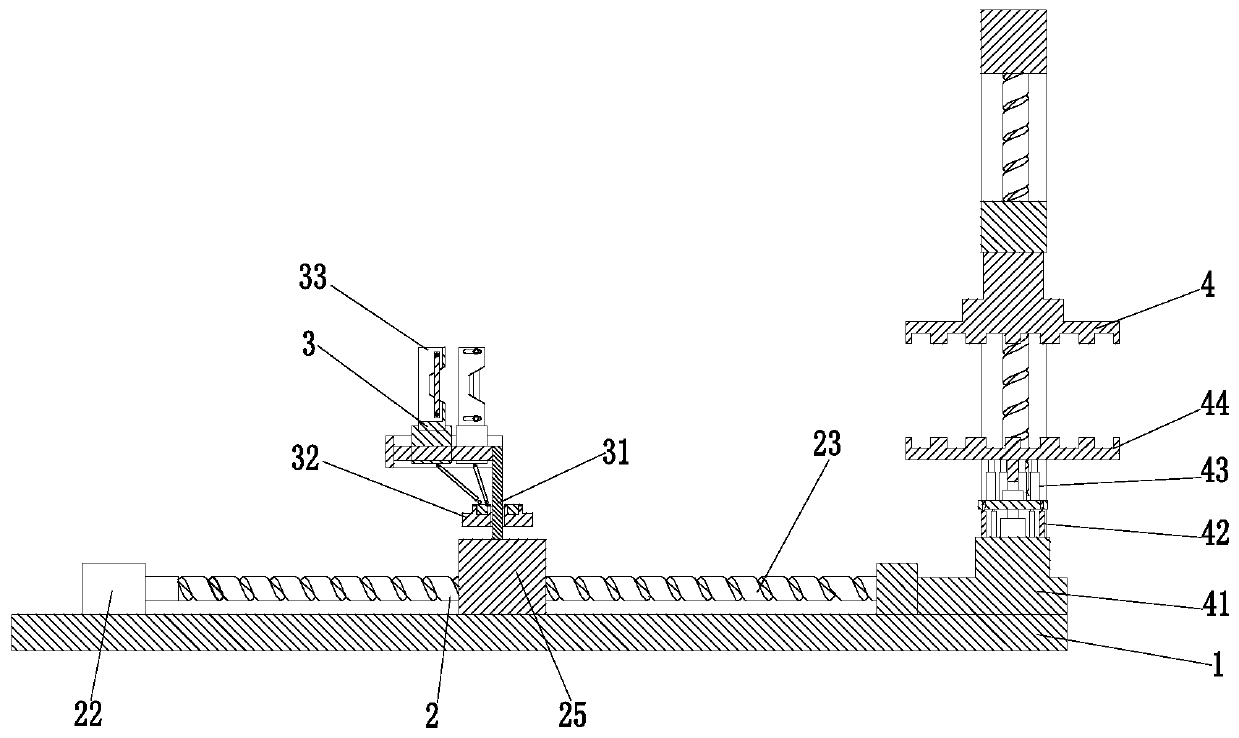

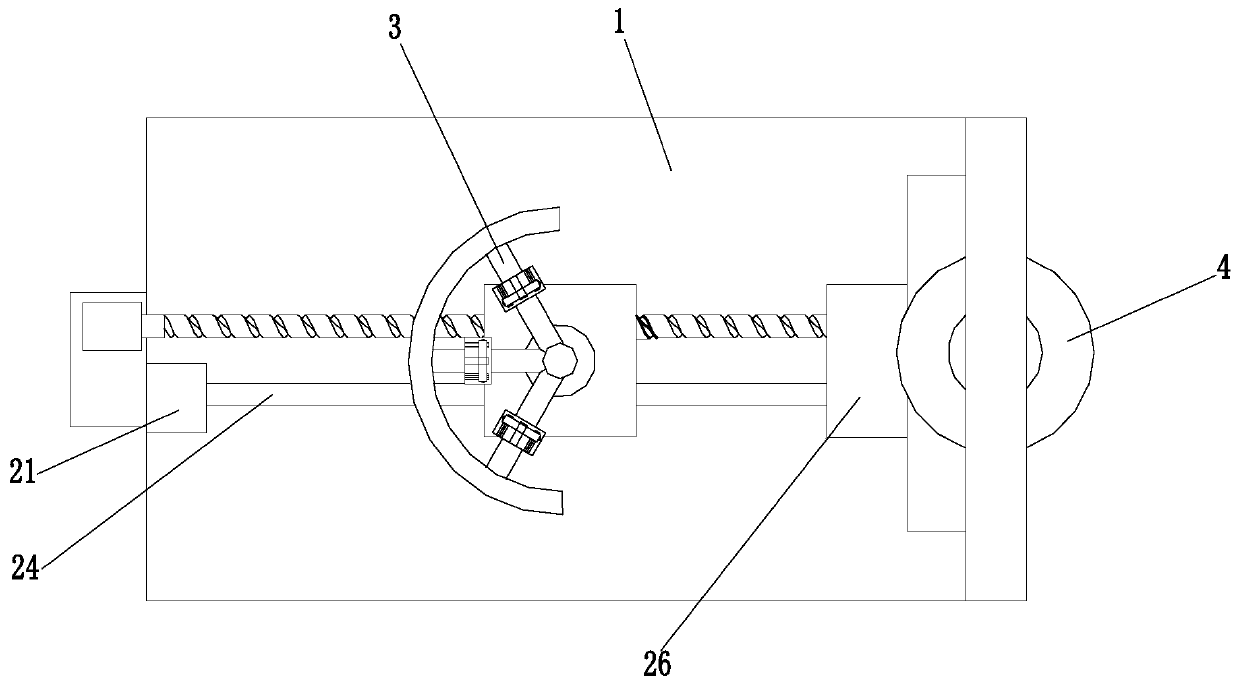

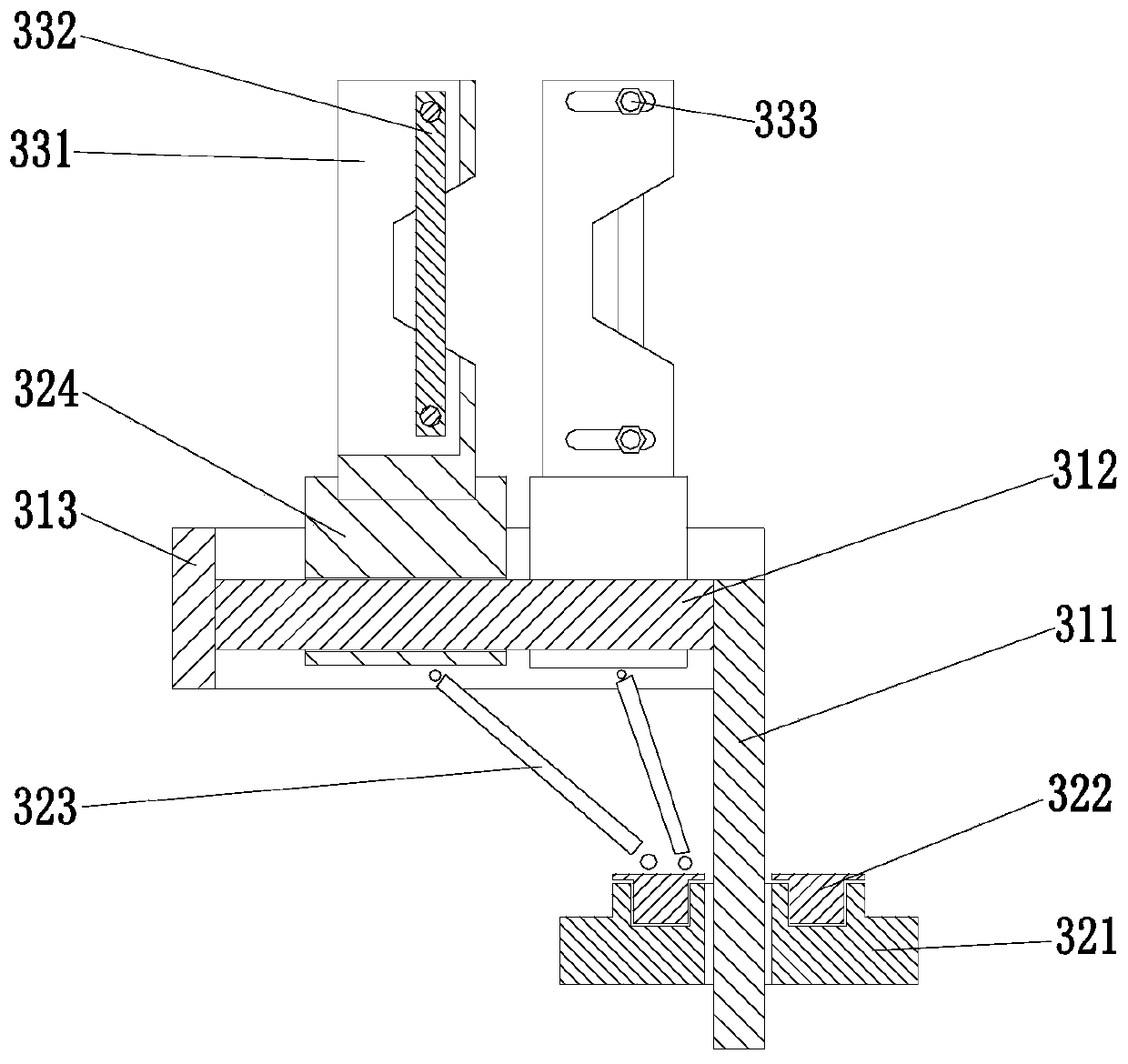

Automobile flywheel cast blank surface grinding process

ActiveCN111590436AReduce grinding efficiencyImprove stabilityGrinding drivesGrinding machinesFlywheelSurface grinding

The invention relates to an automobile flywheel cast blank surface grinding process. The automobile flywheel cast blank surface grinding process is implemented mainly through cooperation of an automobile flywheel cast blank surface grinding device. The automobile flywheel cast blank surface grinding device comprises a rack, a fixed grinding mechanism, a movable grinding mechanism and a rotary clamping mechanism. Through the automobile flywheel cast blank surface grinding process and device, the following problems existing during grinding operation of automobile flywheel cast blanks can be solved, wherein the problems are shown as follows: during the traditional grinding operation process, one grinding mechanism corresponds to one clamping mechanism, the clamping mechanism needs to be replaced if a grinding device conducts grinding on different sizes of automobile flywheel cast blanks, and the process is complicated; and an existing grinding mechanism can only grind some size of the automobile flywheel cast blanks and needs to be replaced when grinding different diameters of the automobile flywheel cast blanks, and the grinding efficiency is lower in the grinding process.

Owner:江苏科华新材料有限公司

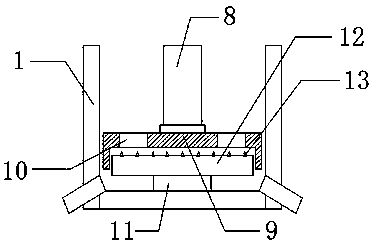

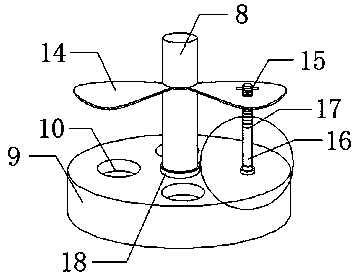

Grinding and powdering device for synthesis essence production

ActiveCN107715991AProtection from overloadingPlay a shock absorbing roleCocoaGrain treatmentsDamping functionEngineering

The invention discloses a grinding and powdering device for synthesis essence production. The grinding and powdering device comprises a grinding bucket, buckles, a top cover, a feeding hole, a motor,a glass window, discharge holes, a rotating rod, an upper grinding disc, leaking holes, a vertical column, a lower grinding disc, needle thorns, stirring blades, an adjusting bolt, a connecting rod, athreaded rod, a rotating disc, a fixing ball, a base, a telescopic rod and a spring. The grinding and powdering device has the beneficial effects that the rotating rod is mounted inside the grindingbucket, the rotating rod is driven by the motor, the stirring blades are arranged on the outer wall of the rotating rod, the upper grinding disc is connected with the bottom of the rotating rod through the rotating disc, the stirring blades are driven to rotate along with the rotating rod, the stirring blades are connected with the upper grinding disc through the connecting rod, then the upper grinding disc is driven to rotate along with the stirring blades, the fixing ball is pressed down by the connecting rod, the telescopic rod and the spring with damping functions are arranged at the bottom of the fixing ball, the connecting rod and the fixing ball have lateral sliding when an excessive amount of materials are fed into the bucket, and the upper grinding disc is dissociated from the stirring blades. The grinding and powdering device has the characteristics that the motor is protected and relatively sufficient grinding is achieved.

