Coal-measure hard kaolin wet method stripping monocular tertiary circular grinding method

A technology of hard kaolin and cyclic grinding, which is applied in grain processing, etc., and can solve the problems of non-adjustable grinding particle size of materials, invariable grinding body gradation, and influence on the chemical reaction effect of the lower unit process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

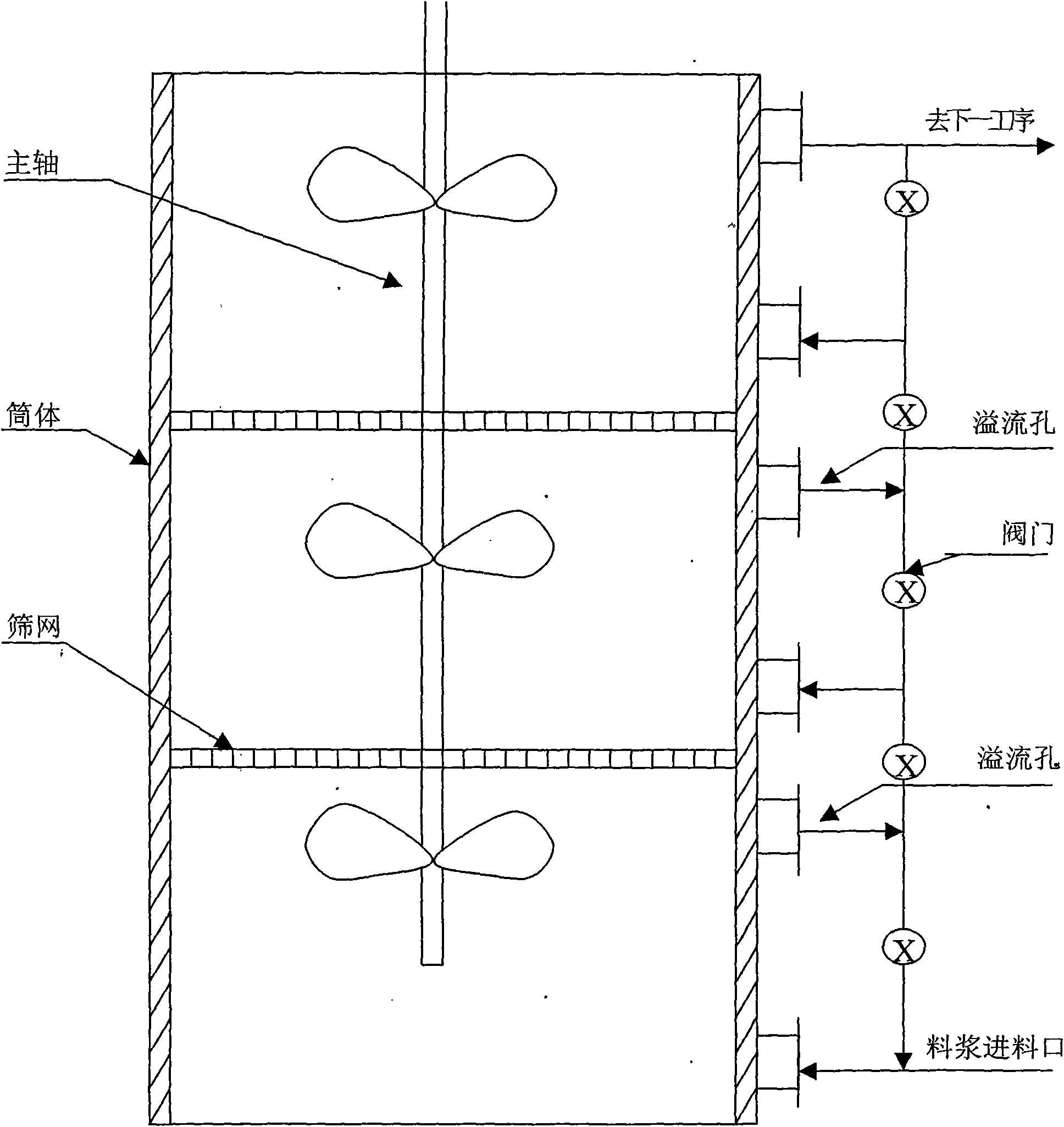

[0006] An embodiment is described in detail below: the slurry from the previous process is pumped into the bottom of the peeling grinder by a pump, and it is ground from bottom to top through three stages. The slurry passes through the screen between the layers. Smaller than the grinding body, larger than the diameter of the particles in the slurry, three stages of circular grinding with different ratios are carried out in the same vertical cylinder, and the same spindle drives three mutually isolated grinding sections. The first grade of grinding body is 12kg of zirconia grinding body, 25kg of ceramic grinding body, and 63kg of glass grinding body; the second grade of grinding body is 15kg of zirconia grinding body, 30kg of ceramic grinding body, and 55kg of glass grinding body; The gradation of the three-stage grinding body is 20kg of zirconia grinding body, 35kg of ceramic grinding body, and 45kg of glass grinding body; the grinding time of the slurry at each level is fed ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com