Owner:郴州市钰丰食品有限公司

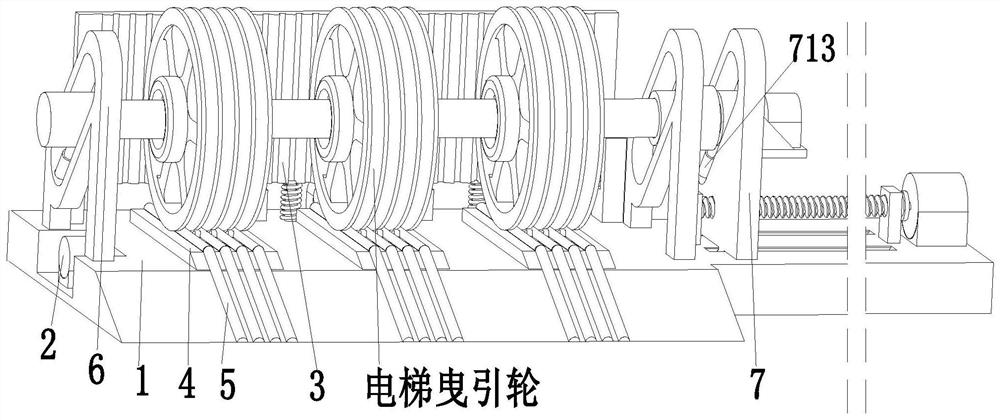

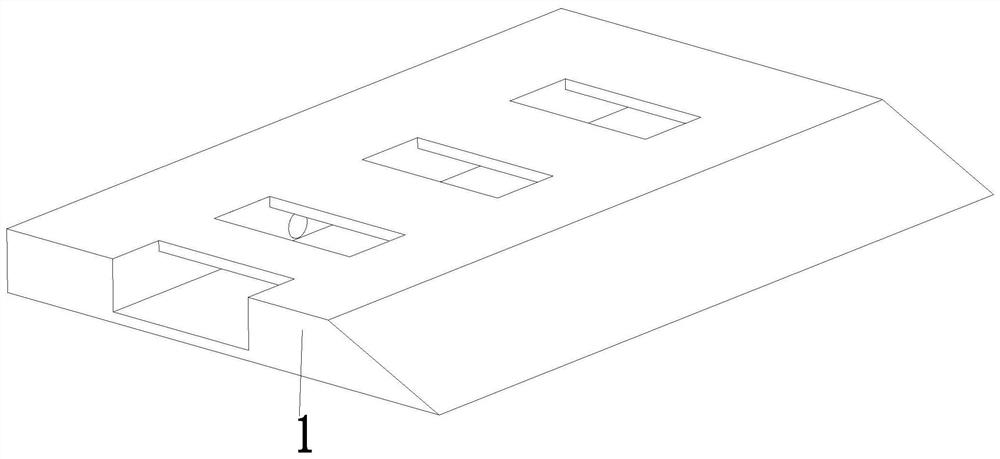

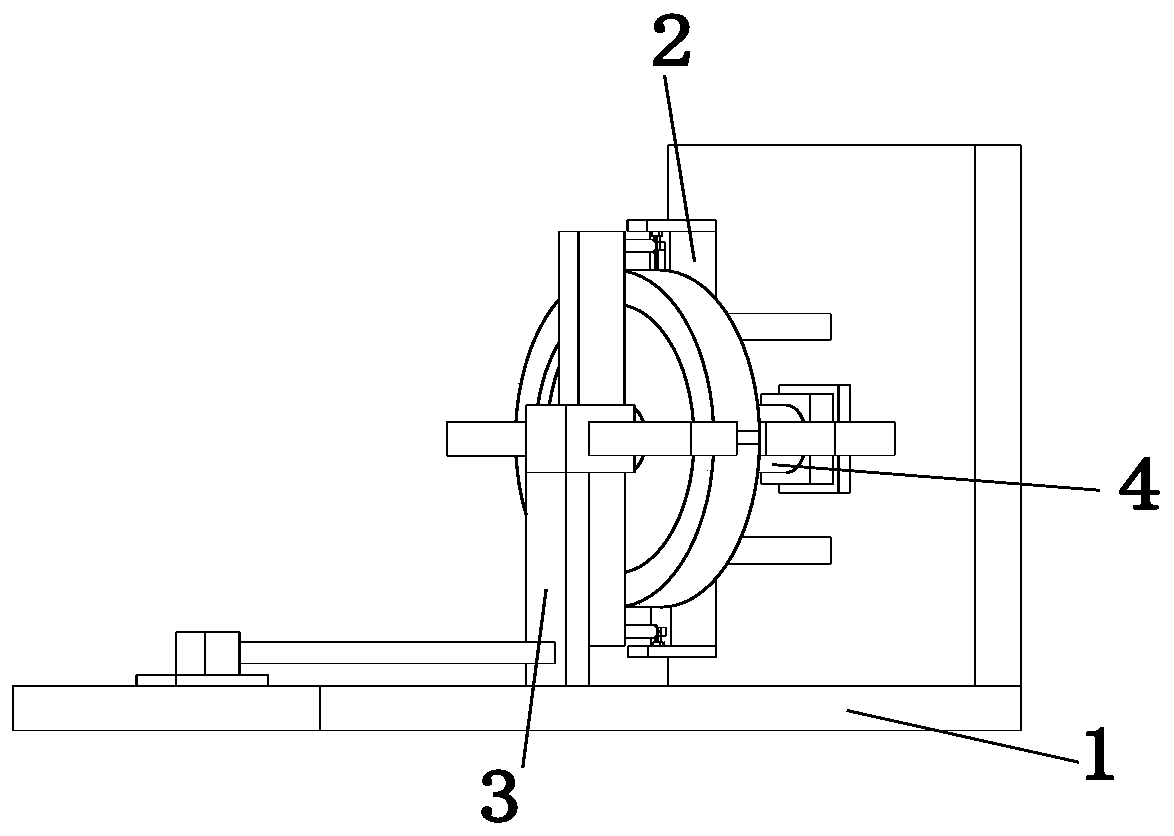

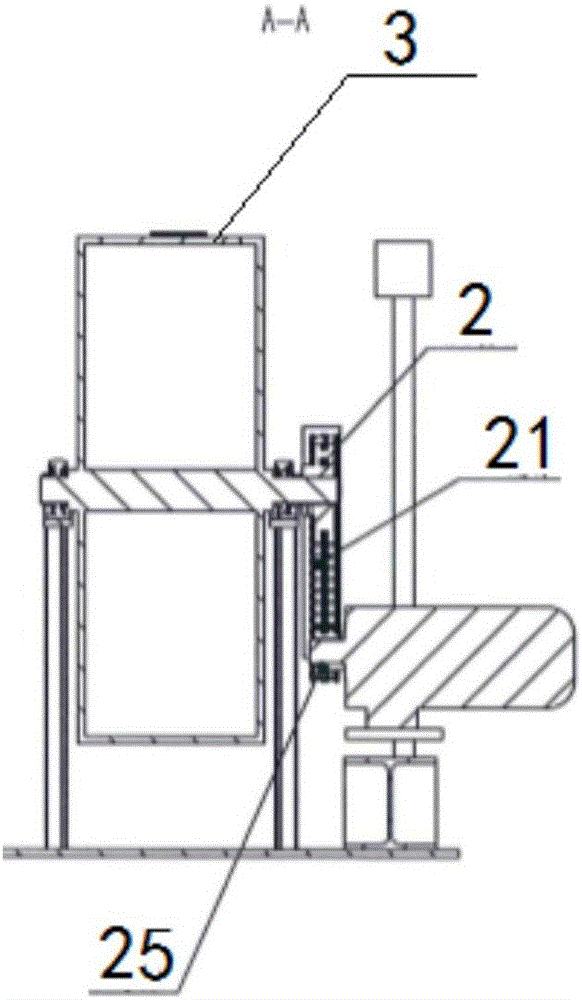

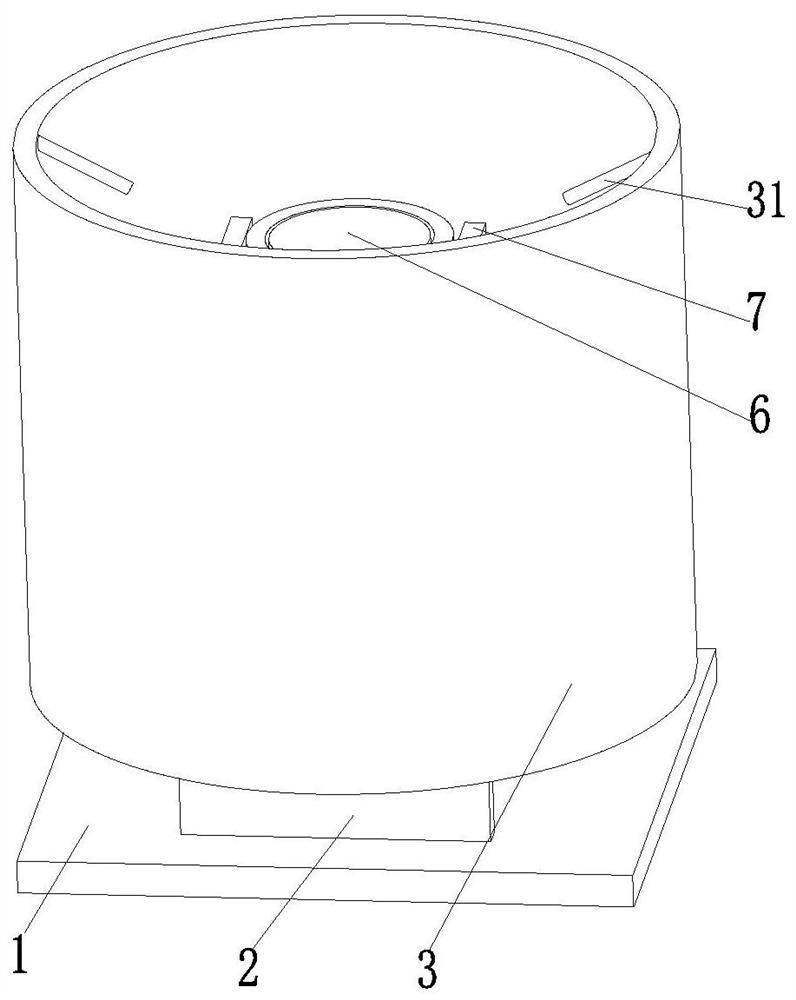

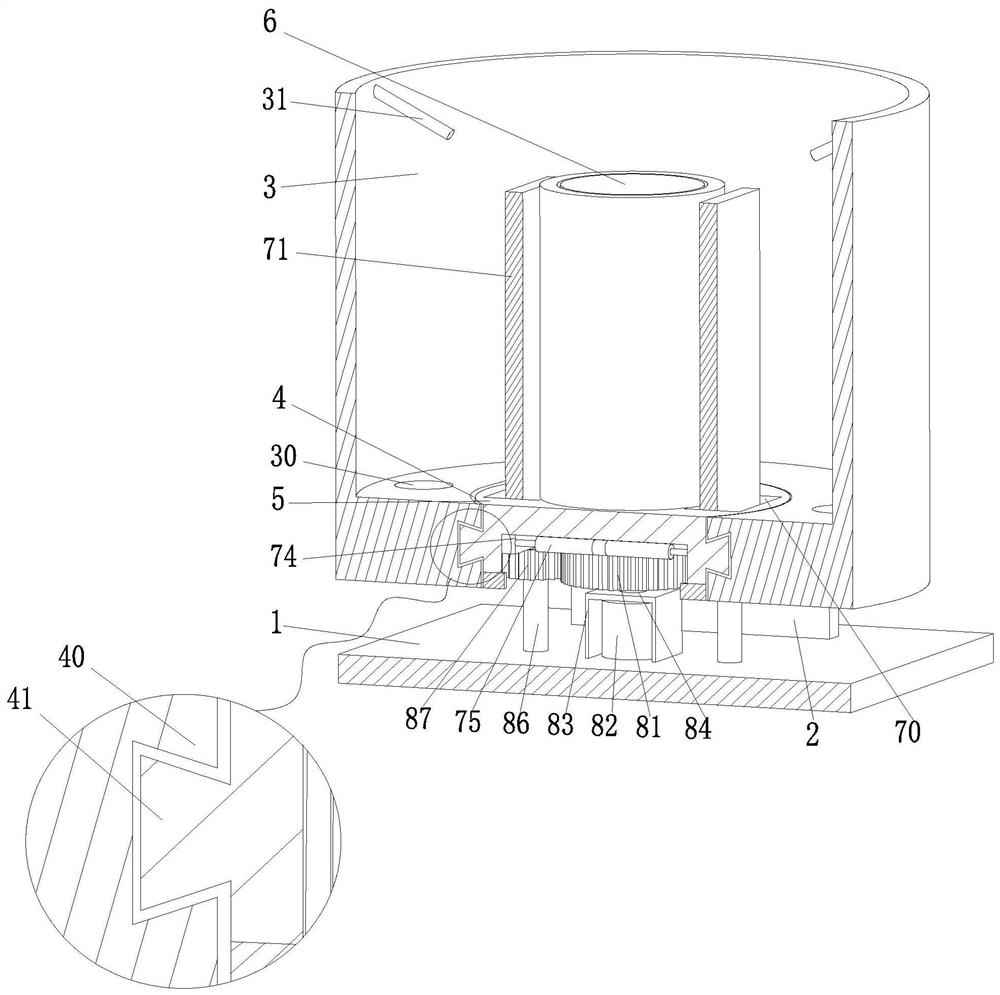

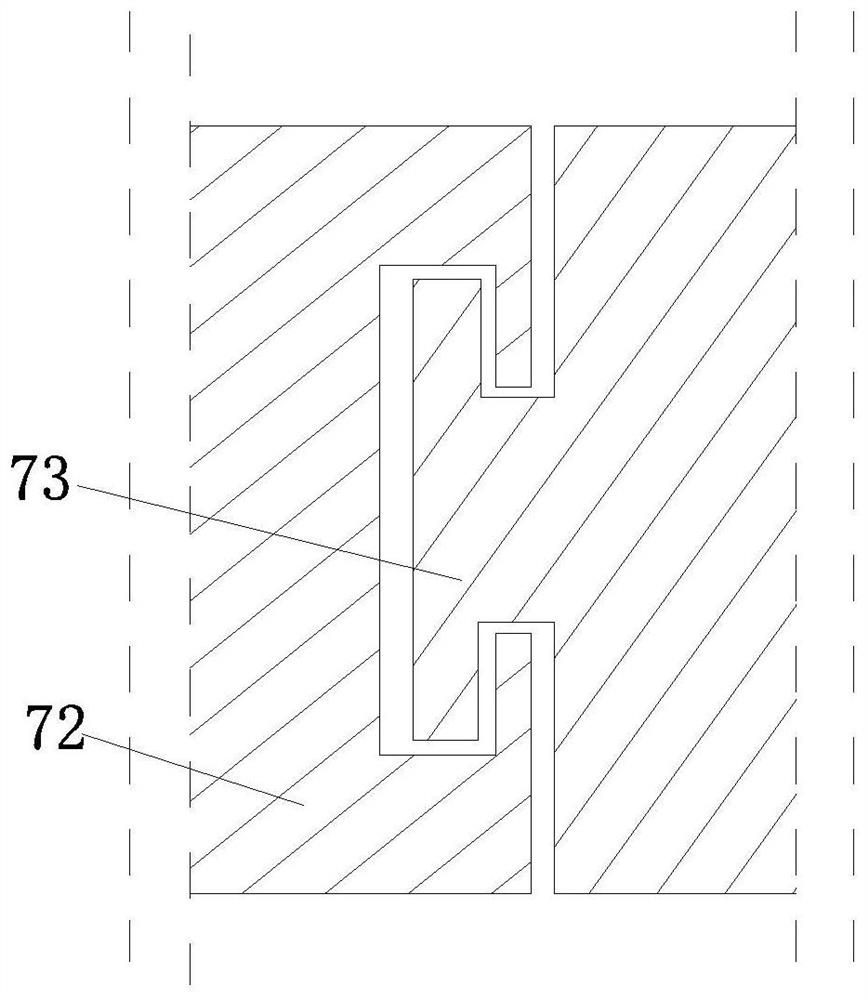

Elevator traction wheel manufacturing and processing device and manufacturing and processing method

InactiveCN111922853AImprove grinding efficiencyAvoid problems such as reduced service lifeGrinding drivesGrinding machinesStructural engineeringMachine

The invention relates to an elevator traction wheel manufacturing and processing device and a manufacturing method. The elevator traction wheel manufacturing and processing device comprises a base, arotating mechanism, a polishing mechanism, placing tables, a limiting bar, a height adjusting mechanism and a driving mechanism. The base is in a trapezoid structure with the upper end of the front side inclined backwards. A mounting groove is formed in the middle of the base. The rotating mechanism is arranged in the mounting groove. The polishing mechanism is arranged on the upper rear side of the upper end surface of the base. The placing tables are uniformly mounted on the upper end surface of the base. The upper end surfaces of the placing tables and the inclined surface of the base are detachably provided with the limiting bar. The height adjusting mechanism is arranged on the upper end surface of the base and is located on the left and right sides of the upper end surface of the base. The driving mechanism is arranged on the right side of the height adjusting mechanism. The elevator traction wheel manufacturing and processing device and the manufacturing method can solve the problems of incapability of removing burrs on the inner wall of a rope groove of an elevator traction wheel in the existing process of polishing the traction wheel by using a traction wheel polishing machine, and only one elevator traction wheel can be polished at a time.

Owner:缪心怡

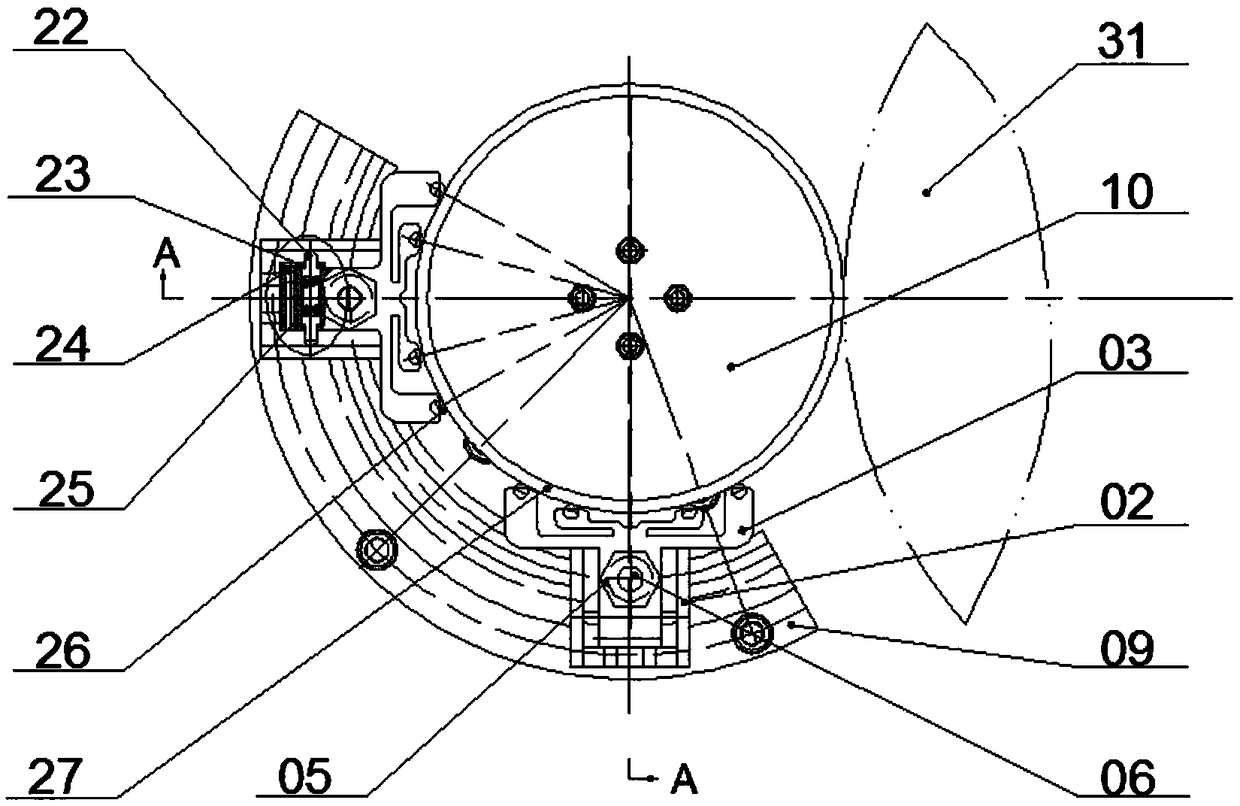

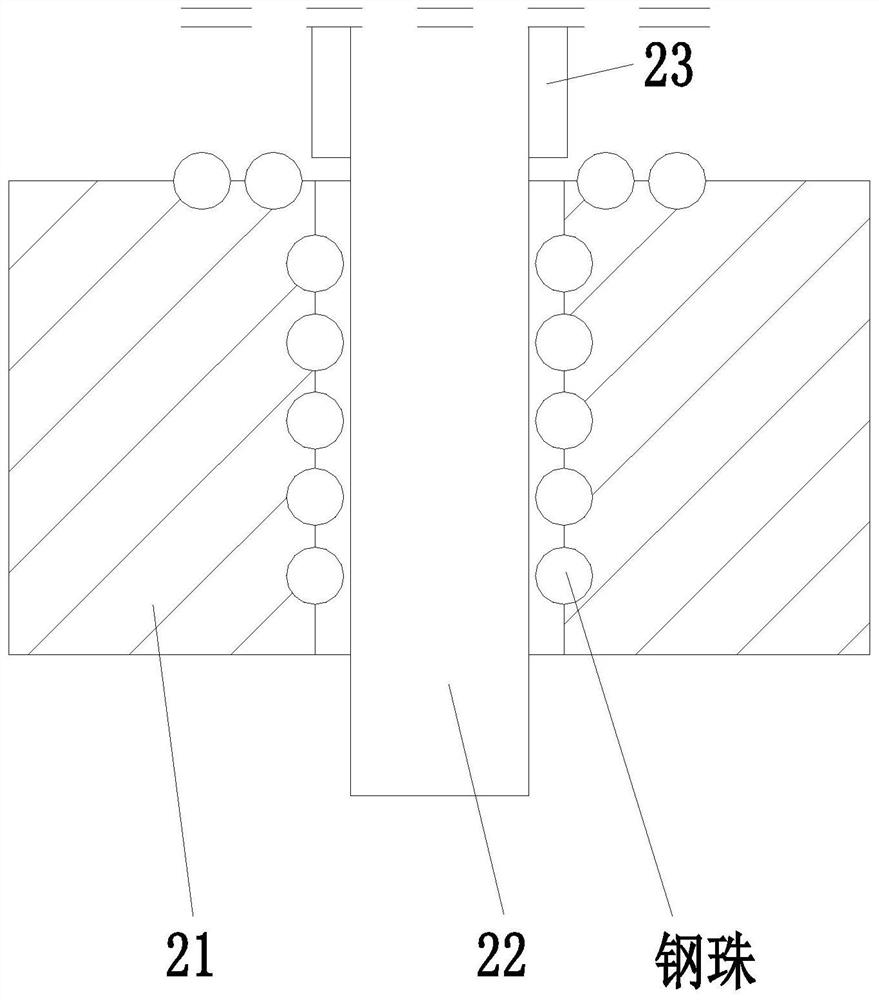

Elastic rolling floating support for centerless grinding of outer circle of annular part

PendingCN108655845ASmall elastic deformationAddress bearing marks and even superficial burnsRevolution surface grinding machinesRolling resistanceMagnetic poles

The invention discloses an elastic rolling floating support for centerless grinding of an outer circle of an annular part. The elastic rolling floating support comprises elastic supporting bodies, supporting sleeves, compressed springs, transition blocks and a supporting seat; the elastic supporting bodies press the supporting sleeves through T-shaped bolts to be connected to the transition blocks, the transition blocks are connected and fixed on the supporting seat of a machine tool shell, one end of each elastic supporting body is provided with a plurality of pairs of supporting heads, alloyballs are correspondingly arranged at the end parts of the supporting heads, and the other ends of the elastic supporting bodies are fixed on the supporting seat; and a coil shell is arranged on theinner side of the supporting seat, a coil is arranged in the coil shell, a sealing body is arranged outside the coil, a magnetic pole is arranged on the outer side of the coil shell, and the magneticpole is fixed on a workpiece shaft. According to the elastic rolling floating support, non-supporting mark grinding is achieved through rolling friction between supporting points and the surface of the workpiece, and follow-up treating matters caused by support marks and even burn are greatly reduced, the influence of the elastic deformation of the workpiece on the grinding efficiency and the quality is reduced, the stress of the elastic supporting points tends to be consistent, and all the points are always in effective supporting states.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

Polishing machine tool for hardware rigging machining

ActiveCN113182993APrevent slidingPolished evenlyGrinding carriagesGrinding drivesComputer hardwarePolishing

The invention discloses a polishing machine tool for hardware rigging machining, and belongs to the field of metal intelligent machining. The polishing machine tool comprises a workbench, a turnover mechanism, a polishing mechanism, an auxiliary mechanism and a fixing mechanism, wherein the turnover mechanism is installed on the workbench, the polishing mechanism is fixedly installed on the turnover mechanism, the auxiliary mechanism is installed on the turnover mechanism, the fixing mechanism is installed on the workbench, the overturning mechanism comprises two overturning assemblies, the two overturning assemblies are installed on the two side walls of the workbench, each overturning assembly comprises an overturning frame, a connecting frame, an overturning electric cylinder and an overturning toothed plate, the overturning frames are rotatably installed on the side walls of the workbench, the tooth grooves are formed in the overturning frames, the connecting frames are welded to the overturning frames, the overturning electric cylinders are installed on the side walls of the workbench, and the overturning toothed plates are installed at the telescopic ends of the overturning electric cylinders. According to the polishing machine tool for hardware rigging machining, the inner side walls of rigging with different radians can be ground.

Owner:温州市聚盛丰达轻工设备有限公司

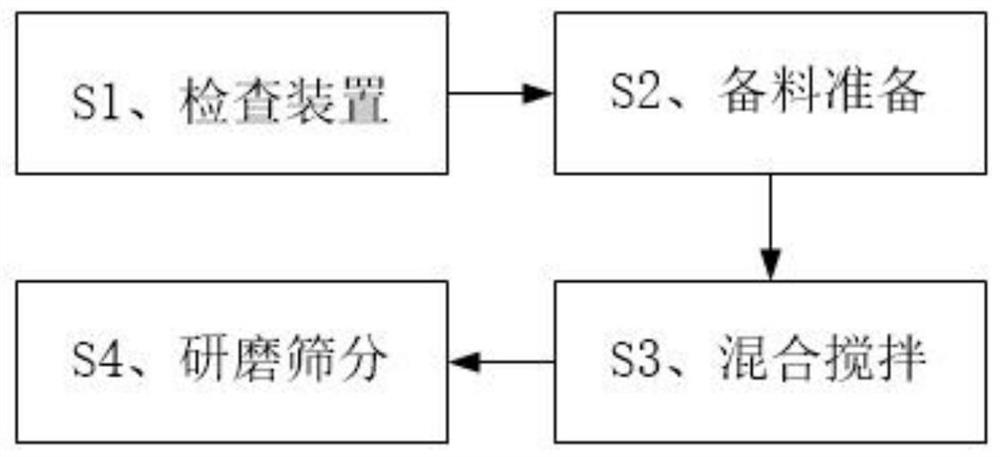

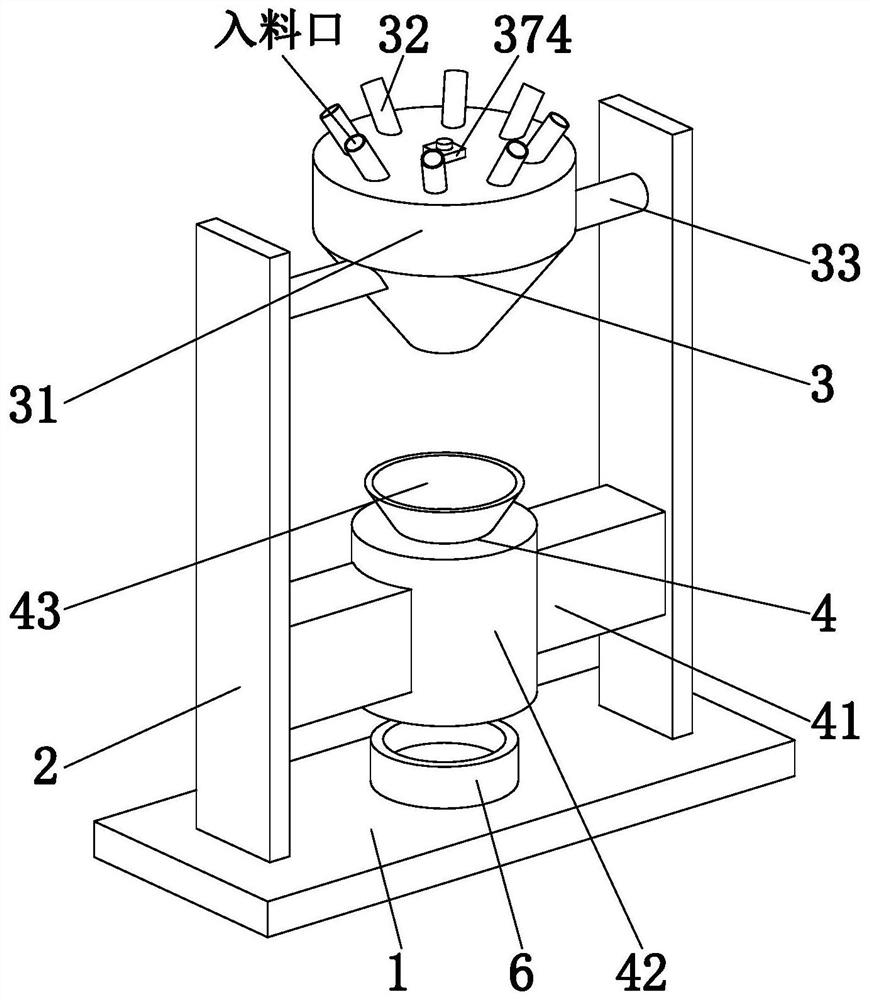

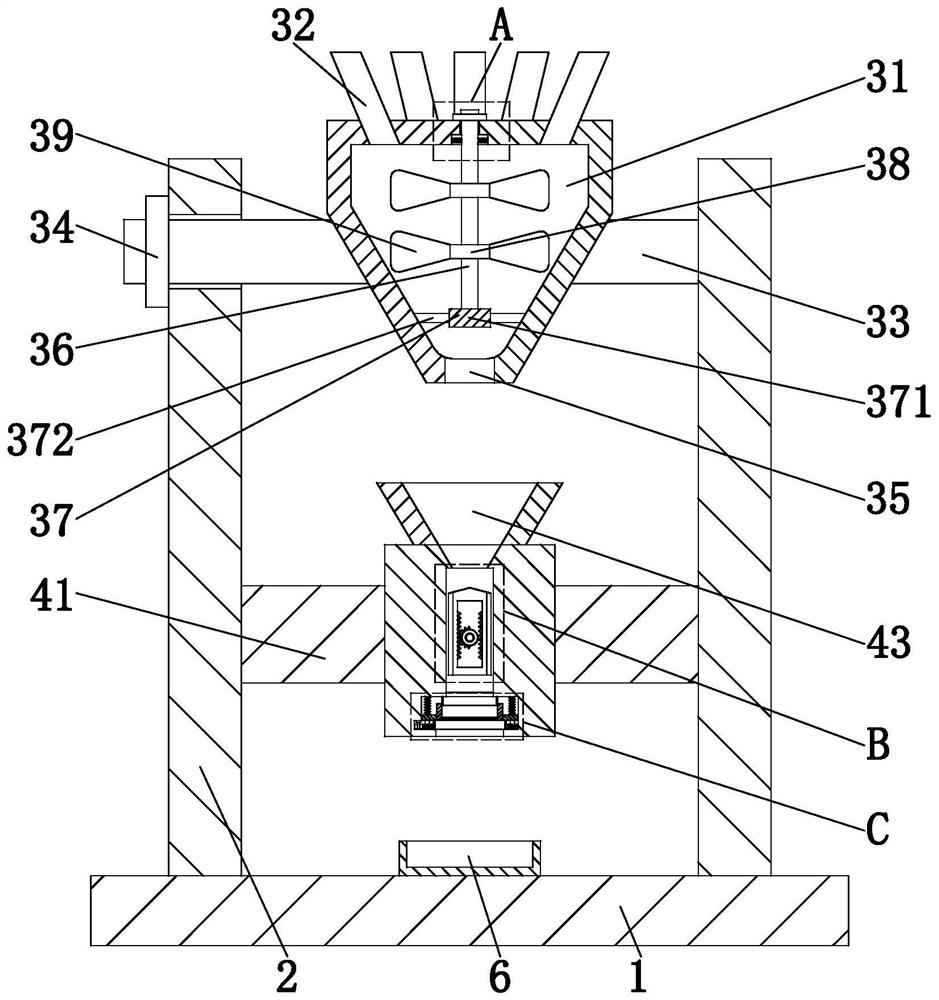

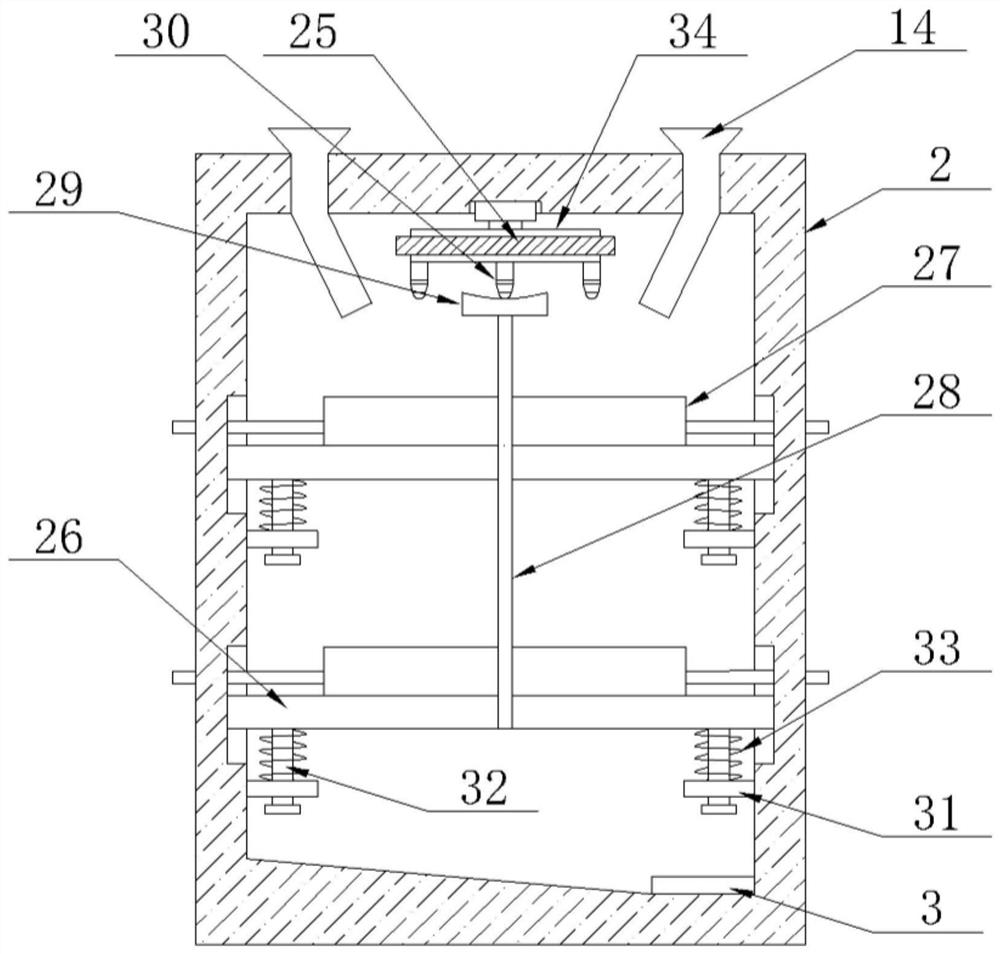

Preparation method of additive powder for cosmetics

InactiveCN112717796AReduce utilizationReduce grinding efficiencyRotating receptacle mixersTransportation and packagingMetallurgyCosmetics

The invention provides a preparation method of additive powder for cosmetics. A preparation device of the additive powder for cosmetics is employed in the preparation method and comprises a base, a support frame, a mixing and stirring mechanism, a grinding mechanism, a vibrating screening mechanism and a collecting frame. The preparation method of the additive powder for cosmetics in the invention can solve the following problems in the preparation process of the additive powder for cosmetics: a, various materials need to be fully mixed in the preparation process of the powder, then the powder is further ground to obtain required mixed powder, the required powder is finally obtained through reprocessing, but however, when a traditional device is used for mixing all the materials, mixing is not uniform, and a required mixed material is difficult to obtain; and b, since the traditional grinding device is insufficient in grinding during grinding, the obtained mixed powder contains powdery particles, the content of available powder is low during filtering and screening, and the content of the powder needs to be increased through secondary grinding, so working intensity is increased.

Owner:盐城拉芬化妆品有限公司

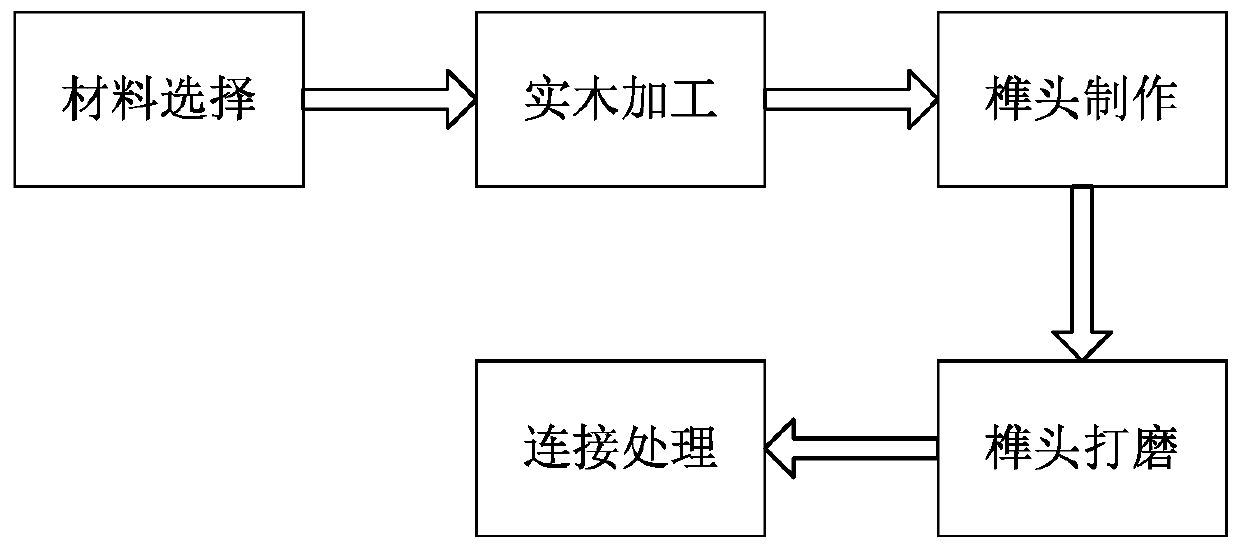

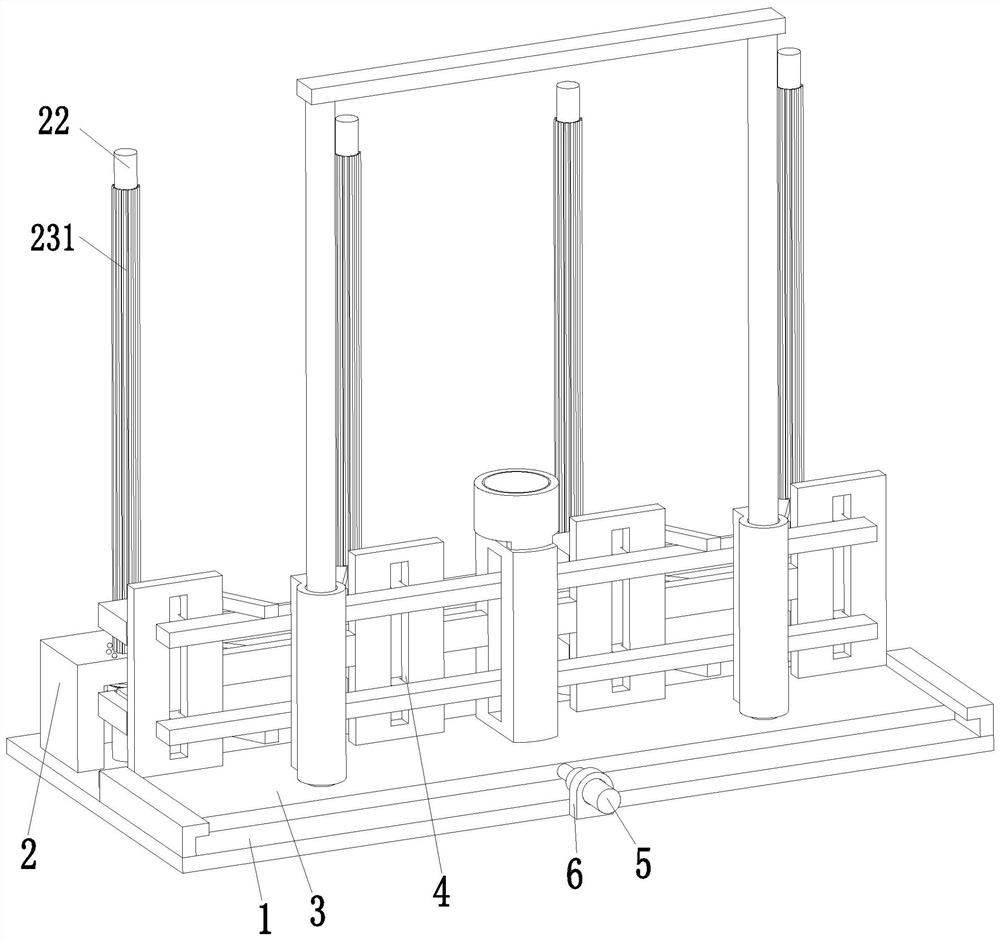

Tenon connection processing method for producing and processing solid wood furniture

ActiveCN110842671AAdd work stepsReduce grinding efficiencyGrinding drivesWood working apparatusSolid woodPolishing

The invention relates to a tenon connection processing method for producing and processing solid wood furniture. The tenon connection processing method for producing and processing the solid wood furniture comprises a bottom plate, a support frame, a polishing device and a bearing device, wherein the polishing device is installed at the upper end of the bottom plate, the support frame is arrangedon the right side of the polishing device, the support frame is installed on the bottom plate, and the support frame is of a U-shaped structure. The tenon connection processing method for producing and processing the solid wood furniture can solve the problems that when an existing dovetail tenon is processed and connected, the end face and the inclined plane of the tenon cannot be polished on thesame equipment, so that the working steps of tenon polishing are increased, the polishing efficiency is reduced, the inclined planes with different inclination angles cannot be polished, and the polishing flexibility is reduced; and meanwhile, when existing equipment polishes the tenon, the polishing depth cannot be determined, the phenomenon of excessive polishing easily occurs, the tenon and atenon groove cannot be completely matched, the polishing fails, the tenon cannot be polished according to the required depth, and the polishing efficiency is reduced.

Owner:南京得嘉精密工具有限公司

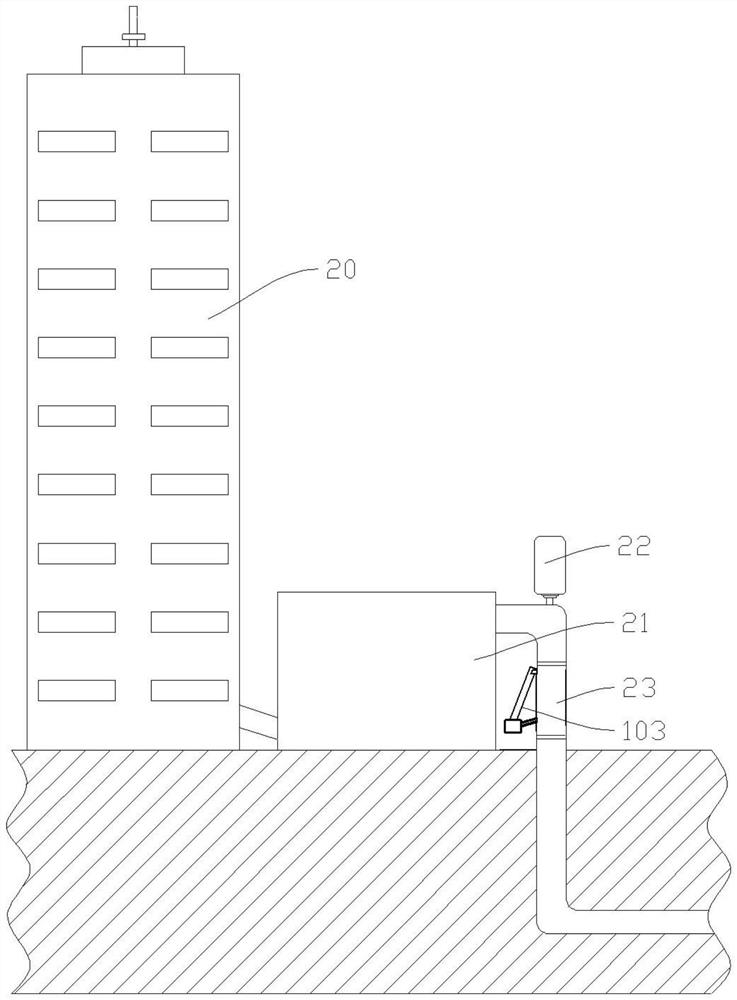

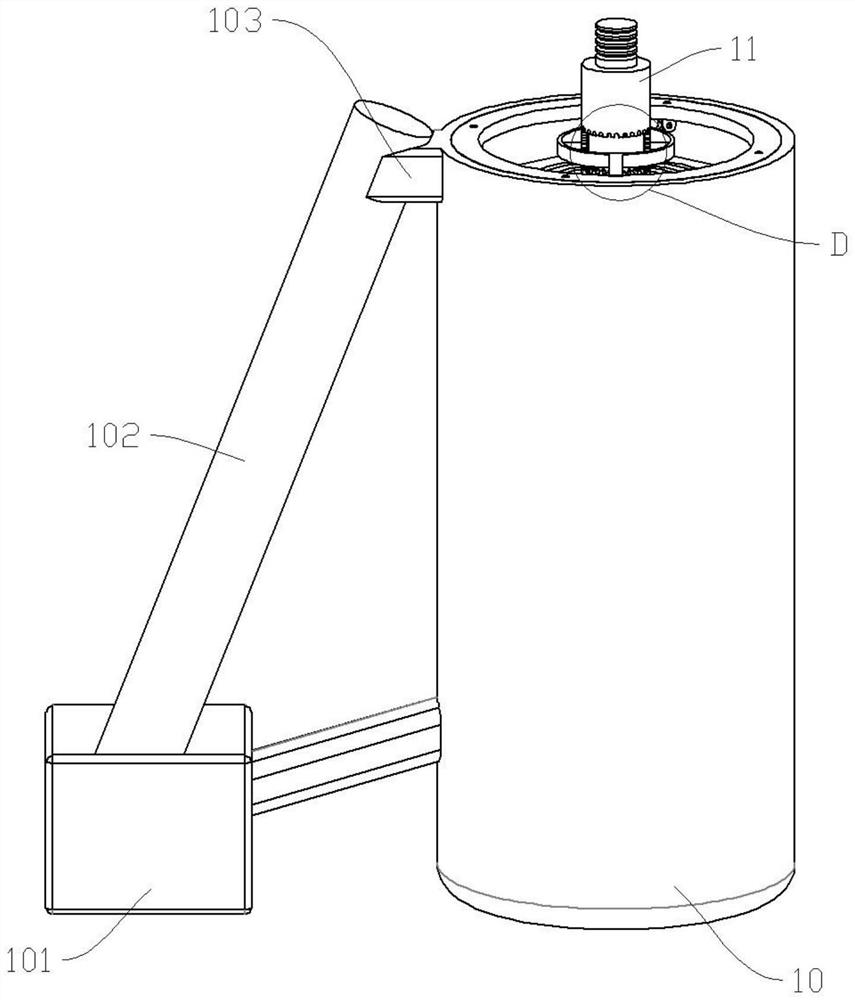

Energy-saving and environment-friendly building drainage device

ActiveCN114011541AReduce grinding efficiencyEven by forceConstruction waste recoveryDomestic plumbingDrive shaftWastewater

The invention relates to the field of drainage structures, in particular to an energy-saving and environment-friendly building drainage device. An opening in the upper end of a grinding cylinder is communicated with a building wastewater pool, an upper transmission shaft is arranged in the grinding cavity, an upper fixing ring is fixed to the opening of the grinding cavity, and an adjusting rotating ring is rotatably arranged on the upper transmission shaft; multiple upper torsion bars are evenly distributed in the circumferential direction of the upper transmission shaft, the upper end of each upper torsion bar is universally hinged to the upper fixing ring, and the lower end of each upper torsion bar is universally hinged to the adjusting rotating ring; the upper grinding mechanism comprises multiple upper grinding discs and multiple upper crushing cutters; the upper grinding disc is in a vortex disc shape, a groove body in the upper grinding disc is a vertically-communicated through groove, the rotating direction of the groove body in the upper grinding disc is opposite to the rotating direction of the upper transmission shaft, and the upper grinding disc is rotatably arranged on the upper transmission shaft in a sleeving mode and can slide up and down; and the upper crushing cutters can be arranged on the upper transmission shaft in a vertically sliding and sleeving mode, and each upper crushing cutter is arranged between every two adjacent upper grinding discs, so that when the upper crushing cutters conduct crushing and grinding, stress is uniform, and the upper crushing cutters are prevented from being damaged.

Owner:ZHENGZHOU ZHENG YAN CONSTR GRP CO LTD

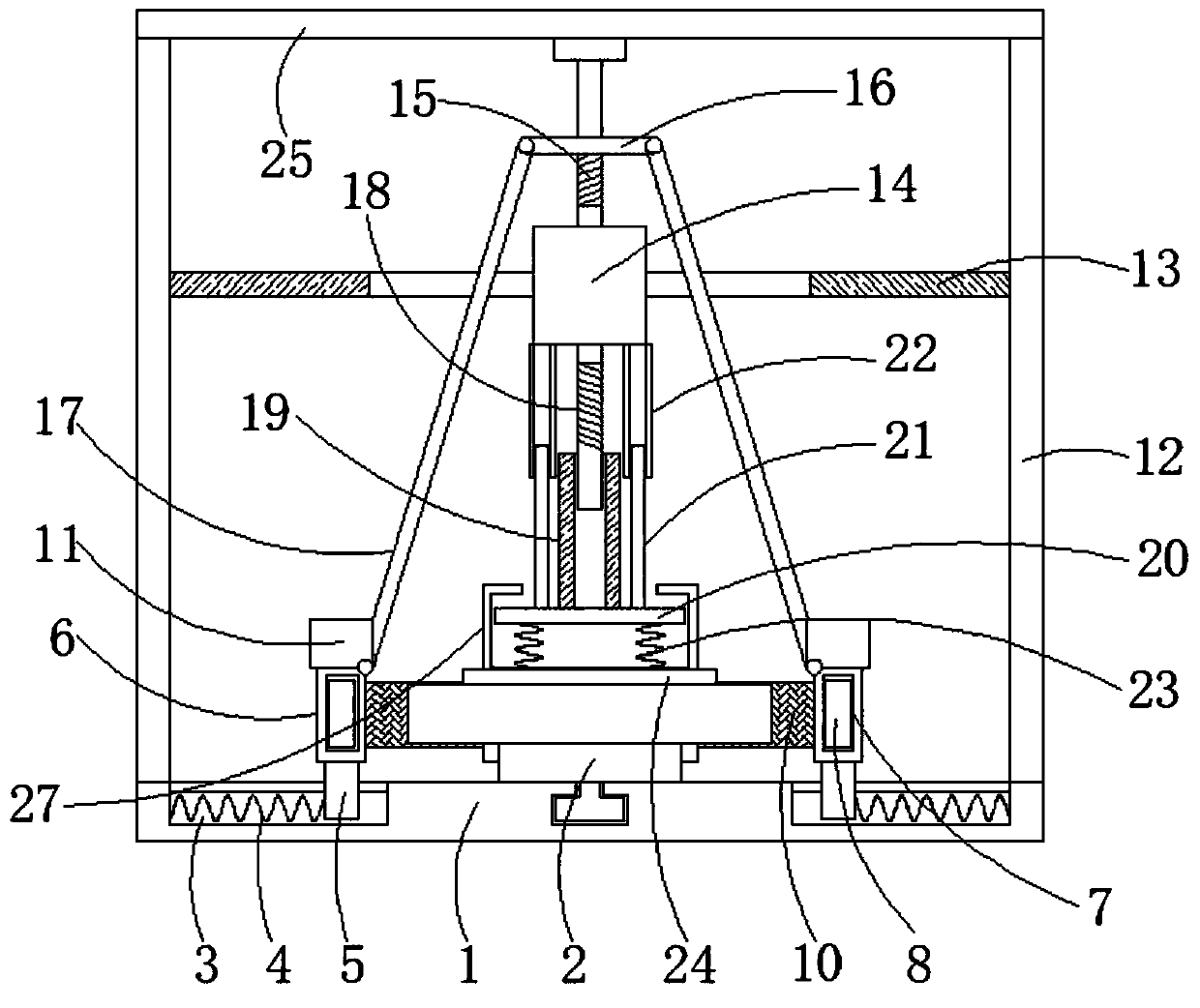

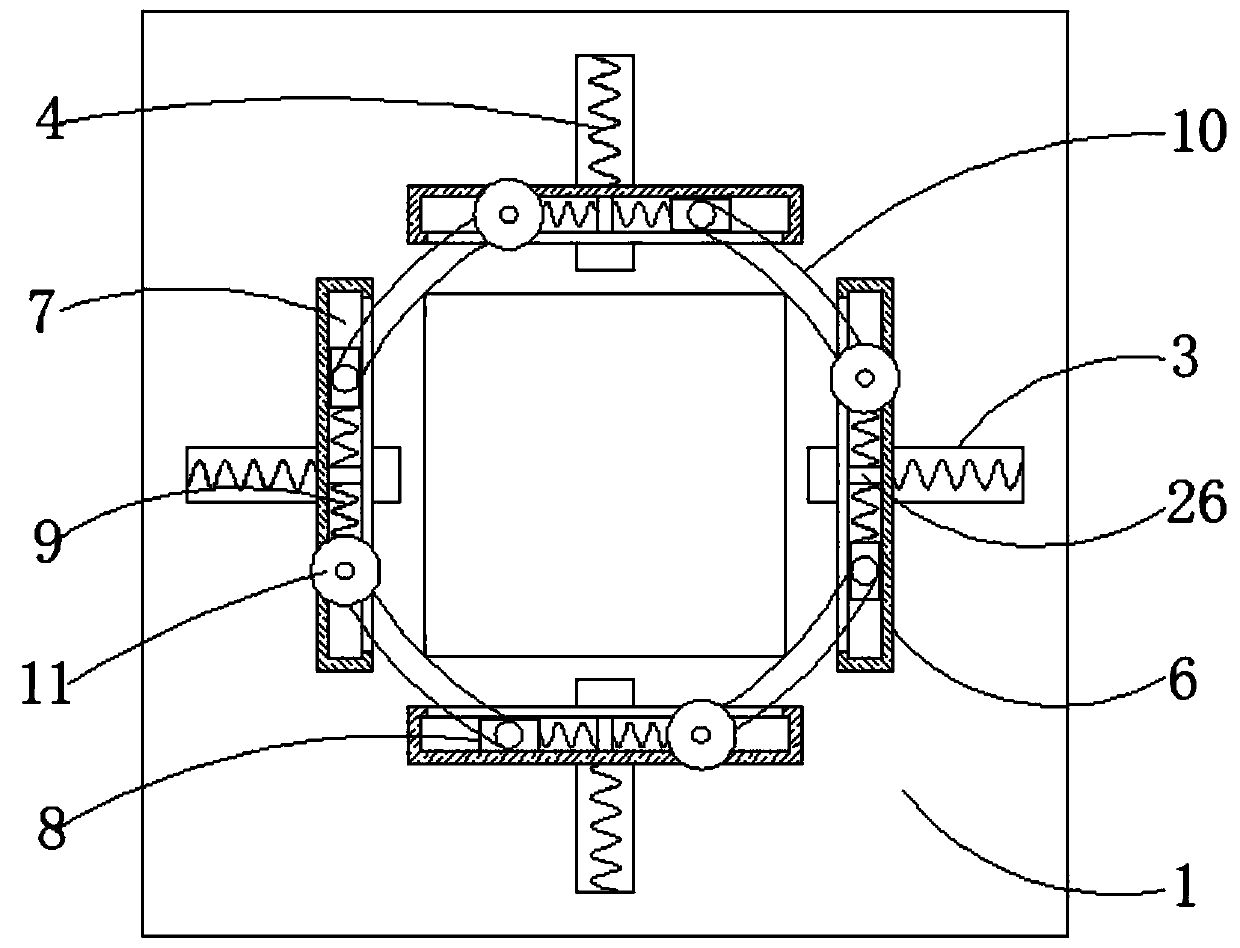

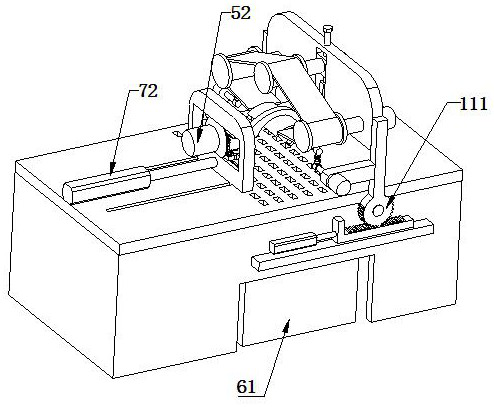

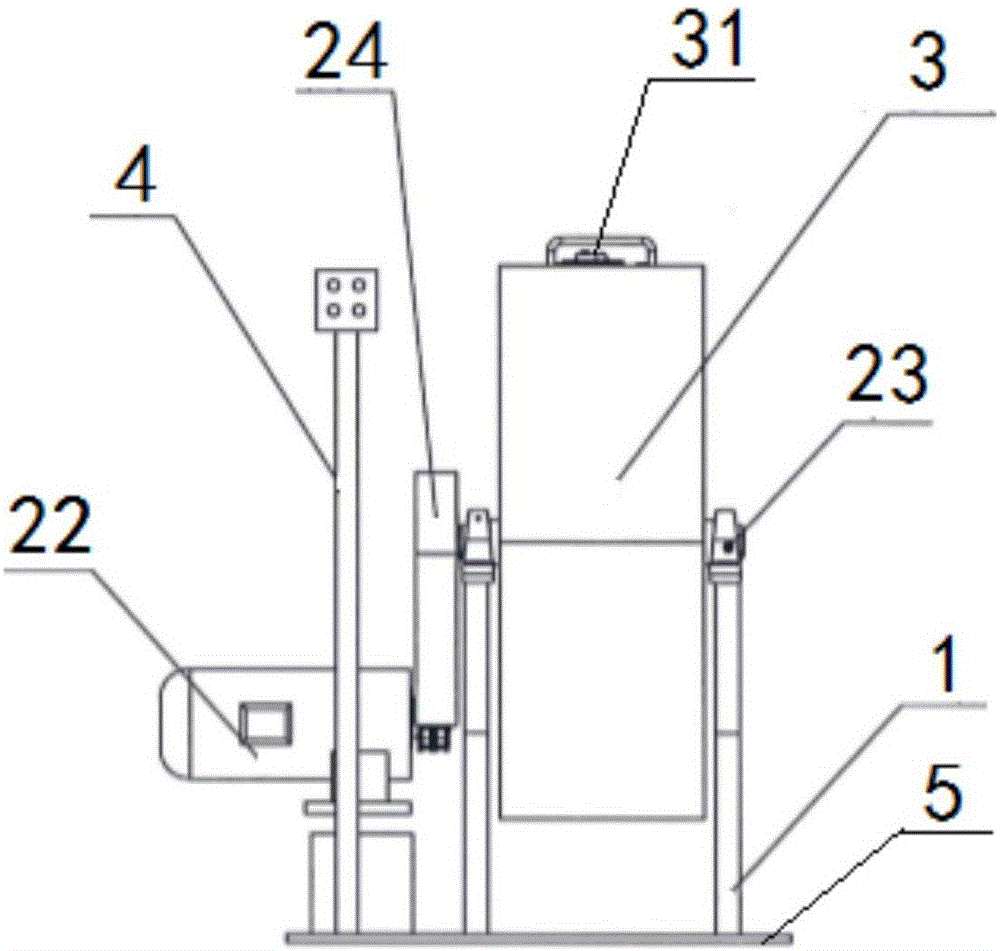

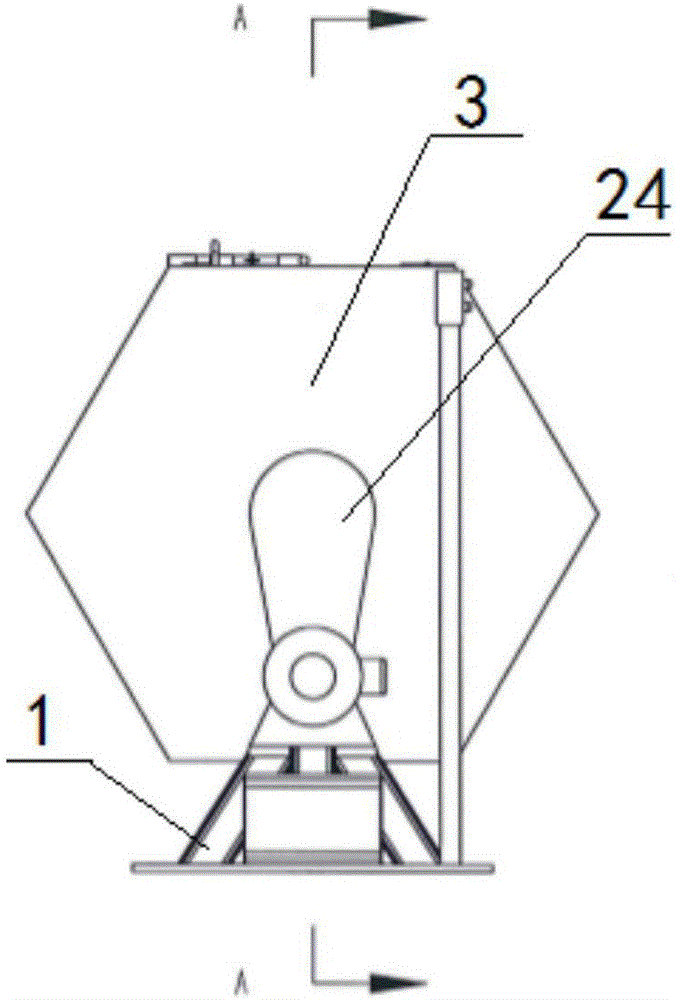

Automobile flywheel blank piece surface polishing equipment

ActiveCN111496627AReduce grinding efficiencyImprove stabilityGrinding carriagesGrinding drivesPolishingFlywheel

The invention relates to automobile flywheel blank piece surface polishing equipment. The automobile flywheel blank piece surface polishing equipment comprises a rack, a fixed polishing mechanism, a moving polishing mechanism and a rotating clamping mechanism. By means of the automobile flywheel blank piece surface polishing equipment, the following problems existing in automobile flywheel castingblank piece polishing operations that a, in the traditional polishing operation process, one polishing mechanism corresponds to one clamping mechanism, if polishing on automobile flywheel casting blank pieces of different specifications needs to be realized, the clamping mechanism needs to be replaced, and the process is relatively complicated; and b, an existing polishing mechanism can only polish the automobile flywheel casting blank pieces of a certain specification, when the polishing is performed on the automobile flywheel casting blank pieces of different diameters, the polishing mechanism needs to be replaced, and the polishing efficiency in the polishing operation process is made to be reduced can be solved.

Owner:徐州市威尔玛科技有限公司

Machining process for extrusion die

The invention provides a machining process for an extrusion die. The machining process is used for machining the extrusion die sleeved on a roll shaft of a granulator. A die blank with die holes is subjected to thermal treatment and finish machining, and each die hole is subjected to extrusion and grinding treatment. The thermally treated extrusion die has strong strength, cannot be cracked after being extruded for a long time, and is long in service life; the die holes are high in compressive resistance and bending resistance, and cannot be deformed by extrusion; after the finish machining, the extrusion die can rotate stably, and the yield is high; in addition, the grinding cost of the extrusion mode is low, and two die blanks can be ground by once extrusion, so that the grinding efficiency is high; and the die holes of the ground die blanks are low in roughness, and extruded products are easy to de-mold.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

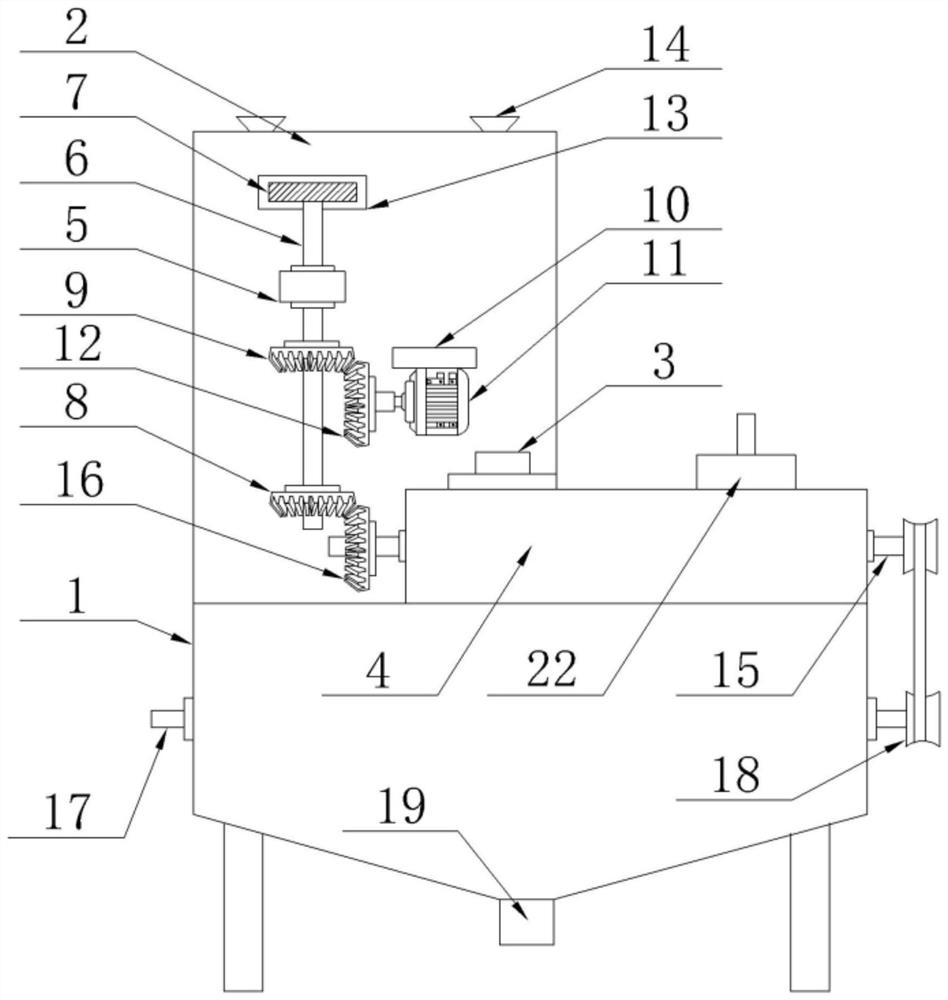

Feeding device for flour processing

ActiveCN112044754AImprove yieldPrevent moistureSievingGas current separationGear wheelAgricultural engineering

The invention discloses a feeding device for flour processing, and belongs to the field of flour processing. The feeding device comprises a drying box, a pretreatment box and a transfer box, wherein athrough hole is formed in the right side of the joint of the transfer box and the drying box; a driving mounting plate is welded to the middle of the front end face of the pretreatment box; a drivingmotor is mounted at the bottom of the driving mounting plate; a fixing block is welded to the left side of the joint of the front end face of the pretreatment box and the driving mounting plate; anda gear and a transmission gear are mounted at the upper end and the lower end of a rotating rod respectively. Screened wheat enters an inner cavity of the transfer box through a discharging pipe, andis conveyed from left to right, and a dust discharging fan operates in the process in order to discharge dust doped in the wheat out of transfer box, so that the situation that quality of flour is affected due to fact that dust is doped in the wheat is avoided. After the wheat falls into an inner cavity of the drying box, a belt wheel drives a steel pipe to rotate, and the steel pipe drives stirring blades to rotate to stir the wheat, so that rapid drying is achieved, moisture of the wheat is avoided, and the grinding efficiency is prevented from being reduced.

Owner:江苏宇宸面粉有限公司

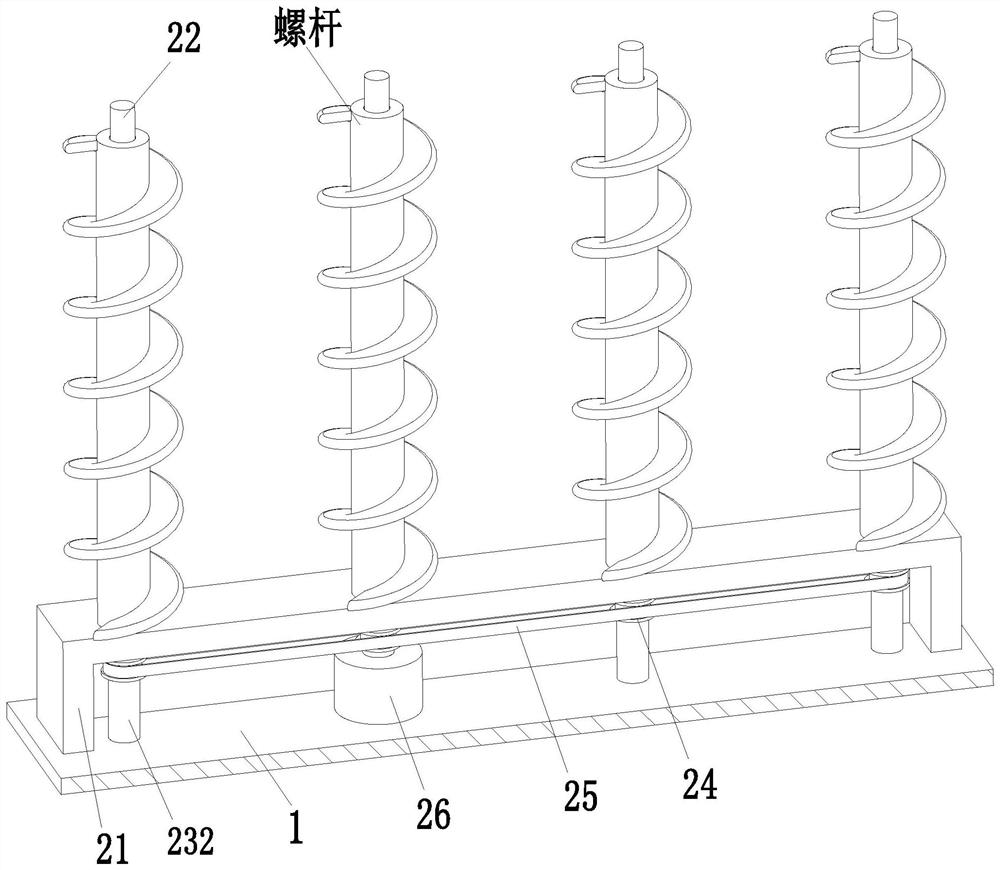

Special engineering plastic product processing system

InactiveCN112264876AReduce grinding efficiencyIncrease the frequency of replacementGrinding carriagesThread cutting machinesEngineering plasticEngineering

The invention relates to a special engineering plastic product processing system. The system comprises a base, a driving mechanism, a sliding bottom plate, a grinding mechanism, an adjusting air cylinder and an air cylinder bottom plate. The driving mechanism is arranged on the rear side of the upper end face of the base, the sliding bottom plate is arranged on the front side of the upper end faceof the base in a sliding fit mode, the grinding mechanism is installed on the upper end face of the sliding bottom plate, and the adjusting air cylinder is installed at the front end of the sliding bottom plate and connected with the base through the air cylinder bottom plate. The system can solve the problems that in the prior art, in the process that a common plastic screw grinding machine is adopted for grinding the surfaces of special engineering plastic screws, the special engineering plastic screws of different sizes can be ground only by disassembling related parts on the existing plastic screw grinding machine, waste materials generated in the grinding process cannot be cleaned away in time, the grinding effect on the special engineering plastic screws is poor, and the grinding efficiency of the special engineering plastic screws is low.

Owner:佛山中易德化工材料有限公司

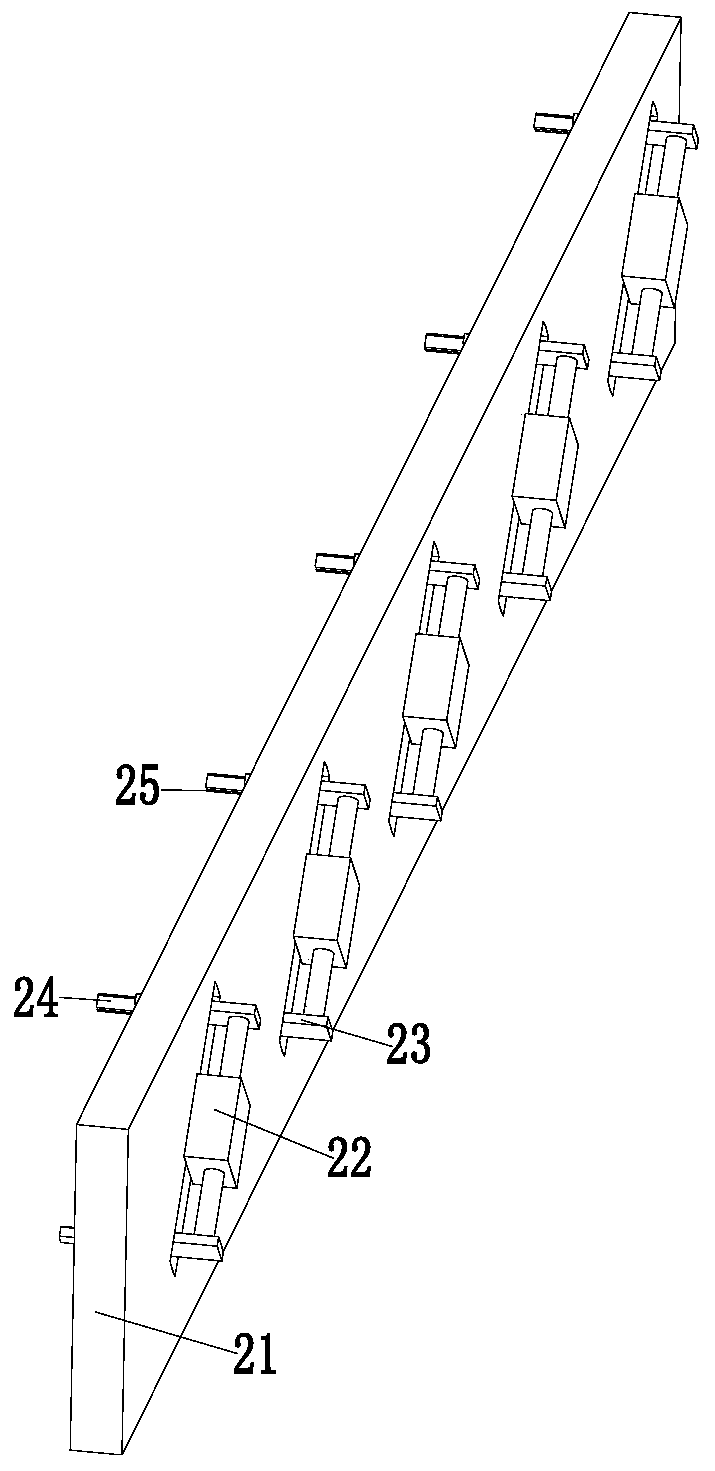

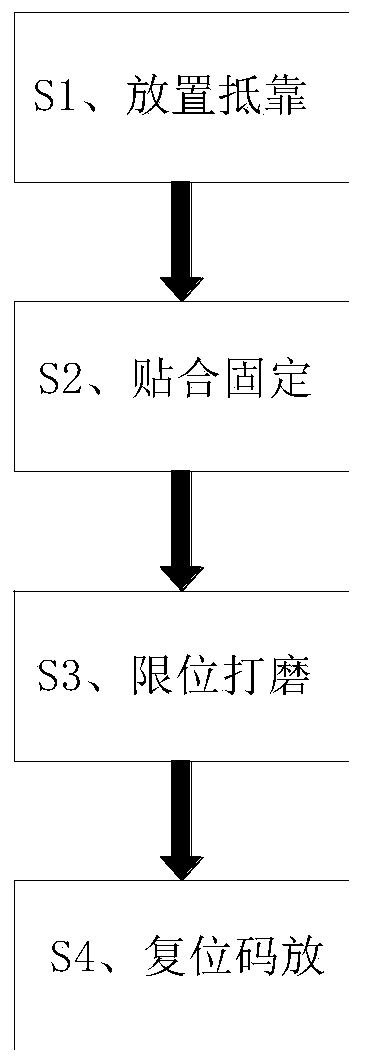

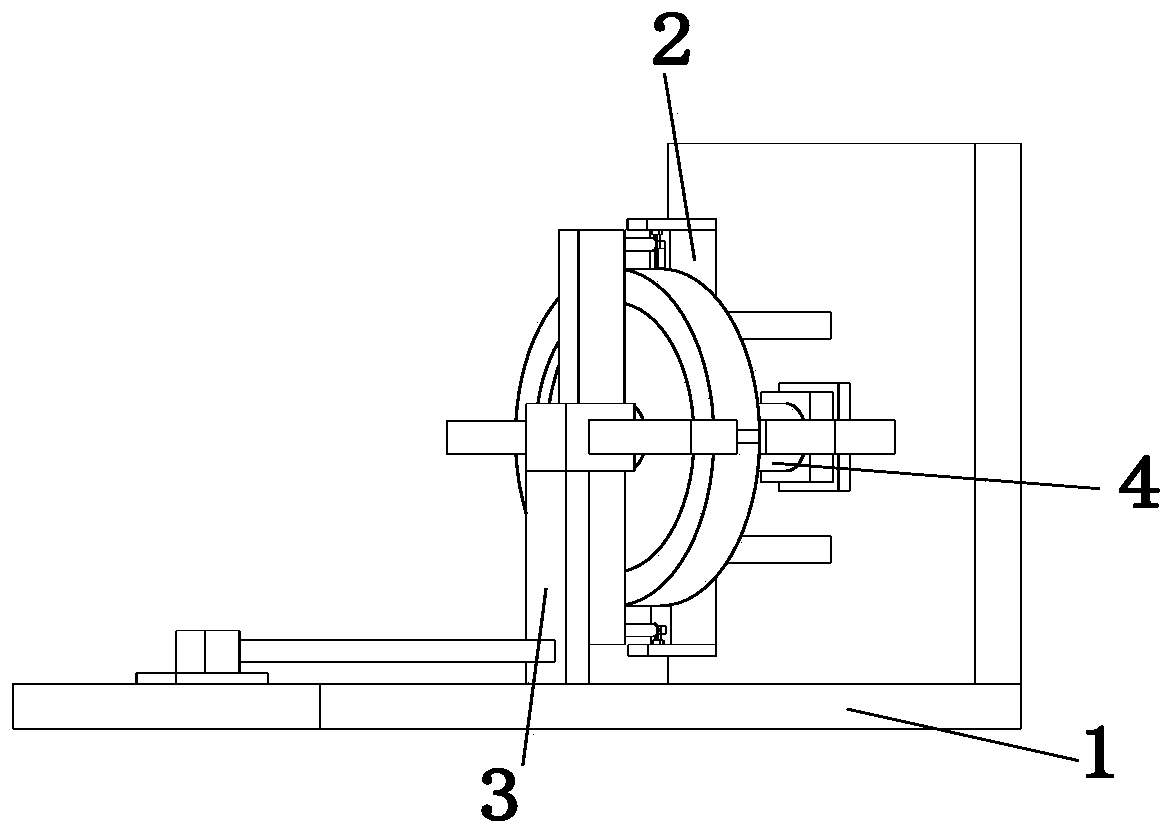

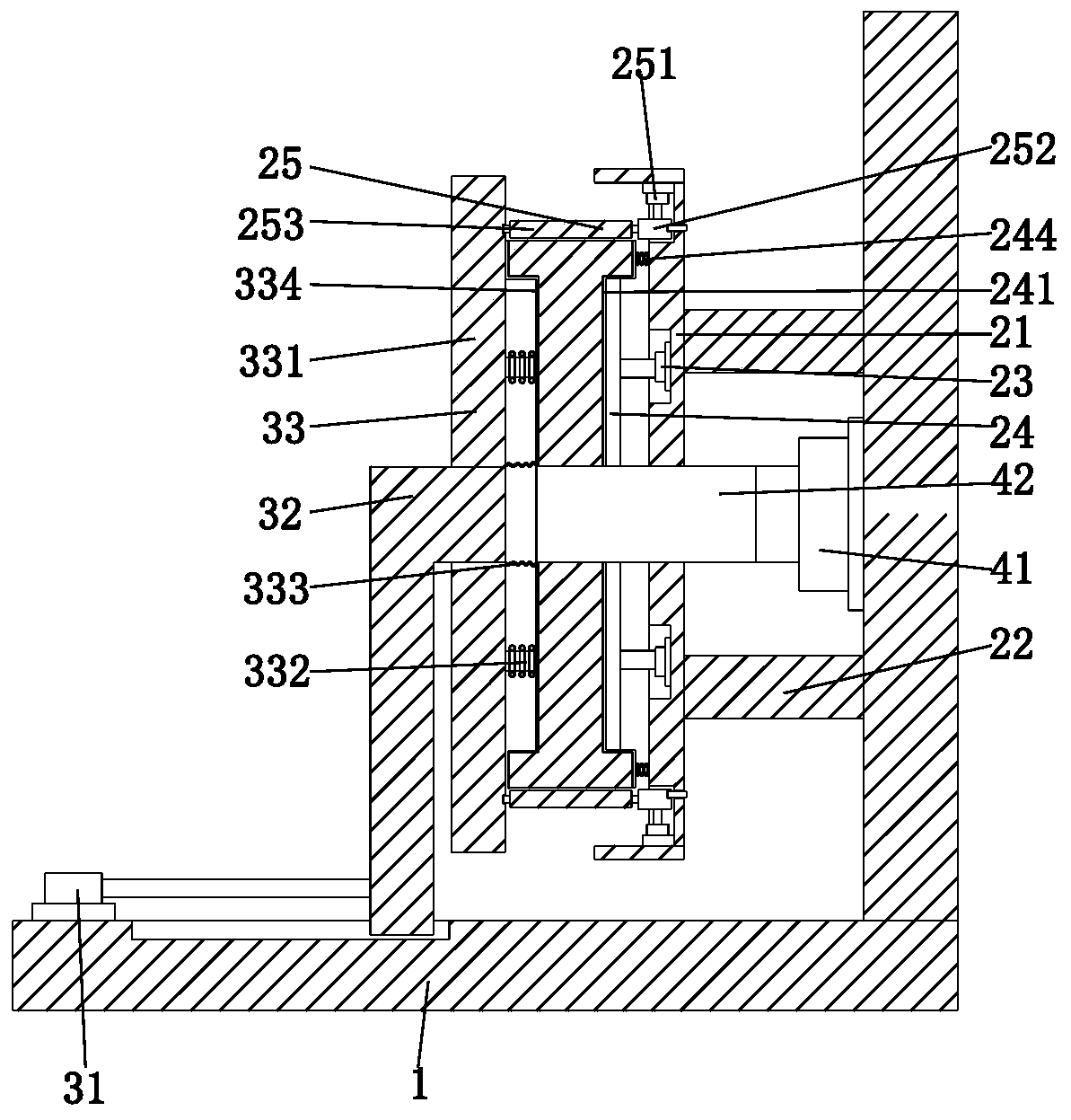

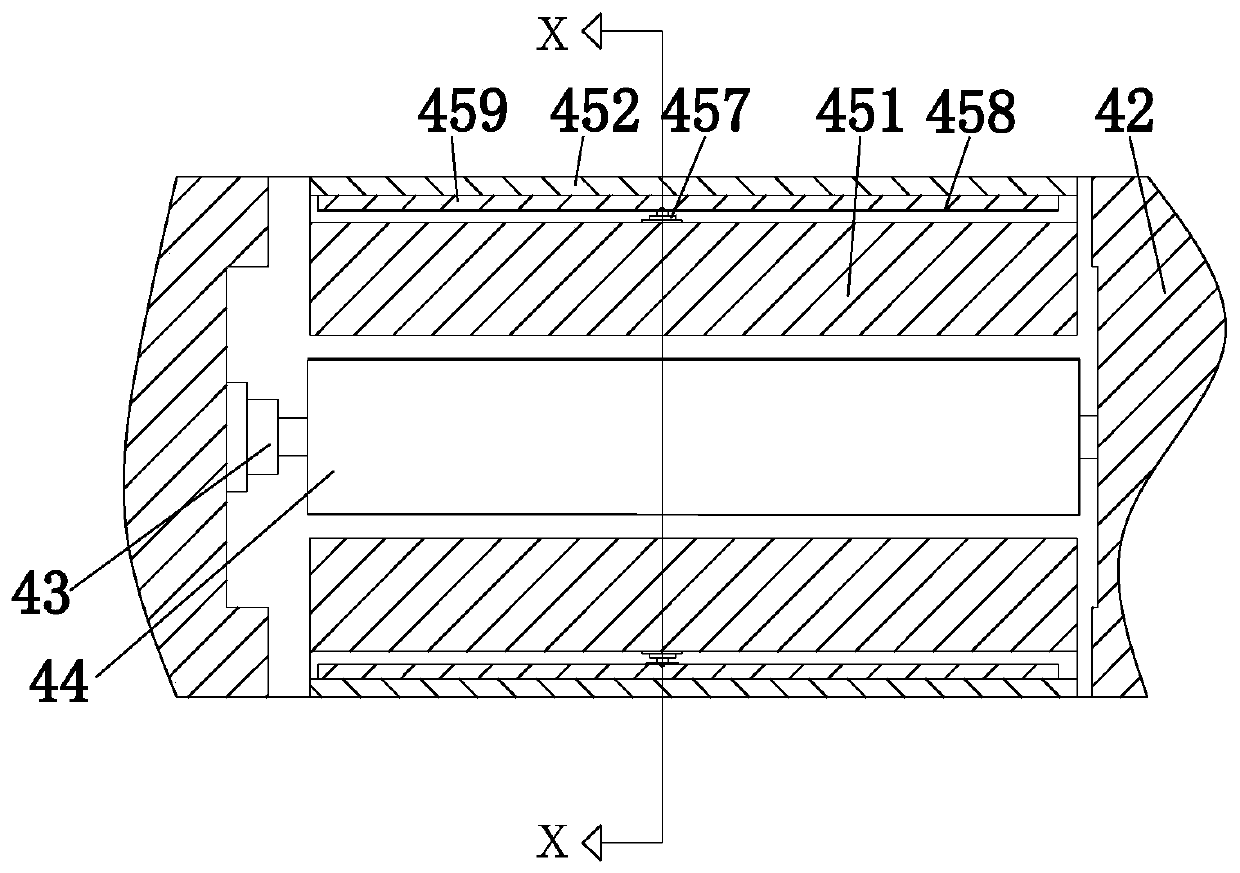

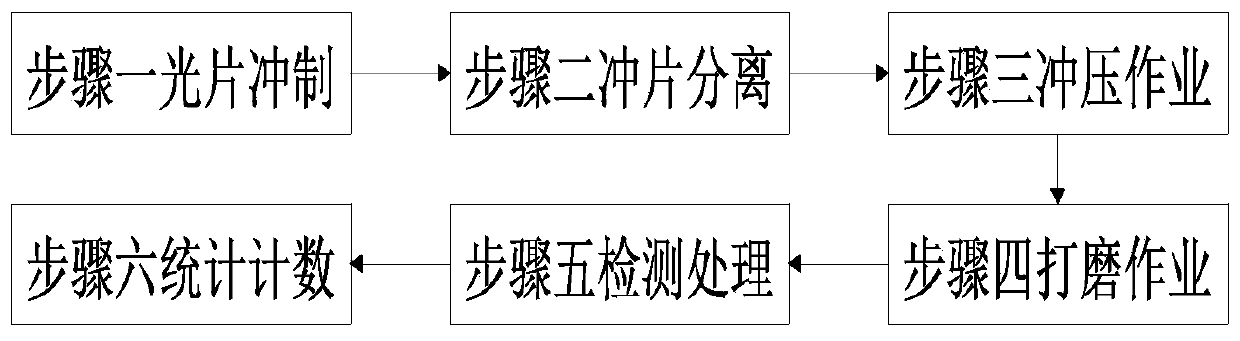

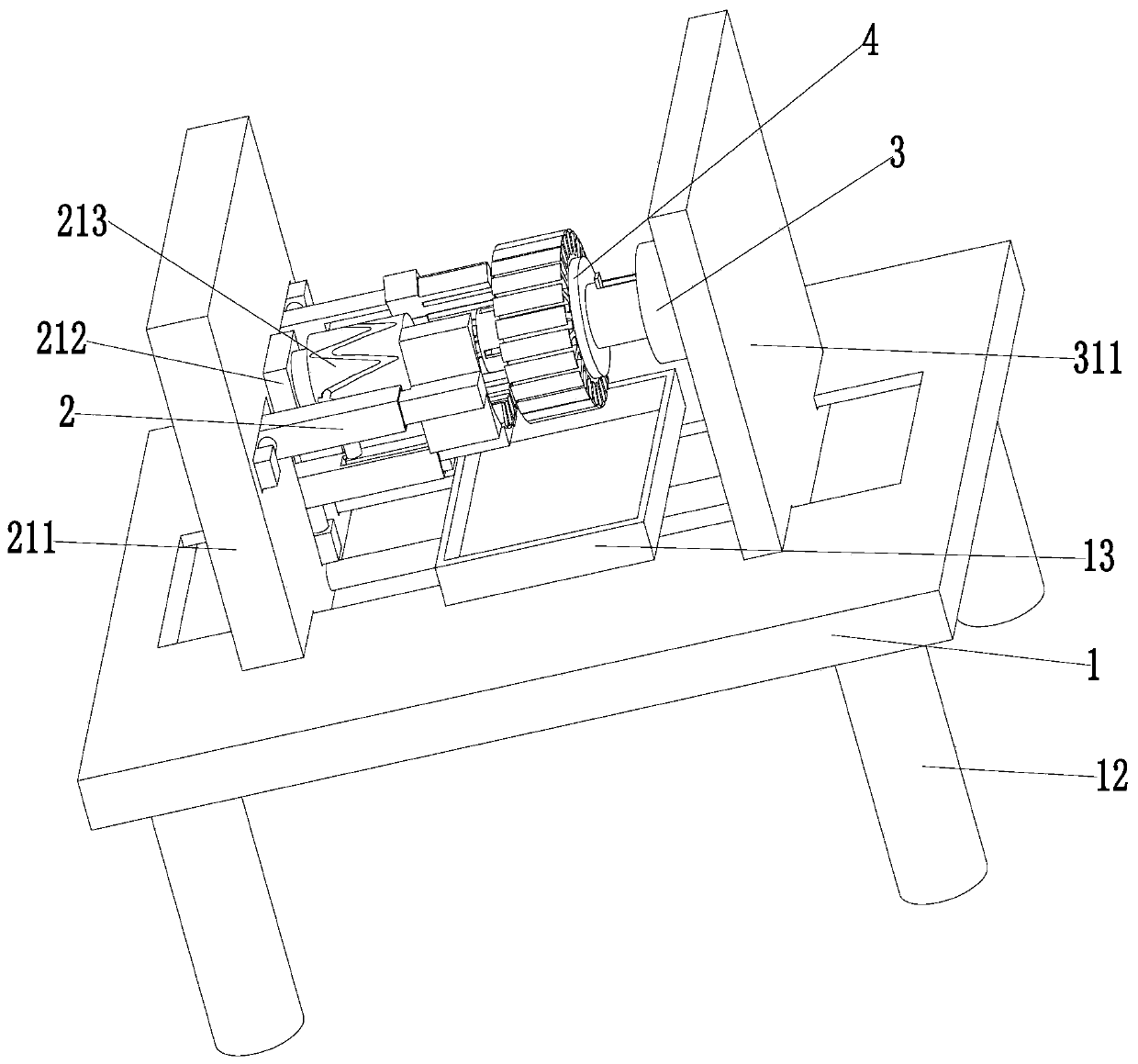

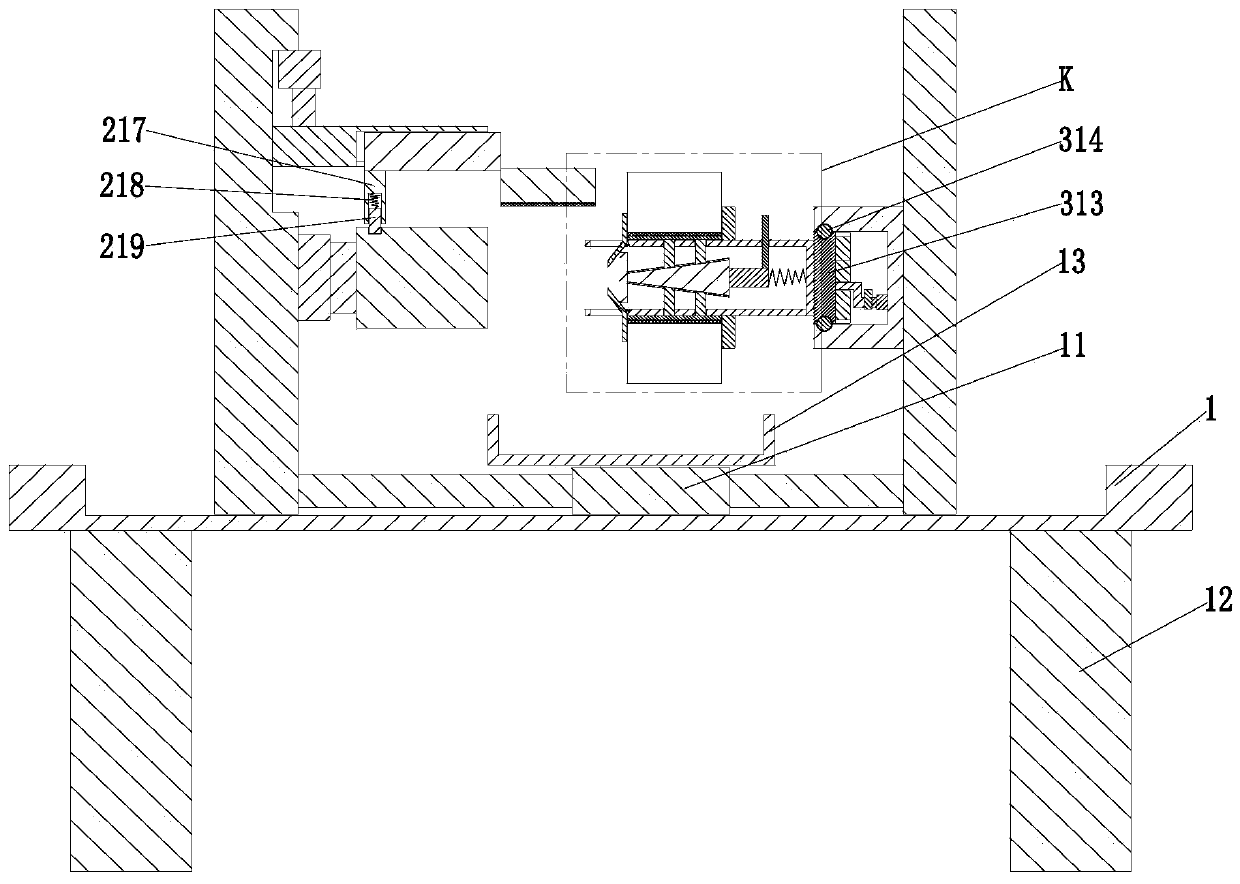

Machining method for manufacturing motor rotor punching sheet

ActiveCN111130283AAvoid product qualityReduce grinding efficiencyGrinding drivesGrinding machinesPunchingElectric machine

The invention relates to a machining method for manufacturing a motor rotor punching sheet. The method mainly comprises the following steps of polished section punching, punched sheet separation, punching operation, polishing operation, detection processing, statistical counting and the like. Used rotor punching sheet grinding equipment comprises a bottom plate, a grinding device, a rotary positioning device and a clamping device. The machining method can be used to solve the following problems existing in grinding of an existing rotor punching sheet: a, a grinding machine is commonly used forgrinding the rotor punching sheet at present, a phenomenon that a slotted hole is not ground or excessive grinding occurs easily when the grinding machine grinds, and production quality of the rotorpunching sheet is reduced, and cost is wasted; and b, only a single rotor punching sheet can be ground when the traditional rotor punching sheet is ground, grinding efficiency is low, a defective rateof products is high, polishing conditions of the rotor punching sheets are inconsistent, and the rotor punching sheets are extremely easy to scrap. A yield of the rotor punching sheets and the grinding efficiency of the rotor punching sheets can be improved.

Owner:福州中研电机有限公司

Galvanized steel sheet production and manufacturing machining machine and machining method

ActiveCN110434721AReduce grinding efficiencyGuaranteed uniformityGrinding carriagesGrinding drivesSheet steelAngle grinder

The invention provides a galvanized steel sheet production and manufacturing machining machine and a machining method. The galvanized steel sheet production and manufacturing machining machine comprises a bottom plate, a conveying device, a grinding device and a clamping device. The conveying device is mounted at the upper end of the bottom plate, the grinding device is mounted on the conveying device, and the clamping device is mounted on the left side above the bottom plate. The problems that in methods for grinding round steel sheets in some small machining plants, mostly, grinding wheels are adopted for grinding the round steel sheets, or an angle grinder is manually held to grind the round steel plates, when the round steel sheets with large areas and large thicknesses are ground, thegrinding efficiency is low, the noise of the grinding wheels is high in the grinding process, the grinding wheels are easily broken and easily hurt people, and the personal safety of staff is threatened can be solved.

Owner:昆山富维金属制品有限公司

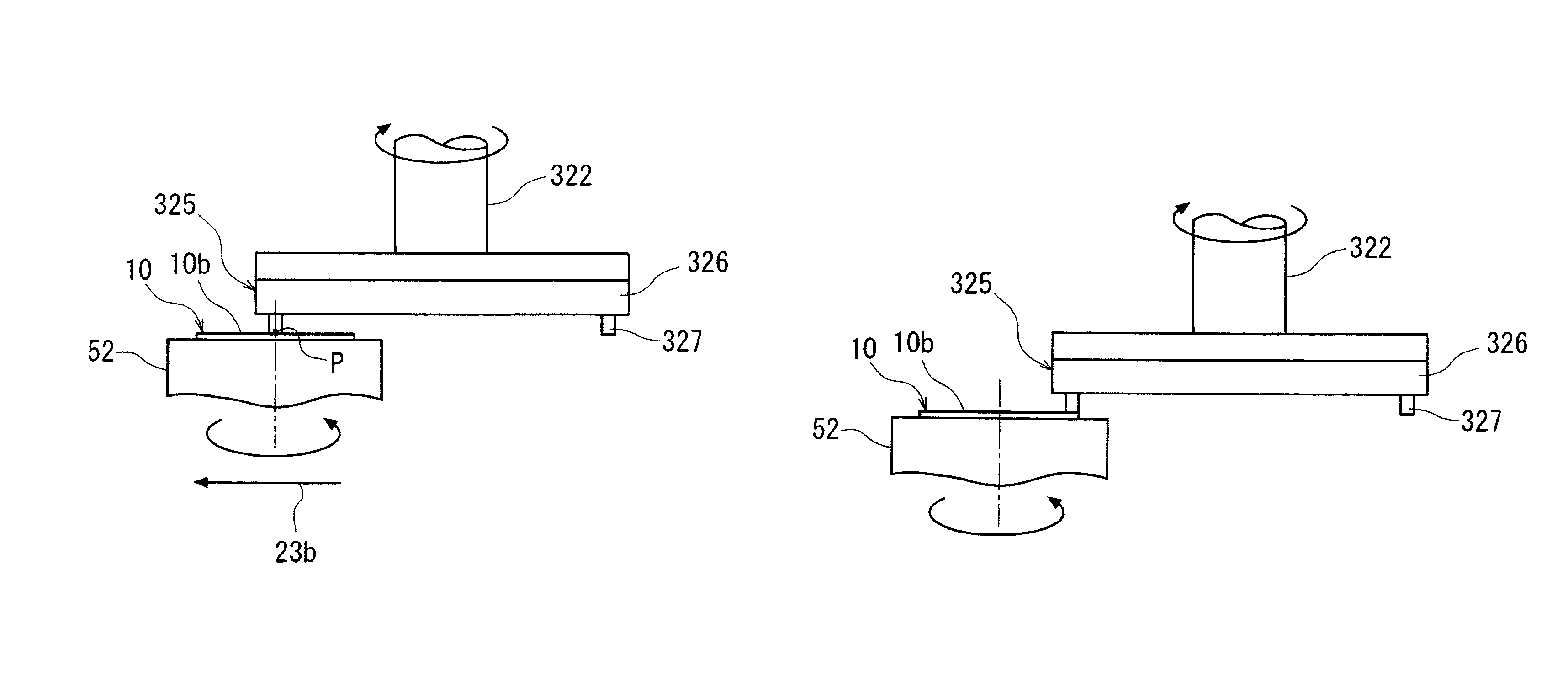

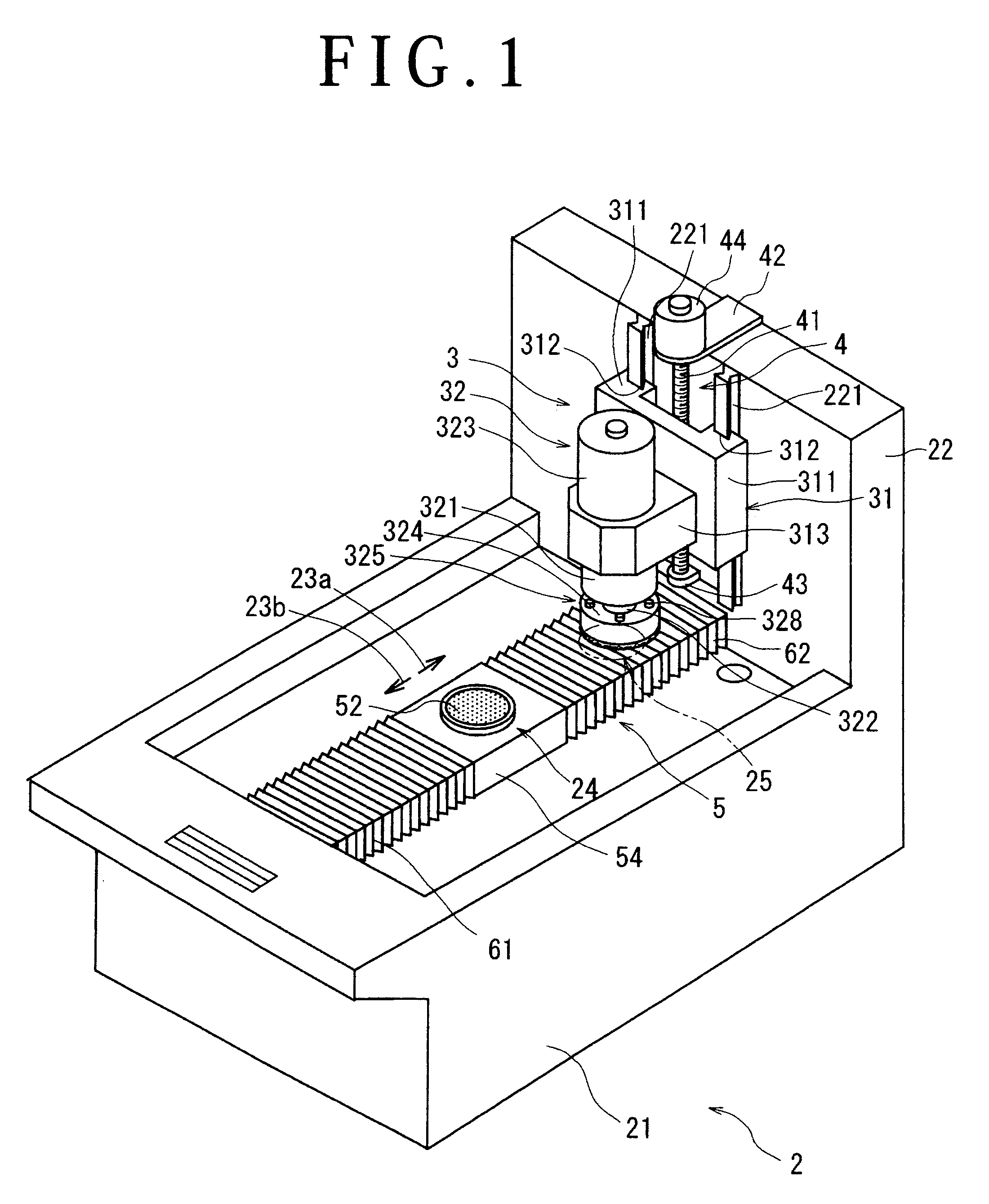

Grinding method for wafer having crystal orientation

ActiveUS8100742B2Reduce grinding efficiencyReduced strengthEdge grinding machinesPlane surface grinding machinesCrystal orientationMechanical engineering

A grinding method for a wafer having a mark indicating the crystal orientation. The grinding method includes a first grinding step for grinding the upper surface of the wafer by rotating a chuck table holding the wafer thereon, rotating a grinding ring, positioning the grinding ring so that the grinding ring is passed through the center of the wafer, and feeding the grinding ring in a direction perpendicular to the chuck table; a wafer positioning step for positioning the upper surface of an outer circumferential portion of the wafer directly below the locus of rotation of the grinding ring; and a second grinding step for grinding the upper surface of the wafer by first stopping the rotation of the chuck table so that the mark indicating the crystal orientation of the wafer held on the chuck table is pointed in a predetermined direction, next feeding the grinding ring in the direction perpendicular to the chuck table, and next relatively moving the chuck table and the grinding ring in parallel.

Owner:DISCO CORP

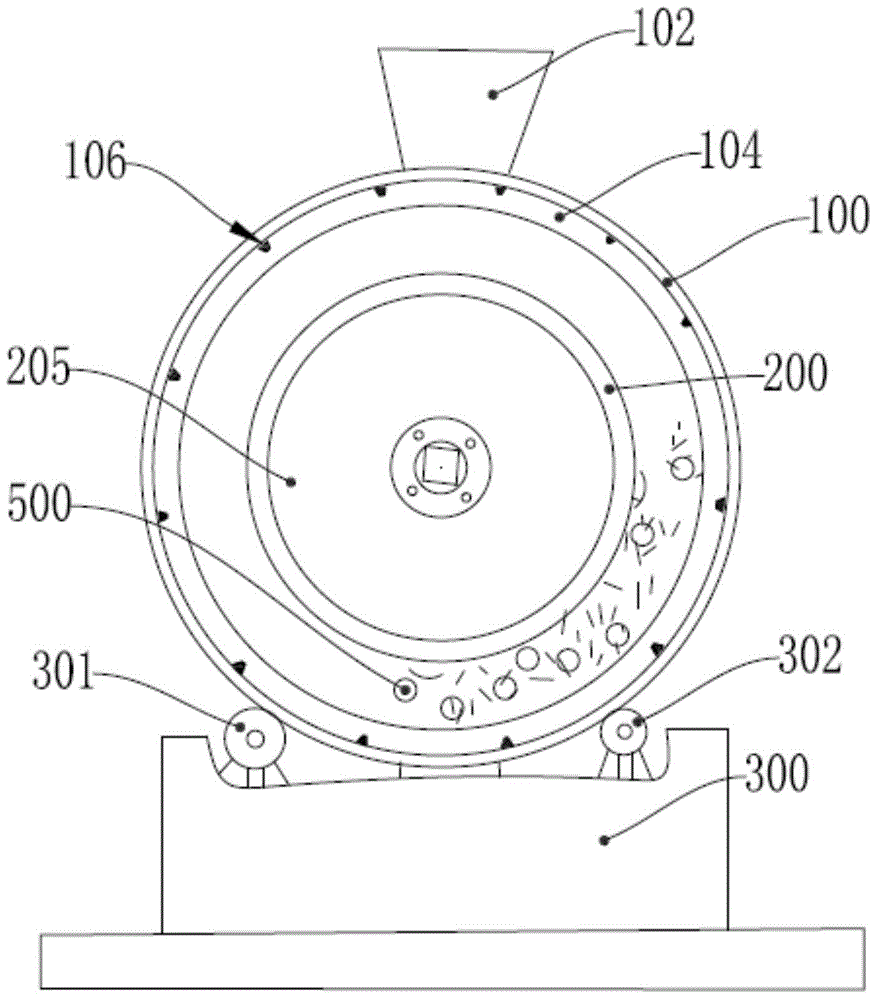

Polisher for workpiece flange burrs and polishing process thereof

ActiveCN106272019ALess investmentReduce manufacturing costEdge grinding machinesGrinding carriagesEngineeringFlange

The invention discloses a polisher for workpiece flange burrs and a polishing process thereof and belongs to the technical field of a polishing device. The polisher for workpiece flange burrs, disclosed by the invention, comprises a bracket, a driving mechanism, a chassis and a self-polishing box, wherein the bracket has two plate structures vertically fixed on the chassis; the self-polishing box is erected in the middle of the bracket through a rotating shaft and is rotatably connected with the bracket; and the driving mechanism is used for supplying rotating power to the rotating shaft of the self-polishing box. The polisher can polish respective flanges through the mutual polishing of the workpieces; the irregularity of different workpieces after the self-polishing box is rotated at a specific rotating speed on the position and posture of the self-polishing box is fully utilized to correctly and comprehensively polish the workpiece flanges; and special polishing accessories are not needed, so that the purposes of low investment, low production cost and good polishing effect can be achieved.

Owner:ANHUI MA STEEL INTELLIGENT STEREOSCOPIC PARKING EQUIP CO LTD +1

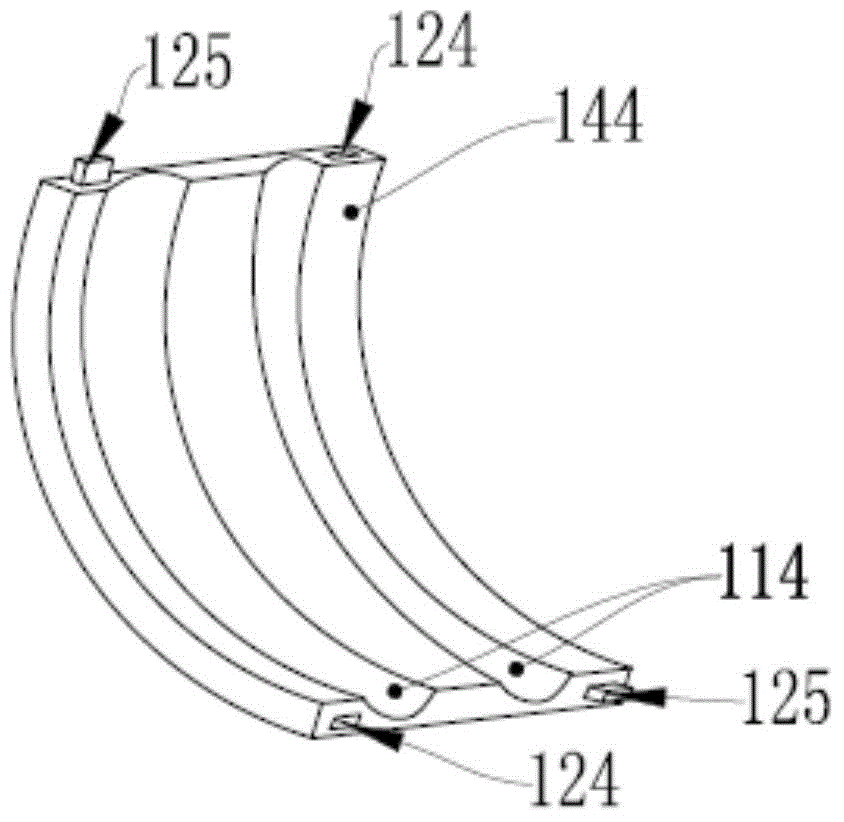

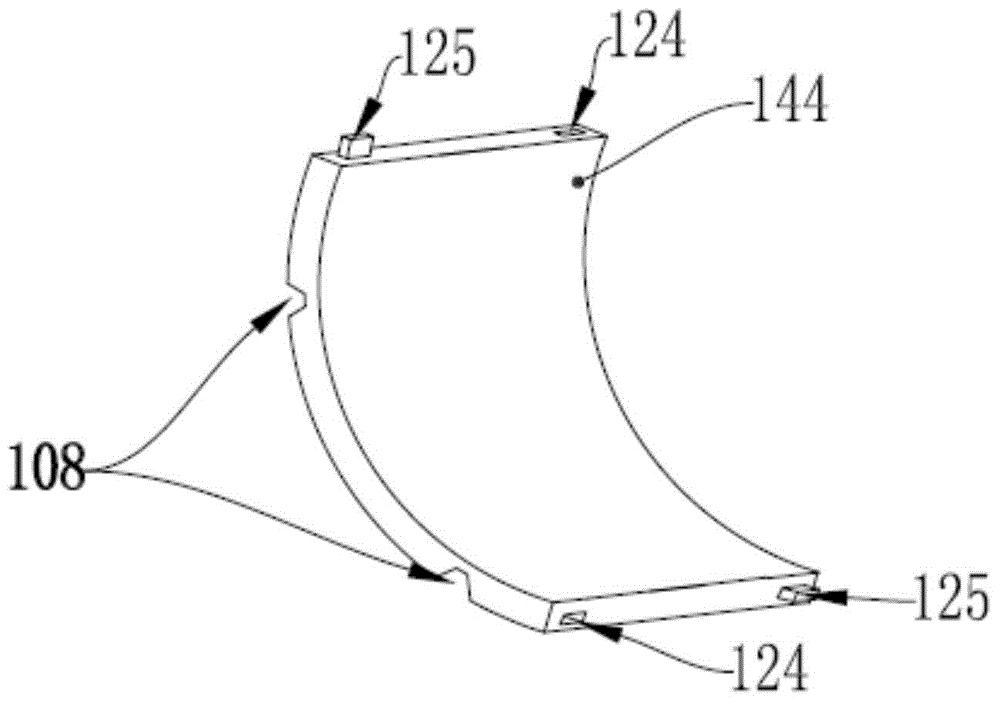

Efficient ball grinding mill with reinforcing ribs

The invention relates to the field of ceramic machinery, in particular to an efficient ball grinding mill with reinforcing ribs. A cylinder body is of a two-layer tubular structure, the first layer is a cylinder body shell, the second layer is a preliminary screening and grinding mesh tube with screening holes, grinding balls are placed inside the cylinder body, a feed port of the cylinder body is connected to a cavity of the preliminary screening and grinding mesh tube, and a discharge port of the cylinder body is connected to a cavity between the inner surface of the cylinder body shell and the outer surface of the preliminary screening and grinding mesh tube; a lining plate is arranged inside the cylinder body shell, is formed by splicing a plurality of lining bricks and is cylindrical, the reinforcing ribs and the lining plate are arranged on the inner surface of the cylinder body shell, grooves are formed in the back surfaces of the lining bricks and cover the reinforcing ribs, the back surface of the lining plate is attached and fixed to the inner surface of the cylinder body shell, and every two adjacent lining bricks are spliced and fixed through mortises and tenons of the lining bricks. The efficient ball grinding mill is convenient to install and stable in structure.

Owner:佛山市铖罡机械制造有限公司

Throttling valve alloy valve body heat treatment system

InactiveCN112809486AReduce grinding efficiencyReduce sanding effectEdge grinding machinesGrinding carriagesEngineeringTreatment system

The invention relates to a throttling valve alloy valve body heat treatment system. The throttling valve alloy valve body heat treatment system comprises a base, supporting plates, a mounting cylinder, a rotating groove, a rotating disc, an inner clamping mechanism, an outer clamping mechanism and a driving mechanism, the supporting plates are arranged on the front side and the rear side of the upper end face of the base, the mounting cylinder is arranged at the upper ends of the supporting plates, and the mounting cylinder is of a cylindrical structure with the upper end open. The rotating groove is formed in the lower end of the mounting cylinder, the rotating disc is mounted in the rotating groove in a rotating fit mode, a round hole is formed in the middle of the rotating disc, the inner clamping mechanism is arranged in the round hole in a rotating fit mode, the outer clamping mechanism is arranged at the position, located on the outer side of the inner clamping mechanism, of the upper end of the rotating disc, and the inner clamping mechanism is connected with the lower end of the outer clamping mechanism through the driving mechanism. The driving mechanism is installed on the upper end face of the base. The problems that a large amount of time is consumed when an existing machine is turned over, clamped and disassembled, so that the grinding efficiency of the machine is reduced; and in the prior art, machines can only be replaced frequently, and the grinding efficiency of the valve body is reduced are solved.

Owner:周圳慧

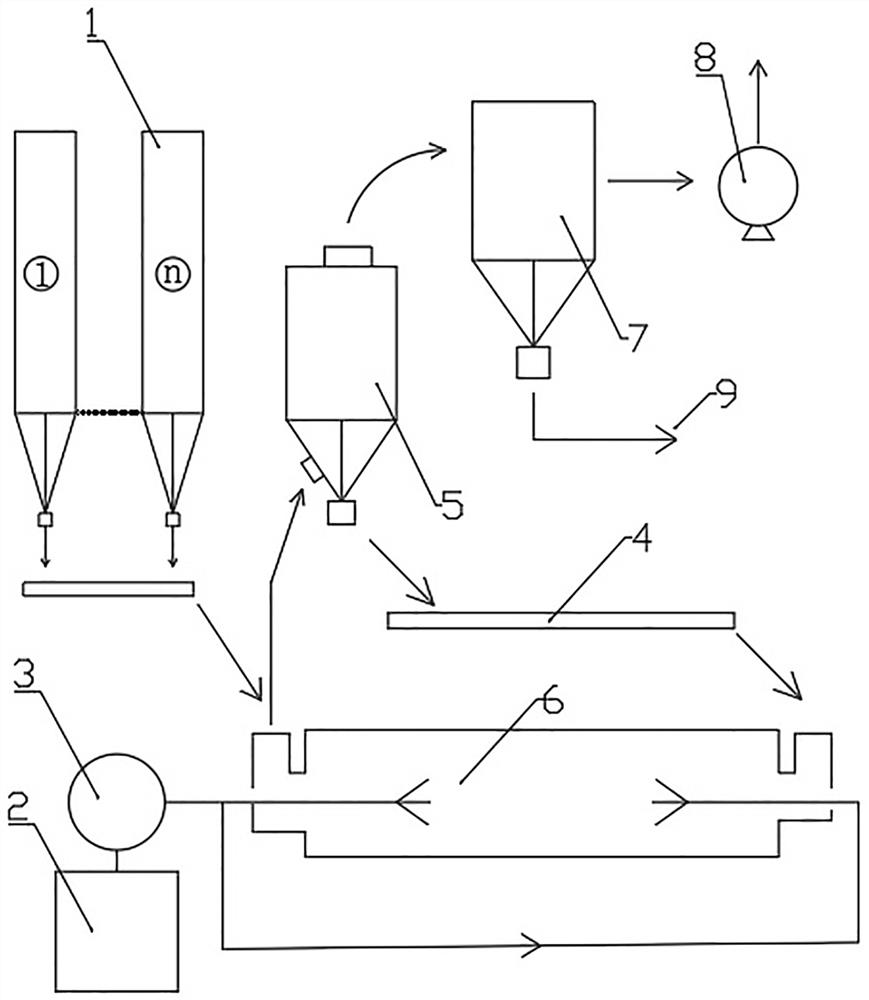

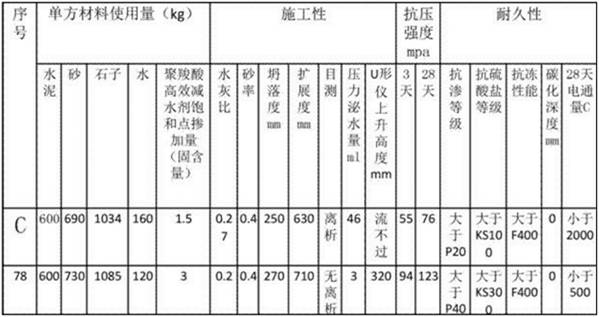

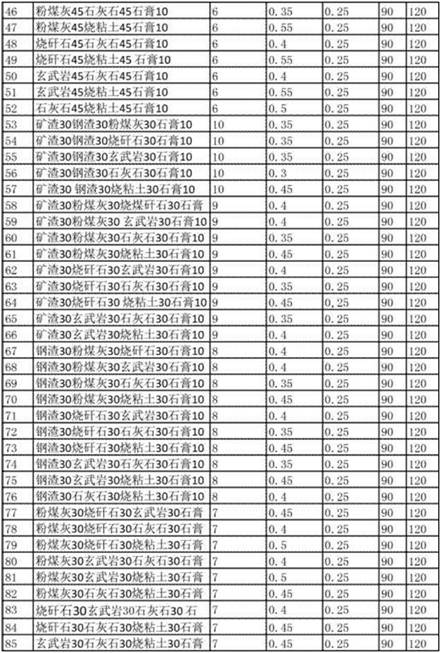

High-strength and high-performance mineral admixture for concrete and production method thereof

The invention relates to a high-strength and high-performance mineral admixture for high-strength and high-performance concrete and a production method thereof. The particle size of 97% of the total weight of the high-strength and high-performance mineral admixture is smaller than 20 microns. A closed-loop microsphere tube mill with a superfine powder concentrator is used for grinding. The production method has the advantages of industrial feasibility, energy conservation and the like. The high-strength and high-performance mineral admixture not only comprehensively utilizes a large amount of industrial waste residues in the industries of metallurgy, coal mine, thermal power, garbage treatment and the like, but also fundamentally improves the constructability of concrete and multiplies the strength and durability.

Owner:郑州无为粉体科技有限公司

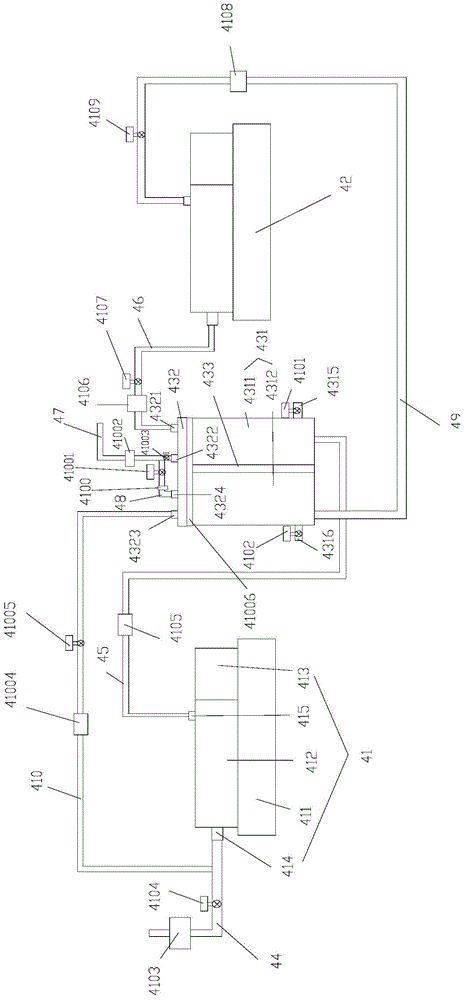

Grinding mechanism for oil paint production

The invention discloses a grinding mechanism for oil paint production. The grinding mechanism comprises a first horizontal grinding machine, a second horizontal grinding machine, a transfer device, a first feed pipe, a first discharge pipe, a second discharge pipe, a third discharge pipe, a fourth discharge pipe, a first return pipe and a second return pipe. The first horizontal grinding machine and the second horizontal grinding machine each comprise a shell, a grinding cylinder and a control device, wherein the grinding cylinder and the control device are arranged on the shell; the control device is connected with the grinding cylinder. The transfer device comprises a cylinder, a cover plate and a baffle, wherein the cover plate covers an opening area in the top of the cylinder; the baffle is vertically arranged in an inner cavity of the cylinder to divide the cylinder into a first cavity body and a second cavity body; the volume of the first cavity body is larger than the volume of the first horizontal grinding machine, and the volume of the second cavity body is larger than the volume of the second horizontal grinding machine. The grinding machine has the advantages of being capable of conducting multiple-time cyclic grinding and good in material grinding effect and sealing effect.

Owner:安徽省思维新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com